Effect Mechanism and Simulation of Voids on Hygrothermal Performances of Composites

Abstract

1. Introduction

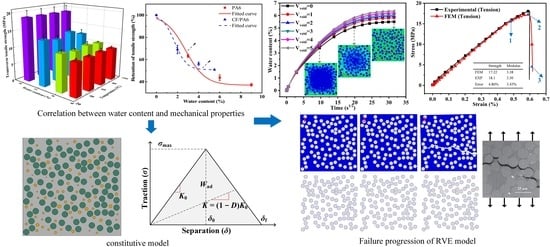

2. Computational Model Considering Hygrothermal Aging

2.1. RVE Model with Voids

2.2. Constitutive Models in Water Diffusion Process

3. Experimental Verification

4. Results and Discussion

4.1. Water Absorption Behavior

4.2. Residual Stress Evolution

4.3. Mechanical Performance and Failure Analysis

4.3.1. Voids Effects on Mechanical Performances

4.3.2. Progressive Failure Analysis

5. Conclusions

- (1)

- Water diffusion is significantly affected by the presence of voids, which significantly accelerate the water absorption rate and increase the water saturation content. Moreover, the modified Halpin–Tsai equation can effectively predict the transverse diffusivity of composite with different volume fractions of voids.

- (2)

- Tensile stress arises for the matrix in the cooling contraction of the molding process, and the stress change from tension to compression after hygrothermal aging. The stress state in CFs is just the opposite of the matrix. Stress distribution can be changed, and the residual stress can be greatly weakened by the presence of voids. Voids have beneficial effects on the relief or decrease the residual stress to some extent.

- (3)

- For the unaged composites, voids induce the decrease of mechanical properties due to stress concentration, and every 1% increase in the voids content results in a 6.4% decrease of transverse tensile strength. However, matrix degradation due to the absorbed water content after hygrothermal aging is the dominant factor, and the corresponding rate is 3.86%. This indicates that the negative effects of voids content are diminished, and hygrothermal aging is the dominant reason for the failure mechanism.

- (4)

- Compared with the failure images of unaged composites, the number and density of cracks increase after hygrothermal aging, which indicates the presence of voids can accelerate the matrix damage and interfacial debonding.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Grunenfelder, L.; Nutt, S. Void formation in composite prepregs—Effect of dissolved moisture. Compos. Sci. Technol. 2010, 70, 2304–2309. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Straumit, I.; Gorbatikh, L.; Lomov, S. Detailed characterization of voids in multidirectional carbon fiber/epoxy composite laminates using X-ray micro-computed tomography. Compos. Part A: Appl. Sci. Manuf. 2019, 125, 105532. [Google Scholar] [CrossRef]

- Luo, L.; Zhang, B.; Lei, Y.; Zhang, G.; Zhang, Z.; Meng, B.; Liu, Z. Identification of voids and interlaminar shear strengths of polymer-matrix composites by optical microscopy experiment and deep learning methodology. Polym. Adv. Technol. 2021, 32, 1853–1865. [Google Scholar] [CrossRef]

- Gagani, A.I.; Echtermeyer, A.T. Influence of delaminations on fluid diffusion in multidirectional composite laminates—Theory and experiments. Int. J. Solids Struct. 2019, 158, 232–242. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 2018, 53, 1579–1669. [Google Scholar] [CrossRef]

- Costa, M.L.; de Almeida, S.F.; Rezende, M.C. The influence of porosity on the interlaminar shear strength of carbon/epoxy and carbon/bismaleimide fabric laminates. Compos. Sci. Technol. 2001, 61, 2101–2108. [Google Scholar] [CrossRef]

- Little, J.E.; Yuan, X.; Jones, M.I. Characterisation of voids in fibre reinforced composite materials. NDT E Int. 2012, 46, 122–127. [Google Scholar] [CrossRef]

- Manta, A.; Gresil, M.; Soutis, C. Infrared thermography for void mapping of a graphene/epoxy composite and its full-field thermal simulation. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 1441–1453. [Google Scholar] [CrossRef]

- Tretiak, I.; Smith, R.A. A parametric study of segmentation thresholds for X-ray CT porosity characterisation in composite materials. Compos. Part A Appl. Sci. Manuf. 2019, 123, 10–24. [Google Scholar] [CrossRef]

- Jiang, H.; Ren, Y.; Liu, Z.; Zhang, S. Microscale finite element analysis for predicting effects of air voids on mechanical properties of single fiber bundle in composites. J. Mater. Sci. 2018, 54, 1363–1381. [Google Scholar] [CrossRef]

- Saenz-Castillo, D.; Martín, M.; Calvo, S.; Rodriguez-Lence, F.; Güemes, A. Effect of processing parameters and void content on mechanical properties and NDI of thermoplastic composites. Compos. Part A Appl. Sci. Manuf. 2019, 121, 308–320. [Google Scholar] [CrossRef]

- AbdElmola, F.; Carlsson, L. Water uptake in epoxy matrix with voids: Experiments and modeling. J. Compos. Mater. 2018, 53, 1049–1065. [Google Scholar] [CrossRef]

- Huang, H.; Talreja, R. Effects of void geometry on elastic properties of unidirectional fiber reinforced composites. Compos. Sci. Technol. 2005, 65, 1964–1981. [Google Scholar] [CrossRef]

- Nikopour, H. A virtual frame work for predication of effect of voids on transverse elasticity of a unidirectionally reinforced composite. Comput. Mater. Sci. 2013, 79, 25–30. [Google Scholar] [CrossRef]

- Vajari, D.A.; González, C.; Llorca, J.; Legarth, B.N. A numerical study of the influence of microvoids in the transverse mechanical response of unidirectional composites. Compos. Sci. Technol. 2014, 97, 46–54. [Google Scholar] [CrossRef]

- Dong, C. Effects of Process-Induced Voids on the Properties of Fibre Reinforced Composites. J. Mater. Sci. Technol. 2016, 32, 597–604. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, P.; Fei, Q.; Guo, F. Computational evaluation of the effects of void on the transverse tensile strengths of unidirectional composites considering thermal residual stress. Compos. Struct. 2019, 227, 111287. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Petrov, N.A.; Straumit, I.; Melro, A.R.; Lomov, S.V.; Gorbatikh, L. The effect of voids on matrix cracking in composite laminates as revealed by combined computations at the micro- and meso-scales. Compos. Part A Appl. Sci. Manuf. 2019, 117, 180–192. [Google Scholar] [CrossRef]

- Hyde, A.; He, J.; Cui, X.; Lua, J.; Liu, L. Effects of microvoids on strength of unidirectional fiber-reinforced composite materials. Compos. Part B Eng. 2020, 187, 107844. [Google Scholar] [CrossRef]

- Gueribiz, D.; Rahmani, M.; Jacquemin, F.; Fréour, S.; Guillen, R.; Loucif, K. Homogenization of Moisture Diffusing Behavior of Composite Materials with Impermeable or Permeable Fibers—Application to Porous Composite Materials. J. Compos. Mater. 2009, 43, 1391–1408. [Google Scholar] [CrossRef][Green Version]

- Bourennane, H.; Gueribiz, D.; Fréour, S.; Jacquemin, F. Modeling the effect of damage on diffusive behavior in a polymeric matrix composite material. J. Reinf. Plast. Compos. 2019, 38, 717–733. [Google Scholar] [CrossRef]

- Lei, Y.; Zhang, J.; Zhang, T.; Li, H. Water diffusion in carbon fiber reinforced polyamide 6 composites: Experimental, theoretical, and numerical approaches. J. Reinf. Plast. Compos. 2019, 38, 578–587. [Google Scholar] [CrossRef]

- Lei, Y.; Zhang, T.; Zhang, J.; Zhang, B. Dimensional stability and mechanical performance evolution of continuous carbon fiber reinforced polyamide 6 composites under hygrothermal environment. J. Mater. Res. Technol. 2021, 13, 2126–2137. [Google Scholar] [CrossRef]

- Pivdiablyk, I.; Rozycki, P.; Jacquemin, F.; Gornet, L.; Auger, S. Experimental analysis of mechanical performance of glass fibre reinforced polyamide 6 under varying environmental conditions. Compos. Struct. 2020, 245, 112338. [Google Scholar] [CrossRef]

- Sang, L.; Wang, C.; Wang, Y.; Hou, W. Effects of hydrothermal aging on moisture absorption and property prediction of short carbon fiber reinforced polyamide 6 composites. Compos. Part B Eng. 2018, 153, 306–314. [Google Scholar] [CrossRef]

- Lin, W.-Q.; Zhang, Y.-X.; Wang, H. Thermal conductivity of unidirectional composites consisting of randomly dispersed glass fibers and temperature-dependent polyethylene matrix. Sci. Eng. Compos. Mater. 2019, 26, 412–422. [Google Scholar] [CrossRef]

- Widom, B. Random Sequential Addition of Hard Spheres to a Volume. J. Chem. Phys. 1966, 44, 3888–3894. [Google Scholar] [CrossRef]

- Yang, L.; Yan, Y.; Liu, Y.; Ran, Z. Microscopic failure mechanisms of fiber-reinforced polymer composites under transverse tension and compression. Compos. Sci. Technol. 2012, 72, 1818–1825. [Google Scholar] [CrossRef]

- Jia, L.; Yu, L.; Zhang, K.; Li, M.; Jia, Y.; Blackman, B.R.K.; Dear, J.P. Combined modelling and experimental studies of failure in thick laminates under out-of-plane shear. Compos. Part B Eng. 2016, 105, 8–22. [Google Scholar] [CrossRef]

- González, C.; Llorca, J. Mechanical behavior of unidirectional fiber-reinforced polymers under transverse compression: Microscopic mechanisms and modeling. Compos. Sci. Technol. 2007, 67, 2795–2806. [Google Scholar] [CrossRef]

- París, F.; Correa, E.; Cañas, J. Micromechanical view of failure of the matrix in fibrous composite materials. Compos. Sci. Technol. 2003, 63, 1041–1052. [Google Scholar] [CrossRef]

- Affdl, J.C.H.; Kardos, J.L. The Halpin-Tsai equations: A review. Polym. Eng. Sci. 1976, 16, 344–352. [Google Scholar] [CrossRef]

- Costa, M.L.; Rezende, M.C.; De Almeida, S.F.M. Effect of Void Content on the Moisture Absorption in Polymeric Composites. Polym. Technol. Eng. 2006, 45, 691–698. [Google Scholar] [CrossRef]

| Matrix | Carbon Fiber | Voids | Composite | |

|---|---|---|---|---|

| ) | Dv | |||

| 4.64 | 0 | 46.4 | 2.16 | |

| Water content (%) | ||||

| 9.4 | 0 | 23.5 | 5.26 |

| Fiber | |||||

| 16.54 | 0.25 | −0.83 | 0 | 1810 | |

| Matrix | |||||

| 2.19 | 0.34 | 25 | 50 | 4 | |

| 0.1 | 1080 | ||||

| Interface | |||||

| 17.11 | 40.67 | ||||

| 40.67 | 0.22 | 0.23 | 0.23 |

| Transverse Tension | Transverse Compression | Transverse Shear | |

|---|---|---|---|

| Strength (MPa) | 18.10 ± 1.87 | 52.69 ± 3.25 | 14.75 ± 1.28 |

| Modulus (GPa) | 3.50 ± 0.38 | 3.59 ± 0.16 | 7.60 ± 0.23 |

| Model | Expression |

|---|---|

| Porous-matrix model | with |

| Four-phase model | with |

| Self-consistent model | with |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Lei, Y.; Zhang, X.; Kang, Z.; Zhang, J. Effect Mechanism and Simulation of Voids on Hygrothermal Performances of Composites. Polymers 2022, 14, 901. https://doi.org/10.3390/polym14050901

Liu Z, Lei Y, Zhang X, Kang Z, Zhang J. Effect Mechanism and Simulation of Voids on Hygrothermal Performances of Composites. Polymers. 2022; 14(5):901. https://doi.org/10.3390/polym14050901

Chicago/Turabian StyleLiu, Zhu, Yongpeng Lei, Xiangyang Zhang, Zhenhang Kang, and Jifeng Zhang. 2022. "Effect Mechanism and Simulation of Voids on Hygrothermal Performances of Composites" Polymers 14, no. 5: 901. https://doi.org/10.3390/polym14050901

APA StyleLiu, Z., Lei, Y., Zhang, X., Kang, Z., & Zhang, J. (2022). Effect Mechanism and Simulation of Voids on Hygrothermal Performances of Composites. Polymers, 14(5), 901. https://doi.org/10.3390/polym14050901