Multi Response Optimization of ECDM Process for Generating Micro Holes in CFRP Composite Using TOPSIS Methodology

Abstract

1. Introduction

2. Motivation and Problem Formulation

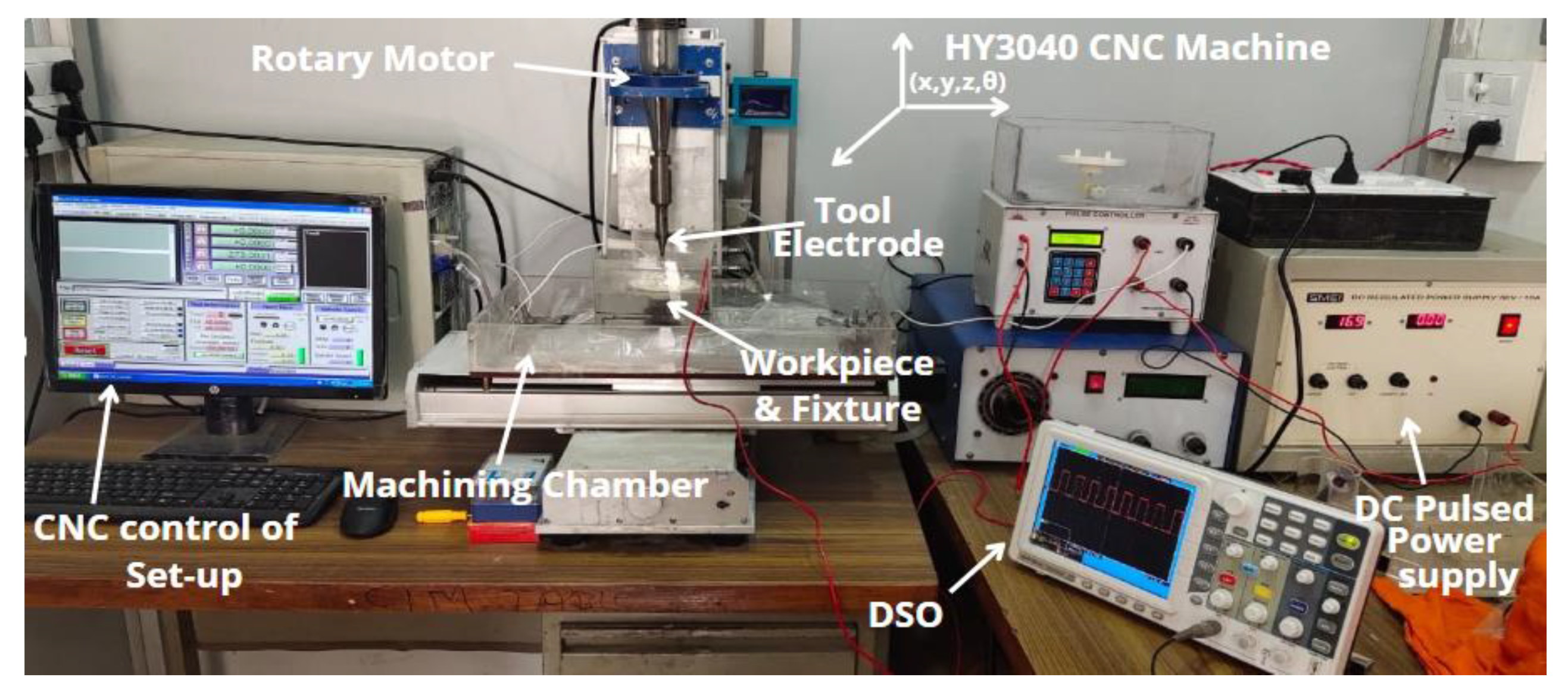

3. Experimentation Strategy

4. Results and Discussion

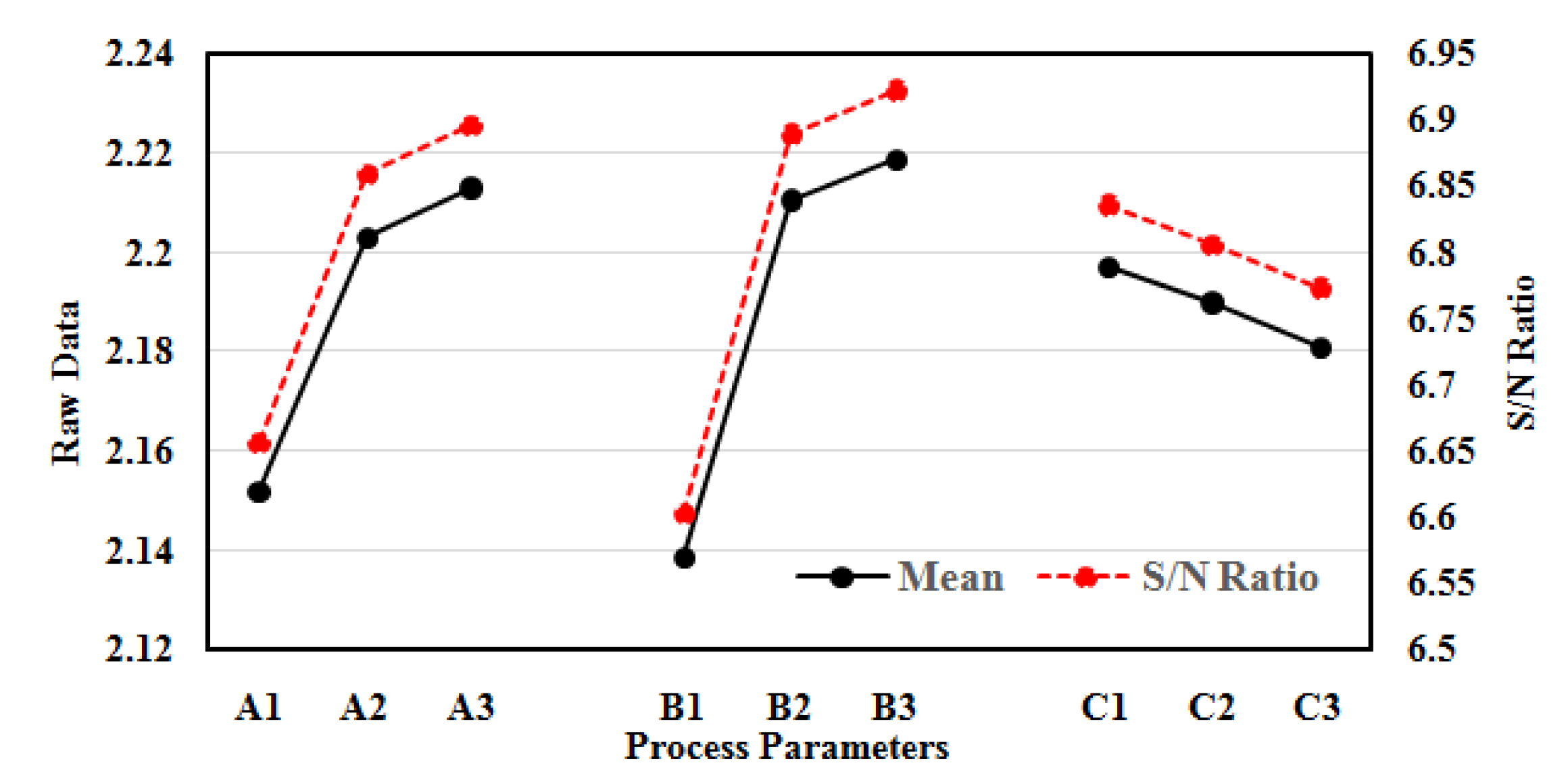

4.1. Material Removal Rate (MRR)

4.2. Overcut

4.3. Process Evaluation Using TOPSIS

| Trial No. | Decision Matrix | Normalized Matrix Nij | Weighted Normalized Matrix Vij | |||

|---|---|---|---|---|---|---|

| MRR | Overcut | MRR | Overcut | MRR | Overcut | |

| 1 | 2.1150 | 49 | 0.3219 | 0.1573 | 0.1287 | 0.0944 |

| 2 | 2.1650 | 69 | 0.3295 | 0.2215 | 0.1318 | 0.1329 |

| 3 | 2.1765 | 61 | 0.3313 | 0.1958 | 0.1325 | 0.1175 |

| 4 | 2.1560 | 88 | 0.3281 | 0.2825 | 0.1312 | 0.1695 |

| 5 | 2.2210 | 80 | 0.3380 | 0.2569 | 0.1352 | 0.1541 |

| 6 | 2.2320 | 121 | 0.3397 | 0.3885 | 0.1359 | 0.2331 |

| 7 | 2.1456 | 110 | 0.3266 | 0.3532 | 0.1306 | 0.2119 |

| 8 | 2.2450 | 160 | 0.3417 | 0.5138 | 0.1366 | 0.3082 |

| 9 | 2.2478 | 140 | 0.3421 | 0.4495 | 0.1368 | 0.2697 |

| Trial No. | Separation Measures | Relative Closeness Index Ci* | Rank | |

|---|---|---|---|---|

| V+ | V− | |||

| 1 | 0.0080 | 0.2138 | 0.9635 | 1 |

| 2 | 0.0388 | 0.1753 | 0.8185 | 3 |

| 3 | 0.0235 | 0.1907 | 0.8902 | 2 |

| 4 | 0.0753 | 0.1387 | 0.6480 | 5 |

| 5 | 0.0597 | 0.1542 | 0.7208 | 4 |

| 6 | 0.1387 | 0.0754 | 0.3523 | 7 |

| 7 | 0.1176 | 0.0963 | 0.4501 | 6 |

| 8 | 0.2138 | 0.0079 | 0.0356 | 9 |

| 9 | 0.1753 | 0.0393 | 0.1833 | 8 |

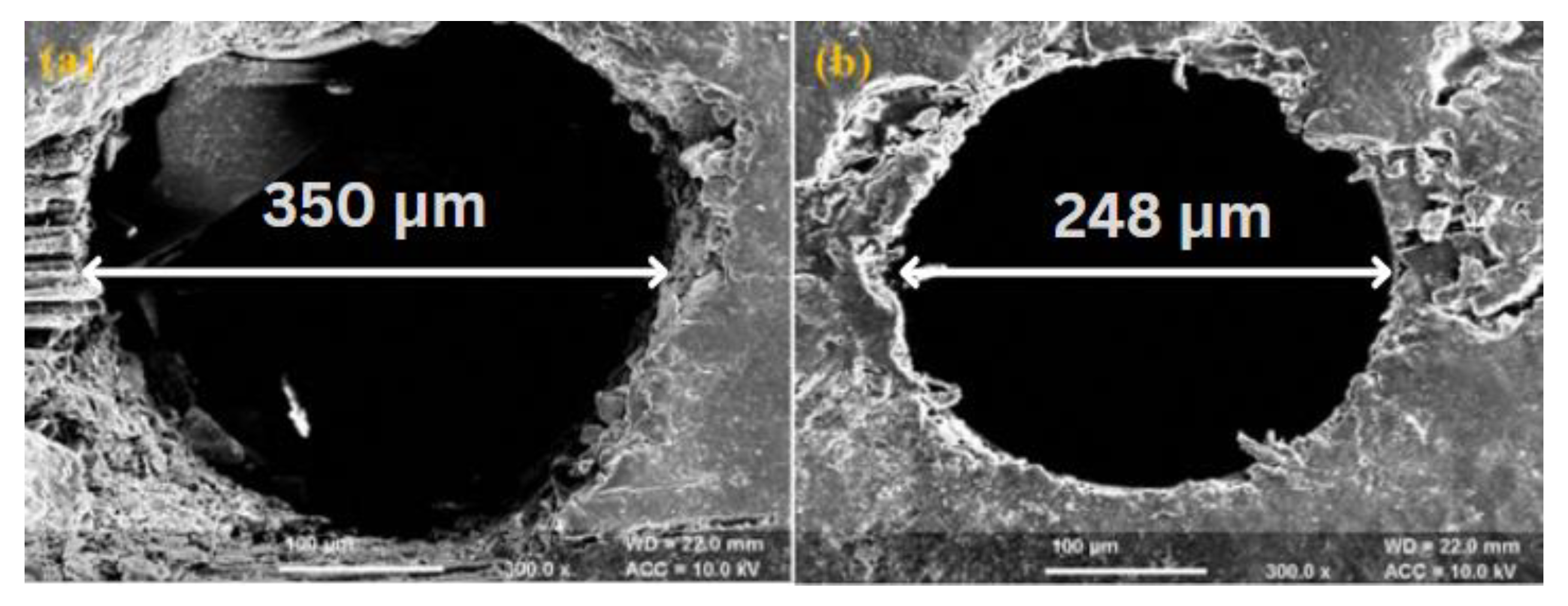

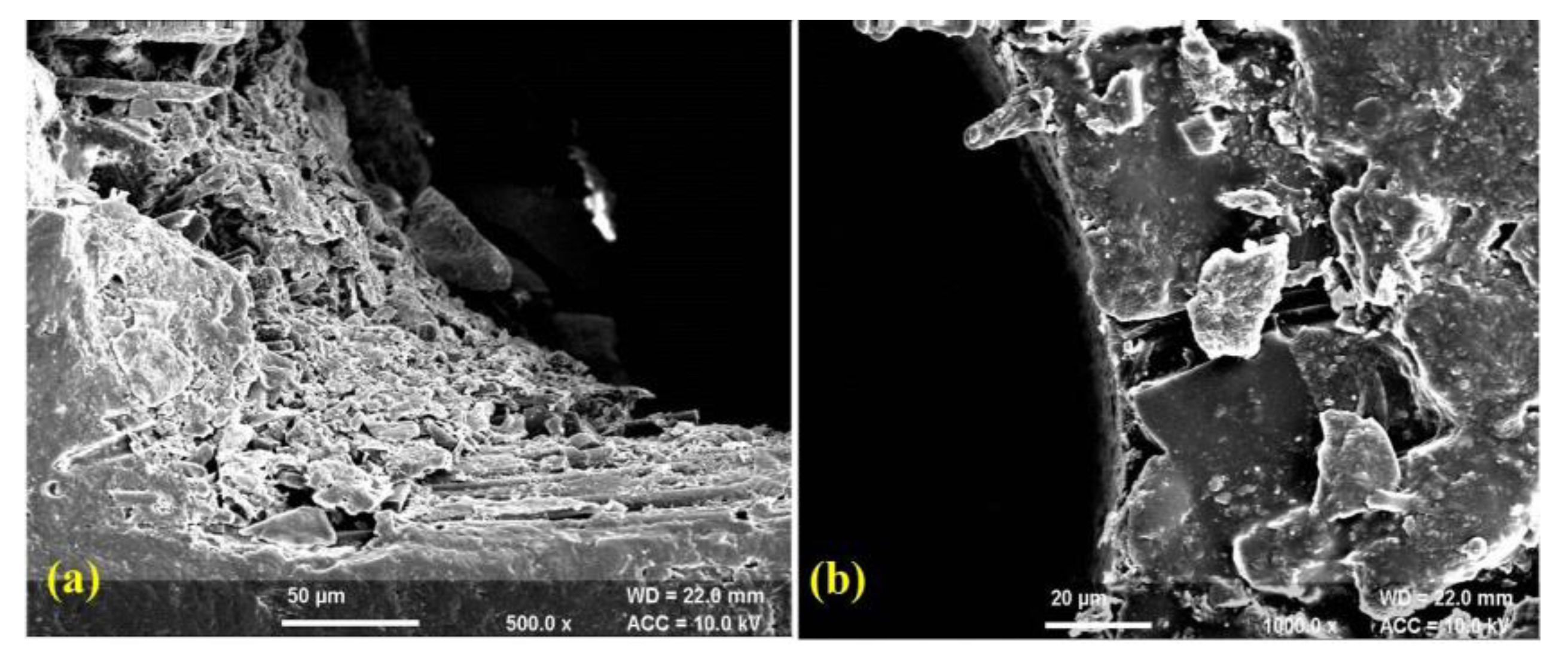

4.4. Confirmatory Test and Morphology of Drilled Hole

5. Conclusions

- Using the TOPSIS approach, the optimal parameters for creating micro holes in CFRP composite were determined to be: voltage 45 V, electrolyte concentration 10%, and inter-electrode spacing 60 mm.

- When compared to electrolyte concentration, the voltage and inter-electrode gap were found to be the most important process parameters that influence the output quality characteristics.

- Increases in applied voltage and electrolyte concentration, while decreases in inter-electrode gap, both have a direct and positive effect on MRR. The ratio of overcut to input values is also roughly the same.

- According to Taguchi’s analysis, the best input process parameters for MRR and overcut are A3B3C1 and A1B1C3, which stand for an applied voltage of 65 V and 45 V, an electrolyte concentration of 30% and an inter-electrode gap of 40 mm and 60 mm, respectively.

- Uneven fibre cutting, microcracks, and minute debris were all visible on the micrograph taken by the SEM across the boundary walls of the machined surface.

- SEM micrograph of machined sample shows improved surface quality and reduced imperfections because of TOPSIS.

- The comparative analysis shows integrated Taguchi-TOPSIS methodology can be effectively used for generating micro holes in fibrous and electrically semi-conductive materials.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kumar, R.; Kumar, A.; Singh, I. Electric discharge drilling of micro holes in CFRP laminates. J. Mater. Processing Technol. 2018, 259, 150–158. [Google Scholar] [CrossRef]

- Bhawal, P.; Das, T.K.; Ganguly, S.; Mondal, S.; Ravindren, R.; Das, N.C. Fabrication of light weight mechanically robust short carbon fiber/ethylene methyl acrylate polymeric nanocomposite for effective electromagnetic interference shielding. J. Polym. Sci. Appl. 2017, 1, 2. [Google Scholar]

- Das, T.K.; Ghosh, P.; Das, N.C. Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: A review. Adv. Compos. Hybrid Mater. 2019, 2, 214–233. [Google Scholar] [CrossRef]

- Geier, N.; Davim, J.P.; Szalay, T. Advanced cutting tools and technologies for drilling carbon fibre reinforced polymer (CFRP) composites: A review. Compos. Part A: Appl. Sci. Manuf. 2019, 125, 105552. [Google Scholar] [CrossRef]

- Ming, W.; Guo, X.; Xu, Y.; Zhang, G.; Jiang, Z.; Li, Y.; Li, X. Progress in non-traditional machining of amorphous alloys. Ceram. Int. 2022. [Google Scholar] [CrossRef]

- Mazarbhuiya, R.M.; Dutta, H.; Debnath, K.; Rahang, M. Surface modification of CFRP composite using reverse-EDM method. Surf. Interfaces 2020, 18, 100457. [Google Scholar] [CrossRef]

- Roldan-Jimenez, L.; Bañon, F.; Valerga, A.P.; Fernandez-Vidal, S.R. Design and Analysis of CFRP Drilling by Electrical Discharge Machining. Polymers 2020, 14, 1340. [Google Scholar] [CrossRef]

- Singh, M.; Singh, S.; Kumar, S. Investigating the impact of LASER assistance on the accuracy of micro-holes generated in carbon fiber reinforced polymer composite by electrochemical discharge machining. J. Manuf. Processes 2020, 60, 586–595. [Google Scholar] [CrossRef]

- Singh, M.; Singh, S.; Kumar, S. Environmental aspects of various electrolytes used in electrochemical discharge machining process. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 1–10. [Google Scholar] [CrossRef]

- Singh, M.; Singh, S. Electrochemical discharge machining: Fumes generations, properties and biological effects. Int. J. Adv. Manuf. Technol. 2020, 106, 357–370. [Google Scholar] [CrossRef]

- Vaishya, R.; Sharma, V.; Gupta, A.; Pathania, J.; Oza, A.; Dixit, A.K.; Patel, A. Finite element modeling of quartz material for analyzing material removal rate in ECDM process. Int. J. Interact. Des. Manuf. 2022; 1–7. [Google Scholar] [CrossRef]

- Saxena, R.; Mandal, A.; Chattopdhya, S.; Oza, A.D.; Kumar, A.; Ramesh, R. Experimental investigation of electrochemical discharge drilling (ECDM-D) performance characteristics for N-BK7 glass material. Int. J. Interact. Des. Manuf. 2022, 1–12. [Google Scholar] [CrossRef]

- Wuthrich, R.; Hof, L.A.; Lal, A.; Fujisaki, K.; Bleuler, H.; Mandin, P.; Picard, G. Physical principles and miniaturization of spark assisted chemical engraving (SACE). J. Micromech. Micro Eng. 2005, 15, S268. [Google Scholar] [CrossRef]

- Sarkar, B.R.; Doloi, B.; Bhattacharyya, B. Parametric analysis on electrochemical discharge machining of silicon nitride ceramics. Int. J. Adv. Manuf. Technol. 2006, 28, 873–881. [Google Scholar] [CrossRef]

- Huang, S.F.; Liu, Y.; Li, J.; Hu, H.X.; Sun, L.Y. Electrochemical discharge machining micro-hole in stainless steel with tool electrode high-speed rotating. Mater. Manuf. Processes 2014, 29, 634–637. [Google Scholar] [CrossRef]

- Liu, J.W.; Yue, T.M.; Guo, Z.N. An analysis of the discharge mechanism in electrochemical discharge machining of particulate reinforced metal matrix composites. Int. J. Mach. Tools Manuf. 2010, 50, 86–96. [Google Scholar] [CrossRef]

- Jha, N.K.; Singh, T.; Dvivedi, A.; Rajesha, S. Experimental investigations into triplex hybrid process of GA-RDECDM during subtractive processing of MMC’s. Mater. Manuf. Processes 2019, 34, 243–255. [Google Scholar] [CrossRef]

- Antil, P.; Singh, S.; Manna, A. Electrochemical Discharge Drilling of SiC Reinforced Polymer Matrix Composite Using Taguchi’s Grey Relational Analysis. Arab. J. Sci. Eng. 2018, 43, 1257–1266. [Google Scholar] [CrossRef]

- Antil, P. Modelling and multi-objective optimization during ECDM of silicon carbide reinforced epoxy composites. Silicon 2020, 12, 275–288. [Google Scholar] [CrossRef]

- Singh, Y.P.; Jain, V.K.; Kumar, P.; Agrawal, D.C. Machining piezoelectric (PZT) ceramics using an electrochemical spark machining (ECSM) process. J. Mater. Processing Technol. 1996, 58, 24–31. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, Z.; Xing, J.; Zhu, D. Effect of tube-electrode inner diameter on electrochemical discharge machining of nickel-based superalloy. Chin. J. Aeronautics 2016, 29, 1103–1110. [Google Scholar] [CrossRef]

- Behzadian, M.; Otaghsara, S.K.; Yazdani, M.; Ignatius, J. A state-of the-art survey of TOPSIS applications. Expert Syst. Appl. 2012, 39, 13051–13069. [Google Scholar] [CrossRef]

- Nayak, B.B.; Mahapatra, S.S. Multi-response optimization of WEDM process parameters using the AHP and TOPSIS method. Int. J. Theor. Appl. Res. Mech. Eng. 2013, 2, 109–215. [Google Scholar]

- Nguyen, P.; Banh, L.; Bui, V.; Hoang, D. Multi-response optimization of process parameters for powder mixed electro-discharge machining according to the surface roughness and surface micro-hardness using Taguchi-TOPSIS. Int. J. Data Netw. Sci. 2018, 2, 109–119. [Google Scholar] [CrossRef]

- Parthiban, K.; Duraiselvam, M.; Manivannan, R. TOPSIS based parametric optimization of laser micro-drilling of TBC coated nickel based superalloy. Opt. Laser Technol. 2018, 102, 32–39. [Google Scholar] [CrossRef]

- Ladeesh, V.G.; Manu, R. Machining of fluidic channels on borosilicate glass using grinding-aided electrochemical discharge engraving (G-ECDE) and process optimization. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 1–19. [Google Scholar] [CrossRef]

- Ananthakumar, K.; Rajamani, D.; Balasubramanian, E.; Davim, J.P. Measurement and optimization of multi-response characteristics in plasma arc cutting of Monel 400™ using RSM and TOPSIS. Measurement 2019, 135, 725–737. [Google Scholar] [CrossRef]

- Chen, Y.F.; Lin, Y.J.; Lin, Y.C.; Chen, S.L.; Hsu, L.R. Optimization of electrodischarge machining parameters on ZrO2 ceramic using the Taguchi method. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 224, 195–205. [Google Scholar] [CrossRef]

- Bhattacharya, B.; Munda, J. Experimental investigation on the influence of electrochemical machining parameters on machining rate and accuracy in micromachining domain. Int. J. Mach. Tools Manuf. 2003, 43, 1301–1310. [Google Scholar]

- Madhavi, J.B.; Hiremath, S.S. Machining and Characterization of Channels and Textures on Quartz Glass Using μ-ECDM Process. Silicon 2019, 11, 2919–2931. [Google Scholar] [CrossRef]

- Ladeesh, V.G.; Manu, R. Grinding-aided electrochemical discharge drilling in the light of electrochemistry. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 1896–1909. [Google Scholar] [CrossRef]

- Bhargav, K.V.J.; Shanthan, P.; Balaji, P.S.; Sahu, R.K.; Sahoo, S.K. Generation of microholes on GFRP composite using ES-µ-ECDM system. CIRP J. Manuf. Sci. Technol. 2022, 38, 695–705. [Google Scholar] [CrossRef]

- Doloi, B.; Bhattacharyya, B.; Sorkhel, S.K. Electrochemical discharge machining of non-conducting ceramics. Def. Sci. J. 1999, 49, 331–338. [Google Scholar] [CrossRef]

- Omashekhar, K.P.; Mathew, J.; Ramachandran, N. Multi-objective optimization of micro wire electric discharge machining parameters using grey relational analysis with Taguchi method. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2011, 225, 1742–1753. [Google Scholar] [CrossRef]

- Tripathy, S.; Tripathy, D.K. Multi-attribute optimization of machining process parameters in powder mixed electro-discharge machining using TOPSIS and grey relational analysis. Eng. Sci. Technol. Int. J. 2016, 19, 62–70. [Google Scholar] [CrossRef]

| Symbols | Process Parameters | Level 1 | Level 2 | Level 3 |

|---|---|---|---|---|

| A | Voltage (Volts) | 45 | 55 | 65 |

| B | Electrolyte Concentration (wt.%/V) | 10 | 20 | 30 |

| C | Inter-Electrode Gap (mm) | 40 | 50 | 60 |

| Trial. No. | Voltage | Electrolyte Concentration | Inter Electrode Gap | MRR (mg/min) | Overcut (µm) | ||

|---|---|---|---|---|---|---|---|

| Mean | S/N Ratio | Mean | S/N Ratio | ||||

| 1 | 45 | 10 | 40 | 2.1150 | 6.50621 | 49 | −33.8039 |

| 2 | 45 | 20 | 50 | 2.1650 | 6.70916 | 69 | −36.7770 |

| 3 | 45 | 30 | 60 | 2.1765 | 6.75517 | 61 | −35.7066 |

| 4 | 55 | 10 | 50 | 2.1560 | 6.67298 | 88 | −38.8897 |

| 5 | 55 | 20 | 60 | 2.2210 | 6.93097 | 80 | −38.0618 |

| 6 | 55 | 30 | 40 | 2.2320 | 6.97388 | 121 | −41.6557 |

| 7 | 65 | 10 | 60 | 2.1456 | 6.63098 | 110 | −40.8279 |

| 8 | 65 | 20 | 40 | 2.2450 | 7.02433 | 160 | −44.0824 |

| 9 | 65 | 30 | 50 | 2.2478 | 7.03515 | 140 | −42.9226 |

| Levels | Process Parameters | ||

|---|---|---|---|

| A | B | C | |

| 1 | 0.8907 | 0.6872 | 0.4505 |

| 2 | 0.5737 | 0.5250 | 0.5499 |

| 3 | 0.2230 | 0.4753 | 0.6870 |

| Delta | 0.6677 | 0.2119 | 0.2366 |

| Rank | 1 | 3 | 2 |

| Source | DF | Adj SS | Adj MS | F Value | p Value |

|---|---|---|---|---|---|

| A | 2 | 0.66937 | 0.334684 | 40.32 | 0.024 |

| B | 2 | 0.07371 | 0.036853 | 4.44 | 0.184 |

| C | 2 | 0.08465 | 0.042327 | 5.10 | 0.164 |

| Error | 2 | 0.01660 | 0.008300 | ||

| Total | 8 | 0.84433 |

| Responses | Initial Parametric Condition (A3B2C1) | Optimum Parametric Condition (A1B1C3) |

|---|---|---|

| MRR (mg/min) | 2.232 | 2.1267 |

| Overcut (µm) | 150 | 48 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, M.; Singh, S.; Arora, J.K.; Antil, P.; Oza, A.D.; Burduhos-Nergis, D.D.; Burduhos-Nergis, D.P. Multi Response Optimization of ECDM Process for Generating Micro Holes in CFRP Composite Using TOPSIS Methodology. Polymers 2022, 14, 5291. https://doi.org/10.3390/polym14235291

Singh M, Singh S, Arora JK, Antil P, Oza AD, Burduhos-Nergis DD, Burduhos-Nergis DP. Multi Response Optimization of ECDM Process for Generating Micro Holes in CFRP Composite Using TOPSIS Methodology. Polymers. 2022; 14(23):5291. https://doi.org/10.3390/polym14235291

Chicago/Turabian StyleSingh, Manpreet, Sarbjit Singh, Jatinder Kaur Arora, Parvesh Antil, Ankit D. Oza, Dumitru Doru Burduhos-Nergis, and Diana Petronela Burduhos-Nergis. 2022. "Multi Response Optimization of ECDM Process for Generating Micro Holes in CFRP Composite Using TOPSIS Methodology" Polymers 14, no. 23: 5291. https://doi.org/10.3390/polym14235291

APA StyleSingh, M., Singh, S., Arora, J. K., Antil, P., Oza, A. D., Burduhos-Nergis, D. D., & Burduhos-Nergis, D. P. (2022). Multi Response Optimization of ECDM Process for Generating Micro Holes in CFRP Composite Using TOPSIS Methodology. Polymers, 14(23), 5291. https://doi.org/10.3390/polym14235291