Recent Advances in Development of Waste-Based Polymer Materials: A Review

Abstract

:1. Introduction

2. Wood Polymer Composites

2.1. Strategies for Compatibilization of Lignocellulose-Rich Filler Reinforced Composites

2.2. New Functionalities of Natural Fillers in Polymer Composites

2.2.1. Antioxidant Activity of Waste Fillers

2.2.2. Effects of Oil/Fat-Rich Fillers on the Polymeric Matrix

2.2.3. Reduction of the Polymers Flammability

2.2.4. Anti-Bacterial Activity of the Fillers

3. Polyurethane Foams

3.1. Open-Cell Bio-Polyurethane Foams

3.2. Closed-Cell Bio-Polyurethane Foams

3.3. Polyurethane Composite Foams

3.4. Polyurethane Recycling

4. Rubber Recycling

4.1. Green Technologies in Rubber Recycling

4.1.1. Grinding and Pulverization Technologies

4.1.2. Low-Temperature Devulcanization and Modification of GTR

4.2. Sustainable Development of Advanced Materials with GTR

4.2.1. Self-Healing, Shape-Memory, and Recyclable Materials

4.2.2. 3D Printable Materials

5. Conclusions, Limitations, and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hsissou, R.; Seghiri, R.; Benzekri, Z.; Hilali, M.; Rafik, M.; Elharfi, A. Polymer composite materials: A comprehensive review. Compos. Struct. 2021, 262, 113640. [Google Scholar] [CrossRef]

- Arefin, A.M.E.; Khatri, N.R.; Kulkarni, N.; Egan, P.F. Polymer 3D printing review: Materials, process, and design strategies for medical applications. Polymers 2021, 13, 1499. [Google Scholar] [CrossRef] [PubMed]

- Formela, K.; Zedler, Ł.; Hejna, A.; Tercjak, A. Reactive extrusion of bio-based polymer blends and composites—Current trends and future developments. Express Polym. Lett. 2018, 12, 24–57. [Google Scholar] [CrossRef]

- Wong, K.K.; Jawad, Z.A. A review and future prospect of polymer blend mixed matrix membrane for CO2 separation. J. Polym. Res. 2019, 26, 289. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Potiyaraj, P. A review on recent trends and future prospects of lignin based green rubber composites. J. Polym. Environ. 2020, 28, 367–387. [Google Scholar] [CrossRef]

- Tiseo, I. Global Plastic Market Size 2016–2028. Published on 24 June 2021. Available online: https://www.statista.com/statistics/1060583/global-market-value-of-plastic/ (accessed on 2 October 2021).

- Tiseo, I. Annual Production of Plastics Worldwide from 1950 to 2020. Published on 11 September 2021. Available online: https://www.statista.com/statistics/282732/global-production-of-plastics-since-1950/ (accessed on 2 October 2021).

- PlasticsEurope (the Association of Plastics Manufacturers in Europe). Plastics—The Facts 2020. An analysis of European Plastics Production, Demand and Waste Data. Available online: https://www.plasticseurope.org (accessed on 19 October 2021).

- Yoshida, A. China’s ban of imported recyclable waste and its impact on the waste plastic recycling industry in China and Taiwan. J. Mater. Cycles Waste Manag. 2022, 24, 73–82. [Google Scholar] [CrossRef]

- Wen, Z.; Xie, Y.; Chen, M.; Dinga, C.D. China’s plastic import ban increases prospects of environmental impact mitigation of plastic waste trade flow worldwide. Nat. Commun. 2021, 12, 425. [Google Scholar] [CrossRef]

- Żenkiewicz, M.; Żuk, T. Physical basis of tribocharging and electrostatic separation of plastics. Polimery 2014, 59, 314–323. [Google Scholar] [CrossRef]

- Żenkiewicz, M.; Żuk, T. Characteristics of separators and some limitations for electrostatic separation of polymer blends. Przem. Chem. 2014, 93, 220–227. [Google Scholar] [CrossRef]

- Żenkiewicz, M.; Żuk, T.; Pietraszek, J.; Rytlewski, P.; Moraczewski, K.; Stepczyńska, M. Electrostatic separation of binary mixtures of some biodegradable polymers and poly(vinyl chloride) or poly(ethylene terephthalate). Polimery 2016, 61, 835–843. [Google Scholar] [CrossRef]

- Żuk, T.; Pietraszak, J.; Żenkiewicz, M. Modeling of electrostatic separation process for some polymer mixtures. Polimery 2016, 61, 519–527. [Google Scholar] [CrossRef]

- Czarnecka-Komorowska, D.; Kanciak, W.; Barczewski, M.; Barczewski, R.; Regulski, R.; Sędziak, D.; Jędryczka, C. Recycling of plastics from cable waste from automotive industry in Poland as an approach to the circular economy. Polymers 2021, 13, 3845. [Google Scholar] [CrossRef] [PubMed]

- Lyskawinski, W.; Baranski, M.; Jedryczka, C.; Mikolajewicz, J.; Regulski, R.; Sedziak, D.; Netter, K.; Rybarczyk, D.; Czarnecka-Komorowska, D.; Barczewski, M. Tribo-electrostatic separation analysis of a beneficial solution in the recycling of mixed poly (ethylene terephthalate) and high-density polyethylene. Energies 2021, 14, 1755. [Google Scholar] [CrossRef]

- Froelich, D.; Maris, E. Sorting mixed polyolefins from end-of-life product by a selective grinding process. Waste Biomass Valor. 2010, 1, 439–450. [Google Scholar] [CrossRef]

- Al-Zubiedy, A.A.A. Analysis of dimensional stability of recycled plastic material obtained by grinding. Polimery 2019, 64, 361–368. [Google Scholar] [CrossRef] [Green Version]

- Flizikowski, J. Rozdrabnianie Tworzyw Sztucznych; Wydawnictwo Akademii Techniczno-Rolniczej: Bydgoszcz, Poland, 1998. [Google Scholar]

- Flizikowski, J.; Wełnowski, J.; Dudziak, P. Analysis and eco-technological evaluation of micro-grain supersonic milling. Part I. Models and indicators. Inż. Ap. Chem. 2017, 56, 161–163. [Google Scholar]

- Flizikowski, J.; Wełnowski, J.; Dudziak, P. Analysis and eco-technological evaluation of micro-grain supersonic milling. Part II. Results and discussion. Inż. Ap. Chem. 2017, 56, 164–165. [Google Scholar]

- Hejna, A. Clays as inhibitors of polyurethane foams’ flammability. Materials 2021, 14, 4826. [Google Scholar] [CrossRef]

- Spina, R.; Cavalcante, B. Evaluation of grinding of unfilled and glass fiber reinforced polyamide 6,6. Polymers 2020, 12, 2288. [Google Scholar] [CrossRef]

- Hoyer, S.; Kroll, L.; Sykutera, D. Technology comparison for the production of fine rubber powder from end of life tyres. Procedia Manuf. 2020, 43, 193–200. [Google Scholar] [CrossRef]

- Guo, X.; Xiang, D.; Duan, G.; Mou, P. A review of mechanochemistry applications in waste management. Waste Manag. 2010, 30, 4–10. [Google Scholar] [CrossRef] [PubMed]

- Cichosz, S.; Masek, A. Superiority of cellulose non-solvent chemical modification over solvent-involving treatment: Solution for green chemistry (Part I). Materials 2020, 13, 2552. [Google Scholar] [CrossRef] [PubMed]

- Bula, K.; Klapiszewski, Ł.; Piasecki, A.; Jesionowski, T. The role of inorganic-organic bio-fillers containing kraft lignin in improvement in functional properties of polyethylene. Materials 2021, 14, 2114. [Google Scholar] [CrossRef] [PubMed]

- Sustainable Plastics Strategy. Available online: http://www.suschem.org/publicationsbySUSCHEM (accessed on 21 November 2021).

- Zaaba, N.F.; Ismail, H. Thermoplastic/natural filler composites: A short review. J. Phys. Sci. 2019, 30, 81–99. [Google Scholar] [CrossRef] [Green Version]

- Thomason, J.L.; Rudeiros-Fernández, J.L. A review of the impact performance of natural fiber thermoplastic composites. Front. Mater. 2018, 5, 60. [Google Scholar] [CrossRef]

- Wahit, M.U.; Akos, N.I.; Laftah, W.A. Influence of natural fibers on the mechanical properties and biodegradation of poly (lactic acid) and poly (ε-caprolactone) composites: A review. Polym. Compos. 2012, 33, 1045–1053. [Google Scholar] [CrossRef]

- Raport Plastics—The Facts 2021 from PlasticEurope. Available online: https://plasticseurope.org/pl/knowledge-hub/plastics-the-facts-2021/ (accessed on 31 January 2022).

- Available online: https://www.european-bioplastics.org/market/ (accessed on 31 January 2022).

- Aniśko, J.; Barczewski, M. Polylactide: From synthesis and modification to final properties. Adv. Sci. Technol. Res. J. 2021, 15, 9–29. [Google Scholar] [CrossRef]

- Thomas, R.J. Wood: Structure and Chemical Composition in Book: Wood Technology: Chemical Aspects; ACS Publications: Washington, DC, USA, 1977; pp. 1–23. [Google Scholar] [CrossRef] [Green Version]

- Kozlowski, R.; Wladyka-Przybylak, M. Natural Polymers, wood and lignocellulosic materials. In Fire Retardant Materials; Horrocks, A.R., Price, D., Eds.; Woodhead Publishing: Cambridge, UK, 2001; pp. 293–317. [Google Scholar] [CrossRef]

- Reszka, P. In-Depth Temperature Profiles in Pyrolzing Wood; University of Edinburgh: Edinburgh, UK, 2008; Available online: http://hdl.handle.net/1842/2602 (accessed on 31 January 2022).

- Olabisi, O.; Adewale, K. Handbook of Thermoplastics; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar] [CrossRef]

- Pradhan, R.; Misra, M.; Erickson, L.; Mohanty, A. Compostability and biodegradation study of PLA–wheat straw and PLA–soy straw based green composites in simulated composting bioreactor. Bioresour. Technol. 2010, 101, 8489–8491. [Google Scholar] [CrossRef]

- Dilucia, F.; Lacivita, V.; Conte, A.; del Nobile, M.A. Sustainable use of fruit and vegetable by-products to enhance food packaging performance. Foods 2020, 9, 857. [Google Scholar] [CrossRef]

- Efenberger-Szmechtyk, M.; Nowak, A.; Czyzowska, A. Plant extracts rich in polyphenols: Antibacterial agents and natural preservatives for meat and meat products. Crit. Rev. Food Sci. Nutr. 2021, 61, 149–178. [Google Scholar] [CrossRef]

- Shah, A.U.R.; Prabhakar, M.N.; Song, J.-I. Current advances in the fire retardancy of natural fiber and bio-based composites—A review. Int. J. Precis. Eng. Manuf. Technol. 2017, 4, 247–262. [Google Scholar] [CrossRef]

- Ashori, A.; Nourbakhsh, A. Bio-based composites from waste agricultural residues. Waste Manag. 2010, 30, 680–684. [Google Scholar] [CrossRef] [PubMed]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Sustainable green composites: Value addition to agricultural residues and perennial grasses. ACS Sustain. Chem. Eng. 2013, 1, 325–333. [Google Scholar] [CrossRef]

- Song, X.; He, W.; Chen, P.; Wei, Q.; Wen, J.; Xiao, G. Fused deposition modeling of poly (lactic acid)/almond shell composite filaments. Polym. Compos. 2021, 42, 899–913. [Google Scholar] [CrossRef]

- Altun, M.; Celebi, M.; Ovali, S. Preparation of the pistachio shell reinforced PLA biocomposites: Effect of filler treatment and PLA maleation. J. Thermoplast. Compos. Mater. 2021. [Google Scholar] [CrossRef]

- Odili, C.; Gbenebor, O.; Adesola, O.E.; Adeosun, S. Characterization of polylactide (PLA) composite reinforced with biowaste. Kufa. J. Eng. 2021, 12, 119–129. [Google Scholar] [CrossRef]

- Hejna, A.; Sulyman, M.; Przybysz, M.; Saeb, M.R.; Klein, M.; Formela, K. On the correlation of lignocellulosic filler composition with the performance properties of poly(ε-caprolactone) based biocomposites. Waste Biomass Valor. 2020, 11, 1467–1479. [Google Scholar] [CrossRef] [Green Version]

- Mirowski, J.; Oliwa, R.; Oleksy, M.; Tomaszewska, J.; Ryszkowska, J.; Budzik, G. Poly (vinyl chloride) composites with raspberry pomace filler. Polymers 2021, 13, 1079. [Google Scholar] [CrossRef]

- Sałasińska, K.; Osica, A.; Ryszkowska, J. The use of tree leaves as reinforcement in composites with recycled PE-HD matrix. Polimery 2012, 57, 646–655. [Google Scholar] [CrossRef]

- Kengkhetkit, N.; Amornsakchai, T. A new approach to “greening” plastic composites using pineapple leaf waste for performance and cost effectiveness. Mater. Des. 2014, 55, 292–299. [Google Scholar] [CrossRef]

- Kufel, A.; Kuciel, S. Composites based on polypropylene modified with natural fillers to increase stiffness. Czas. Tech. 2019, 1, 187–195. [Google Scholar] [CrossRef] [Green Version]

- Stark, N.M.; Rowlands, R.E. Effects of wood fiber characteristics on mechanical properties of wood/polypropylene composites. Wood Fiber Sci. 2003, 35, 167–174. [Google Scholar]

- Amir, N.; Abidin, K.A.Z.; Shiri, F.B.M. Effects of fibre configuration on mechanical properties of banana fibre/PP/MAPP natural fibre reinforced polymer composite. Procedia Eng. 2017, 184, 573–580. [Google Scholar] [CrossRef]

- Dun, M.; Fu, H.; Hao, J.; Shan, W.; Wang, W. Tailoring flexible interphases in bamboo fiber-reinforced linear low-density polyethylene composites. Compos. Part A Appl. Sci. Manuf. 2021, 150, 106606. [Google Scholar] [CrossRef]

- Sherwani, S.; Sapuan, S.; Leman, Z.; Zainudin, E.; Khalina, A. Effect of alkaline and benzoyl chloride treatments on the mechanical and morphological properties of sugar palm fiber-reinforced poly (lactic acid) composites. Text. Res. J. 2022, 92, 593–607. [Google Scholar] [CrossRef]

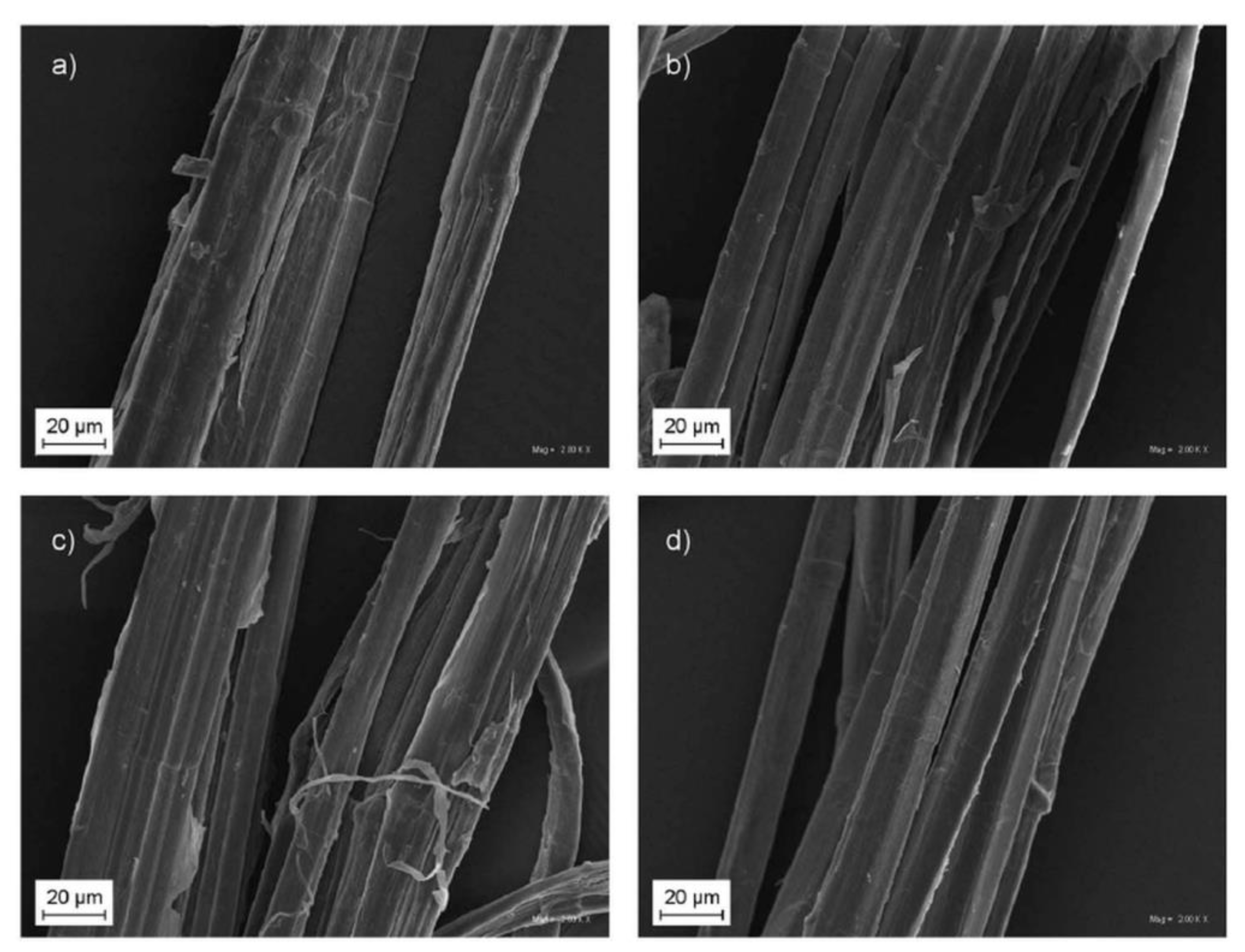

- Matykiewicz, D.; Barczewski, M.; Mysiukiewicz, O.; Skórczewska, K. Comparison of various chemical treatments efficiency in relation to the properties of flax, hemp fibers and cotton trichomes. J. Nat. Fibers 2021, 18, 735–751. [Google Scholar] [CrossRef]

- Rojas-Lema, S.; Lascano, D.; Ivorra-Martinez, J.; Gomez-Caturla, J.; Balart, R.; Garcia-Garcia, D. Manufacturing and Characterization of high-density polyethylene composites with active fillers from persimmon peel flour with improved antioxidant activity and hydrophobicity. Macromol. Mater. Eng. 2021, 306, 2100430. [Google Scholar] [CrossRef]

- Barczewski, M.; Matykiewicz, D.; Piasecki, A.; Szostak, M. Polyethylene green composites modified with post agricultural waste filler: Thermo-mechanical and damping properties. Compos. Interfaces 2018, 25, 287–299. [Google Scholar] [CrossRef]

- Paukszta, D.; Doczekalska, B.; Ostrowski, A.; Bartkowiak, M. Modification of rapeseed straw with organic acid anhydrides. J. Compos. Mater. 2015, 49, 1369–1378. [Google Scholar] [CrossRef]

- Hejna, O.; Marć, M.; Korol, J. Modification of cellulosic filler with diisocyanates–volatile organic compounds emission assessment and stability of chemical structure over time. Nord. Pulp Pap. Res. J. 2021, 36, 353–372. [Google Scholar] [CrossRef]

- Hejna, A.; Barczewski, M.; Skórczewska, K.; Szulc, J.; Chmielnicki, B.; Korol, J.; Formela, K. Sustainable upcycling of brewers’ spent grain by thermo-mechanical treatment in twin-screw extruder. J. Clean. Prod. 2021, 285, 124839. [Google Scholar] [CrossRef]

- Rytlewski, P.; Moraczewski, K.; Malinowski, R.; Żenkiewicz, M. Assessment of dicumyl peroxide ability to improve adhesion between polylactide and flax or hemp fibres. Compos. Interfaces 2014, 21, 671–683. [Google Scholar] [CrossRef]

- Luo, S.; Cao, J.; Armando, G.; McDonald, A.G. Interfacial improvements in a green biopolymer alloy of polyn (3-hydroxybutyrate-co-3-hydroxyvalerate) and lignin via in situ reactive extrusion. ACS Sustain. Chem. Eng. 2016, 4, 3465–3476. [Google Scholar] [CrossRef]

- Dhar, P.; Gaur, S.S.; Soundararajan, N.; Gupta, A.; Bhasney, S.M.; Milli, M.; Kumar, A.; Katiyar, V. Reactive extrusion of polylactic acid/cellulose nanocrystal films for food packaging applications: Influence of filler type on thermomechanical, rheological, and barrier properties. Ind. Eng. Chem. Res. 2017, 56, 4718–4735. [Google Scholar] [CrossRef]

- Reinaldo, J.S.; Milfont, C.H.R.; Gomes, F.P.C.; Mattos, A.L.A.; Medeiros, F.G.M.; Lopes, P.F.N.; Filho, M.; de Sá, M.S.; Matsui, K.N.; Ito, E.N. Influence of grape and acerola residues on the antioxidant, physicochemical and mechanical properties of cassava starch biocomposites. Polym. Test. 2021, 93, 107015. [Google Scholar] [CrossRef]

- Napolitano, A.; Fogliano, V.; Tafuri, A.; Ritieni, A. Natural occurrence of ochratoxin A and antioxidant activities of green and roasted coffees and corresponding byproducts. J. Agric. Food Chem. 2007, 55, 10499–10504. [Google Scholar] [CrossRef]

- Battegazzore, D.; Bocchini, S.; Alongi, J.; Frache, A. Plasticizers, antioxidants and reinforcement fillers from hazelnut skin and cocoa by-products: Extraction and use in PLA and PP. Polym. Degrad. Stab. 2014, 108, 297–306. [Google Scholar] [CrossRef]

- Gaur, A.; Tiwari, S.; Kumar, C.; Maiti, P. Bio-waste orange peel and polymer hybrid for efficient energy harvesting. Energy Rep. 2020, 6, 490–496. [Google Scholar] [CrossRef]

- Hejna, A. Potential applications of by-products from the coffee industry in polymer technology—Current state and perspectives. Waste Manag. 2021, 121, 296–330. [Google Scholar] [CrossRef]

- Oliveira, G.; Passos, C.P.; Ferreira, P.; Coimbra, M.A.; Gonçalves, I. Coffee by-products and their suitability for developing active food packaging materials. Foods 2021, 10, 683. [Google Scholar] [CrossRef]

- Janissen, B.; Huynh, T. Chemical composition and value-adding applications of coffee industry by-products: A review. Resour. Conserv. Recycl. 2018, 128, 110–117. [Google Scholar] [CrossRef]

- Totaro, G.; Sisti, L.; Fiorini, M.; Lancellotti, I.; Andreola, F.N.; Saccani, A. Formulation of green particulate composites from PLA and PBS matrix and wastes deriving from the coffee production. J. Polym. Environ. 2019, 27, 1488–1496. [Google Scholar] [CrossRef]

- Sarasini, F.; Luzi, F.; Dominici, F.; Maffei, G.; Iannone, A.; Zuorro, A.; Lavecchia, R.; Torre, L.; Carbonell-Verdu, A.; Balart, R.; et al. Effect of different compatibilizers on sustainable composites based on a PHBV/PBAT matrix filled with coffee silverskin. Polymers 2018, 10, 1256. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kumar, T.S.M.; Rajini, N.; Huafeng, T.; Rajulu, A.V.; Ayrilmis, N.; Siengchin, S. Improved mechanical and thermal properties of spent coffee bean particulate reinforced poly (propylene carbonate) composites. Part. Sci. Technol. 2019, 37, 643–650. [Google Scholar] [CrossRef]

- Iyer, K.A.; Zhang, L.; Torkelson, J.M. Direct use of natural antioxidant-rich agro-wastes as thermal stabilizer for polymer: Processing and recycling. ACS Sustain. Chem. Eng. 2016, 4, 881–889. [Google Scholar] [CrossRef]

- Nanni, A.; Battegazzore, D.; Frache, A.; Messori, M. Thermal and UV aging of polypropylene stabilized by wine seeds wastes and their extracts. Polym. Degrad. Stab. 2019, 165, 49–59. [Google Scholar] [CrossRef]

- Moraczewski, K.; Karasiewicz, T.; Jagodziński, B.; Trafarski, A.; Pawłowska, A.; Stepczyńska, M.; Rytlewski, P. Recyclability of new polylactide based biodegradable materials with plant extracts containing natural polyphenols. Sustain. Mater. Technol. 2021, 30, e00351. [Google Scholar] [CrossRef]

- Jóźwik, A.; Strzałkowska, N.; Markiewicz-Keszycka, M.; Krzyżewski, J.; Lipińska, P.; Rutkowska, J.; Wróblewska, B.; Klusek, J.; Cooper, R. Effects of replacing rapeseed cake with linseed cake in a corn-grass silage-based diet for milking cows. Anim. Sci. Pap. Rep. 2016, 34, 129–142. [Google Scholar]

- Łopusiewicz, Ł.; Drozłowska, E.; Tarnowiecka-Kuca, A.; Bartkowiak, A.; Mazurkiewicz-Zapałowicz, K.; Salachna, P. Biotransformation of flaxseed oil cake into bioactive camembert-analogue using lactic acid bacteria, Penicillium camemberti and Geotrichum candidum. Microorganisms 2020, 8, 1266. [Google Scholar] [CrossRef]

- Łopusiewicz, Ł.; Drozłowska, E.; Siedlecka, P.; Mężyńska, M.; Bartkowiak, A.; Sienkiewicz, M.; Zielińska-Bliźniewska, H.; Kwiatkowski, P. Development, characterization, and bioactivity of non-dairy kefir-like fermented beverage based on flaxseed oil cake. Foods 2019, 8, 544. [Google Scholar] [CrossRef] [Green Version]

- Arrieta, M.P.; Samper, M.D.; Jiménez-López, M.; Aldas, M.; López, J. Combined effect of linseed oil and gum rosin as natural additives for PVC. Ind. Crops Prod. 2017, 99, 196–204. [Google Scholar] [CrossRef]

- Fenollar, O.; Garcia-Sanoguera, D.; Sanchez-Nacher, L.; Lopez, J.; Balart, R. Effect of the epoxidized linseed oil concentration as natural plasticizer in vinyl plastisols. J. Mater. Sci. 2010, 45, 4406–4413. [Google Scholar] [CrossRef]

- Garcia-Campo, M.; Quiles-Carrillo, L.; Masia, J.; Reig-Pérez, M.; Montanes, N.; Balart, R. Environmentally friendly compatibilizers from soybean oil for ternary blends of poly (lactic acid)-PLA, poly (ε-caprolactone)-PCL and poly (3-hydroxybutyrate)-PHB. Materials 2017, 10, 1339. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Quiles-Carrillo, L.; Duart, S.; Montanes, N.; Torres-Giner, S.; Balart, R. Enhancement of the mechanical and thermal properties of injection-molded polylactide parts by the addition of acrylated epoxidized soybean oil. Mater. Des. 2018, 140, 54–63. [Google Scholar] [CrossRef]

- Mittal, V.; Luckachan, G.E.; Chernev, B.; Matsko, N.B. Bio-polyester-date seed powder composites: Morphology and component migration. Polym. Eng. Sci. 2015, 55, 877–888. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Barczewski, M. Utilization of linseed cake as a postagricultural functional filler for poly (lactic acid) green composites. J. Appl. Polym. Sci. 2019, 136, 47152. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Barczewski, M. Crystallization of polylactide-based green composites filled with oil-rich waste fillers. J. Polym. Res. 2020, 27, 374. [Google Scholar] [CrossRef]

- Barczewski, M.; Mysiukiewicz, O.; Szulc, J.; Kloziński, A. Poly (lactic acid) green composites filled with linseed cake as an agricultural waste filler. Influence of oil content within the filler on the rheological behavior. J. Appl. Polym. Sci. 2019, 136, 47651. [Google Scholar] [CrossRef]

- Kozłowski, R.; Władyka-Przybylak, M. Flammability and fire resistance of composites reinforced by natural fibers. Polym. Adv. Technol. 2008, 19, 446–453. [Google Scholar] [CrossRef]

- John, M.J. Chapter 2: Flammability performance of biocomposites. In Green Composites for Automotive Applications; Koronis, G., Silva, A., Eds.; Woodhead Publishing: Cambridge, UK, 2018; pp. 43–58. [Google Scholar] [CrossRef]

- Duarah, P.; Haldar, D.; Purkait, M.K. Technological advancement in the synthesis and applications of lignin-based nanoparticles derived from agro-industrial waste residues: A review. Int. J. Biol. Macromol. 2020, 163, 1828–1843. [Google Scholar] [CrossRef]

- Yu, Y.; Fu, S.; Song, P.; Luo, X.; Jin, Y.; Lu, F.; Wu, Q.; Ye, J. Functionalized lignin by grafting phosphorus-nitrogen improves the thermal stability and flame retardancy of polypropylene. Polym. Degrad. Stab. 2012, 97, 541–546. [Google Scholar] [CrossRef]

- Wang, Y.; Yue, J.; Xie, R.; Liu, C.; Gan, L.; Huang, J. High-value use of lignocellulosic-rich eucommia residue for promoting mechanical properties and flame retardancy of poly (butylene succinate). J. Appl. Polym. Sci. 2020, 137, 48543. [Google Scholar] [CrossRef]

- Sałasińska, K.; Barczewski, M.; Borucka, M.; Górny, R.L.; Kozikowski, P.; Celiński, M.; Gajek, A. Thermal stability, fire and smoke behaviour of epoxy composites modified with plant waste fillers. Polymers 2019, 11, 1234. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sałasińska, K.; Celiński, M.; Mizera, K.; Kozikowski, P.; Leszczyński, M.K.; Gajek, A. Synergistic effect between histidine phosphate complex and hazelnut shell for flammability reduction of low-smoke emission epoxy resin. Polym. Degrad. Stab. 2020, 181, 109292. [Google Scholar] [CrossRef]

- Sałasińska, K.; Mizera, K.; Barczewski, M.; Borucka, M.; Gloc, M.; Celiński, M.; Gajek, A. The influence of degree of fragmentation of Pinus sibirica on flammability, thermal and thermomechanical behavior of the epoxy-composites. Polym. Test. 2019, 79, 106036. [Google Scholar] [CrossRef]

- Vahabi, H.; Jouyandeh, M.; Parpaite, T.; Saeb, M.R.; Ramakrishna, S. Coffee wastes as sustainable flame retardants for polymer materials. Coatings 2021, 11, 1021. [Google Scholar] [CrossRef]

- Hajj, R.; el Hage, R.; Sonnier, R.; Otazaghine, B.; Gallard, B.; Rouif, S.; Nakhl, M.; Lopez-Cuesta, J.M. Grafting of phosphorus flame retardants on flax fabrics: Comparison between two routes. Polym. Degrad. Stab. 2018, 147, 25–34. [Google Scholar] [CrossRef]

- le Moigne, N.; Sonnier, R.; El Hage, R.; Rouif, S. Radiation-induced modifications in natural fibres and their biocomposites: Opportunities for controlled physico-chemical modification pathways? Ind. Crops Prod. 2017, 109, 199–213. [Google Scholar] [CrossRef]

- Al Hokayem, K.; El Hage, R.; Svecova, L.; Otazaghine, B.; le Moigne, N.; Sonnier, R. Flame retardant-functionalized cotton cellulose using phosphonate-based ionic liquids. Molecules 2020, 25, 1629. [Google Scholar] [CrossRef] [Green Version]

- Oatway, L.; Vasanthan, T.; Helm, J.H. Phytic acid. Food Rev. Int. 2001, 17, 419–431. [Google Scholar] [CrossRef]

- Yang, W.; Tawiah, B.; Yu, C.; Qian, Y.-F.; Wang, L.-L.; Yuen, C.-Y.A.; Zhu, S.-E.; Hu, E.-Z.; Chen, B.-Y.T.; Yu, B.; et al. Manufacturing, mechanical and flame retardant properties of poly (lactic acid) biocomposites based on calcium magnesium phytate and carbon nanotubes. Compos. Part A Appl. Sci. 2018, 110, 227–236. [Google Scholar] [CrossRef]

- Costes, L.; Laoutid, F.; Dumazert, L.; Lopez-Cuesta, J.M.; Brohez, S.; Delvosalle, C.; Dubois, P. Metallic phytates as efficient bio-based phosphorous flame retardant additives for poly (lactic acid). Polym. Degrad. Stab. 2015, 119, 217–227. [Google Scholar] [CrossRef]

- Yang, Y.X.; Haurie, L.; Zhang, J.; Zhang, X.-Q.; Wang, R.; Wang, D.-Y. Effect of bio-based phytate (PA-THAM) on the flame retardant and mechanical properties of polylactide (PLA). Express Polym. Lett. 2020, 14, 705–716. [Google Scholar] [CrossRef]

- El-Nemr, K.F.; Mohamed, H.R.; Ali, M.A.; Fathy, R.M.; Dhmees, A.S. Polyvinyl alcohol/gelatin irradiated blends filled by lignin as green filler for antimicrobial packaging materials. Int. J. Environ. Anal. Chem. 2020, 100, 1578–1602. [Google Scholar] [CrossRef]

- Spiridon, I.; Anghel, N.C.; Darie-Nita, R.N.; Iwańczuk, A.; Ursu, R.G.; Spiridon, I.A. New composites based on starch/Ecoflex®/biomass wastes: Mechanical, thermal, morphological and antimicrobial properties. Int. J. Biol. Macromol. 2020, 156, 1435–1444. [Google Scholar] [CrossRef]

- Eswaranandam, S.; Hettiarachchy, N.S.; Johnson, M.G. Antimicrobial activity of citric, lactic, malic, or tartaric acids and nisin-incorporated soy protein film against Listeria monocytogenes, Escherichia coli O157:H7, and Salmonella gaminara. J. Food Sci. 2006, 69, FMS79–FMS84. [Google Scholar] [CrossRef]

- Spiridon, I.; Ursu, R.G.; Spiridon, I.A.C. New polylactic acid composites for packaging applications: Mechanical properties, thermal behavior, and antimicrobial activity. Int. J. Polym. Anal. Charact. 2015, 20, 681–692. [Google Scholar] [CrossRef]

- Klapiszewski, Ł.; Oliwa, R.; Oleksy, M.; Jesionowski, T. Calcium lignosulfonate as eco-friendly additive for crosslinking fibrous composites with phenol-formaldehyde resin matrix. Polimery 2018, 63, 102–108. [Google Scholar] [CrossRef]

- Kawalerczyk, J.; Dziurka, D.; Mirski, R.; Trociński, A. Flour fillers with urea-formaldehyde resin in plywood. BioResources 2019, 14, 6727–6735. [Google Scholar]

- Pączkowski, P.; Puszka, A.; Gawdzik, B. Green composites based on unsaturated polyester resin from recycled poly (ethylene terephthalate) with wood flour as filler—Synthesis, characterization and aging effect. Polymers 2020, 12, 2966. [Google Scholar] [CrossRef]

- Sienkiewicz, A.; Czub, P. Blocked isocyanates as alternative curing agents for epoxy-polyurethane resins based on modified vegetable oil. Express Polym. Lett. 2019, 13, 642–655. [Google Scholar] [CrossRef]

- Jankowski, A.; Grabiec, E.; Nocoń-Szmajda, K.; Marcinkowski, A.; Janeczek, H.; Wolińska-Grabczyk, A. Polyimide-based membrane materials for CO2 separation: A comparison of segmented and aromatic (co)polyimides. Membranes 2021, 11, 274. [Google Scholar] [CrossRef] [PubMed]

- Głowińska, E.; Wolak, W.; Datta, J. Eco-friendly route for thermoplastic polyurethane elastomers with bio-based hard segments composed of bio-glycol and mixtures of aromatic–aliphatic and aliphatic–aliphatic diisocyanate. J. Polym. Environ. 2021, 29, 2140–2149. [Google Scholar] [CrossRef]

- Sardon, H.; Mecerreyes, D.; Basterretxea, A.; Avérous, L.; Jehanno, C. From lab to market: Current strategies for the production of biobased polyols. ACS Sustain. Chem. Eng. 2021, 9, 10664–10677. [Google Scholar] [CrossRef]

- Borowicz, M.; Paciorek-Sadowska, J.; Lubczak, J.; Czupryński, B. Biodegradable, flame-retardant, and bio-based rigid polyurethane/polyisocyanurate foams for thermal insulation application. Polymers 2019, 11, 1816. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fridrihsone, A.; Abolins, A.; Kirpluks, M. Screening life cycle assessment of tall oil-based polyols suitable for rigid polyurethane foams. Energies 2020, 13, 5249. [Google Scholar] [CrossRef]

- Pietrzak, K.; Kirpluks, M.; Cabulis, U.; Ryszkowska, J. Effect of the addition of tall oil-based polyols on the thermal and mechanical properties of ureaurethane elastomers. Polym. Degrad. Stab. 2014, 108, 201–211. [Google Scholar] [CrossRef]

- de Luca Bossa, F.; Verdolotti, L.; Russo, V.; Campaner, P.; Minigher, A.; Lama, G.C.; Boggioni, L.; Tesser, R.; Lavorgna, M. Upgrading sustainable polyurethane foam based on greener polyols: Succinic-based polyol and Mannich-based polyol. Materials 2020, 13, 3170. [Google Scholar] [CrossRef]

- Abril-Milán, D.; Valdés, O.; Mirabal-Gallardo, Y.F.; de la Torre, A.; Bustamante, C.; Contreras, J. Preparation of renewable bio-polyols from two species of Colliguaja for rigid polyurethane foams. Materials 2018, 11, 2244. [Google Scholar] [CrossRef] [Green Version]

- Kurańska, M.; Beneš, H.; Prociak, A.; Trhlíková, O.; Walterová, Z.; Stochlińska, W. Investigation of epoxidation of used cooking oils with homogeneous and heterogeneous catalysts. J. Clean. Prod. 2019, 236, 117615. [Google Scholar] [CrossRef]

- Kurańska, M.; Malewska, E.; Polaczek, K.; Prociak, A.; Kubacka, J. A pathway toward a new era of open-cell polyurethane foams—Influence of bio-polyols derived from used cooking oil on foams properties. Materials 2020, 13, 5161. [Google Scholar] [CrossRef] [PubMed]

- Kurańska, M.; Niemiec, M. Cleaner production of epoxidized cooking oil using a heterogeneous catalyst. Catalysts 2020, 10, 1261. [Google Scholar] [CrossRef]

- Kurańska, M.; Beneš, H.; Polaczek, K.; Trhlikova, O.; Walterova, Z.; Prociak, A. Effect of homogeneous catalysts on ring opening reactions of epoxidized cooking oils. J. Clean. Prod. 2019, 230, 162–169. [Google Scholar] [CrossRef]

- Kurańska, M.; Banaś, J.; Polaczek, K.; Banaś, M.; Prociak, A.; Kuc, J.; Uram, K.; Lubera, T. Evaluation of application potential of used cooking oils in the synthesis of polyol compounds. J. Environ. Chem. Eng. 2019, 7, 103506. [Google Scholar] [CrossRef]

- Polaczek, K.; Kurańska, M.; Auguścik-Królikowska, M.; Prociak, A.; Ryszkowska, J. Open-cell polyurethane foams of very low density modified with various palm oil-based bio-polyols in accordance with cleaner production. J. Clean. Prod. 2021, 290, 125875. [Google Scholar] [CrossRef]

- Serrano, L.; Rincón, E.; García, A.; Rodríguez, J.; Briones, R. Bio-degradable polyurethane foams produced by liquefied polyol from wheat straw biomass. Polymers 2020, 12, 2646. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Tuohedi, N. Polyurethane foams and bio-polyols from liquefied cotton stalk agricultural waste. Sustainability 2020, 12, 4214. [Google Scholar] [CrossRef]

- Jiang, W.; Hosseinpourpia, R.; Biziks, V.; Ahmed, S.A.; Militz, H.; Adamopoulos, S. Preparation of polyurethane adhesives from crude and purified liquefied wood sawdust. Polymers 2021, 13, 3267. [Google Scholar] [CrossRef]

- Gosz, K.; Tercjak, A.; Olszewski, A.; Haponiuk, J.; Piszczyk, Ł. Bio-based polyurethane networks derived from liquefied sawdust. Materials 2021, 14, 3138. [Google Scholar] [CrossRef]

- Olszewski, A.; Nowak, P.; Kosmela, P.; Piszczyk, Ł. Characterization of highly filled glass fiber/carbon fiber polyurethane composites with the addition of bio-polyol obtained through biomass liquefaction. Materials 2021, 14, 1391. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Kairytė, A. Application of walnut shells-derived biopolyol in the synthesis of rigid polyurethane foams. Materials 2020, 13, 2687. [Google Scholar] [CrossRef]

- Lubczak, R.; Szczęch, D.; Broda, D.; Wojnarowska-Nowak, R.; Kus-Liśkiewicz, M.; Dębska, B.; Lubczak, J. Polyetherols and polyurethane foams from starch. Polym. Test. 2021, 93, 106884. [Google Scholar] [CrossRef]

- Szpiłyk, M.; Lubczak, R.; Lubczak, J. The biodegradable cellulose-derived polyol and polyurethane foam. Polym. Test. 2021, 100, 107250. [Google Scholar] [CrossRef]

- Ionescu, M.; Wan, X.; Bilić, N.; Petrović, Z.S. Polyols and rigid polyurethane foams from cashew nut shell liquid. J. Polym. Environ. 2012, 20, 647–658. [Google Scholar] [CrossRef]

- Gandhi, T.S.; Patel, M.R.; Dholakiya, B.Z. Mechanical, thermal and fire properties of sustainable rigid polyurethane foam derived from cashew nut shell liquid. Int. J. Plast. Technol. 2015, 19, 30–46. [Google Scholar] [CrossRef]

- Abolins, A.; Pomilovskis, R.; Vanags, E.; Mierina, I.; Michalowski, S.; Fridrihsone, A.; Kirpluks, M. Impact of different epoxidation approaches of tall oil fatty acids on rigid polyurethane foam thermal insulation. Materials 2021, 14, 894. [Google Scholar] [CrossRef] [PubMed]

- Borowicz, M.; Paciorek-Sadowska, J.; Isbrandt, M.; Grzybowski, Ł.; Czupryński, B. Glycerolysis of poly (lactic acid) as a way to extend the “life cycle” of this material. Polymers 2019, 11, 1963. [Google Scholar] [CrossRef] [Green Version]

- Datta, J.; Kopczyńska, P. From polymer waste to potential main industrial products: Actual state of recycling and recovering. Crit. Rev. Environ. Sci. Technol. 2016, 46, 905–946. [Google Scholar] [CrossRef]

- Paciorek-Sadowska, J.; Borowicz, M.; Isbrandt, M. New poly(lactide-urethane-isocyanurate) foams based on bio-polylactide waste. Polymers 2019, 11, 481. [Google Scholar] [CrossRef] [Green Version]

- Borowicz, M.; Isbrandt, M.; Paciorek-Sadowska, J. Effect of new eco-polyols based on PLA waste on the basic properties of rigid polyurethane and polyurethane/polyisocyanurate foams. Int. J. Mol. Sci. 2021, 22, 8981. [Google Scholar] [CrossRef]

- Kurańska, M.; Polaczek, K.; Auguścik-Królikowska, M.; Prociak, A.; Ryszkowska, J. Open-cell rigid polyurethane bio-foams based on modified used cooking oil. Polymer 2020, 190, 122164. [Google Scholar] [CrossRef]

- Gao, T.-Y.; Wang, F.-D.; Xu, Y.; Wei, C.-X.; Zhu, S.-E.; Yang, W.; Lu, H.-D. Luteolin-based epoxy resin with exceptional heat resistance, mechanical and flame retardant properties. Chem. Eng. J. 2022, 428, 131173. [Google Scholar] [CrossRef]

- Tian, Y.; Wang, Q.; Cheng, J.; Zhang, J. A fully biomass based monomer from itaconic acid and eugenol to build degradable thermosets via thiol–ene click chemistry. Green Chem. 2020, 22, 921–932. [Google Scholar] [CrossRef]

- Taung Mai, L.L.; Aung, M.M.; Muhamad Saidi, S.A.; H’ng, P.S.; Rayung, M.; Jaafar, A.M. Non edible oil-based epoxy resins from Jatropha oil and their shape memory behaviors. Polymers 2021, 13, 2177. [Google Scholar] [CrossRef] [PubMed]

- Sienkiewicz, A.; Czub, P.; Milo, A. Palm oil as a renewable raw material in the synthesis of new polymeric materials through the epoxy fusion process. Express Polym. Lett. 2021, 15, 582–599. [Google Scholar] [CrossRef]

- Sienkiewicz, A.; Czub, P. Rheological analysis of the synthesis of high-molecular-weight epoxy resins from modified soybean oil and bisphenol A or BPA-based epoxy resins. Materials 2021, 14, 6770. [Google Scholar] [CrossRef] [PubMed]

- Lascano, D.; Lerma-Canto, A.; Fombuena, V.; Balart, R.; Montanes, N.; Quiles-Carrillo, L. Kinetic analysis of the curing process of biobased epoxy resin from epoxidized linseed oil by dynamic differential scanning calorimetry. Polymers 2021, 13, 1279. [Google Scholar] [CrossRef]

- Sienkiewicz, N.; Dominic, M.; Parameswaranpillai, J. Natural fillers as potential modifying agents for epoxy composition: A review. Polymers 2022, 14, 265. [Google Scholar] [CrossRef]

- Gioia, C.; Colonna, M.; Tagami, A.; Medina, L.; Sevastyanova, O.; Berglund, L.A.; Lawoko, M. Lignin-based epoxy resins: Unravelling the relationship between structure and material properties. Biomacromolecules 2020, 21, 1920–1928. [Google Scholar] [CrossRef]

- Roszowska-Jarosz, M.; Masiewicz, J.; Kostrzewa, M.; Kucharczyk, W.; Żurowski, W.; Kucińska-Lipka, J.; Przybyłek, P. Mechanical properties of bio-composites based on epoxy resin and nanocellulose fibres. Materials 2021, 14, 3576. [Google Scholar] [CrossRef]

- Gargol, M.; Klepka, T.; Klapiszewski, Ł.; Podkościelna, B. Synthesis and thermo-mechanical study of epoxy resin-based composites with waste fibers of hemp as an eco-friendly filler. Polymers 2021, 13, 503. [Google Scholar] [CrossRef] [PubMed]

- Hodul, J.; Mészárosová, L.; Drochytka, R. Recovery of industrial wastes as fillers in the epoxy thermosets for building application. Materials 2021, 14, 3490. [Google Scholar] [CrossRef] [PubMed]

- Kurańska, M.; Polaczek, K.; Auguścik-Królikowska, M.; Prociak, A.; Ryszkowska, J. Open-cell polyurethane foams based on modified used cooking oil. Polimery 2020, 65, 216–225. [Google Scholar] [CrossRef]

- Kurańska, M.; Barczewski, R.; Barczewski, M.; Prociak, A.; Polaczek, K. Thermal insulation and sound absorption properties of open-cell polyurethane foams modified with bio-polyol based on used cooking oil. Materials 2020, 13, 5673. [Google Scholar] [CrossRef]

- Kurańska, M.; Beneš, H.; Sałasińska, K.; Prociak, A.; Malewska, E.; Polaczek, K. Development and characterization of “green open-cell polyurethane foams” with reduced flammability. Materials 2020, 13, 5459. [Google Scholar] [CrossRef] [PubMed]

- Kurańska, M.; Leszczyńska, M.; Kubacka, J.; Prociak, A.; Ryszkowska, J. Effects of modified used cooking oil on structure and properties of closed-cell polyurethane foams. J. Polym. Environ. 2020, 28, 2780–2788. [Google Scholar] [CrossRef]

- Kurańska, M.; Leszczyńska, M.; Malewska, E.; Prociak, A.; Ryszkowska, J. Implementation of circular economy principles in the synthesis of polyurethane foams. Polymers 2020, 12, 2068. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Strzelec, K.; Adamus-Włodarczyk, A.; Kairytė, A.; Vaitkus, S. Composites of rigid polyurethane foams reinforced with POSS. Polymers 2019, 11, 336. [Google Scholar] [CrossRef] [Green Version]

- Uram, K.; Leszczyńska, M.; Prociak, A.; Czajka, A.; Gloc, M.; Leszczyński, M.K.; Michałowski, S.; Ryszkowska, J. Polyurethane composite foams synthesized using bio-polyols and cellulose filler. Materials 2021, 14, 3474. [Google Scholar] [CrossRef]

- Członka, S.; Bertino, M.F.; Strzelec, K.; Strąkowska, A.; Masłowski, M. Rigid polyurethane foams reinforced with solid waste generated in leather industry. Polym. Test. 2018, 69, 225–237. [Google Scholar] [CrossRef]

- Członka, S.; Bertino, M.F.; Strzelec, K. Rigid polyurethane foams reinforced with industrial potato protein. Polym. Test. 2018, 68, 135–145. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Kairytė, A. Effect of walnut shells and silanized walnut shells on the mechanical and thermal properties of rigid polyurethane foams. Polym. Test. 2020, 87, 106534. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Strzelec, K.; Kairytė, A.; Kremensas, A. Bio-based polyurethane composite foams with improved mechanical, thermal, and antibacterial properties. Materials 2020, 13, 1108. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Członka, S.; Strąkowska, A. Rigid polyurethane foams based on bio-polyol and additionally reinforced with silanized and acetylated walnut shells for the synthesis of environmentally friendly insulating materials. Materials 2020, 13, 3245. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Kairytė, A. The impact of hemp shives impregnated with selected plant oils on mechanical, thermal, and insulating properties of polyurethane composite foams. Materials 2020, 13, 4709. [Google Scholar] [CrossRef]

- Hejna, A.; Olszewski, A.; Zedler, Ł.; Kosmela, P.; Formela, K. The impact of ground tire rubber oxidation with H2O2 and KMnO4 on the structure and performance of flexible polyurethane/ground tire rubber composite foams. Materials 2021, 14, 499. [Google Scholar] [CrossRef]

- Kosmela, P.; Olszewski, A.; Zedler, Ł.; Burger, P.; Piasecki, A.; Formela, K.; Hejna, A. Ground tire rubber filled flexible polyurethane foam—Effect of waste rubber treatment on composite performance. Materials 2021, 14, 3807. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Kairytė, A.; Kremensas, A. Nutmeg filler as a natural compound for the production of polyurethane composite foams with antibacterial and anti-aging properties. Polym. Test. 2020, 86, 106479. [Google Scholar] [CrossRef]

- Paciorek-Sadowska, J.; Borowicz, M.; Isbrandt, M. Effect of evening primrose (Oenothera biennis) oil cake on the properties of polyurethane/polyisocyanurate bio-composites. Int. J. Mol. Sci. 2021, 22, 8950. [Google Scholar] [CrossRef]

- Leszczyńska, M.; Ryszkowska, J.; Szczepkowski, L.; Kurańska, M.; Prociak, A.; Leszczyński, M.K.; Gloc, M.; Antos-Bielska, M.; Mizera, K. Cooperative effect of rapeseed oil-based polyol and egg shells on the structure and properties of rigid polyurethane foams. Polym. Test. 2020, 90, 106696. [Google Scholar] [CrossRef]

- Kairytė, A.; Kremensas, A.; Vaitkus, S.; Członka, S.; Strąkowska, A. Fire suppression and thermal behavior of biobased rigid polyurethane foam filled with biomass incineration waste ash. Polymers 2020, 12, 683. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Członka, S.; Strąkowska, A.; Pospiech, P.; Strzelec, K. Effects of chemically treated eucalyptus fibers on mechanical, thermal and insulating properties of polyurethane composite foams. Materials 2020, 13, 1781. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Reghunadhan, A.; Datta, J.; Jaroszewski, M.; Kalarikkal, N.; Thomas, S. Polyurethane glycolysate from industrial waste recycling to develop low dielectric constant, thermally stable materials suitable for the electronics. Arab. J. Chem. 2020, 13, 2110–2120. [Google Scholar] [CrossRef]

- Kemona, A.; Piotrowska, M. Polyurethane recycling and disposal: Methods and prospects. Polymers 2020, 12, 1752. [Google Scholar] [CrossRef]

- Heiran, R.; Ghaderian, A.; Reghunadhan, A.; Sedaghati, F.; Thomas, S.; Haghighi, A.H. Glycolysis: An efficient route for recycling of end of life polyurethane foams. J. Polym. Res. 2021, 28, 22. [Google Scholar] [CrossRef]

- Deng, Y.; Dewil, R.; Appels, L.; Ansart, R.; Baeyens, J.; Kang, Q. Reviewing the thermo-chemical recycling of waste polyurethane foam. J. Environ. Manag. 2021, 278, 111527. [Google Scholar] [CrossRef]

- Jutrzenka Trzebiatowska, P.; Dzierbicka, A.; Kamińska, N.; Datta, J. The influence of different glycerine purities on chemical recycling process of polyurethane waste and resulting semi-products. Polym. Int. 2018, 67, 1368–1377. [Google Scholar] [CrossRef]

- Jutrzenka-Trzebiatowska, P.; Beneš, H.; Datta, J. Evaluation of the glycerolysis process and valorisation of recovered polyol in polyurethane synthesis. React. Funct. Polym. 2019, 139, 25–33. [Google Scholar] [CrossRef]

- Datta, J.; Pasternak, S. Oligourethane glycols obtained in glycolysis of polyurethane foam as semi-finished products for cast urethane elastomers preparation. Polimery 2005, 50, 352–357. [Google Scholar] [CrossRef] [Green Version]

- Molero, C.; de Lucas, A.; Rodríguez, J.F. Activities of octoate salts as novel catalysts for the transesterification of flexible polyurethane foams with diethylene glycol. Polym. Degrad. Stab. 2009, 94, 533–539. [Google Scholar] [CrossRef]

- Njuguna, J.K.; Muchiri, P.; Mwema, F.M.; Karuri, N.W.; Herzog, M.; Dimitrov, K. Determination of thermo-mechanical properties of recycled polyurethane from glycolysis polyol. Sci. Afr. 2021, 12, e00755. [Google Scholar] [CrossRef]

- Simón, D.; Borreguero, A.M.; de Lucas, A.; Rodríguez, J.F. Glycolysis of viscoelastic flexible polyurethane foam wastes. Polym. Degrad. Stab. 2015, 116, 23–35. [Google Scholar] [CrossRef]

- Zahedifar, P.; Pazdur, L.; Vande Velde, C.M.L.; Billen, P. Multistage chemical recycling of polyurethanes and dicarbamates: A glycolysis–hydrolysis demonstration. Sustainability 2021, 13, 3583. [Google Scholar] [CrossRef]

- del Amo, J.; Borreguero, A.M.; Ramos, M.J.; Rodríguez, J.F. Glycolysis of polyurethanes composites containing nanosilica. Polymers 2021, 13, 1418. [Google Scholar] [CrossRef]

- Simón, D.; de Lucas, A.; Rodríguez, J.F.; Borreguero, A.M. Glycolysis of high resilience flexible polyurethane foams containing polyurethane dispersion polyol. Polym. Degrad. Stab. 2016, 133, 119–130. [Google Scholar] [CrossRef]

- Simón, D.; Borreguero, A.M.; de Lucas, A.; Rodríguez, J.F. Glycolysis of flexible polyurethane wastes containing polymeric polyols. Polym. Degrad. Stab. 2014, 109, 115–121. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, C.; Shi, Z.; Yin, L.; Tian, M. Tailoring vinylogous urethane chemistry for the cross-linked polybutadiene: Wide freedom design, multiple recycling methods, good shape memory behavior. Polymer 2018, 148, 202–210. [Google Scholar] [CrossRef]

- Imiela, M.; Anyszka, R.; Bieliński, D.M.; Masłowski, M.; Pędzich, Z.; Ziąbka, M.; Rybiński, P.; Syrek, B. Effect of graphite and common rubber plasticizers on properties and performance of ceramizable styrene–butadiene rubber-based composites. J. Therm. Anal. Calorim. 2019, 138, 2409–2417. [Google Scholar] [CrossRef] [Green Version]

- Marzec, A.; Szadkowski, B.; Rogowski, J.; Rybiński, P.; Maniukiewicz, W. Novel eco-friendly hybrid pigment with improved stability as a multifunctional additive for elastomer composites with reduced flammability and pH sensing properties. Dyes Pigm. 2021, 186, 108965. [Google Scholar] [CrossRef]

- Paszkiewicz, S.; Irska, I.; Zubkiewicz, A.; Szymczyk, A.; Piesowicz, E.; Rozwadowski, Z.; Goracy, K. Biobased thermoplastic elastomers: Structure-property relationship of poly (hexamethylene 2,5-furanodicarboxylate)-block-poly (tetrahydrofuran) copolymers prepared by melt polycondensation. Polymers 2021, 13, 397. [Google Scholar] [CrossRef]

- Reghunadhan, A.; Jibin, K.P.; Kaliyathan, A.V.; Velayudhan, P.; Strankowski, M.; Thomas, S. Shape memory materials from rubbers. Materials 2021, 14, 7216. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, P.; Bhowmick, A.K. Sustainable rubbers and rubber additives. J. Appl. Polym. Sci. 2018, 135, 45701. [Google Scholar] [CrossRef] [Green Version]

- Hassan, A.A.; Abbas, A.; Rasheed, T.; Bilal, M.; Iqbal, H.M.N.; Wang, S. Development, influencing parameters and interactions of bioplasticizers: An environmentally friendlier alternative to petro industry-based sources. Sci. Total Environ. 2019, 682, 394–404. [Google Scholar] [CrossRef] [PubMed]

- Dziemidkiewicz, A.; Anyszka, R.; Blume, A.; Maciejewska, M. Reaction mechanism of halogenated rubber crosslinking using a novel environmentally friendly curing system. Polym. Test. 2020, 84, 106354. [Google Scholar] [CrossRef]

- Dominic, C.D.M.; Joseph, R.; Begum, P.M.S.; Joseph, M.; Padmanabhan, D.; Morris, L.A.; Kumar, A.S.; Formela, K. Cellulose nanofibers isolated from the Cuscuta reflexa plant as a green reinforcement of natural rubber. Polymers 2020, 12, 814. [Google Scholar] [CrossRef] [Green Version]

- Greenough, S.; Dumont, M.-J.; Prasher, S. The physicochemical properties of biochar and its applicability as a filler in rubber composites: A review. Mater. Today Commun. 2021, 29, 102912. [Google Scholar] [CrossRef]

- Bockstal, L.; Berchem, T.; Schmetz, Q.; Richel, A. Devulcanisation and reclaiming of tires and rubber by physical and chemical processes: A review. J. Clean. Prod. 2019, 236, 117574. [Google Scholar] [CrossRef]

- Dierkes, W.K.; Dijkhuis, K.; Hoek, H.V.; Noordermeer, J.W.M.; Reuvekamp, L.A.E.M.; Saiwari, S.; Blume, A. Designing of cradle-to-cradle loops for elastomer products. Plast. Rubber Compos. 2019, 48, 3–13. [Google Scholar] [CrossRef]

- Markl, E.; Lackner, M. Devulcanization technologies for recycling of tire-derived rubber: A review. Materials 2020, 13, 1246. [Google Scholar] [CrossRef] [Green Version]

- Saputra, R.; Walvekar, R.; Khalid, M.; Mubarak, N.M.; Sillanpää, M. Current progress in waste tire rubber devulcanization. Chemosphere 2021, 265, 129033. [Google Scholar] [CrossRef]

- Formela, K. Sustainable development of waste tires recycling technologies—Recent advances, challenges and future trends. Adv. Ind. Eng. Polym. Res. 2021, 4, 209–222. [Google Scholar] [CrossRef]

- Chittella, H.; Yoon, L.W.; Ramarad, S.; Lai, Z.-W. Rubber waste management: A review on methods, mechanism, and prospects. Polym. Degrad. Stab. 2021, 194, 109761. [Google Scholar] [CrossRef]

- Massarotto, M.; da Silva Crespo, J.; Zattera, A.J.; Zeni, M. Characterization of ground SBR scraps from shoe industry. Mater. Res. 2008, 11, 81–84. [Google Scholar] [CrossRef] [Green Version]

- Luna, C.B.B.; Araújo, E.M.; Siqueira, D.D.; de Souza Morais, D.D.; dos Santos Filho, E.A.; Fook, M.V.L. Incorporation of a recycled rubber compound from the shoe industry in polystyrene: Effect of SBS compatibilizer content. J. Elastom. Plast. 2020, 52, 3–28. [Google Scholar] [CrossRef]

- Tozzi, K.A.; Canto, L.B.; Scuracchio, C.H. Reclaiming of vulcanized rubber foam waste from the shoe industry through solid-state shear extrusion and compounding with SBR. Macromol. Symp. 2020, 394, 2000094. [Google Scholar] [CrossRef]

- Rajan, V.V.; Dierkes, W.K.; Joseph, R.; Noordermeer, J.W.M. Recycling of NR based cured latex material reclaimed with 2,2′-dibenzamidodiphenyldisulphide in a truck tire tread compound. J. Appl. Polym. Sci. 2006, 102, 4194–4206. [Google Scholar] [CrossRef]

- ALbiajawi, M.I.; Alkasawneh, R.W.; Mostafa, S.A.; Johari, I.; Embong, R.; Muthusamy, K. Performance of sustainable concrete containing recycled latex gloves and silicone catheter under elevated temperature. J. King Saud. Univ. Eng. Sci. 2021. [Google Scholar] [CrossRef]

- Polat, K.; Bursalı, E.A. A promising strategy for the utilization of waste nitrile gloves: Cost-effective adsorbent synthesis. J. Mater. Cycles Waste. Manag. 2019, 21, 659–665. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Ding, Y.N.; Jalali, S. Properties and durability of concrete containing polymeric wastes (type rubber and polyethylene terephthalate bottles): An overview. Constr. Build. Mater. 2012, 30, 714–724. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.; Cai, G.; Zhang, J.; Liu, X.; Liu, K. Evaluation of engineering properties and environmental effect of recycled waste tire-sand/soil in geotechnical engineering: A compressive review. Renew. Sustain. Energy Rev. 2020, 126, 109831. [Google Scholar] [CrossRef]

- Przydatek, G.; Budzik, G.; Janik, M. Effectiveness of selected issues related to used tyre management in Poland. Environ. Sci. Pollut. Res. 2022. [Google Scholar] [CrossRef] [PubMed]

- European Tyre and Rubber Manufacturers’ Association: End of Life Tyres Management—Europe—2019. published on 11 May 2021. Available online: https://www.etrma.org/wp-content/uploads/2021/05/20210520_ETRMA_PRESS-RELEASE_ELT-2019.pdf (accessed on 2 December 2021).

- Williams, P.T.; Besler, S. Pyrolysis-thermogravimetric analysis of tyres and tyre components. Fuel 1995, 74, 1277–1283. [Google Scholar] [CrossRef]

- Zedler, Ł.; Kowalkowska-Zedler, D.; Vahabi, H.; Saeb, M.R.; Colom, X.; Cañavate, J.; Wang, S.; Formela, K. Preliminary investigation on auto-thermal extrusion of ground tire rubber. Materials 2019, 12, 2090. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Available online: https://tyromer.com/product/ (accessed on 2 December 2021).

- Ghavibazoo, A.; Abdelrahman, M. Composition analysis of crumb rubber during interaction with asphalt and effect on properties of binder. Int. J. Pavement Eng. 2013, 14, 517–530. [Google Scholar] [CrossRef]

- Thodesen, C.; Shatanawi, K.; Amirkhanian, S. Effect of crumb rubber characteristics on crumb rubber modified (CRM) binder viscosity. Constr. Build. Mater. 2009, 23, 295–303. [Google Scholar] [CrossRef]

- Liu, S.; Cao, W.; Fang, J.; Shang, S. Variance analysis and performance evaluation of different crumb rubber modified (CRM) asphalt. Constr. Build. Mater. 2009, 23, 2701–2708. [Google Scholar] [CrossRef]

- Rajalingham, P.; Sharpe, J.; Baker, W.E. Ground rubber tire/thermoplastic composites: Effect of different ground rubber tires. Rubber Chem. Technol. 1993, 66, 664–677. [Google Scholar] [CrossRef]

- Colom, X.; Marín-Genescà, M.; Mujal, R.; Formela, K.; Cañavate, J. Structural and physico-mechanical properties of natural rubber/GTR composites devulcanized by microwaves: Influence of GTR source and irradiation time. J. Compos. Mater. 2018, 52, 3099–3108. [Google Scholar] [CrossRef]

- Pehlken, A.; Müller, D.H. Using information of the separation process of recycling scrap tires for process modeling. Resour. Conserv. Recy. 2009, 54, 140–148. [Google Scholar] [CrossRef]

- Adhikari, K.; Das, A.; Sinha, T.; Saha, P.; Kuk Kim, J. Chapter 1: Grinding of waste rubber. In Rubber Recycling: Challenges and Developments; Kim, J.K., Saha, P., Thomas, S., Haponiuk, J.T., Aswathi, M.K., Eds.; Royal Society of Chemistry Publishing: London, UK, 2018; pp. 1–23. [Google Scholar] [CrossRef]

- Shen, J.; Amirkhanian, S.; Xiao, F.; Tang, B. Influence of surface area and size of crumb rubber on high temperature properties of crumb rubber modified binders. Constr. Build. Mater. 2009, 23, 304–310. [Google Scholar] [CrossRef]

- Product catalog 2021—Granulates. Available online: https://www.recykl.pl (accessed on 4 February 2022).

- Seghar, S.; Asaro, L.; Rolland-Monnet, M.; Aït Hocine, N. Thermo-mechanical devulcanization and recycling of rubber industry waste. Resour. Conserv. Recycl. 2019, 144, 180–186. [Google Scholar] [CrossRef]

- Isayev, A.I.; Liang, T.; Lewis, T.M. Effect of particle size on ultrasonic devulcanization of tire rubber in twin-screw extruder. Rubber Chem. Technol. 2014, 87, 86–102. [Google Scholar] [CrossRef]

- Tao, G.; He, Q.; Xia, Y.; Jia, G.; Yang, H.; Ma, W. The effect of devulcanization level on mechanical properties of reclaimed rubber by thermal-mechanical shearing devulcanization. J. Appl. Polym. Sci. 2013, 129, 2598–2605. [Google Scholar] [CrossRef]

- Yazdani, H.; Karrabi, M.; Ghasmi, I.; Azizi, H.; Bakhshandeh, G.R. Devulcanization of waste tires using a twin-screw extruder: The effects of processing conditions. J. Vinyl Addit. Technol. 2011, 17, 64–69. [Google Scholar] [CrossRef]

- de Sousa, F.D.B.; Zanchet, A.; Scuracchio, C.H. Influence of reversion in compounds containing recycled natural rubber: In search of sustainable processing. J. Appl. Polym. Sci. 2017, 134, 45325. [Google Scholar] [CrossRef]

- de Sousa, F.D.B.; Ornaghi Júnior, H.L. From devulcanization of ground tire rubber by microwaves to revulcanization: A revulcanization kinetic approach using a simple prediction model. ACS Sustain. Chem. Eng. 2020, 8, 16304–16319. [Google Scholar] [CrossRef]

- de Sousa, F.D.B.; Zanchet, A.; Ornaghi, H.L., Jr.; Ornaghi, F.G. Revulcanization kinetics of waste tire rubber devulcanized by microwaves: Challenges in getting recycled tire rubber for technical application. ACS Sustain. Chem. Eng. 2019, 7, 15413–15426. [Google Scholar] [CrossRef]

- Sripornsawat, B.; Saiwari, S.; Pichaiyut, S.; Nakason, C. Influence of ground tire rubber devulcanization conditions on properties of its thermoplastic vulcanizate blends with copolyester. Eur. Polym. J. 2016, 85, 279–297. [Google Scholar] [CrossRef]

- Garcia, P.S.; Gouveia, R.F.; Maia, J.M.; Scuracchio, C.H.; Cruz, S.A. 2D and 3D imaging of the deformation behavior of partially devulcanized rubber/polypropylene blends. Express Polym. Lett. 2018, 12, 1047–1060. [Google Scholar] [CrossRef]

- Xu, G.; Kong, P.; Yu, Y.; Yang, J.; Zhu, M.; Chen, X. Rheological properties of rubber modified asphalt as function of waste tire rubber reclaiming degree. J. Clean. Prod. 2022, 332, 130113. [Google Scholar] [CrossRef]

- Kroll, L.; Hoyer, S. Zero-waste production: Technology for the in-house recycling of technical elastomers. Procedia Manuf. 2019, 33, 335–342. [Google Scholar] [CrossRef]

- Dobrotă, D.; Dobrotă, G. An innovative method in the regeneration of waste rubber and the sustainable development. J. Clean. Prod. 2018, 172, 3591–3599. [Google Scholar] [CrossRef]

- Holka, H.; Wełnowski, J. Non-conventional method of tires utilization. Inżynieria Masz. 2011, 16, 139–145. [Google Scholar]

- Wang, Z.; Kang, Y.; Cheng, Y. Multiresponse optimization of process parameters in water jet pulverization via response surface methodology. Int. J. Precis. Eng. Manuf. 2017, 18, 1855–1871. [Google Scholar] [CrossRef]

- Wang, Z.; Kang, Y.; Wang, Z. Pulverization of end-of-life tires by ultra-high pressure water jet process. J. Polym. Eng. 2017, 37, 211–225. [Google Scholar] [CrossRef]

- Holka, H.; Jarzyna, T. Recycling of car tires by means of Waterjet technologies. AIP Conf. Proc. 2017, 1822, 020008. [Google Scholar] [CrossRef] [Green Version]

- Bowles, A.J.; Fowler, G.D.; O’Sullivan, C.; Parker, K. Sustainable rubber recycling from waste tyres by waterjet: A novel mechanistic and practical analysis. Sustain. Mater. Technol. 2020, 25, e00173. [Google Scholar] [CrossRef]

- Zefeng, W.; Yong, K.; Zhao, W.; Yi, C. Recycling waste tire rubber by water jet pulverization: Powder characteristics and reinforcing performance in natural rubber composites. J. Polym. Eng. 2018, 38, 51–62. [Google Scholar] [CrossRef]

- Park, J.-M.; An, J.-Y.; Bang, D.; Kim, B.-S.; Oh, M.-H. Characteristics studies of waste tire rubber powders using the different grinding methods. J. Korean Inst. Resour. Recycl. 2014, 23, 44–50. [Google Scholar]

- Hrdlička, Z.; Brejcha, J.; Šubrt, J.; Vrtiška, D.; Malinová, L.; Čadek, D.; Kadeřábková, A. Ground tyre rubber produced via ambient, cryogenic, and waterjet milling: The influence of milling method and particle size on the properties of SBR/NR/BR compounds for agricultural tyre treads. Plast. Rubber Compos. 2021. [Google Scholar] [CrossRef]

- Li, X.; Xu, X.; Liu, Z. Cryogenic grinding performance of scrap tire rubber by devulcanization treatment with scCO2. Powder Technol. 2020, 374, 609–617. [Google Scholar] [CrossRef]

- Wang, Z.; Zeng, D. Preparation of devulcanized ground tire rubber with supercritical carbon dioxide jet pulverization. Mater. Lett. 2021, 282, 128878. [Google Scholar] [CrossRef]

- Scuracchio, C.H.; Bretas, R.E.S.; Isayev, A.I. Blends of PS with SBR devulcanized by ultrasound: Rheology and morphology. J. Elastom. Plast. 2004, 36, 45–75. [Google Scholar] [CrossRef]

- de Sousa, F.D.B.; Zanchet, A.; Scuracchio, C.H. From devulcanization to revulcanization: Challenges in getting recycled tire rubber for technical applications. ACS Sustain. Chem. Eng. 2019, 7, 8755–8765. [Google Scholar] [CrossRef]

- Gągol, M.; Boczkaj, G.; Haponiuk, J.; Formela, K. Investigation of volatile low molecular weight compounds formed during continuous reclaiming of ground tire rubber. Polym. Degrad. Stab. 2015, 119, 113–120. [Google Scholar] [CrossRef]

- Simon, D.A.; Bárány, T. Effective thermomechanical devulcanization of ground tire rubber with a co-rotating twin-screw extruder. Polym. Degrad. Stab. 2021, 190, 109626. [Google Scholar] [CrossRef]

- Shi, J.; Jiang, K.; Ren, D.; Zou, H.; Wang, Y.; Lv, X.; Zhang, L. Structure and performance of reclaimed rubber obtained by different methods. J. Appl. Polym. Sci. 2013, 129, 999–1007. [Google Scholar] [CrossRef]

- Saiwari, S.; Dierkes, W.K.; Noordermeer, J.W.M. Comparative investigation of the devulcanization parameters of tire rubbers. Rubber Chem. Technol. 2014, 87, 31–42. [Google Scholar] [CrossRef] [Green Version]

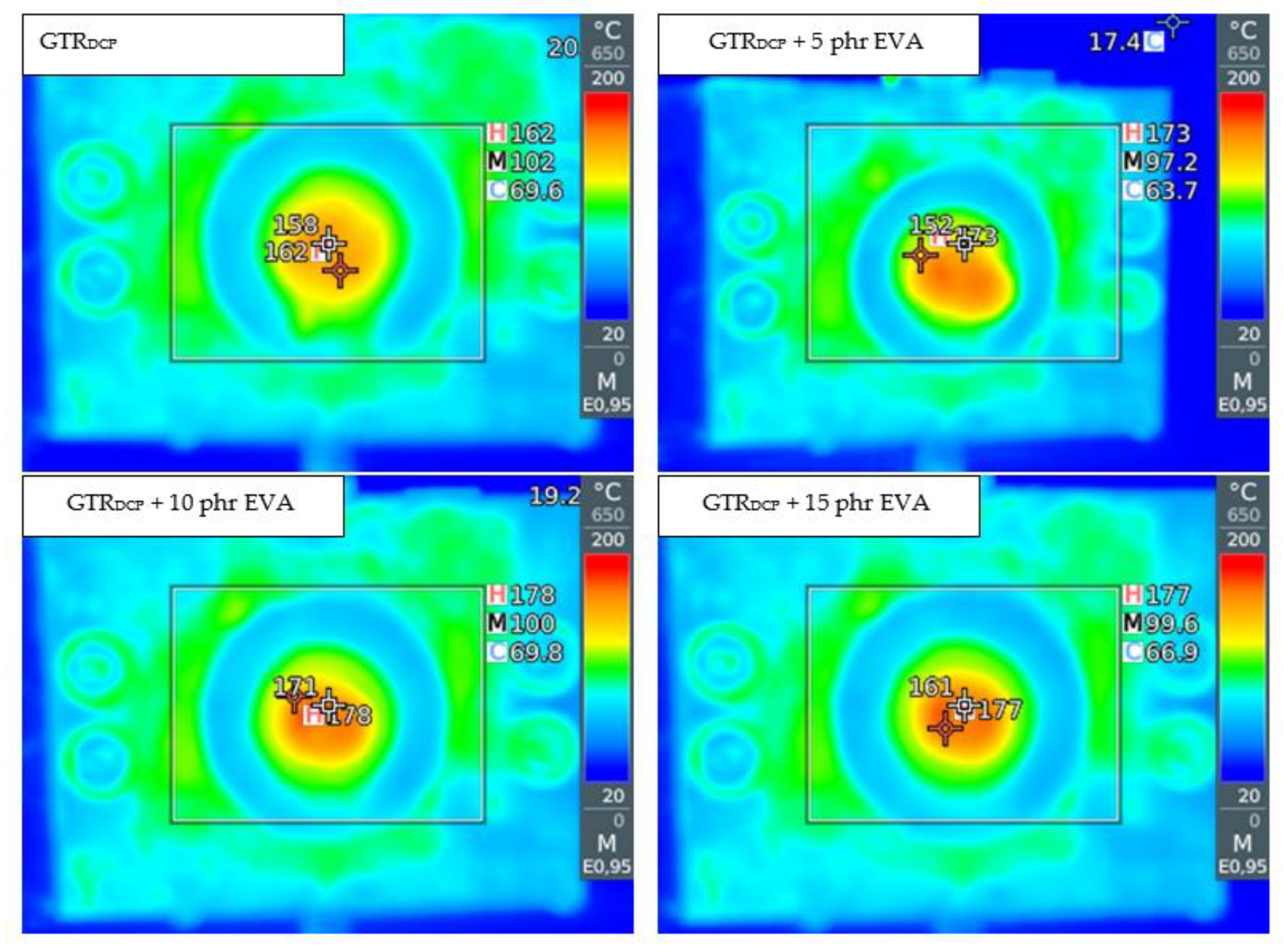

- Wiśniewska, P.; Zedler, Ł.; Formela, K. Processing, performance properties, and storage stability of ground tire rubber modi-fied by dicumyl peroxide and ethylene-vinyl acetate copolymers. Polymers 2021, 13, 4014. [Google Scholar] [CrossRef]

- Formela, K.; Cysewska, M.; Haponiuk, J. Thermomechanical reclaiming of ground tire rubber via extrusion at low temperature: Efficiency and limits. J. Vinyl Addit. Technol. 2016, 22, 213–221. [Google Scholar] [CrossRef]

- Formela, K.; Klein, M.; Colom, X.; Saeb, M.R. Investigating the combined impact of plasticizer and shear force on the efficiency of low temperature reclaiming of ground tire rubber (GTR). Polym. Degrad. Stab. 2016, 125, 1–11. [Google Scholar] [CrossRef]

- Zedler, Ł.; Klein, M.; Saeb, M.R.; Colom, X.; Cañavate, J.; Formela, K. Synergistic effects of bitumen plasticization and microwave treatment on short-term devulcanization of ground tire rubber. Polymers 2018, 10, 1265. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nunes, A.T.; dos Santos, R.E.; Pereira, J.S.; Barbosa, R.; Ambrósio, J.D. Characterization of waste tire rubber devulcanized in twin-screw extruder with thermoplastics. Prog. Rubber Plast. Recycl. Technol. 2018, 34, 143–157. [Google Scholar] [CrossRef]

- Barbosa, R.; Ambrósio, J.D. Devulcanization of natural rubber compounds by extrusion using thermoplastics and characterization of revulcanized compounds. J. Polym. Res. 2019, 26, 160. [Google Scholar] [CrossRef]

- Zedler, Ł.; Kowalkowska-Zedler, D.; Colom, X.; Cañavate, J.; Saeb, M.R.; Formela, K. Reactive sintering of ground tire rubber (GTR) modified by a trans-polyoctenamer rubber and curing additives. Polymers 2020, 12, 3018. [Google Scholar] [CrossRef]

- Formela, K.; Hejna, A.; Zedler, Ł.; Colom, X.; Cañavate, J. Microwave treatment in waste rubber recycling—recent advances and limitations. Express Polym. Lett. 2019, 13, 565–588. [Google Scholar] [CrossRef]

- Paulo, G.D.; Hirayama, D.; Saron, C. Microwave devulcanization of waste rubber with inorganic salts and nitric acid. Adv. Mater. Res. 2012, 418–420, 1072–1075. [Google Scholar] [CrossRef]

- Seghar, S.; Aït Hocine, N.; Mittal, V.; Azem, S.; Al-Zohbi, F.; Schmaltz, B.; Poirot, N. Devulcanization of styrene butadiene rubber by microwave energy: Effect of the presence of ionic liquid. Express Polym. Lett. 2015, 9, 1076–1086. [Google Scholar] [CrossRef]

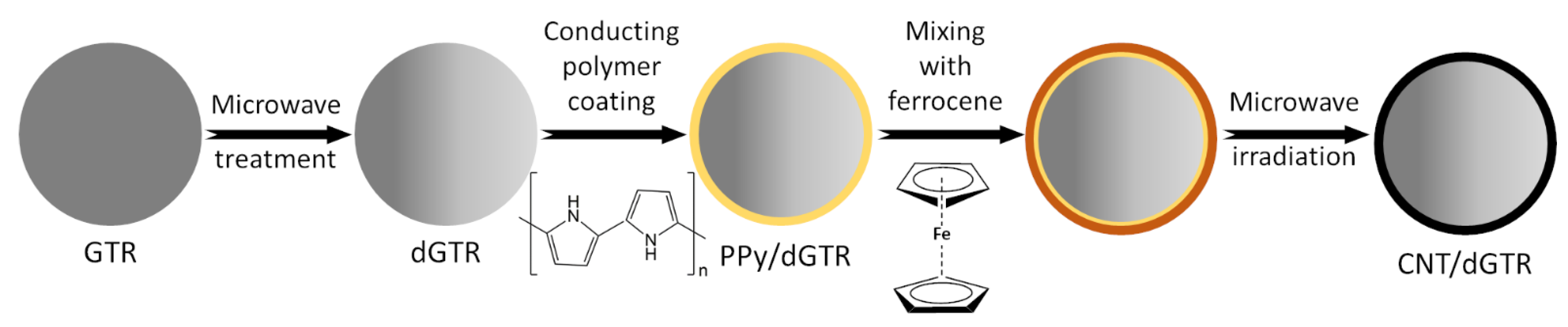

- Poyraz, S.; Liu, Z.; Liu, Y.; Zhang, X. Devulcanization of scrap ground tire rubber and successive carbon nanotube growth by microwave irradiation. Curr. Org. Chem. 2013, 17, 2243–2248. [Google Scholar] [CrossRef]

- Jia, L.-C.; Li, Y.-K.; Yan, D.-X. Flexible and efficient electromagnetic interference shielding materials from ground tire rubber. Carbon 2017, 121, 267–273. [Google Scholar] [CrossRef]

- Liu, J.; Liu, P.; Zhang, X.; Lu, P.; Zhang, X.; Zhang, M. Fabrication of magnetic rubber composites by recycling waste rubber powders via a microwave-assisted in situ surface modification and semi-devulcanization process. Chem. Eng. J. 2016, 295, 73–79. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, X.; Liang, M.; Lu, C. Improvement of the properties of ground tire rubber (GTR)-filled nitrile rubber vulcanizates through plasma surface modification of GTR powder. J. Appl. Polym. Sci. 2009, 114, 1118–1125. [Google Scholar] [CrossRef]

- Cheng, X.; Chen, H.; Huang, S.; Li, Z.; Guo, X. Improvement of the properties of plasma-modified ground tire rubber filled cement paste. J. Appl. Polym. Sci. 2012, 126, 1837–1843. [Google Scholar] [CrossRef]

- Nisticò, R.; Lavagna, L.; Boot, E.A.; Ivanchenko, P.; Lorusso, M.; Bosia, F.; Pugno, N.M.; D’Angelo, D.; Pavese, M. Improving rubber concrete strength and toughness by plasma-induced end-of-life tire rubber surface modification. Plasma Process Polym. 2021, 18, 2100081. [Google Scholar] [CrossRef]

- Rungrodnimitchai, S.; Kotatha, D. Chemically modified ground tire rubber as fluoride ions adsorbents. Chem. Eng. J. 2015, 282, 161–169. [Google Scholar] [CrossRef]

- Araujo-Morera, J.; Verdugo-Manzanares, R.; González, S.; Verdejo, R.; Lopez-Manchado, M.A.; Hernández Santana, M. On the use of mechano-chemically modified ground tire rubber (GTR) as recycled and sustainable filler in styrene-butadiene rubber (SBR) composites. J. Compos. Sci. 2021, 5, 68. [Google Scholar] [CrossRef]

- Klajn, K.; Gozdek, T.; Bieliński, D.M.; Siciński, M.; Zarzecka-Napierała, M.; Pędzich, Z. SBR vulcanizates filled with modified ground tire rubber. Materials 2021, 14, 3991. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, Z.; Peng, Z.; Formela, K.; Wang, S. Dynamic mechanical properties and flexing fatigue resistance of tire sidewall rubber as function of waste tire rubber reclaiming degree. J. Appl. Polym. Sci. 2021, 138, 51290. [Google Scholar] [CrossRef]

- Shi, J.; Zou, H.; Ding, L.; Li, X.; Jiang, K.; Chen, T.; Zhang, X.; Zhang, L.; Ren, D. Continuous production of liquid reclaimed rubber from ground tire rubber and its application as reactive polymeric plasticizer. Polym. Degrad. Stab. 2014, 99, 166–175. [Google Scholar] [CrossRef]

- Formela, K.; Korol, J.; Saeb, M.R. Interfacially modified LDPE/GTR composites with non-polar elastomers: From microstructure to macro-behavior. Polym. Test. 2015, 42, 89–98. [Google Scholar] [CrossRef]

- Formela, K.; Sulkowski, M.; Saeb, M.R.; Colom, X.; Haponiuk, J.T. Assessment of microstructure, physical and thermal properties of bitumen modified with LDPE/GTR/elastomer ternary blends. Constr. Build. Mater. 2016, 106, 160–167. [Google Scholar] [CrossRef]

- Boczkowska, A. Advanced Elastomers. Technology, Properties and Applications; IntechOpen: London, UK, 2012. [Google Scholar] [CrossRef]

- Utrera-Barrios, S.; Verdejo, R.; Angel López-Manchado, M.; Hernández Santana, M. Evolution of self-healing elastomers, from extrinsic to combined intrinsic mechanisms: A review. Mater. Horiz. 2020, 7, 2882–2902. [Google Scholar] [CrossRef]

- Ma, Z.; Li, H.; Jing, X.; Liu, Y.; Mia, H.-Y. Recent advancements in self-healing composite elastomers for flexible strain sensors: Materials, healing systems, and features. Sens. Actuator A Phys. 2021, 329, 112800. [Google Scholar] [CrossRef]

- Hernández Santana, M.; Huete, M.; Lameda, P.; Araujo, J.; Verdejo, R.; López-Manchado, M.A. Design of a new generation of sustainable SBR compounds with good trade-off between mechanical properties and self-healing ability. Eur. Polym. J. 2018, 106, 273–283. [Google Scholar] [CrossRef]

- Araujo-Morera, J.; Hernández Santana, M.; Verdejo, R.; López-Manchado, M.A. Giving a second opportunity to tire waste: An alternative path for the development of sustainable self-healing styrene-butadiene rubber compounds overcoming the magic triangle of tires. Polymers 2019, 11, 2122. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alonso Pastor, L.E.; Núñez Carrero, K.C.; Araujo-Morera, J.; Hernández Santana, M.; Pastor, J.M. Setting relationships between structure and devulcanization of ground tire rubber and their effect on self-healing elastomers. Polymers 2022, 14, 11. [Google Scholar] [CrossRef]

- Toczek, K.; Lipińska, M.; Pietrasik, J. Smart TPE materials based on recycled rubber shred. Materials 2021, 14, 6237. [Google Scholar] [CrossRef]

- Zedler, Ł.; Burger, P.; Wang, S.; Formela, K. Ground tire rubber modified by ethylene-vinyl acetate copolymer: Processing, physico-mechanical properties, volatile organic compounds emission and recycling possibility. Materials 2020, 13, 4669. [Google Scholar] [CrossRef]

- Domingues, J.; Marques, T.; Mateus, A.; Carreira, P.; Malça, C. An additive manufacturing solution to produce big green parts from tires and recycled plastics. Procedia Manuf. 2017, 12, 242–248. [Google Scholar] [CrossRef]

- Alkadi, F.; Lee, J.; Yeo, J.S.; Hwang, S.-H.; Choi, J.-W. 3D printing of ground tire rubber composites. Int. J. Precis. Eng. Manuf.-Green Tech. 2019, 6, 211–222. [Google Scholar] [CrossRef]

- Toncheva, A.; Brison, L.; Dubois, P.; Laoutid, F. Recycled tire rubber in additive manufacturing: Selective laser sintering for polymer-ground rubber composites. Appl. Sci. 2021, 11, 8778. [Google Scholar] [CrossRef]

- Laoutid, F.; Lafqir, S.; Toncheva, A.; Dubois, P. Valorization of recycled tire rubber for 3D printing of ABS- and TPO-based composites. Materials 2021, 14, 5889. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Grinding Technology | |||

|---|---|---|---|---|

| Cryogenic | Solid-State Shear Extrusion | Wet Grinding | Hyperboloidal Cutting Mill | |

| Average energy demand (kW) | 138 | 165 | 32 | 1.2 |

| Throughput (kg/h) | 588 | 53 | 61 | 1.2 |

| Energy consumption (Wh/kg) | 1207 | 3132 | 525 | 967 |

| Sustainable Plastics Strategy | ||

|---|---|---|

| Sustainable-By-Design | Sustainable Recycling | Alternative Feedstock |

Material design:

| Plastic waste pre-treatment:

| Agricultural and forest biomass waste-based raw materials |

Plastic waste preparation:

| ||

Article design:

| Sorting and separation:

| Technologies able to convert CO2 and/or CO into polymers or building blocks which can in turn be converted into polymers |

Recycling technologies:

| ||

Post-processing (actions focused on decontamination of the recycled polymers):

| ||

| Polymer Matrix | Percent of Works Published in Scopus® in 2016–2022 (%) |

|---|---|

| PE (bio-PE) | 30.1 |

| PP | 19.8 |

| PLA | 7.8 |

| PVC | 5.2 |

| PS and ABS | 4.0 |

| PHA and PHB | 2.8 |

| PA | 1.4 |

| PET | 1.3 |

| PCL | 1.0 |

| PBAT | 0.4 |

| PPC | 0.1 |

| Others (mainly thermosets) | 26.1 |

| Fiber Kind | Humidity and TGA * Data | Surface Treatment Method | ||||

|---|---|---|---|---|---|---|

| Untreated | Silanization | Acetylation | Benzoylation | Mercerization | ||

| Hemp | Humidity (%) | 6.5 | 4.0 | 6.0 | 3.0 | 3.9 |

| T-10% (°C) | 318.9 | 320.0 | 289.6 | 320.4 | 332.6 | |

| T-50% (°C) | 366.1 | 360.1 | 342.7 | 357.4 | 360.3 | |

| Char residue (%) | 11.3 | 12.5 | 7.0 | 10.1 | 11.7 | |

| Flax | Humidity (%) | 7.0 | 5.4 | 6.0 | 4.4 | 5.4 |

| T-10% (°C) | 251.4 | 318.1 | 301.8 | 312.5 | 264.8 | |

| T-50% (°C) | 356.2 | 363.3 | 345.1 | 346.6 | 358.1 | |

| Char residue (%) | 15.4 | 18.2 | 5.7 | 7.1 | 7.1 | |

| Cotton | Humidity (%) | 7.5 | 3.0 | 4.0 | 4.0 | 6.0 |

| T-10% (°C) | 284.7 | 322.4 | 316.3 | 312.7 | 287.2 | |

| T-50% (°C) | 344.4 | 361.9 | 350.0 | 349.9 | 349.1 | |

| Char residue (%) | 13.5 | 3.8 | 0.7 | 0.1 | 6.7 | |

| Material | Maximum Torque (Nm) | Torque at 300 s (Nm) | Plasticization Energy (kJ) | MFI200 °C/2.16 kg (g/10 min) |

|---|---|---|---|---|

| PLA | 57.8 | 9.9 | 15.5 | 10.2 |

| PLA + 5 wt.% of linseed cake | 46.2 | 9.5 | 15.0 | 27.0 |

| PLA + 10 wt.% of linseed cake | 49.8 | 6.3 | 10.2 | 31.6 |

| PLA + 20 wt.% of linseed cake | 28.0 | 2.3 | 4.1 | 127.0 |

| PLA + 30 wt.% of linseed cake | 23.4 | 0.8 | 2.1 | 141.0 |

| PLA + 40 wt.% of linseed cake | 18.4 | 0.1 | 1.2 | 278.5 |

| PLA + 5 wt.% of linseed cake defatted | 43.7 | 9.6 | 15.3 | 23.0 |

| PLA + 10 wt.% of linseed cake defatted | 45.4 | 5.3 | 9.9 | 33.0 |

| PLA + 20 wt.% of linseed cake defatted | 23.5 | 4.3 | 7.3 | 88.0 |

| PLA + 30 wt.% of linseed cake defatted | 21.1 | 1.6 | 2.7 | 195.1 |

| PLA + 40 wt.% of linseed cake defatted | 21.8 | 1.1 | 3.3 | 218.7 |

| Raw Materials | Synthesis Method | LOH, mg KOH/g | Mn, g/mol | η, mPa·s | %BioP, php | References |

|---|---|---|---|---|---|---|

| Extracts from seeds of Colliguaja integerrima and Colliguaja salicifolia | Single-step reaction using a mixture of hydrogen peroxide and acetic acid | 225; 241 | 1122; 1166 | 3637; 5746 (mm2/s) | na | [121] |

| Used cooking oil | Transesterification with diethylene glycol or triethanolamine | 277; 348 | 492; 522 | 56; 182 | 20–100 | [123] |

| Epoxidation and opening oxirane rings with diethylene glycol | 150 | 2557 | na | 20 | [127] | |

| Epoxidation and opening oxirane rings with diethylene glycol | 140; 159 | 250 | 961; 3275 | 20–100 | [143] | |

| Biomass from forest waste | Liquefaction with PEG400 and/or glycerol | 238–815 | na | na | 90 | [131,132] |

| Walnut shells | Liquefaction with PEG400 and glycerol | 340 | 420 | 2550 | 10–30 | [133] |

| Starch | Reaction of starch with propylene carbonate or ethylene carbonate in aqueous solution | 275; 323 | - | 17,956; 19,058 | 100 | [134] |

| Cellulose | Hydroxyalkylation with glycidol and ethylene carbonate | 688 | 1650 | 5538 | na | [135] |

| Tall oil | Epoxidation and opening oxirane rings followed by esterification reactions with different polyfunctional alcohols: trimethylolpropane and triethanolamine | 335–519 | 893–2112 | 7400–278,300 | 85 | [138] |

| Waste PLA | Transesterification with diethylene glycol | 210–262 | 341–414 | 2459–8681 | 15–62 | [142] |

| Filler | Filler Content | Biopolyol | Main Findings and Observations | References |

|---|---|---|---|---|

| Cellulose | 1–3 php | Rapeseed oil-based polyol |

| [161] |

| Solid waste generated in leather industry | 0.1–5 php | no |

| [162] |

| Potato protein | 0.1–5 php | no |

| [163] |

| Walnut shells silanized | 1–5 php | no |

| [164] |

| Cloves | 1, 2, and 5 wt.% | Soybean oil-based polyol |

| [165] |

| Walnut shells (unmodified and treated) | 2 php | Walnut shells-based polyol |

| [166] |

| Hemp shives and impregnated hemp shives | 2 php | no |

| [167] |

| Nutmeg | 1–5 wt.% | no |

| [170] |

| By-product from vegetable oil industry–rapeseed cake | 30–60 wt.% | no |

| [171] |

| Egg shells | 20 php | Rapeseed oil-based polyol 10–50 php |

| [172] |

| Biomass incineration waste ash | 10–50 php | Rapeseed oil-based polyol 60 php |

| [173] |

| Eucalyptus fibers (unmodified and treated) | 2 php | no |

| [174] |

| Particle Size (mm) | Percentage Content (%) * | |||||||

|---|---|---|---|---|---|---|---|---|

| GTR 4–7 | GTR 2–6 | GTR 1–4 | GTR 1–3 | GTR 0.5–2.5 | GTR 0.0–2.5 | GTR 0.5–2.0 | GTR 0.3–1.5 | |

| 8.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| 7.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| 6.0 | 8.1 | 5.2 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| 5.0 | 24.0 | 18.5 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| 4.0 | 41.7 | 33.8 | 0.6 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| 3.0 | 22.8 | 28.1 | 23.1 | 0.6 | 0.7 | 0.0 | 0.0 | 0.0 |

| 2.0 | 3.4 | 14.3 | 59.2 | 59.1 | 54.6 | 8.5 | 6.5 | 17.8 |

| 1.0 | 0.0 | 0.1 | 17.1 | 40.3 | 43.7 | 80.1 | 83.1 | 39.9 |

| <1.0 | 0.0 | 0.0 | 0.0 | 0.0 | 1.0 | 11.4 | 10.4 | 42.3 |

| Property | Standard | Reference | Recycling Step | ||

|---|---|---|---|---|---|

| 1st | 2nd | 3rd | |||

| Tensile strength (MPa) | ISO 37 | 3.2 ± 0.5 | 2.9 ± 0.4 | 3.1 ± 0.4 | 2.7 ± 0.5 |

| Elongation at break (%) | ISO 37 | 146 ± 11 | 136 ± 17 | 143 ± 17 | 123 ± 25 |

| Hardness (Shore A) | ISO 7619-1 | 63 ± 1 | 63 ± 1 | 64 ± 1 | 63 ± 1 |

| Appearance of sample | Digital camera |  |  | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Formela, K.; Kurańska, M.; Barczewski, M. Recent Advances in Development of Waste-Based Polymer Materials: A Review. Polymers 2022, 14, 1050. https://doi.org/10.3390/polym14051050

Formela K, Kurańska M, Barczewski M. Recent Advances in Development of Waste-Based Polymer Materials: A Review. Polymers. 2022; 14(5):1050. https://doi.org/10.3390/polym14051050

Chicago/Turabian StyleFormela, Krzysztof, Maria Kurańska, and Mateusz Barczewski. 2022. "Recent Advances in Development of Waste-Based Polymer Materials: A Review" Polymers 14, no. 5: 1050. https://doi.org/10.3390/polym14051050

APA StyleFormela, K., Kurańska, M., & Barczewski, M. (2022). Recent Advances in Development of Waste-Based Polymer Materials: A Review. Polymers, 14(5), 1050. https://doi.org/10.3390/polym14051050