Tailoring PLA/ABS Blends Compatibilized with SEBS-g-MA through Annealing Heat Treatment

Abstract

:1. Introduction

- The first approach was to examine the effect of SEBS-g-MA, assuming that the styrene blocks of SEBS are miscible with the styrene groups of ABS [24]. In contrast, the maleic anhydride groups would react with the hydroxyl groups of PLA [26,31], which should be preferentially located at the interface to act as an effective compatibilizer;

- In the second approach, we examined the effect of annealing heat treatment in relieving internal stresses and preventing secondary crystallization.

2. Materials

Blend Processing

3. Methodology

3.1. Rheological Characterization

3.2. Mechanical Characterization

3.3. Thermomechanical Properties

3.4. Differential Scanning Calorimetry (DSC)

3.5. Thermogravimetric Analysis (TGA)

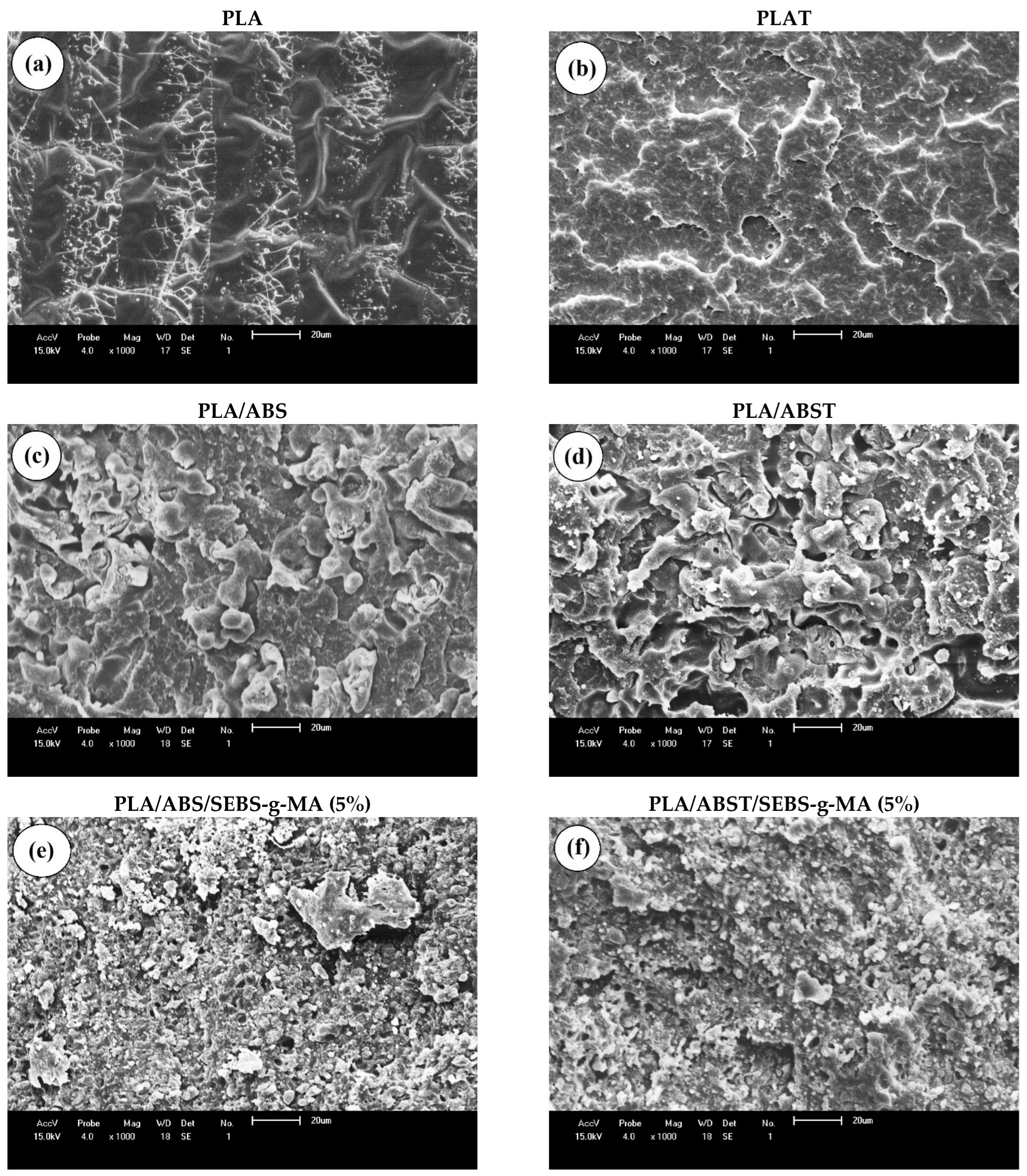

3.6. Scanning Electron Microscopy (SEM)

3.7. X-ray Diffraction (XRD)

3.8. Fourier Transform Infrared Spectroscopy (FTIR)

4. Results and Discussions

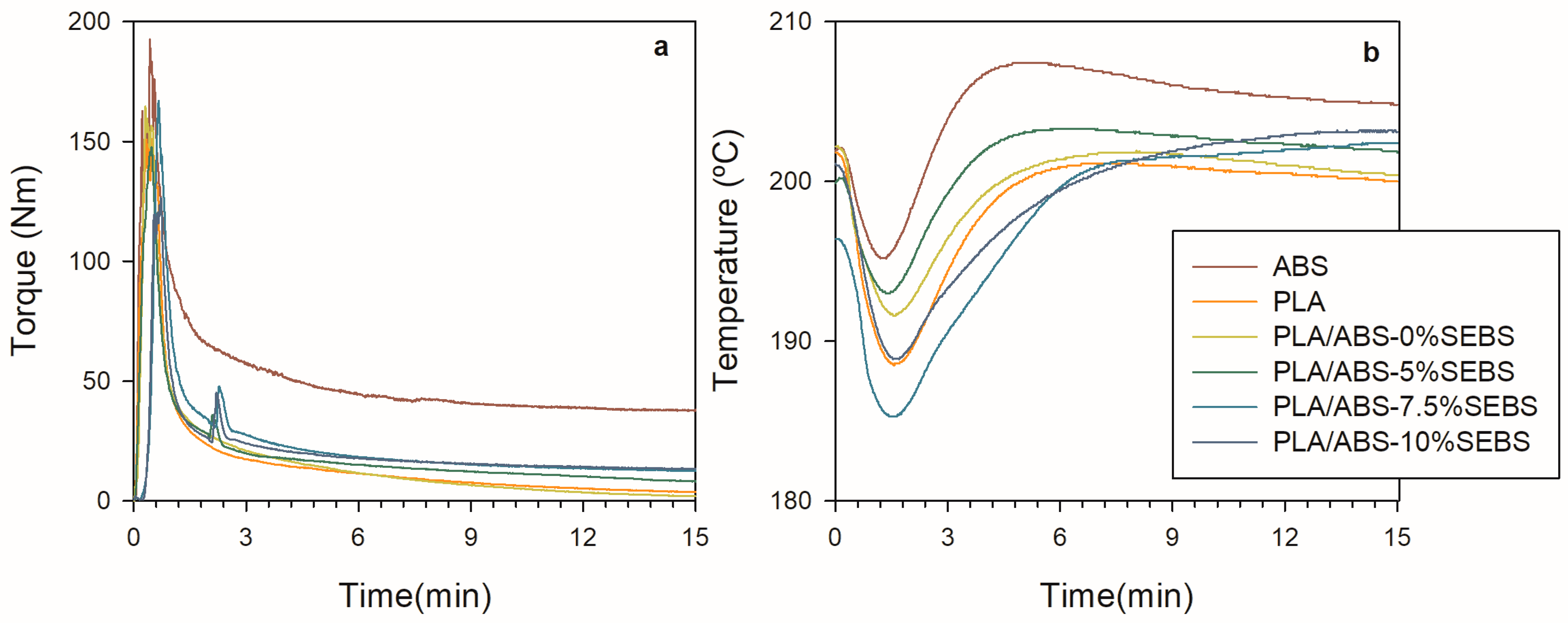

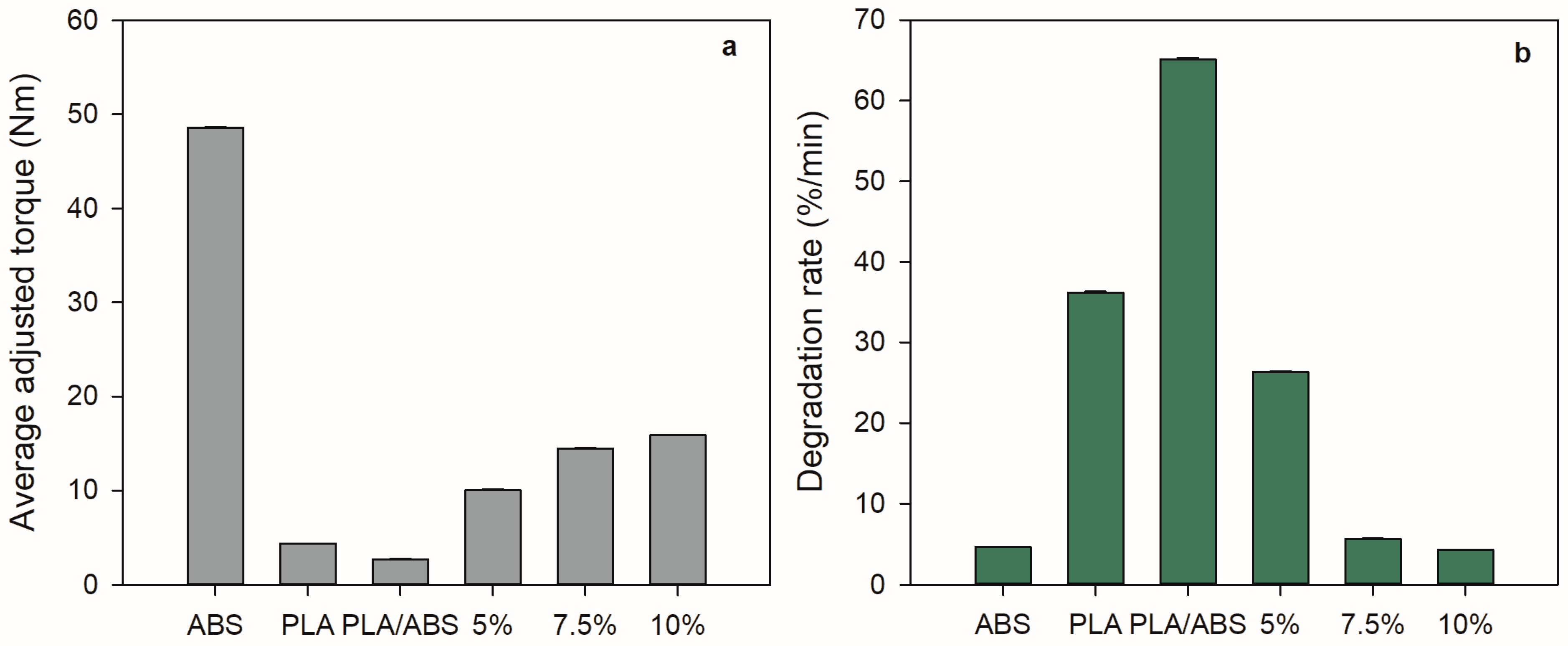

4.1. Degradation during Processing

4.2. X-ray Diffraction (XRD)

4.3. FTIR

4.4. Mechanical Properties

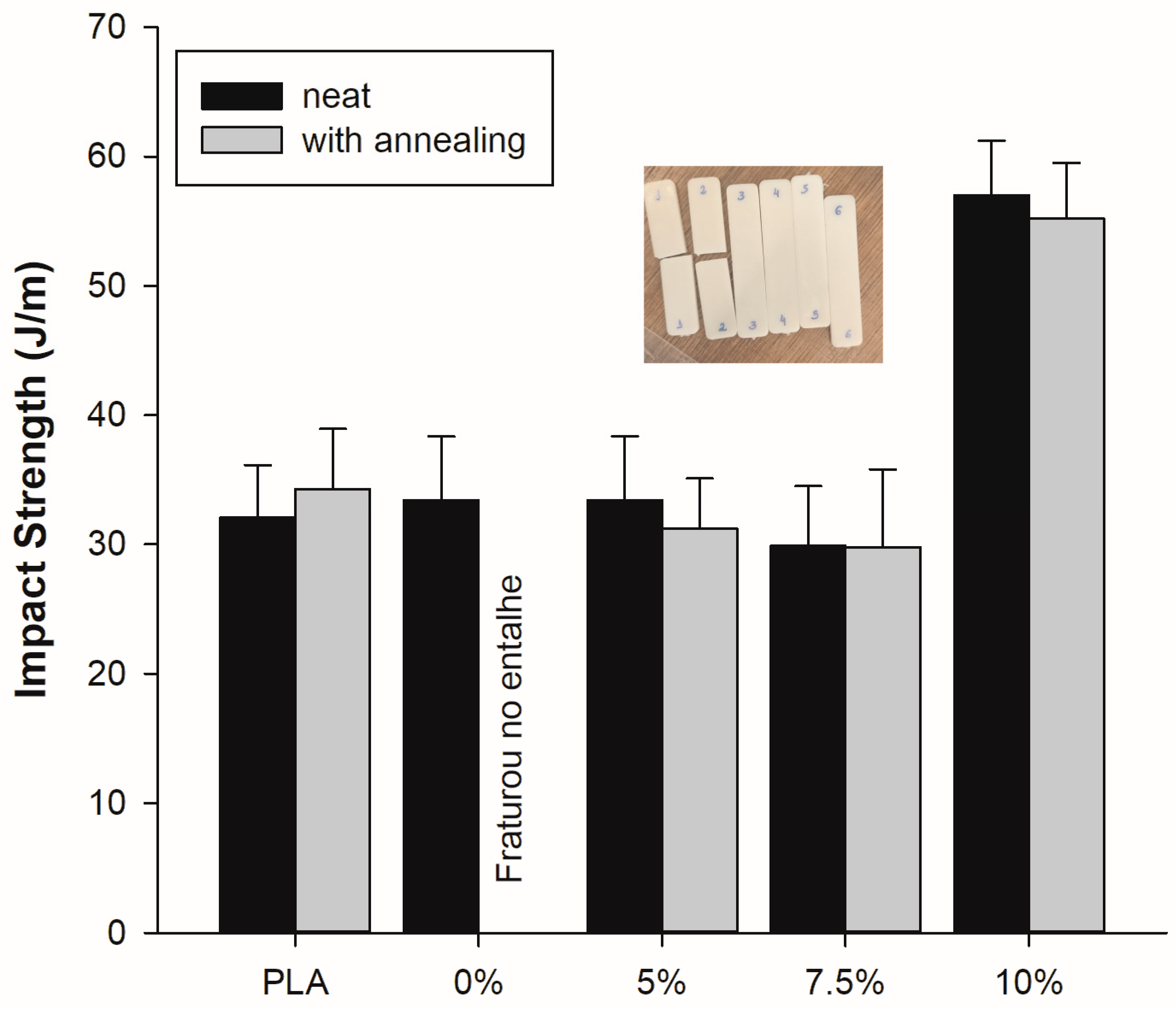

4.5. Impact Strength

4.6. Thermogravimetric Analysis (TGA)

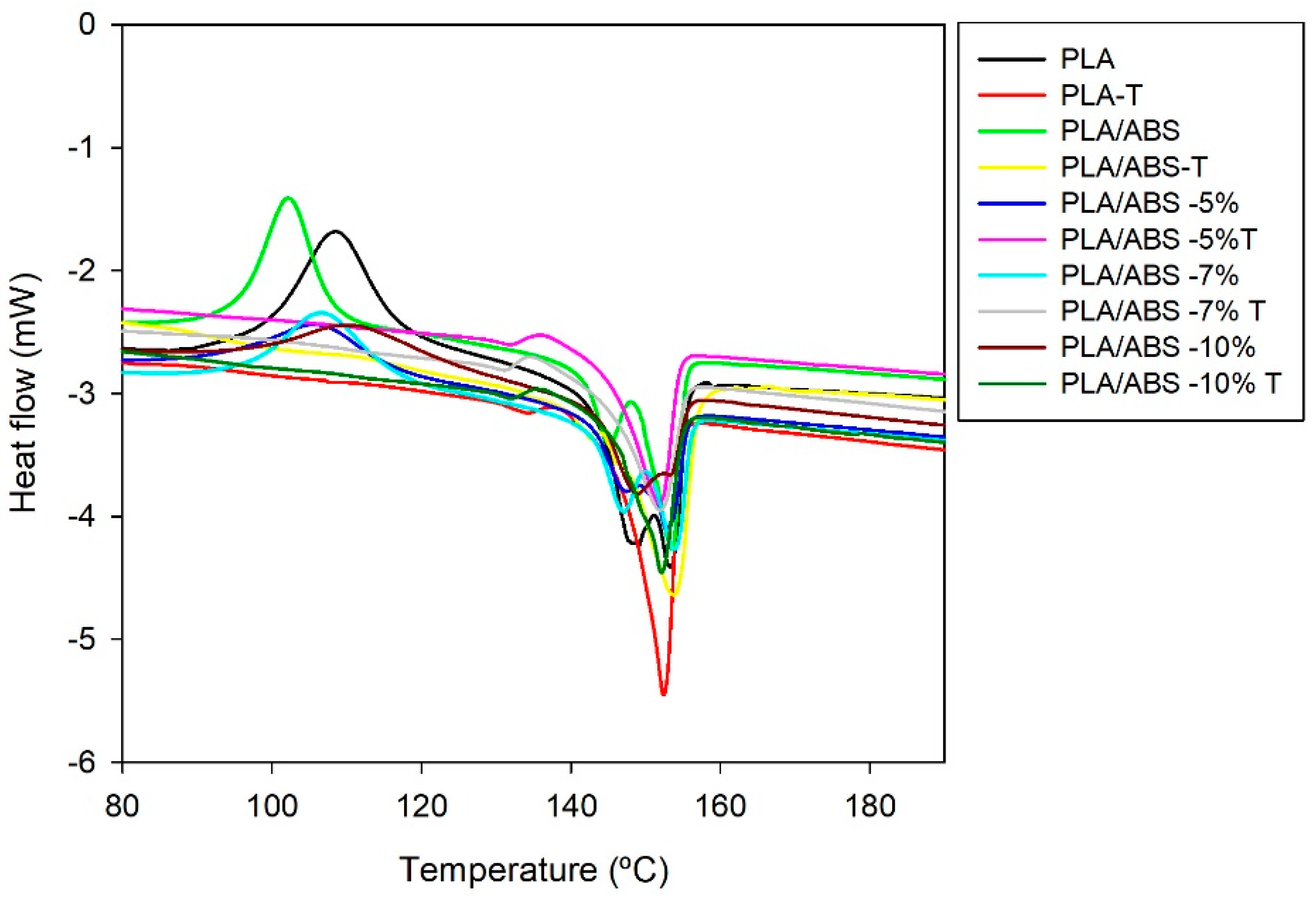

4.7. Differential Scanning Calorimetry (DSC)

4.8. HDT

4.9. MEV

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aversa, C.; Barletta, M.; Cappiello, G.; Gisario, A. Compatibilization strategies and analysis of morphological features of poly(butylene adipate-co-terephthalate) (PBAT)/poly(lactic acid) PLA blends: A state-of-art review. Eur. Polym. J. 2022, 173, 111304. [Google Scholar] [CrossRef]

- Kervran, M.; Vagner, C.; Cochez, M.; Ponçot, M.; Saeb, M.R.; Vahabi, H. Thermal degradation of polylactic acid (PLA)/polyhydroxybutyrate (PHB) blends: A systematic review. Polym. Degrad. Stab. 2022, 201, 109995. [Google Scholar] [CrossRef]

- Aliotta, L.; Gigante, V.; Geerinck, R.; Coltelli, M.-B.; Lazzeri, A. Micromechanical analysis and fracture mechanics of Poly(lactic acid) (PLA)/Polycaprolactone (PCL) binary blends. Polym. Test. 2023, 121, 107984. [Google Scholar] [CrossRef]

- Ferreira, E.D.S.B.; Luna, C.B.B.; dos Santos Filho, E.A.; Wellen, R.M.R.; Araújo, E.M. Use of crosslinking agent to produce high-performance PLA/EVA blends via reactive processing. J. Vinyl Addit. Technol. 2023, 29, 161–175. [Google Scholar] [CrossRef]

- Luzi, F.; Fortunati, E.; Jiménez, A.; Puglia, D.; Pezzolla, D.; Gigliotti, G.; Kenny, J.; Chiralt, A.; Torre, L. Production and characterization of PLA_PBS biodegradable blends reinforced with cellulose nanocrystals extracted from hemp fibres. Ind. Crops Prod. 2016, 93, 276–289. [Google Scholar] [CrossRef]

- Hongdilokkul, P.; Keeratipinit, K.; Chawthai, S.; Hararak, B.; Seadan, M.; Suttiruengwong, S. A study on properties of PLA/PBAT from blown film process. IOP Conf. Ser. Mater. Sci. Eng. 2015, 87, 012112. [Google Scholar] [CrossRef]

- Xie, D.; Zhao, Y.; Li, Y.; LaChance, A.M.; Lai, J.; Sun, L.; Chen, J. Rheological, Thermal, and Degradation Properties of PLA/PPG Blends. Materials 2019, 12, 3519. [Google Scholar] [CrossRef]

- Luna, C.B.B.; Siqueira, D.D.; Araújo, E.M.; Wellen, R.M.R.; de Mélo, T.J.A. Approaches on the acrylonitrile-butadiene-styrene functionalization through maleic anhydride and dicumyl peroxide. J. Vinyl Addit. Technol. 2020, 27, 308–318. [Google Scholar] [CrossRef]

- Pelto, J.; Barreto, C.; Anwar, H.; Strobl, L.; Schlummer, M. Compatibilized PC/ABS blends from solvent recycled PC and ABS polymers from electronic equipment waste. Polym. Test. 2023, 120, 107969. [Google Scholar] [CrossRef]

- Dadashi, P.; Babaei, A.; Khoshnood, M. Investigating the role of PA6/GO interactions on the morphological, rheological, and mechanical properties of PA6/ABS/GO nanocomposites. Polym. Technol. Mater. 2022, 62, 756–770. [Google Scholar] [CrossRef]

- Ramanjaneyulu, B.; Venkatachalapathi, N.; Prasanthi, G. Thermal and Mechanical Properties of PLA/ABS/TCS Polymer Blend Composites. J. Inst. Eng. Ser. C 2021, 102, 799–806. [Google Scholar] [CrossRef]

- Shi, X.; Chen, B.; Tuo, X.; Gong, Y.; Guo, J. Study on performance characteristics of fused deposition modeling 3D-printed composites by blending and lamination. J. Appl. Polym. Sci. 2021, 138, 1–7. [Google Scholar] [CrossRef]

- Carrasco, F.; Santana, O.; Cailloux, J.; Sánchez-Soto, M.; Maspoch, M. Thermal degradation of poly(lactic acid) and acrylonitrile-butadiene-styrene bioblends: Elucidation of reaction mechanisms. Thermochim. Acta 2017, 654, 157–167. [Google Scholar] [CrossRef]

- Ramanjaneyulu, B.; Venkatachalapathi, N.; Prasanthi, G. Melt rheology properties of PLA/ABS/TCS polymer blends. Int. J. Ambient. Energy 2022, 43, 2536–2539. [Google Scholar] [CrossRef]

- Dhinesh, S.; Arun, P.S.; Senthil, K.K.; Megalingam, A. Study on flexural and tensile behavior of PLA, ABS and PLA-ABS materials. Mater. Today Proc. 2021, 45, 1175–1180. [Google Scholar] [CrossRef]

- Chaudry, U.M.; Hamad, K. Fabrication and characterization of PLA/PP/ABS ternary blend. Polym. Eng. Sci. 2019, 59, 2273–2278. [Google Scholar] [CrossRef]

- Rigoussen, A.; Raquez, J.-M.; Dubois, P.; Verge, P. A dual approach to compatibilize PLA/ABS immiscible blends with epoxidized cardanol derivatives. Eur. Polym. J. 2019, 114, 118–126. [Google Scholar] [CrossRef]

- Utracki, L.A. Compatibilization of polymer blends. Can. J. Chem. Eng. 2002, 80, 1008–1016. [Google Scholar] [CrossRef]

- Jo, M.Y.; Ryu, Y.J.; Ko, J.H.; Yoon, J.-S. Effects of compatibilizers on the mechanical properties of ABS/PLA composites. J. Appl. Polym. Sci. 2012, 125, E231–E238. [Google Scholar] [CrossRef]

- Rigoussen, A.; Verge, P.; Raquez, J.-M.; Habibi, Y.; Dubois, P. In-depth investigation on the effect and role of cardanol in the compatibilization of PLA/ABS immiscible blends by reactive extrusion. Eur. Polym. J. 2017, 93, 272–283. [Google Scholar] [CrossRef]

- Ekiz, I.; Cetin, M.S.; Toprakci, O.; Toprakci, H.A.K. Effects of S/EB ratio on some properties of PLA/SEBS blends. Bull. Mater. Sci. 2022, 45, 251. [Google Scholar] [CrossRef]

- Chaikeaw, C.; Srikulkit, K. Preparation and Properties of Poly(lactic Acid)/PLA-g-ABS Blends. Fibers Polym. 2018, 19, 2016–2022. [Google Scholar] [CrossRef]

- Luna, C.B.B.; Siqueira, D.D.; Araújo, E.M.; do Nascimento, E.P.; da Costa Agra de Melo, J.B. Evaluation of the SEBS copolymer in the compatibility of PP/ABS blends through mechanical, thermal, thermomechanical properties, and morphology. Polym. Adv. Technol. 2022, 33, 111–124. [Google Scholar] [CrossRef]

- Essabir, H.; El Mechtali, F.Z.; Nekhlaoui, S.; Raji, M.; Bensalah, M.O.; Rodrigue, D.; Bouhfid, R.; Qaiss, A. Compatibilization of PA6/ABS blend by SEBS-g-MA: Morphological, mechanical, thermal, and rheological properties. Int. J. Adv. Manuf. Technol. 2020, 110, 1095–1111. [Google Scholar] [CrossRef]

- Sangeetha, V.H.; Varghese, T.O.; Nayak, S.K. Toughening of polylactic acid using styrene ethylene butylene styrene: Mechanical, thermal, and morphological studies. Polym. Eng. Sci. 2016, 56, 669–675. [Google Scholar] [CrossRef]

- Ferreira, E.D.S.B.; Luna, C.B.B.; Siqueira, D.D.; Araújo, E.M.; de França, D.C.; Wellen, R.M.R. Annealing Effect on Pla/Eva Blends Performance. J. Polym. Environ. 2022, 30, 541–554. [Google Scholar] [CrossRef]

- Lluch-Cerezo, J.; Meseguer, M.D.; García-Manrique, J.A.; Benavente, R. Influence of Thermal Annealing Temperatures on Powder Mould Effectiveness to Avoid Deformations in ABS and PLA 3D-Printed Parts. Polymers 2022, 14, 2607. [Google Scholar] [CrossRef]

- Nofar, M.; Maani, A.; Sojoudi, H.; Heuzey, M.C.; Carreau, P.J. Interfacial and rheological properties of PLA/PBAT and PLA/PBSA blends and their morphological stability under shear flow. J. Rheol. 2015, 59, 317–333. [Google Scholar] [CrossRef]

- Lv, S.; Gu, J.; Cao, J.; Tan, H.; Zhang, Y. Effect of annealing on the thermal properties of poly (lactic acid)/starch blends. Int. J. Biol. Macromol. 2015, 74, 297–303. [Google Scholar] [CrossRef]

- Jayanth, N.; Jaswanthraj, K.; Sandeep, S.; Mallaya, N.H.; Siddharth, S.R. Effect of heat treatment on mechanical properties of 3D printed PLA. J. Mech. Behav. Biomed. Mater. 2021, 123, 104764. [Google Scholar] [CrossRef]

- CLEARTUF TURBO II M&G. Available online: https://plastics.ulprospector.com/pt/datasheet/e103441/cleartuf-turbo-ii (accessed on 16 September 2020).

- Lima, P.S.; Brito, R.S.F.; Santos, B.F.F.; Tavares, A.A.; Agrawal, P.; Andrade, D.L.A.C.S.; Wellen, R.M.R.; Canedo, E.L.; Silva, S.M.L. Rheological properties of HDPE/chitosan composites modified with PE-g-MA. J. Mater. Res. 2017, 32, 775–787. [Google Scholar] [CrossRef]

- Almeida, T.G.; Neto, J.E.S.; Costa, A.R.M.; Da Silva, A.S.; Carvalho, L.H.; Canedo, E.L. Degradation during processing in poly(butylene adipate-co-terephthalate)/vegetable fiber compounds estimated by torque rheometry. Polym. Test. 2016, 55, 204–211. [Google Scholar] [CrossRef]

- Tavares, A.A.; Silva, D.F.; Lima, P.S.; Andrade, D.L.; Silva, S.M.; Canedo, E.L. Chain extension of virgin and recycled polyethylene terephthalate. Polym. Test. 2016, 50, 26–32. [Google Scholar] [CrossRef]

- Reul, L.T.A.; Pereira, C.A.B.; Sousa, F.M.; Santos, R.M.; Carvalho, L.H.; Canedo, E.L. Polycaprolactone/babassu compounds: Rheological, thermal, and morphological characteristics. Polym. Compos. 2018, 40, E540–E549. [Google Scholar] [CrossRef]

- Duarte, I.S.; Tavares, A.A.; Lima, P.S.; Andrade, D.L.; Carvalho, L.H.; Canedo, E.L.; Silva, S.M. Chain extension of virgin and recycled poly(ethylene terephthalate): Effect of processing conditions and reprocessing. Polym. Degrad. Stab. 2016, 124, 26–34. [Google Scholar] [CrossRef]

- Canedo, E.L. Polymer Processing in the Internal Laboratory Mixer; PPGCEMat/UFCG: Campina Grande, Brazil, 2017. [Google Scholar]

- Alves, T.S.; Neto, J.E.S.; Silva, S.M.; Carvalho, L.H.; Canedo, E.L. Process simulation of laboratory internal mixers. Polym. Test. 2016, 50, 94–100. [Google Scholar] [CrossRef]

- Carrasco, F.; Santana, O.; Cailloux, J.; Sánchez-Soto, M.; Maspoch, M.L. Poly (lactic acid) and acrylonitrile−butadiene−styrene blends: Influence of adding ABS−g−MAH compatibilizer on the kinetics of the thermal degradation. Polym. Test. 2018, 67, 468–476. [Google Scholar] [CrossRef]

- Andrés, M.S.; Chércoles, R.; Navarro, E.; de la Roja, J.M.; Gorostiza, J.; Higueras, M.; Blanch, E. Use of 3D printing PLA and ABS materials for fine art. Analysis of composition and long-term behaviour of raw filament and printed parts. J. Cult. Herit. 2023, 59, 181–189. [Google Scholar] [CrossRef]

- De Araújo, J.P.; Agrawal1, P.; De Mélo, T.J.A. Blendas PLA/PEgAA: Avaliação da reatividade entre os polímeros e da concentração de PEgAA nas propriedades e na morfologia. Rev. Eletrônica Mater. Process. 2015, 10, 118–127. [Google Scholar]

- Filho, E.A.d.S.; Luna, C.B.B.; Ferreira, E.d.S.B.; Siqueira, D.D.; Araújo, E.M. Production of PLA/NR blends compatibilized with EE-g-GMA and POE-g-GMA: An investigation of mechanical, thermal, thermomechanical properties and morphology. J. Polym. Res. 2023, 30, 132. [Google Scholar] [CrossRef]

- Detyothin, S.; Selke, S.E.M.; Narayan, R.; Rubino, M.; Auras, R.A. Effects of molecular weight and grafted maleic anhydride of functionalized polylactic acid used in reactive compatibilized binary and ternary blends of polylactic acid and thermoplastic cassava starch. J. Appl. Polym. Sci. 2015, 132, 1–15. [Google Scholar] [CrossRef]

- Koning, C.; Van Duin, M.; Pagnoulle, C.; Jerome, R. Strategies for compatibilization of polymer blends. Prog. Polym. Sci. 1998, 23, 707–757. [Google Scholar] [CrossRef]

- Singh, P.; Katiyar, P.; Singh, H. Impact of compatibilization on polypropylene (PP) and acrylonitrile butadiene styrene (ABS) blend: A review. Mater. Today Proc. 2023, 78, 189–197. [Google Scholar] [CrossRef]

| Designation | Composition | ||

|---|---|---|---|

| (%) PLA | (%) ABS | (%) SEBS-g-MA | |

| PLA | 60 | 0 | 0 |

| PLA/ABS | 60 | 40 | 0 |

| PLA/ABS-5%SEBS-g-MA | 60 | 35 | 5 |

| PLA/ABS-7.5%SEBS-g-MA | 60 | 32.5 | 7.5 |

| PLA/ABS-10%SEBS-g-MA | 60 | 30 | 10 |

| Systems | Processing Parameters | ||||

|---|---|---|---|---|---|

| (°C) | Z (Nm) | (Nm) | (Nm/min) | RZ (%/min) | |

| ABS | 205.0 ± 0.01 | 38.2 ± 0.02 | 48.6 ± 0.05 | −2.26 ± 0.75 | 4.6 ± 0.02 |

| PLA | 200.2 ± 0.01 | 4.3 ± 0.03 | 4.34 ± 0.03 | −1.58 ± 0.54 | 36.2 ± 0.12 |

| PLA/ABS | 200.7 ± 0.01 | 2.6 ± 0.03 | 2.7 ± 0.04 | −1.77 ± 0.59 | 65.1 ± 0.21 |

| 5% SEBS | 202.1 ± 0.01 | 9.1 ± 0.05 | 10.0 ± 0.06 | −2.64 ± 0.87 | 26.3 ± 0.09 |

| 7.5% SEBS | 202.2 ± 0.01 | 13.0 ± 0.02 | 14.5 ± 0.02 | −0.82 ± 0.87 | 5.7 ± 0.14 |

| 10% SEBS | 203.1 ± 0.08 | 13.7 ± 0.02 | 15.8 ± 0.02 | −0.69 ± 0.45 | 4.3 ± 0.05 |

| Mechanical Properties | ||||||

|---|---|---|---|---|---|---|

| Designation | Impact Strength (J/m) | Young’s Modulus (MPa) | Tensile Strength (MPa) | Elongation at Break (%) | Hardness Shore D | |

| Neat | PLA | 32.1 ± 4.05 | 2101.4 ± 85.70 | 50.2 ± 4.90 | 3.8 ± 0.60 | 77.5 ± 0.15 |

| PLA/ABS-0% | 33.4 ± 4.94 | 1823.8 ± 137.10 | 26.8 ± 3.20 | 1.8 ± 0.40 | 72.4 ± 0.69 | |

| PLA/ABS-5% | 33.4 ± 4.94 | 1675.0 ± 83.40 | 31.9 ± 2.10 | 3.3 ± 0.20 | 70.5 ± 0.22 | |

| PLA/ABS-7.5% | 29.9 ± 4.61 | 1574.6 ± 43.60 | 32.6 ± 1.50 | 4.2 ± 0.60 | 68.2 ± 0.46 | |

| PLA/ABS-10% | 57.2 ± 4.22 | 1437.0 ± 30.90 | 30.1 ± 0.80 | 4.3 ± 0.50 | 67.4 ± 0.60 | |

| With annealing | PLA | 34.2 ± 4.67 | 2176.4 ± 152.80 | 51.3 ± 5.50 | 3.5 ± 0.40 | 77.8 ± 0.25 |

| PLA/ABS-0% | - | 1903.2 ± 40.10 | 14.7 ± 3.20 | 1.1 ± 0.20 | 76.5 ± 0.15 | |

| PLA/ABS-5% | 31.2 ± 3.91 | 1747.4 ± 40.10 | 31.3 ± 2.10 | 2.0 ± 0.20 | 71.1 ± 0.18 | |

| PLA/ABS-7.5% | 29.8 ± 6.01 | 1615.6 ± 19.20 | 31.8 ± 2.00 | 3.4 ± 0.20 | 69.2 ± 0.40 | |

| PLA/ABS-10% | 55.2 ± 4.30 | 1471.6 ± 19.20 | 28.8 ± 0.70 | 3.4 ± 0.20 | 69.1 ± 0.64 | |

| Systems | Tonset (°C) | Tendset (°C) | |

|---|---|---|---|

| Neat | PLA | 342.9 | 385.2 |

| PLA/ABS-0% | 328.1 | 518.3 | |

| PLA/ABS-5% | 333.1 | 513.9 | |

| PLA/ABS-7.5% | 334.4 | 520.0 | |

| PLA/ABS-10% | 332.9 | 503.6 | |

| With annealing | PLA T | 317.5 | 490.8 |

| PLA/ABS T | 333.1 | 505.8 | |

| PLA/ABS-5%T | 331.3 | 489.1 | |

| PLA/ABS-7.5%T | 332.4 | 499.6 | |

| PLA/ABS-10%T | 334.5 | 497.1 | |

| Systems | Melting and Crystallization Parameters | ||||||

|---|---|---|---|---|---|---|---|

| tg | Tc (°C) | Tm (°C) | DHc (J/g) | DHm (J/g) | Xc (%) | ||

| neat | PLA | 57.4. | 108.5 | 149.1 153.3 | 23.8 | 33.5 | 28.7 |

| PLA/ABS-0% | 56.4 | 102.2 | 146.3 (1) 153.5 (2) | 39.6 | 45.7 | 38.8 | |

| PLA/ABS-5% | 59.2 | 105.9 | 149.8 (1) 152.8 (2) | 29.9 | 37.9 | 40.4 | |

| PLA/ABS-7.5% | 59.1 | 106.7 | 147.1 (1) 153.8 (2) | 34.6 | 41.1 | 43.9 | |

| PLA/ABS-10% | 59.4 | 110.5 | 152.2 | 18.5 | 37.1 | 39.5 | |

| With annealing | PLA T | 59.6 | - | 150.8 | - | 28.7 | 30.7 |

| PLA/ABS T | 59.7 | - | 153.7 | - | 30.8 | 40.3 | |

| PLA/ABS-5%T | 58.5 | - | 151.8 | - | 42.2 | 45.1 | |

| PLA/ABS-7.5%T | 56.8 | - | 150.2 | - | 42.1 | 44.9 | |

| PLA/ABS-10%T | 58.3 | - | 152.2 | - | 37.9 | 39.9 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costa, A.R.d.M.; Luna, C.B.B.; do Nascimento, E.P.; Ferreira, E.d.S.B.; Costa, C.d.M.; de Almeida, Y.M.B.; Araújo, E.M. Tailoring PLA/ABS Blends Compatibilized with SEBS-g-MA through Annealing Heat Treatment. Polymers 2023, 15, 3434. https://doi.org/10.3390/polym15163434

Costa ARdM, Luna CBB, do Nascimento EP, Ferreira EdSB, Costa CdM, de Almeida YMB, Araújo EM. Tailoring PLA/ABS Blends Compatibilized with SEBS-g-MA through Annealing Heat Treatment. Polymers. 2023; 15(16):3434. https://doi.org/10.3390/polym15163434

Chicago/Turabian StyleCosta, Anna Raffaela de Matos, Carlos Bruno Barreto Luna, Emanuel Pereira do Nascimento, Eduardo da Silva Barbosa Ferreira, Claudia de Matos Costa, Yeda Medeiros Bastos de Almeida, and Edcleide Maria Araújo. 2023. "Tailoring PLA/ABS Blends Compatibilized with SEBS-g-MA through Annealing Heat Treatment" Polymers 15, no. 16: 3434. https://doi.org/10.3390/polym15163434

APA StyleCosta, A. R. d. M., Luna, C. B. B., do Nascimento, E. P., Ferreira, E. d. S. B., Costa, C. d. M., de Almeida, Y. M. B., & Araújo, E. M. (2023). Tailoring PLA/ABS Blends Compatibilized with SEBS-g-MA through Annealing Heat Treatment. Polymers, 15(16), 3434. https://doi.org/10.3390/polym15163434