Physical, Mechanical and Perforation Resistance of Natural-Synthetic Fiber Interply Laminate Hybrid Composites

Abstract

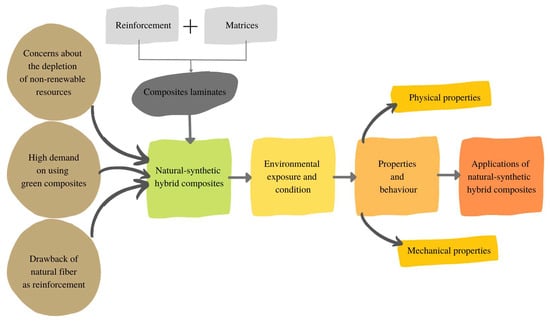

:1. Introduction

2. Natural and Synthetic Fibers

3. Hybrid Composite Laminates

4. Physical Properties of Interply Hybrid Composites

4.1. Thermal Analysis

4.2. Fibre Volume Fractions

4.3. Water/Moisture Absorption and Swelling

5. Mechanical Properties of Interply Hybrid Composites

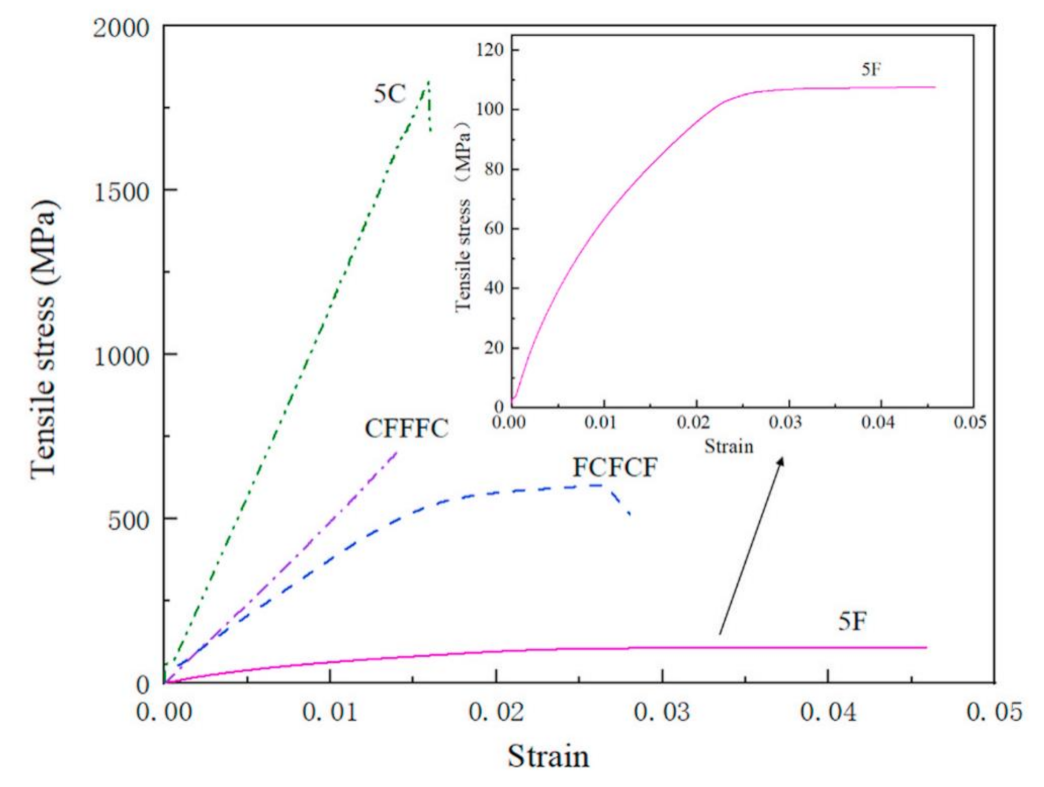

5.1. Tensile Properties of Interply Hybrid Composites

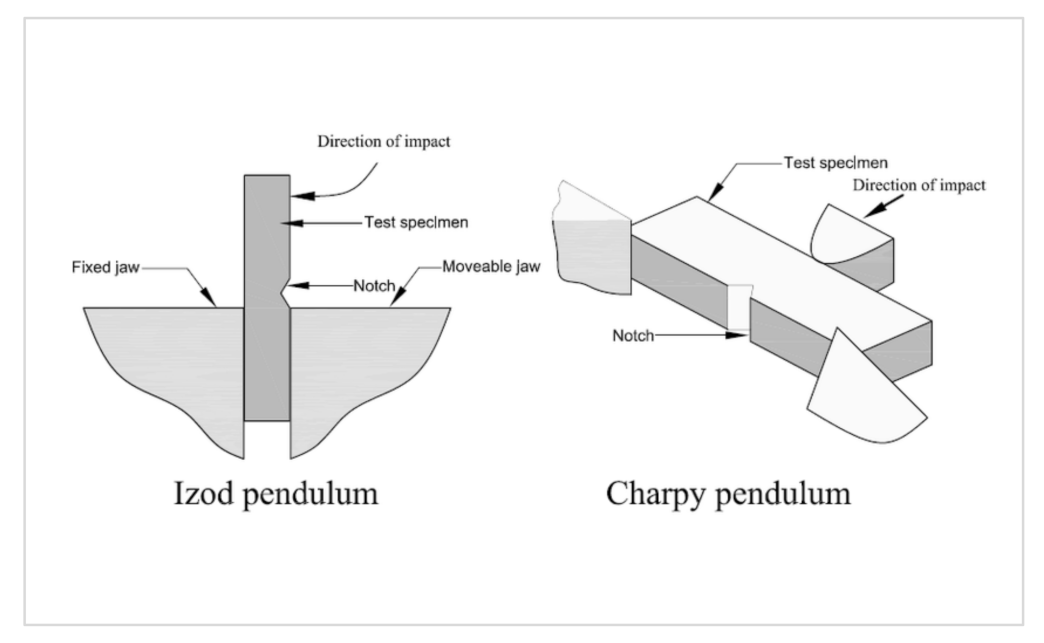

5.2. Charpy and Izod Test

5.3. Flexural Strength

6. Perforation Resistance of Hybrid Composite

7. Failure Mode of Perforation Resistance on Hybrid Composites

8. Applications

8.1. Aerospace

8.2. Automotive

8.3. Defense

9. Future Directions

10. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dolah, R.; Zafar, S.; Hassan, M.Z. Chapter 8-Alternative jet fuels: Biojet fuels’ challenges and opportunities. In Value-Chain of Biofuels; Elsevier: Amsterdam, The Netherlands, 2022; pp. 181–194. [Google Scholar]

- Lamb, W.F.; Wiedmann, T.; Pongratz, J.; Andrew, R.; Crippa, M.; Olivier, J.G.J.; Wiedenhofer, D.; Mattioli, G.; Khourdajie, A.A.; House, J.; et al. A review of trends and drivers of greenhouse gas emissions by sector from 1990 to 2018. Environ. Res. Lett. 2021, 16, 073005. [Google Scholar] [CrossRef]

- Bakhori, S.N.M.; Zuikafly, S.N.F.; Ahmad, F.; Hassan, M.Z. Tensile properties for MWCNT filled jute-Epoxy composites. J. Adv. Res. Appl. Mech. 2017, 31, 16–21. [Google Scholar]

- Nor, A.F.M.; Hassan, M.Z.; Rasid, Z.A.; Aziz, S.A.A.; Sarip, S.; Md Daud, M.Y. Optimization on Tensile Properties of Kenaf/Multi-walled CNT Hybrid Composites with Box-Behnken Design. Appl. Compos. Mater. 2021, 28, 607–632. [Google Scholar] [CrossRef]

- Abang Haji Abdul Majid, D.L.; Jamal, Q.; Manan, N. Low-velocity Impact Performance of Glass Fiber, Kenaf Fiber, and Hybrid Glass/Kenaf Fiber Reinforced Epoxy Composite Laminates. BioResources 2018, 13, 8839–8852. [Google Scholar]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Adi, D.S.; Ismadi; Damayanti, R.; Subiyanto, B.; Fatriasari, W.; Fudholi, A. A review on natural fibers for development of eco-friendly bio-composite: Characteristics, and utilizations. J. Mater. Res. Technol. 2021, 13, 2442–2458. [Google Scholar] [CrossRef]

- Halip, J.A.; Hua, L.S.; Ashaari, Z.; Tahir, P.M.; Chen, L.W.; Anwar Uyup, M.K. 8-Effect of treatment on water absorption behavior of natural fiber-reinforced polymer composites, in Mechanical and Physical Testing of Biocomposites. In Fibre-Reinforced Composites and Hybrid Composites; Woodhead Publishing: Philadelphia, PA, USA, 2019; pp. 141–156. [Google Scholar]

- Hassan, M.; Ibrahim, M.; Sapuan, S. Tensile Properties Analysis and Characterizations of Single Fiber and Biocomposites. In Value-Added Biocomposites; CRC Press: Boca Raton, FL, USA, 2021; pp. 87–101. [Google Scholar]

- Kurien, R.A.; Dirviyam, P.S.; Sekar, M.; Preno, C. Green composite materials for green technology in the automotive industry. IOP Conf. Ser. Mater. Sci. Eng. 2020, 872, 012064. [Google Scholar] [CrossRef]

- Ibrahim, I.; Sarip, S.; Bani, N.; Ibrahim, M.; Hassan, M. The Weibull probabilities analysis on the single kenaf fiber. AIP Conf. Proc. 1958, 2018, 020009. [Google Scholar]

- Hassan, M.Z.; Roslan, S.A.; Sapuan, S.; Rasid, Z.A.; Mohd Nor, A.F.; Daud, M.Y.; Dolah, R.; Mohamed Yusoff, M.Z. Mercerization optimization of bamboo (bambusa vulgaris) fiber-reinforced epoxy composite structures using a box-behnken design. Polymers 2020, 12, 1367. [Google Scholar] [CrossRef]

- Ibrahim, M.I.; Dolah, R.; Yusoff, M.Z.M.; Salit, M.S.; Hassan, M.Z. Chemical treatment evaluation of tensile properties for single kenaf fiber. J. Adv. Res. Appl. Mech. 2016, 32, 9–14. [Google Scholar]

- Sapuan, S.M.; Aulia, H.S.; Ilyas, R.A.; Atiqah, A.; Dele-Afolabi, T.T.; Nurazzi, M.N.; Supian, A.B.M.; Atikah, M.S.N. Mechanical Properties of Longitudinal Basalt/Woven-Glass-Fiber-reinforced Unsaturated Polyester-Resin Hybrid Composites. Polymers 2020, 12, 2211. [Google Scholar] [CrossRef]

- Dong, C. Review of natural fibre-reinforced hybrid composites. J. Reinf. Plast. Compos. 2017, 37, 073168441774536. [Google Scholar] [CrossRef] [Green Version]

- Mochane, M.J.; Mokhena, T.C.; Mokhothu, T.H.; Mtibe, A.; Sadiku, E.R.; Ray, S.S.; Ibrahim, I.D.; Daramola, O.O. Recent progress on natural fiber hybrid composites for advanced applications: A review. Res. Publ. Outputs 2019, 13, 159–198. [Google Scholar] [CrossRef]

- Kumar, S.; Manna, A.; Dang, R. A review on applications of natural Fiber-Reinforced composites (NFRCs). Mater. Today Proc. 2022, 50, 1632–1636. [Google Scholar] [CrossRef]

- Peças, P.; Carvalho, H.; Salman, H.; Leite, M. Natural Fibre Composites and Their Applications: A Review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef] [Green Version]

- Hunter, L. 10-Mohair, cashmere and other animal hair fibres. In Handbook of Natural Fibres, 2nd ed.; Woodhead Publishing: Philadelphia, PA, USA, 2020; pp. 279–383. [Google Scholar]

- Bonifazi, G.; Capobianco, G.; Serranti, S. Asbestos containing materials detection and classification by the use of hyperspectral imaging. J. Hazard. Mater. 2018, 344, 981–993. [Google Scholar] [CrossRef] [PubMed]

- Ching Hao, L.; Abdan, K.; Lee, S.H.; Liu, M. A Comprehensive Review on Bast Fibre Retting Process for Optimal Performance in Fibre-Reinforced Polymer Composites. Adv. Mater. Sci. Eng. 2020, 2020, 1–27. [Google Scholar]

- Thiyagu, K.; Gnanasekaran, M.; Gunasekaran, M. Combining ability and heterosis for seed cotton yield, its components and fibre quality traits in upland cotton (Gossypium hirsutum L.). Electron. J. Plant Breed. 2019, 10, 1501–1511. [Google Scholar] [CrossRef]

- Jones, D.; Ormondroyd, G.O.; Curling, S.F.; Popescu, C.M.; Popescu, M.C. Chemical compositions of natural fibres. In Advanced High Strength Natural Fibre Composites in Construction; Elsevier: Amsterdam, The Netherlands, 2017; pp. 23–58. [Google Scholar]

- Bayer, J.; Granda, L.A.; Méndez, J.A.; Pèlach, M.A.; Vilaseca, F.; Mutjé, P. 5-Cellulose polymer composites (WPC). In Advanced High Strength Natural Fibre Composites in Construction; Woodhead Publishing: Philadelphia, PA, USA, 2017; pp. 115–139. [Google Scholar]

- Turci, F.; Tomatis, M.; Pacella, A. Surface and bulk properties of mineral fibres relevant to toxicity. In Mineral Fibres: Crystal Chemistry, Chemical-Physical Properties, Biological Interaction and Toxicity; Mineralogical Society of the UK and Ireland: Middlesex, UK, 2017; pp. 171–214. [Google Scholar]

- Akter, T.; Hossain, M.S. Application of plant fibers in environmental friendly composites for developed properties: A review. Clean. Mater. 2021, 2, 100032. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Hossain, M.; Sahadat Hossain, M.; Molla, J.; Khan, R.; Chowdhury, A.M.S. Studies on the Degradation of Jute-Blended Cotton Fabric in Soil. Water Ambient. Atmos. 2018, 4, 2456–5245. [Google Scholar]

- Asim, M.; Abdan, K.; Jawaid, M.; Nasir, M.; Dashtizadeh, Z.; Ishak, M.; Hoque, M.E. A Review on Pineapple Leaves Fibre and Its Composites. Int. J. Polym. Sci. 2015, 2015, 950567. [Google Scholar] [CrossRef] [Green Version]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.; Gupta, R. Review: Raw Natural Fiber–Based Polymer Composites. Int. J. Polym. Anal. Charact. 2014, 19, 256–271. [Google Scholar] [CrossRef]

- Sood, M.; Dwivedi, G. Effect of fiber treatment on flexural properties of natural fiber reinforced composites: A review. Egypt. J. Pet. 2018, 27, 775–783. [Google Scholar] [CrossRef]

- Chokshi, S.; Parmar, V.; Gohil, P.; Chaudhary, V. Chemical composition and mechanical properties of natural fibers. J. Nat. Fibers 2020, 1–12. [Google Scholar] [CrossRef]

- Lotfi, A.; Li, H.; Dao, D.V.; Prusty, G. Natural fiber–reinforced composites: A review on material, manufacturing, and machinability. J. Thermoplast. Compos. Mater. 2021, 34, 238–284. [Google Scholar] [CrossRef]

- Jariwala, H.; Jain, P. A review on mechanical behavior of natural fiber reinforced polymer composites and its applications. J. Reinf. Plast. Compos. 2019, 38, 441–453. [Google Scholar] [CrossRef]

- Pawar, M.D.; Joshi, R. Vibrational behaviour and mechanical properties of hybrid polymer matrix composites reinforced with natural fibres: A review. Mater. Today Proc. 2021, 54, 341–347. [Google Scholar] [CrossRef]

- Ankit, R.M.; Chauhan, P.; Suresh, D.; Kumar, S.; Santhosh Kumar, R. A review on mechanical properties of natural fiber reinforced polymer (NFRP) composites. Mater. Today Proc. 2021, in press. [Google Scholar] [CrossRef]

- Jeyapragash, R.; Srinivasan, V.; Sathiyamurthy, S. Mechanical properties of natural fiber/particulate reinforced epoxy composites—A review of the literature. Mater. Today Proc. 2020, 22, 1223–1227. [Google Scholar] [CrossRef]

- Yadav, V.; Singh, S. A comprehensive review of natural fiber composites: Applications, processing techniques and properties. Mater. Today Proc. 2021, in press. [Google Scholar] [CrossRef]

- Sriram, M.; Aswin Sidhaarth, K.R. Various properties of natural and artificial fibers with cementitious composites in hybrid form–A review. Mater. Today Proc. 2022, in press. [Google Scholar] [CrossRef]

- Lakshmi Narayana, V.; Bhaskara Rao, L. A brief review on the effect of alkali treatment on mechanical properties of various natural fiber reinforced polymer composites. Mater. Today Proc. 2021, 44, 1988–1994. [Google Scholar] [CrossRef]

- Sathish, S.; Karthi, N.; Prabhu, L.; Gokulkumar, S.; Balaji, D.; Vigneshkumar, N.; Ajeem Farhan, T.S.; AkilKumar, A.; Dinesh, V.P. A review of natural fiber composites: Extraction methods, chemical treatments and applications. Mater. Today Proc. 2021, 45, 8017–8023. [Google Scholar] [CrossRef]

- Ramu, P.; Jaya Kumar, C.V.; Palanikumar, K. Mechanical Characteristics and Terminological Behavior Study on Natural Fiber Nano reinforced Polymer Composite—A Review. Mater. Today Proc. 2019, 16, 1287–1296. [Google Scholar] [CrossRef]

- Nayak, S.; Jesthi, D.K.; Saroj, S.; Sadarang, J. Assessment of impact and hardness property of natural fiber and glass fiber hybrid polymer composite. Mater. Today Proc. 2022, 49, 497–501. [Google Scholar] [CrossRef]

- Awais, H.; Nawab, Y.; Amjad, A.; Anjang, A.; Md Akil, H.; Zainol Abidin, M.S. Environmental benign natural fibre reinforced thermoplastic composites: A review. Compos. Part C Open Access 2021, 4, 100082. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Pruncu, C.I.; Khan, A. A comprehensive review of techniques for natural fibers as reinforcement in composites: Preparation, processing and characterization. Carbohydr. Polym. 2019, 207, 108–121. [Google Scholar]

- Antov, P.; Savov, V.; Neykov, N. Utilization of Agricultural Waste and Wood Industry Residues in the Production of Natural Fiber-Reinforced Composite Materials. Int. J. Wood Des. Technol. 2018, 6, 64–71. [Google Scholar]

- Bartoli, M.; Giorcelli, M.; Tagliaferro, A. Morphology and Mechanical Properties of Epoxy/Synthetic Fiber Composites. In Handbook of Epoxy/Fiber Composites; Springer: Berlin/Heidelberg, Germany, 2021; pp. 1–24. [Google Scholar]

- Karthi, N.; Kumaresan, K.; Sathish, S.; Gokulkumar, S.; Prabhu, L.; Vigneshkumar, N. An overview: Natural fiber reinforced hybrid composites, chemical treatments and application areas. Mater. Today Proc. 2020, 27, 2828–2834. [Google Scholar] [CrossRef]

- El-Wazery, M.S.; El-Elamy, M.I.; Zoalfakar, S.H. Mechanical Properties Of Glass Fiber Reinforced Polyester Composites. Int. J. Appl. Sci. Eng. 2017, 14, 121–131. [Google Scholar]

- Ertekin, M. 7-Aramid fibers. In Fiber Technology for Fiber-Reinforced Composites; Woodhead Publishing: Philadelphia, PA, USA, 2017; pp. 153–167. [Google Scholar]

- Thomason, J.L. Glass fibre sizing: A review. Compos. Part A Appl. Sci. Manuf. 2019, 127, 105619. [Google Scholar] [CrossRef]

- Koohestani, A.S.; Bashari, A. Chapter 12-Advanced bulletproof and stab- and spike-resistant textiles. In Advances in Functional and Protective Textiles; Woodhead Publishing: Philadelphia, PA, USA, 2020; pp. 261–289. [Google Scholar]

- Tanzi, M.C.; Fare, S.; Candiani, G. Organization, Structure, and Properties of Materials. Found. Biomater. Eng. 2019, 3–103. [Google Scholar]

- Bhatt, P.; Goe, A. Carbon Fibres: Production, Properties and Potential Use. Mater. Sci. Res. India 2017, 14, 52–57. [Google Scholar] [CrossRef]

- Park, S.-J. History and Structure of Carbon Fibers; Springer: Berlin/Heidelberg, Germany, 2018; pp. 1–30. [Google Scholar]

- Varley, D.; Yousaf, S.; Youseffi, M.; Mozafari, M.; Khurshid, Z.; Sefat, F. Fiber-reinforced composites. In Advanced Dental Biomaterials; Elsevier: Berlin/Heidelberg, Germany, 2019; pp. 301–315. [Google Scholar]

- Bermudez, V.; Lukubira, S.; Ogale, A.A. 1.3 Pitch Precursor-Based Carbon Fibers. In Comprehensive Composite Materials II; Elsevier: Oxford, UK, 2018; pp. 41–65. [Google Scholar]

- Jesthi, D.K.; Nayak, R.K. Evaluation of mechanical properties and morphology of seawater aged carbon and glass fiber reinforced polymer hybrid composites. Compos. Part B Eng. 2019, 174, 106980. [Google Scholar] [CrossRef]

- Selmy, A.I.; Abd El-baky, M.A.; Hegazy, D.A. Mechanical properties of inter-ply hybrid composites reinforced with glass and polyamide fibers. J. Thermoplast. Compos. Mater. 2018, 32, 267–293. [Google Scholar] [CrossRef]

- Hassan, M.Z.; Rasid, Z.A.; Dolah, R.; Sapuan, S.; Fadzullah, S.H.S.M. Crashworthiness Measurement on Axial Compression Loading of Biocomposite Structures: Prospect Development. In Value-Added Biocomposites; CRC Press: Boca Raton, FL, USA, 2021; pp. 103–123. [Google Scholar]

- Czech, K.; Oliwa, R.; Krajewski, D.; Bulanda, K.; Oleksy, M.; Budzik, G.; Mazurkow, A. Hybrid Polymer Composites Used in the Arms Industry: A Review. Materials 2021, 14, 3047. [Google Scholar] [CrossRef]

- Kröger, H.; Mock, S.; Greb, C.; Gries, T. Damping Properties of Hybrid Composites Made from Carbon, Vectran, Aramid and Cellulose Fibers. J. Compos. Sci. 2022, 6, 13. [Google Scholar] [CrossRef]

- Bandaru, A.K.; Patel, S.; Ahmad, S.; Bhatnagar, N. An experimental and numerical investigation on the low velocity impact response of thermoplastic hybrid composites. J. Compos. Mater. 2017, 52, 877–889. [Google Scholar] [CrossRef]

- Dalfi, H.; Al-Obaidi, A.J.; Razaq, H. The influence of the inter-ply hybridisation on the mechanical performance of composite laminates: Experimental and numerical analysis. Sci. Prog. 2021, 104, 00368504211023285. [Google Scholar] [CrossRef]

- Cagri, U.; Mete Han, B.; Melih, B.; Necdet, G. Effect of post-curing heat treatment on mechanical properties of fiber reinforced polymer (FRP) composites. Mater. Test. 2017, 59, 366–372. [Google Scholar]

- Haris, N.I.N.; Ilyas, R.A.; Hassan, M.Z.; Sapuan, S.M.; Afdzaluddin, A.; Jamaludin, K.R.; Zaki, S.A.; Ramlie, F. Dynamic Mechanical Properties and Thermal Properties of Longitudinal Basalt/Woven Glass Fiber Reinforced Unsaturated Polyester Hybrid Composites. Polymers 2021, 13, 3343. [Google Scholar] [CrossRef] [PubMed]

- Arjun, K.P.; de Barros, S.; Budhe, S. Theoretical determination of elastic and flexural modulus for inter-ply and intra-ply hybrid composite material. Compos. Struct. 2022, 281, 114971. [Google Scholar] [CrossRef]

- Wu, W.; Wang, Q.; Li, W. Comparison of Tensile and Compressive Properties of Carbon/Glass Interlayer and Intralayer Hybrid Composites. Materials 2018, 11, 1105. [Google Scholar] [CrossRef] [Green Version]

- Saba, N.; Jawaid, M. A review on thermomechanical properties of polymers and fibers reinforced polymer composites. J. Ind. Eng. Chem. 2018, 67, 1–11. [Google Scholar] [CrossRef]

- Gupta, M.K. Thermal and dynamic mechanical analysis of hybrid jute/sisal fibre reinforced epoxy composite. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2016, 232, 743–748. [Google Scholar] [CrossRef]

- Ridzuan, M.J.M.; Majid, M.S.A.; Afendi, M.; Mazlee, M.N.; Gibson, A.G. Thermal behaviour and dynamic mechanical analysis of Pennisetum purpureum/glass-reinforced epoxy hybrid composites. Compos. Struct. 2016, 152, 850–859. [Google Scholar] [CrossRef]

- Naveen, J.; Jawaid, M.; Zainudin, E.S.; Sultan, M.T.H.; Yahaya, R.; Abdul Majid, M.S. Thermal degradation and viscoelastic properties of Kevlar/Cocos nucifera sheath reinforced epoxy hybrid composites. Compos. Struct. 2019, 219, 194–202. [Google Scholar] [CrossRef]

- Norizan, M.; Abdan, K.; Sapuan, S.; Rafiqah, S.R.A.I.; Zin, M. Thermal properties of treated sugar palm yarn/glass fiber reinforced unsaturated polyester hybrid composites. J. Mater. Res. Technol. 2020, 9, 1606–1618. [Google Scholar]

- Atiqah, A.; Jawaid, M.; Sapuan, S.M.; Ishak, M.R.; Ansari, M.N.M.; Ilyas, R.A. Physical and thermal properties of treated sugar palm/glass fibre reinforced thermoplastic polyurethane hybrid composites. J. Mater. Res. Technol. 2019, 8, 3726–3732. [Google Scholar] [CrossRef]

- Manuneethi Arasu, P.; Karthikayan, A.; Venkatachalam, R. Mechanical and thermal behavior of hybrid glass/jute fiber reinforced composites with epoxy/polyester resin. Polimery 2019, 64, 504–508. [Google Scholar] [CrossRef]

- Aisyah, H.A.; Paridah, M.T.; Sapuan, S.M.; Khalina, A.; Berkalp, O.B.; Lee, S.H.; Lee, C.H.; Nurazzi, N.M.; Ramli, N.; Wahab, M.S. Thermal properties of woven kenaf/carbon fibre-reinforced epoxy hybrid composite panels. Int. J. Polym. Sci. 2019, 2019, 5258621. [Google Scholar] [CrossRef] [Green Version]

- Thakare, P.A.; Kumar, D.N.; Ugale, D.V. Study of Hybrid FRP Composite Made of Flax and Hemp Fibers with Kevlar. 2020, Volume 6. Available online: https://www.gyanvihar.org/ (accessed on 28 February 2020).

- Ghani, M.U.; Siddique, A.; Abraha, K.G.; Yao, L.; Li, W.; Khan, M.Q.; Kim, I.-S. Performance Evaluation of Jute/Glass-Fiber-Reinforced Polybutylene Succinate (PBS) Hybrid Composites with Different Layering Configurations. Materials 2022, 15, 1055. [Google Scholar] [CrossRef] [PubMed]

- Biricik, G.D.; Celebi, H.; Seyhan, A.T.; Ates, F. Thermal and mechanical properties of flax char/carbon fiber reinforced polyamide 66 hybrid composites. Polym. Compos. 2022, 43, 503–516. [Google Scholar] [CrossRef]

- Karthi, N.; Kumaresan, K.; Sathish, S.; Loganathan, P.; Sivanantham, G.; Balaji, D.; Vigneshkumar, N.; Rohinth, S.; Rafiq, S.; Muniyaraj, S.; et al. Effect of weight fraction on the mechanical properties of flax and jute fibers reinforced epoxy hybrid composites. Mater. Today Proc. 2021, 45, 8006–8010. [Google Scholar] [CrossRef]

- Ismail, A.S.; Jawaid, M.; Sultan, M.T.H.; Hassan, A. Physical and Mechanical Properties of Woven Kenaf/Bamboo Fiber Mat Reinforced Epoxy Hybrid Composites. BioResources 2019, 14, 15. [Google Scholar]

- Pujari, S.; Ramakrishna, A.; Balaram Padal, K.T. Prediction of Swelling Behaviour of Jute and Banana Fiber Composites by using ANN and Regression Analysis. Mater. Today Proc. 2017, 4, 8548–8557. [Google Scholar] [CrossRef]

- Asim, M.; Paridah, M.T.; Saba, N.; Jawaid, M.; Alothman, O.Y.; Nasir, M.; Almutairi, Z. Thermal, physical properties and flammability of silane treated kenaf/pineapple leaf fibres phenolic hybrid composites. Compos. Struct. 2018, 202, 1330–1338. [Google Scholar] [CrossRef]

- Ramesh, M.; Logesh, R.; Manikandan, M.; Kumar, N.S.; Pratap, D.V. Mechanical and Water Intake Properties of Banana-Carbon Hybrid Fiber Reinforced Polymer Composites. Mater. Res. Ibero Am. J. Mater. 2017, 20, 365–376. [Google Scholar] [CrossRef]

- Karimzadeh, A.; Yahya, M.Y.; Abdullah, M.N.; Wong, K.J. Effect of Stacking Sequence on Mechanical Properties and Moisture Absorption Characteristic of Hybrid PALF/Glass Fiber Composites. Fibers Polym. 2020, 21, 1583–1593. [Google Scholar] [CrossRef]

- RaviKumar, P.; Rajeshkumar, G.; Prakash Maran, J.; Al-Dhabi, N.A.; Karuppiah, P. Evaluation of Mechanical and Water Absorption Behaviors of Jute/Carbon Fiber Reinforced Polyester Hybrid Composites. J. Nat. Fibers 2021, 34, 1–13. [Google Scholar] [CrossRef]

- El-Wazery, M.S.; El-Kelity, A.M.; Elsad, R.A. Effect of Water Absorption on the Tensile Characteristics of Natural/ Synthetic Fabrics Reinforced Hybrid Composites. Int. J. Eng. 2020, 33, 2339–2346. [Google Scholar]

- Nasimudeen, N.; Karounamourthy, S.; Selvarathinam, J.; Thiagamani, S.M.K.; Pulikkalparambil, H.; Krishnasamy, S.; Muthukumar, C. Mechanical, Absorption and Swelling Properties of Vinyl Ester Based Natural Fibre Hybrid Composites. Appl. Sci. Eng. Prog. 2021, 14, 680–688. [Google Scholar] [CrossRef]

- Thiagamani, S.M.K.; Krishnasamy, S.; Muthukumar, C.; Tengsuthiwat, J.; Nagarajan, R.; Siengchin, S.; Ismail, S.O. Investigation into mechanical, absorption and swelling behaviour of hemp/sisal fibre reinforced bioepoxy hybrid composites: Effects of stacking sequences. Int. J. Biol. Macromol. 2019, 140, 637–646. [Google Scholar] [CrossRef] [PubMed]

- Mert, Y.; Aderie, N.T.; Ali, K.; Zeki, C. Development and characterization of hybrid composites from sustainable green materials. Green Mater. 2021, 9, 182–191. [Google Scholar]

- Mat Jusoh, M.S.; Israr, H.A.; Yahya, M. Indentation and Low Velocity Impact Properties of Woven E-Glass Hybridization with Basalt, Jute and Flax Toughened Epoxy Composites; IEEE Xplore: New York, NY, USA, 2017; pp. 164–168. [Google Scholar]

- Jamal, S.K.H.S.; Jye, W.K.; Yahya, M.Y. Flexural and interlaminar shear study of hybrid woven kenaf/recycled GFRP (rGFRP) composites subjected to bending load. Int. J. Adv. Appl. Sci. 2017, 4, 45–50. [Google Scholar] [CrossRef] [Green Version]

- Jambari, S.; Yahya, M.; Abdullah, M.; Jawaid, M. Woven Kenaf/Kevlar Hybrid Yarn as Potential Fiber Reinforced for Anti-Ballistic Composite Material. Fibers Polym. 2017, 18, 563–568. [Google Scholar] [CrossRef]

- Mohammed, M.; Rozyanty, A.R.; Adam, T.; Betar, B. Study of the weathering effect in a natural environment on the hybrid kenaf bast/glass fibre-filled unsaturated polyester composite. AIP Conf. Proc. 2017, 1885, 020201. [Google Scholar]

- Mittal, M.; Chaudhary, R. Development of PALF/Glass and COIR/Glass Fiber Reinforced Hybrid Epoxy Composites. J. Mater. Sci. Surf. Eng. 2018, 6, 851–861. [Google Scholar]

- Mostafa, N.; Hunain, M. Mechanical Performance and Vibration Characteristics of Glass/Jute Fibre-Reinforced Polyester Hybrid Composites. Int. J. Mech. Mechatron. Eng. 2019, 19, 40–51. [Google Scholar]

- Rashid, A.; Mohamad, S.; Nasir, K.; Shaari, M.F.; Roslan, M.N.; Marsi, N.; Nasir, S.; Esa, M.; Mahmood, S. Puncture Impact Performance of Coir-Aramid/Epoxy Hybrid Composite: Effects of Stacking Configurations. Int. J. Mech. Eng. Robot. Res. 2019, 8, 368–373. [Google Scholar] [CrossRef]

- Ismail, M.; Rejab, R.; Siregar, J.; Muhamad, Z.; Ma, Q. Tensile Properties of Hybrid Woven Glass Fibre/PALF Reinforced Polymer Composite; Springer: Singapore, 2020; pp. 448–454. [Google Scholar]

- Syed Pauzi, S.M.R.; Suhaimi, S. Alkali Treatment on Hybrid Pineapple Leaf and Glass Fibre Reinforced Epoxy Composites. Malays. J. Sci. Health Technol. 2019, 3. [Google Scholar] [CrossRef]

- Sathiyamoorthy, M.; Senthilkumar, S. Mechanical, thermal, and water absorption behaviour of jute/carbon reinforced hybrid composites. Sādhanā 2020, 45, 1–12. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Nasir, M.A.; Ali, A.; Al Rashid, A.; Khan, M.R. Experimental and numerical characterization of tensile property of jute/carbon fabric reinforced epoxy hybrid composites. SN Appl. Sci. 2020, 2, 577. [Google Scholar] [CrossRef] [Green Version]

- Venkatasudhahar, M.; Paleti, K.; Raja, D. Influence of stacking sequence and fiber treatment on mechanical properties of carbon-jute-banana reinforced epoxy hybrid composites. Int. J. Polym. Anal. Charact. 2020, 25, 1–14. [Google Scholar] [CrossRef]

- Chandramohan, D.; Manickam, D.; Sathish, T.; Kumar, S. Characterization of hybrid Aloe Vera/Bamboo/Palm/Kevlar fibers for better mechanical properties. Mater. Today Proc. 2020, 37, 2223–2227. [Google Scholar] [CrossRef]

- Hashim, M.K.R.; Abdul Majid, M.S.; Jamir, M.R.M.; Kasim, F.H.; Sultan, M.T.H. The Effect of Stacking Sequence and Ply Orientation on the Mechanical Properties of Pineapple Leaf Fibre (PALF)/Carbon Hybrid Laminate Composites. Polymers 2021, 13, 455. [Google Scholar] [CrossRef]

- Banu, M.; Madhavan, V.; Manickam, D.; Devarajan, C. Experimental investigation on stacking sequence of Kevlar and natural fibres/epoxy polymer composites. Polímeros 2021, 31. [Google Scholar] [CrossRef]

- Muthalagu, R.; Murugesan, J.; Sathees Kumar, S.; Sridhar Babu, B. Tensile attributes and material analysis of kevlar and date palm fibers reinforced epoxy composites for automotive bumper applications. Mater. Today Proc. 2021, 46, 433–438. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Sultan, M.T.H. An Overview of Mechanical and Physical Testing of Composite Materials; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–12. [Google Scholar]

- Suhot, M.A.; Hassan, M.Z.; Aziz, S.a.A.; Daud, M.Y. Recent Progress of Rice Husk Reinforced Polymer Composites: A Review. Polymers 2021, 13, 2391. [Google Scholar] [CrossRef]

- Wang, A.; Wang, X.; Xian, G. Mechanical, low-velocity impact, and hydrothermal aging properties of flax/carbon hybrid composite plates. Polym. Test. 2020, 90, 106759. [Google Scholar] [CrossRef]

- Rihayat, T.; Suryani, S.; Fauzi, T.; Agusnar, H.; Wirjosentono, B.; Syafruddin; Helmi; Zulkifli; Alam, P.N.; Sami, M. Mechanical properties evaluation of single and hybrid composites polyester reinforced bamboo, PALF and coir fiber. IOP Conf. Ser. Mater. Sci. Eng. 2018, 334, 012081. [Google Scholar] [CrossRef] [Green Version]

- Abidin, N.; Sultan, M.; Md Shah, A.; Safri, S. Charpy and Izod impact properties of natural fibre composites. IOP Conf. Ser. Mater. Sci. Eng. 2019, 670, 012031. [Google Scholar] [CrossRef]

- Navaranjan, N.; Neitzert, T. Impact Strength of Natural Fibre Composites Measured by Different Test Methods: A Review. MATEC Web Conf. 2017, 109, 01003. [Google Scholar] [CrossRef] [Green Version]

- Pham, T.M.; Hao, H. Review of concrete structures strengthened with FRP against impact loading. In Structures; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Yap, C.; Ming, T.; Wong, K.J.; Israr, H.A. Mechanical properties of bamboo and bamboo composites: A Review. J. Adv. Res. Mater. Sci. 2017, 35, 7–26. [Google Scholar]

- Erkliğ, A.; Bulut, M. Experimental investigation on tensile and Charpy impact behavior of Kevlar/S-glass/epoxy hybrid composite laminates. J. Polym. Eng. 2017, 37, 177–184. [Google Scholar] [CrossRef]

- Wang, B.; He, B.; Wang, Z.; Qi, S.; Zhang, D.; Tian, G.; Wu, D. Enhanced Impact Properties of Hybrid Composites Reinforced by Carbon Fiber and Polyimide Fiber. Polymers 2021, 13, 2599. [Google Scholar] [CrossRef]

- Kannan, R.; Aidy, A.; Muhadir, S. Evaluation the Effect of Laminated Layer Sequence of Plain-Woven Bamboo on Tensile and Impact Performance of E-glass Woven/Epoxy Hybrid Composites. Int. J. Integr. Eng. 2021, 13, 194–200. [Google Scholar]

- Thakur, A.; Purohit, R.; Rana, R.S.; Bandhu, D. Characterization and Evaluation of Mechanical Behavior of Epoxy-CNT-Bamboo Matrix Hybrid Composites. Mater. Today Proc. 2018, 5 Pt 1, 3971–3980. [Google Scholar] [CrossRef]

- Jogi, S.A.; Moazam Baloch, M.; Chandio, A.D.; Memon, I.A.; Chandio, G.S. Evaluation of Impact Strength of Epoxy Based Hybrid Composites Reinforced with E-Glass/Kevlar 49. Mehran Univ. Res. J. Eng. Technol. 2017, 36, 1009–1016. [Google Scholar] [CrossRef]

- da Vieira, S.J.; Lopes, F.P.D.; de Moraes, Y.M.; Monteiro, S.N.; Margem, F.M.; Margem, J.I.; Souza, D. Comparative Mechanical Analysis of Epoxy Composite Reinforced with Malva/Jute Hybrid Fabric by Izod and Charpy Impact Test; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar]

- Wagih, A.; Sebaey, T.A.; Yudhanto, A.; Lubineau, G. Post-impact flexural behavior of carbon-aramid/epoxy hybrid composites. Compos. Struct. 2020, 239, 112022. [Google Scholar] [CrossRef]

- Sharma, K.K.; Shrivastava, Y.; Neha, E.; Singh, B.; Jain, A. Investigation of flexural properties of fabricated hybrid fibres reinforced composites. AIP Conf. Proc. 2021, 2317, 020016. [Google Scholar]

- Margabandu, S.; Subramaniam, S.K. Experimental evaluation and numerical validation of bending and impact behaviours of hybrid composites with various stacking arrangements. Mater. Res. Express 2019, 6, 125305. [Google Scholar] [CrossRef]

- Nagaraja, K.C.; Rajanna, S.; Prakash, G.S.; Koppad, P.G.; Alipour, M. Studying the effect of different carbon and glass fabric stacking sequence on mechanical properties of epoxy hybrid composite laminates. Compos. Commun. 2020, 21, 100425. [Google Scholar] [CrossRef]

- Ary Subagia, I.D.G.; Kim, Y.; Tijing, L.D.; Kim, C.S.; Shon, H.K. Effect of stacking sequence on the flexural properties of hybrid composites reinforced with carbon and basalt fibers. Compos. Part B Eng. 2014, 58, 251–258. [Google Scholar] [CrossRef]

- Sadashiva, M.; Praveen Kumar, S.; Yathish, M.K.; Satish, V.T.; Srinivasa, M.R.; Sharanraj, V. Experimental investigation of bending characteristics of hybrid composites fabricated by hand layup method. J. Phys. Conf. Ser. 2021, 2089, 012033. [Google Scholar] [CrossRef]

- Indra Reddy, M.; Anil Kumar, M.; Rama Bhadri Raju, C. Tensile and Flexural properties of Jute, Pineapple leaf and Glass Fiber Reinforced Polymer Matrix Hybrid Composites. Mater. Today Proc. 2018, 5 Pt 1, 458–462. [Google Scholar] [CrossRef]

- Ramana, M.V.; Ramprasad, S. Experimental Investigation on Jute/Carbon Fibre reinforced Epoxy based Hybrid Composites. Mater. Today Proc. 2017, 4, 8654–8664. [Google Scholar] [CrossRef]

- Abd El-baky, M.A.; Attia, M.A. Water absorption effect on the in-plane shear properties of jute–glass–carbon-reinforced composites using Iosipescu test. J. Compos. Mater. 2019, 53, 3033–3045. [Google Scholar] [CrossRef]

- Vajjiram, S.; Ramachandran, D.; Chandrasekaran, D.M.; Narayanan, V.; Baskar, S. Experimental investigation on the mechanical properties of woven hybrid fiber reinforced epoxy composite. Mater. Today Proc. 2020, 37, 1850–1853. [Google Scholar]

- Babu, S.; Kumar, K.; JayaChristiyan, K. Studies on factors influencing Low Velocity Impact of Composite Materials—A Review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1126, 012079. [Google Scholar]

- Chok, E.; Abang Haji Abdul Majid, D.L.; Harmin, M. Effect of low velocity impact damage on the natural frequency of composite plates. IOP Conf. Ser. Mater. Sci. Eng. 2017, 270, 012025. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Sarasini, F.; Tirilló, J.; Calabrese, L. Salt-fog spray aging of jute-basalt reinforced hybrid structures: Flexural and low velocity impact response. Compos. Part B Eng. 2017, 116, 99–112. [Google Scholar] [CrossRef]

- Zivkovic, I.; Fragassa, C.; Pavlovic, A.; Brugo, T. Influence of moisture absorption on the impact properties of flax, basalt and hybrid flax/basalt fiber reinforced green composites. Compos. Part B Eng. 2016, 111, 148–164. [Google Scholar] [CrossRef]

- Fragassa, C.; Pavlovic, A.; Santulli, C. Mechanical and impact characterisation of flax and basalt fibre vinylester composites and their hybrids. Compos. Part B Eng. 2018, 137, 247–259. [Google Scholar] [CrossRef]

- Gemi, L. Investigation of the effect of stacking sequence on low velocity impact response and damage formation in hybrid composite pipes under internal pressure. A comparative study. Compos. Part B Eng. 2018, 153, 217–232. [Google Scholar] [CrossRef]

- Dhar Malingam, S.; Ng, L.F.; Chan, K.; Subramaniam, K.; Selamat, M.; Zakaria, K.A. The Static and Dynamic Mechanical Properties of Kenaf/Glass Fibre Reinforced Hybrid Composites. Mater. Res. Express 2018, 5, 095304. [Google Scholar] [CrossRef]

- Salman, S.; Leman, Z.; Ishak, M.; Sultan, M.T.H.; Cardona, F. Quasi-static penetration behavior of plain woven kenaf/aramid reinforced polyvinyl butyral hybrid laminates. J. Ind. Text. 2017, 47, 152808371769259. [Google Scholar] [CrossRef]

- Nor, A.F.M.; Sultan, M.T.H.; Hamdan, A.; Azmi, A.; Kandasamy, J. Hybrid Composites Based On Kenaf, Jute, Fiberglass Woven Fabrics: Tensile And Impact Properties. Mater. Today Proc. 2018, 5, 11198–11207. [Google Scholar] [CrossRef]

- Al-Hajaj, Z.; Sy, B.; Bougherara, H.; Zdero, R. Impact Properties of a New Hybrid Composite Material made from Woven Carbon Fibres plus Flax Fibres in an Epoxy Matrix. Compos. Struct. 2018, 208, 346–356. [Google Scholar] [CrossRef]

- Chen, D.; Luo, Q.; Meng, M.; Li, Q.; Sun, G. Low velocity impact behavior of interlayer hybrid composite laminates with carbon/glass/basalt fibres. Compos. Part B Eng. 2019, 176, 1359–8368. [Google Scholar] [CrossRef]

- Ismail, M.; Hameed Sultan, M.T.; Hamdan, A.; Md Shah, A.; Jawaid, M. Low velocity impact behaviour and post-impact characteristics of kenaf/glass hybrid composites with various weight ratios. J. Mater. Res. Technol. 2019, 8, 2662–2673. [Google Scholar] [CrossRef]

- Subramaniam, K.; Dhar Malingam, S.; Ng, L.F.; Bapokutty, O. The Effects of Stacking Configuration on the Response of Tensile and Quasi-Static Penetration to Woven Kenaf/Glass Hybrid Composite Metal Laminate. Polym. Compos. 2019, 40, 568–577. [Google Scholar] [CrossRef]

- Ravandi, M.; Kureemun, U.; Banu, M.; Teo, W.S.; Tong, L.; Tay, T.E.; Lee, H.P. Effect of interlayer carbon fiber dispersion on the low-velocity impact performance of woven flax-carbon hybrid composites. J. Compos. Mater. 2018, 53, 1717–1734. [Google Scholar] [CrossRef]

- Prasath, A.; Pandian, A.; Arumugaprabu, V.; Vairavan, M. Low velocity impact and compression after impact damage responses on flax/basalt fiber hybrid composites. Mater. Res. Express 2019, 6, 115308. [Google Scholar] [CrossRef]

- Ng, L.F.; Dhar Malingam, S.; Subramaniam, K.; Selamat, M.; Juan, W. The investigation of the tensile and quasi-static indentation properties of pineapple leaf/kevlar fibre reinforced hybrid composites. Def. S T Tech. Bull. 2020, 13, 117–129. [Google Scholar]

- Zulkafli, N.; Dhar Malingam, S.; Sheikh Fadzullah, S.; Razali, N. Quasi and dynamic impact performance of hybrid cross-ply banana/glass fibre reinforced polypropylene composites. Mater. Res. Express 2019, 6, 125344. [Google Scholar] [CrossRef]

- Ismail, K.I.; Sultan, M.T.H.; Shah, A.U.M.; Jawaid, M.; Safri, S.N.A. Low velocity impact and compression after impact properties of hybrid bio-composites modified with multi-walled carbon nanotubes. Compos. Part B Eng. 2019, 163, 455–463. [Google Scholar] [CrossRef]

- Farhan, A.; Sultan, M.; Jawaid, M.; Azmi, A.; Md Shah, A. Analysing impact properties of CNT filled bamboo/glass hybrid nanocomposites through drop-weight impact testing, UWPI and compression-after-impact behaviour. Compos. Part B Eng. 2018, 168, 166–174. [Google Scholar]

- Selver, E.; Dalfi, H.; Yousaf, Z. Investigation of the impact and post-impact behaviour of glass and glass/natural fibre hybrid composites made with various stacking sequences: Experimental and theoretical analysis. J. Ind. Text. 2020, 51, 1528083719900670. [Google Scholar] [CrossRef]

- Paturel, A.; Dhakal, H. Influence of Water Absorption on the Low Velocity Falling Weight Impact Damage Behaviour of Flax/Glass Reinforced Vinyl Ester Hybrid Composites. Molecules 2020, 25, 278. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bhanupratap, R. Impact damage resistance of Jute/Kevlar hybrid composite laminates subjected to varying heights: An experimental approach. Mater. Today Proc. 2021, 39, 1396–1401. [Google Scholar] [CrossRef]

- Md Shah, A.U.; Hameed Sultan, M.T.; Safri, S.N.A. Experimental Evaluation of Low Velocity Impact Properties and Damage Progression on Bamboo/Glass Hybrid Composites Subjected to Different Impact Energy Levels. Polymers 2020, 12, 1288. [Google Scholar] [CrossRef] [PubMed]

- Amir, M.; Irmawaty, R.; Hustim, M.; Rahim, I.R. Tensile strength of glass fiber-reinforced waste PET and Kenauf hybrid composites. IOP Conf. Ser. Earth Environ. Sci. 2020, 419, 012061. [Google Scholar] [CrossRef]

- Ferrante, L.; Sergi, C.; Tirillò, J.; Russo, P.; Calzolari, A.; Sarasini, F. Temperature effect on the single and repeated impact responses of intraply flax/basalt hybrid polypropylene composites. Polym. Compos. 2021, 42, 4397–4411. [Google Scholar] [CrossRef]

- Basha, M.; Wagih, A.; Melaibari, A.; Lubineau, G.; Abdraboh, A.M.; Eltaher, M.A. Impact and post-impact response of lightweight CFRP/wood sandwich composites. Compos. Struct. 2022, 279, 114766. [Google Scholar] [CrossRef]

- Mahesh, V.; Sharnappa, J.; Kulkarni, S.M. Study on Stacking Sequence of Plies in Green Sandwiches for Low Velocity Impact Application. Key Eng. Mater. 2019, 801, 59–64. [Google Scholar] [CrossRef]

- Santulli, C. Mechanical and Impact Damage Analysis on Carbon/Natural Fibers Hybrid Composites: A Review. Materials 2019, 12, 517. [Google Scholar] [CrossRef] [Green Version]

- Muhammad Amir, S.M.; Hameed Sultan, M.T.; Md Shah, A.U.; Jawaid, M.; Safri, S.N.A.; Mohd, S.; Mohd Salleh, K.A. Low Velocity Impact and Compression after Impact Properties on Gamma Irradiated Kevlar/Oil Palm Empty Fruit Bunch Hybrid Composites. Coatings 2020, 10, 646. [Google Scholar] [CrossRef]

- Mohd Sabee, S.S.N.; Yusof, N.; Rasid, Z.A.; Yahaya, H.; Yakub, F.; Hassan, M.Z. Progressive failure analysis of laminated composite plates. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1051, 012041. [Google Scholar] [CrossRef]

- Gholizadeh, S. A review of impact behaviour in composite materials. Int. J. Mech. Prod. Eng. 2019, 7, 2320-2092. [Google Scholar]

- Papa, I.; Ricciardi, M.R.; Antonucci, V.; Pagliarulo, V.; Lopresto, V. Impact behaviour of hybrid basalt/flax twill laminates. Compos. Part B Eng. 2018, 153, 17–25. [Google Scholar] [CrossRef]

- Ali, A.; Nasir, M.A.; Khalid, M.Y.; Nauman, S.; Shaker, K.; Khushnood, S.; Altaf, K.; Zeeshan, M.; Hussain, A. Experimental and numerical characterization of mechanical properties of carbon/jute fabric reinforced epoxy hybrid composites. J. Mech. Sci. Technol. 2019, 33, 4217–4226. [Google Scholar] [CrossRef]

- Barouni, A.K.; Dhakal, H.N. Damage investigation and assessment due to low-velocity impact on flax/glass hybrid composite plates. Compos. Struct. 2019, 226, 111224. [Google Scholar] [CrossRef]

- Fazio, D.; Cuomo, S.; Boccarusso, L.; Pinto, F.; Durante, M.; Meo, M. Design and characterization of hybrid hemp/carbon laminates with improved impact resistance. Mater. Today Proc. 2020, 34, 194–201. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Ferrante, L.; Sergi, C.; Russo, P.; Simeoli, G.; Cimino, F.; Ricciardi, M.R.; Antonucci, V. Quasi-Static and Low-Velocity Impact Behavior of Intraply Hybrid Flax/Basalt Composites. Fibers 2019, 7, 26. [Google Scholar] [CrossRef] [Green Version]

- Chapman, M.; Dhakal, H. Effects of Hybridisation on the Low Velocity Falling Weight Impact and Flexural Properties of Flax-Carbon/Epoxy Hybrid Composites. Fibers 2019, 7, 95. [Google Scholar] [CrossRef] [Green Version]

- Ridzuan, M.J.M.; Abdul Majid, M.S.; Khasri, A.; Gan, E.H.D.; Razlan, Z.M.; Syahrullail, S. Effect of pineapple leaf (PALF), napier, and hemp fibres as filler on the scratch resistance of epoxy composites. J. Mater. Res. Technol. 2019, 8, 5384–5395. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Méner, E.L.; Feldner, M.; Jiang, C.; Zhang, Z. Falling Weight Impact Damage Characterisation of Flax and Flax Basalt Vinyl Ester Hybrid Composites. Polymers 2020, 12, 806. [Google Scholar] [CrossRef] [Green Version]

- Boria, S.; Santulli, C.; Raponi, E.; Sarasini, F.; Tirillò, J. Analytical modeling and experimental validation of the low-velocity impact response of hemp and hemp/glass thermoset composites. J. Compos. Mater. 2019, 54, 409–421. [Google Scholar] [CrossRef]

- Karamooz, M.R.; Rahmani, H.; Khosravi, H. Hybrid Effects of Basalt and Kevlar Fibers on Low-velocity Impact Behavior of Epoxy-based Composites. Fibers Polym. 2020, 21, 2590–2598. [Google Scholar] [CrossRef]

- Hassan, M.Z.; Sapuan, S.M.; Rasid, Z.A.; Nor, A.F.M.; Dolah, R.; Md Daud, M.Y. Impact Damage Resistance and Post-Impact Tolerance of Optimum Banana-Pseudo-Stem-Fiber-Reinforced Epoxy Sandwich Structures. Appl. Sci. 2020, 10, 684. [Google Scholar] [CrossRef] [Green Version]

- Nabeel, M.; Nasir, M.A.; Sattar, M.; Malik, R.A.; Alzaid, M.; Butt, M.S.; Saleem, M.; Alrobei, H. Numerical and experimental evaluation of the mechanical behavior of Kevlar/glass fiber reinforced epoxy hybrid composites. J. Mech. Sci. Technol. 2020, 34, 4613–4619. [Google Scholar] [CrossRef]

- Najeeb, M.I.; Hameed Sultan, M.T.; Md Shah, A.U.; Muhammad Amir, S.M.; Safri, S.N.A.; Jawaid, M.; Shari, M.R. Low-Velocity Impact Analysis of Pineapple Leaf Fiber (PALF) Hybrid Composites. Polymers 2021, 13, 3194. [Google Scholar] [CrossRef] [PubMed]

- Hoekstra, B.; Shekarian, A.; Kolasangiani, K.; Oguamanam, D.C.D.; Zitoune, R.; Bougherara, H. Effect of machining processes on the damage response and surface quality of open hole hybrid carbon/flax composites: An experimental study. Compos. Struct. 2022, 285, 115244. [Google Scholar] [CrossRef]

- Rajaei, M.; Kim, N.K.; Bhattacharyya, D. Effects of heat-induced damage on impact performance of epoxy laminates with glass and flax fibres. Compos. Struct. 2018, 185, 515–523. [Google Scholar] [CrossRef]

- Valença, S.L.; Griza, S.; Gomes de Oliveira, V.; Sussuchi, E.M.; Carvalho de Cunha, F.G. Evaluation of the mechanical behavior of epoxy composite reinforced with Kevlar plain fabric and glass/Kevlar hybrid fabric. Compos. Part B Eng. 2015, 70, 1–8. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Fatimah Athiyah, S.; Shazleen, S.S.; Rafiqah, S.A.; Harussani, M.M.; Kamarudin, S.H.; Razman, M.R.; Rahmah, M.; Zainudin, E.S.; et al. A Review on Mechanical Performance of Hybrid Natural Fiber Polymer Composites for Structural Applications. Polymers 2021, 13, 2170. [Google Scholar] [CrossRef]

- Kasim, F.M.; Roslan, S.; Rasid, Z.; Yakub, F.; Hassan, M.; Yahaya, H. Post-buckling of bamboo reinforced composite plates. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021. [Google Scholar]

- Bodie, M.; Russell, G.; McCarthy, K.; Lucas, E.; Zumberge, J.; Wolff, M. Thermal analysis of an integrated aircraft model. In Proceedings of the 48th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2010. [Google Scholar]

- Ashikhmina, E.R.; Ageyeva, T.G.; Prosuntsov, P.V. Hybrid composites in reusable space vehicles wing structures. IOP Conf. Ser. Mater. Sci. Eng. 2019, 683, 012067. [Google Scholar] [CrossRef]

- Haris, M.Y.M. Applicability of kenaf-based hybrid composite for aircraft radome. In Faculty of Engineering; Universiti Putra Malaysia: Serdang, Malaysia, 2014; pp. 1–104. [Google Scholar]

- Chinvorarat, S. Composite wing structure of light amphibious airplane design, optimization, and experimental testing. Heliyon 2021, 7, e08410. [Google Scholar] [CrossRef]

- Sushma Chinta, V.; Reddy, P.R.; Prasad, K.E.; Vadapally, K.S.; Anand, S.; Sai Kiran, B. Characterization of Glass/Jute Hybrid Fibre Reinforced Epoxy Composite for Axial Flow Fan Blade. J. Polym. Compos. 2019, 7, 3. [Google Scholar] [CrossRef]

- Ravishankar, B.; Nayak, S.K.; Kader, M.A. Hybrid composites for automotive applications—A review. J. Reinf. Plast. Compos. 2019, 38, 835–845. [Google Scholar]

- Ahmad Sabri, A.S.A.a.A.R.; Zainudin, H.; Mohamad, Z. Failure of steel helical gear used for automotive transmission. J. Adv. Res. Mater. Sci. 2017, 37, 1–9. [Google Scholar]

- Rana, R.S.; Nigrawal, A.; Rana, S.; Purohit, R. Design and development of epoxy hybrid composite gears for low-powered application. Adv. Mater. Processing Technol. 2020, 6, 328–337. [Google Scholar] [CrossRef]

- Abdul Wahab, M.A.F.; Sapuan, S.M.; Saleh, A.; Mohamed Yusoff, M.Z. Conceptual Design of Glass/Renewable Natural Fibre-Reinforced Polymer Hybrid Composite Motorcycle Side Cover. J. Renew. Mater. 2021, 9, 1973–1989. [Google Scholar] [CrossRef]

- Anaidhuno, U.P.; Edelugo, S.O.; Nwobi-Okoye, C.C. Evaluation of the Mechanical Properties and Simulation of Sisal/Jute Hybrid Polymer Composite Failure in Automobile Chassis Panel. Evaluation 2017, 7, 9744. [Google Scholar]

- Das, P.P.; Chaudhary, V.; Kumar Singh, R.; Singh, D.; Aditya Bachchan, A. Advancement in hybrid materials, its applications and future challenges: A review. Mater. Today Proc. 2021, 47, 3794–3801. [Google Scholar] [CrossRef]

- Salman, S.D. Kenaf-Ramid fiber-reinforced polyvinyl butyral hybrid composites for military helmet. In Faculty of Engineering; Universiti Putra Malaysia: Putra, Malaysia, 2017; p. 136. [Google Scholar]

- Azmi, A.M.R.; Sultan, M.T.H.; Jawaid, M.; Nor, A.F.M. 9-A newly developed bulletproof vest using kenaf–X-ray film hybrid composites. In Mechanical and Physical Testing of Biocomposites Fibre-Reinforced Composites and Hybrid Composites; Woodhead Publishing: Philadelphia, PA, USA, 2019; pp. 157–169. [Google Scholar]

- Petre, R.; Zecheru, T.; Petrea, N.; Ginghina, R.; Sandu, S.; Muresan, M.; Matache, L.C.; Sava, A.C.; Neatu, F. Synthesis and Mechanical Properties of Polyurea-Based Hybrid Composites for Ballistic Individual Protection. Mater. Plast. 2018, 55, 315. [Google Scholar] [CrossRef]

- Kumar, A.P. Recent Advances of Hybrid Fiber Composites for Various Applications; Wiley: Hoboken, NJ, USA, 2020; pp. 381–404. [Google Scholar]

- Swolfs, Y. Perspective for Fibre-Hybrid Composites in Wind Energy Applications. Materials 2017, 10, 1281. [Google Scholar] [CrossRef] [Green Version]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [Green Version]

- Atmakuri, A.; Palevicius, A.; Vilkauskas, A.; Janusas, G. Review of Hybrid Fiber Based Composites with Nano Particles—Material Properties and Applications. Polymers 2020, 12, 2088. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.W. Prospects and Future Directions of Self-Healing Fiber-Reinforced Composite Materials. Polymers 2020, 12, 379. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Natural Fibre | Animal | Animal Hair | Wool, human hair, feather |

| Silk | |||

| Mineral | Asbestos | Amosite, crocidolite, Tremolite, Actinolite, Anthophyllite | |

| Plant | Bast Fibre | Flax, Ramie, Hemp | |

| Leaf Fibre | Sisal, Pineapple | ||

| Seed Fibre | Cotton | ||

| Fruit Fibre | Coir | ||

| Stalk Fibre | Rice |

| Natural Fibre | Cellulose | Hemicellulose | Lignin | Ash | MC | References |

|---|---|---|---|---|---|---|

| Banana | 60–65 | 6–8 | 5–10 | 2.7–10.2 | 10–15 | [26] |

| Cotton | 89–96 | 2.3 | 0.2–0.5 | 0.6–1.5 | 0.5–0.8 | [27] |

| Bamboo | 73.83 | 12.49 | 10.15 | 9.6 | 3.16 | [28] |

| Bagasse | 55.2 | 16.8 | 25.3 | 1.5–5 | 8.8 | [29] |

| Hemp | 68 | 15 | 10 | 0.8 | 6.2–12 | [29] |

| Kenaf | 45–57 | 21.5 | 8–13 | - | - | [30] |

| Pineapple | 70–80 | 18.8 | 12.7 | 0.9–1.2 | 11.8 | [30] |

| Flax | 71 | 18.6–20.6 | 2.2 | - | 8–12 | [29] |

| Natural Fibre | Density (g/cm3) | Tensile Strength (MPa) | Elongation (%) | Elastic Modulus (GPa) | References |

|---|---|---|---|---|---|

| Banana | 1.35 | 529–914 | 2.6–5.9 | 27–32 | [35] |

| Cotton | 1.51 | 400 | 3–10 | 12 | [36] |

| Bamboo | 1.5 | 575 | 3 | 27 | [37] |

| Bagasse | 1.25 | 290 | 2.11 | 11 | [38] |

| Hemp | 1.47 | 690 | 2.38 | 70 | [39] |

| Kenaf | 1.45 | 930 | 1.6 | 53 | [40] |

| Pineapple | 1.5 | 900–1600 | 3.0 | 70–82 | [41] |

| Flax | 1.4 | 1400 | 1.6 | 70 | [42] |

| Jue | 1.5 | 393–1000 | 2.5 | 13–54 | [43] |

| Sisal | 1.33–1.5 | 80–855 | 2.14 | 9–22 | [44] |

| Advantages | Disadvantages |

|---|---|

| Renewable resources | Inhomogeneous structure of fibres |

| Lower production costs | Dimensional instability as a negative consequence of water absorption |

| Good specific mechanical properties | Lower water and thermal resistance |

| Lower density of composites | Susceptibility to microbial attacks and rotting |

| Reduced energy consumption during manufacturing | Insufficient adhesion and incompatibility with the polymer matrix |

| Biodegradability and eco-friendly materials | Degradation and aging |

| Lower risk to human health | Restricted processing temperature (to avoid thermal degradation) |

| Synthetic Fibers | Density (g/cm3) | Tensile Strength (MPa) | Tensile Modulus (GPa) | Elongation (%) |

|---|---|---|---|---|

| Aramid | 1.4 | 3000–3150 | 63–67 | 3.3–3.7 |

| Glass fiber | ||||

| E-glass | 2.5 | 2000–3500 | 70 | 2.5 |

| S-glass | 4570 | 86 | 2.8 | |

| Carbon fiber | 1.4 | 4000 | 230–240 | 1.4–1.8 |

| Hybrid Fibre | Thermogravimetric Analysis (TGA) | Differential Scanning Calorimetric (DSC) | References | |||

|---|---|---|---|---|---|---|

| Initial Degradation Temperature IDT (°C) | Final Degradation Temperature FDT (°C) | Final Residue (%) | Tg | Td | ||

| Pennisetum purpureum/glass | 76.30–121.10 | 440–534 | 1.6–22.9 | 64 | [71] | |

| Cocos nucifera/glass | 100–150 | 500 | 11–24 | 70–80 | 350–400 | [72] |

| Sugar palm/glass | 299–340 | 360–400 | 7–16 | 82.50 | 80–130 | [73] |

| Sugar palm/glass | 138–156 | 440–534 | 5 | [74] | ||

| Jute/glass | 270–300 | 300–336 | 100 | [75] | ||

| Kenaf/Carbon | 341334 | 315–390 | 13–54 | 100 | [76] | |

| Kevlar/jute/flax/hemp/sisal | 210 | 340 | 30–51 | 90–105 | 400 | [77] |

| Jute/Glass | 318–390 | 437–439 | 6–46 | [78] | ||

| Flax/Carbon | 600 | 41 | 80 | 240 | [79] | |

| Matrix | Fiber | Parametric | Tensile Strength (MPa) | Tensile Modulus (GPa) | Flexural Strength (MPa) | Impact Strength (k/Jm2) | References |

|---|---|---|---|---|---|---|---|

| Epoxy | Glass-Basalt/Flax/Jute | Fiber loading | 450 | 9.20 | 410 | - | [91] |

| Epoxy | Banana/carbon | Hybridization Water absorption | 277 | - | 307 | - | [84] |

| Polyester | Kenaf/rGlass | Hybridization | - | - | 181.98 | - | [92] |

| Epoxy | Kenaf/Aramide | Hybridization Fiber loading | 114.49 | 1.75 | - | - | [93] |

| Polyester | Kenaf/Glass | Hybridization Weathering effect | 70 | 3.0 | 120 | - | [94] |

| Epoxy | Palf/glass Coir/glass | Fiber loading Water absorption | 52 | 2.10 | 120 | - | [95] |

| Epoxy | Banana/Palf/Glass | Fiber loading Thermal | 132.29 | 11.52 | - | - | [73] |

| Polyester | Glass/Jute | Fiber loading | 78.61 | 4.26 | 146.30 | 45 | [96] |

| Epoxy | Aramide/Coir | Fiber loading | - | - | - | 149 | [97] |

| Epoxy | Glass/Kenaf | Fiber loading | 175.68 | 1.72 | - | - | [98] |

| Epoxy | PALF/Carbon | Fiber loading Water absorption | 43.13 | 1.86 | - | - | [85] |

| Epoxy | PALF/Glass | Fiber loading Water absorption | 40.43 | 2.40 | 171 | - | [99] |

| Epoxy | Jute/Carbon | Fiber loading, Thermal, Water absorption | 301 | - | - | 127 | [100] |

| Epoxy | Jute/Carbon | Fiber loading | 257.60 | 9.80 | - | - | [101] |

| Epoxy | Carbon/Jute/Banana | Fiber loading | 160 | 380 | - | - | [102] |

| Epoxy | Aloevera/ Bamboo/Palm/Kevlar | Hybridization | 123 | 210 | - | - | [103] |

| Epoxy | PALF/Carbon | Fiber loading | 187.67 | 7.87 | 247.61 | - | [104] |

| Epoxy | Kevlar/Aloe Vera/Bamboo | Fiber loading | 127 | 298.38 | 223.48 | - | [105] |

| Epoxy | Date Palm /Kevlar | Fiber loading | 237 | 3.60 | - | - | [106] |

| Type of Test | Izod | Charpy |

|---|---|---|

| Specimen Position | Vertical | Horizontal |

| Point of Strike | Upper tip of specimen | Point of notch but in opposite direction |

| Direction of Notch | Facing the striker that is fastened to the pendulum | Away from striker |

| Type of Notch | V-notch | V-notch and U-notch |

| Type of Hammer | Farming hammer | Ball in hammer |

| References | Hybrid Composite | Parameters | Low-Velocity Impact Performance | Remarks | |

|---|---|---|---|---|---|

| Peak Force (kN) | Energy Absorbed (J) | ||||

| [63] | Kevlar Basalt | Stacking sequence | 5.04 | 70.60 | Alternative stacking of basalt and Kevlar fabrics enhanced 15.58–20.79% and 13.47–20.47% improvement in the peak force and energy absorption. |

| [132] | Kenaf glass | Clamping conditions | Natural frequency decreases with increasing impact level. | ||

| [133] | Jute Basalt | Environmental conditions | 4.00 | 7.71 | Result exhibited a higher degree of strength retention after environmental aging, thus confirming the positive role played by basalt fibres in enhancing the durability of natural fibre composites |

| [91] | E-glass Jute Basalt Flax | Fibre loading | 3.00 | 30.00 | Impact test showed a higher peak force while maximum deflection was governed by indentation test for hybrid and homogeneous composites |

| [134] | Flax Basalt | Environment conditions | - | - | Did not exhibit such a large difference in impact behaviour between dry and conditioned |

| [135] | Flax Basalt | Stacking sequence | - | - | The more complex structure presented by the hybrid, including two materials with different strength, is likely to reduce the extent of the striker rebound |

| [136] | Carbon Glass | Stacking sequence | 3.94 | 19.24 | Pipes with CGG stacking represents higher impact resistance while the GCG stacking has a better response of damage formation since this stacking does not show leakage damage. |

| [137] | Kenaf Kevlar | Fiber configurations | 4.00 | 30.00 | The bending stiffness of each fibre ply determines the penetration resistance of composite laminates. As a result, the inclusion of Kevlar fibre in the surface layers increased the laminates’ penetrating resistance. |

| [138] | Aramid Kenaf | Stacking sequence | 44.63 | 409.70 | The composites exhibited a larger effective displacement for complete penetration because of the visco-elastic-plastic behaviour of the polypropylene system |

| [139] | Kenaf Jute glass | Stacking sequence | 6.20 | 30.00 | Alternate sequence of hybrid composite exhibits more impact resistance |

| [140] | Carbon Flax | Stacking sequence | - | - | Composite with alternate sequence exhibit lower absorbed energy, higher penetration energy, smaller crack lengths, smaller indentation depths, smaller damage areas, lower temperature rise, and higher impact strength. |

| [5] | Glass Kenaf | hybridization | 2.60 | - | Impact peak force and displacement increase with energy level |

| [141] | Carbon Glass Basalt | Fiber configuration | 9.17 | 59.43 | Carbon fibre as the core exhibited superior impact resistance and weave fabric composite of basalt fibre laminates exhibited better energy absorption capability and deformation resistance |

| [142] | Flax Carbon Glass MWCNT | Nanofiller enhancement | 2.00 | 13.18 | The value of absorbed energy for carbon/flac was higher compared to that of glass/flax due to severe damage occurred on carbon/flax surface compared to that of glass/flax. |

| [143] | Aluminium Glass Carbon | Stacking sequence | 6.70 | 87.61 | Hybrid laminates shows 15% improvement of energy absorption and glass plies in H1 hybrid FMLs were able to distribute the contact stress, while the middle layer acted as a barrier in resisting crack propagation. |

| [144] | Carbon Flax | Stacking sequence | 5.80 | - | Compared to a non-hybrid flax composite of same thickness, flax plies on the affected side result in a considerable improvement in impact resistance |

| [145] | Flax Basalt | Stacking sequence | 3.10 | - | Due to the interlaminar strength of the fibres, alternate layers of basalt and flax fibres suffered less damage. |

| [146] | PALF Glass | Stacking sequence/hybridization | 1.47 | 15.10 | Glass fibre was partially included into the composite laminates, which increased indentation resistance and energy absorption. |

| [147] | Banana Glass | Stacking sequence | 4.69 | 27.12 | The addition of glass fibre to a banana fibre reinforced composite improves energy absorption and overall impact performance. |

| [148] | Kenaf Glass | Fibre loading | 9.31 | 23.23 | The hybrid composites can endure up to 40 J of impact energy, with the peak impact load and absorbed energy increasing as the incident impact energy increased. |

| [149] | Bamboo glass | Nanofiller enhancement | - | - | CNTs absorbed less energy than bamboo/glass hybrids without them, resulting in less physical damage. |

| [109] | Flax Carbon | Fibre configuration | 2.41 | 19.94 | When compared to 5 carbon layers, the energy absorption of the hybrid composites rises by 13.25 percent for the FCFCF sample and 28.89 percent for the CFFFC sample. |

| [150] | Jute Glass | Stacking sequence | 5.60 | 46.89 | In comparison to composites with glass fabric layers in the inside and flax or jute textiles, hybrid composites with glass fabric layers on the exterior had greater impact resistance. |

| [151] | Flax Glass | Fibre loading | - | - | Hybridization of glass fibre onto flax fibre composite improves impact damage characteristics by generating a balanced effect. |

| [152] | Jute Kevlar | Impactor height | 0.22 | 4.20 | The dynamic reaction of these frameworks relies upon the flexible properties of the fibre material |

| [153] | Bamboo Glass | Hybridization | 6.10 | 27.92 | Increased filler loading reduced the severity of damage in non-hybrid composites, while the addition of woven glass fibre slowed the impactor’s penetration, lessening the risk of total failure. |

| [154] | Oil palm EFB Kevlar | Stacking sequence | 5.00 | 30.00 | The layering sequence K/OP/K in Kevlar/OPEFB hybrid composites can resist up to 35 J of impact energy, with the optimal gamma radiation dosage at 50 kGy |

| [155] | Flax Basalt | Energy level, temperature, and number of impacts | 5.81 | - | Decreasing temperatures caused an embrittlement effect on neat PP composites with an increase maximum force and a decrease of maximum displacement, whereas increasing temperatures led to a softening of compatibilized composites with a decrease of maximum force and an increase maximum displacement |

| [156] | CFRP Wood | Fibre loading | 3.50 | - | Wood cells deform during impact and hence dissipate more energy |

| References | Hybrid Composite | Parameters | Failure Modes |

|---|---|---|---|

| [137] | Kenaf Glass | Fiber configuration | Microcracks, fiber pull out, fiber breakage, fiber bridging, debonding, and delamination at the interface. |

| [162] | Flax Basalt epoxy | Hybridization | Matrix cracking, delamination, propagation and fibre failure |

| [162] | Glass Flax epoxy | Temperature exposure | The heat exposed specimen indicates the delaminated regions and/or fibre-matrix separation. |

| [163] | Carbon Jute epoxy | Fiber configuration | Matrix and fiber failure, ply failure, fiber pullout, delamination. |

| [164] | Flax Glass VE | Hybridization | Matrix cracking, delamination, fibre breakage and, finally, penetration |

| [165] | Hemp Carbon epoxy | Fiber configuration | Localized buckling, fiber breakage, matrix cracking |

| [166] | Flax Basalt PP/Epoxy | Matrix hybridization | Shows ductile response to impact loading. An extensive plastic deformation and a wider damaged area can be easily observed with the presence of matrix cracks and flax fiber failures on the impacted side. |

| [167] | Carbon Flax epoxy | Fiber configuration | Fiber debonding, bending, fiber breakage |

| [168] | Pennisetum purpureum Glass epoxy | Environment ondition | Matric cracking, delamination and fiber breakage. The damage pattern was more visible and extended at higher temperatures |

| [169] | Flax Basalt VE | Environment conditions | Matrix cracking, delamination, fibre breakage, and fibre pull out. |

| [170] | Hemp Glass epoxy | Fiber configuration | Delamination, fiber fracture, matrix cracking |

| [146] | PALF Kevlar PP | Fiber configuration | Crack initiation and propagation, fiber pull-out, fiber- matrix delamination and fiber breakage were |

| [171] | Basalt Kevlar Epoxy | Fiber configuration | Matrix cracking, delamination. |

| [172] | Banana Carbon Kevlar epoxy | Hybridization | Matric cracking, delamination and fiber breakage corresponds to delamination of the skin and brittle fracture of the core |

| [173] | Kevlar Glass epoxy | Fiber configuration | Delamination. The damaged area is increased with an increase in the glass fabric percentage. |

| [174] | PALF Glass epoxy | Fiber configuration | Matrix crack, fiber breakage. Presence of glass fiber increase the elasticity of composite and the damage clearly visible. |

| [175] | Carbon Flax epoxy | Fiber configuration | Fiber matrix debonding and fiber breakage |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohd Bakhori, S.N.; Hassan, M.Z.; Mohd Bakhori, N.; Jamaludin, K.R.; Ramlie, F.; Md Daud, M.Y.; Abdul Aziz, S. Physical, Mechanical and Perforation Resistance of Natural-Synthetic Fiber Interply Laminate Hybrid Composites. Polymers 2022, 14, 1322. https://doi.org/10.3390/polym14071322

Mohd Bakhori SN, Hassan MZ, Mohd Bakhori N, Jamaludin KR, Ramlie F, Md Daud MY, Abdul Aziz S. Physical, Mechanical and Perforation Resistance of Natural-Synthetic Fiber Interply Laminate Hybrid Composites. Polymers. 2022; 14(7):1322. https://doi.org/10.3390/polym14071322

Chicago/Turabian StyleMohd Bakhori, Siti Nadia, Mohamad Zaki Hassan, Noremylia Mohd Bakhori, Khairur Rijal Jamaludin, Faizir Ramlie, Mohd Yusof Md Daud, and Sa’ardin Abdul Aziz. 2022. "Physical, Mechanical and Perforation Resistance of Natural-Synthetic Fiber Interply Laminate Hybrid Composites" Polymers 14, no. 7: 1322. https://doi.org/10.3390/polym14071322

APA StyleMohd Bakhori, S. N., Hassan, M. Z., Mohd Bakhori, N., Jamaludin, K. R., Ramlie, F., Md Daud, M. Y., & Abdul Aziz, S. (2022). Physical, Mechanical and Perforation Resistance of Natural-Synthetic Fiber Interply Laminate Hybrid Composites. Polymers, 14(7), 1322. https://doi.org/10.3390/polym14071322