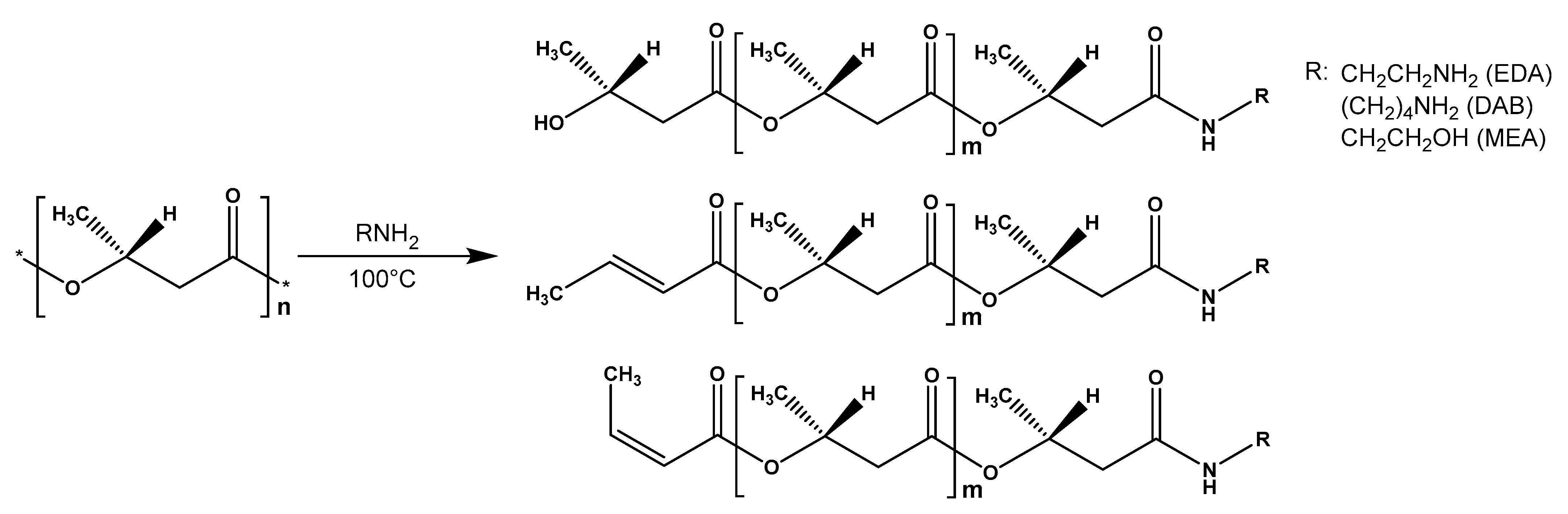

Aminolysis of Poly-3-Hydroxybutyrate in N,N-Dimethylformamide and 1,4-Dioxane and Formation of Functionalized Oligomers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Aminolysis and Oligomeric Samples Isolation

2.2.2. Molecular Weight Analysis

2.2.3. Differential Scanning Calorimetry (DSC)

2.2.4. Nuclear Magnetic Resonance (NMR) Spectroscopy

2.2.5. FTIR (Fourier Transformed Infra-Red) Spectroscopy

3. Results

3.1. Change in the Molecular Weight of PHB during Amine-Assisted Degradation

3.2. Characteristics of Oligomeric PHB Samples

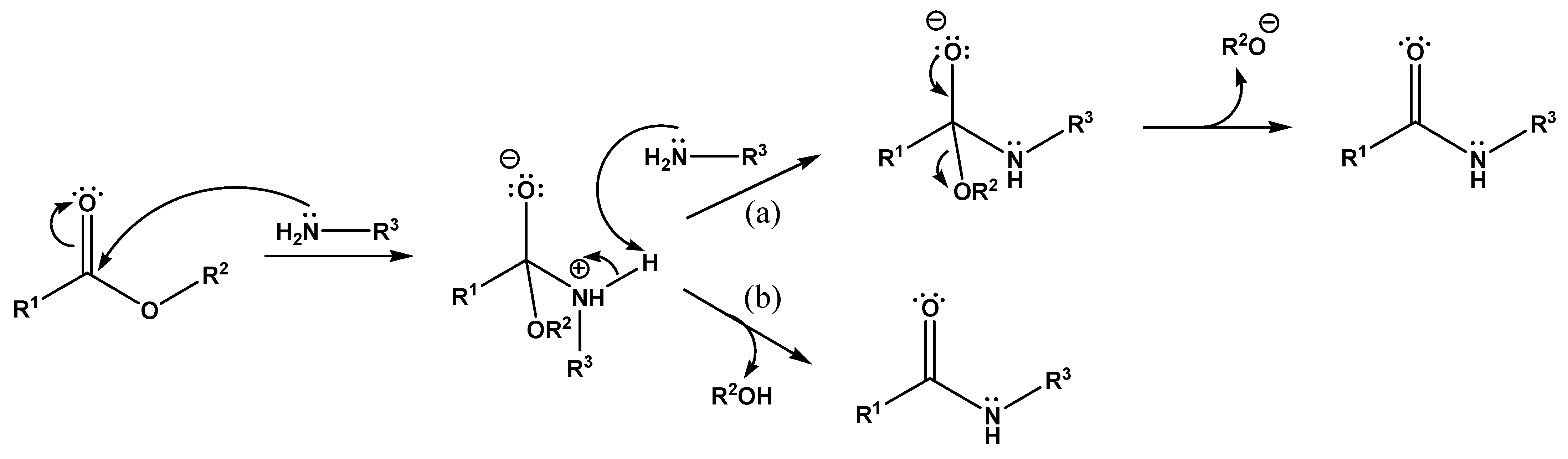

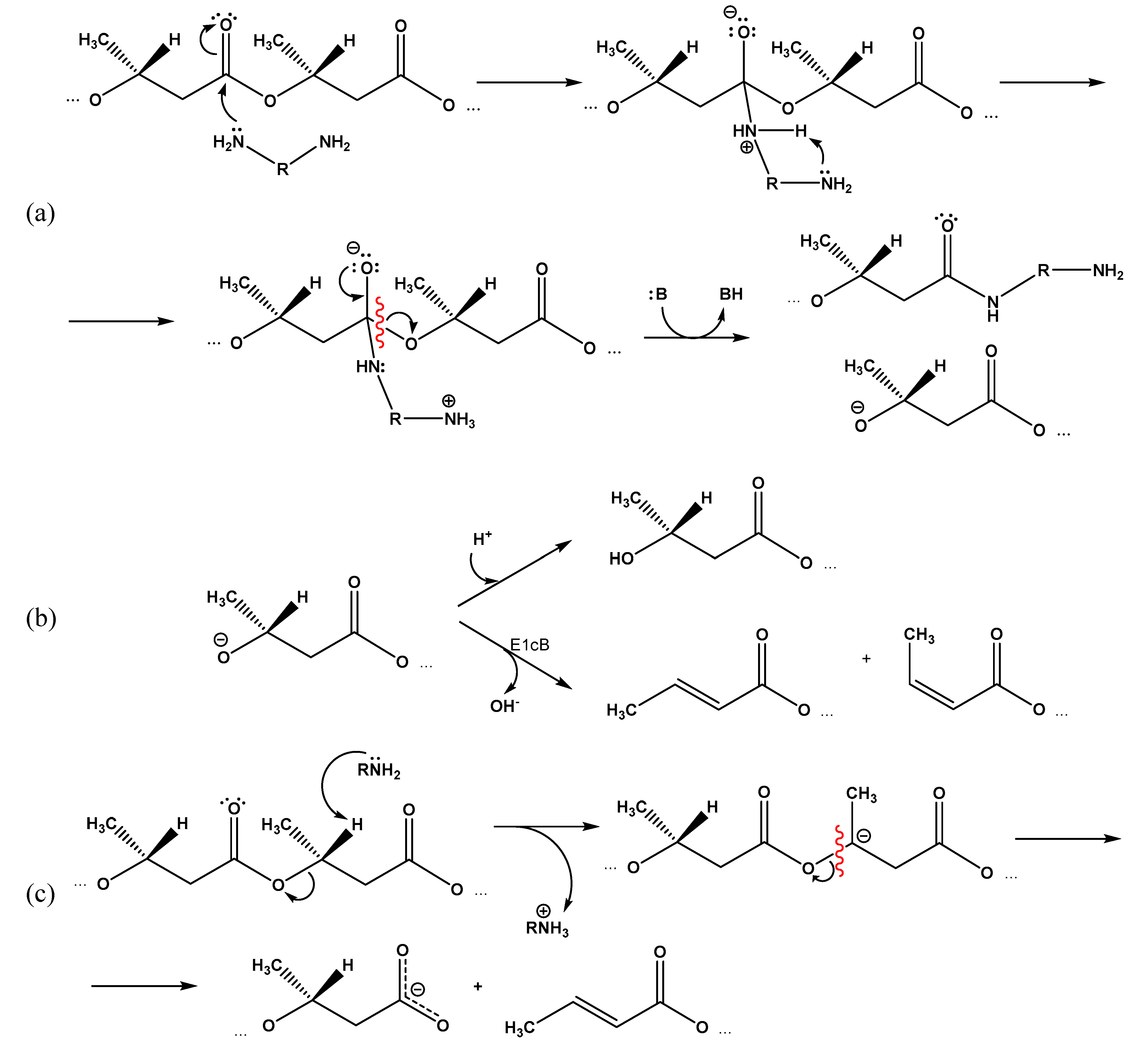

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liechty, W.B.; Kryscio, D.R.; Slaughter, B.V.; Peppas, N.A. Polymers for drug delivery systems. Annu. Rev. Chem. Biomol. Eng. 2010, 1, 149–173. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Diacon, A. Polymers Functionalized with Chromophores for Applications in Photovoltaics, Photonics and Medicine. Ph.D. Thesis, Université d’Angers, Angers, France, 2011. [Google Scholar]

- Ritter, H. Functionalized polymers: Synthesis and properties. Beilstein J. Org. Chem. 2010, 6, 55. [Google Scholar] [CrossRef] [PubMed]

- Koller, M. Biodegradable and biocompatible polyhydroxyalkanoates (PHA): Auspicious microbial macromolecules for pharmaceutical and therapeutic applications. Molecules 2018, 23, 362. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Priegue, J.M.; Crisan, D.N.; Martínez-Costas, J.; Granja, J.R.; Fernandez-Trillo, F.; Montenegro, J. In situ functionalized polymers for siRNA delivery. Angew. Chem. Int. Ed. Engl. 2016, 55, 7492–7495. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, L.-P. (Ed.) Polyhydroxyalkanoates (PHAs): Biosynthesis, Industrial Production and Applications in Medicine; Nova Science Publishers, Inc.: New York, NY, USA, 2014; 357p. [Google Scholar]

- Ekere, A.I.; Radecka, I.; Kurcok, P.; Adamus, G.; Konieczny, T.; Zięba, M.; Chaber, P.; Tchuenbou-Magaia, F.; Kowalczuk, M. Oligomers derived from natural PHA. 4. Bioactive and functional oligomers derived from natural PHA and their synthetic analogs. In The Handbook of Polyhydroxyalkanoates, Three Volume Set; Koller, M., Ed.; CRC Press: Boca Raton, FL, USA, 2020; 1416p. [Google Scholar]

- Ravenelle, F.; Marchessault, R.H. One-step synthesis of amphiphilic diblock copolymers from bacterial poly([R]-3-hydroxybutyric acid). Biomacromolecules 2002, 3, 1057–1064. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Wang, L.; Wang, X.; Xu, K. Synthesis, characterizations and biocompatibility of novel biodegradable star block copolymers based on poly[(R)-3-hydroxybutyrate] and poly(ε-caprolactone). Acta Biomater. 2010, 6, 1079–1089. [Google Scholar] [CrossRef]

- Hiroe, A.; Sakurai, T.; Mizuno, S.; Miyahara, Y.; Goto, S.; Yamada, M.; Tsuge, T.; Taguchi, S. Microbial oversecretion of (R)-3-hydroxybutyrate oligomer with diethylene glycol terminal as a macromonomer for polyurethane synthesis. Int. J. Biol. Macromol. 2021, 167, 1290–1296. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, L.; Dong, Y.F.; Zhang, X.Y.; Lin, J.; Chen, Z. Folate-mediated poly(3-hydroxybutyrate-co-3-hydroxyoctanoate) nanoparticles for targeting drug delivery. Eur. J. Pharm. Biopharm. 2010, 76, 10–16. [Google Scholar] [CrossRef]

- Ravi Kumar, M.N.V. (Ed.) Handbook of Polyester Drug Delivery Systems; CRC Press: New York, NY, USA, 2016; 738p. [Google Scholar]

- Dalton, B.; Bhagabati, P.; De Micco, J.; Padamati, R.B.; O’Connor, K. A Review on biological synthesis of the biodegradable polymers polyhydroxyalkanoates and the development of multiple applications. Catalysts 2022, 12, 319. [Google Scholar] [CrossRef]

- Raza, Z.A.; Riaz, S.; Banat, I.M. Polyhydroxyalkanoates: Properties and chemical modification approaches for their functionalization. Biotechnol. Prog. 2018, 34, 29–41. [Google Scholar] [CrossRef]

- Nguyen, S.; Yu, G.; Marchessault, R.H. Thermal degradation of poly(3-hydroxyalkanoates): preparation of well-defined oligomers. Biomacromolecules 2002, 3, 219–224. [Google Scholar] [CrossRef] [PubMed]

- Ramier, J.; Grande, D.; Langlois, V.; Renard, E. Toward the controlled production of oligoesters by microwave-assisted degradation of poly (3-hydroxyalkanoate)s. Polym. Degr. Stab. 2012, 97, 322–328. [Google Scholar] [CrossRef]

- Kawalec, M.; Sobota, M.; Scandola, M.; Kowalczuk, M.; Kurcok, P. A convenient route to PHB macromonomers via anionically controlled moderate-temperature degradation of PHB. J. Polym. Sci. Part A Polym. Chem. 2010, 48, 5490–5497. [Google Scholar] [CrossRef]

- Kawalec, M.; Adamus, G.; Kurcok, P.; Kowalczuk, M.; Foltran, I.; Focarete, M.L.; Scandola, M. Carboxylate-induced degradation of poly(3-hydroxybutyrate)s. Biomacromolecules 2007, 8, 1053–1058. [Google Scholar] [CrossRef]

- Adamus, G.; Kurcok, P.; Radecka, I.; Kowalczuk, M. Bioactive oligomers from natural polyhydroxyalkanoates and their synthetic analogues. Polymer 2017, 62, 317–322. [Google Scholar] [CrossRef]

- Špitalský, Z.; Lacík, I.; Lathová, E.; Janigová, I.; Chodák, I. Controlled degradation of polyhydroxybutyrate via alcoholysis with ethylene glycol or glycerol. Polym. Degrad. Stab. 2006, 91, 856–861. [Google Scholar] [CrossRef]

- Wendels, S.; Heinrich, B.; Donnio, B.; Avérous, L. Green and controlled synthesis of short diol oligomers from polyhydroxyalkanoate to develop fully biobased thermoplastics. Eur. Polym. J. 2021, 153, 110531. [Google Scholar] [CrossRef]

- Erduranlı, H.; Hazer, B.; Borcaklı, M. Post polymerization of saturated and unsaturated poly(3-hydroxy alkanoate)s. Macromol. Symp. 2008, 269, 161–169. [Google Scholar] [CrossRef]

- Yalpani, M.; Marchessault, R.H.; Morin, F.G.; Monasterios, C.J. Synthesis of poly(3-hydroxyalkanoate) (PHA) conjugates: PHA-carbohydrate and PHA-synthetic polymer conjugates. Macromolecules 1991, 24, 6046–6049. [Google Scholar] [CrossRef]

- Yu, G.; Marchessault, R.H. Characterization of low molecular weight poly(β-hydroxybutyrate)s from alkaline and acid hydrolysis. Polymer 2000, 41, 1087–1098. [Google Scholar] [CrossRef]

- Yu, J.; Plackett, D.; Chen, L.X.L. Kinetics and mechanism of the monomeric products from abiotic hydrolysis of poly[(R)-3-hydroxybutyrate] under acidic and alkaline conditions. Polym. Degrad. Stab. 2005, 89, 289–299. [Google Scholar] [CrossRef]

- Kalia, V.C.; Kumar, P. Microbial Applications Vol. 1: Bioremediation and Bioenergy; Springer: Berlin, Germany, 2017; 331p. [Google Scholar]

- Leimann, F.V.; Cardozo Filho, L.; Sayer, C.; Araújo, P.H.H. Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) nanoparticles prepared by a miniemulsion/solvent evaporation technique: Effect of PHBV molar mass and concentration. Braz. J. Chem. Eng. 2013, 30, 369–377. [Google Scholar] [CrossRef] [Green Version]

- Chaber, P.; Kwiecień, M.; Zięba, M.; Sobota, M.; Adamus, G. The heterogeneous selective reduction of PHB as a useful method for preparation of oligodiols and surface modification. RSC Adv. 2017, 7, 35096–35104. [Google Scholar] [CrossRef] [Green Version]

- Michalak, M.; Kwiecien, I.; Kwiecien, M.; Adamus, G.; Odelius, K.; Hakkarainen, M.; Kurcok, P. Diversifying polyhydroxyalkanoates—end-group and side-chain functionality. Curr. Org. Synth. 2017, 14, 757–767. [Google Scholar] [CrossRef]

- Zhu, Y.; Mao, Z.; Gao, C. Aminolysis-based surface modification of polyesters for biomedical applications. RSC Adv. 2013, 3, 2509–2519. [Google Scholar] [CrossRef]

- Volova, T.G.; Kiselev, E.G.; Vinogradova, O.N.; Nikolaeva, E.D.; Chistyakov, A.A.; Sukovatyi, A.G.; Shishatskaya, E.I. A glucose-utilizing strain, Cupriavidus eutrophus B-10646: Growth kinetics, characterization and synthesis of multicomponent PHAs. PLoS ONE 2014, 9, e87551. [Google Scholar] [CrossRef]

- Benz, G. Synthesis of amides and related compounds. In Comprehensive Organic Synthesis; Trost, B.M., Fleming, I., Winterfeldt, E., Eds.; Pergamon Press: Oxford, UK, 1991; Volume 6, pp. 381–417. [Google Scholar]

- Shawali, A.S.A.S.; Biechler, S.S. Aminolysis of esters. I. Kinetics and mechanism in anhydrous dioxane. J. Am. Chem. Soc. 1967, 89, 3020–3026. [Google Scholar] [CrossRef]

- Satchell, D.P.N.; Secemski, I.I. Acylation. Part XXIX. The mechanism of ester aminolysis in non-hydroxylic media and the effect of nitrogen-containing leaving groups. J. Chem. Soc. B 1969, 0, 130–137. [Google Scholar] [CrossRef]

- Menger, F.M.; Smith, J.H. Mechanism of ester aminolyses in aprotic solvents. J. Am. Chem. Soc. 1972, 94, 3824–3829. [Google Scholar] [CrossRef]

- Talvik, A.-T.; Tuulmets, A.; Vaino, E. Kinetics and mechanism of aminolysis of aliphatic esters in aprotic solvents. J. Phys. Org. Chem. 1999, 12, 747–750. [Google Scholar] [CrossRef]

- Buchholz, B.A.; Zahn, J.M.; Kenward, M.; Slater, G.W.; Barron, A.E. Flow-induced chain scission as a physical route to narrowly distributed, high molar mass polymers. Polymer 2004, 45, 1223–1234. [Google Scholar] [CrossRef]

| Solvent | Time | Reagent and Molar Ratio | |||||

|---|---|---|---|---|---|---|---|

| EDA | DAB | MEA | |||||

| 1:10 | 1:5 | 1:10 | 1:5 | 1:10 | 1:5 | ||

| DMF 1 | 10 min | 81.9 | 48.9 | 45.6 | 25.4 | 362 | 297 |

| DMF | 1 h | 14.3 | 7.06 | 9.49 | 5.04 | 161 | 96.3 |

| DMF | 4 h | 3.37 | 2.88 | 3.48 | 2.25 | 39.2 | 22.2 |

| DMF | 10 h | 2.07 | – | 2.47 | – | 15.6 | 8.80 |

| Dioxane | 10 min | 731 | 534 | 199 | 138 | 754 | 632 |

| Dioxane | 1 h | 388 | 243 | 103 | 58.9 | 498 | 322 |

| Dioxane | 4 h | 124 | 60.3 | 30.72 | 19.3 | 220 | 94.4 |

| Dioxane | 10 h | 50.6 | 21.9 | 12.97 | 6.69 | 95.6 | 42.6 |

| Structure | 1H δ (ppm) |

|---|---|

| –O–CH(CH3)–CH2–CO– | δCH3 1.28, δCH2 2.48, δCH 5.27 |

| –O–CH2–CH2–CH2–CO– | δαCH2 1.70, δβCH2 1.42, δγCH2 3.40 |

| –O–CH(C2H5)–CH2–CO– | δCH 5.13, δCH2 2.04, δCH3 0.85 |

| HO–CH(CH3)–CH2–CO– | δCH3 1.20, δCH2 2.42, δCH 4.19 |

| trans-CH3–CH=CH–CO– | δβCH 6.96, δαCH 5.80, δCH3 1.87 |

| cis-CH3–CH=CH–CO– | δβCH 6.33, δαCH 5.75, δCH3 2.13 |

| –O–CH(CH3)–CH2–CO–NH–CH2–CH2–NH2 | δNH 4.03, δCH2NH 2.92, δCH3 1.21 |

| –O–CH(CH3)–CH2–CO–NH–CH2–CH2–CH2–CH2–NH2 | δNH 4.03, δCH2NH 3.0–2.75, δCH2CH2NH 1.60, δCH3 1.21 |

| –O–CH(CH3)–CH2–CO–NH–CH2–CH2–OH | δOH 9.45, δNH 4.03, δCH2NH 1.66, δCH3 1.21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boyandin, A.N.; Bessonova, V.A.; Ertiletskaya, N.L.; Sukhanova, A.A.; Shalygina, T.A.; Kondrasenko, A.A. Aminolysis of Poly-3-Hydroxybutyrate in N,N-Dimethylformamide and 1,4-Dioxane and Formation of Functionalized Oligomers. Polymers 2022, 14, 5481. https://doi.org/10.3390/polym14245481

Boyandin AN, Bessonova VA, Ertiletskaya NL, Sukhanova AA, Shalygina TA, Kondrasenko AA. Aminolysis of Poly-3-Hydroxybutyrate in N,N-Dimethylformamide and 1,4-Dioxane and Formation of Functionalized Oligomers. Polymers. 2022; 14(24):5481. https://doi.org/10.3390/polym14245481

Chicago/Turabian StyleBoyandin, Anatoly Nikolayevich, Viktoriya Aleksandrovna Bessonova, Natalya Leonidovna Ertiletskaya, Anna Alekseevna Sukhanova, Taisiya Aleksandrovna Shalygina, and Alexander Alexandrovich Kondrasenko. 2022. "Aminolysis of Poly-3-Hydroxybutyrate in N,N-Dimethylformamide and 1,4-Dioxane and Formation of Functionalized Oligomers" Polymers 14, no. 24: 5481. https://doi.org/10.3390/polym14245481

APA StyleBoyandin, A. N., Bessonova, V. A., Ertiletskaya, N. L., Sukhanova, A. A., Shalygina, T. A., & Kondrasenko, A. A. (2022). Aminolysis of Poly-3-Hydroxybutyrate in N,N-Dimethylformamide and 1,4-Dioxane and Formation of Functionalized Oligomers. Polymers, 14(24), 5481. https://doi.org/10.3390/polym14245481