Use of Cement Mortar Incorporating Superabsorbent Polymer as a Passive Fire-Protective Layer

Abstract

:1. Introduction

2. Research Methodology

2.1. Materials

- Portland cement Type I (OPC) with properties in accordance with ASTM C150 [56]. It has a specific gravity of 3.15 and a specific surface area of 0.35 m2/g.

- Fine aggregate, which was natural river sand with specific gravity of 2.47 and fineness modulus of 3.08. The gradation conformed to ASTM C33 [57] with a maximum particle size smaller than 4.75 mm.

- Tap water with pH between 6 and 7.

- Polycarboxylate-based superplasticizer with properties according to ASTM C494 [58].

- Superabsorbent polymer (SP), sodium polyacrylate type, with particle size ranging from 297 to 1000 μm, maximum water absorption rate of 200 to 350 times the mass of water, and density of about 1.22 g/cm3. The properties are shown in Table 1.

2.2. Mix Proportion and Specimen Preparation

2.2.1. Bare-Type Specimen

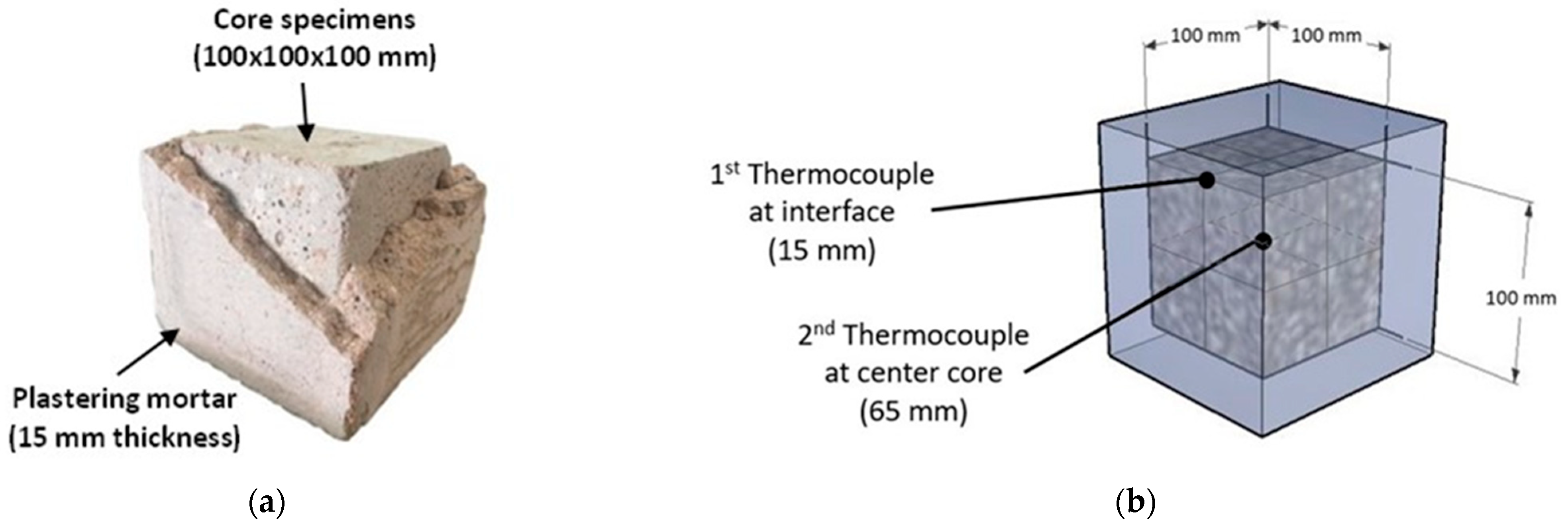

2.2.2. Plastered Specimen

2.3. Experimental Series

2.3.1. Stage 1: Properties of Mortar-Incorporated SP

2.3.2. Stage 2: Passive Fire Resistance of SP Plastering Mortar

3. Results and Discussion

3.1. Stage 1: Properties of Mortar-Incorporated SP

3.1.1. Surface Characteristics

3.1.2. Effect of SP on Dry Density

3.1.3. Effect of SP on Compressive Strength

3.1.4. Effect of SP on Thermal Properties

3.1.5. Heat Exposure Test

3.2. Stage 2: Passive Fire Resistance of SP Plastering Mortar

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, Q.; Guo, R.; Zhao, Z.; Lin, Z.; He, K. Mechanical properties of concrete at high temperature—A review. Constr. Build. Mater. 2015, 93, 371–383. [Google Scholar] [CrossRef]

- Husem, M. The effects of high temperature on compressive and flexural strengths of ordinary and high-performance concrete. Fire Saf. J. 2006, 41, 155–163. [Google Scholar] [CrossRef]

- Arioz, O. Effects of elevated temperatures on properties of concrete. Fire Saf. J. 2007, 42, 516–522. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Pomchiengpin, W.; Songpiriyakij, S. Post-crack (or post-peak) flexural response and toughness of fiber reinforced concrete after exposure to high temperature. Constr. Build. Mater. 2010, 24, 1967–1974. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Sukontasukkul, P.; Sata, V.; Cao, T. Fire resistance of recycled aggregate alkali-activated concrete. In Handbook of Advances in Alkali-Activated Concrete; Woodhead Publishing: Philadelphia, PA, USA, 2022; pp. 489–506. [Google Scholar]

- Nuaklong, P.; Boonchoo, N.; Jongvivatsakul, P.; Charinpanitkul, T.; Sukontasukkul, P. Hybrid effect of carbon nanotubes and polypropylene fibers on mechanical properties and fire resistance of cement mortar. Constr. Build. Mater. 2021, 275, 122189. [Google Scholar] [CrossRef]

- Chan, Y.; Luo, X.; Sun, W. Compressive strength and pore structure of high-performance concrete after exposure to high temperature up to 800 °C. Cem. Concr. Res. 2000, 30, 247–251. [Google Scholar] [CrossRef]

- Caetano, H.; Laím, L.; Santiago, A.; Durães, L.; Shahbazian, A. Development of Passive Fire Protection Mortars. Appl. Sci. 2022, 12, 2093. [Google Scholar] [CrossRef]

- Giudice, C.; Canosa, G. (Eds.) New Technologies in Protective Coatings; IntechOpen: London, UK, 2017. [Google Scholar]

- Xia, W.; Wang, S.; Xu, T.; Jin, G. Flame retarding and smoke suppressing mechanisms of nano composite flame retardants on bitumen and bituminous mixture. Constr. Build. Mater. 2021, 266, 121203. [Google Scholar] [CrossRef]

- Wang, S.; Tan, L.; Xu, T. Compounding Scheme Optimization of Composite Flame Retardant and Its Synergistic Inhibitory Effects on Bituminous Combustion. J. Mater. Civ. Eng. 2022, 34, 04022146. [Google Scholar] [CrossRef]

- Maho, B.; Sukontasukkul, P.; Sua-Iam, G.; Sappakittipakorn, M.; Intarabut, D.; Suksiripattanapong, C.; Chindaprasirt, P.; Limkatanyu, S. Mechanical properties and electrical resistivity of multiwall carbon nanotubes incorporated into high calcium fly ash geopolymer. Case Stud. Constr. Mater. 2021, 15, e00785. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Sukontasukkul, P.; Techaphatthanakon, A.; Kongtun, S.; Ruttanapun, C.; Yoo, D.-Y.; Tangchirapat, W.; Limkatanyu, S.; Banthia, N. Effect of graphene oxide on single fiber pullout behavior. Constr. Build. Mater. 2021, 280, 122539. [Google Scholar] [CrossRef]

- Jamnam, S.; Maho, B.; Techaphatthanakon, A.; Ruttanapun, C.; Aemlaor, P.; Zhang, H.; Sukontasukkul, P. Effect of graphene oxide nanoparticles on blast load resistance of steel fiber reinforced concrete. Constr. Build. Mater. 2022, 343, 128139. [Google Scholar] [CrossRef]

- Intarabut, D.; Sukontasukkul, P.; Phoo-Ngernkham, T.; Zhang, H.; Yoo, D.-Y.; Limkatanyu, S.; Chindaprasirt, P. Influence of Graphene Oxide Nanoparticles on Bond-Slip Reponses between Fiber and Geopolymer Mortar. Nanomaterials 2022, 12, 943. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Nontiyutsirikul, N.; Songpiriyakij, S.; Sakai, K.; Chindaprasirt, P. Use of phase change material to improve thermal properties of lightweight geopolymer panel. Mater. Struct. 2016, 49, 4637–4645. [Google Scholar] [CrossRef]

- Uthaichotirat, P.; Sukontasukkul, P.; Jitsangiam, P.; Suksiripattanapong, C.; Sata, V.; Chindaprasirt, P. Thermal and sound properties of concrete mixed with high porous aggregates from manufacturing waste impregnated with phase change material. J. Build. Eng. 2020, 29, 101111. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Sutthiphasilp, T.; Chalodhorn, W.; Chindaprasirt, P. Improving thermal properties of exterior plastering mortars with phase change materials with different melting temperatures: Paraffin and polyethylene glycol. Adv. Build. Energy Res. 2019, 13, 220–240. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Intawong, E.; Preemanoch, P.; Chindaprasirt, P. Use of paraffin impregnated lightweight aggregates to improve thermal properties of concrete panels. Mater. Struct. 2015, 49, 1793–1803. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Sangpet, T.; Newlands, M.; Yoo, D.-Y.; Tangchirapat, W.; Limkatanyu, S.; Chindaprasirt, P. Thermal storage properties of lightweight concrete incorporating phase change materials with different fusion points in hybrid form for high temperature applications. Heliyon 2020, 6, e04863. [Google Scholar] [CrossRef] [PubMed]

- Pongsopha, P.; Sukontasukkul, P.; Phoo-Ngernkham, T.; Imjai, T.; Jamsawang, P.; Chindaprasirt, P. Use of burnt clay aggregate as phase change material carrier to improve thermal properties of concrete panel. Case Stud. Constr. Mater. 2019, 11, e00242. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Sangpet, T.; Newlands, M.; Tangchirapat, W.; Limkatanyu, S.; Chindaprasirt, P. Thermal behaviour of concrete sandwich panels incorporating phase change material. Adv. Build. Energy Res. 2022, 16, 64–88. [Google Scholar] [CrossRef]

- Pongsopha, P.; Sukontasukkul, P.; Maho, B.; Intarabut, D.; Phoo-Ngernkham, T.; Hanjitsuwan, S.; Choi, D.; Limkatanyu, S. Sustainable rubberized concrete mixed with surface treated PCM lightweight aggregates subjected to high temperature cycle. Constr. Build. Mater. 2021, 303, 124535. [Google Scholar] [CrossRef]

- Sappakittipakorn, M.; Sukontasukkul, P.; Higashiyama, H.; Chindaprasirt, P. Properties of hooked end steel fiber reinforced acrylic modified concrete. Constr. Build. Mater. 2018, 186, 1247–1255. [Google Scholar] [CrossRef]

- Jamnam, S.; Maho, B.; Techaphatthanakon, A.; Sonoda, Y.; Yoo, D.-Y.; Sukontasukkul, P. Steel fiber reinforced concrete panels subjected to impact projectiles with different caliber sizes and muzzle energies. Case Stud. Constr. Mater. 2020, 13, e00360. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Jamnam, S.; Sappakittipakorn, M.; Banthia, N. Preliminary study on bullet resistance of double-layer concrete panel made of rubberized and steel fiber reinforced concrete. Mater. Struct. 2014, 47, 117–125. [Google Scholar] [CrossRef]

- Wongprachum, W.; Sappakittipakorn, M.; Sukontasukkul, P.; Chindaprasirt, P.; Banthia, N. Resistance to sulfate attack and underwater abrasion of fiber reinforced cement mortar. Constr. Build. Mater. 2018, 189, 686–694. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Jamnam, S.; Sappakittipakorn, M.; Fujikake, K.; Chindaprasirt, P. Residual flexural behavior of fiber reinforced concrete after heating. Mater. Struct. 2018, 51, 98. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Panklum, K.; Maho, B.; Banthia, N.; Jongvivatsakul, P.; Imjai, T.; Sata, V.; Limkatanyu, S.; Chindaprasirt, P. Effect of synthetic microfiber and viscosity modifier agent on layer deformation, viscosity, and open time of cement mortar for 3D printing application. Constr. Build. Mater. 2022, 319, 126111. [Google Scholar] [CrossRef]

- Hanjitsuwan, S.; Injorhor, B.; Phoo-Ngernkham, T.; Damrongwiriyanupap, N.; Li, L.-Y.; Sukontasukkul, P.; Chindaprasirt, P. Drying shrinkage, strength and microstructure of alkali-activated high-calcium fly ash using FGD-gypsum and dolomite as expansive additive. Cem. Concr. Compos. 2020, 114, 103760. [Google Scholar] [CrossRef]

- Dueramae, S.; Tangchirapat, W.; Chindaprasirt, P.; Jaturapitakkul, C.; Sukontasukkul, P. Autogenous and drying shrinkages of mortars and pore structure of pastes made with activated binder of calcium carbide residue and fly ash. Constr. Build. Mater. 2020, 230, 116962. [Google Scholar] [CrossRef]

- Lee, S.K.; Oh, T.; Chun, B.; Chu, S.; Sukontasukkul, P.; Yoo, D.-Y. Surface refinement of steel fiber using nanosilica and silver and its effect on static and dynamic pullout resistance of reactive powder concrete. J. Build. Eng. 2022, 51, 104269. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Chindaprasirt, P.; Pongsopha, P.; Phoo-Ngernkham, T.; Tangchirapat, W.; Banthia, N. Effect of fly ash/silica fume ratio and curing condition on mechanical properties of fiber-reinforced geopolymer. J. Sustain. Cem. Mater. 2020, 9, 218–232. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Jamnam, S.; Rodsin, K.; Banthia, N. Use of rubberized concrete as a cushion layer in bulletproof fiber reinforced concrete panels. Constr. Build. Mater. 2013, 41, 801–811. [Google Scholar] [CrossRef]

- Chaikaew, C.; Sukontasukkul, P.; Chaisakulkiet, U.; Sata, V.; Chindaprasirt, P. Properties of Concrete Pedestrian Blocks Containing Crumb Rubber from Recycle Waste Tyres Reinforced with Steel Fibres. Case Stud. Constr. Mater. 2019, 11, e00304. [Google Scholar] [CrossRef]

- Jensen, O.M. Use of Superabsorbent Polymers in Concrete. Concr. Int. 2013, 35, 48–52. [Google Scholar]

- Mechtcherine, V. Use of superabsorbent polymers (SP) as concrete additive. RILEM Tech. Lett. 2016, 1, 81. [Google Scholar] [CrossRef] [Green Version]

- Schröfl, C.; Erk, K.A.; Siriwatwechakul, W.; Wyrzykowski, M.; Snoeck, D. Recent progress in superabsorbent polymers for concrete. Cem. Concr. Res. 2022, 151, 106648. [Google Scholar] [CrossRef]

- Wang, F.; Zhou, Y.; Peng, B.; Liu, Z.; Hu, S. Autogenous shrinkage of concrete with super-absorbent polymer. ACI Mater. J. 2009, 106, 123–127. [Google Scholar]

- Zhong, P.; Wyrzykowski, M.; Toropovs, N.; Li, L.; Liu, J.; Lura, P. Internal curing with superabsorbent polymers of different chemical structures. Cem. Concr. Res. 2019, 123, 105789. [Google Scholar] [CrossRef]

- Wong, H.S. Concrete with superabsorbent polymer. In Eco-Efficient Repair and Rehabilitation of Concrete Infrastructures; Elsevier Ltd.: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Liu, J.; Khayat, K.H.; Shi, C. Effect of superabsorbent polymer characteristics on rheology of ultra-high performance concrete. Cem. Concr. Compos. 2020, 112, 103636. [Google Scholar] [CrossRef]

- Schröfl, C.; Snoeck, D.; Mechtcherine, V. A review of characterisation methods for superabsorbent polymer (SP) samples to be used in cement-based construction materials: Report of the RILEM TC 260-RSC. Mater. Struct. 2017, 50, 197. [Google Scholar] [CrossRef]

- Oh, S.; Choi, Y.C. Superabsorbent polymers as internal curing agents in alkali activated slag mortars. Constr. Build. Mater. 2018, 159, 1–8. [Google Scholar] [CrossRef]

- Xu, F.; Lin, X.; Zhou, A. Performance of internal curing materials in high-performance concrete: A review. Constr. Build. Mater. 2021, 311, 125250. [Google Scholar] [CrossRef]

- Faxiang, X.; Dingpeng, C.; Lin, J.; Chuanlong, Z.; Jing, R.; Xiao, L. Combined compression-shear performance and failure criteria of internally cured concrete with super absorbent polymer. Constr. Build. Mater. 2021, 266, 120888. [Google Scholar] [CrossRef]

- Beushausen, H.; Gillmer, M.; Alexander, M. The influence of superabsorbent polymers on strength and durability properties of blended cement mortars. Cem. Concr. Compos. 2014, 52, 73–80. [Google Scholar] [CrossRef]

- Senff, L.; Modolo, R.; Ascensão, G.; Hotza, D.; Ferreira, V.; Labrincha, J. Development of mortars containing superabsorbent polymer. Constr. Build. Mater. 2015, 95, 575–584. [Google Scholar] [CrossRef]

- Manzur, T.; Iffat, S.; Noor, M.A. Efficiency of Sodium Polyacrylate to Improve Durability of Concrete under Adverse Curing Condition. Adv. Mater. Sci. Eng. 2015, 2015, 685785. [Google Scholar] [CrossRef] [Green Version]

- Dang, J.; Zhao, J.; Du, Z. Effect of Superabsorbent Polymer on the Properties of Concrete. Polymers 2017, 9, 672. [Google Scholar] [CrossRef] [Green Version]

- Chindasiriphan, P.; Yokota, H.; Pimpakan, P. Effect of fly ash and superabsorbent polymer on concrete self-healing ability. Constr. Build. Mater. 2020, 233, 116975. [Google Scholar] [CrossRef]

- Al-Nasra, M. Concrete made for energy conservation mixed with sodium polyacrylates. Int. J. Eng. Res. Appl. 2013, 3, 601–604. [Google Scholar]

- Liu, K.; Chen, W.; Ye, J.; Bai, Y.; Jiang, J.; Tong, Y.; Chen, W. Improved fire resistance of cold-formed steel walls by using super absorbent polymers. Thin-Walled Struct. 2021, 160, 107355. [Google Scholar] [CrossRef]

- Jin, Z.-F.; Asako, Y.; Yamaguchi, Y.; Harada, M. Fire resistance test for fire protection materials with high water content. Int. J. Heat Mass Transf. 2000, 43, 4395–4404. [Google Scholar] [CrossRef]

- Lura, P.; Terrasi, G.P. Reduction of fire spalling in high-performance concrete by means of superabsorbent polymers and polypropylene fibers: Small scale fire tests of carbon fiber reinforced plastic-prestressed self-compacting concrete. Cem. Concr. Compos. 2014, 49, 36–42. [Google Scholar] [CrossRef] [Green Version]

- ASTM C150; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C33; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C494; Standard Specification for Chemical Admixtures for Concrete. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C305; Standard Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2018.

- Venkatachalam, D.; Kaliappa, S. Superabsorbent polymers: A state-of-art review on their classification, synthesis, physicochemical properties, and applications. Rev. Chem. Eng. 2021. [Google Scholar] [CrossRef]

- Al-Nasra, M.; Daoudb, M.; Abu-Lebdeh, T.M. The Use of the Super Absorbent Polymer as Water Blocker in Concrete Structures. Am. J. Eng. Appl. Sci. 2015, 8, 659–665. [Google Scholar] [CrossRef]

- Al-Nasra, M. Investigating the effect of the ultra-high absorbent polymer on the sealing property of concrete. Cogent Eng. 2019, 6, 1599550. [Google Scholar] [CrossRef]

- Zheng, X.; Han, M.; Liu, L. Effect of Superabsorbent Polymer on the Mechanical Performance and Microstructure of Concrete. Materials 2021, 14, 3232. [Google Scholar] [CrossRef] [PubMed]

- Yu, P.; Deng, M. Synergetic effect of MEA and SP on the deformation and mechanical properties of concrete. Mag. Concr. Res. 2019, 72, 1289–1296. [Google Scholar] [CrossRef]

- Askarian, R.; Darbhanzi, A.; Ranjbar-Karimi, R. Internal Curing of Concrete by Superabsorbent Polymer Particles. Iran. J. Sci. Technol. Trans. Civ. Eng. 2022, 46, 3979–3994. [Google Scholar] [CrossRef]

- Guan, Y.; Zhang, Z.; Zhang, X.; Zhu, J.; Zhou, W.; Huang, Q.; Zhang, Y. Effect of superabsorbent polymer on mechanical properties of cement stabilized base and its mechanism. Transp. Saf. Environ. 2020, 2, 58–68. [Google Scholar] [CrossRef]

- De Sensale, G.R.; Goncalves, A.F. Effects of Fine LWA and SP as Internal Water Curing Agents. Int. J. Concr. Struct. Mater. 2014, 8, 229–238. [Google Scholar] [CrossRef]

- Morinaga, Y.; Akao, Y.; Fukuda, D.; Elakneswaran, Y. Delayed Absorption Superabsorbent Polymer for Strength Development in Concrete. Materials 2022, 15, 2727. [Google Scholar] [CrossRef] [PubMed]

- Hager, I. Colour Change in Heated Concrete. Fire Technol. 2014, 50, 945–958. [Google Scholar] [CrossRef] [Green Version]

- Babrauskas, V. Fire safety design and concrete. Fire Saf. J. 1994, 23, 439–442. [Google Scholar] [CrossRef]

- Short, N.; Purkiss, J.; Guise, S. Assessment of fire damaged concrete using colour image analysis. Constr. Build. Mater. 2001, 15, 9–15. [Google Scholar] [CrossRef]

- Colombo, M.; Felicetti, R. New NDT techniques for the assessment of fire-damaged concrete structures. Fire Saf. J. 2007, 42, 461–472. [Google Scholar] [CrossRef]

- Lee, T.; Jeong, K.; Choi, H. Effect of Thermal Properties of Aggregates on the Mechanical Properties of High Strength Concrete under Loading and High Temperature Conditions. Materials 2021, 14, 6093. [Google Scholar] [CrossRef]

- Drzymała, T.; Jackiewicz-Rek, W.; Tomaszewski, M.; Kuś, A.; Gałaj, J.; Šukys, R. Effects of High Temperature on the Properties of High Performance Concrete (HPC). Procedia Eng. 2017, 172, 256–263. [Google Scholar] [CrossRef]

- Li, Q.; Wang, M.; Sun, H.; Yu, G. Effect of heating rate on the free expansion deformation of concrete during the heating process. J. Build. Eng. 2020, 34, 101896. [Google Scholar] [CrossRef]

- Tufail, M.; Shahzada, K.; Gencturk, B.; Wei, J. Effect of Elevated Temperature on Mechanical Properties of Limestone, Quartzite and Granite Concrete. Int. J. Concr. Struct. Mater. 2017, 11, 17–28. [Google Scholar] [CrossRef]

- BS EN 1992-1-2; Eurocode 2. Design of Concrete Structures. Part 1.2: General Rules Structural Fire Design. Commission of European Communities: Brussels, Belgium, 2004.

- ACI 216R-90; Guide for Determining the Fire Endurance of Concrete Elements. American Concrete Institute: Farmington Hills, MI, USA, 1994.

| Structure | Dimension (Mesh) | Water Absorption Capacity (g/g) | Water Content (%) | pH | Density (kg/m3) |

|---|---|---|---|---|---|

| 20–50 | 350 | ≥7 | 5.5–6.5 | 1220 |

|  | ||||

| Dry | Wet | ||||

| Designation | w/c | OPC (kg/m3) | Fine Aggregate (kg/m3) | Coarse Aggregate | Water (kg/m3) | Superplasticizer (%) | SP (%) |

|---|---|---|---|---|---|---|---|

| CON | 0.5 | 550 | 1513 | - | 275 | 3.0 | 0 |

| SP-0.5 | 0.5 | 550 | 1513 | - | 275 | 3.0 | 0.5 |

| SP-1.0 | 0.5 | 550 | 1513 | - | 275 | 3.0 | 1.0 |

| CONC | 0.5 | 550 | 1100 | 2200 | 275 | - | - |

| Designation (a/b) | Mix Proportion for CONC (a) | Plastering Material (b) | |||||

|---|---|---|---|---|---|---|---|

| w/c | OPC (kg/m3) | Fine Aggregate (kg/m3) | Coarse Aggregate (kg/m3) | Water (kg/m3) | Superplasticizer (%) | ||

| CONC/CON | 0.5 | 550 | 1100 | 2200 | 275 | 3.0 | CON |

| CONC/SP-0.5 | 0.5 | 550 | 1100 | 2200 | 275 | 3.0 | SP-0.5 |

| CONC/SP-1.0 | 0.5 | 550 | 1100 | 2200 | 275 | 3.0 | SP-1.0 |

| Designation | Thermal Conductivity (k-Value) (W/m·K) | Specific Heat Capacity (C-Value) (kJ/kg·K) |

|---|---|---|

| CON | 1.95 | 0.81 |

| SP-0.5 | 1.72 | 0.78 |

| SP-1.0 | 1.53 | 0.75 |

| Temperature (°C) | CON | SP-0.5 | SP-1.0 |

|---|---|---|---|

| 400 |  |  |  |

| 600 |  |  |  |

| 800 |  |  |  |

| Temperature (°C) | Compressive Strength (MPa) | Strength Reduction Coefficient (SRC) | ||||||

|---|---|---|---|---|---|---|---|---|

| CON | SP-0.5 | SP-1.0 | CON | SP-0.5 | SP-1.0 | Eurocode | ACI | |

| Room | 37.9 | 35.3 | 34.2 | - | - | - | - | - |

| 400 °C | 29.9 | 30.2 | 29.5 | 0.788 | 0.856 | 0.862 | 0.850 | 0.850 |

| 600 °C | 26.6 | 26.8 | 27.4 | 0.702 | 0.760 | 0.800 | 0.600 | 0.750 |

| 800 °C | 17.2 | 18.2 | 18.8 | 0.455 | 0.516 | 0.549 | 0.260 | 0.400 |

| Specimen Type | Compressive Strength (MPa) | Strength Loss (%) | Remark |

|---|---|---|---|

| CONC | 25.9 | - | Room temperature |

| CONC/CON | 18.9 | −26.5% | 800 °C Exposure |

| CONC/SP-0.5 | 20.5 | −20.3% | 800 °C Exposure |

| CONC/SP-1.0 | 21.3 | −17.2% | 800 °C Exposure |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jamnam, S.; Sua-iam, G.; Maho, B.; Pianfuengfoo, S.; Sappakittipakorn, M.; Zhang, H.; Limkatanyu, S.; Sukontasukkul, P. Use of Cement Mortar Incorporating Superabsorbent Polymer as a Passive Fire-Protective Layer. Polymers 2022, 14, 5266. https://doi.org/10.3390/polym14235266

Jamnam S, Sua-iam G, Maho B, Pianfuengfoo S, Sappakittipakorn M, Zhang H, Limkatanyu S, Sukontasukkul P. Use of Cement Mortar Incorporating Superabsorbent Polymer as a Passive Fire-Protective Layer. Polymers. 2022; 14(23):5266. https://doi.org/10.3390/polym14235266

Chicago/Turabian StyleJamnam, Sittisak, Gritsada Sua-iam, Buchit Maho, Satharat Pianfuengfoo, Manote Sappakittipakorn, Hexin Zhang, Suchart Limkatanyu, and Piti Sukontasukkul. 2022. "Use of Cement Mortar Incorporating Superabsorbent Polymer as a Passive Fire-Protective Layer" Polymers 14, no. 23: 5266. https://doi.org/10.3390/polym14235266

APA StyleJamnam, S., Sua-iam, G., Maho, B., Pianfuengfoo, S., Sappakittipakorn, M., Zhang, H., Limkatanyu, S., & Sukontasukkul, P. (2022). Use of Cement Mortar Incorporating Superabsorbent Polymer as a Passive Fire-Protective Layer. Polymers, 14(23), 5266. https://doi.org/10.3390/polym14235266