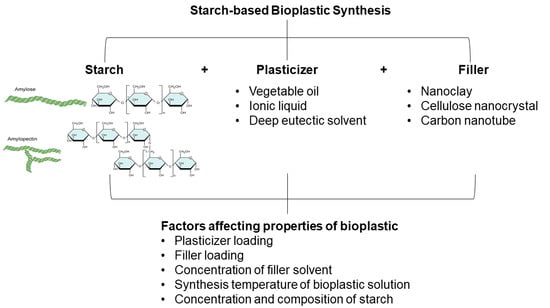

A Comprehensive Review on the Emerging Roles of Nanofillers and Plasticizers towards Sustainable Starch-Based Bioplastic Fabrication

Abstract

:1. Introduction

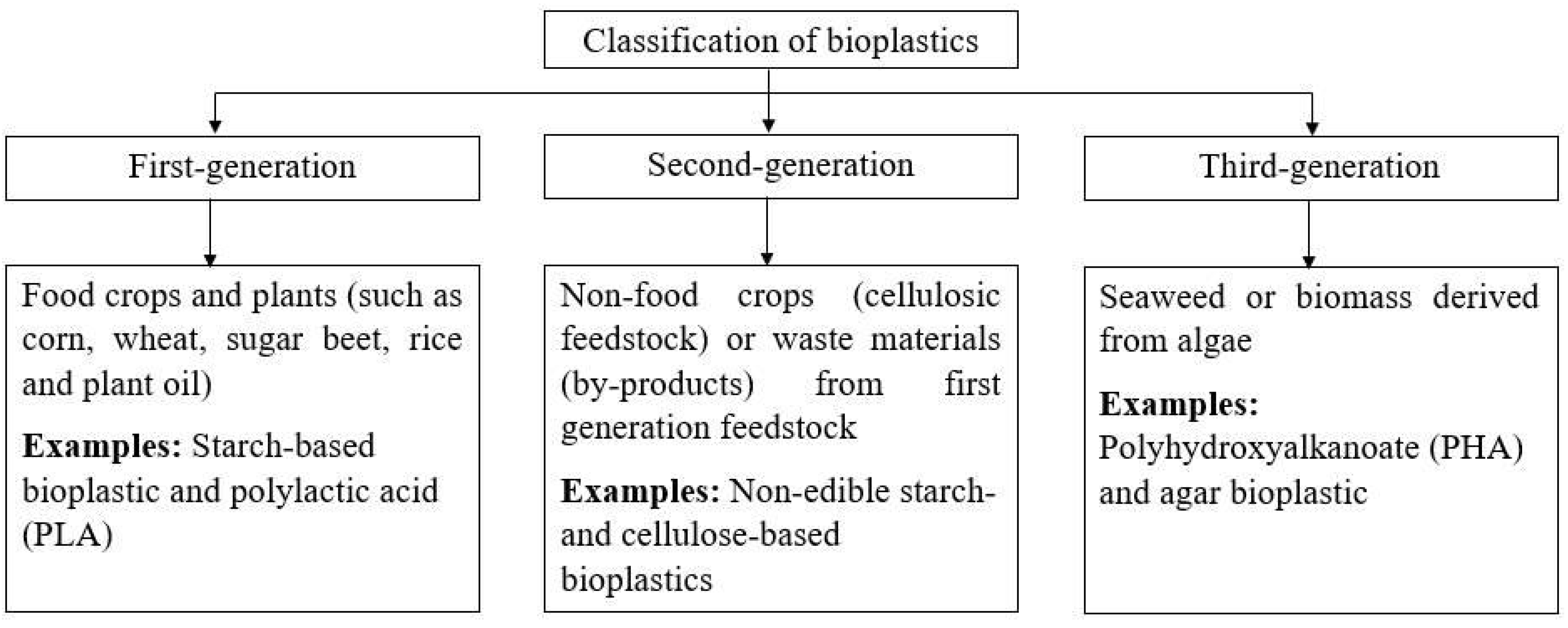

2. Classifications of Bioplastics

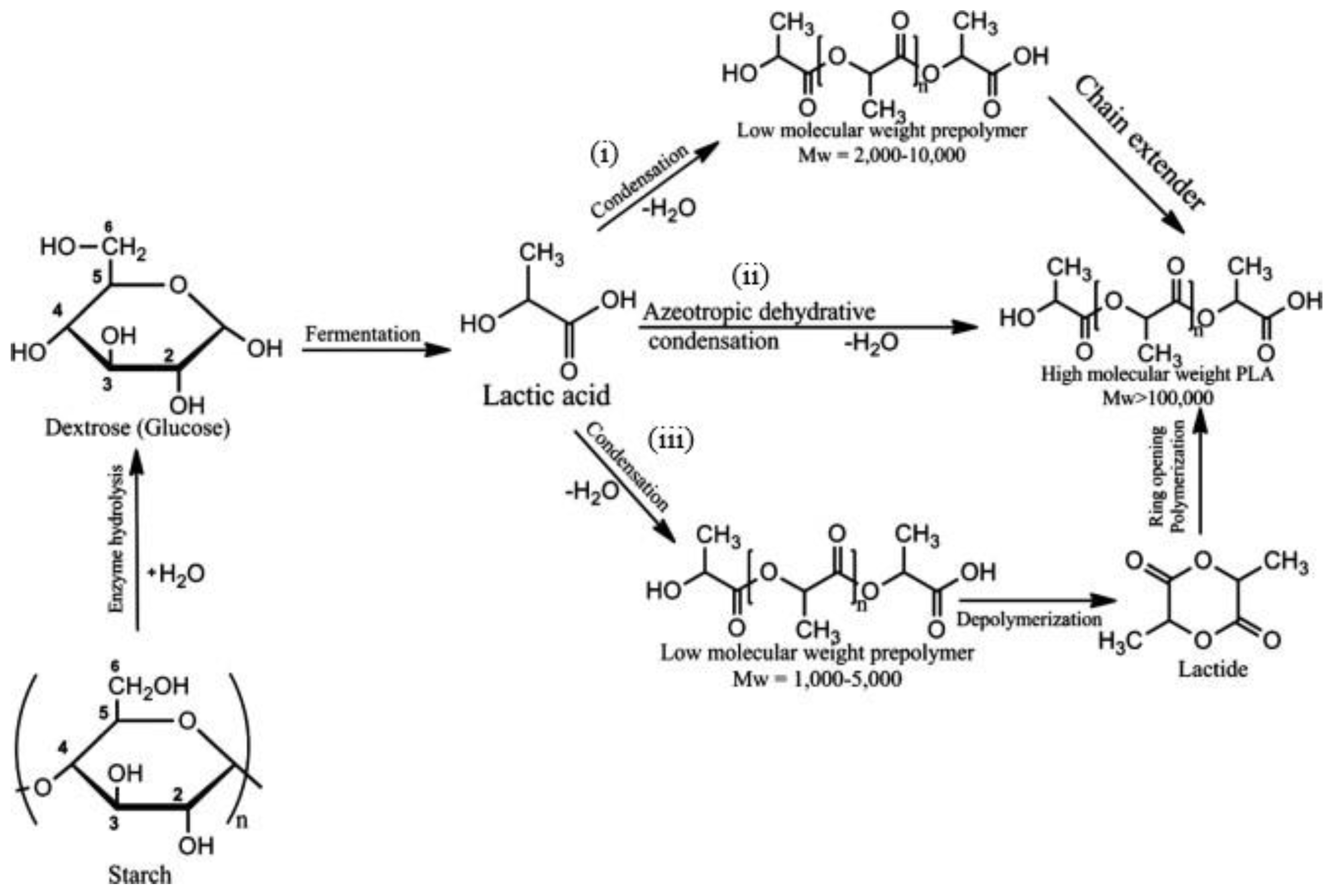

2.1. First-Generation Bioplastic

2.2. Second-Generation Bioplastic

2.3. Third-Generation Bioplastic

3. Nanofillers for Property Enhancement in Bioplastics

3.1. Layered Silicates

3.2. Organic Nanofillers

3.3. Inorganic Nanofillers

3.4. Carbonaceous Nanofillers

4. Plasticizers Applied in Bioplastic Fabrication

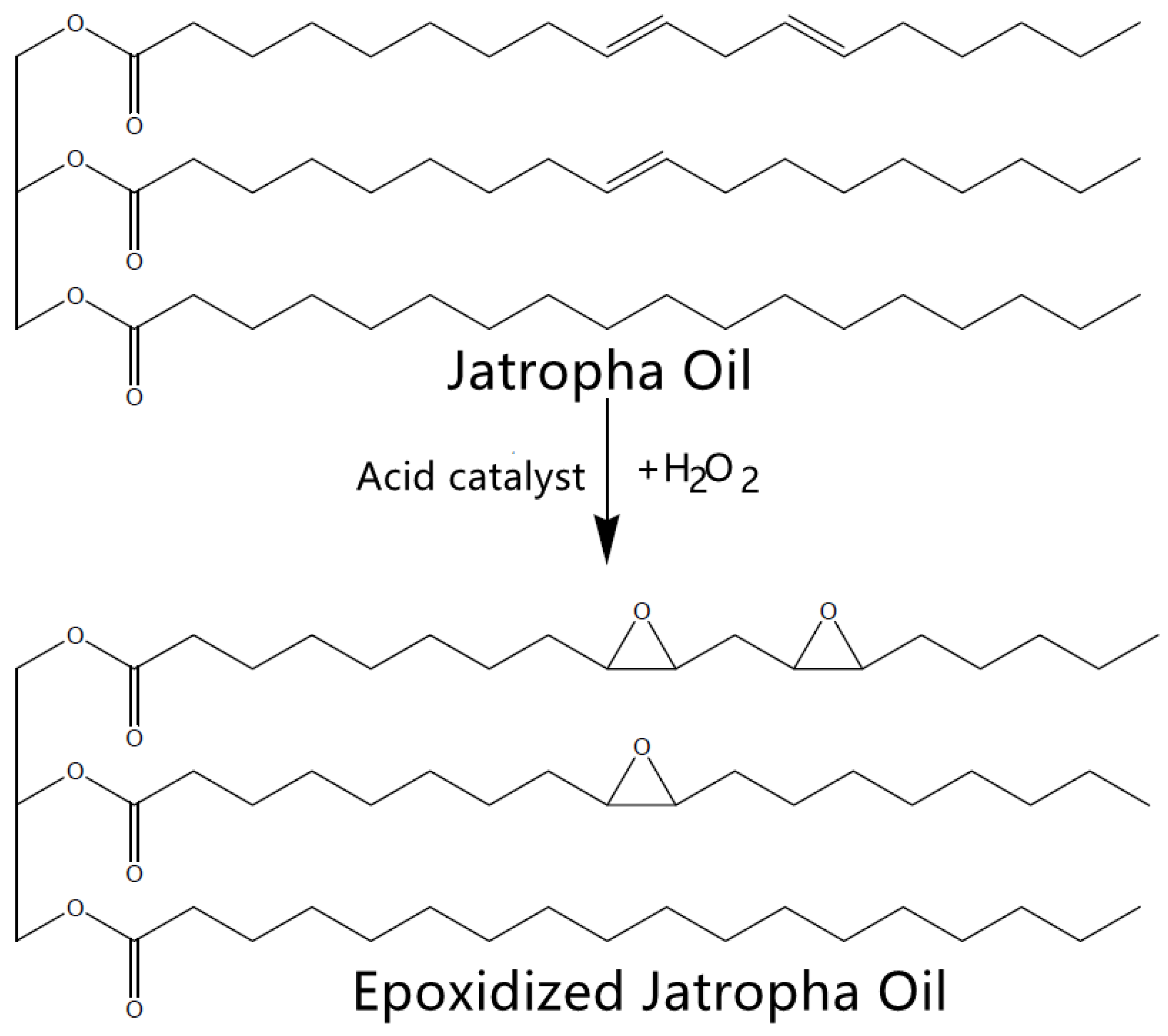

4.1. Vegetable Oil

4.2. Ionic Liquid (IL)

4.3. Deep Eutectic Solvent (DES)

5. Critical Factors Affecting Properties of Bioplastic Using Solvent-Casting Technique

5.1. Plasticizer Loading

5.2. Filler Loading

5.3. Concentration of Chitosan Solvent

5.4. Processing Temperature of Bioplastic Solution

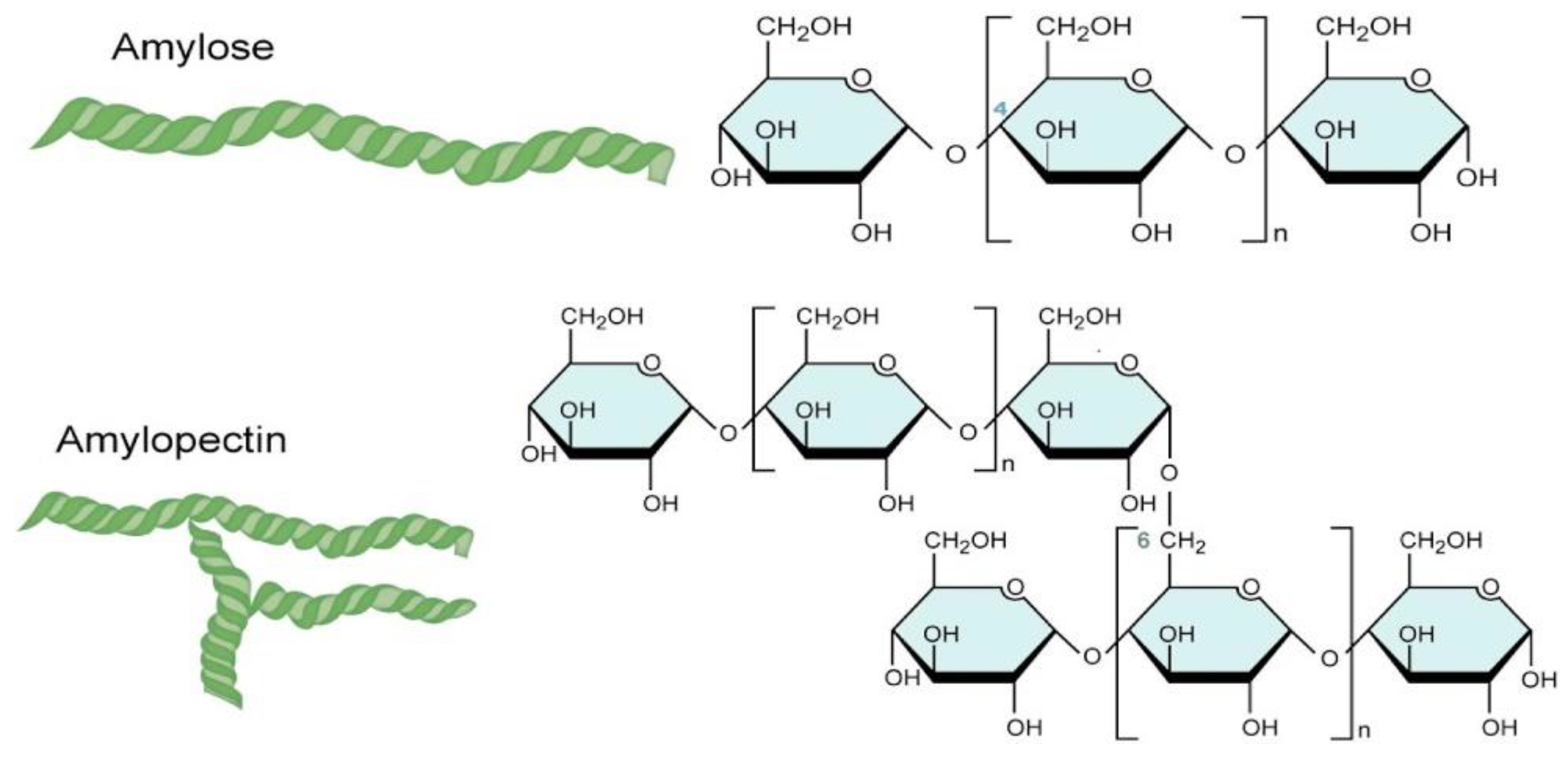

5.5. Concentration and Composition of Starch

6. Challenges and Potential for Future Sustainable Development

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hasan, M.; Rahmayani, R. Bioplastic from Chitosan and Yellow Pumpkin Starch with Castor Oil as Plasticizer. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Surakarta, Indonesia, 4–5 September 2017. [Google Scholar]

- Pathak, S.; Sneha, C.; Mathew, B.B. Bioplastics: Its timeline based scenario & challenges. J. Polym. Biopolym. Phys. Chem. 2014, 2, 84–90. [Google Scholar]

- Zeller, M.A.; Hunt, R.; Jones, A.; Sharma, S. Bioplastics and their thermoplastic blends from Spirulina and Chlorella microalgae. J. Appl. Polym. Sci. 2013, 130, 3263–3275. [Google Scholar] [CrossRef]

- Khalil, H.A.; Tehrani, M.; Davoudpour, Y.; Bhat, A.; Jawaid, M.; Hassan, A. Natural fiber reinforced poly (vinyl chloride) composites: A review. J. Reinf. Plast. Compos. 2013, 32, 330–356. [Google Scholar] [CrossRef]

- Bilo, F.; Pandini, S.; Sartore, L.; Depero, L.E.; Gargiulo, G.; Bonassi, A.; Federici, S.; Bontempi, E. A sustainable bioplastic obtained from rice straw. J. Clean. Prod. 2018, 200, 357–368. [Google Scholar] [CrossRef]

- Delacuvellerie, A.; Cyriaque, V.; Gobert, S.; Benali, S.; Wattiez, R. The plastisphere in marine ecosystem hosts potential specific microbial degraders including Alcanivorax borkumensis as a key player for the low-density polyethylene degradation. J. Hazard. Mater. 2019, 380, 120899. [Google Scholar] [CrossRef] [PubMed]

- Ross, S.; Evans, D. The environmental effect of reusing and recycling a plastic-based packaging system. J. Clean. Prod. 2003, 11, 561–571. [Google Scholar] [CrossRef]

- Wu, C.-S. Renewable resource-based green composites of surface-treated spent coffee grounds and polylactide: Characterisation and biodegradability. Polym. Degrad. Stab. 2015, 121, 51–59. [Google Scholar] [CrossRef]

- Rujnić-Sokele, M.; Pilipović, A. Challenges and opportunities of biodegradable plastics: A mini review. Waste Manag. Res. 2017, 35, 132–140. [Google Scholar] [CrossRef]

- Wahyuningtiyas, N.E.; Suryanto, H. Effect of ultrasonic treatment on morphology and mechanical properties of bioplastic from cassava starch with nanoclay reinforcement. J. Metastable Nanocrystalline Mater. 2017, 29, 35–41. [Google Scholar] [CrossRef]

- Jabeen, N.; Majid, I.; Nayik, G.A. Bioplastics and food packaging: A review. Cogent Food Agric. 2015, 1, 1–6. [Google Scholar] [CrossRef]

- Lubis, M.; Harahap, M.; Manullang, A.; Ginting, M.; Sartika, M. Utilization starch of jackfruit seed (Artocarpus heterophyllus) as raw material for bioplastics manufacturing using sorbitol as plasticizer and chitosan as filler. In Proceedings of the International Conference on Computing and Applied Informatics 2016, Medan, Indonesia, 14–15 December 2016. [Google Scholar]

- Cifriadi, A.; Panji, T.; Wibowo, N.A.; Syamsu, K. Bioplastic production from cellulose of oil palm empty fruit bunch. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Bogor, Indonesia, 10–11 October 2016. [Google Scholar]

- Zhao, X.; Cornish, K.; Vodovotz, Y. Narrowing the Gap for Bioplastic Use in Food Packaging: An Update. Environ. Sci. Technol. 2020, 54, 4712–4732. [Google Scholar] [CrossRef] [PubMed]

- Kasmuri, N.; Zait, M.S.A. Enhancement of Bio-plastic using Eggshells and Chitosan on Potato Starch Based. Int. J. Eng. Technol. 2018, 7, 110–115. [Google Scholar] [CrossRef]

- Lim, W.; Chin, N.; Yusof, A.; Yahya, A.; Tee, T. Food waste handling in Malaysia and comparison with other Asian countries. Int. Food Res. J. 2016, 23, S1–S6. [Google Scholar]

- Reddy, M.V.; Hayashi, S.; Choi, D.; Cho, H.; Chang, Y.-C. Short chain and medium chain fatty acids production using food waste under non-augmented and bio-augmented conditions. J. Clean. Prod. 2018, 176, 645–653. [Google Scholar] [CrossRef]

- Kartika, T.; Harahap, M.B.; Ginting, M.H.S. Utilization of mango seed starch in manufacture of bioplastic reinforced with microparticle clay using glycerol as plasticizer. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Sumatera Utara, Indonesia, 7–8 September 2017. [Google Scholar]

- Ginting, M.H.S.; Tarigan, F.R.; Singgih, A.M. Effect of gelatinization temperature and chitosan on mechanical properties of bioplastics from avocado seed starch (Persea Americana mill) with plasticizer glycerol. Int. J. Eng. Sci. 2015, 4, 36–43. [Google Scholar]

- Ginting, M.H.S.; Hasibuan, R.; Lubis, M.; Tanjung, D.; Iqbal, N. Effect of Hydrochloric Acid Concentration as Chitosan Solvent on Mechanical Properties of Bioplastics from Durian Seed Starch (Durio Zibethinus) with Filler Chitosan and Plasticizer Sorbitol. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Bandung, Indonesia, 16–18 November 2016. [Google Scholar]

- Maulida, S.M.; Tarigan, P. Production of starch based bioplastic from cassava peel reinforced with microcrystalline celllulose avicel PH101 using sorbitol as plasticizer. J. Phys. Conf. Ser. 2016, 710, 012012. [Google Scholar] [CrossRef] [Green Version]

- Zuo, Y.; Gu, J.; Yang, L.; Qiao, Z.; Zhang, Y. Study on the preparation of maleated thermoplastic starch by reactive extrusion. J. Thermoplast. Compos. Mater. 2016, 29, 397–409. [Google Scholar] [CrossRef]

- Zdanowicz, M.; Johansson, C. Impact of additives on mechanical and barrier properties of starch-based films plasticized with deep eutectic solvents. Starch-Stärke 2017, 69, 1700030. [Google Scholar] [CrossRef]

- Bhat, A.; Khan, I.; Usmani, M.A.; Rather, J.A. Bioplastics and Bionanocomposites Based on Nanoclays and Other Nanofillers. In Nanoclay Reinforced Polymer Composites; Springer: Berlin/Heidelberg, Germany, 2016; pp. 115–139. [Google Scholar] [CrossRef]

- Al-Battashi, H.; Annamalai, N.; Al-Kindi, S.; Nair, A.S.; Al-Bahry, S.; Verma, J.P.; Sivakumar, N. Production of bioplastic (poly-3-hydroxybutyrate) using waste paper as a feedstock: Optimization of enzymatic hydrolysis and fermentation employing Burkholderia sacchari. J. Clean. Prod. 2019, 214, 236–247. [Google Scholar] [CrossRef]

- Folino, A.; Fazzino, F.; Komilis, D. Preliminary evaluation of the anaerobic biodegradability of three biobased materials used for the production of disposable plastics. J. Hazard. Mater. 2019, 390, 121653. [Google Scholar]

- Ashok, A.; Rejeesh, C.; Renjith, R. Biodegradable polymers for sustainable packaging applications: A review. Int. J. Bionics Biomater. 2016, 2, 1–11. [Google Scholar]

- Zia, F.; Zia, K.M.; Zuber, M.; Kamal, S.; Aslam, N. Starch based polyurethanes: A critical review updating recent literature. Carbohydr. Polym. 2015, 134, 784–798. [Google Scholar] [CrossRef] [PubMed]

- Moran, J.I.; Vazquez, A.; Cyras, V.P. Bio-nanocomposites based on derivatized potato starch and cellulose, preparation and characterization. J. Mater. Sci. 2013, 48, 7196–7203. [Google Scholar] [CrossRef]

- Chan, Y.; Phang, S.; Tee, T.; Lee, T.; Soo, T. Preliminary Study of Mechanical Properties in Thermoplastic Starch (TPS)/Coffee-Waste-Derived Fillers Composites. In Proceedings of the Engineering Undergraduate Research Catalyst Conference (EURECA), Sunway, Selangor, Malaysia, 1–2 July 2015; pp. 1–14. [Google Scholar]

- Waterschoot, J.; Gomand, S.V.; Fierens, E.; Delcour, J.A. Production, structure, physicochemical and functional properties of maize, cassava, wheat, potato and rice starches. Starch-Stärke 2015, 67, 14–29. [Google Scholar] [CrossRef]

- Amri, A.; Ekawati, L.; Herman, S.; Yenti, S.; Aziz, Y.; Utami, S. Properties enhancement of cassava starch based bioplastics with addition of graphene oxide. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Pekanbaru-Riau, Indonesia, 29–30 November 2017. [Google Scholar]

- Mallakpour, S. Fructose functionalized MWCNT as a filler for starch nanocomposites: Fabrication and characterizations. Prog. Org. Coat. 2018, 114, 244–249. [Google Scholar] [CrossRef]

- Reddy, R.L.; Reddy, V.S.; Gupta, G.A. Study of bio-plastics as green and sustainable alternative to plastics. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 76–81. [Google Scholar]

- Laadila, M.A.; Hegde, K.; Rouissi, T.; Brar, S.K.; Galvez, R.; Sorelli, L.; Cheikh, R.B.; Paiva, M.; Abokitse, K. Green synthesis of novel biocomposites from treated cellulosic fibers and recycled bio-plastic polylactic acid. J. Clean. Prod. 2017, 164, 575–586. [Google Scholar] [CrossRef]

- Chieng, B.W.; Ibrahim, N.A.; Then, Y.Y.; Loo, Y.Y. Epoxidized jatropha oil as a sustainable plasticizer to poly (lactic acid). Polymers 2017, 9, 204. [Google Scholar] [CrossRef] [Green Version]

- Hu, Y.; Daoud, W.A.; Fei, B.; Chen, L.; Kwan, T.H.; Lin, C.S.K. Efficient ZnO aqueous nanoparticle catalysed lactide synthesis for poly (lactic acid) fibre production from food waste. J. Clean. Prod. 2017, 165, 157–167. [Google Scholar] [CrossRef]

- Lopes, M.; Jardini Filho, A. Synthesis and characterizations of poly (lactic acid) by ring-opening polymerization for biomedical applications. Chem. Eng. 2014, 38, 331–336. [Google Scholar]

- Brodin, M.; Vallejos, M.; Opedal, M.T.; Area, M.C.; Chinga-Carrasco, G. Lignocellulosics as sustainable resources for production of bioplastics—A review. J. Clean. Prod. 2017, 162, 646–664. [Google Scholar] [CrossRef]

- Othman, M.; Rashid, H.; Jamal, N.; Shaharuddin, S.; Sulaiman, S.; Hairil, H.; Khalid, K.; Zakaria, M. Effect of Cinnamon Extraction Oil (CEO) for Algae Biofilm Shelf-Life Prolongation. Polymers 2019, 11, 4. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Chen, M.-J.; Shi, Q.-S. Transforming sugarcane bagasse into bioplastics via homogeneous modification with phthalic anhydride in ionic liquid. ACS Sustain. Chem. Eng. 2015, 3, 2510–2515. [Google Scholar] [CrossRef]

- Li, M.-C.; Wu, Q.; Song, K.; Lee, S.; Qing, Y.; Wu, Y. Cellulose Nanoparticles: Structure–Morphology–Rheology Relationships. ACS Sustain. Chem. Eng. 2015, 3, 821–832. [Google Scholar] [CrossRef]

- Mood, S.H.; Golfeshan, A.H.; Tabatabaei, M.; Jouzani, G.S.; Najafi, G.H.; Gholami, M.; Ardjmand, M. Lignocellulosic biomass to bioethanol, a comprehensive review with a focus on pretreatment. Renew. Sustain. Energy Rev. 2013, 27, 77–93. [Google Scholar] [CrossRef]

- Alekhina, M.; Mikkonen, K.S.; Alén, R.; Tenkanen, M.; Sixta, H. Carboxymethylation of alkali extracted xylan for preparation of bio-based packaging films. Carbohydr. Polym. 2014, 100, 89–96. [Google Scholar] [CrossRef]

- Müller, Y.; Tot, I.; Potthast, A.; Rosenau, T.; Zimmermann, R.; Eichhorn, K.-J.; Nitschke, C.; Scherr, G.; Freudenberg, U.; Werner, C. The impact of esterification reactions on physical properties of cellulose thin films. Soft Matter 2010, 6, 3680–3684. [Google Scholar] [CrossRef]

- Özçimen, D.; İnan, B.; Morkoç, O.; Efe, A. A Review on Algal Biopolymers. J. Chem. Eng. Res. Updates 2017, 4, 7–14. [Google Scholar] [CrossRef]

- Hii, S.-L.; LIM, J.; Ong, W.-T.; Wong, C.-L. Agar from Malaysian red seaweed as potential material for synthesis of bioplastic film. J. Eng. Sci. Technol. 2016, 11, 1–15. [Google Scholar]

- Bhatia, S.K.; Gurav, R.; Choi, T.-R.; Jung, H.-R.; Yang, S.-Y.; Moon, Y.-M.; Song, H.-S.; Jeon, J.-M.; Choi, K.-Y.; Yang, Y.-H. Bioconversion of plant biomass hydrolysate into bioplastic (polyhydroxyalkanoates) using Ralstonia eutropha 5119. Bioresour. Technol. 2019, 271, 306–315. [Google Scholar] [CrossRef] [PubMed]

- Jost, V.; Langowski, H.-C. Effect of different plasticisers on the mechanical and barrier properties of extruded cast PHBV films. Eur. Polym. J. 2015, 68, 302–312. [Google Scholar] [CrossRef]

- Arvizu-Higuera, D.L.; Rodríguez-Montesinos, Y.E.; Murillo-Álvarez, J.I.; Muñoz-Ochoa, M.; Hernández-Carmona, G. Effect of alkali treatment time and extraction time on agar from Gracilaria vermiculophylla. In Proceedings of the Nineteenth International Seaweed Symposium, Kobe, Japan, 26–31 March 2007. [Google Scholar]

- Guerrero, P.; Etxabide, A.; Leceta, I.; Peñalba, M.; De la Caba, K. Extraction of agar from Gelidium sesquipedale (Rodhopyta) and surface characterization of agar based films. Carbohydr. Polym. 2014, 99, 491–498. [Google Scholar] [CrossRef]

- Brodie, J. Systematics of the Species-Rich Algae: Red Algal Classification, Phylogeny and Speciation. In Reconstructing the Tree of life: Taxonomy and Systematics of Species Rich Taxa; CRC Press: Boca Raton, FL, USA, 2007; pp. 323–336. [Google Scholar]

- Chu, W.-L.; Mohamed, N.; Phang, S.-M. Fatty acid composition of some Malaysian seaweeds. Malays. J. Sci. 2003, 22, 21–27. [Google Scholar]

- Agustin, M.B.; Ahmmad, B.; Alonzo, S.M.M.; Patriana, F.M. Bioplastic based on starch and cellulose nanocrystals from rice straw. J. Reinf. Plast. Compos. 2014, 33, 2205–2213. [Google Scholar] [CrossRef]

- Ilyas, R.; Sapuan, S.; Sanyang, M.; Ishak, M. Nanocrystalline cellulose reinforced starch-based nanocomposite: A review. In Proceedings of the 5th Postgraduate Seminar on Natural Fiber Composites, Universiti Putra Malaysia, Serdang, Malaysia, 28 December 2016; pp. 82–87. [Google Scholar]

- Harunsyah; Yunus, M.; Fauzan, R. Mechanical properties of bioplastics cassava starch film with Zinc Oxide nanofiller as reinforcement. In Proceedings of the IOP Conference Series: Materials Science and Engineering, University of Malaya, Kuala Lumpur, Malaysia, 5–6 April 2017. [Google Scholar]

- Pasquini, D.; de Morais Teixeira, E.; da Silva Curvelo, A.A.; Belgacem, M.N.; Dufresne, A. Extraction of cellulose whiskers from cassava bagasse and their applications as reinforcing agent in natural rubber. Ind. Crops Prod. 2010, 32, 486–490. [Google Scholar] [CrossRef]

- Abreu, A.S.; Oliveira, M.; de Sá, A.; Rodrigues, R.M.; Cerqueira, M.A.; Vicente, A.A.; Machado, A. Antimicrobial nanostructured starch based films for packaging. Carbohydr. Polym. 2015, 129, 127–134. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.-X.; Liang, Z.-S.; Liang, J.-N.; Liao, L.-Y. Effect of different surface properties of nanosilica on retrogradation behavior and structures of thermoplastic cassava starch. J. Polym. Res. 2021, 28, 1–12. [Google Scholar] [CrossRef]

- Li, J.L.; Zhou, M.; Cheng, G.; Cheng, F.; Lin, Y.; Zhu, P.X. Comparison of mechanical reinforcement effects of cellulose nanofibers and montmorillonite in starch composite. Starch-Stärke 2019, 71, 1800114. [Google Scholar] [CrossRef] [Green Version]

- Noshirvani, N.; Hong, W.; Ghanbarzadeh, B.; Fasihi, H.; Montazami, R. Study of Cellulose Nanocrystal Doped Starch-Polyvinyl Alcohol Bionanocomposite Films. Int. J. Biol. Macromol. 2018, 107, 2065–2074. [Google Scholar] [CrossRef]

- Xu, Y.; Rehmani, N.; Alsubaie, L.; Kim, C.; Sismour, E.; Scales, A. Tapioca starch active nanocomposite films and their antimicrobial effectiveness on ready-to-eat chicken meat. Food Packag. Shelf Life 2018, 16, 86–91. [Google Scholar] [CrossRef]

- Lopez, O.; Garcia, M.A.; Villar, M.A.; Gentili, A.; Rodriguez, M.; Albertengo, L. Thermo-compression of biodegradable thermoplastic corn starch films containing chitin and chitosan. LWT-Food Sci. Technol. 2014, 57, 106–115. [Google Scholar] [CrossRef]

- Estevez-Areco, S.; Guz, L.; Candal, R.; Goyanes, S. Active bilayer films based on cassava starch incorporating ZnO nanorods and PVA electrospun mats containing rosemary extract. Food Hydrocoll. 2020, 108, 106054. [Google Scholar] [CrossRef]

- Ceballos, R.L.; von Bilderling, C.; Guz, L.; Bernal, C.; Famá, L. Effect of greenly synthetized silver nanoparticles on the properties of active starch films obtained by extrusion and compression molding. Carbohydr. Polym. 2021, 261, 117871. [Google Scholar] [CrossRef] [PubMed]

- Domene-López, D.; Delgado-Marín, J.J.; García-Quesada, J.C.; Martin-Gullon, I.; Montalbán, M.G. Electroconductive starch/multi-walled carbon nanotube films plasticized by 1-ethyl-3-methylimidazolium acetate. Carbohydr. Polym. 2020, 229, 115545. [Google Scholar] [CrossRef] [PubMed]

- Alves, Z.; Abreu, B.; Ferreira, N.M.; Marques, E.F.; Nunes, C.; Ferreira, P. Enhancing the dispersibility of multiwalled carbon nanotubes within starch-based films by the use of ionic surfactants. Carbohydr. Polym. 2021, 273, 118531. [Google Scholar] [CrossRef] [PubMed]

- Mallakpour, S.; Rashidimoghadam, S. Application of ultrasonic irradiation as a benign method for production of glycerol plasticized-starch/ascorbic acid functionalized MWCNTs nanocomposites: Investigation of methylene blue adsorption and electrical properties. Ultrason. Sonochem. 2018, 40, 419–432. [Google Scholar] [CrossRef] [PubMed]

- Mallakpour, S.; Rashidimoghadam, S. Starch/MWCNT-vitamin C nanocomposites: Electrical, thermal properties and their utilization for removal of methyl orange. Carbohydr. Polym. 2017, 169, 23–32. [Google Scholar] [CrossRef]

- Mallakpour, S.; Nezamzadeh Ezhieh, A. Preparation and characterization of starch nanocomposite embedded with functionalized MWCNT: Investigation of optical, morphological, thermal, and copper ions adsorption properties. Adv. Polym. Technol. 2018, 37, 2195–2203. [Google Scholar] [CrossRef]

- Shima, A.; Hossein, B. Investigation the effect of graphene oxide and gelatin/starch weight ratio on the properties of starch/gelatin/GO nanocomposite films: The RSM study. Int. J. Biol. Macromol. 2017, 109, 1019–1028. [Google Scholar]

- Nazir, M.S.; Kassim, M.H.M.; Mohapatra, L.; Gilani, M.A.; Raza, M.R.; Majeed, K. Characteristic Properties of Nanoclays and Characterization of Nanoparticulates and Nanocomposites. In Nanoclay Reinforced Polymer Composites; Springer: Berlin/Heidelberg, Germany, 2016; pp. 35–55. [Google Scholar]

- Wahyuningtiyas, N.E.; Suryanto, H. Properties of cassava starch based bioplastic reinforced by nanoclay. J. Mech. Eng. Sci. Technol. 2018, 2, 20–26. [Google Scholar] [CrossRef]

- Martins, J.T.; Bourbon, A.I.; Pinheiro, A.C.; Souza, B.W.; Cerqueira, M.A.; Vicente, A.A. Biocomposite films based on κ-carrageenan/locust bean gum blends and clays: Physical and antimicrobial properties. Food Bioprocess Technol. 2013, 6, 2081–2092. [Google Scholar] [CrossRef] [Green Version]

- Jamróz, E.; Kulawik, P.; Kopel, P. The effect of nanofillers on the functional properties of biopolymer-based films: A review. Polymers 2019, 11, 675. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brinchi, L.; Cotana, F.; Fortunati, E.; Kenny, J. Production of nanocrystalline cellulose from lignocellulosic biomass: Technology and applications. Carbohydr. Polym. 2013, 94, 154–169. [Google Scholar] [CrossRef]

- Chiulan, I.; Frone, A.N.; Panaitescu, D.M.; Nicolae, C.A.; Trusca, R. Surface properties, thermal, and mechanical characteristics of poly (vinyl alcohol)–starch-bacterial cellulose composite films. J. Appl. Polym. Sci. 2018, 135, 45800. [Google Scholar] [CrossRef]

- Jakubowska, E.; Gierszewska, M.; Nowaczyk, J.; Olewnik-Kruszkowska, E. The role of a deep eutectic solvent in changes of physicochemical and antioxidative properties of chitosan-based films. Carbohydr. Polym. 2021, 255, 117527. [Google Scholar] [CrossRef]

- Azadi, A.; Supriyadi, S.; Herawati, H. Starch Based Biocomposite from Sago (Metroxylon sagu) with Nano-Chitosan reinforcement: Mechanical and Thermal Characteristics. J. Pure Appl. Chem. Res. 2020, 9, 98–107. [Google Scholar] [CrossRef]

- Gudikandula, K.; Charya Maringanti, S. Synthesis of silver nanoparticles by chemical and biological methods and their antimicrobial properties. J. Exp. Nanosci. 2016, 11, 714–721. [Google Scholar] [CrossRef]

- Khodashenas, B.; Ghorbani, H. Evaluation of the effective factors on size and anti-bacterial properties of biosynthesized silver nanoparticles. Int. J. Nano Dimens. 2015, 6, 111–127. [Google Scholar]

- Garza-Cervantes, J.A.; Mendiola-Garza, G.; de Melo, E.M.; Dugmore, T.I.; Matharu, A.S.; Morones-Ramirez, J.R. Antimicrobial activity of a silver-microfibrillated cellulose biocomposite against susceptible and resistant bacteria. Sci. Rep. 2020, 10, 1–7. [Google Scholar] [CrossRef]

- Ahmed, S.; Ahmad, M.; Swami, B.L.; Ikram, S. A review on plants extract mediated synthesis of silver nanoparticles for antimicrobial applications: A green expertise. J. Adv. Res. 2016, 7, 17–28. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sirelkhatim, A.; Mahmud, S.; Seeni, A.; Kaus, N.H.M.; Ann, L.C.; Bakhori, S.K.M.; Hasan, H.; Mohamad, D. Review on zinc oxide nanoparticles: Antibacterial activity and toxicity mechanism. Nano-Micro Lett. 2015, 7, 219–242. [Google Scholar] [CrossRef] [Green Version]

- Famá, L.M.; Pettarin, V.; Goyanes, S.N.; Bernal, C.R. Starch/multi-walled carbon nanotubes composites with improved mechanical properties. Carbohydr. Polym. 2011, 83, 1226–1231. [Google Scholar] [CrossRef]

- Koh, B.; Cheng, W. Mechanisms of carbon nanotube aggregation and the reversion of carbon nanotube aggregates in aqueous medium. Langmuir 2014, 30, 10899–10909. [Google Scholar] [CrossRef] [PubMed]

- Siljander, S.; Keinänen, P.; Räty, A.; Ramakrishnan, K.R.; Tuukkanen, S.; Kunnari, V.; Harlin, A.; Vuorinen, J.; Kanerva, M. Effect of surfactant type and sonication energy on the electrical conductivity properties of nanocellulose-CNT nanocomposite films. Int. J. Mol. Sci. 2018, 19, 1819. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zdanowicz, M.; Jędrzejewski, R.; Pilawka, R. Deep eutectic solvents as simultaneous plasticizing and crosslinking agents for starch. Int. J. Biol. Macromol. 2019, 129, 1040–1046. [Google Scholar] [CrossRef] [PubMed]

- Khodaverdian, S.; Dabirmanesh, B.; Heydari, A.; Dashtban-Moghadam, E.; Khajeh, K.; Ghazi, F. Activity, stability and structure of laccase in betaine based natural deep eutectic solvents. Int. J. Biol. Macromol. 2018, 107, 2574–2579. [Google Scholar] [CrossRef] [PubMed]

- Zdanowicz, M.; Spychaj, T. Ionic liquids as starch plasticizers or solvents. Polimery 2011, 56, 861–864. [Google Scholar] [CrossRef]

- Zdanowicz, M.; Wilpiszewska, K.; Spychaj, T. Deep eutectic solvents for polysaccharides processing. A review. Carbohydr. Polym. 2018, 200, 361–380. [Google Scholar] [CrossRef]

- Zdanowicz, M.; Johansson, C. Mechanical and barrier properties of starch-based films plasticized with two-or three component deep eutectic solvents. Carbohydr. Polym. 2016, 151, 103–112. [Google Scholar] [CrossRef]

- Tan, Y.T.; Ngoh, G.C.; Chua, A.S.M. Evaluation of fractionation and delignification efficiencies of deep eutectic solvents on oil palm empty fruit bunch. Ind. Crops Prod. 2018, 123, 271–277. [Google Scholar] [CrossRef]

- Hassan, A.A.; Abbas, A.; Rasheed, T.; Bilal, M.; Iqbal, H.M.; Wang, S. Development, influencing parameters and interactions of bioplasticizers: An environmentally friendlier alternative to petro industry-based sources. Sci. Total Environ. 2019, 682, 394–404. [Google Scholar] [CrossRef] [PubMed]

- Webb, H.; Arnott, J.; Crawford, R.; Ivanova, E. Plastic degradation and its environmental implications with special reference to poly (ethylene terephthalate). Polymers 2013, 5, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Nowak, A.P.; Lisowska-Oleksiak, A. Red algae—An alternative source of carbon material for energy storage application. Int. J. Electrochem. Sci. 2014, 9, 3715–3724. [Google Scholar]

- Haq, M.A.; Habu, Y.; Yamamoto, K.; Takada, A.; Ka-dokawa, J.-I. Ionic Liquid Induces Flexibility and Thermoplasticity in Cellulose Film. Carbohydr. Polym. 2019, 223, 115058. [Google Scholar] [CrossRef]

- Feng, L.; Chen, Z.-L. Research progress on dissolution and functional modification of cellulose in ionic liquids. J. Mol. Liq. 2008, 142, 1–5. [Google Scholar] [CrossRef]

- Pang, J.; Liu, X.; Zhang, X.; Wu, Y.; Sun, R. Fabrication of cellulose film with enhanced mechanical properties in ionic liquid 1-allyl-3-methylimidaxolium chloride (AmimCl). Materials 2013, 6, 1270–1284. [Google Scholar] [CrossRef] [Green Version]

- Peng, H.; Wang, S.; Xu, H.; Dai, G. Preparations, properties, and formation mechanism of novel cellulose hydrogel membrane based on ionic liquid. J. Appl. Polym. Sci. 2018, 135, 45488. [Google Scholar] [CrossRef]

- Liu, X.; Pang, J.; Zhang, X.; Wu, Y.; Sun, R. Regenerated cellulose film with enhanced tensile strength prepared with ionic liquid 1-ethyl-3-methylimidazolium acetate (EMIMAc). Cellulose 2013, 20, 1391–1399. [Google Scholar] [CrossRef]

- Macário, I.P.; Veloso, T.; Pereira, J.L.; Ventura, S.P.; Coutinho, J.A. Potential Threats of Ionic Liquids to the Environment and Ecosphere. In Encyclopedia of Ionic Liquids; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar] [CrossRef]

- Almeida, C.M.; Magalhães, J.M.; Souza, H.K.; Gonçalves, M.P. The role of choline chloride-based deep eutectic solvent and curcumin on chitosan films properties. Food Hydrocoll. 2018, 81, 456–466. [Google Scholar] [CrossRef]

- Sousa, A.M.; Souza, H.K.; Latona, N.; Liu, C.-K.; Goncalves, M.P.; Liu, L. Choline chloride based ionic liquid analogues as tool for the fabrication of agar films with improved mechanical properties. Carbohydr. Polym. 2014, 111, 206–214. [Google Scholar] [CrossRef] [PubMed]

- Santana, R.F.; Bonomo, R.C.F.; Gandolfi, O.R.R.; Rodrigues, L.B.; Santos, L.S.; dos Santos Pires, A.C.; de Oliveira, C.P.; Fontan, R.d.C.I.; Veloso, C.M. Characterization of starch-based bioplastics from jackfruit seed plasticized with glycerol. J. Food Sci. Technol. 2018, 55, 278–286. [Google Scholar] [CrossRef] [PubMed]

- Ezeoha, S.; Ezenwanne, J. Production of biodegradable plastic packaging film from cassava starch. IOSR J. Eng. 2013, 3, 14–20. [Google Scholar] [CrossRef]

- Ginting, M.H.S.; Kristiani, M.; Amelia, Y.; Hasibuan, R. The effect of chitosan, sorbitol, and heating temperature bioplastic solution on mechanical properties of bioplastic from durian seed starch (Durio zibehinus). Int. J. Eng. Res. Appl. 2015, 6, 33–38. [Google Scholar]

- Anggraini, T.; Ulfimarjan; Azima, F.; Yenrina, R. The effect of chitosan concentration on the characteristics of sago (Metroxylon sp.) starch bioplastics. Res. J. Pharm. Biol. Chem. Sci. 2017, 8, 1339–1351. [Google Scholar]

- Zhang, W.; Jiang, W. Antioxidant and antibacterial chitosan film with tea polyphenols-mediated green synthesis silver nanoparticle via a novel one-pot method. Int. J. Biol. Macromol. 2020, 155, 1252–1261. [Google Scholar] [CrossRef]

- Valizadeh, S.; Naseri, M.; Babaei, S.; Hosseini, S.M.H.; Imani, A. Development of bioactive composite films from chitosan and carboxymethyl cellulose using glutaraldehyde, cinnamon essential oil and oleic acid. Int. J. Biol. Macromol. 2019, 134, 604–612. [Google Scholar] [CrossRef]

- Jacquot, C.; Jacquot, M.; Marques, P.; Jasniewski, J.; Akhtar, M.J.; Didelot, A.S.; Desobry, S. Influence of microwave heating time on the structure and properties of chitosan films. J. Appl. Polym. Sci. 2014, 131, 40779. [Google Scholar] [CrossRef]

- Arihara, K.; Zhou, L.; Ohata, M. Bioactive properties of Maillard reaction products generated from food protein-derived peptides. Adv. Food Nutr. Res. 2017, 81, 161–185. [Google Scholar]

- Zhang, Q.; Benoit, M.; Vigier, K.D.O.; Barrault, J.; Jégou, G.; Philippe, M.; Jérôme, F. Pretreatment of microcrystalline cellulose by ultrasounds: Effect of particle size in the heterogeneously-catalyzed hydrolysis of cellulose to glucose. Green Chem. 2013, 15, 963–969. [Google Scholar] [CrossRef]

- Poovarodom, N.; Permyanwattana, W. Development of starch/shellac-based composites for food contact applications. J. Thermoplast. Compos. Mater. 2015, 28, 597–609. [Google Scholar] [CrossRef]

- Setyaningsih, D.; Muna, N.; Suryawan, N.B.; Nurfauzi, A.A. Cellulose nanofiber isolation from palm oil Empty Fruit Bunches (EFB) through strong acid hydrolysis. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Bogor, Indonesia, 24–25 July 2017. [Google Scholar]

- Salaberria, A.M.; Diaz, R.H.; Labidi, J.; Fernandes, S.C. Role of chitin nanocrystals and nanofibers on physical, mechanical and functional properties in thermoplastic starch films. Food Hydrocoll. 2015, 46, 93–102. [Google Scholar] [CrossRef]

- Ren, L.; Yan, X.; Zhou, J.; Tong, J.; Su, X. Influence of chitosan concentration on mechanical and barrier properties of corn starch/chitosan films. Int. J. Biol. Macromol. 2017, 105, 1636–1643. [Google Scholar] [CrossRef] [PubMed]

- Haryanti, P.; Setyawati, R.; Wicaksono, R. Pengaruh Suhu dan Lama Pemanasan Suspensi Pati serta Konsentrasi Butanol terhadap Karakteristik Fisikokimia Pati Tinggi Amilosa dari Tapioka. Agritech J. Fak. Teknol. Pertan. UGM 2014, 34, 308–315. [Google Scholar] [CrossRef]

- Wojciechowska, P. The Effect of Concentration and Type of Plasticizer on the Mechanical Properties of Cellulose Acetate Butyrate Organic-Inorganic Hybrids. In Recent Advances in Plasticizers; IntechOpen: London, UK, 2012; pp. 141–164. [Google Scholar]

- Sifuentes-Nieves, I.; Flores-Silva, P.C.; Gallardo-Vega, C.; Hernández-Hernández, E.; Neira-Velázquez, G.; Mendez-Montealvo, G.; Velazquez, G. Films made from plasma-modified corn starch: Chemical, mechanical and barrier properties. Carbohydr. Polym. 2020, 237, 116103. [Google Scholar] [CrossRef]

- Basiak, E.; Lenart, A.; Debeaufort, F. Effect of starch type on the physico-chemical properties of edible films. Int. J. Biol. Macromol. 2017, 98, 348–356. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, Q.; Wu, T.; Zhang, M. Glass transition temperature, rheological, and gelatinization properties of high amylose corn starch and waxy cassava starch blends. J. Food Process. Preserv. 2020, 44, e14682. [Google Scholar] [CrossRef]

- Arikan, E.B.; Ozsoy, H.D. A review: Investigation of bioplastics. Civ. Eng. Archit. 2015, 9, 188–192. [Google Scholar]

- Spierling, S.; Knüpffer, E.; Behnsen, H.; Mudersbach, M.; Krieg, H.; Springer, S.; Albrecht, S.; Herrmann, C.; Endres, H.-J. Bio-based plastics-A review of environmental, social and economic impact assessments. J. Clean. Prod. 2018, 185, 16–491. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Velis, C.A.; Weber, R.; Iacovidou, E.; Purnell, P. An overview of chemical additives present in plastics: Migration, release, fate and environmental impact during their use, disposal and recycling. J. Hazard. Mater. 2018, 344, 179–199. [Google Scholar] [CrossRef]

| Nanofiller | Proposed Application | Findings/Enhancement as Compared to the Control Film | Ref. |

|---|---|---|---|

| Layered silicates | |||

| Nanoclay | Food packaging film | Reduction of water vapour permeability (WVP) by 14% Reduction of OP by 15% Presence of microbial growth against C. albicans Reduction of microbial growth against S. aureus and E. coli (bacteriostatic effect) | [59] |

| Nanoclay | Packaging material | Improvement of tensile strength from 5.2 to 6.3 MPa Increase in moisture absorption from 44.44% to 69.58% Complete degradation of thermoplastic starch (TPS)/nanoclay film on the 6th day | [10] |

| Nanosilica (nano-SiO2) | Packaging material | TPS film with hydrophilic nano-SiO2 had lower retrogradation rate than that with hydrophobic nano-SiO2. | [60] |

| MMT | Packaging material | Improvement of tensile strength by 32% with MMT loading of 5 wt.% Improvement of Young’s modulus from 2338 to 3237 MPa Improvement of surface hydrophobicity of film (from 51.97° to 67.77°) Reduction of moisture uptake by 11% | [61] |

| Organic nanofillers | |||

| Cellulose nanofibers (CNF) | Packaging material | Improvement of tensile strength by 33% with CNF loading of 3 wt.% Improvement of Young’s modulus from 2338 to 3173 MPa Improvement of surface hydrophobicity of film (from 51.97° to 53.89°) Reduction of moisture uptake by 13% | [61] |

| Cellulose nanocrystals (CNC) | Packaging film | Reduction of water absorption and water solubility by 21% and 50% with CNC loading of 20 wt.%, respectively Reduction of WVP by 8% with CNC loading of 15 wt.%.; WVP value increased with 20 wt.% CNC loading Optimum tensile strength of 4.59 MPa at 10 wt.% CNC loading; reduction in tensile strength with addition of 15 and 20 wt.% CNC loadings | [62] |

| Cellulose nanocrystals (CNC) | Food packaging film | Improvement of tensile strength by 56% with CNC loading of 10 vol.% Reduction of WVP by 17% | [63] |

| Chitosan | Packaging film | Improvement of tensile strength by 17% with chitosan loading of 10 wt.% Improvement of Young’s modulus by 13% Reduction of WVP by 35% TPS/chitosan film had higher opacity than TPS film Reduction of microbial growth against S. aureus and Escherichia coli | [64] |

| Chitosan | Packaging film | Optimum tensile strength of ~6.79 MPa at TPS/chitosan ratio of 4:6 Higher biodegradation rate with increase of starch content | [1] |

| Inorganic nanofillers | |||

| Zinc oxide (ZnO) nanorods | Food packaging film | Improvement of tensile strength (47 to 90 MPa) and Young’s modulus (2.1 to 3.2 MPa) Slight reduction of elongation at break from 50% to 47%. Reduction of WVP by 42%. Improvement of antimicrobial activity against E. coli from 1.5 × 107 to 9 × 105 CFU/mL | [65] |

| Silver nanoparticles (Ag-NP) | Active packaging film | Improvement of tensile strength (2.8 to 9.0 MPa) and Young’s modulus (50 to 530 MPa) Reduction of EB from 63% to 20% Improvement of antibacterial activity against E. coli from 5.0 × 107 to 1.5 × 106 CFU/mL Film with AgNP disintegrated slower than the control film in soil (after 2 weeks vs. after 1 week) | [66] |

| Ag-NP | Food packaging film | Reduction of WVP by 16% Reduction of OP by 11% No microorganism growth against S. aureus, E. coli and C. albicans (microbiostatic effect) | [59] |

| Ag-NP/nanoclay | Food packaging film | Reduction of WVP by 33% Reduction of OP by 35% No microorganism growth against S. aureus, E. coli and C. albicans (microbiostatic effect) | [59] |

| Carbonaceous fillers | |||

| Multi-walled carbon nanotubes (MWCNT) | For packaging and electroconductive applications | Improvement of tensile strength by 327% and Young’s modulus by 2484% at MWCNT loading of 0.5 wt.% Highest electrical conductivity of 56.3 S/m with 5 wt.% loading as compared to control film (1.08 × 10−3 S/m) Shifting of thermal degradation temperature to lower temperature with increasing MWCNT loading | [67] |

| Multi-walled carbon nanotubes functionalized with cetyltrimethylammonium bromide (MWCNT-CTAB) | Production of conductive film | Improvement of 2,2′-azino-bis-(3-ethylbenzothiazoline-6-sulfonic acid) (ABTS) radical scavenging activity (from ~2.5% to 30.2% after 1.5 h) Improvement of electrical conductivity (from 2.03 × 10−6 S/m to 14.75 S/m) | [68] |

| Multi-walled carbon nanotubes functionalized with ascorbic acid (MWCNT-AA) | As adsorbent for removal of methylene blue (MB) dye from aqueous solution | Enhancement of thermal stability Suitable to be used as adsorbent for removal of MB dye but not reusable | [69] |

| Multi-walled carbon nanotubes functionalized with ascorbic acid (MWCNT-AA) | As adsorbent for removal of methylene range (MO) dye from aqueous solution | Enhancement of thermal stability Suitable to be used as adsorbent for removal of MO dye but not reusable | [70] |

| Multi-walled carbon nanotubes functionalized with fructose (MWCNT-Fr) | As adsorbent for dye removal from aqueous solution | Film was too brittle for tensile test | [33] |

| Multi-walled carbon nanotubes functionalized with Valine (MWCNT-Valine) | As adsorbent for removal of copper ions from aqueous solution | Enhancement of thermal stability Suitable to be used as adsorbent for removal of copper ions but not reusable | [71] |

| Graphene oxide (GO) | Food packaging film | Improvement of tensile strength (from 57.97 to 76.09 MPa) and Young’s modulus (from 20.59 to 35.91 MPa). Slight reduction of EB from 6.60% to 3.13%. Enhancement of thermal stability Improvement of surface hydrophobicity of film (from 71.33° to 112.04°) Improvement of water vapour permeability Starch/gelatin/GO film had lower biodegradability than the control film (~30% vs. 50%) after 6 weeks of soil burial degradation. | [72] |

| Plasticizer | Examples | Advantages | Disadvantages | Ref. |

|---|---|---|---|---|

| Vegetable oil | Jatropha oil Castor oil | Biodegradable Renewable | Edible vegetable oil competes with food supply | [1,36] |

| IL | 1-allyl-3-methylimidazolium chloride 1-butyl-3-methylimidazolium chloride | Non-volatile due to negligible vapour pressure Non-flammable Good ionic conductivity High thermal stability High chemical stability High electrochemical stability | Difficult to prepare High production cost (time consuming fabrication and purification) | [90,91,92] |

| DES | Deep eutectic salts based on choline chloride | Cheaper to produce Easy to prepare in large quantity Less toxic than IL | Sometimes biodegradable | [91,93,94] |

| Sources of Starch | Filler; Starch to Filler Ratio | Filler; Optimum Loading | Plasticizer; Optimum Loading | Processing Temperature (°C) | Tensile Strength (MPa) | Young’s Modulus (MPa) | Elongation at Break (%) | Moisture Uptake (%) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Corn | - | CNC; 10 wt.% | Glycerol; 3 wt.% | 70 | 26.80 | 898 | 4.20 | 10 | [55] |

| Avocado seed | Chitosan; 7:3 | - | Glycerol; 0.2 mL/g | 90 | 5.10 | 36.36 | 14.03 | - | [19] |

| Cassava peel | - | MCC Avicel PH101; 6 wt./v% | Sorbitol; 20 wt.% | 70 | 9.12 | - | - | 70 * | [21] |

| Cassava | - | Nanoclay; 5 wt.% | Glycerol; 1.5 vol.% | 80 | 13.50 | 47 | - | - | [10] |

| Cassava | - | ZnO; 0.6 wt.% | Glycerol; 25 wt.% | 85 ± 5 | 22.30 | - | 220 * | - | [57] |

| Jackfruit seed | Chitosan; 8:2 | - | Sorbitol; 25 wt.% | 88.82 | 13.52 | - | - | - | [12] |

| Sago | - | Chitosan; 20 wt.% | Sorbitol; 25 wt.% | 70 | 46.71 | - | 0.32 | 130.31 | [109] |

| Durian seed | - | Chitosan; 15 wt.% | Sorbitol; 45 wt.% | 70 | 10.63 | 129.51 | 8.21 | - | [20] |

| Yellow pumpkin | Chitosan; 6:4 | - | Castor oil; 15 wt.% | - | 6.79 | 6.09 | 13.45 | - | [1] |

| Mango seed | - | Clay; 6 wt.% | Glycerol; 25 wt./v% | - | 5.66 | - | 43.43 | 32.28 | [18] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, S.X.; Andriyana, A.; Ong, H.C.; Lim, S.; Pang, Y.L.; Ngoh, G.C. A Comprehensive Review on the Emerging Roles of Nanofillers and Plasticizers towards Sustainable Starch-Based Bioplastic Fabrication. Polymers 2022, 14, 664. https://doi.org/10.3390/polym14040664

Tan SX, Andriyana A, Ong HC, Lim S, Pang YL, Ngoh GC. A Comprehensive Review on the Emerging Roles of Nanofillers and Plasticizers towards Sustainable Starch-Based Bioplastic Fabrication. Polymers. 2022; 14(4):664. https://doi.org/10.3390/polym14040664

Chicago/Turabian StyleTan, Shiou Xuan, Andri Andriyana, Hwai Chyuan Ong, Steven Lim, Yean Ling Pang, and Gek Cheng Ngoh. 2022. "A Comprehensive Review on the Emerging Roles of Nanofillers and Plasticizers towards Sustainable Starch-Based Bioplastic Fabrication" Polymers 14, no. 4: 664. https://doi.org/10.3390/polym14040664