Highly Enhanced Mechanical, Thermal, and Crystallization Performance of PLA/PBS Composite by Glass Fiber Coupling Agent Modification

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

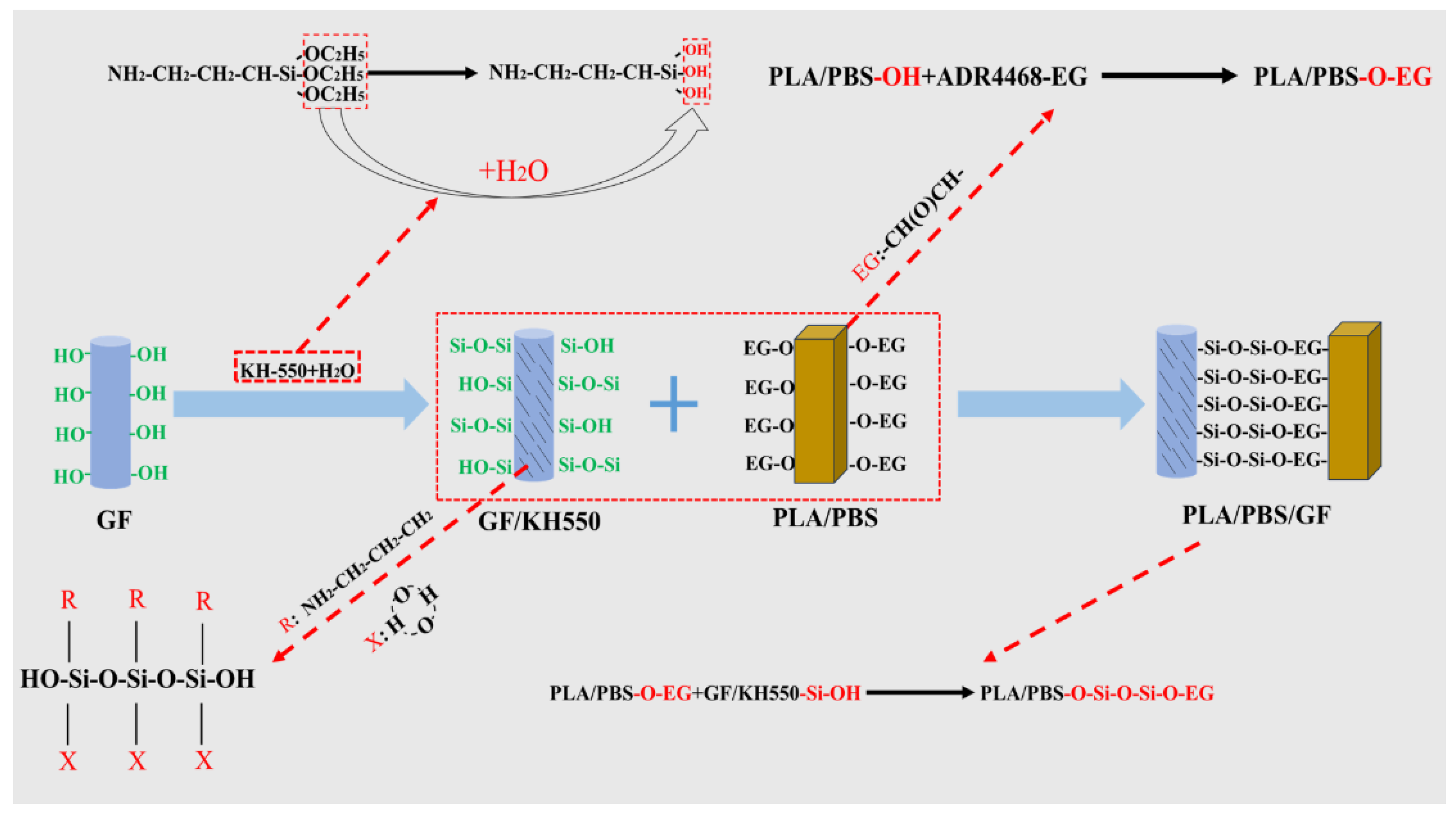

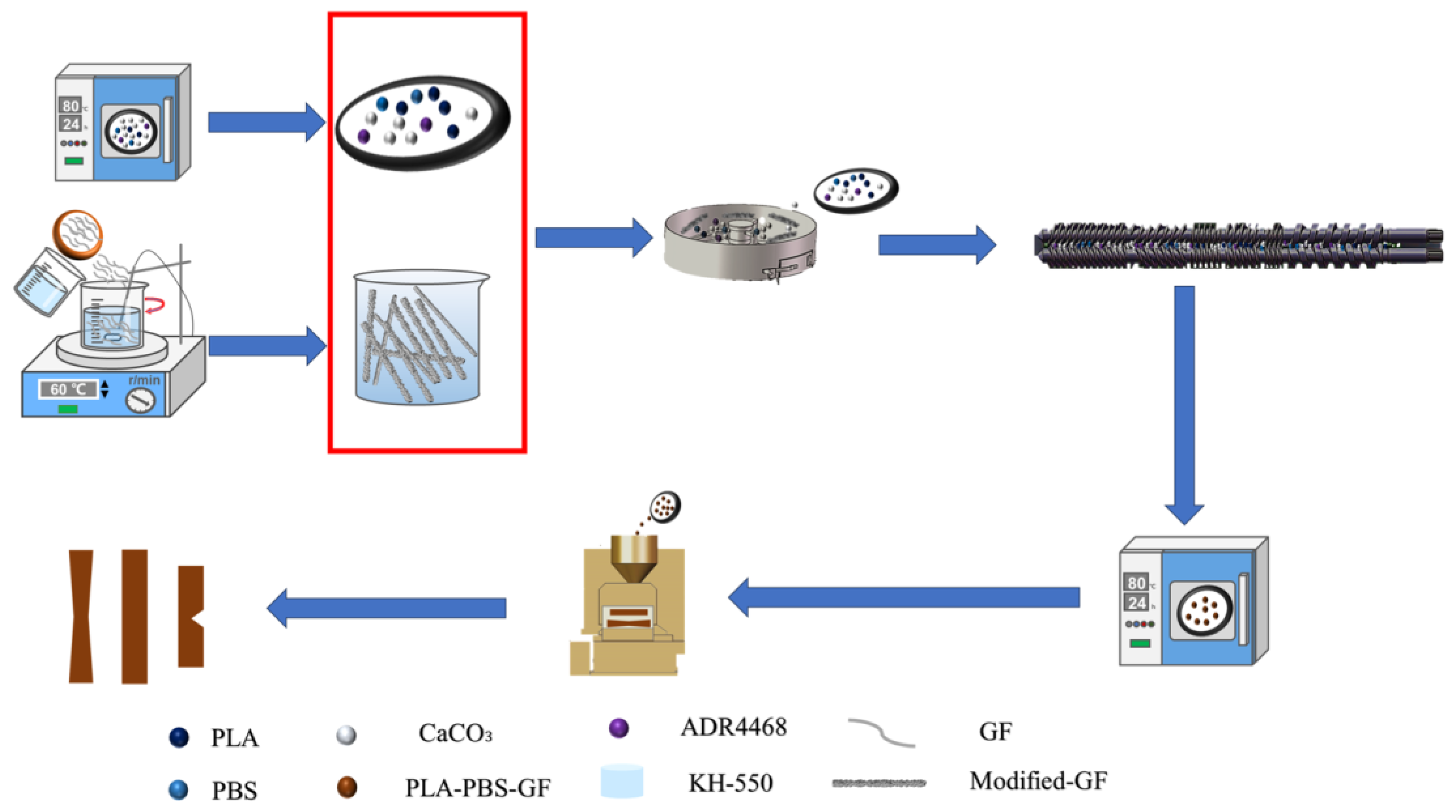

2.2. Preparation of KH-GF

2.3. Preparation of Modified PLA/PBS Composite Materials

2.4. Testing Methods

2.4.1. Fourier Transform Infrared Spectroscopy (FTIR)

2.4.2. Mechanical Properties

2.4.3. Thermal Properties

2.4.4. Crystallization Properties

2.4.5. Rheological Properties

2.4.6. Microscopic Morphology

3. Results and Discussion

3.1. FTIR Spectroscopy

3.2. Mechanical Properties

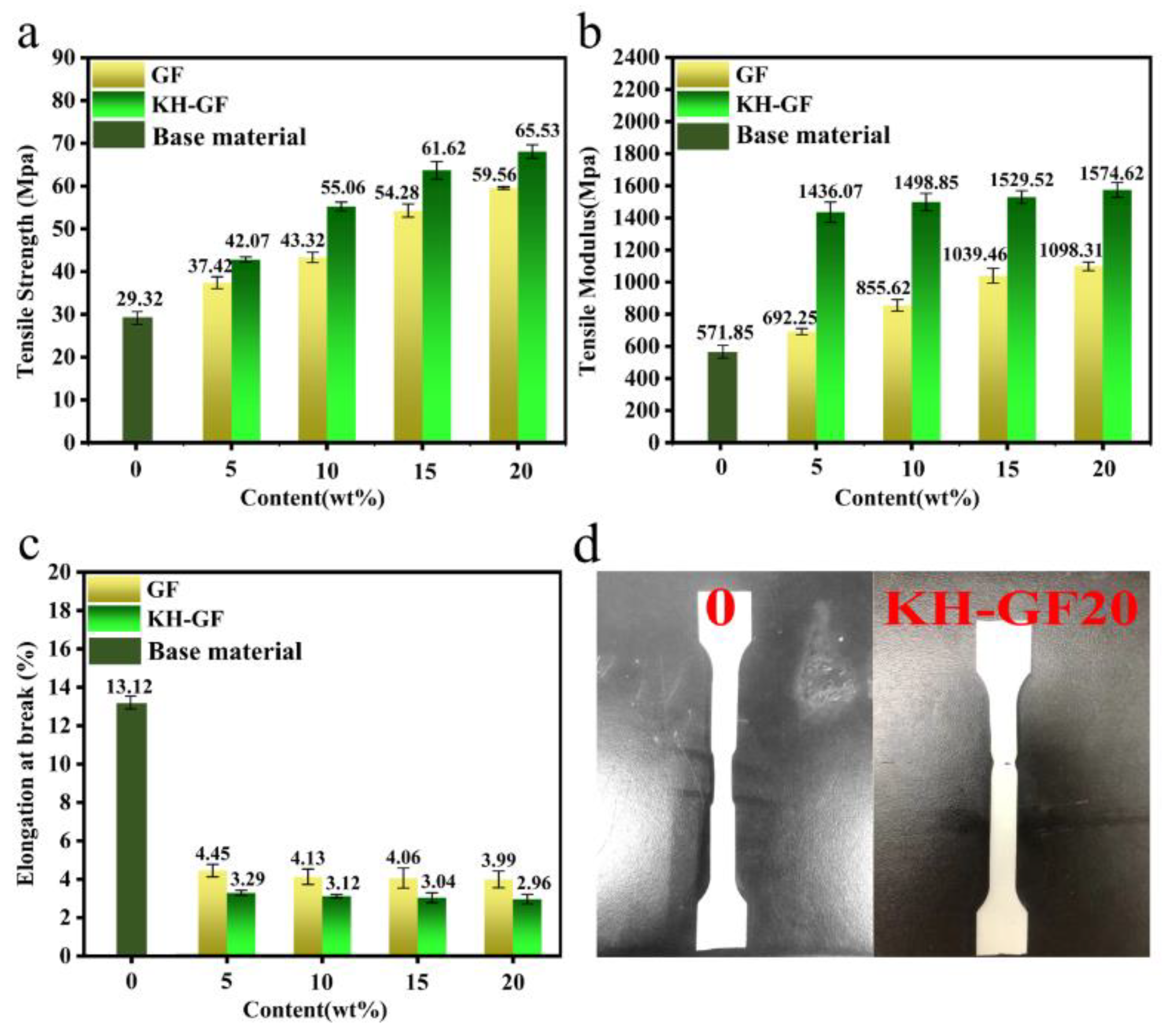

3.2.1. Tensile Properties

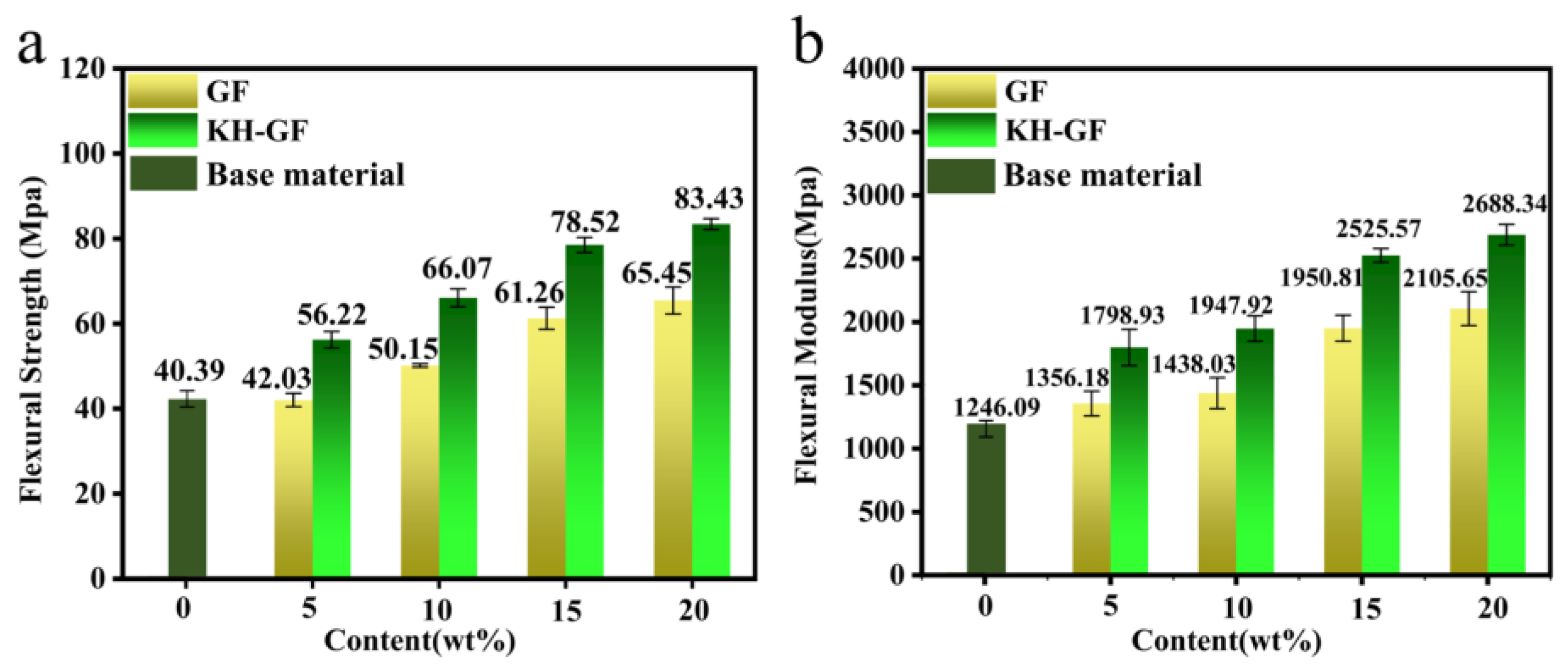

3.2.2. Flexural Properties

3.2.3. Impact Properties

3.3. Thermal Analysis

3.3.1. DSC Analysis

3.3.2. XRD Analysis

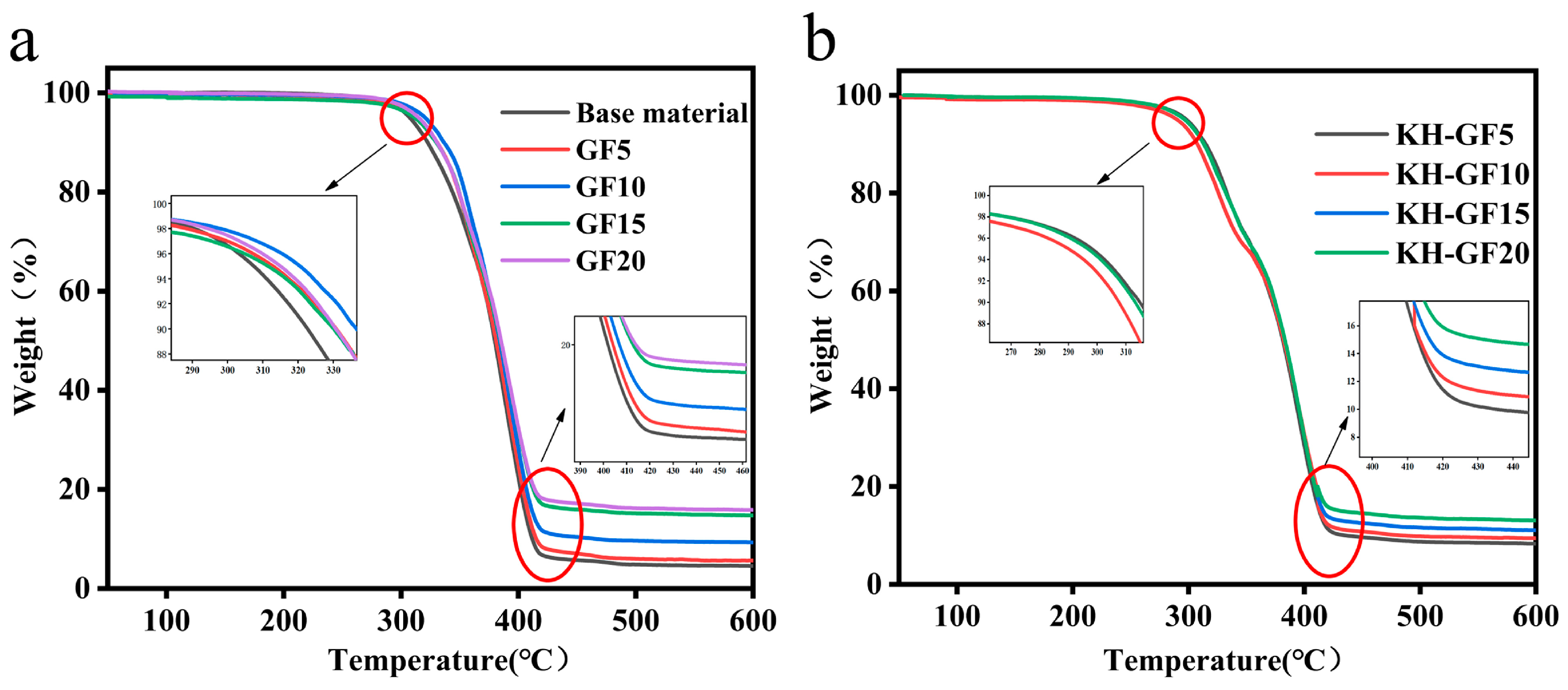

3.3.3. TGA Analysis

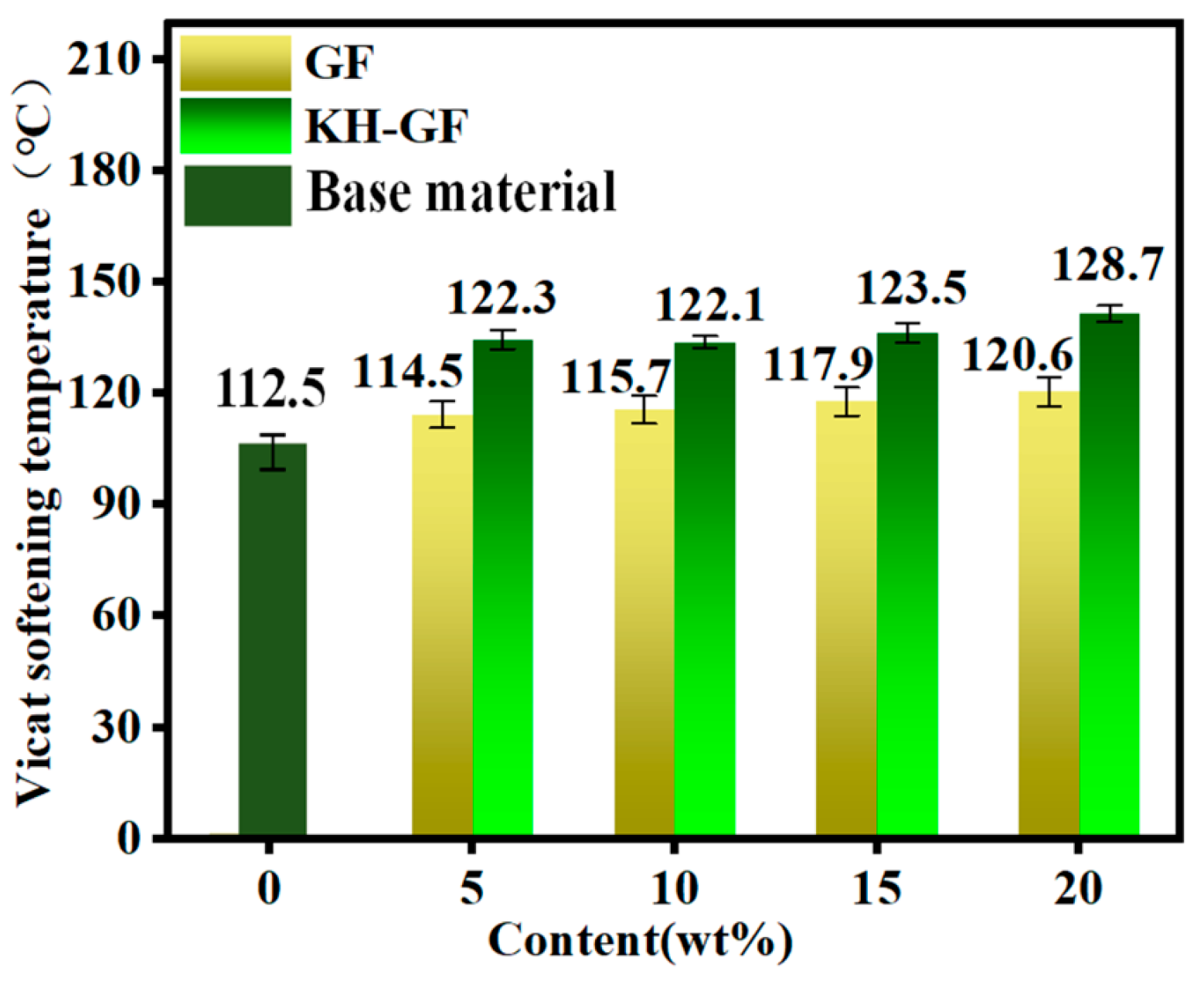

3.3.4. Vicat Softening Temperature (VST) Analysis

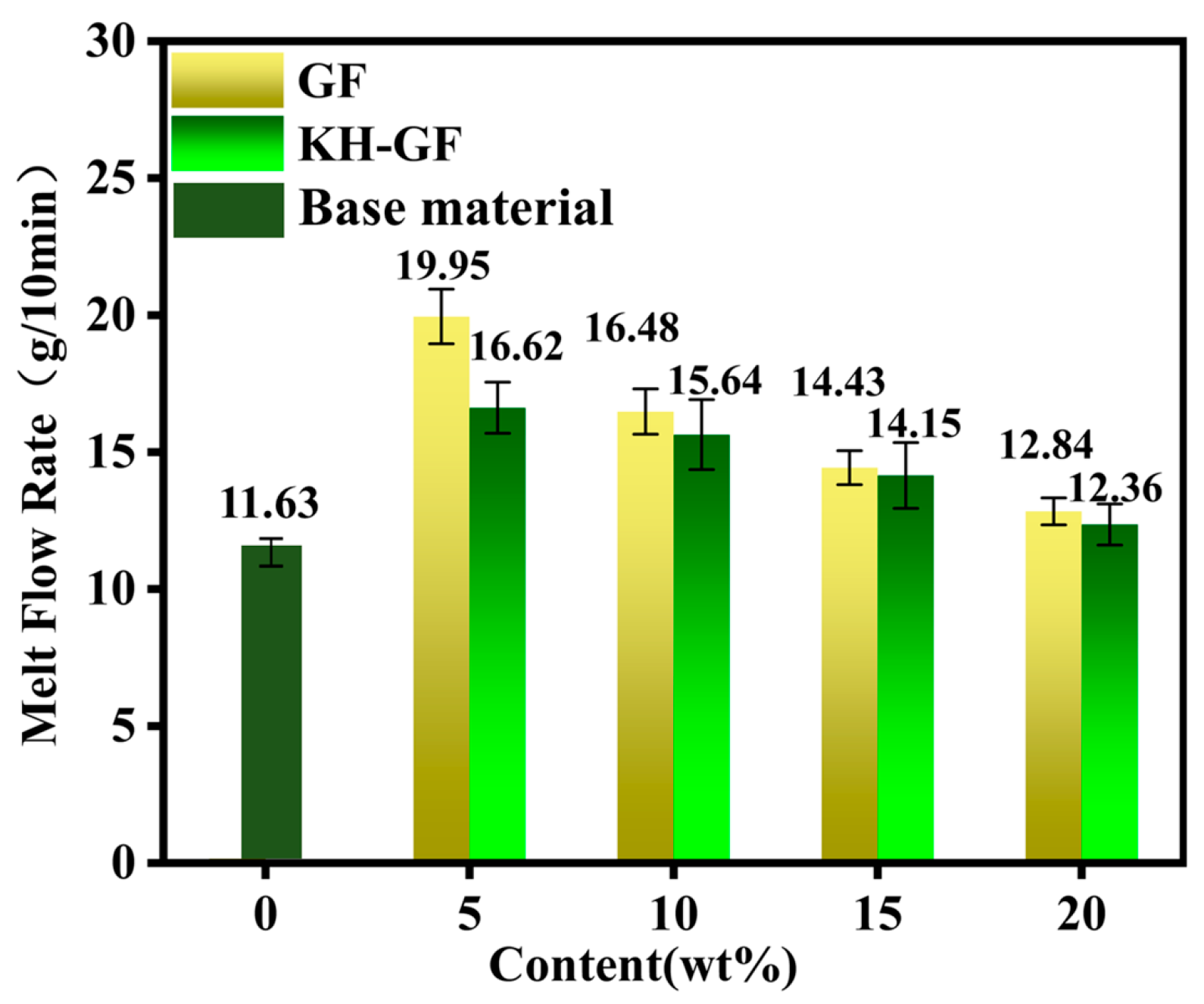

3.4. Rheological Properties

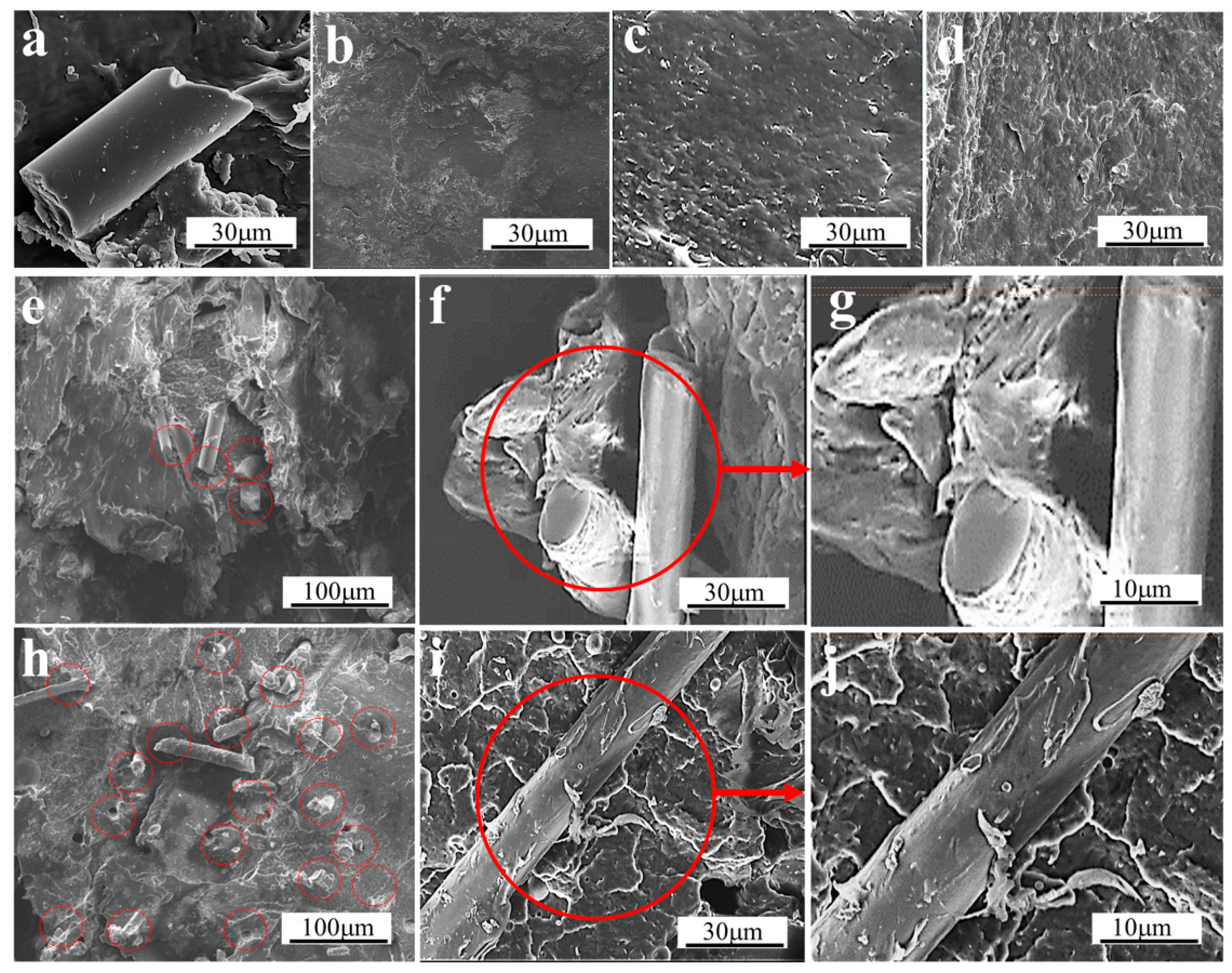

3.5. Morphological Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Tan, S.X.; Andriyana, A.; Ong, H.C.; Lim, S.; Pang, Y.L.; Ngoh, G.C. A comprehensive review on the emerging roles of nanofillers and plasticizers towards sustainable starch-based bioplastic fabrication. Polymers 2022, 14, 664. [Google Scholar] [CrossRef]

- Choochottiros, C. Thermal crosslinking of polylactide/star-shaped polycaprolactone for toughening and resistance to thermal deformation. Polym. J. 2022, 54, 83–90. [Google Scholar] [CrossRef]

- Akindoyo, J.O.; Hidayah, I.N.; Mariatti, M. Performance of poly(vinyl alcohol) nanocomposite reinforced with hybrid TEMPO mediated cellulose-graphene filler. Polym. Test. 2019, 80, 106140. [Google Scholar] [CrossRef]

- Zhao, X.P.; Yu, J.J.; Liang, X.Y.; Huang, Z.P.; Li, J.C.; Peng, S.X. Crystallization behaviors regulations and mechanical performances enhancement approaches of polylactic acid (PLA) biodegradable materials modified by organic nucleating agents. Int. J. Biol. Macromol 2023, 233, 123581. [Google Scholar] [CrossRef] [PubMed]

- Ucpinar Durmaz, B.; Aytac, A. Investigation of the mechanical, thermal, morphological and rheological properties of bio-based polyamide11/poly(lactic acid) blend reinforced with short carbon fiber. Mater. Today Commun. 2022, 30, 103030. [Google Scholar] [CrossRef]

- Apiwat, S.; Wutthikrai, B.; Wonchalerm, R.; Siriwat, S.; Kanjana, T.; Chokchai, W. Structural and mechanical properties of biodegradable poly(lactic acid) and pectin composites: Using bionucleating agent to improve crystallization behavior. Polym. J. 2022, 54, 921–930. [Google Scholar]

- Yang, R.; Cao, H.W.; Zhang, P.L.; Chen, L.; Zou, G.X.; Zhang, X.; Li, J.C. Highly toughened and heat-resistant poly(lactic acid) with balanced strength using an unsaturated liquid crystalline polyester via dynamic vulcanization. ACS Appl. Polym. Mater. 2021, 3, 299–309. [Google Scholar] [CrossRef]

- Yang, D.D.; Wu, C.; Wu, G.; Chen, S.C.; Wang, Y.Z. Toughening of polylactide with high tensile strength via constructing an integrative physical crosslinking network based on ionic interactions. Macromolecules 2021, 54, 291–301. [Google Scholar] [CrossRef]

- Gao, X.R.; Li, Y.; Huang, H.D.; Xu, J.Z.; Xu, L.; Ji, X.; Zhong, G.J.; Li, Z.M. Extensional stress-induced orientation and crystallization can regulate the balance of toughness and stiffness of polylactide films: Interplay of oriented amorphous chains and crystallites. Macromolecules 2019, 52, 5278–5288. [Google Scholar] [CrossRef]

- Siracusa, V.; Karpova, S.; Olkhov, A.; Zhulkina, A.; Kosenko, R.; Iordanskii, A. Gas Transport Phenomena and Polymer Dynamics in PHB/PLA Blend Films as Potential Packaging Materials. Polymers 2020, 12, 647. [Google Scholar] [CrossRef] [Green Version]

- Ma, M.; Xu, L.; Liu, K.; Chen, S.; He, H.W.; Shi, Y.Q.; Wang, X. Effect of triphenyl phosphite as a reactive compatibilizer on the properties of poly((L)-lactic acid)/ poly(butylene succinate) blends. J. Appl. Polym. Sci. 2020, 137, 9. [Google Scholar] [CrossRef]

- Shafqat, A.; Tahir, A.; Mahmood, A.; Tabinda, A.B.; Yasar, A.; Pugazhendhi, A. A review on environmental significance carbon foot prints of starch based bio-plastic: A substitute of conventional plastics. Biocatal. Agric. Biotechnol. 2020, 27, 101540. [Google Scholar] [CrossRef]

- Mejias, S.H.; López-Martínez, E.; Fernandez, M.; Couleaud, P.; Martin-Lasanta, A.; Romera, D.; Sanchez-Iglesias, A.; Casado, S.; Osorio, M.R.; Abad, J.M. Engineering conductive protein films through nanoscale self-assembly and gold nanoparticles doping. Nanoscale 2021, 13, 6772–6779. [Google Scholar] [CrossRef] [PubMed]

- Nagy, B.; Miskolczi, N.; Eller, Z. Improving mechanical properties of PLA/starch blends using masterbatch containing vegetable oil based active ingredients. Polymers 2021, 13, 2981. [Google Scholar] [CrossRef]

- Jia, S.L.; Zhao, L.; Wang, X.Y.; Chen, Y.J.; Pan, H.W.; Han, L.J.; Zhang, H.L.; Dong, L.S.; Zhang, H.X. Poly (lactic acid) blends with excellent low temperature toughness: A comparative study on poly (lactic acid) blends with different toughening agents. Int. J. Biol. Macromol. 2022, 201, 662–675. [Google Scholar] [CrossRef]

- Qu, Y.D.; Rong, C.Y.; Ling, X.Y.; Wu, J.L.; Chen, Y.H.; Wang, H.T.; Li, Y.J. Role of interfacial postreaction during thermal treatment: Toward a better understanding of the toughness of PLLA/reactive elastomer blends. Macromolecules 2022, 55, 1321–1331. [Google Scholar] [CrossRef]

- Brounstein, Z.; Yeager, C.M.; Labouriau, A. Development of antimicrobial PLA composites for fused filament fabrication. Polymers 2021, 13, 580. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Yang, B.; Fan, B.; Sun, H.; Zhang, H. Enhanced Nonisothermal Crystallization and Heat Resistance of Poly(L-lacticacid) by D-Sorbitol as a Homogeneous Nucleating Agent. ACS Macro Lett. 2021, 10, 154–160. [Google Scholar] [CrossRef] [PubMed]

- Safari, M.; Otaegi, I.; Aramburu, N.; Guerrica-Echevarria, G.; de Ilarduya, A.; Sardon, H.; Müller, A. Synthesis, Structure, Crystallization and Mechanical Properties of Isodimorphic PBS-ran-PCL Copolyesters. Polymers 2021, 13, 2263. [Google Scholar] [CrossRef]

- Aliotta, L.; Seggiani, M.; Lazzeri, A.; Gigante, V.; Cinelli, P. A Brief Review of Poly (Butylene Succinate) (PBS) and Its Main Copolymers: Synthesis, Blends, Composites, Biodegradability, and Applications. Polymers 2022, 14, 844. [Google Scholar] [CrossRef] [PubMed]

- Tian, X.Z.; Bai, H.Z.; Chen, T.; Sang, S.; Deng, H.B.; Jiang, X. Poly(lactic acid)/poly (butylene succinate)/boron nitride nanosheet composites with high thermal conductivity: A novel biodegradable electronic packaging material. Polym. Bull. 2023, 5, 278. [Google Scholar] [CrossRef]

- Kamau-Devers, K.; Miller, S.A. The environmental attributes of wood fiber composites with bio-based or petroleum-based plastics. Int. J. Life Cycle Assess. 2020, 25, 1145–1159. [Google Scholar] [CrossRef]

- Ail, M.A.; Nag, A.; Singh, M. Microbial-derived polymers and their degradability behavior for future prospects. Environ. Agric. Microbiol. 2021, 1, 63–82. [Google Scholar]

- Niu, W.D.; Guo, Y.F.; Huang, W.; Song, L.L.; Xiao, Z.F.; Xie, Y.J.; Wang, Y.G. Aliphatic chains grafted cellulose nanocrystals with core-corona structures for efficient toughening of PLA composites. Carbohydr. Polym. 2022, 285, 119200. [Google Scholar] [CrossRef] [PubMed]

- Su, S.; Kopitzky, R.; Tolga, S.; Kabasci, S. Polylactide (PLA) and Its Blends with Poly(butylene succinate) (PBS): A Brief Review. Polymers 2019, 11, 1193. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vieira, M.G.A.; da Silva, M.A.; dos Santos, L.O.; Beppu, M.M. Natural-based plasticizers and biopolymer films: A review. Eur. Polym. J. 2011, 47, 254–263. [Google Scholar] [CrossRef] [Green Version]

- Wang, R.; Wang, S.; Zhang, Y.; Wan, C.; Ma, P. Toughening modification of PLLA/PBS blends via in situ compatibilization. Polym. Eng. Sci. 2009, 49, 26–33. [Google Scholar] [CrossRef]

- Imre, B.; Pukánszky, B. Compatibilization in bio-based and biodegradable polymer blends. Eur. Polym. J. 2013, 49, 1215–1233. [Google Scholar] [CrossRef] [Green Version]

- Manning, S.C.; Moore, R.B. Reactive compatibilization of polypropylene and polymide-6,6 with carboxylated and maleated polypropylene. Polym. Eng. Sci. 1999, 39, 1921–1929. [Google Scholar] [CrossRef]

- Seyed Khabbaz, H.; Garmabi, H. Modification of polylactide by reactive blending with polyhydroxybutyrate oligomers formed by thermal recycling through E1cB-elimination pathway. Eur. Polym. J. 2022, 166, 111043. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Skorczewska, K.; Klozinski, A. Improving the toughness and thermal resistance of polyoxymethylene/poly(lactic acid) blends: Evaluation of structure-properties correlation for reactive processing. Polymers 2020, 12, 307. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Petchwattana, N.; Sukkaneewat, B.; Naknaen, P. Synergistic effects of bio-plasticizer and core-shell rubber on poly(lactic acid) toughness for sustainable flexible packaging applications. J. Appl. Polym. Sci. 2022, 139, 51894. [Google Scholar] [CrossRef]

- Luo, C.; Li, S.; Fang, M.; Sun, J.; Xiao, W.; Tang, F.; Chen, W. Effects of polylactide-functionalized multi-walled carbon nanotubes on the crystallization behavior and thermal stability of poly (L-lactic acid). J. Appl. Polym. Sci. 2022, 139, 51676. [Google Scholar] [CrossRef]

- Khosravi, A.; Fereidoon, A.; Khorasani, M.M.; Saeb, M.R. Experimental and theoretical mechanical behavior of compatibilized polylactic acid/polyolefin elastomer blends for potential packaging applications. Iran. Polym. J. 2022, 31, 651–663. [Google Scholar] [CrossRef]

- Parna, N.; Dipayan, D. Mechanical, thermo-mechanical and biodegradation behaviour of surface-silanized nettle fabric-reinforced poly(lactic acid) composites. Mater. Chem. Phys. 2023, 297, 127381. [Google Scholar]

- Cousins, D.S.; Suzuki, Y.; Murray, R.E.; Samaniuk, J.R.; Stebner, A.P. Recycling glass fiber thermoplastic composites from wind turbine blades. J. Clean. Prod. 2019, 209, 1252–1263. [Google Scholar] [CrossRef]

- Gao, J.C.; Wu, Y.D.; Li, J.; Peng, X.Q.; Yin, D.W.; Wang, J.C.; Wang, X.H.; Jin, M.J.; Yao, Z.W.; Shen, X.J.; et al. Toughening and heat-resistant modification of degradable PLA/PBS-based composites by using glass fiber/silicon dioxide hybrid fillers. Polymers 2022, 14, 3237. [Google Scholar] [CrossRef]

- Wang, G.L.; Zhang, D.M.; Li, B.; Wan, G.P.; Zhao, G.Q.; Zhang, A.M. Strong and thermal-resistance glass fiber-reinforced polylactic acid (PLA)composites enabled by heat treatment. Int. J. Biol. Macromol. 2019, 129, 448–459. [Google Scholar] [CrossRef] [PubMed]

- Yin, X.; Bao, J. Glass fiber coated with graphene constructed through electrostatic self-assembly and its application in poly(lactic acid) composite. J. Appl. Polym. Sci. 2016, 133, 43–296. [Google Scholar] [CrossRef]

- Wan, X.R.; Lu, H.; Kang, J.F.; Li, S.; Yue, Y.L. Preparation of graphene-glass fiber-resin composites and its electromagnetic shielding performance. Compos. Interfaces 2018, 25, 883–900. [Google Scholar] [CrossRef]

- Luo, W.; Wang, X.; Huang, R.; Fang, P. Interface enhancement of glass fiber/unsaturated polyester resin composites with nano-silica treated using silane coupling agent. Wuhan Univ. J. Nat. Sci. 2014, 19, 34–40. [Google Scholar] [CrossRef]

- Da Silva Barbosa Ferreira, E.; Luna, C.B.B.; Siqueira, D.D. Annealing effect on pla/eva blends performance. J. Polym. Environ. 2022, 30, 541–554. [Google Scholar] [CrossRef]

- Justyna, O.; Waldemar, S.; Magdalena, P.P.; Jakub, B. The effect of poly(butylene succinate) content on the structure and thermal and mechanical properties of its blends with polylactide. Polym. Int. 2019, 68, 1271–1279. [Google Scholar]

- Marcuello, C.; Chabbert, B.; Berzin, F.; Bercu, N.B.; Molinari, M.; Aguié-Béghin, V. Influence of Surface Chemistry of Fiber and Lignocellulosic Materials on Adhesion Properties with Polybutylene Succinate at Nanoscale. Materials 2023, 16, 2440. [Google Scholar] [CrossRef] [PubMed]

- Lostao, A.; Lim, K.; Pallares, M.C.; Ptak, A.; Marcuello, C. Recent advances in sensing the inter-biomolecular interactions at the nanoscale—A comprehensive review of AFM-based force spectroscopy. Int. J. Biol. Macromol. 2023, 238, 124089. [Google Scholar] [CrossRef] [PubMed]

- Hashima, K.; Nishitsuji, S.; Inoue, T. Structure-properties of super-tough PLA alloy with excellent heat resistance. Polymer 2010, 51, 3934–3939. [Google Scholar] [CrossRef]

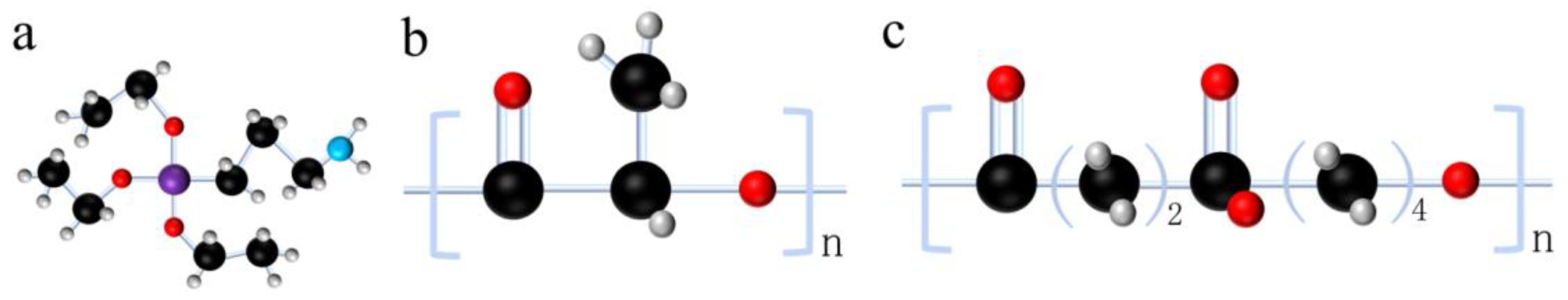

= C;

= C;  = O;

= O;  = H;

= H;  = Si;

= Si;  = N).

= N).

= C;

= C;  = O;

= O;  = H;

= H;  = Si;

= Si;  = N).

= N).

| Sample | PLA | PBS | CaCO3 | ADR4468 | GF | KH-GF |

|---|---|---|---|---|---|---|

| Base material | 70 | 30 | 3 | 3 | / | / |

| GF5 | 70 | 30 | 3 | 3 | 5 | / |

| GF10 | 70 | 30 | 3 | 3 | 10 | / |

| GF15 | 70 | 30 | 3 | 3 | 15 | / |

| GF20 | 70 | 30 | 3 | 3 | 20 | / |

| KH-GF5 | 70 | 30 | 3 | 3 | / | 5 |

| KH-GF10 | 70 | 30 | 3 | 3 | / | 10 |

| KH-GF15 | 70 | 30 | 3 | 3 | / | 15 |

| KH-GF20 | 70 | 30 | 3 | 3 | / | 20 |

| GF (wt%) | 0 | 5 | 10 | 15 | 20 | ||||

|---|---|---|---|---|---|---|---|---|---|

| Code | GF | GF | KH-GF | GF | KH-GF | GF | KH-GF | GF | KH-GF |

| TC (°C) | 79.53 | 74.02 | 71.78 | 76.34 | 71.24 | 77.01 | 71.76 | 77.64 | 74.51 |

| ∆HC (J/g) | 42.56 | 42.67 | 41.84 | 41.85 | 39.42 | 38.78 | 39.18 | 35.04 | 26.59 |

| TCC (°C) | 103.26 | 101.33 | 98.64 | 100.18 | 97.52 | 101.85 | 99.52 | 102.03 | 99.58 |

| ∆HCC (J/g) | 1.94 | 4.25 | 4.03 | 4.75 | 4.14 | 2.98 | 4.23 | 2.42 | 2.61 |

| Tm1 (°C) | 112.64 | 113.95 | 117.46 | 112.75 | 117.86 | 113.78 | 118.69 | 113.43 | 119.89 |

| ∆Hm1 (J/g) | 34.47 | 41.47 | 42.71 | 43.53 | 41.06 | 37.23 | 40.66 | 34.33 | 26.61 |

| Tm2 (°C) | 144.12 | 144.53 | 141.84 | 144.81 | 143.28 | 145.23 | 147.58 | 145.61 | 148.24 |

| ∆Hm2 (J/g) | 1.88 | 2.09 | 3.44 | 1.93 | 3.78 | 1.98 | 1.87 | 1.16 | 1.37 |

| χ (%) | 34.72 | 39.72 | 41.28 | 41.39 | 45.29 | 36.75 | 40.38 | 34.09 | 39.53 |

| GF (wt%) | 0 | 5 | 10 | 15 | 20 | ||||

|---|---|---|---|---|---|---|---|---|---|

| Code | GF | GF | KH-GF | GF | KH-GF | GF | KH-GF | GF | KH-GF |

| T0 | 214 | 231 | 210 | 249 | 208 | 266 | 200 | 273 | 198 |

| T5% | 307 | 312 | 297 | 319 | 289 | 310 | 295 | 312 | 295 |

| T10% | 322 | 330 | 314 | 335 | 307 | 329 | 312 | 329 | 312 |

| T50% | 379 | 381 | 381 | 383 | 381 | 384 | 383 | 385 | 382 |

| Td | 418 | 421 | 422 | 422 | 421 | 423 | 422 | 421 | 420 |

| Residue (%) at T ≥ 600 °C | 4.56 | 5.53 | 10.93 | 9.25 | 12.17 | 14.75 | 13.63 | 15.82 | 15.47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, Z.; Gao, J.; Wu, Y.; Yin, D.; Chen, S.; Tu, H.; Wei, T.; Zhang, C.; Zhu, H.; Jin, H. Highly Enhanced Mechanical, Thermal, and Crystallization Performance of PLA/PBS Composite by Glass Fiber Coupling Agent Modification. Polymers 2023, 15, 3164. https://doi.org/10.3390/polym15153164

Fan Z, Gao J, Wu Y, Yin D, Chen S, Tu H, Wei T, Zhang C, Zhu H, Jin H. Highly Enhanced Mechanical, Thermal, and Crystallization Performance of PLA/PBS Composite by Glass Fiber Coupling Agent Modification. Polymers. 2023; 15(15):3164. https://doi.org/10.3390/polym15153164

Chicago/Turabian StyleFan, Zhiqiang, Junchang Gao, Yadong Wu, Dewu Yin, Shunxing Chen, Hua Tu, Tiantian Wei, Chaoran Zhang, Haoxiang Zhu, and Huile Jin. 2023. "Highly Enhanced Mechanical, Thermal, and Crystallization Performance of PLA/PBS Composite by Glass Fiber Coupling Agent Modification" Polymers 15, no. 15: 3164. https://doi.org/10.3390/polym15153164

APA StyleFan, Z., Gao, J., Wu, Y., Yin, D., Chen, S., Tu, H., Wei, T., Zhang, C., Zhu, H., & Jin, H. (2023). Highly Enhanced Mechanical, Thermal, and Crystallization Performance of PLA/PBS Composite by Glass Fiber Coupling Agent Modification. Polymers, 15(15), 3164. https://doi.org/10.3390/polym15153164