The Study Influence Analysis of the Mathematical Model Choice for Describing Polymer Behavior

Abstract

:1. Introduction

1.1. Research Objectives

- The behavior description of polymeric materials in viscoelastic terms using the generalized Maxwell model;

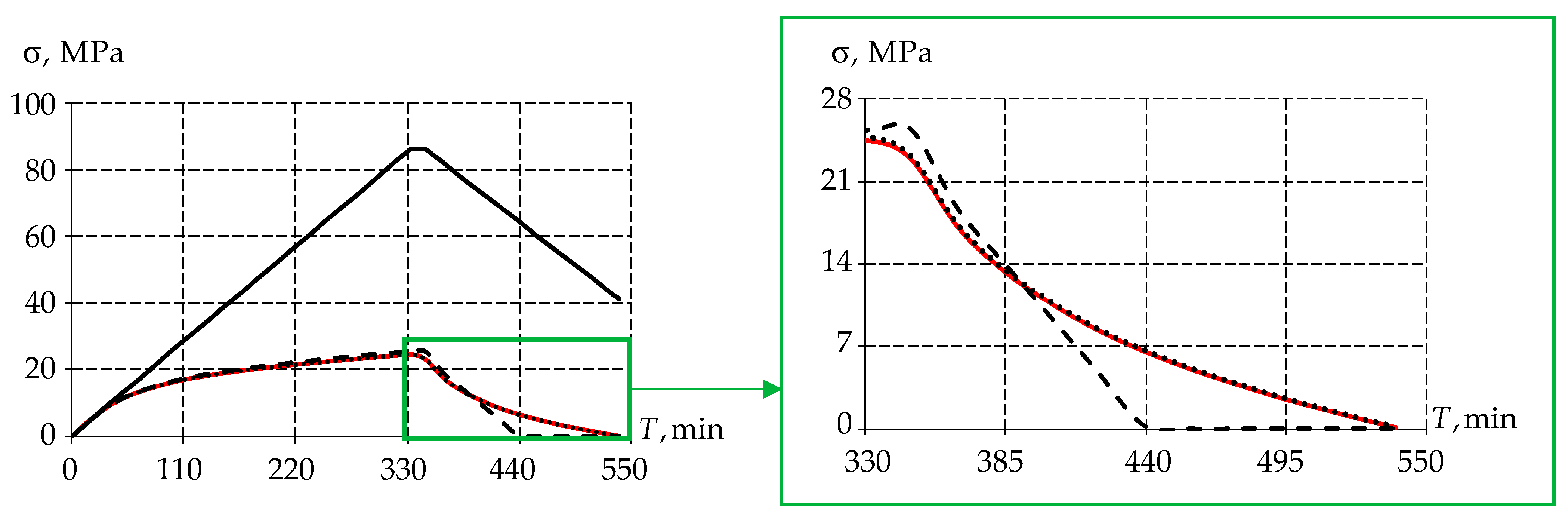

- Comparison of experimental data and numerical solutions of three different mathematical models of material behavior: elastic, plastic, and viscoelastic;

- Carrying out verification of the numerical Hertz problem;

- Constructing numerical models of the specimen behavior (elastic–plastic, viscoelastic);

- The influence study of mathematical models of polymers’ behavior in a dynamic setting (loading and subsequent exposure for 1 h at room temperature).

1.2. Problem Context

1.3. Problem Description

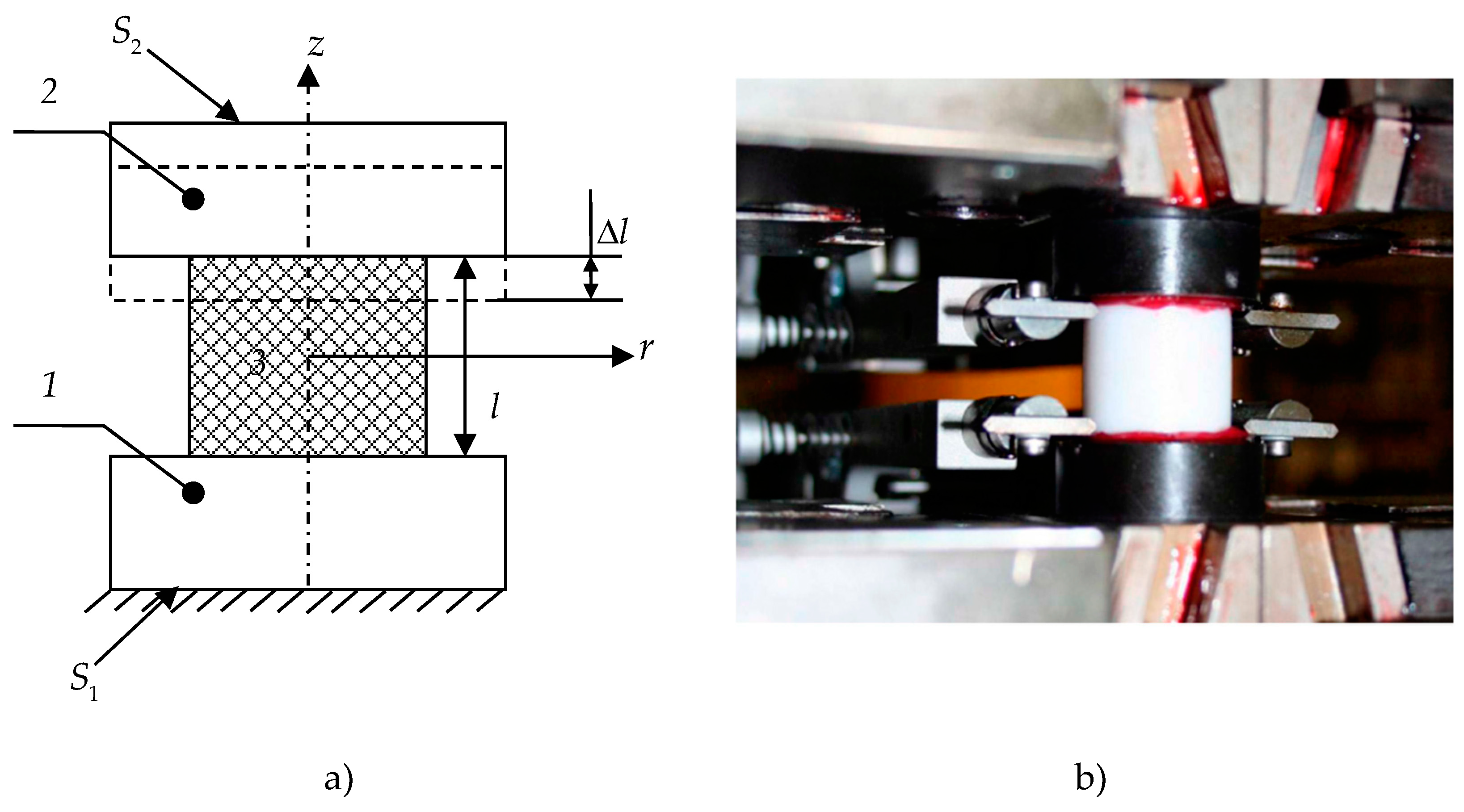

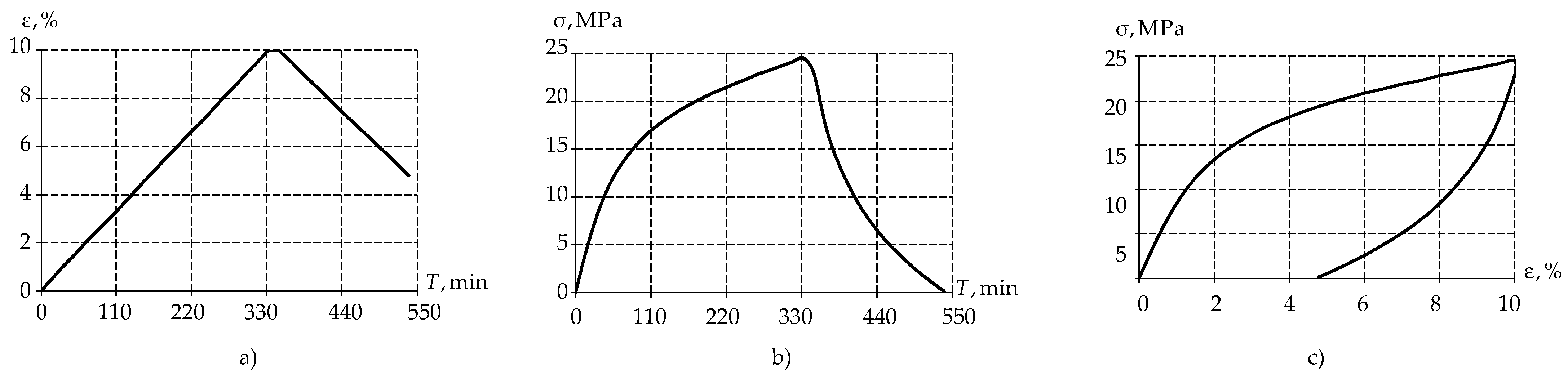

2. Materials and Methods

2.1. Materials

- -

- The specimen was tested at a strain rate of 0.006 mm/min up to 10%;

- -

- Constant strain was held for 15 min;

- -

- The load was removed from the material until normal stresses of 0.1 MPa was reached at a rate of 0.006 mm/min.

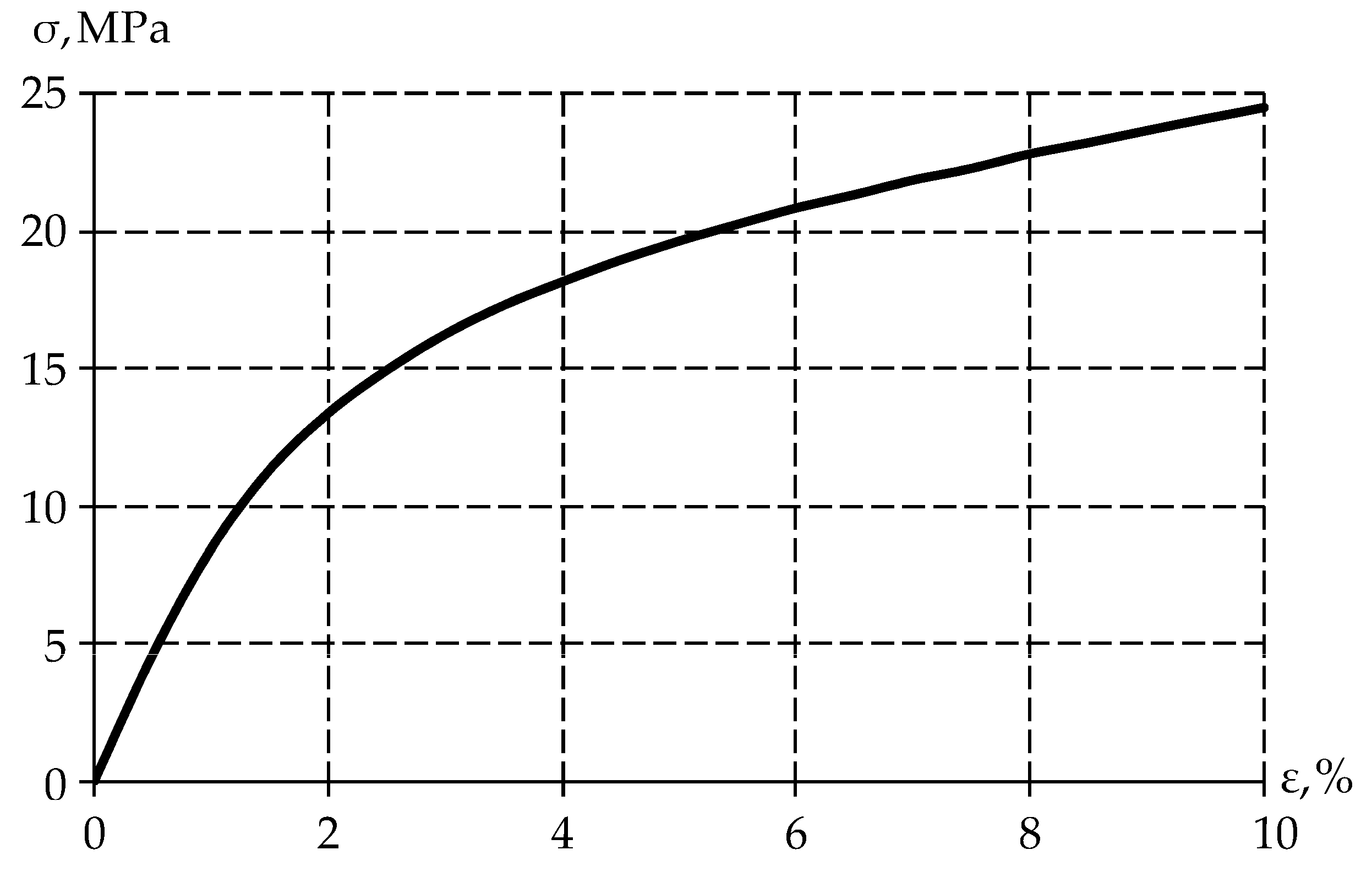

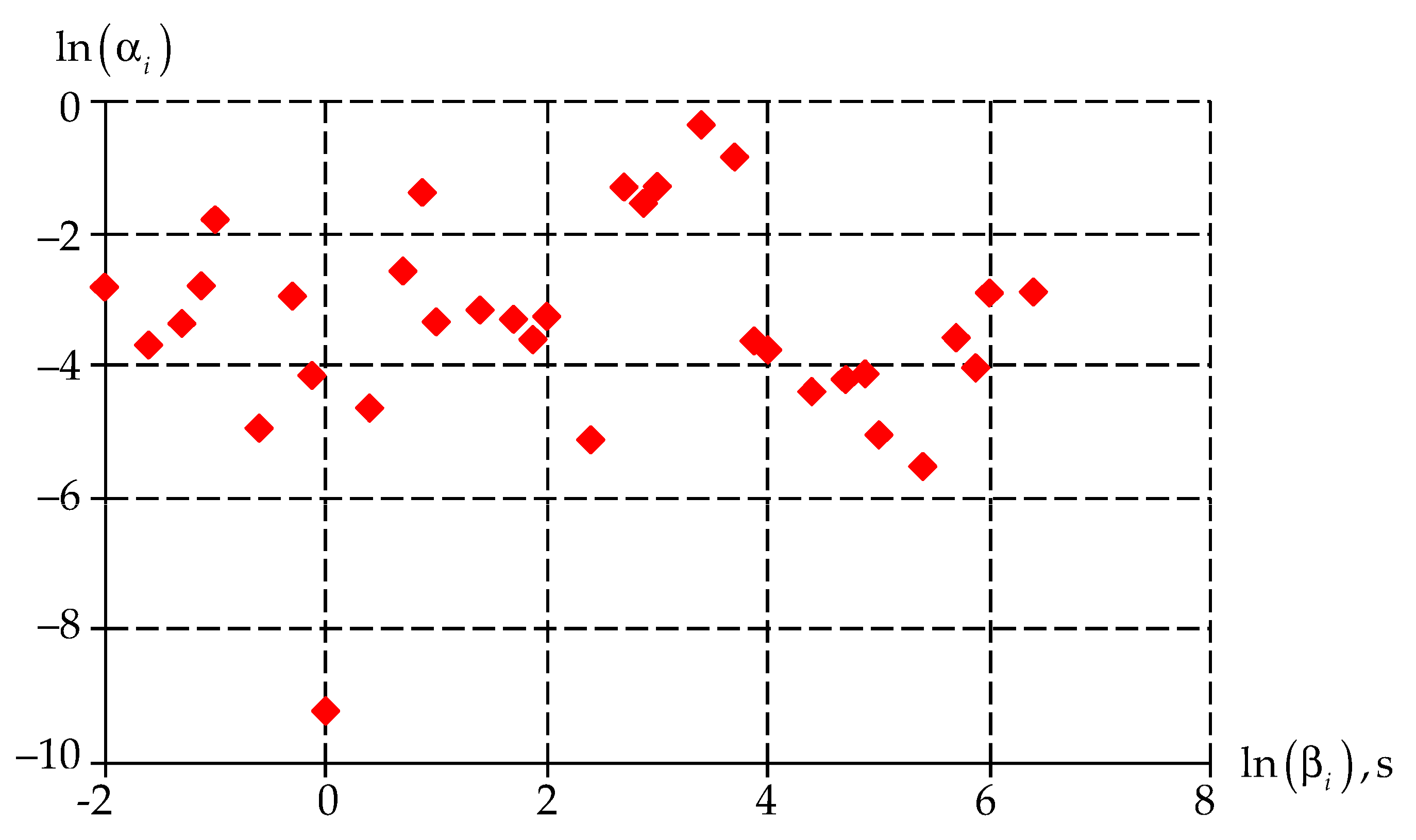

2.2. Description of Polymer Behavior

- -

- Elastic body:

- -

- Elastoplastic body:

- -

- Viscoelastic body:

- -

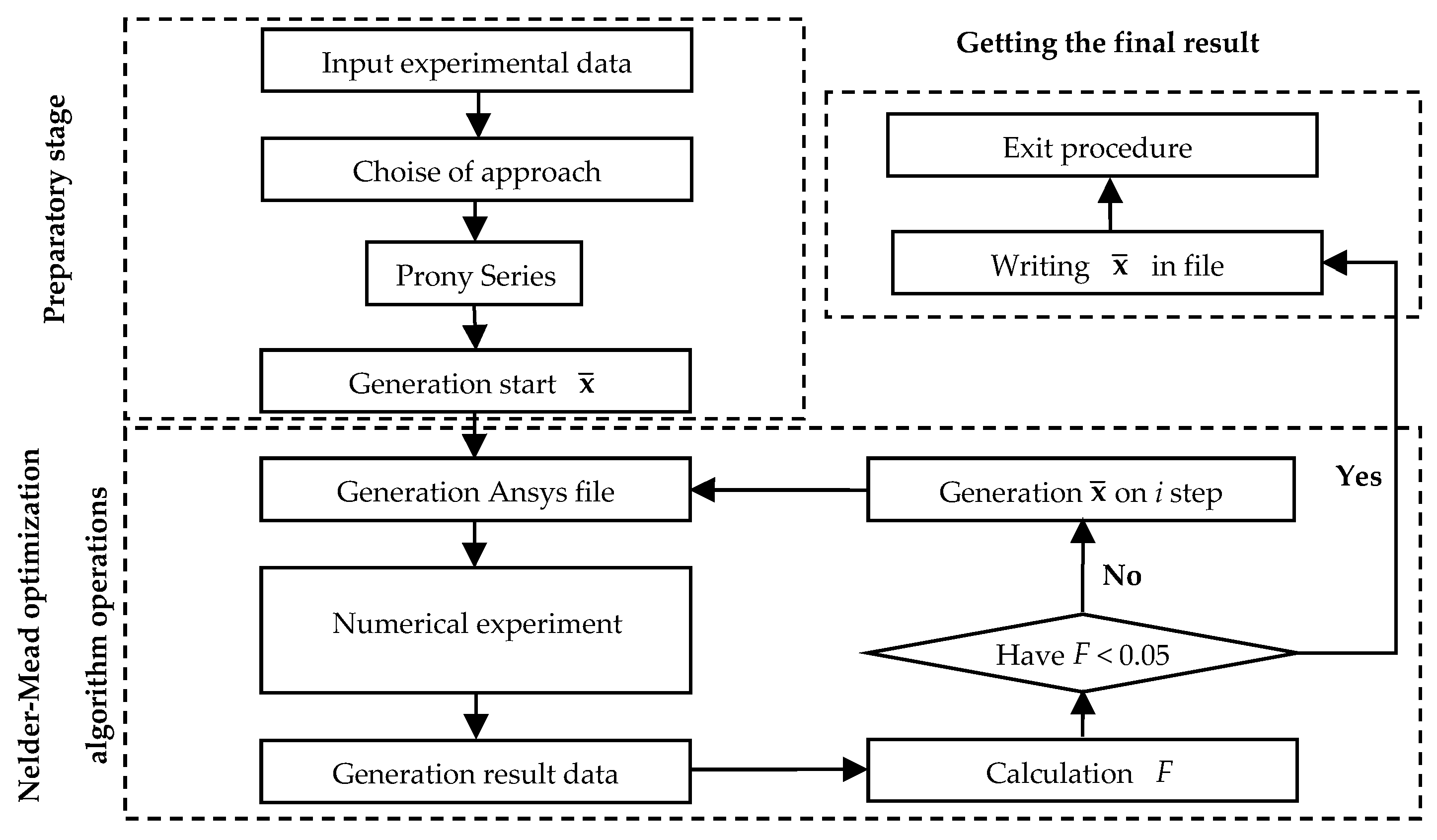

- First (preliminary) stage: input of experimental data in the form of a text file with data, model selection, and generation of the initial vector of unknowns from Equation (5);

- -

- The second stage is based on the Nelder–Mead optimization algorithm: creation of a script-file describing the numerical experiment in ANSYS Mechanical APDL, conducting the numerical experiment, obtaining the results file, comparison of numerical and experimental data, generation of the vector of unknowns from Equation (5) at step i, and transition to the next iteration;

- -

- The third (and final) step is performed when the error between the experimental and numerical data reaches 5%: formation of the final vector of unknowns from Equation (5) and exit from the procedure.

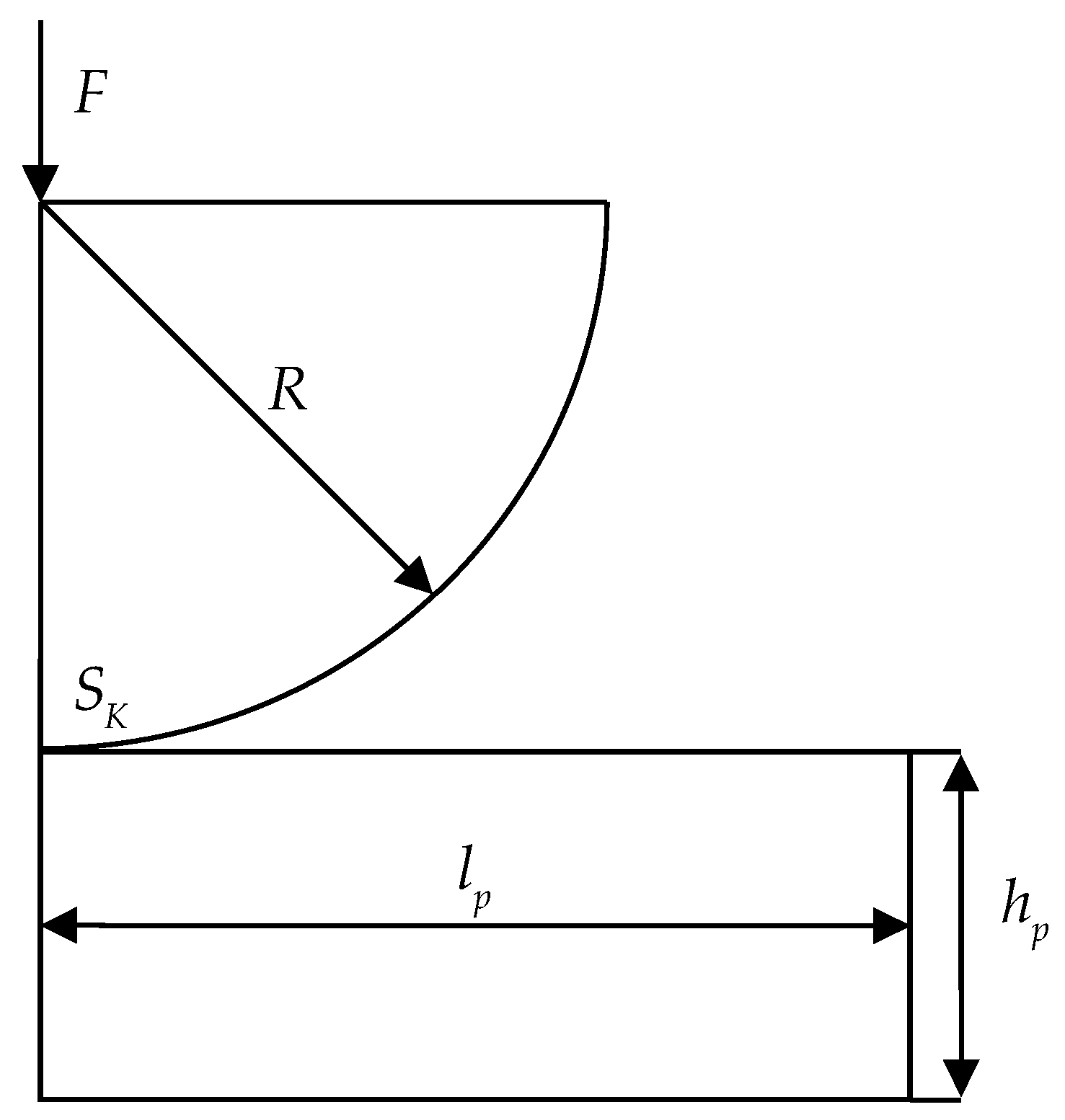

2.3. The Hertz Formulation

- -

- Sliding friction: , , , , , , when ;

- -

- No contact: , ;

- -

- Adhesion: , , , ,

3. Results

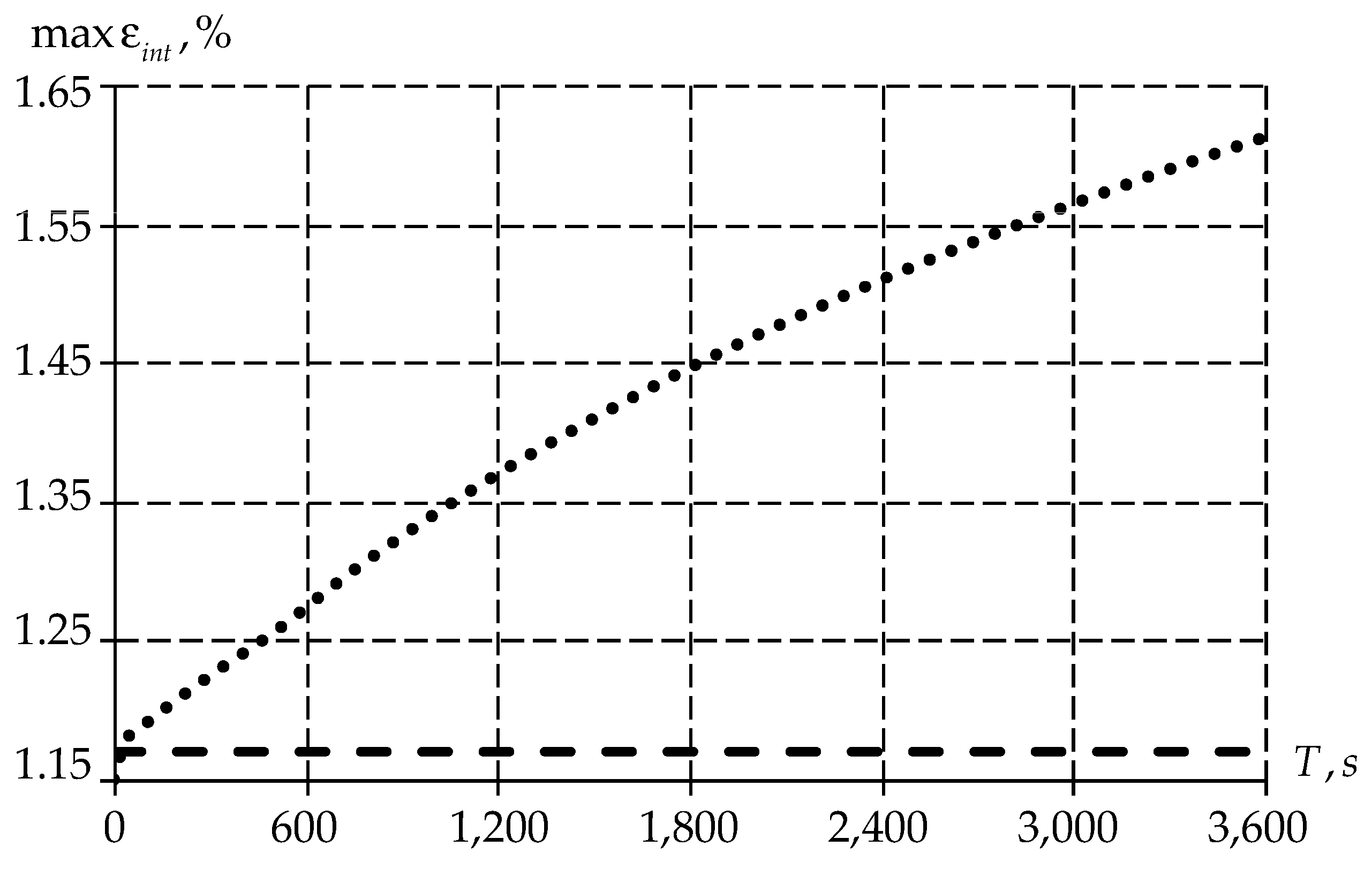

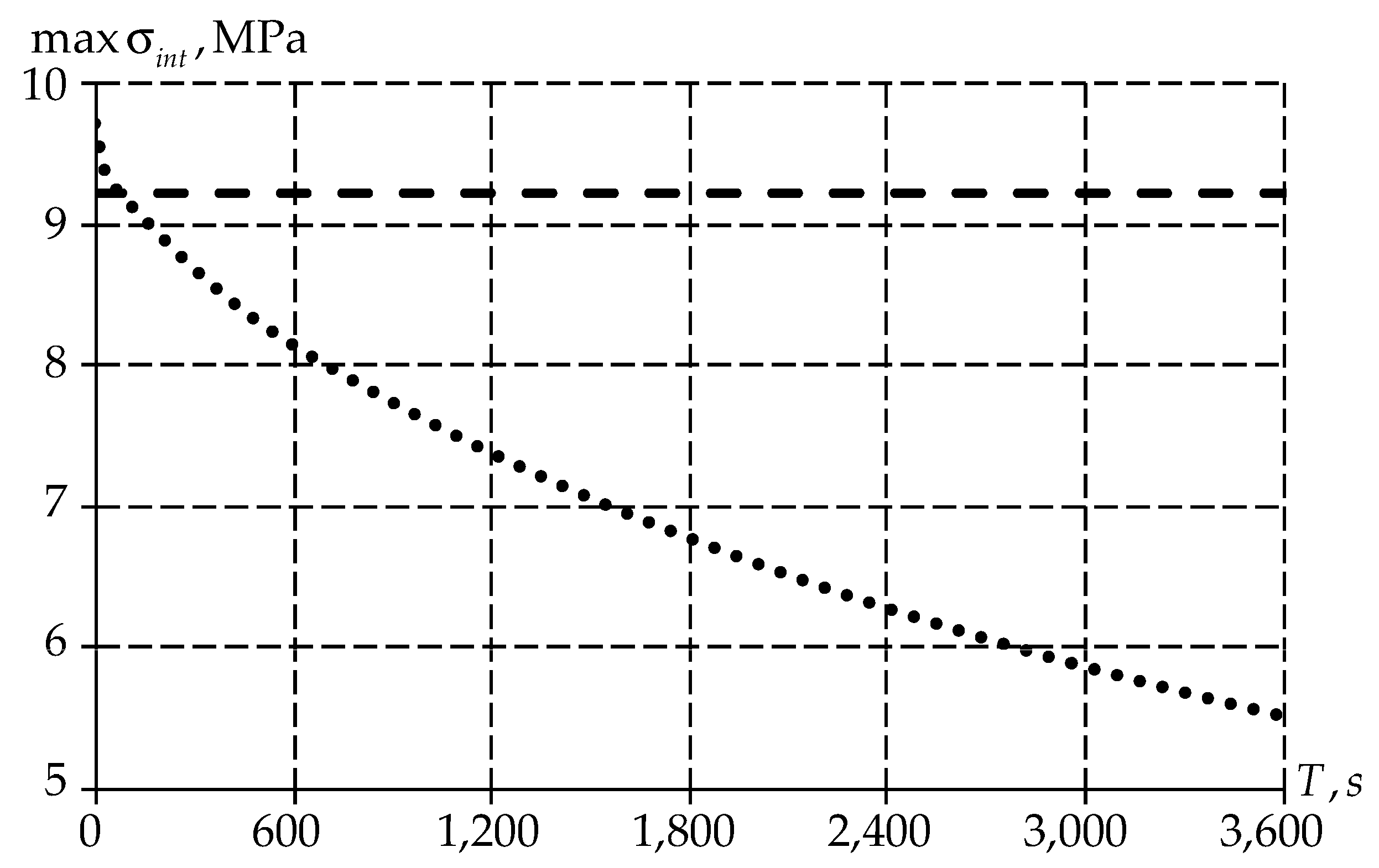

3.1. Invastigation of Mathematical Models

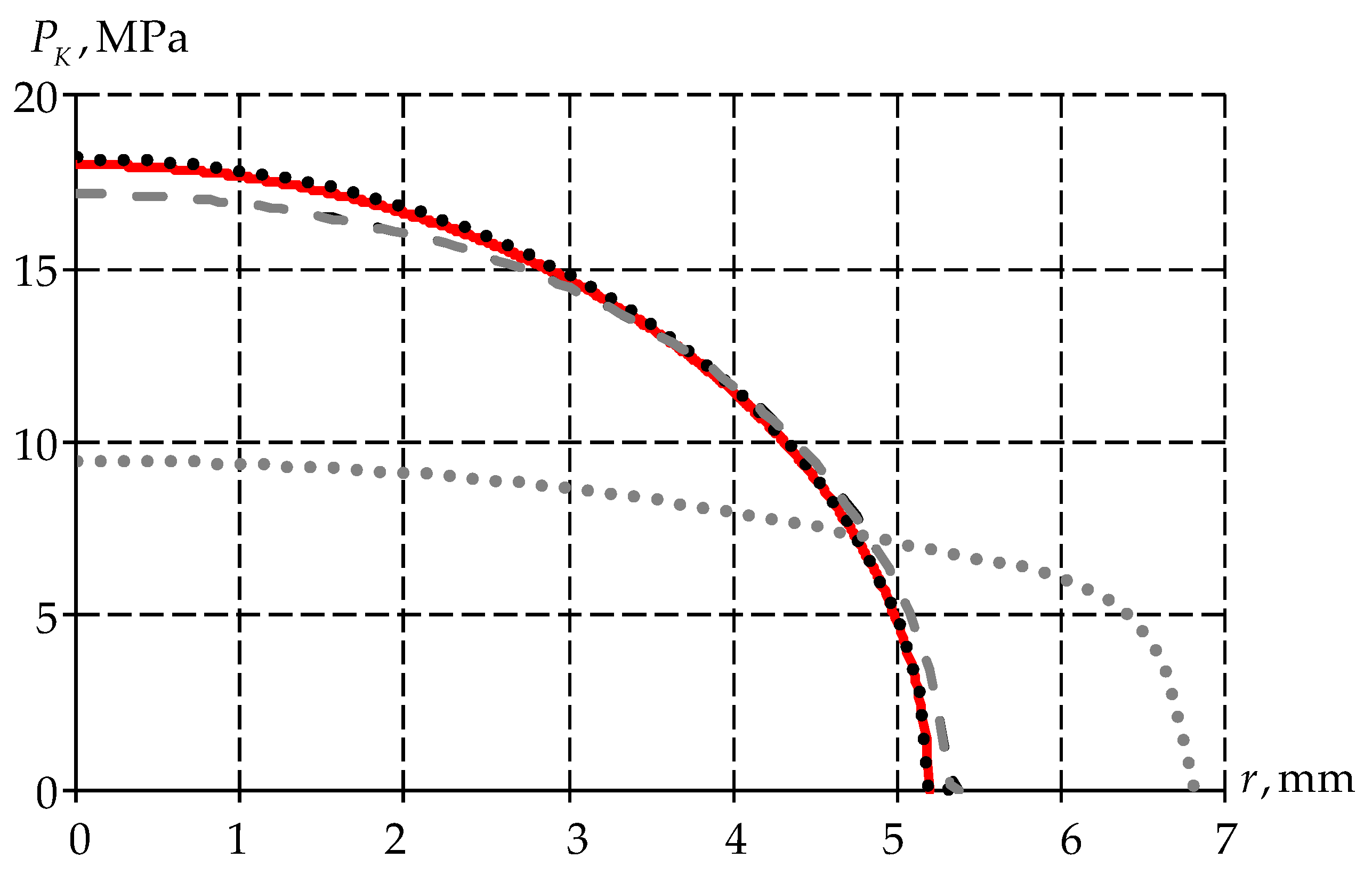

3.2. Hertz Contact Calculation Model

4. Discussion

4.1. Limitation Statement

- The material behavior is considered at a constant temperature of 20 °C;

- The model problem of spherical indenter penetration into a half-space is considered;

- For each material, it is necessary to carry out a separate description of the mathematical model;

- Long time ranges are not considered, while the material works for a long time.

- Investigation of the material on a large range of operating temperatures;

- Study of the material on the dependence on the load impact rate on the polymer material;

- Study of temperature characteristics of the material;

- Realization of the problem on the example of a bridge bearing structure under cyclic loading.

4.2. On the Choice of a Mathematical Model

4.3. Applicability of the Research

5. Conclusions

- -

- The use of an elastic–plastic body to describe the material behavior can be used only in static problems to determine the strength properties of the structure;

- -

- The use of a viscoelastic body to describe the mathematical model of material behavior allows for evaluation of the performance of a structure at the entire stage of its life cycle.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bernard, C.A.; Correia, J.P.M.; Ahzi, S.; Bahlouli, N. Numerical implementation of an elastic-viscoplastic constitutive model to simulate the mechanical behaviour of amorphous polymers. Int. J. Mater. Form. 2017, 10, 607–621. [Google Scholar] [CrossRef]

- Hartmann, S.; Gilbert, R.R. Identifiability of material parameters in solid mechanics. Arch. Appl. Mech. 2018, 88, 3–26. [Google Scholar] [CrossRef]

- Varna, J.; Pupure, L. Effect of Material State and Temperature on Nonlinear Viscoelastic Response: 3D Constitutive Model and Incremental Formulation for Numerical Analysis. Mech. Compos. Mater. 2023, 59, 193–218. [Google Scholar] [CrossRef]

- Yin, B.; Kaliske, M. Fracture simulation of viscoelastic polymers by the phase-field method. Comput. Mech. 2020, 65, 293–309. [Google Scholar] [CrossRef]

- Forintos, N.; Czigany, T. Multifunctional application of carbon fiber reinforced polymer composites: Electrical properties of the reinforcing carbon fibers—A short review. Compos. Part B Eng. 2018, 162, 331–343. [Google Scholar] [CrossRef]

- Umar, K.; Yaqoob, A.A.; Ibrahim, M.N.M.; Parveen, T.; Safian, M.T.U. Chapter Thirteen-Environmental applications of smart polymer composites. Smart Polym. Nanocomposites 2021, 295–312. [Google Scholar] [CrossRef]

- Bakbak, O.; Colak, O. Modeling wide range of viscoelastic–viscoplastic behavior of Araldite LY 564 epoxy using cooperative viscoplasticity theory based on overstress model. J. Appl. Polym. Sci. 2023, 140, e53557. [Google Scholar] [CrossRef]

- Yao, B.; Hong, W.; Chen, T.; Han, Z.; Xu, X.; Hu, R.; Hao, J.; Li, C.; Li, H.; Perini, S.E.; et al. Highly Stretchable Polymer Composite with Strain-Enhanced Electromagnetic Interference Shielding Effectiveness. Adv. Mater. 2020, 32, e1907499. [Google Scholar] [CrossRef]

- Van Meter, K.E.; Junk, C.P.; Campbell, K.L.; Babuska, T.F.; Krick, B.A. Ultralow Wear Self-Mated PTFE Composites. Macromolecules 2022, 55, 3924–3935. [Google Scholar] [CrossRef]

- Peng, S.; Zhang, L.; Xie, G.; Guo, Y.; Si, L.; Luo, J. Friction and wear behavior of PTFE coatings modified with poly (methyl methacrylate). Compos. Part B Eng. 2019, 172, 316–322. [Google Scholar] [CrossRef]

- Mashtalyar, D.V.; Pleshkova, A.I.; Piatkova, M.A.; Nadaraia, K.V.; Imshinetskiy, I.M.; Belov, E.A.; Suchkov, S.N.; Sinebryukhov, S.L.; Gnedenkov, S.V. PTFE-Containing Coating Obtained on Ti by Spraying and PEO Pretreatment. Coatings 2023, 13, 1249. [Google Scholar] [CrossRef]

- Gooneratne, R.; Iroh, J.O. Thermomechanical and Pre-Ignition Properties of Multicomponent Poly(Vnylidene Fluoride)/Aluminum Oxide/Single-Walled Carbon Nanotube Hybrid Nanocomposites. J. Compos. Sci. 2022, 6, 380. [Google Scholar] [CrossRef]

- Zhang, G.; Yin, J.; Yan, M.; Zhang, H.; Yin, X. Improved Through-Plane Thermal Conductivity and Mechanical Properties of Low-Dielectric FEP/HBN Composites by Adding PTFE Nanoparticles. ACS Appl. Electron. Mater. 2021, 3, 4568–4578. [Google Scholar] [CrossRef]

- Stoporev, A.; Kadyrov, R.; Adamova, T.; Statsenko, E.; Nguyen, T.H.; Yarakhmedov, M.; Semenov, A.; Manakov, A. Three-Dimensional-Printed Polymeric Cores for Methane Hydrate Enhanced Growth. Polymers 2023, 15, 2312. [Google Scholar] [CrossRef] [PubMed]

- Rezvova, M.A.; Klyshnikov, K.Y.; Gritskevich, A.A.; Ovcharenko, E.A. Polymeric Heart Valves Will Displace Mechanical and Tissue Heart Valves: A New Era for the Medical Devices. Int. J. Mol. Sci. 2023, 24, 3963. [Google Scholar] [CrossRef] [PubMed]

- Bembenek, M.; Popadyuk, O.; Shihab, T.; Ropyak, L.; Uhryński, A.; Vytvytskyi, V.; Bulbuk, O. Optimization of Technological Parameters of the Process of Forming Therapeutic Biopolymer Nanofilled Films. Nanomaterials 2022, 12, 2413. [Google Scholar] [CrossRef] [PubMed]

- Tretiak, O.; Kritskiy, D.; Kobzar, I.; Arefieva, M.; Nazarenko, V. The Methods of Three-Dimensional Modeling of the Hydrogenerator Thrust Bearing. Computation 2022, 10, 152. [Google Scholar] [CrossRef]

- Bakkara, A.; Sadykov, B.; Zhapekova, A.; Oserov, T.; Batkal, A.; Khairullina, A.; Mofa, N. Efficiency and Prospects of the Use of Mechanochemical Treatment to Obtain Innovative Composite Systems. Chemengineering 2022, 6, 90. [Google Scholar] [CrossRef]

- Tretiak, O.; Kritskiy, D.; Kobzar, I.; Arefieva, M.; Selevko, V.; Brega, D.; Maiorova, K.; Tretiak, I. Stress-Strained State of the Thrust Bearing Disc of Hydrogenerator-Motor. Computation 2023, 11, 60. [Google Scholar] [CrossRef]

- Mylsamy, G.; Krishnasamy, P. A Review on Electrical Properties of Fiber-Reinforced Polymer Material: Fabrication, Measurement, and Performances. Trans. Indian Inst. Met. 2023, 76, 1691–1708. [Google Scholar] [CrossRef]

- Yang, G.; Meng, G.; Gao, H.; Lin, Q. Micromorphology and mechanical properties of UHMWPE/CNF composites under accelerated aging. Polym. Compos. 2022, 43, 3716–3730. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Vuluga, Z.; Frone, A.N.; Gabor, A.R.; Nicolae, C.-A.; Uşurelu, C.-D. Complex Effects of Hemp Fibers and Impact Modifiers in Multiphase Polypropylene Systems. Polymers 2023, 15, 409. [Google Scholar] [CrossRef] [PubMed]

- Zhu, R.; Li, X.; Wu, C.; Du, L.; Du, X. The In-Situ Mechanical Properties of Carbon Fiber/Epoxy Composite under the Electric-Current Loading. Polymers 2022, 14, 4452. [Google Scholar] [CrossRef] [PubMed]

- Doh, J.; Hur, S.H.; Lee, J. Viscoplastic parameter identification of temperature-dependent mechanical behavior of modified polyphenylene oxide polymers. Polym. Eng. Sci. 2019, 59, E200–E211. [Google Scholar] [CrossRef]

- Liu, E.; Wu, J.; Li, H.; Liu, H.; Xiao, G.; Shen, Q.; Kong, L.; Lin, J. Research on viscoelastic behavior of semi-crystalline polymers using instrumented indentation. J. Polym. Sci. 2021, 59, 1795–1806. [Google Scholar] [CrossRef]

- Alam, I.; Khan, D.; Mittal, Y.; Kumar, S. Effect of crack tip shape on near-tip deformation and fields in plastically compressible solids. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 441. [Google Scholar] [CrossRef]

- O’connor, J.; dos Santos, B.B.; Borges, L.; da Costa, M.F.; Castello, D.A. Computational modeling of viscoplastic polymeric material response during micro-indentation tests. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 438. [Google Scholar] [CrossRef]

- Nunes, S.G.; Saseendran, S.; Joffe, R.; Amico, S.C.; Fernberg, P.; Varna, J. On Temperature-Related Shift Factors and Master Curves in Viscoelastic Constitutive Models for Thermoset Polymers. Mech. Compos. Mater. 2020, 56, 573–590. [Google Scholar] [CrossRef]

- Chae, S.-H.; Zhao, J.-H.; Edwards, D.R.; Ho, P.S. Characterization of the Viscoelasticity of Molding Compounds in the Time Domain. J. Electron. Mater. 2010, 39, 419–425. [Google Scholar] [CrossRef]

- Freire, R.T.S.; Nunes, S.G.; Amico, S.C.; Al-Ramahi, N.J.; Joffe, R.; Varna, J. On Determination of the Linear Viscoelastic Compliance and Relaxation Functions for Polymers in One Tensile Test. Mech. Compos. Mater. 2023, 58, 765–786. [Google Scholar] [CrossRef]

- Gonabadi, H.; Oila, A.; Yadav, A.; Bull, S. Investigation of the Effects of Environmental Fatigue on the Mechanical Properties of GFRP Composite Constituents Using Nanoindentation. Exp. Mech. 2022, 62, 585–602. [Google Scholar] [CrossRef]

- Wan, Y.; Yu, Y.; Cao, L.; Zhang, M.; Gao, J.; Qi, C. Corrosion and tribological performance of PTFE-coated electroless nickel boron coatings. Surf. Coatings Technol. 2016, 307, 316–323. [Google Scholar] [CrossRef]

- Sajid, M.; Ilyas, M. PTFE-coated non-stick cookware and toxicity concerns: A perspective. Environ. Sci. Pollut. Res. 2017, 24, 23436–23440. [Google Scholar] [CrossRef] [PubMed]

- Vahabi, H.; Laoutid, F.; Mehrpouya, M.; Saeb, M.R.; Dubois, P. Flame retardant polymer materials: An update and the future for 3D printing developments. Mater. Sci. Eng. R Rep. 2021, 144, 100604. [Google Scholar] [CrossRef]

- El-Sheikh, M.N.; Metwally, B.S.; Mubarak, M.F.; Ahmed, H.A.; Moghny, T.A.; Zayed, A.M. Fabrication of electrospun polyamide–weathered basalt nano-composite as a non-conventional membrane for basic and acid dye removal. Polym. Bull. 2023, 80, 8511–8533. [Google Scholar] [CrossRef]

- Murtada, K.; Nazdrajić, E.; Pawliszyn, J. Polybenzimidazole: A novel, fluorocarbon-free, SPME sorbent binder with good thermal and solvent resistance properties for GC and LC analysis. Microchim. Acta 2023, 190, 323. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, M.I.; Yahia, I.S.; El-Sayed, F. Study the microstructure, optical, mechanical, and dielectric characteristics of Cu2+/Zn2+-codoped PVA for CUT-OFF laser filters. Polym. Bull. 2023, 80, 8377–8405. [Google Scholar] [CrossRef]

- Chulliyote, R.; Hareendrakrishnakumar, H.; Kannan, S.K.; Joseph, M.G. Biomass-derived inherently doped multifunctional hierarchically porous carbon as an efficient electrode material for high-performance supercapacitors. J. Porous Mater. 2023, 30, 1129–1141. [Google Scholar] [CrossRef]

- Pavlov, A.A.; Soboleva, E.S. Anti-Frictional Copper-Fluoroplast Coating for Parts of Power Equipment. Chem. Petrol. Eng. 2021, 57, 56–59. [Google Scholar] [CrossRef]

- Adamov, A.A.; Kamenskikh, A.A.; Pankova, A.P.; Strukova, V.I. Comparative Analysis of the Work of Bridge Spherical Bearing at Different Antifriction Layer Locations. Lubricants 2022, 10, 207. [Google Scholar] [CrossRef]

- Zhu, G.; Zhang, C.; Li, K.; Xi, X.; Zhang, X.; Lei, H. A multifunctional zeolitic imidazolate framework-8@wood aerogel composite intergrating superior performance of dye adsorption capacity and flame-retardant property. J. Porous Mater. 2023, 30, 1171–1182. [Google Scholar] [CrossRef]

- Adamov, A.A.; Kamenskih, A.A.; Pankova, A.P. Numerical analysis of the spherical bearing geometric configuration with antifriction layer made of different materials. PNRPU Mech. Bull. 2020, 4, 15–26. [Google Scholar] [CrossRef]

- Chebakov, M.I.; Danil’chenko, S.A. Theoretical-Experimental Approach to Determining the Mechanical Characteristics of Thin Polymer Composite Coatings. Mech. Compos. Mater. 2023, 58, 803–810. [Google Scholar] [CrossRef]

- Polychronopoulos, N.; Vlachopoulos, J. Polymer Processing and Rheology. Funct. Polym. 2019, 1–47. [Google Scholar] [CrossRef]

- Nosov, Y.O.; Kamenskikh, A.A. Influence Analysis of Lubricant Recesses on the Working Capacity of the Bridge Span Spherical Bearing. Lubricants 2022, 10, 283. [Google Scholar] [CrossRef]

- Khokhlov, A.V.; Shaporev, A.V.; Stolyarov, O.N. Loading-Unloading-Recovery Curves for Polyester Yarns and Identification of the Nonlinear Maxwell-Type Viscoelastoplastic Model. Mech. Compos. Mater. 2023, 59, 129–146. [Google Scholar] [CrossRef]

- Khokhlov, A.V. Generalization of a Nonlinear Maxwell-Type Viscoelastoplastic Model and Simulation of Creep and Recovery Curves. Mech. Compos. Mater. 2023, 59, 441–454. [Google Scholar] [CrossRef]

- Lesnikova, Y.I.; Trufanov, A.N.; Kamenskikh, A.A. Analysis of the Polymer Two-Layer Protective Coating Impact on Panda-Type Optical Fiber under Bending. Polymers 2022, 14, 3840. [Google Scholar] [CrossRef]

- Liu, T.; Fan, J.; Peng, Z. Central Load-Bearing Control in the Construction Process of the Concrete Spherical Joint Nandu River Swing Bridge: A Case Study. Buildings 2022, 12, 511. [Google Scholar] [CrossRef]

- Chen, Y.; Smith, L.V. A nonlinear viscoelastic–viscoplastic constitutive model for adhesives under creep. Mech. Time-Depend. Mater. 2022, 26, 663–681. [Google Scholar] [CrossRef]

- Sofiyev, A. On the Solution of Dynamic Stability Problem of Functionally Graded Viscoelastic Plates with Different Initial Conditions in Viscoelastic Media. Mathematics 2023, 11, 823. [Google Scholar] [CrossRef]

- Reza, A.; Shishesaz, M.; Sedighi, H.M. Micromechanical approach to viscoelastic stress analysis of a pin-loaded hole in unidirectional laminated PMC. Polym. Polym. Compos. 2021, 29, S1144–S1157. [Google Scholar] [CrossRef]

- Reichl, K.K.; Avci, O.; Inman, D.J. Temperature Dependent Damping in Additively Manufactured Polymer Structures. J. Appl. Comput. Mech. 2021, 7, 993–1008. [Google Scholar] [CrossRef]

- Endo, V.T.; de Carvalho Pereira, J.C. Linear orthotropic viscoelasticity model for fiber reinforced thermoplastic material based on Prony series. Mech. Time-Depend. Mater. 2017, 21, 199–221. [Google Scholar] [CrossRef]

- Nosov, Y.O.; Kamenskikh, A.A. Experimental Study of the Rheology of Grease by the Example of CIATIM-221 and Identification of Its Behavior Model. Lubricants 2023, 11, 295. [Google Scholar] [CrossRef]

- Adamov, A.A.; Kamenskikh, A.A.; Pankova, A.P. Influence Analysis of the Antifriction Layer Materials and Thickness on the Contact Interaction of Spherical Bearings Elements. Lubricants 2022, 10, 30. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamenskikh, A.A.; Nosov, Y.O.; Bogdanova, A.P. The Study Influence Analysis of the Mathematical Model Choice for Describing Polymer Behavior. Polymers 2023, 15, 3630. https://doi.org/10.3390/polym15173630

Kamenskikh AA, Nosov YO, Bogdanova AP. The Study Influence Analysis of the Mathematical Model Choice for Describing Polymer Behavior. Polymers. 2023; 15(17):3630. https://doi.org/10.3390/polym15173630

Chicago/Turabian StyleKamenskikh, Anna A., Yuriy O. Nosov, and Anastasia P. Bogdanova. 2023. "The Study Influence Analysis of the Mathematical Model Choice for Describing Polymer Behavior" Polymers 15, no. 17: 3630. https://doi.org/10.3390/polym15173630

APA StyleKamenskikh, A. A., Nosov, Y. O., & Bogdanova, A. P. (2023). The Study Influence Analysis of the Mathematical Model Choice for Describing Polymer Behavior. Polymers, 15(17), 3630. https://doi.org/10.3390/polym15173630