Experimental Study of the Influence of Selected Factors on the Particle Board Ignition by Radiant Heat Flux

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples

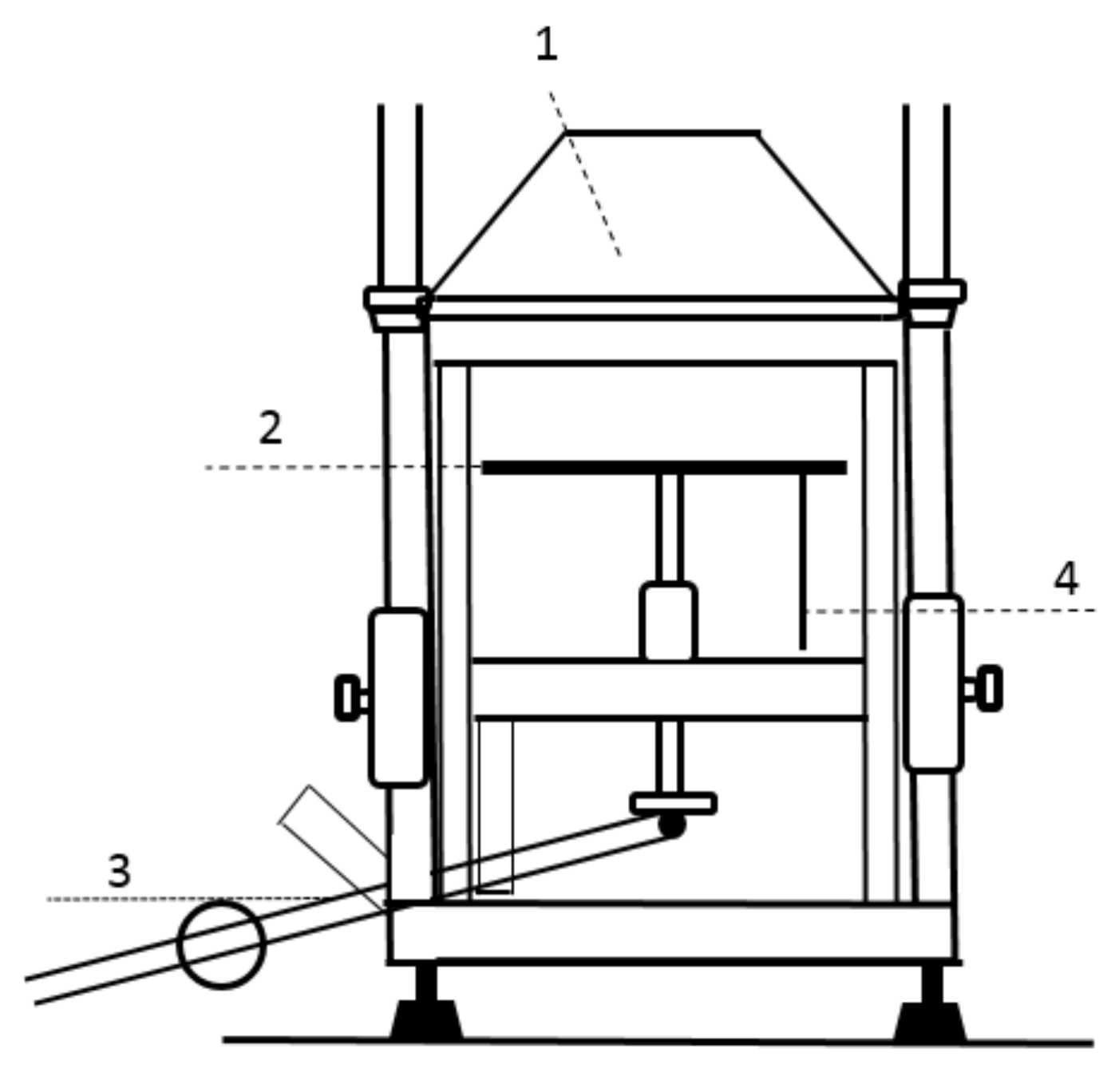

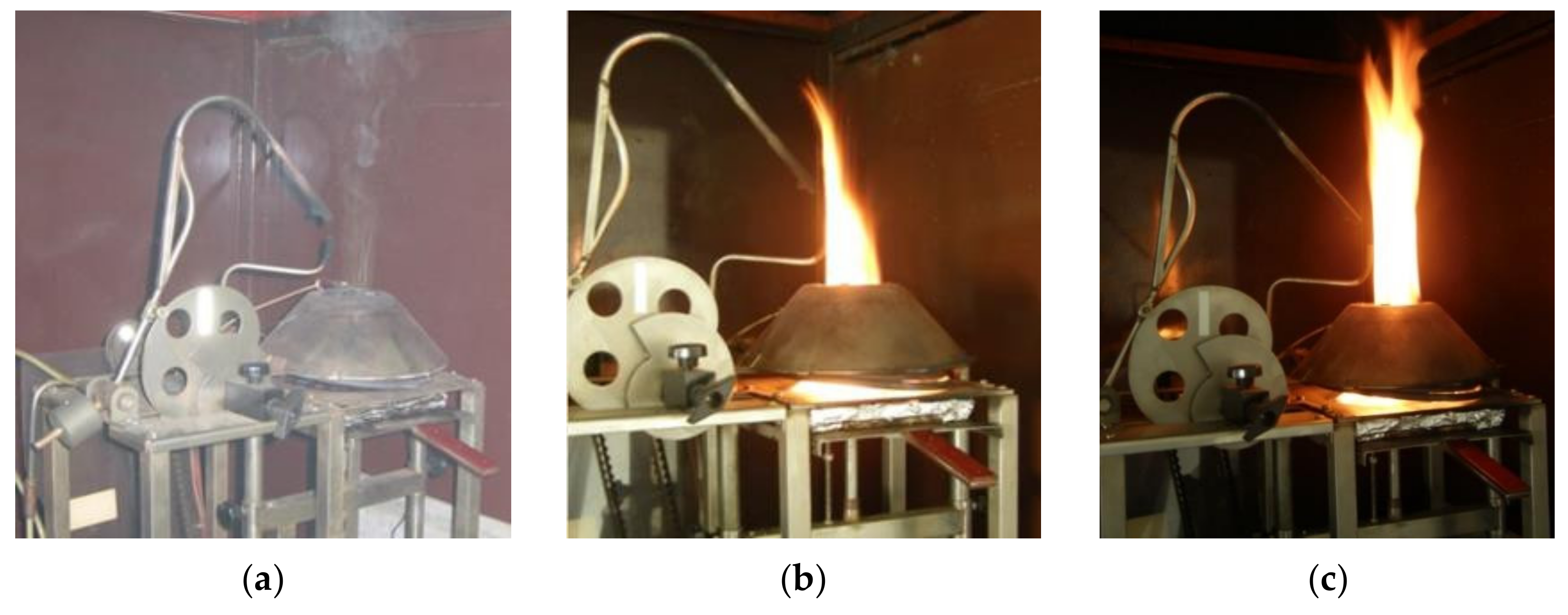

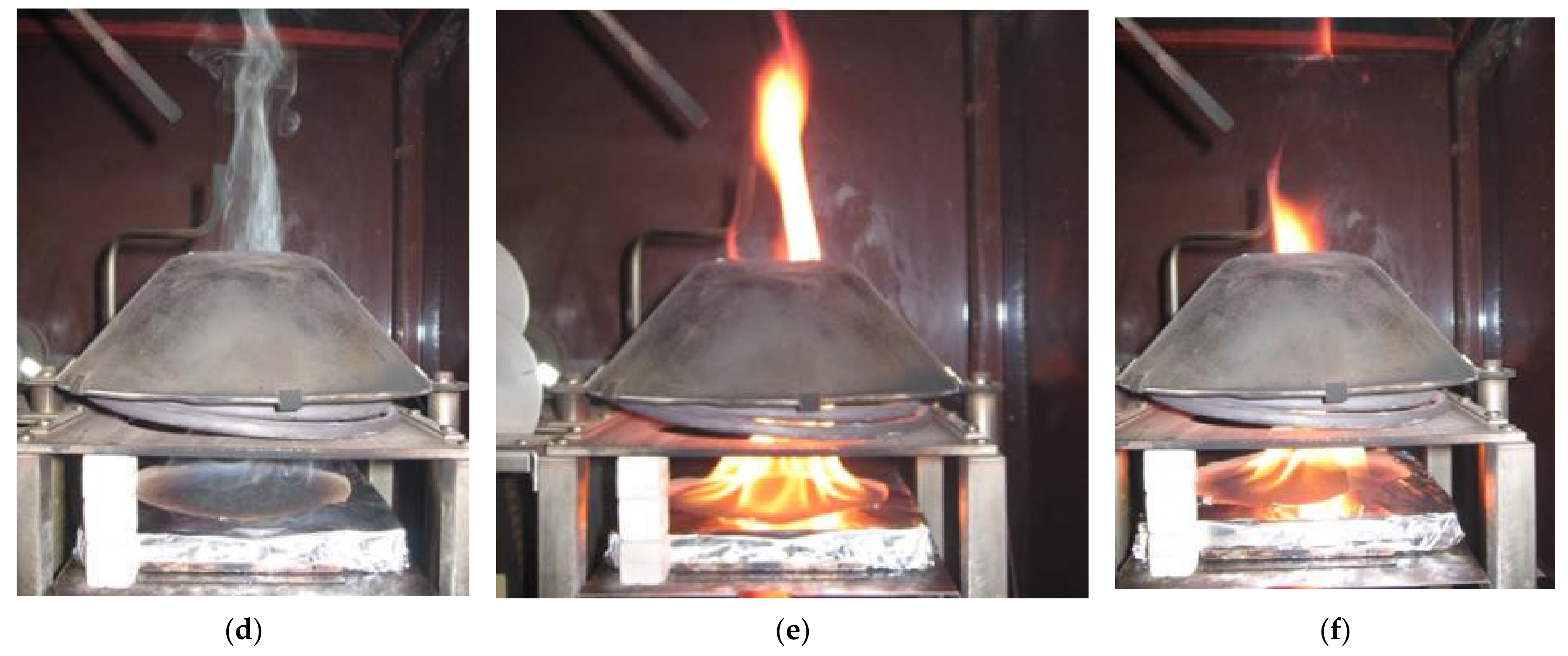

2.2. Methodology

- Thickness and density of the board material;

- Radiant heat flux density;

- Distance of particleboards from the radiant heat source.

2.3. Mathematical and Statistical Processing of Data and Evaluation of Results

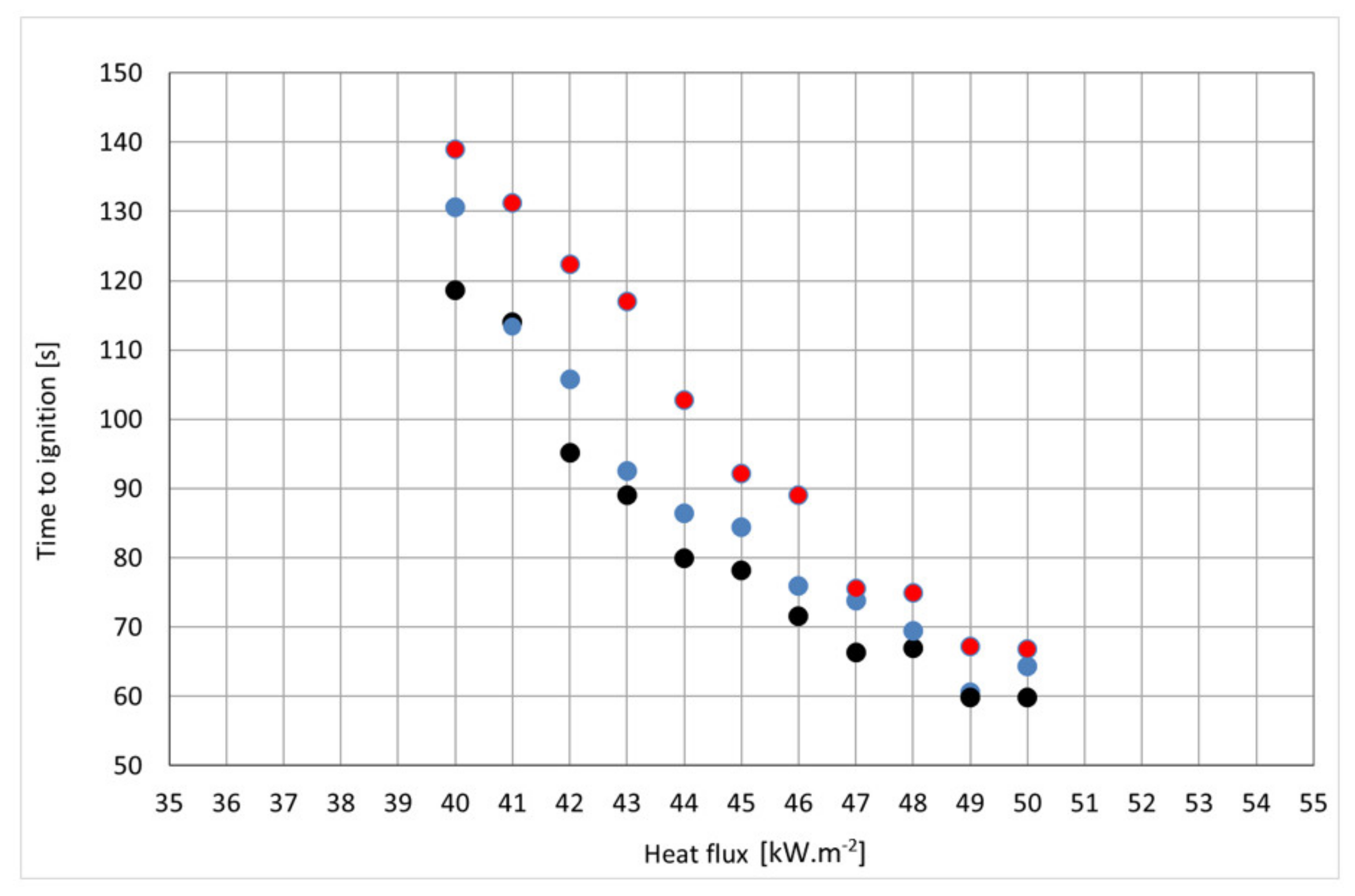

3. Results and Discussion

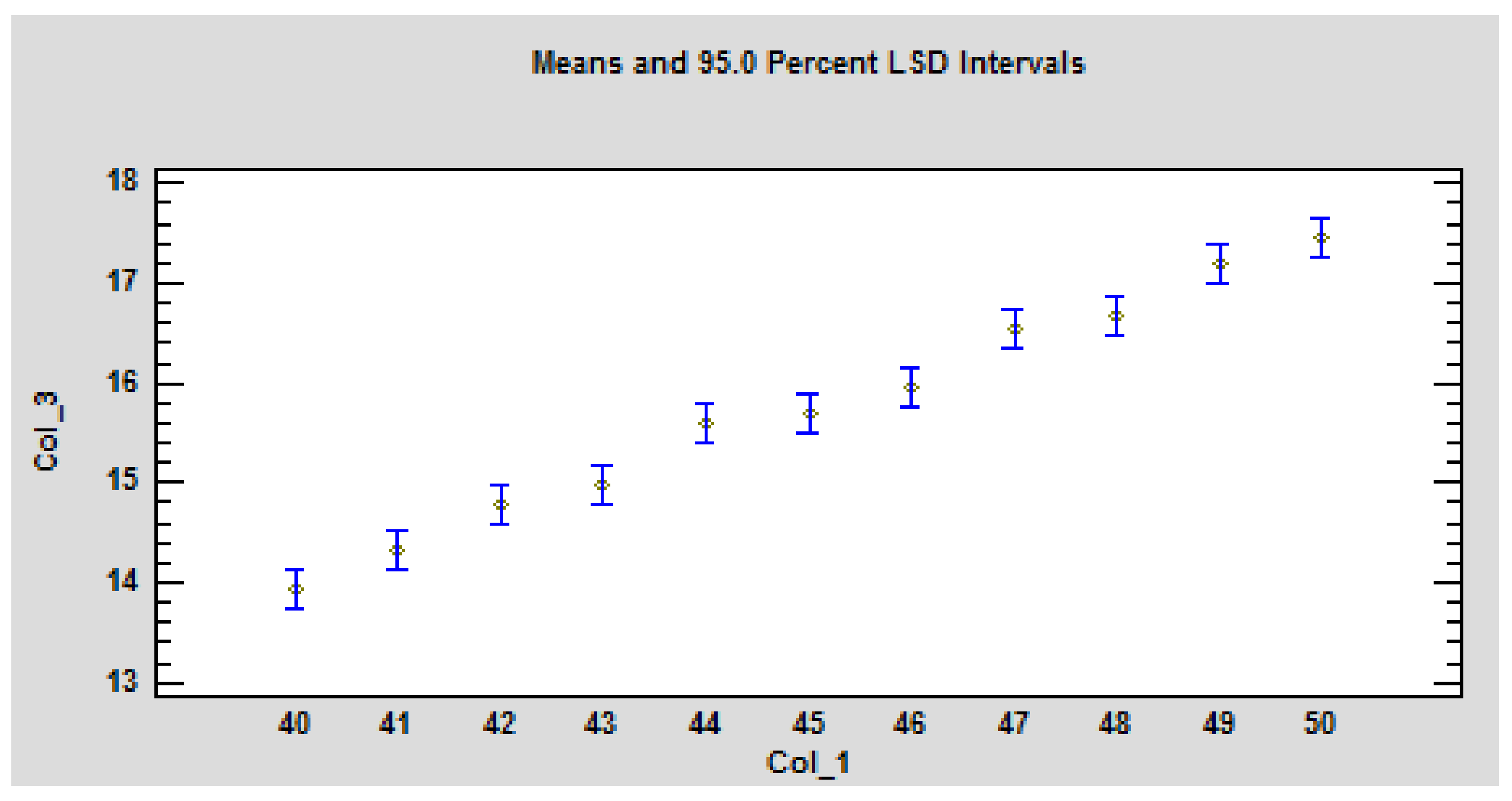

3.1. Determination of Ignition Temperature and Weight Loss

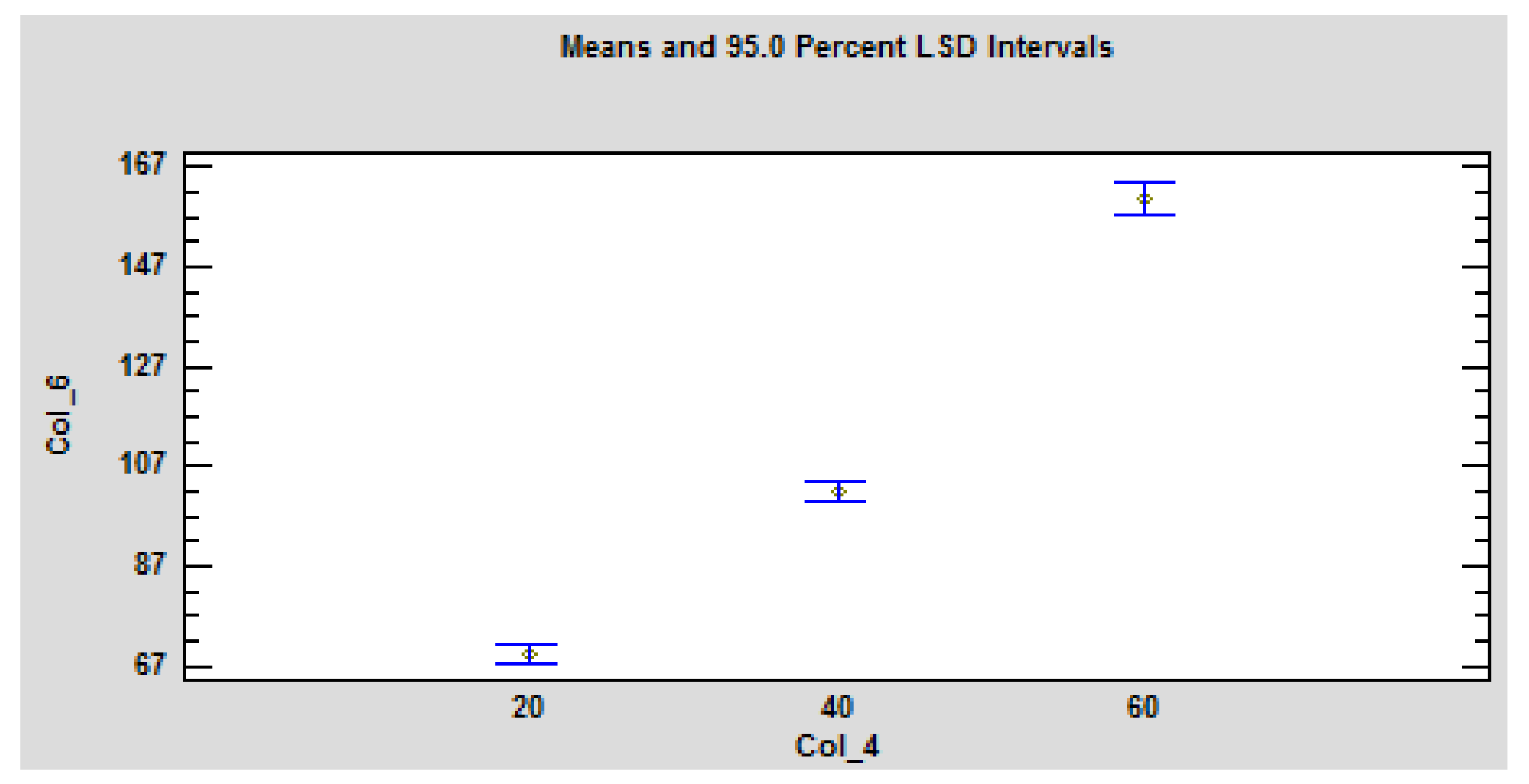

3.2. Monitoring the Effect of the Distance of Board Material from the Ignition Source

4. Conclusions

- It was statistically confirmed that the time to ignition is significantly dependent on the thickness of the particleboard sample and the heat flux value. It was also possible to calculate the thermal inertia based on the measurements. The obtained results of the calculated inertia were very similar to the published values reported by Babrauskas [48];

- It was confirmed that the weight loss was significantly dependent on the thickness of the particleboard. Selected thicknesses of particleboards which were exposed to radiant heat flux of 40–50 kW·m−2 recorded on average by 0.4% (absolute % number) of weight loss with increasing heat flux density (for a change of the heat flux of 1 kW·m−2). The largest weight loss values were recorded in particleboards with a thickness of 12 mm;

- Statistically significant dependence was confirmed by monitoring the time to ignition and the distance of a sample with a thickness of 12 mm from the radiant heat source. At a distance of 60 mm and heat fluxes of 44 and 46 kW·m−2, the particleboards with a thickness of 12 mm did not ignite.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shaha, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Antov, P.; Kristak, L.; Reh, R.; Savov, V.; Papadopoulos, A.N. Eco-Friendly Fiberboard Panels from Recycled Fibers Bonded with Calcium Lignosulfonate. Polymers 2021, 13, 639. [Google Scholar] [CrossRef]

- Langova, N.; Reh, R.; Igaz, R.; Kristak, L.; Hitka, M.; Joscak, P. Construction of Wood-Based Lamella for Increased Load on Seating Furniture. Forests 2019, 10, 525. [Google Scholar] [CrossRef]

- STN EN 309; Particleboards. Definition and Classification. Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2005.

- Antov, P.; Savov, V.; Krišťák, L.; Réh, R.; Mantanis, G.I. Eco-Friendly, High-Density Fiberboards Bonded with Urea-Formaldehyde and Ammonium Lignosulfonate. Polymers 2021, 13, 220. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.G.; Tian, Y. Furniture of Environmental Protection Materials. Appl. Mech. Mater. 2015, 727, 197–200. [Google Scholar] [CrossRef]

- Hoffman, A.; Muehlnikel, R. Experimental and numerical investigation of fire development in areal fire in a five-storey apartment building. Fire Mater. 2011, 35, 453–462. [Google Scholar] [CrossRef]

- Krišťák, L.; Igaz, R.; Brozman, D.; Réh, R.; Šiagiová, P.; Stebila, J.; Očkajová, A. Life Cycle Assessment of Timber Formwork: Case Study. Adv. Mater. Res. 2014, 1001, 155–161. [Google Scholar] [CrossRef]

- Galla, Š. A analysis of a fire in a storehouse of fibreboards from the fire investigation point of view—Case study. Košická Bezpeč. Rev. 2015, 1, 26–31. (In Slovak) [Google Scholar]

- Kubjatko, T.; Gortz, M.; Macurova, L.; Ballay, M. Synergy of Forensic and Security Engineering in Relation to the Model of Deformation Energies on Vehicles After Traffic Accidents. In Proceedings of the Transport Means—Proceedings of the International Conference, Trakai, Lithuania, 3–5 October 2018; pp. 1342–1348. [Google Scholar]

- Iringová, A. Impact of fire protection on the design of energy-efficient and eco-friendly building envelopes in timber structures. In Proceedings of the Fire Protection, Safety and Security, Zvolen, Slovakia, 3–5 May 2017; pp. 79–85. [Google Scholar] [CrossRef]

- Očkajová, A.; Kučerka, M. Materials and Technologies 1. Wood Technology, 1st ed.; UMB: Banská Bystrica, Slovakia, 2011; ISBN 978-80-557-0262-9. (In Slovak) [Google Scholar]

- Warguła, Ł.; Dziechciarz, A.; Kaczmarzyk, P. The assessment of fire risk of non-road mobile wood chopping machines. J. Res. Appl. Agric. Eng. 2019, 64, 58–64. [Google Scholar]

- Sydor, M.; Mirski, R.; Stuper-Szablewska, K.; Rogozinski, T. Efficiency of Machine Sanding of Wood. Appl. Sci. 2021, 11, 2860. [Google Scholar] [CrossRef]

- Jin, C.D.; Li, J.; Zheng, R.X. Thermal and Combustion Characteristics of Binderless Fiberboard. Adv. Mater. Res. 2010, 113, 1063–1070. [Google Scholar] [CrossRef]

- Marková, I.; Hroncova, E.; Tomaskin, J.; Turekova, I. Thermal analysis of granulometry selected wood dust particles. BioResources 2018, 13, 8041–8060. [Google Scholar] [CrossRef]

- Szabová, Z.; Pastier, M.; Harangózo, J.; Chrebet, T. Determination of characteristics predicting the ignition of organic dusts. In Occupational Safety and Hygiene II: 10th Annual Congress of the Portuguese Society of Occupational Safety and Hygiene on Occupational Safety an Hygiene (SPOSHO) Guimaraes, Portugal, 13–14 February 2014; CRC Press: Boca Raton, FL, USA, 2014; pp. 143–145. ISBN 978-1-315-77352-0. [Google Scholar]

- Turekova, I.; Markova, I. Ignition of Deposited Wood Dust Layer by Selected Sources. Appl. Sci. 2020, 10, 5779. [Google Scholar] [CrossRef]

- Vandličková, M.; Markova, I.; Osvaldová, L.M.; Gašpercová, S.; Svetlík, J. Evaluation of African padauk (Pterocarpus soyauxii) explosion dust. BioResources 2020, 15, 401–414. [Google Scholar]

- Lišková, Z.; Olbřímek, J. Comparison of Requirements in Slovak and Selected Foreign Legislation on the Issue of Safe Distance of the Wooden Building Structures from the Flue. Appl. Mech. Mater. 2016, 820, 396–401. [Google Scholar] [CrossRef]

- Pedzik, M.; Auriga, R.; Kristak, L.; Antov, P.; Rogozinski, T. Physical and Mechanical Properties of Particleboard Produced with Addition of Walnut (Juglans regia L.) Wood Residues. Materials 2022, 15, 1280. [Google Scholar] [CrossRef]

- Kristak, L.; Kubovsky, I.; Reh, R. New Challenges in Wood and Wood-Based Materials. Polymers 2021, 13, 2538. [Google Scholar] [CrossRef]

- Bekhta, P.; Noshchenko, G.; Reh, R.; Kristak, L.; Sedliacik, J.; Antov, P.; Mirski, R.; Savov, V. Properties of Eco-Friendly Particleboards Bonded with Lignosulfonate-Urea-Formaldehyde Adhesives and pMDI as a Crosslinker. Materials 2021, 14, 4875. [Google Scholar] [CrossRef]

- Krist’ak, L.; Reh, R. Application of Wood Composites. Appl. Sci. 2021, 11, 3479. [Google Scholar] [CrossRef]

- Baskaran, M.; Azmi, N.A.C.H.; Hashim, R.; Sulaiman, O. Addition of Urea Formaldehyde Made from Oil Palm Trunk Waste. J. Phys. Sci. 2017, 28, 151–159. [Google Scholar] [CrossRef][Green Version]

- Lee, C.L.; Chin, K.L.; H’ng, P.S.; Chuah, A.L.; Khoo, P.S. Enhanced properties of single-layer particleboard made from oil palm empty fruit bunch fibre with additional water-soluble additives. BioResources 2021, 16, 6159–6173. [Google Scholar] [CrossRef]

- Mirindi, D.; Onchiri, R.O.; Thuo, J. Physico-Mechanical Properties of Particleboards Produced from Macadamia Nutshell and Gum Arabic. Appl. Sci. 2021, 11, 11138. [Google Scholar] [CrossRef]

- Bardak, S.; Nemli, G.; Bardak, T. The quality comparison of particleboards produced from heartwood and sapwood of European larch. Maderas. Cienc. Y Tecnol. 2019, 21, 511–520. [Google Scholar] [CrossRef]

- Grigorieva, L.; Oleinik, P. Recycling Waste Wood of Construction. Mater. Sci. Forum 2016, 871, 126–131. [Google Scholar] [CrossRef]

- Iringová, A.; Vandlíčková, D. Analysis of a Fire in an Apartment of Timber Building Depending on the Ventilation Parameter. Civ. Environ. Eng. 2021, 17, 549–558. [Google Scholar] [CrossRef]

- Safety Data Sheet Particleboard, Raw un-Sanded; Bučina DDD: Zvolen, Slovakia, 2019.

- List of technical data. In Particleboard Pressed Flat, un-Sanded, without Surface Treatment; Bučina DDD: Zvolen, Slovakia, 2019.

- Osvald, A. Evaluation velocity of the facade fire-based wood. In Proceedings of the International Scientific Conference, Rajec, Slovakia, 10 November 2017; Volume 1, pp. 197–215. (In Slovak). [Google Scholar]

- ISO 5657; Reaction to Fire Tests. Ignitability of Building Products Using Radiant Heat Source. ISO: Geneva, Switzerland, 1997.

- STN EN 323; Wood-Based Panels. Determination of Density. Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 1996.

- Tureková, I.; Marková, I.; Ivanovičová, M.; Harangozo, J. Experimental Study of Oriented Strand Board Ignition by Radiant Heat Fluxes. Polymers 2021, 13, 709. [Google Scholar] [CrossRef]

- Morozov, M.; Strizhak, P.A. Researches of Advanced Thermal Insulating Materials for Improving the Building Energy Efficiency. Key Eng. Mater. 2016, 683, 617–625. [Google Scholar] [CrossRef]

- Mitrenga, P.; Vandlíčková, M.; Dušková, M. Evaluation of the new fire retardants on wood by proposed testing method. In Proceedings of the International Conference on Engineering Science and Production Management (ESPM), Tatranská Štrba, Slovakia, 16–17 April 2015; pp. 481–485. [Google Scholar] [CrossRef]

- MakovickáOsvaldová, L.; Janigová, I.; Rychlý, J. Non-Isothermal Thermogravimetry of Selected Tropical Woods and Their Degradation under Fire Using Cone Calorimetry. Polymers 2021, 13, 708. [Google Scholar] [CrossRef]

- Liu, Z.H.; Zhao, Y.S.; Hu, Y.M. Research on Improved Thermal Inertia Model for Retrieving Soil Moisture. Appl. Mech. Mater. 2013, 295, 2075–2083. [Google Scholar] [CrossRef]

- Schieldge, J.P.; Kahle, A.B.; Alley, R.E.; Gillespie, A.R. Use of thermal-inertia properties for material indetification. Soc. Photo-Opt. Instrum. Eng. 1980, 238, 350–357. [Google Scholar]

- Shulga, G.; Neiberte, B.; Verovkins, A.; Jaunslavietis, J.; Shakels, V.; Vitolina, S.; Sedliačik, J. Eco-Friendly Constituents for Making Wood-Polymer Composites. Key Eng. Mater. 2016, 688, 122–130. [Google Scholar] [CrossRef]

- Östman, B.A.L.; Mikkola, E. European Classes for the Reaction to Fire Performance of Wood Products. Holz Roh Werkstoff 2006, 64, 327–337. [Google Scholar] [CrossRef]

- STN EN 13501-2; Fire Classification of Construction Products and Building Elements. Part 1: Classification Using Data from Reaction to fire tests. European Committe for Standartion: Brussels, Belgium, 2018.

- STN EN ISO 11925-2; Reaction to Fire Tests—Ignitability of Building Products Subjected to Direct Impingement of Flame—Part 2: Single-Flame Source Test. Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2021.

- Valarmathi, T.N.; Palanikumar, K.; Sekar, S. Thrust Force Studies in Drilling of Medium Density Fiberboard Panels. Adv. Mater. Res. 2012, 622, 1285–1289. [Google Scholar] [CrossRef]

- Babrauskas, V. Ignition Handbook, 1st ed.; Fire Science Publishers: Issaquah, WA, USA, 2003; ISBN 0-9728111-3-3. [Google Scholar]

- Babrauskas, V. Ignition of wood: A Review of the State of the Art. J. Fire Eng. 2002, 12, 163–189. [Google Scholar] [CrossRef]

- Valcheva, L.; Savov, V. The Effect of Thickness of Medium Density Fiberboard Produced of Hardwood Tree Species on their Selected Physical and Mechanical Properties. Key Eng. Mater. 2016, 688, 115–121. [Google Scholar] [CrossRef]

| Parameters | Thickness of Particleboard Sample (mm) | ||

|---|---|---|---|

| 12 | 15 | 18 | |

| Density (kg·m−3) (average) | 690 | 713 | 644 |

| Moisture (%) | 5.05 | 5.25 | 5.45 |

| Bending strength (N·mm−2) | 13.2 | 12.5 | 12 |

| Modulus of elasticity (N·mm−2) | 2500 | 2450 | 2750 |

| Swelling after 24 h (%) | 3.5 | 3.5 | 3.5 |

| Thermal conductivity (W·m−2·K−1) | 0.10–0.14 | 0.10–0.14 | 0.10–0.14 |

| Free formaldehyde content (mg·100 g−1) (Emission class E1) | 6.5 | 6.5 | 6.5 |

| Reaction to fire | D-s1, d0 | ||

| Radiant Heat Flux (kW·m−2) | Thickness (mm) | Density (kg·m−3) | Thermal Inertia (kJ2·m−4·s−1·K−2) | Time to Ignition (s) | Weight Loss (%) |

|---|---|---|---|---|---|

| 40 | 12 | 689 ± 10 | 0.32 ± 0.002 | 130.6 ± 3.44 | 16.3 ± 0.3 |

| 15 | 711 ± 10 | 0.31 ± 0.026 | 118.6 ± 3.83 | 13.5 ± 0.3 | |

| 18 | 644 ± 6 | 0.27 ± 0.080 | 139.0 ± 3.16 | 11.9 ± 0.2 | |

| 41 | 12 | 689 ± 9 | 0.32 ± 0.002 | 114.0 ± 3.52 | 16.7 ± 0.29 |

| 15 | 714 ± 11 | 0.33 ± 0.002 | 113.4 ± 4.03 | 13.8 ± 0.33 | |

| 18 | 644 ± 7 | 0.27 ± 0.082 | 131.2 ± 2.99 | 12.5 ± 0.21 | |

| 42 | 12 | 688 ± 9 | 0.32 ± 0.002 | 95.2 ± 6.82 | 17.3 ± 0.39 |

| 15 | 714 ± 10 | 0.33 ± 0.002 | 105.8 ± 3.06 | 14.3 ± 0.32 | |

| 18 | 645 ± 6 | 0.31 ± 0.001 | 122.4 ± 1.96 | 12.7 ± 0.18 | |

| 43 | 12 | 691 ± 10 | 0.32 ± 0.002 | 89.0 ± 5.215 | 17.1 ± 0.52 |

| 15 | 716 ± 11 | 0.33 ± 0.002 | 92.6 ± 3.441 | 14.6 ± 0.37 | |

| 18 | 642 ± 7 | 0.31 ± 0.008 | 117.0 ± 5.513 | 13.2 ± 0.17 | |

| 44 | 12 | 691 ± 10 | 0.32 ± 0.002 | 80.0 ± 5.37 | 17.6 ± 0.41 |

| 15 | 715 ± 10 | 0.33 ± 0.002 | 86.4 ± 4.88 | 15.4 ± 0.35 | |

| 18 | 643 ± 7 | 0.31 ± 0.002 | 102.8 ± 4.31 | 13.7 ± 0.24 | |

| 45 | 12 | 691 ± 9 | 0.321 ± 0.002 | 78.2 ± 0.748 | 17.9 ± 0.30 |

| 15 | 714 ± 11 | 0.327 ± 0.002 | 84.4 ± 2.057 | 15.3 ± 0.29 | |

| 18 | 645 ± 7 | 0.311 ± 0.002 | 92.2 ± 2.481 | 13.9 ± 0.29 | |

| 46 | 12 | 690 ± 11 | 0.32 ± 0.002 | 71.6 ± 1.62 | 18.4 ± 0.52 |

| 15 | 711 ± 9 | 0.33 ± 0.002 | 76.0 ± 2.28 | 15.7 ± 0.29 | |

| 18 | 644 ± 8 | 0.31 ± 0.001 | 89.0 ± 7.97 | 13.8 ± 0.56 | |

| 47 | 12 | 690 ± 11 | 0.32 ± 0.002 | 66.4 ± 2.87 | 18.9 ± 0.29 |

| 15 | 715 ± 10 | 0.33 ± 0.002 | 73.8 ± 0.80 | 16.2 ± 0.36 | |

| 18 | 645 ± 8 | 0.31 ± 0.002 | 75.6 ± 3.72 | 14.5 ± 0.34 | |

| 48 | 12 | 689 ± 10 | 0.32 ± 0.002 | 64.4 ± 1.49 | 19.1 ± 0.34 |

| 15 | 710 ± 8 | 0.33 ± 0.001 | 69.4 ± 1.96 | 16.3 ± 0.37 | |

| 18 | 644 ± 7 | 0.31 ± 0.001 | 75.0 ± 2.00 | 14.6 ± 0.22 | |

| 49 | 12 | 692 ± 11 | 0.32 ± 0.002 | 60.6 ± 2.24 | 19.7 ± 0.44 |

| 15 | 713 ± 10 | 0.33 ± 0.002 | 66.0 ± 2.28 | 16.6 ± 0.33 | |

| 18 | 644 ± 11 | 0.31 ± 0.002 | 67.2 ± 1.17 | 15.2 ± 0.13 | |

| 50 | 12 | 689 ± 8 | 0.32 ± 0.001 | 59.8 ± 2.64 | 19.9 ± 0.41 |

| 15 | 713 ± 11 | 0.33 ± 0.002 | 64.4 ± 2.50 | 16.5 ± 0.33 | |

| 18 | 643 ± 7 | 0.31 ± 0.001 | 66.8 ± 2.09 | 15.9 ± 0.94 |

| Source | Sum of Squares | Df | Mean Square | F-Ratio | p-Value |

|---|---|---|---|---|---|

| Covariates | |||||

| Col_3 Thermal interaction | 664.125 | 1 | 664.125 | 1.34 | 0.2481 |

| Main Effects | |||||

| Col_2 Board thickness | 4018.06 | 2 | 2009.03 | 4.06 | 0.0190 |

| Residual | 79,573.2 | 161 | 494.244 | ||

| Total | 87,085.1 | 164 |

| Source | Sum of Squares | Df | Mean Square | F-Ratio | p-Value |

|---|---|---|---|---|---|

| Main Effects | |||||

| Col_1 Heat flux | 15,376.7 | 10 | 1537.67 | 58.29 | 0.0000 |

| Col_2 Board thickness | 1405.32 | 2 | 702.658 | 26.64 | 0.0000 |

| Residual | 527.564 | 20 | 26.3782 | ||

| Total | 17,309.6 | 32 |

| Source | Sum of Squares | Df | Mean Square | F-Ratio | p-Value |

|---|---|---|---|---|---|

| Main Effects | |||||

| Col_1 Heat flux | 40.2861 | 10 | 4.028 | 76.04 | 0.0000 |

| Col_2 Board thickness | 103.654 | 2 | 51.826 | 978.28 | 0.0000 |

| Residual | 1.05955 | 20 | 0.0529 | ||

| Total | 144.999 | 32 |

| Source | Sum of Squares | Df | Mean Square | F-Ratio | p-Value |

|---|---|---|---|---|---|

| Main Effects | |||||

| Col_4 Distance from the source | 47,980.0 | 2 | 23,990.0 | 534.73 | 0.0000 |

| Col_5 Heat flux | 6798.83 | 3 | 2266.28 | 50.51 | 0.0000 |

| Residual | 1974.02 | 44 | 44.8642 | ||

| Total | 52,250.3 | 49 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tureková, I.; Ivanovičová, M.; Harangózo, J.; Gašpercová, S.; Marková, I. Experimental Study of the Influence of Selected Factors on the Particle Board Ignition by Radiant Heat Flux. Polymers 2022, 14, 1648. https://doi.org/10.3390/polym14091648

Tureková I, Ivanovičová M, Harangózo J, Gašpercová S, Marková I. Experimental Study of the Influence of Selected Factors on the Particle Board Ignition by Radiant Heat Flux. Polymers. 2022; 14(9):1648. https://doi.org/10.3390/polym14091648

Chicago/Turabian StyleTureková, Ivana, Martina Ivanovičová, Jozef Harangózo, Stanislava Gašpercová, and Iveta Marková. 2022. "Experimental Study of the Influence of Selected Factors on the Particle Board Ignition by Radiant Heat Flux" Polymers 14, no. 9: 1648. https://doi.org/10.3390/polym14091648

APA StyleTureková, I., Ivanovičová, M., Harangózo, J., Gašpercová, S., & Marková, I. (2022). Experimental Study of the Influence of Selected Factors on the Particle Board Ignition by Radiant Heat Flux. Polymers, 14(9), 1648. https://doi.org/10.3390/polym14091648