A Self-Matting Waterborne Polyurethane Coating for PVC Artificial Leather

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Synthesis of ESMWPU

2.3. Preparation of WPU Films

2.4. Measurements

3. Results and Discussion

3.1. Characterization of ESMWPU

3.2. Relationship between Synthesis Parameters and Coating Properties

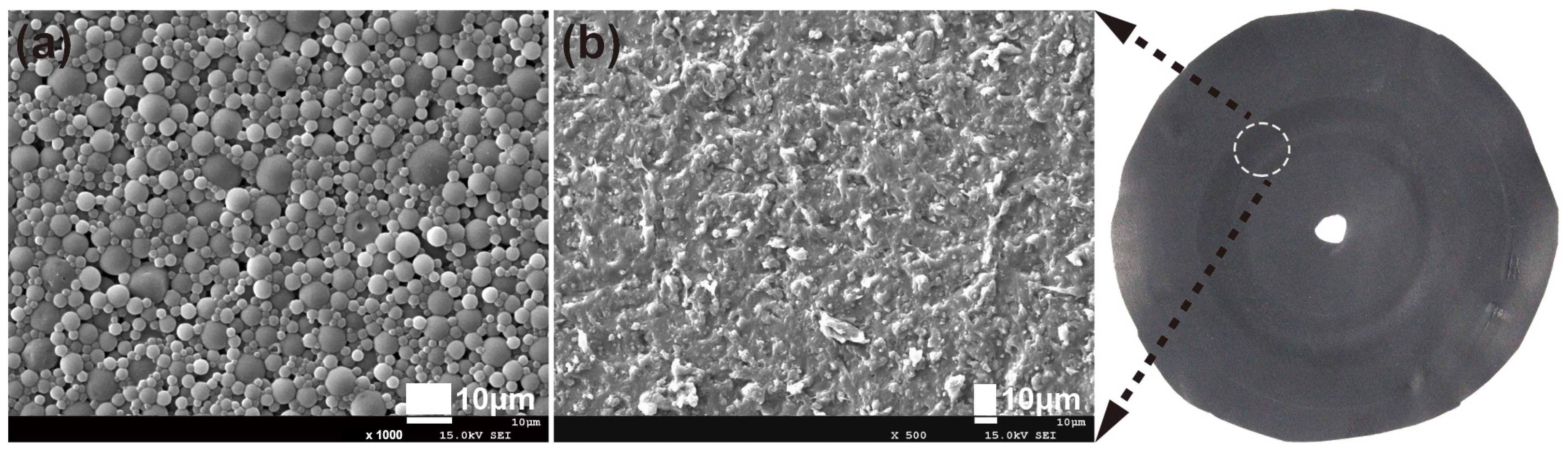

3.2.1. Effect of R Value on Surface Morphology and Optical Properties

3.2.2. Effect of TMP Content on Surface Morphology and Optical Properties

3.2.3. Effect of DMPA Content on Surface Morphology and Optical Properties

3.3. Application of ESMWPU on PVC Artificial Leather

3.3.1. Wetting Properties

3.3.2. Adhesion

3.3.3. Resistance to Thermal Adhesion

3.3.4. Wear Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mahmud, J.; Yusop, S.H.M.; Noor, S.N.A.M. Leather and Synthetic Leather: A Mechanical Viewpoint for Sustainability. In Engineering and Technical Development for a Sustainable Environment; Apple Academic Press: Palm Bay, FL, USA, 2017; pp. 125–146. [Google Scholar]

- Tian, Y.; Wang, J.; Zheng, S.; He, X.; Liu, X. Research on the Preparation and Application of Synthetic Leather from Coffee Grounds for Sustainable Development. Sustainability 2022, 14, 13971. [Google Scholar] [CrossRef]

- Wang, Y.; Jin, L. Preparation and characterization of self-colored waterborne polyurethane and its application in eco-friendly manufacturing of microfiber synthetic leather base. Polymers 2018, 10, 289. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gurera, D.; Bhushan, B. Fabrication of bioinspired superliquiphobic synthetic leather with self-cleaning and low adhesion. Colloids Surf. A Physicochem. Eng. Asp. 2018, 545, 130–137. [Google Scholar] [CrossRef]

- Ma, Y.; Dang, X.; Shan, Z. Thermal analysis and identification of potential fire-proof energy building material based on artificial leather. J. Therm. Sci. 2019, 28, 88–96. [Google Scholar] [CrossRef]

- Zhao, B.; Qian, X.; Qian, Y.; Duo, Y.; Feng, Y.; Fan, J.; Chen, Y. The application of hollow segmented pie bicomponent spunbond hydro-entangled microfiber nonwovens for microfiber synthetic leather apparel. AATCC J. Res. 2019, 6, 45–49. [Google Scholar] [CrossRef]

- Tian, S. Recent advances in functional polyurethane and its application in leather manufacture: A review. Polymers 2020, 12, 1996. [Google Scholar] [CrossRef] [PubMed]

- Kan, C.; Kwong, C.; Ng, S. Atmospheric pressure plasma surface treatment of rayon flock synthetic leather with tetramethylsilane. Appl. Sci. 2016, 6, 59. [Google Scholar] [CrossRef] [Green Version]

- Kumar, V.; Misra, N.; Paul, J.; Bhardwaj, Y.; Goel, N.; Francis, S.; Sarma, K.; Varshney, L. Organic/inorganic nanocomposite coating of bisphenol A diglycidyl ether diacrylate containing silica nanoparticles via electron beam curing process. Prog. Org. Coat. 2013, 76, 1119–1126. [Google Scholar] [CrossRef]

- Ou, J.; Zhang, M.; Liu, H.; Zhang, L.; Pang, H. Matting films prepared from waterborne acrylic/micro-SiO2 blends. J. Appl. Polym. Sci. 2015, 132, 41707. [Google Scholar] [CrossRef]

- Sun, Z.; Fan, H.; Chen, Y.; Huang, J. Synthesis of self-matting waterborne polyurethane coatings with excellent transmittance. Polym. Int. 2018, 67, 78–84. [Google Scholar] [CrossRef]

- Yong, Q.; Nian, F.; Liao, B.; Guo, Y.; Huang, L.; Wang, L.; Pang, H. Synthesis and surface analysis of self-matt coating based on waterborne polyurethane resin and study on the matt mechanism. Polym. Bull. 2017, 74, 1061–1076. [Google Scholar] [CrossRef]

- Yong, Q.; Nian, F.; Liao, B.; Huang, L.; Wang, L.; Pang, H. Synthesis and characterization of solvent-free waterborne polyurethane dispersion with both sulfonic and carboxylic hydrophilic chain-extending agents for matt coating applications. RSC Adv. 2015, 5, 107413–107420. [Google Scholar] [CrossRef]

- Tian, L.; Su, M.; Yu, F.; Xu, Y.; Li, X.; Li, L.; Liu, H.; Tan, W. Liquid-state quantitative SERS analyzer on self-ordered metal liquid-like plasmonic arrays. Nat. Commun. 2018, 9, 1–12. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, D.; Dai, P.-Q.; Luo, X.-B.; Zhang, Y.-C. Novel characterization of wetting properties and the calculation of liquid-solid interface tension (I). Sci. Technol. Eng 2007, 7, 3057–3062. [Google Scholar]

- Chen, Y.; Zhou, S.; Pan, S.; Zhao, D.; Wei, J.; Zhao, M.; Fan, H. Methods for determination of plasticizer migration from polyvinyl chloride synthetic materials: A mini review. J. Leather Sci. Eng. 2022, 4, 1–10. [Google Scholar] [CrossRef]

- Li, J.; Li, Y.; Song, Y.; Wang, Z.; Zhang, Q. Properties of quaternary ammonium surfactant with hydroxyethyl group and anionic surfactant mixed systems. J. Mol. Liq. 2018, 271, 373–379. [Google Scholar] [CrossRef]

| Synthesis Parameters | Values | Gloss (°) | Transmittance (%) |

|---|---|---|---|

| R value | 1.9 | 0.8 | 78.5 |

| 2.1 | 4.0 | 88.5 | |

| 2.3 | 4.9 | 89.0 | |

| TMP content (wt%) | 0 | 5.1 | 88.0 |

| 0.5 | 1.1 | 80.8 | |

| 1.0 | 1.0 | 80.0 | |

| 1.5 | 0.9 | 79.1 | |

| 2.0 | 0.8 | 78.5 | |

| DMPA content (wt%) | 1.75 | 0.8 | 78.5 |

| 1.90 | 1.7 | 85.5 | |

| 2.05 | 3.2 | 88.5 | |

| 2.20 | 4.8 | 88.8 |

| Leveling Agent (wt%) | Contact Angle (°) | γSL (mJ/m2) | γL (mN/m) | Sc (mJ/m2) |

|---|---|---|---|---|

| 0 | 73.9 | 25.5 | 46.0 | −23 |

| 0.5 | 53.0 | 7.5 | 22.1 | 18.9 |

| 1.0 | 43.8 | 5.4 | 22.0 | 21.1 |

| 1.5 | 36.3 | 3.9 | 22.0 | 22.6 |

| 2.0 | 27.7 | 2.4 | 22.0 | 24.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Z.; Ren, S.; Wu, T.; Wen, J.; Fang, J.; Fan, H. A Self-Matting Waterborne Polyurethane Coating for PVC Artificial Leather. Polymers 2023, 15, 127. https://doi.org/10.3390/polym15010127

Sun Z, Ren S, Wu T, Wen J, Fang J, Fan H. A Self-Matting Waterborne Polyurethane Coating for PVC Artificial Leather. Polymers. 2023; 15(1):127. https://doi.org/10.3390/polym15010127

Chicago/Turabian StyleSun, Zhe, Song Ren, Tong Wu, Jiating Wen, Jian Fang, and Haojun Fan. 2023. "A Self-Matting Waterborne Polyurethane Coating for PVC Artificial Leather" Polymers 15, no. 1: 127. https://doi.org/10.3390/polym15010127

APA StyleSun, Z., Ren, S., Wu, T., Wen, J., Fang, J., & Fan, H. (2023). A Self-Matting Waterborne Polyurethane Coating for PVC Artificial Leather. Polymers, 15(1), 127. https://doi.org/10.3390/polym15010127