Jute Fiber-Reinforced Polymer Tube-Confined Sisal Fiber-Reinforced Recycled Aggregate Concrete Waste

Abstract

:1. Introduction

2. Experimental Works

2.1. Material Properties

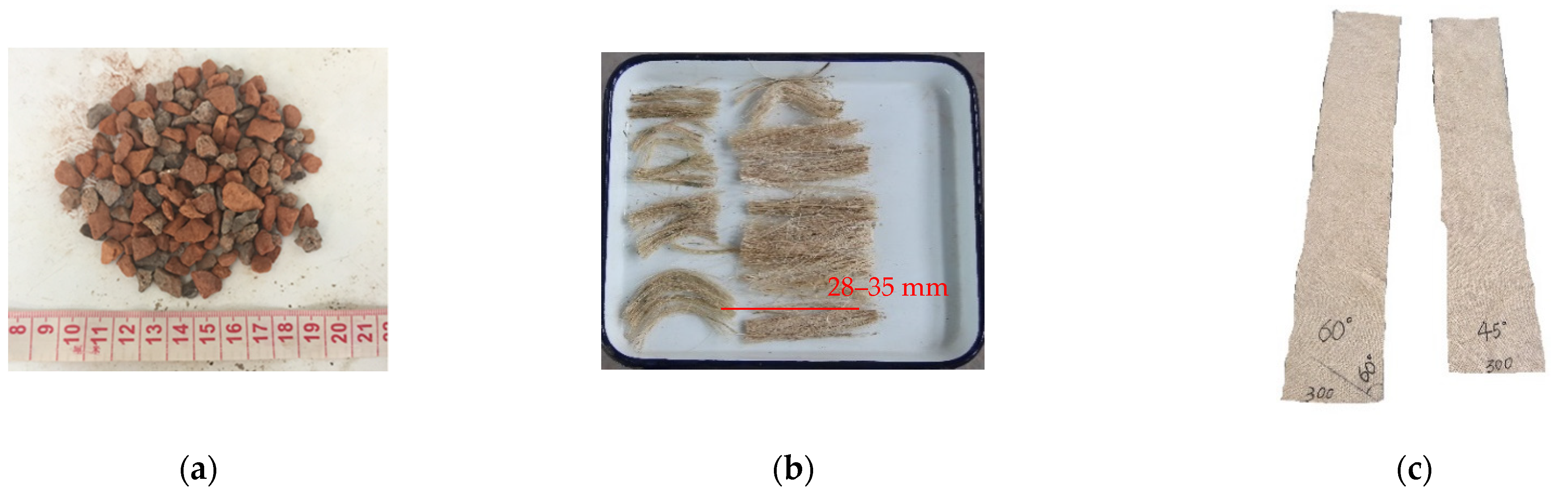

2.1.1. Sisal Fiber, RAs and RAC

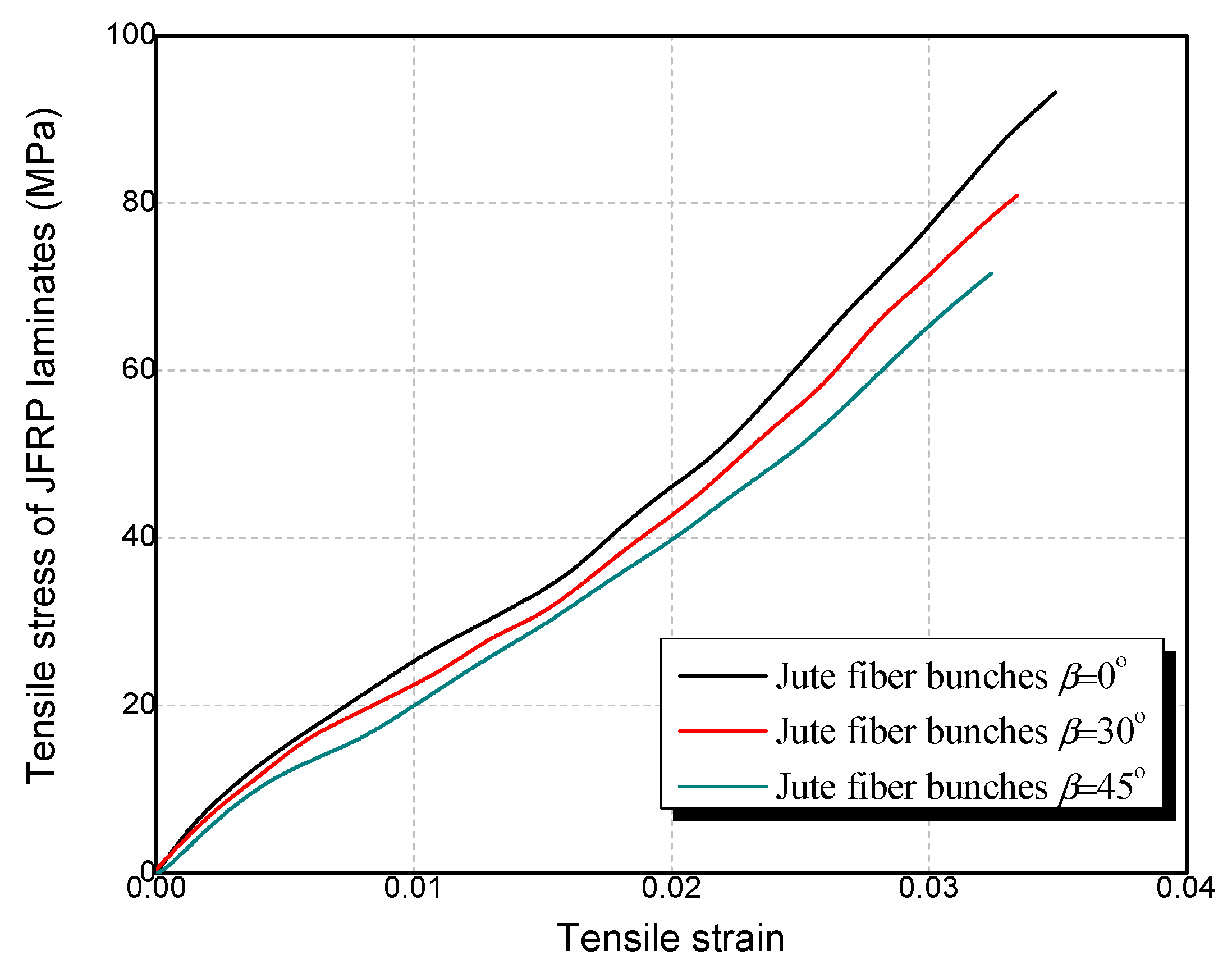

2.1.2. JFRP Composites

2.2. Specimen Preparation

2.3. Test Matrix

2.4. Test Setup

3. Test Results and Discussion

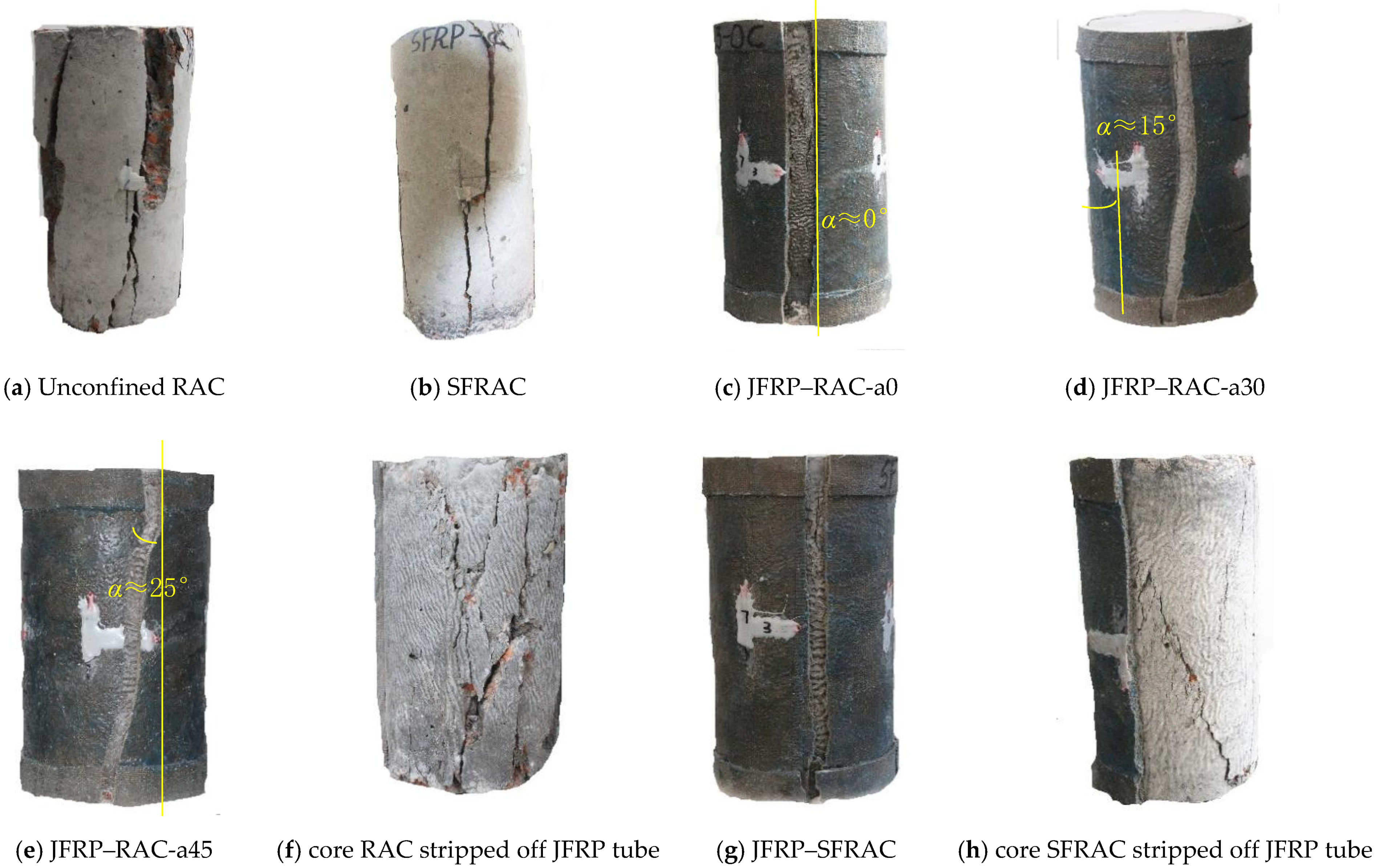

3.1. Failure Modes

3.2. Compressive Stress–Strain Behavior and Ultimate Condition

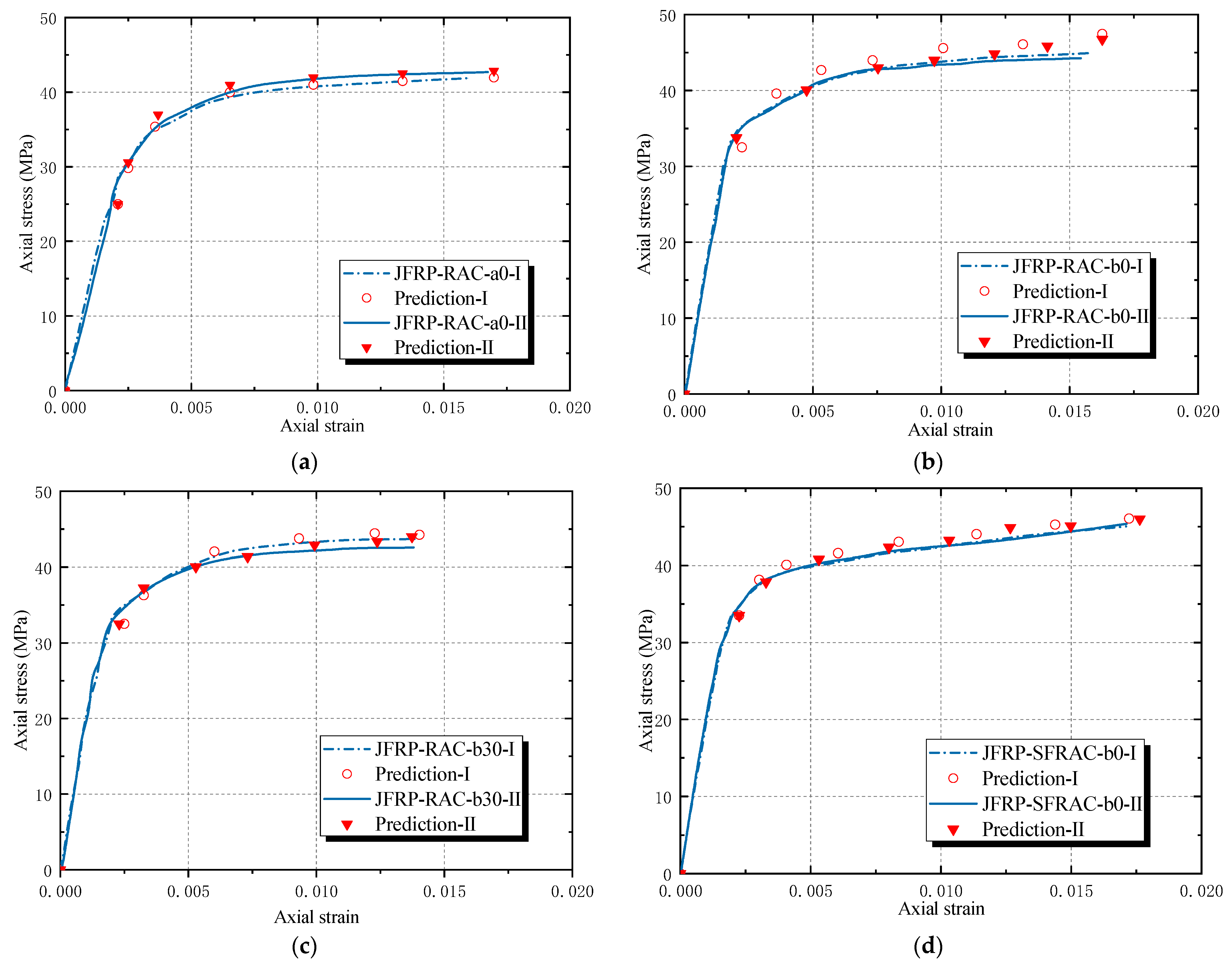

3.2.1. Axial Stress–Strain Curves

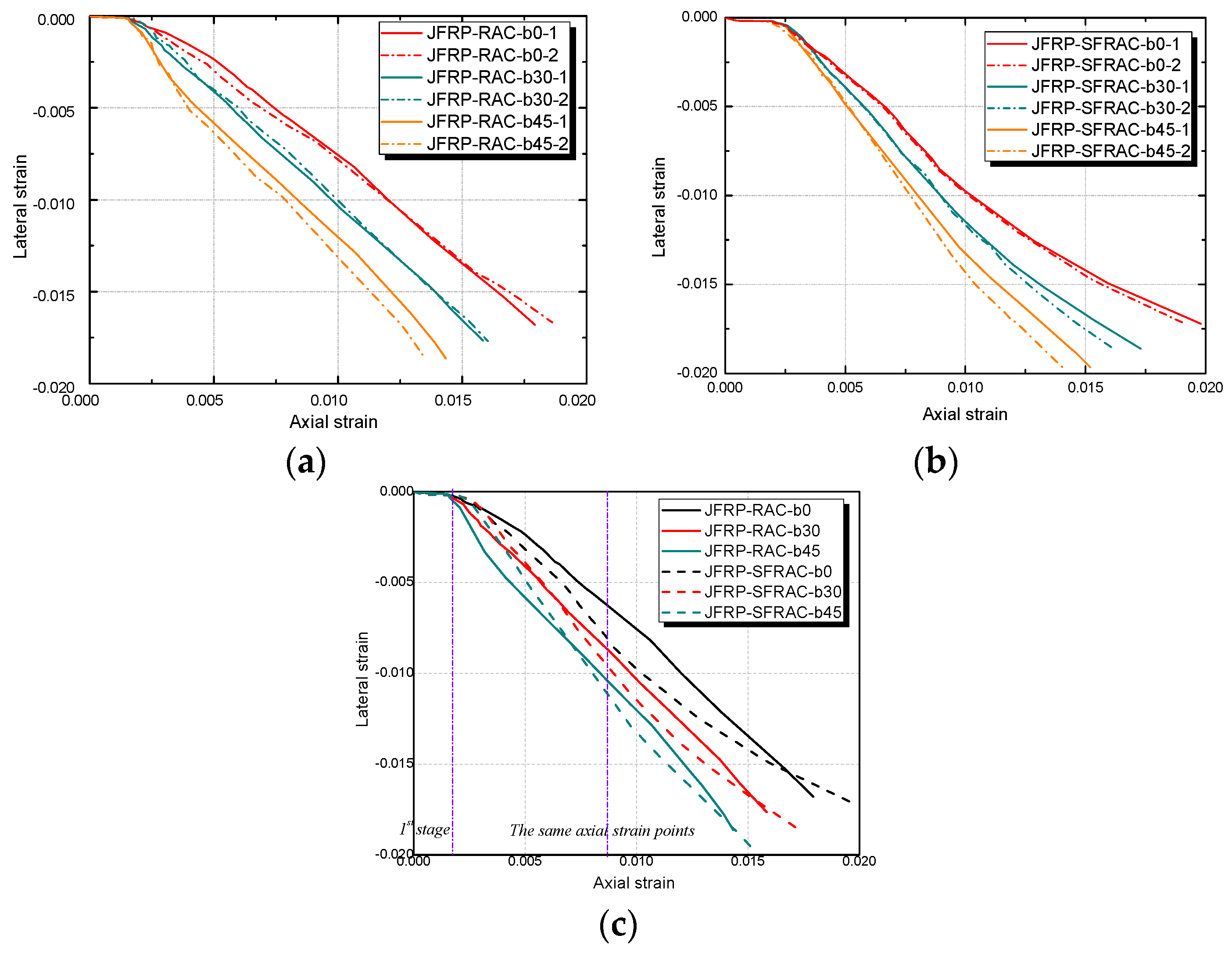

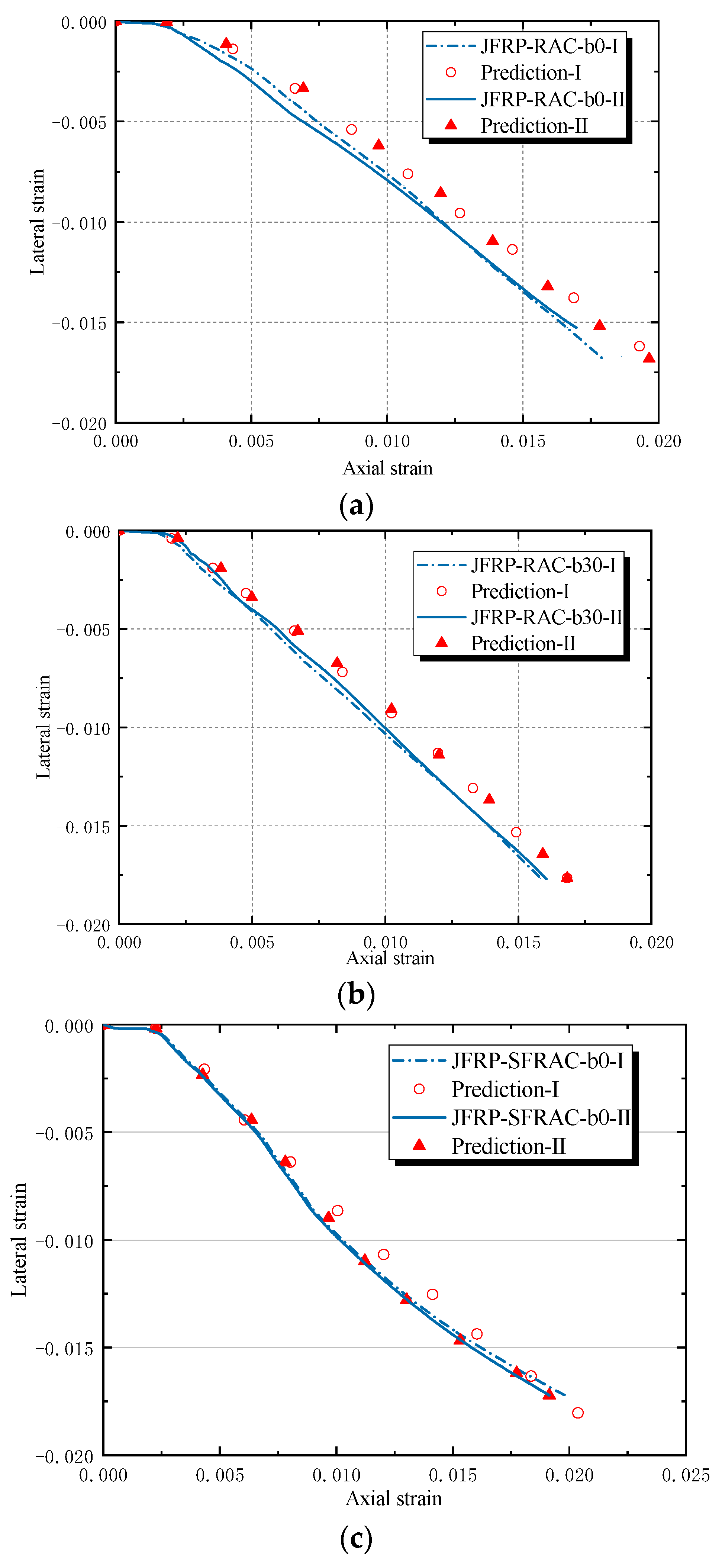

3.2.2. Lateral Strain–Axial Strain Relation

3.3. Compressive Strength and Ultimate Strains

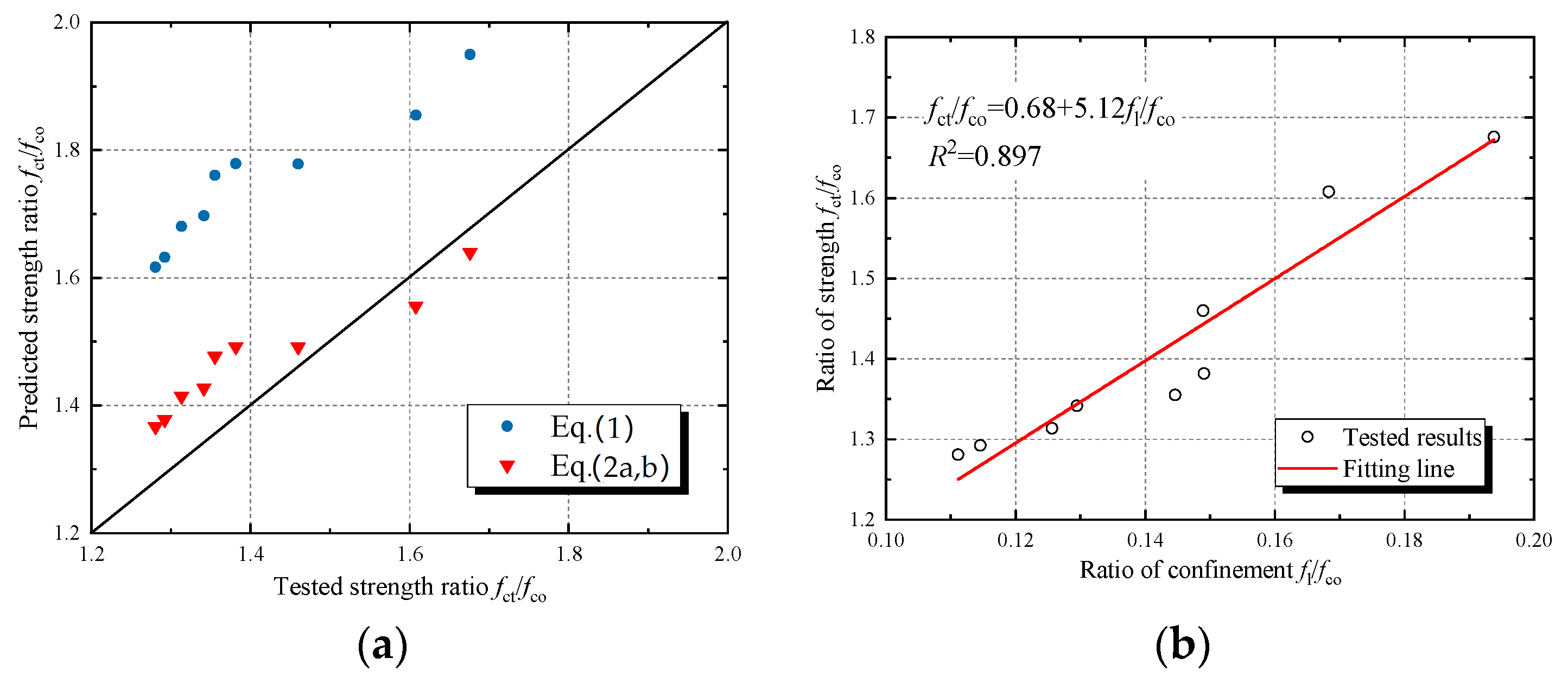

3.3.1. Strength Ratio

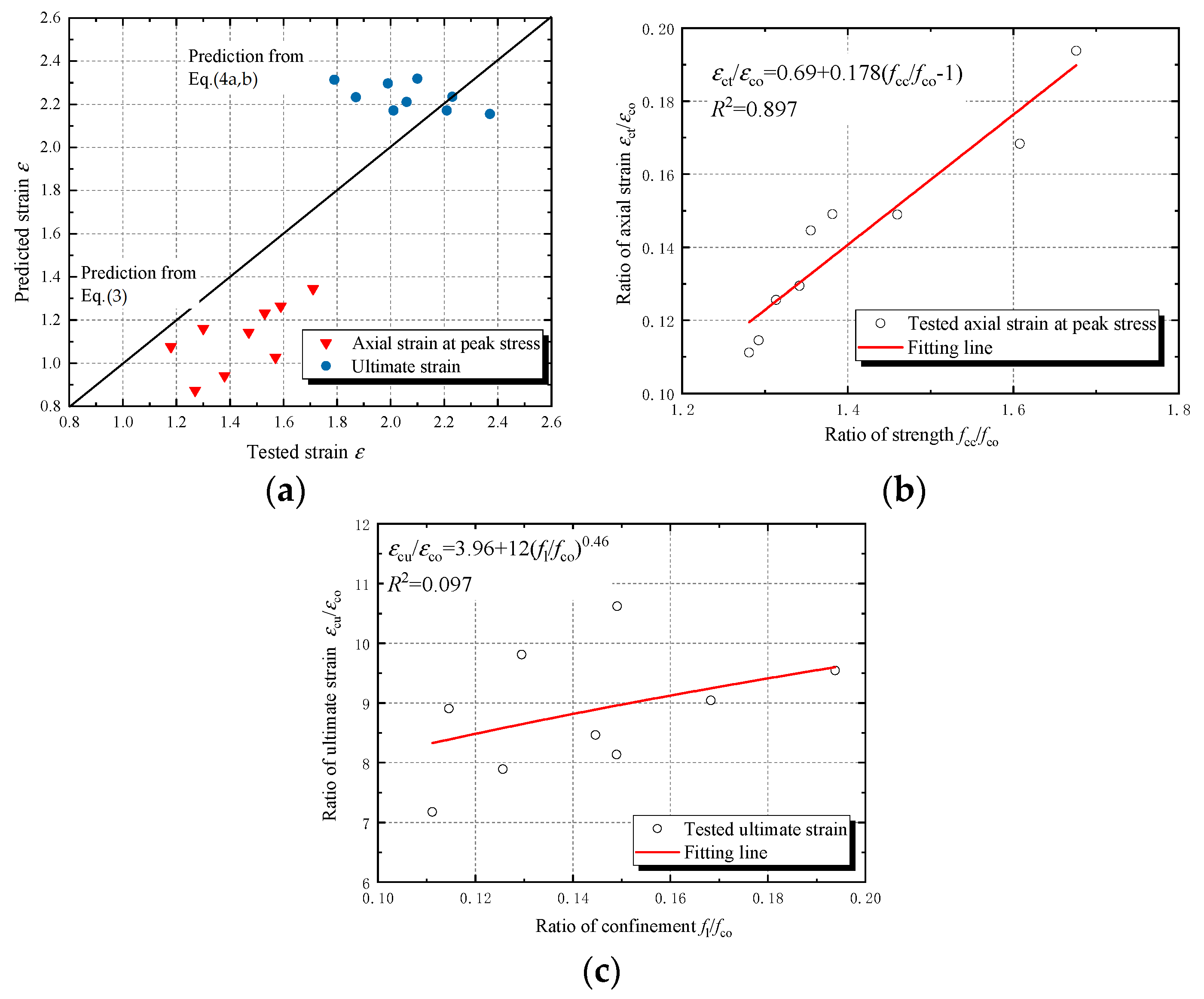

3.3.2. Ductility Ratio

4. Theoretical Models

4.1. Ultimate Condition Equations

4.2. Stress–Strain Model

4.3. Lateral-to-Axial Strain Model

5. Conclusions

- (1)

- The confinement of JFRP increased the compressive strength of RAC by 28~68%. The compressive strength of JFRP-confined specimens with 0°, 30° and 45° jute fiber orientations decreased in sequence. The reinforcement of sisal fiber slightly increased the compressive strength of the RAC.

- (2)

- JFRP increased the ultimate strain of RAC and SFRAC by around 6.18 to 9.62 times. The ultimate strain of confined specimens with 0°, 30° and 45° jute fiber orientations decreased slightly in sequence. The sisal fiber reinforcement in RAC increased the ultimate strain of the composite columns.

- (3)

- JFRP confinement was regarded as weak confinement, but the JFRP presented effective confinement because the ultimate strength was larger than the compressive strength of unconfined concrete .

- (4)

- The sisal fiber reinforcement slowed down the development of the lateral dilation of RAC by reducing the propagation of cracks in the concrete due to the bridging effect.

- (5)

- The ultimate condition equations of FRP confined natural aggregate concrete exhibited deviation in prediction of the ultimate conditions of JFRP–RAC and JFRP–SFRAC. The predicted stress–strain behavior by Lam and Teng’s model with the revised ultimate condition equations demonstrated good agreement with the tested results.

- (6)

- The predicted lateral–axial strain model used in the study presented a slight overestimation of the dilation of JFRP–RAC, and the coefficient was considered to revise the overestimation by regression analysis.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A comprehensive review on recycled aggregate and recycled aggregate concrete. Resour. Conserv. Recycl. 2022, 171, 105565. [Google Scholar] [CrossRef]

- Gao, C.; Huang, L.; Yan, L.; Kasal, B.; Li, W.; Jin, R.; Wang, Y.; Li, Y.; Deng, P. Compressive performance of fiber reinforced polymer encased recycled aggregate concrete with nanoparticles. J. Mater. Res. Technol. 2021, 14, 2727–2738. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Wei, C.; Ruoyu, J.; Yidong, X.; Dariusz, W.; Bo, L.; Libo, Y.; Zhihong, P.; Yang, Y. Adopting recycled aggregates as sustainable construction materials: A review of the scientific literature. Constr. Build. Mater. 2019, 218, 483–496. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Fresh-state performance of recycled aggregate concrete: A review. Constr. Build. Mater. 2018, 178, 19–31. [Google Scholar] [CrossRef]

- Kisku, N.; Joshi, H.; Ansari, M.; Panda, S.K.; Nayak, S.; Dutta, S.C. A critical review and assessment for usage of recycled aggregate as sustainable construction material. Constr. Build. Mater. 2017, 131, 721–740. [Google Scholar] [CrossRef]

- Tang, Z.; Li, W.; Tam, V.W.Y. Mechanical performance of CFRP-confined sustainable geopolymeric recycled aggregate concrete under axial compression. Eng. Struct. 2021, 224, 111246. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Sagoe-Crentsil, K.K.; Brown, T.; Taylor, A.H. Performance of concrete made with commercially produced coarse recycled concrete aggregate. Cem. Concr. Res. 2001, 31, 707–712. [Google Scholar] [CrossRef]

- Gao, C.; Huang, L.; Jin, R.; Chen, H. Mechanical properties of recycled aggregate concrete modified by nano-particles. Constr. Build. Mater. 2021, 241, 118030. [Google Scholar] [CrossRef]

- Kharuddin, F.S.; Wan Azahar, W.N.A.; Ramadhansyah, P.J.; Hainin, M.R.; Mohamed Jaafar, Z.F. Performance of asphaltic concrete modified with recycled crushed bricks. IOP Conf. Ser. Earth Environ. Sci. 2021, 682, 012061. [Google Scholar] [CrossRef]

- Hansen, T.C. Recycling of Demolished Concrete and Masonry; RILEM Report 6; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Khalaf Fouad, M.; De Venny Alan, S. Properties of new and recycled clay brick aggregates for use in concrete. J. Mater. Civ. Eng. 2005, 17, 456–464. [Google Scholar] [CrossRef]

- Khalaf Fouad, M. Using crushed clay brick as coarse aggregate in concrete. J. Mater. Civ. Eng. 2006, 18, 518–526. [Google Scholar] [CrossRef]

- De Matos, P.R.; Sakata, R.D.; Onghero, L.; Uliano, V.G.; de Brito, J.; Campos, C.E.M.; Gleize, P.J.P. Utilization of ceramic tile demolition waste as supplementary cementitious material: An early-age investigation. J. Build. Eng. 2021, 38, 102187. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Huang, Y.J.; Yang, J.; Zhang, C. Mechanical properties of confined recycled aggregate concrete under axial compression. Constr. Build. Mater. 2012, 26, 591–603. [Google Scholar] [CrossRef]

- Huang, L.; Liang, J.; Gao, C.; Yan, L. Flax FRP tube and steel spiral dual-confined recycled aggregate concrete: Experimental and analytical studies. Constr. Build. Mater. 2021, 300, 124023. [Google Scholar] [CrossRef]

- Tang, Z.; Li, W.; Tam, V.W.Y. Mechanical behaviors of CFRP-confined sustainable geopolymeric recycled aggregate concrete under both static and cyclic compression. Compos. Struct. 2020, 252, 112750. [Google Scholar] [CrossRef]

- Teng, J.G.; Zhao, J.L.; Yu, T.; Li, L.J.; Guo, Y.C. Behavior of FRP-Confined Compound Concrete Containing Recycled Concrete Lumps. J. Compos. Constr. 2016, 20, 04015038. [Google Scholar] [CrossRef]

- Islam, M.M.; Choudhury, M.S.I.; Abdulla, M.; Amin, A.F.M.S. Confinement effect of fiber reinforced polymer wraps in circular and square concrete columns. In Proceedings of the 4th Annual Paper Meet and 1st Civil Engineering Congress, The Institution of Engineers (IEB), Dhaka, Bangladesh, 22–24 December 2011; pp. 359–362. [Google Scholar]

- Gao, C.; Huang, L.; Yan, L.B.; Kasal, B.; Li, W.G. Behavior of glass and carbon FRP tube encased recycled aggregate concrete with recycled clay brick aggregate. Compos. Struct. 2016, 155, 245–254. [Google Scholar] [CrossRef]

- Yazdanbakhsh, A.; Bank, L.C.; Chen, C. Use of recycled FRP reinforcing bar in concrete as coarse aggregate and its impact on the mechanical properties of concrete. Constr. Build. Mater. 2016, 121, 278–284. [Google Scholar] [CrossRef] [Green Version]

- Bompa, D.V.; Elghazouli, A.Y. Stress-strain response and practical design expressions for FRP-confined recycled tyre rubber concrete. Constr. Build. Mater. 2020, 237, 117633. [Google Scholar] [CrossRef]

- Yan, L.; Kasal, B.; Huang, L. A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. Part B Eng. 2016, 92, 94–132. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N. A comparative study of steel reinforced concrete and flax fibre reinforced polymer tube confined coconut fibre reinforced concrete beams. J. Reinf. Plast. Compos. 2013, 32, 1155–1164. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Effect of column parameters on flax FRP confined coir fibre reinforced concrete. Constr. Build. Mater. 2014, 55, 299–312. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef] [Green Version]

- Silva, F.; Mobasher, B.; Toledo Filho, R.D. Cracking mechanisms in durable sisal fiber reinforced cement composites. Cem. Concr. Compos. 2009, 31, 721–730. [Google Scholar] [CrossRef]

- Tara, S.; Ashim, P. Confining concrete with sisal and jute FRP as alternatives for CFRP and GFRP. Int. J. Sustain. Built Environ. 2015, 4, 248–264. [Google Scholar] [CrossRef] [Green Version]

- Sen, T.; Reddy, H.N. Jagannatha Reddy. Pretreatment of Woven Jute FRP Composite and Its Use in Strengthening of Reinforced Concrete Beams in Flexure. Adv. Mater. Sci. Eng. 2013, 2013, 128158. [Google Scholar] [CrossRef] [Green Version]

- Tan, H.Z.; Yan, L.B.; Huang, L.; Wang, Y.; Li, H.; Chen, J.Y. Behavior of sisal fiber concrete cylinders externally wrapped with jute FRP. Polym. Compos. 2017, 38, 1910–1917. [Google Scholar] [CrossRef]

- Sadeghian, P.; Rahai, A.R.; Ehsani, M.R. Effect of fiber orientation on compressive behaviour of CFRP-confined concrete columns. J. Reinf. Plast. Compos. 2010, 29, 1335–1346. [Google Scholar] [CrossRef]

- Arunothayan, A.R.; Nematollahia, B.; Ranade, R.; Bong, S.H.; Sanjayan, J.G.; Khayat, K.H. Fiber orientation effects on ultra-high performance concrete formed by 3D printing. Cem. Concr. Res. 2021, 143, 106384. [Google Scholar] [CrossRef]

- Au, C.; Buyukozturk, O. Effect of fiber orientation and ply mix on fiber reinforced polymer-confined concrete. ASCE J. Compos. Constr. 2005, 9, 397–407. [Google Scholar] [CrossRef] [Green Version]

- GB/T50081-2002; Standard for Test Method of Mechanical Properties on Ordinary Concrete. China Architecture and Building Press: Beijing, China, 2002.

- ASTM D3039/D3039M-2000; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: Pittsfield, MA, USA, 2006.

- Codispoti, R.; Oliveira, D.V.; Olivito, R.S.; Lourenço, P.B.; Fangueiro, R. Mechanical performance of natural fiber-reinforced composites for the strengthening of masonry. Compos. Part B Eng. 2015, 77, 74–83. [Google Scholar] [CrossRef]

- Madhavi, K.; Harshith, V.V.; Gangadhar, M.; Kumar, V.C.; Raghavendra, T. External strengthening of concrete with natural and synthetic fiber composites. Mater. Today Proc. 2021, 38, 2803–2809. [Google Scholar] [CrossRef]

- Bai, Y.L.; Yan, Z.W.; Jia, J.F.; Ozbakkaloglu, T.; Liu, Y. Dynamic compressive behavior of concrete confined with unidirectional natural flax FRP based on SHPB tests. Compos. Struct. 2021, 259, 113233. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Lim, J.C. Axial compressive behavior of FRP-confined concrete: Experimental test database and a new design-oriented model. Compos. Part B Eng. 2013, 55, 607–634. [Google Scholar] [CrossRef] [Green Version]

- Jiang, T.; Teng, J.G. Analysis-oriented stress-strain models for FRP-confined concrete. Eng. Struct. 2007, 29, 2968–2986. [Google Scholar] [CrossRef] [Green Version]

- Mirmiran, A.; Shahawy, M. Dilation characteristics of confined concrete. Mech. Cohesive-Frict. Mater. 1997, 2, 237–249. [Google Scholar] [CrossRef]

- Spoelstra, M.R.; Monti, G. FRP-confined concrete model. J. Compos. Constr.-ASCE 1999, 3, 143–150. [Google Scholar] [CrossRef]

- Fam, A.Z.; Rizkalla, S.H. Confinement model for axially loaded concrete confined by circular fiber-reinforced polymer tubes. ACI Struct. J. 2001, 98, 451–461. [Google Scholar] [CrossRef]

- Chun, S.S.; Park, H.C. Load carrying capacity and ductility of RC columns confined by carbon fiber reinforced polymer. In Proceedings of the 3rd International Conference on Composites in Infrastructure (CD-Rom), San Francisco, CA, USA, 10–12 June 2002. [Google Scholar]

- Lam, L.; Teng, J.G. Design-oriented stress-strain model for FRP-confined concrete. Constr. Build. Mater. 2003, 17, 471–489. [Google Scholar] [CrossRef]

- Richart, F.E.; Brandtzaeg, A.; Brown, R.L. The Failure of Plain and Spirally Reinforced Concrete in Compression; University of Illinois, Engineering Experimental Station: Champaign, IL, USA, 1929. [Google Scholar]

- Teng, J.G.; Huang, Y.L.; Lam, L.; Ye, L.P. Theoretical model for fiber-reinforced polymer-confined concrete. J. Compos. Constr. 2007, 11, 201–210. [Google Scholar] [CrossRef]

| Type of Aggregates | Diameter (mm) | Density (kg/m3) | Water Absorption (%) | Moisture Content (%) | Crushing Index (%) |

|---|---|---|---|---|---|

| Fine aggregate | 0.35–0.50 | 1480 | 5.62 | 3.07 | - |

| Natural coarse aggregates | 5–10 | 1594 | 4.37 | 0.29 | 12.70 |

| Recycled coarse aggregates | 10 | 1216 | 12.00 | 6.81 | 50.90 |

| Index | SO3 | MgO | Loss on Ignition | Alkali Content | Fineness | Initial Setting Time | Final Setting Time | Stability |

|---|---|---|---|---|---|---|---|---|

| Value | 3.06% | 1.67% | 2.55% | 0.57% | 80 mm residue: 6.37% | 1.82 h | 6.43 h | Rex expansion 3.7 mm |

| Items | Compressive Strength (MPa) | Flexural Strength (MPa) | ||

|---|---|---|---|---|

| 3 d | 28 d | 3 d | 28 d | |

| Value | 23.4 | 46.7 | 4.3 | 6.9 |

| No. | Water (kg/m3) | Cement (kg/m3) | Fine Natural Aggregate (kg/m3) | Coarse Natural Aggregate (kg/m3) | Recycled Coarse Aggregate (kg/m3) | Replacement Percentage of RAs | Sisal Fiber Content (%) | |

|---|---|---|---|---|---|---|---|---|

| RAC-a | 0.55 | 260.4 | 473.5 | 633.7 | 403.3 | 748.9 | 65% | - |

| RAC-b | 0.40 | 260.4 | 651.1 | 570.7 | 363.2 | 674.5 | 65% | - |

| SFRAC-b | 0.40 | 260.4 | 651.1 | 570.7 | 363.2 | 674.5 | 65% | 0.3 |

| Type of FRP | Orientation of Fibers β | Thickness of FRP Laminate tfrp (mm) | Elastic Modulus (GPa) | Tensile Strength ffrp (MPa) | SD | Tensile Strain (%) | SD | Price of Fiber Fabric per m2 (US) |

|---|---|---|---|---|---|---|---|---|

| JFRP 1 | 0° | 3.9 | 2.67 | 93.16 | 1.49 | 3.49 | 0.17 | $0.4 |

| JFRP 1 | 30° | 3.9 | 2.43 | 80.92 | 0.88 | 3.33 | 0.06 | |

| JFRP 1 | 45° | 3.9 | 2.21 | 71.61 | 1.12 | 3.24 | 0.03 |

| Sample | Number of JFRP Layers | Orientation of Jute Fibers (°) | Untreated RAC Strength (MPa) | Sisal Fiber Mass Content |

|---|---|---|---|---|

| RAC-a | - | - | 25.0 | - |

| JFRP–RAC-a0 | 6 | 0 | 25.0 | - |

| JFRP–RAC-a30 | 6 | 30 | 25.0 | - |

| JFRP–RAC-a45 | 6 | 45 | 25.0 | - |

| RAC-b | - | - | 32.5 | - |

| JFRP–RAC-b0 | 6 | 0 | 32.5 | - |

| JFRP–RAC-b30 | 6 | 30 | 32.5 | - |

| JFRP–RAC-b45 | 6 | 45 | 32.5 | - |

| SFRAC-b | - | - | 33.5 | 0.3% |

| JFRP–SFRAC-b0 | 6 | 0 | 33.5 | 0.3% |

| JFRP–SFRAC-b30 | 6 | 30 | 33.5 | 0.3% |

| JFRP–SFRAC-b45 | 6 | 45 | 33.5 | 0.3% |

| Specimen Group | fco (MPa) | εco (%) | fct (MPa) | SD | εct (%) | fcu (MPa) | fcu/fco | εcu (%) | εh,rup (%) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| JFRP–RAC-a0 | 25.0 | 0.22 | 41.9 | 1.7 | 1.67 | 1.59 | 39.8 | 1.59 | 2.10 | 9.55 | 1.66 |

| JFRP–RAC-a30 | 25.0 | 0.22 | 40.2 | 1.6 | 1.61 | 1.30 | 36.9 | 1.47 | 1.99 | 9.05 | 1.70 |

| JFRP–RAC-a45 | 25.0 | 0.22 | 36.5 | 1.6 | 1.46 | 1.18 | 30.2 | 1.21 | 1.79 | 8.14 | 1.83 |

| JFRP–RAC-b0 | 32.5 | 0.21 | 44.9 | 1.7 | 1.38 | 1.57 | 40.2 | 1.24 | 2.23 | 10.62 | 1.68 |

| JFRP–RAC-b30 | 32.5 | 0.21 | 43.6 | 1.7 | 1.34 | 1.38 | 39.4 | 1.22 | 2.06 | 9.81 | 1.71 |

| JFRP–RAC-b45 | 32.5 | 0.21 | 42.0 | 1.7 | 1.29 | 1.27 | 35.8 | 1.10 | 1.87 | 8.91 | 1.86 |

| JFRP–SFRAC-b0 | 33.5 | 0.28 | 45.4 | 2.0 | 1.36 | 1.71 | 39.8 | 1.19 | 2.37 | 8.46 | 1.72 |

| JFRP–SFRAC-b30 | 33.5 | 0.28 | 44.0 | 2.1 | 1.31 | 1.53 | 39.6 | 1.18 | 2.21 | 7.89 | 1.86 |

| JFRP–SFRAC-b45 | 33.5 | 0.28 | 42.9 | 1.6 | 1.28 | 1.47 | 35.9 | 1.07 | 2.01 | 7.18 | 1.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, C.; Fu, Q.; Huang, L.; Yan, L.; Gu, G. Jute Fiber-Reinforced Polymer Tube-Confined Sisal Fiber-Reinforced Recycled Aggregate Concrete Waste. Polymers 2022, 14, 1260. https://doi.org/10.3390/polym14061260

Gao C, Fu Q, Huang L, Yan L, Gu G. Jute Fiber-Reinforced Polymer Tube-Confined Sisal Fiber-Reinforced Recycled Aggregate Concrete Waste. Polymers. 2022; 14(6):1260. https://doi.org/10.3390/polym14061260

Chicago/Turabian StyleGao, Chang, Qiuni Fu, Liang Huang, Libo Yan, and Guangming Gu. 2022. "Jute Fiber-Reinforced Polymer Tube-Confined Sisal Fiber-Reinforced Recycled Aggregate Concrete Waste" Polymers 14, no. 6: 1260. https://doi.org/10.3390/polym14061260