Engineering Characteristics of Cement Composites Containing a Chitosan-Based Polymer and Steel Slag Aggregates

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Proportions and Specimen Preparation

2.3. CBP Synthesis

3. Results and Discussion

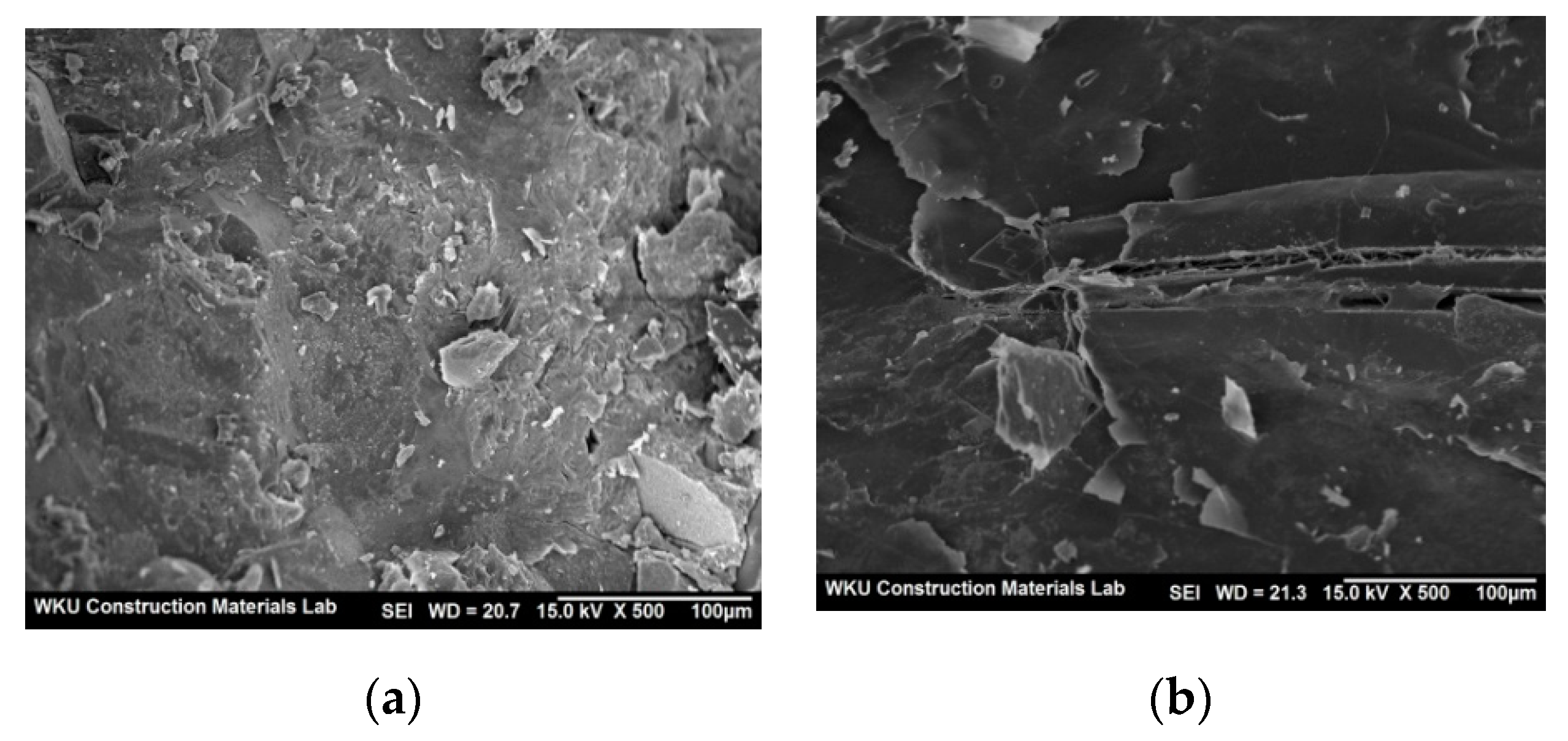

3.1. CBP Characteristics

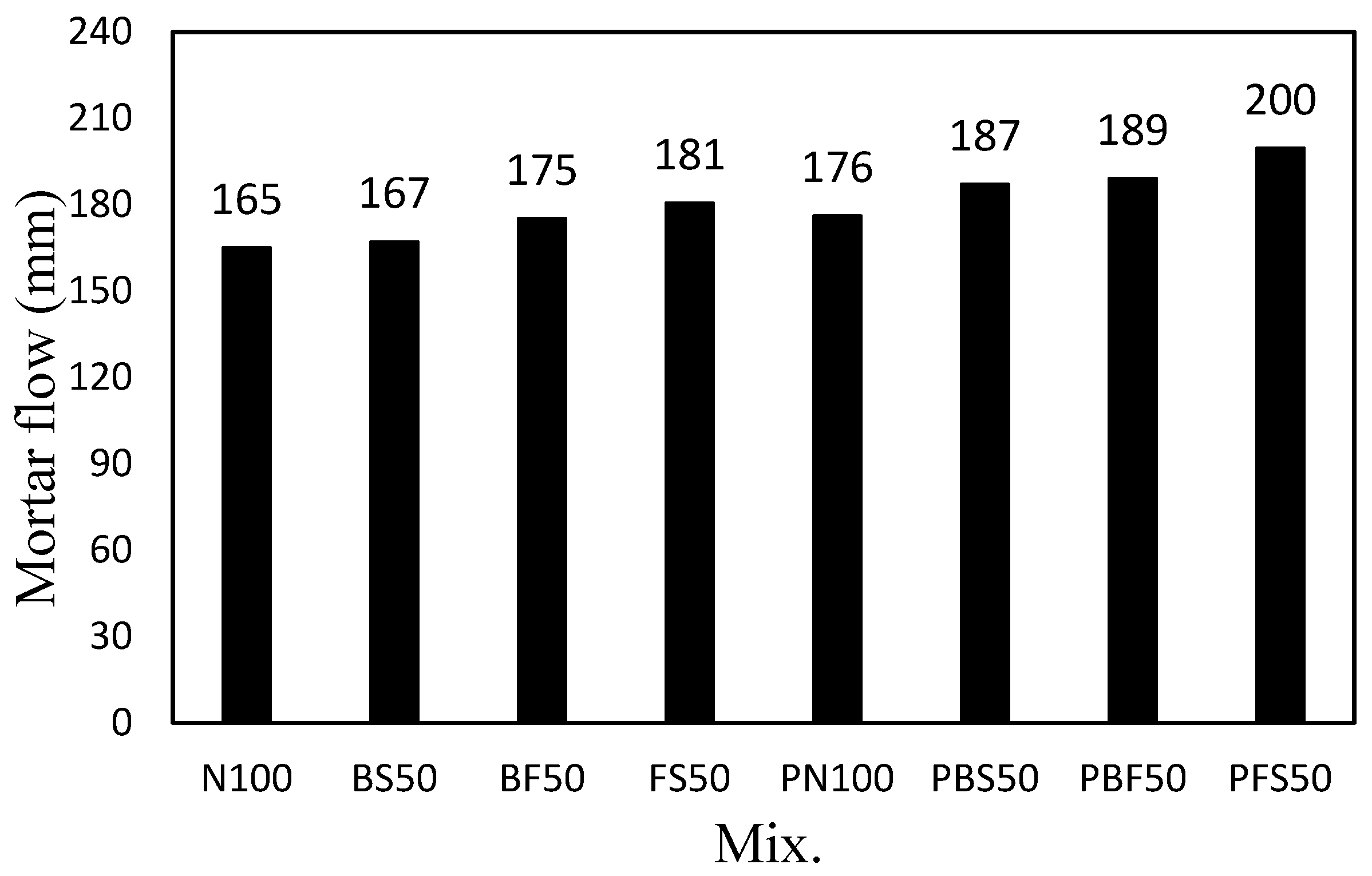

3.2. Mortar Flow

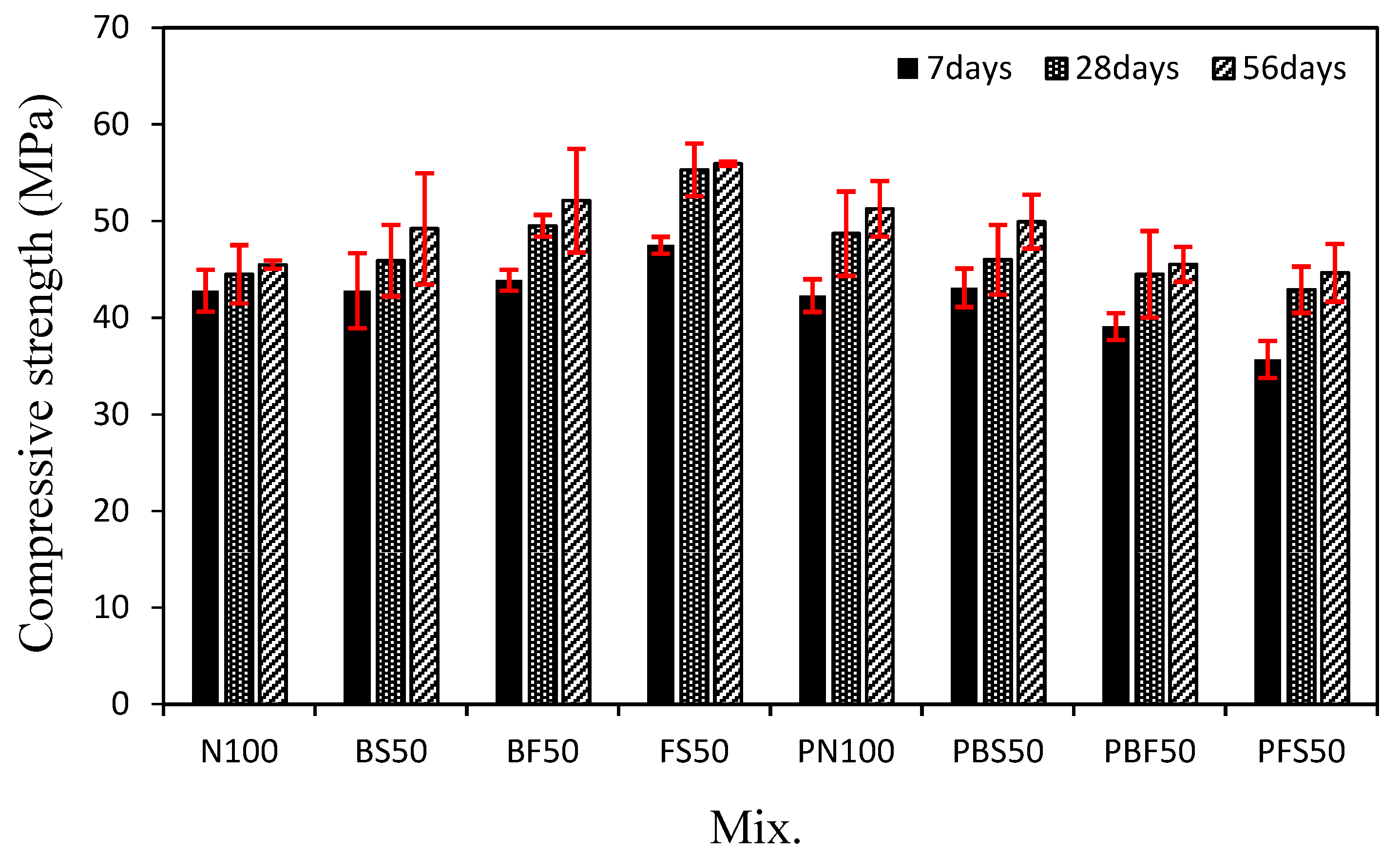

3.3. Compressive Strength

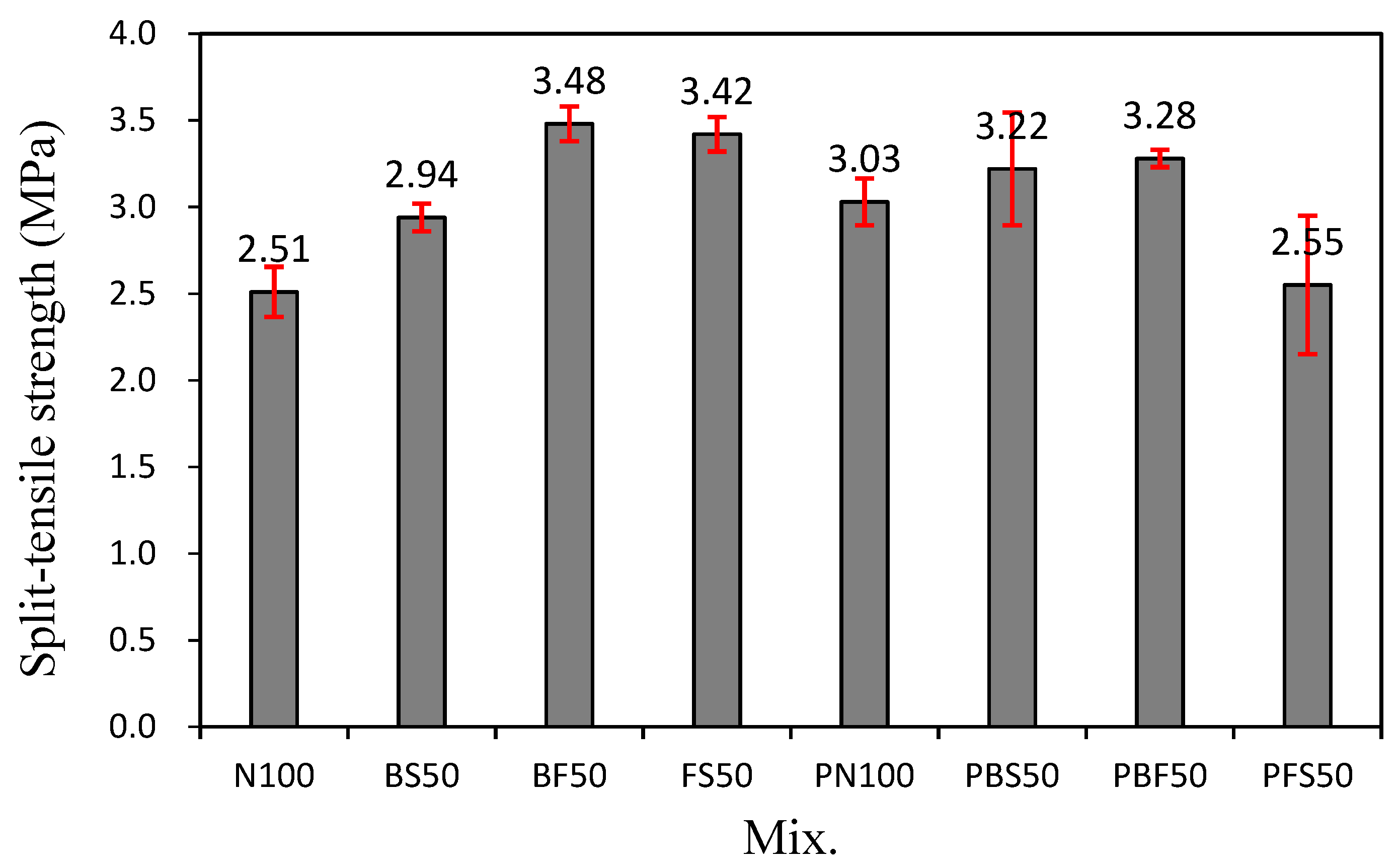

3.4. Split-Tensile Strength

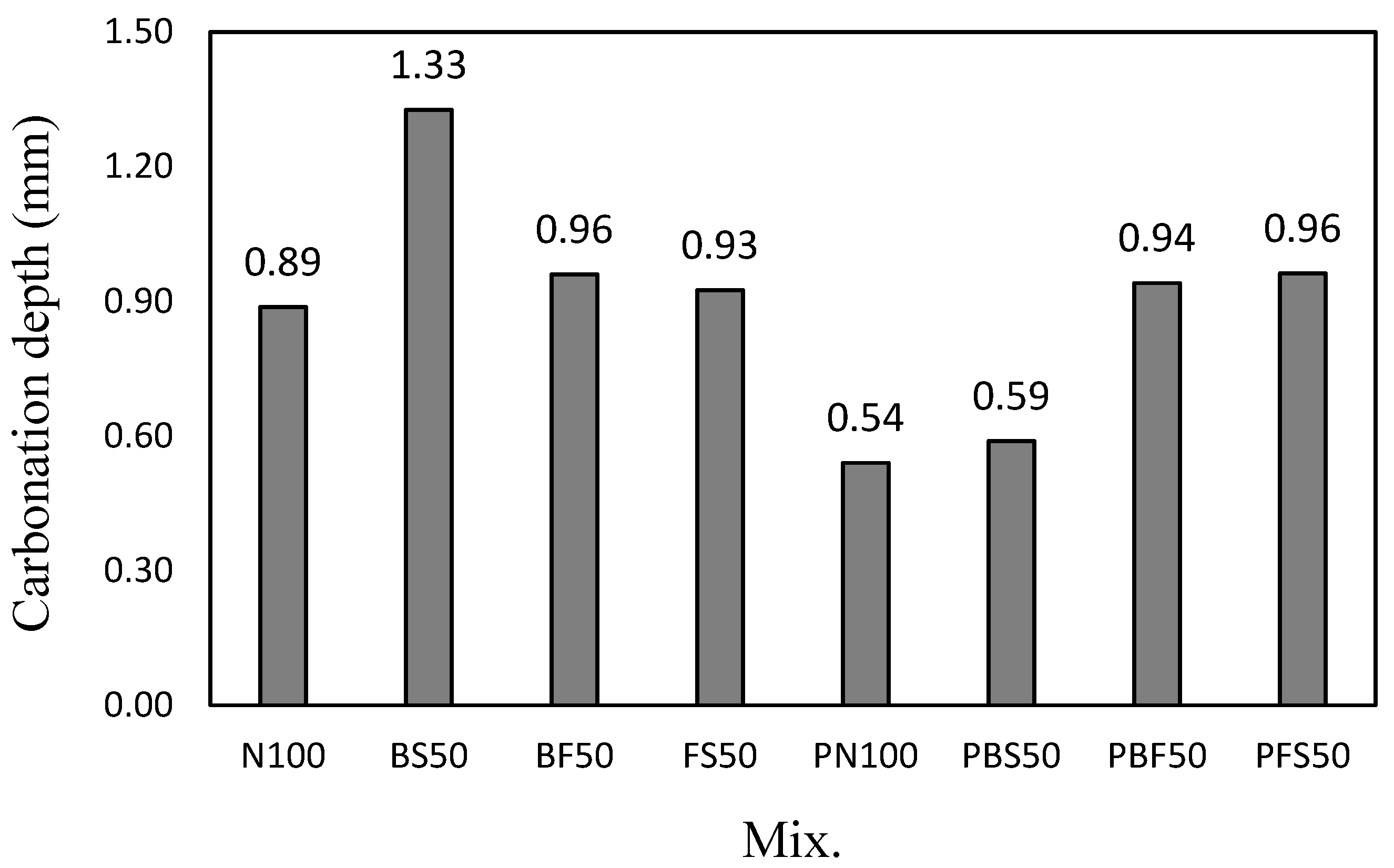

3.5. Carbonation Depth

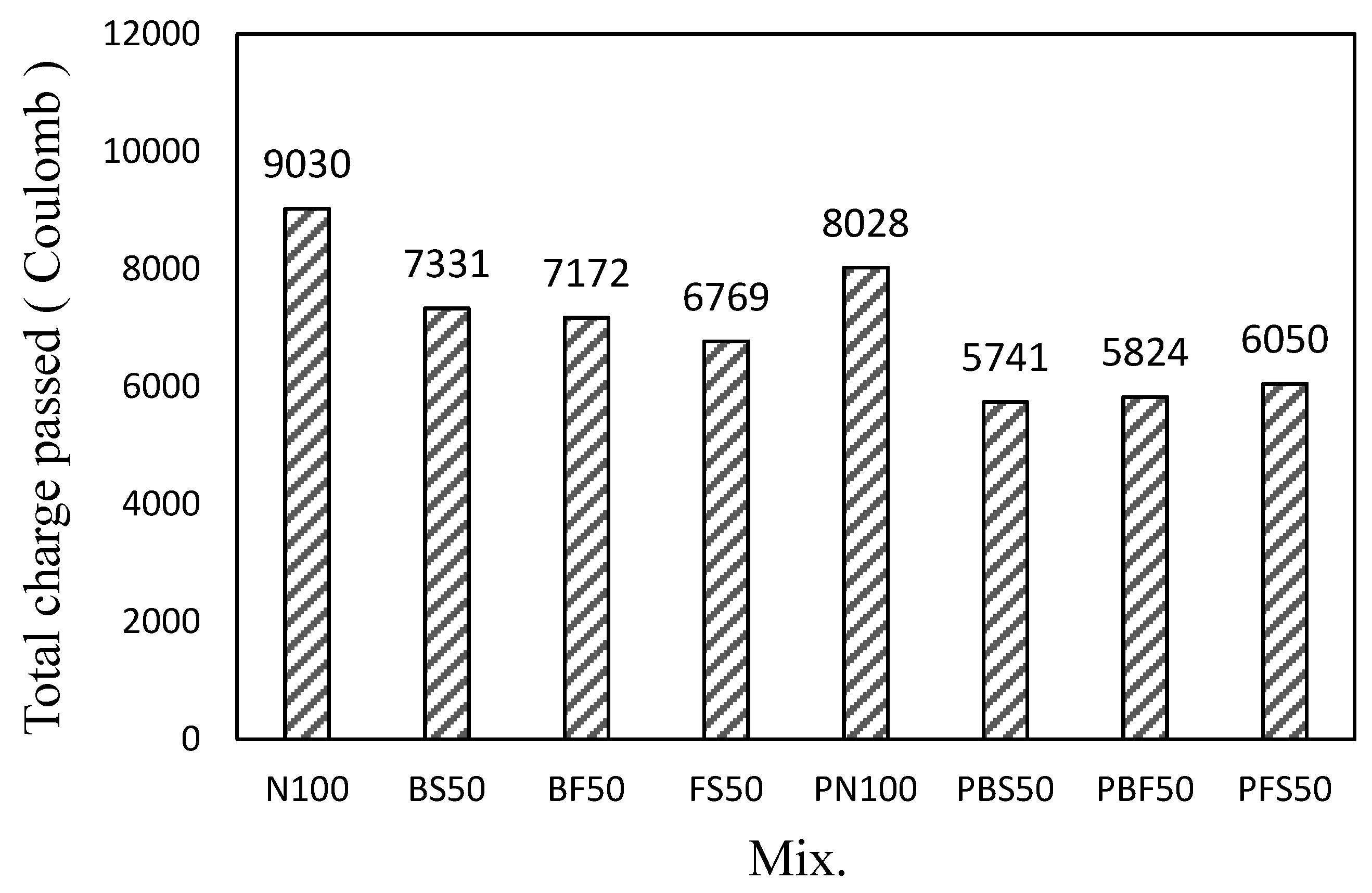

3.6. Chloride-ion Penetrability

4. Conclusions

- (1)

- The 56-day compressive strengths of PN100 and PBS50 were higher than those of N100 and BS50, respectively. However, the compressive strengths of PBF50 and PFS50 were lower than those of BF50 and FS50, respectively. Therefore, BS was more effective than FS for improving the compressive strength of the mixes wherein the CBP and steel slag aggregates were used.

- (2)

- In the samples using NS or BS, the compressive and tensile strengths improved when the CBP was added. However, in the samples using FS, the tensile strength decreased by ~5.7–25.4% after CBP addition.

- (3)

- The carbonation depth of PBS50 was ~0.59 mm, which is remarkably (~55.6%) lower than that of BS50.

- (4)

- The total charge passed through the samples decreased after CBP addition. The chloride-ion penetration resistance of the mortar samples increased when both CBP and steel slag aggregates were used.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nadeem:, M.; Pofale, A. Experimental investigation of using slag as an alternative to normal aggregates (coarse and fine) in concrete. Int. J. Civ. Struct. Eng. 2012, 3, 117–127. [Google Scholar]

- Siddique, R.; Singh, G. Utilization of waste foundry sand (WFS) in concrete manufacturing. Resour. Conserv. Recycl. 2011, 55, 885–892. [Google Scholar] [CrossRef]

- Demirel, B. The effect of the using waste marble dust as fine sand on the mechanical properties of the concrete. Int. J. Phys. Sci. 2010, 5, 1372–1380. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Gholampour, A.; Xie, T. Mechanical and durability properties of recycled aggregate concrete: Effect of recycled aggregate properties and content. J. Mater. Civ. Eng. 2018, 30, 0417275. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Gu, L.; Fallah Pour, A. Normal- and high-strength concretes incorporating air-cooled blast furnace slag coarse aggregates: Effect of slag size and content on the behavior. Constr. Build. Mater. 2016, 126, 138–146. [Google Scholar] [CrossRef]

- Ulubeyli, G.C.; Artir, R. Sustainability for blast furnace slag: Use of some construction wastes. Procedia Soc. Behav. Sci. 2015, 195, 2191–2198. [Google Scholar] [CrossRef] [Green Version]

- Rashad, A.M.; Sadek, D.M.; Hassan, H.A. An investigation on blast-furnace stag as fine aggregate in alkali-activated slag mortars subjected to elevated temperatures. J. Clean. Prod. 2016, 112, 1086–1096. [Google Scholar] [CrossRef]

- Saha, A.K.; Sarker, P.K. Sustainable use of ferronickel slag fine aggregate and fly ash in structural concrete: Mechanical properties and leaching study. J. Clean. Prod. 2017, 162, 438–448. [Google Scholar] [CrossRef]

- Sun, J.; Feng, J.; Chen, Z. Effect of ferronickel slag as fine aggregate on properties of concrete. Constr. Build. Mater. 2019, 206, 201–209. [Google Scholar] [CrossRef]

- Choi, S.J.; Kim, Y.U.; Oh, T.G.; Cho, B.S. Compressive strength, chloride ion penetrability, and carbonation characteristic of concrete with mixed slag aggregate. Materials 2020, 13, 940. [Google Scholar] [CrossRef] [Green Version]

- Saha, A.K.; Sarker, P.K. Compressive strength of mortar containing ferronickel slag as replacement of natural sand. Procedia Eng. 2017, 171, 689–694. [Google Scholar] [CrossRef]

- Liu, X.; Li, T.; Tian, W.; Wang, Y.; Chen, Y. Study on the durability of concrete with FNS fine aggregate. J. Hazard. Mater. 2020, 381, 120936. [Google Scholar] [CrossRef] [PubMed]

- Ngii, E.; Kadir, A.; Rachman, R.M.; Serah, M. Optimum combination of ferro-nickel slag (FeNi4) to the normal sand for the concrete compressive strength. IOP Conf. Ser. Earth Environ. Sci. 2021, 622, 012038. [Google Scholar] [CrossRef]

- Qasrawi, H. Fresh properties of green SCC made with recycled steel slag coarse aggregate under normal and hot weather. J. Clean. Prod. 2018, 204, 980–991. [Google Scholar] [CrossRef]

- Valcuende, M.; Benito, F.; Parra, C.; Miñano, I. Shrinkage of self-compacting concrete made with blast furnace slag as fine aggregate. Constr. Build. Mater. 2015, 76, 1–9. [Google Scholar] [CrossRef]

- Choi, S.; Kim, J.; Bae, S.; Oh, T. Effect of fly ash on compressive strength, drying shrinkage, and carbonation depth of mortar with ferronickel-slag powder. Appl. Sci. 2021, 11, 1037. [Google Scholar] [CrossRef]

- Jafari, K.; Tabatabaeian, M.; Joshaghani, A.; Ozbakkaloglu, T. Optimizing the mixture design of polymer concrete: An experimental investigation. Constr. Build. Mater. 2018, 167, 185–196. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Wong, H.S.; Abousnina, R.; AlAjarmeh, O.S.; Zhuge, Y.; Schubel, P. Optimal design for epoxy polymer concrete based on mechanical properties and durability aspects. Constr. Build. Mater. 2020, 232, 117229. [Google Scholar] [CrossRef]

- Hameed, A.M.; Hamza, M.T. Characteristics of polymer concrete produced from wasted construction materials. Energy Procedia. 2019, 157, 43–50. [Google Scholar] [CrossRef]

- Douba, A.; Emiroglu, M.; Kandil, U.F.; Taha, M.M.R. Very ductile polymer concrete using carbon nanotubes. Constr. Build. Mater. 2019, 196, 468–477. [Google Scholar] [CrossRef]

- Niaki, M.H.; Fereidoon, A.; Ahangari, M.G. Experimental study on the mechanical and thermal properties of basalt fiber and nanoclay reinforced polymer concrete. Compos. Struct. 2018, 191, 231–238. [Google Scholar] [CrossRef]

- Wang, J.; Dai, Q.; Guo, S.; Si, R. Mechanical and durability performance evaluation of crumb rubber-modified epoxy polymer concrete overlays. Constr. Build. Mater. 2019, 203, 469–480. [Google Scholar] [CrossRef]

- Asdollah-Tabar, M.; Heidari-Rarani, M.; Aliha, M.R.M. The effect of recycled PET bottles on the fracture toughness of polymer concrete. Compos. Commun. 2021, 25, 100684. [Google Scholar] [CrossRef]

- Younes, I.; Rinaudo, M. Chitin and chitosan preparation from marine sources. Structure, properties and applications. Mar. Drugs 2015, 13, 1133–1174. [Google Scholar] [CrossRef] [Green Version]

- Lizardi-Mendoza, J.; Monal, W.M.A.; Valencia, F.M.G. Chemical characteristics and functional properties of chitosan. In Chitosan in the Preservation of Agricultural Commodities; Bautista-Banos, S., Romanazzi, G., Jiménez-Aparicio, A., Eds.; Academic Press, Elsevier, Inc.: Cambridge, MA, USA, 2016; pp. 3–31. [Google Scholar]

- Bedian, L.; Villalba-Rodríguez, A.M.; Hernández-Vargas, G.; Parra-Saldivar, R.; Iqbal, H.M.N. Bio-based materials with novel characteristics for tissue engineering applications—A review. Int. J. Biol. Macromol. 2017, 98, 837–846. [Google Scholar] [CrossRef]

- Verlee, A.; Mincke, S.; Stevens, C.V. Recent developments in antibacterial and antifungal chitosan and its derivatives. Carbohydr. Polym. 2017, 164, 268–283. [Google Scholar] [CrossRef]

- Chang, K.L.B.; Tsai, G.; Lee, J.; Fu, W.R. Heterogeneous N-deacetylation of chitin in alkaline solution. Carbohydr. Res. 1997, 303, 327–332. [Google Scholar] [CrossRef]

- Kim, K.; Kim, K.; Ryu, J.H.; Lee, H. Chitosan-catechol: A polymer with long-lasting mucoadhesive properties. Biomaterials 2015, 52, 161–170. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Ryu, J.H.; Lee, D.Y.; Lee, H. Bio-inspired catechol conjugation converts water-insoluble chitosan into a highly water-soluble, adhesive chitosan derivative for hydrogels and LbL assembly. Biomater. Sci. 2013, 1, 783–790. [Google Scholar] [CrossRef]

- Choi, S.; Bae, S.; Lee, J.; Bang, E.; Ko, H. Strength, carbonation resistance, and chloride-ion penetrability of cement mortars containing catechol-functionalized chitosan. J. Polym. Mater. 2021, 14, 6395. [Google Scholar] [CrossRef] [PubMed]

- KS L 5105; Testing Method for Compressive Strength of Hydraulic Cement Mortars. Korea Industrial Standards, Korean Standards & Certification Information Center: Seoul, Korea, 2007.

- KS F 2423; Standards Test Method for Tensile Splitting Strength of Concrete. Korea Industrial Standards, Korean Standards & Certification Information Center: Seoul, Korea, 2016.

- KS F 2584; Standard Test Method for Accelerated Carbonation of Concrete. Korea Industrial Standards, Korean Standards & Certification Information Center: Seoul, Korea, 2015.

- ASTM C1202; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- Ha, N.S.; Lu, G. A review of recent research on bio-inspired structures and materials for energy absorption applications. Compos. B Eng. 2020, 181, 107496. [Google Scholar] [CrossRef]

- Lee, H.A.; Park, E.; Lee, H. Polydopamine and its derivative surface chemistry in material science: A focused review for studies at KAIST. Adv. Mater. 2020, 32, 1907505. [Google Scholar] [CrossRef] [PubMed]

- Bae, S.H.; Lee, J.I.; Choi, S.J. Characteristics of mortars with blast furnace slag powder and mixed fine aggregates containing ferronickel-slag aggregate. Materials 2021, 14, 5879. [Google Scholar] [CrossRef] [PubMed]

| Fine Aggregates | FM | Density (g/cm3) | Water Absorption Ratio (%) |

|---|---|---|---|

| NS | 2.89 | 2.60 | 1.0 |

| BS | 2.37 | 2.81 | 2.1 |

| FS | 3.51 | 3.05 | 0.6 |

| Mix | CBP Solution (wt%) | Fine Aggregate (%) | W/C (%) | Cement (kg/m3) | Water (kg/m3) | ||

|---|---|---|---|---|---|---|---|

| NS | BS | FS | |||||

| N100 | 0 | 100 | – | – | |||

| BS50 | 0 | 50 | 50 | – | |||

| BF50 | 0 | 50 | 25 | 25 | |||

| FS50 | 0 | 50 | – | 50 | 50 | 340 | 170 |

| PN100 | 10 | 100 | – | – | |||

| PBS50 | 10 | 50 | 50 | ||||

| PBF50 | 10 | 50 | 25 | 25 | |||

| PFS50 | 10 | 50 | – | 50 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, S.-J.; Bae, S.-H.; Choi, H.Y.; Ko, H.M. Engineering Characteristics of Cement Composites Containing a Chitosan-Based Polymer and Steel Slag Aggregates. Polymers 2022, 14, 626. https://doi.org/10.3390/polym14030626

Choi S-J, Bae S-H, Choi HY, Ko HM. Engineering Characteristics of Cement Composites Containing a Chitosan-Based Polymer and Steel Slag Aggregates. Polymers. 2022; 14(3):626. https://doi.org/10.3390/polym14030626

Chicago/Turabian StyleChoi, Se-Jin, Sung-Ho Bae, Hoe Young Choi, and Haye Min Ko. 2022. "Engineering Characteristics of Cement Composites Containing a Chitosan-Based Polymer and Steel Slag Aggregates" Polymers 14, no. 3: 626. https://doi.org/10.3390/polym14030626

APA StyleChoi, S.-J., Bae, S.-H., Choi, H. Y., & Ko, H. M. (2022). Engineering Characteristics of Cement Composites Containing a Chitosan-Based Polymer and Steel Slag Aggregates. Polymers, 14(3), 626. https://doi.org/10.3390/polym14030626