Experimental Study of Curing Temperature Effect on Mechanical Performance of Carbon Fiber Composites with Application to Filament Winding Pressure Vessel Design

Abstract

:1. Introduction

2. Experimental Program

2.1. Material

2.2. Pure Epoxy Resin Matrix Preparation

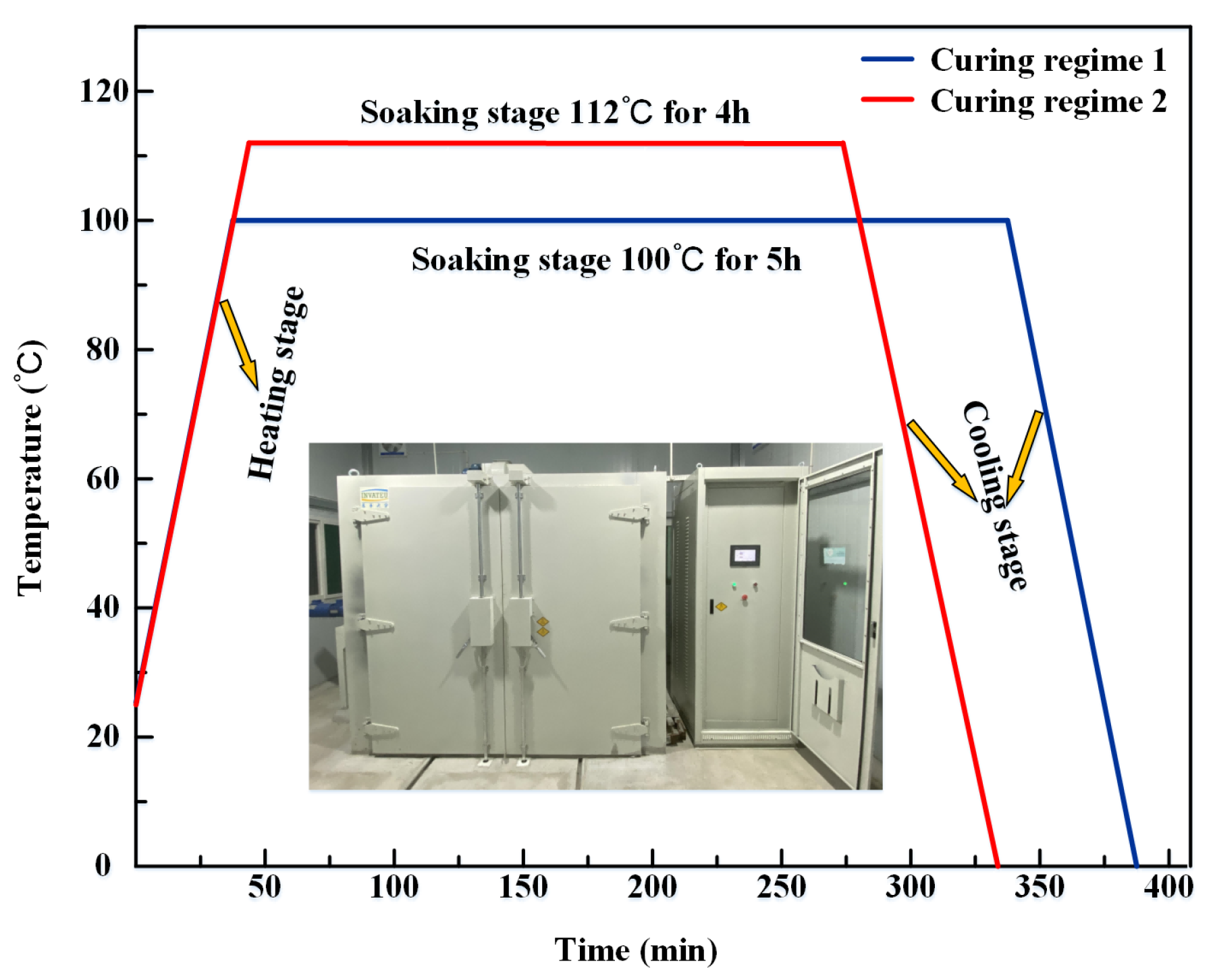

2.3. Preparation of Composite NOL Rings and Unidirectional Plates

2.4. Thermal Analysis

2.5. Mechanical Performance Test

2.6. Material Scanning Electron Microscopy (SEM) Testing

3. Results and Discussion

3.1. Curing Kinetics Analysis

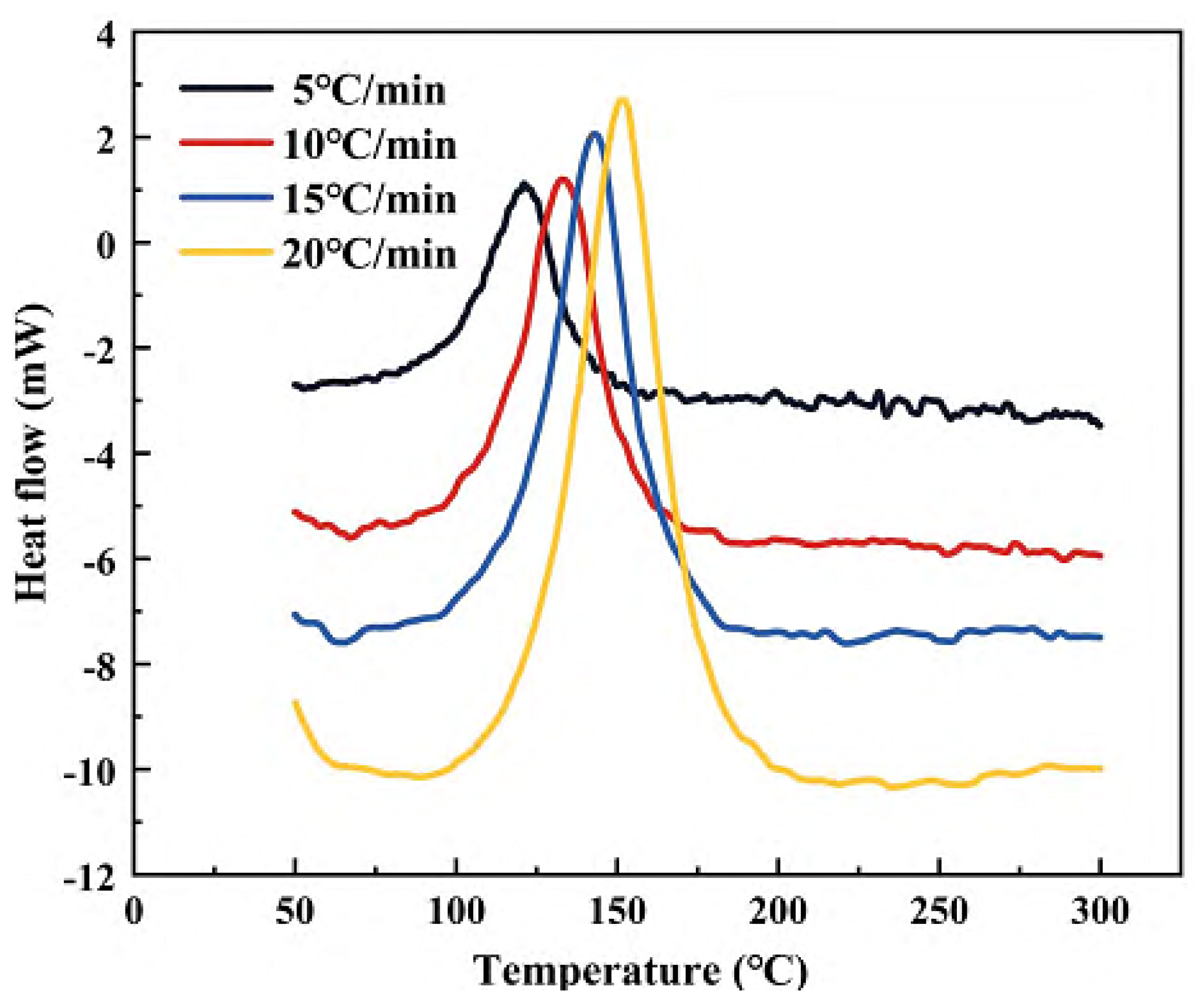

3.1.1. Differential Scanning Calorimetry Curve Analysis

- (1)

- The onset temperature, peak temperature, and termination temperature of the resin system increase as the heating rate rises;

- (2)

- The appearance of the exothermic peak of the resin system increases with the rate of temperature rise and moves to the right, that is, in the direction of high temperature;

- (3)

- With the increase in the heating rate, the curing temperature rises, the curing rate increases, and the curing time is shortened.

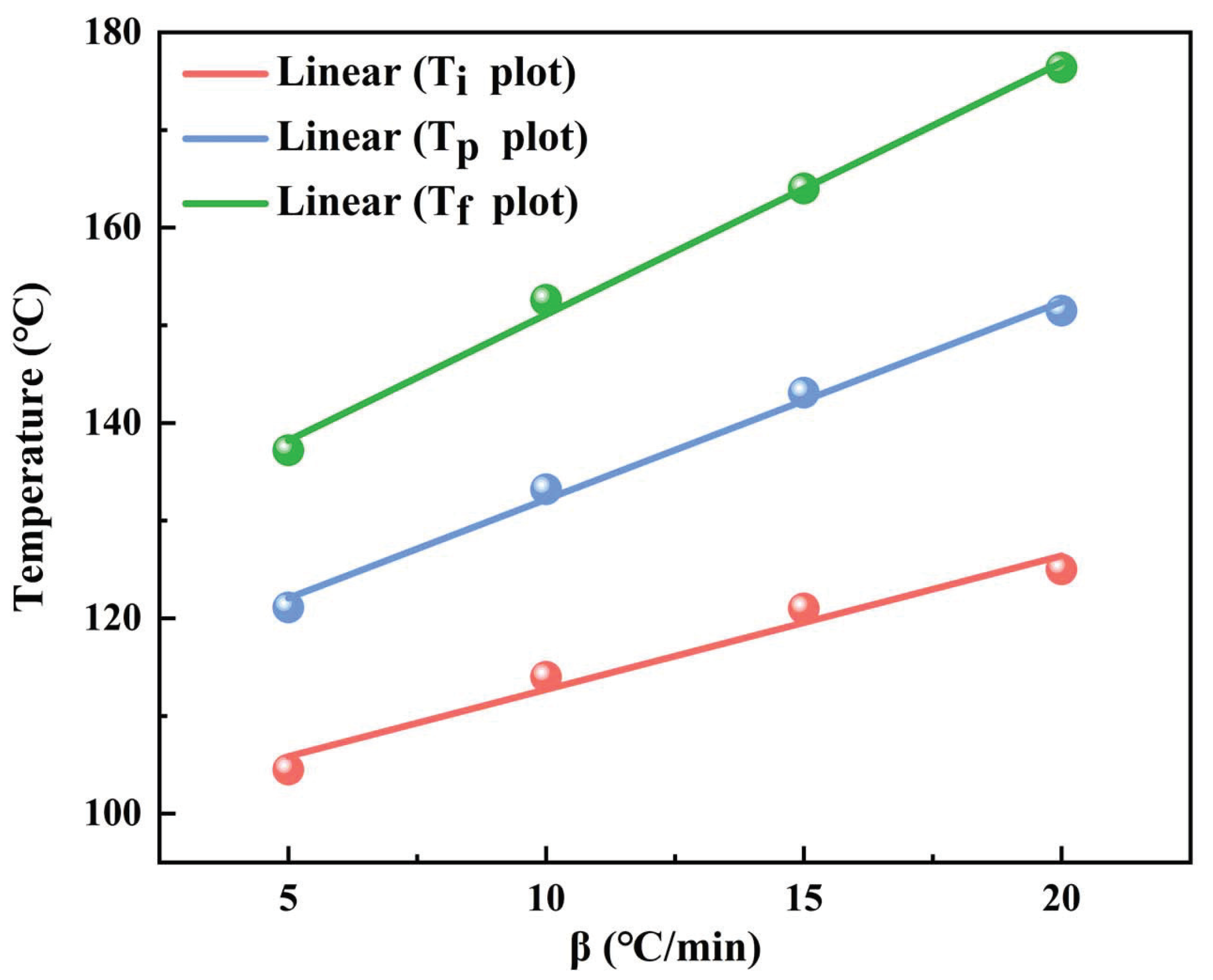

3.1.2. Curing Kinetics Parameters Analysis

3.1.3. Determination of Curing Temperature

3.2. Effect of Curing Temperature on the Mechanical Properties of Pure Epoxy Resin Matrix

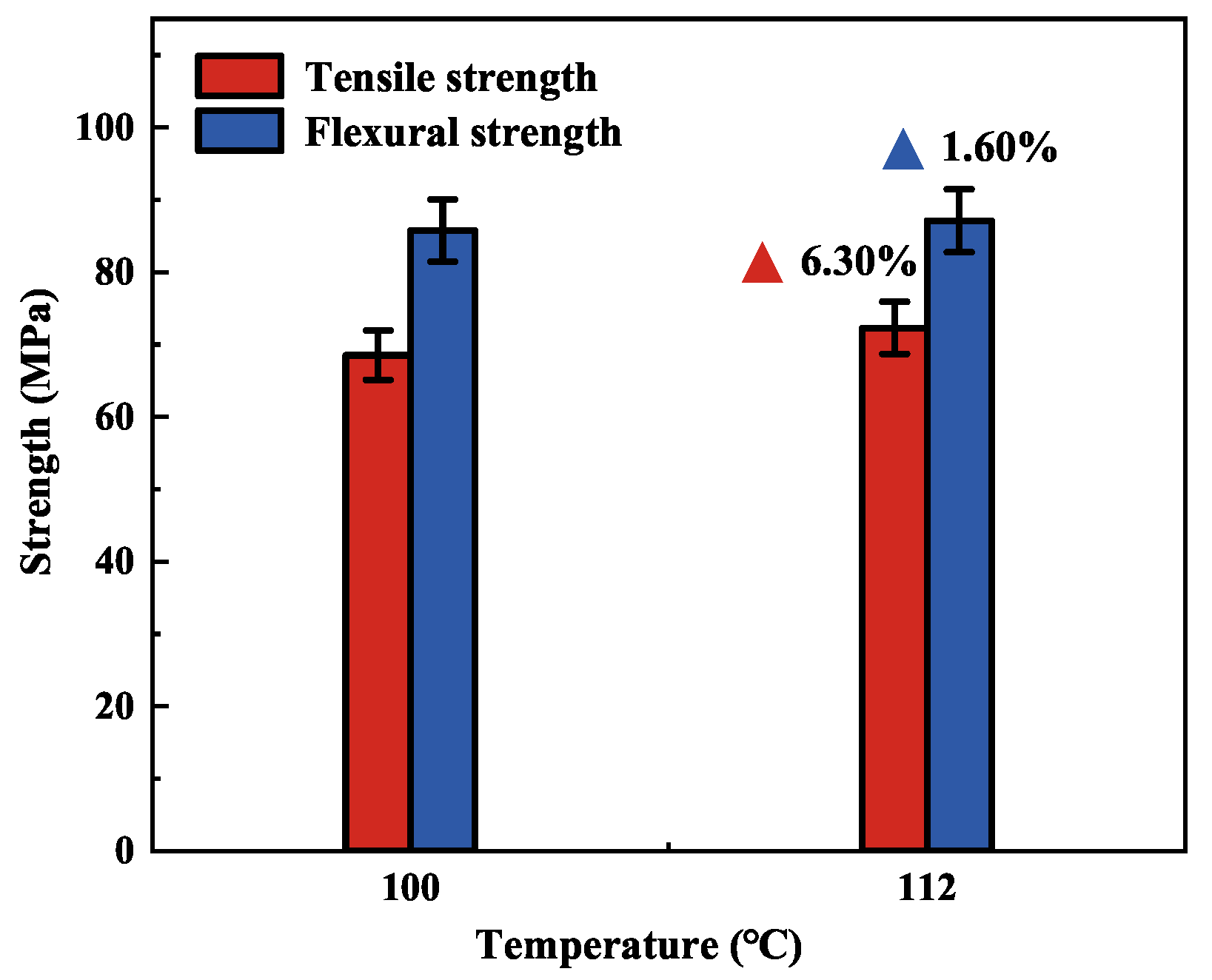

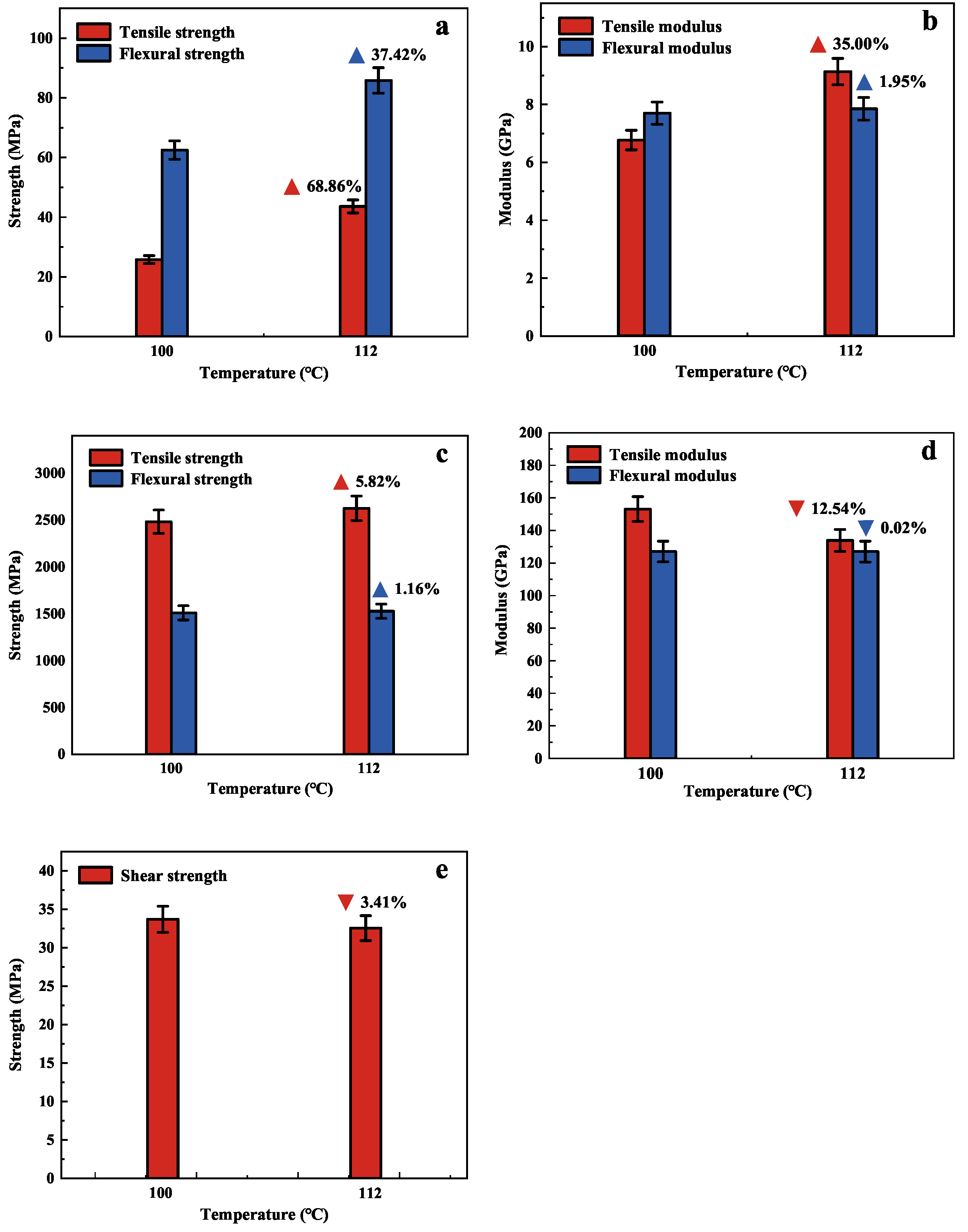

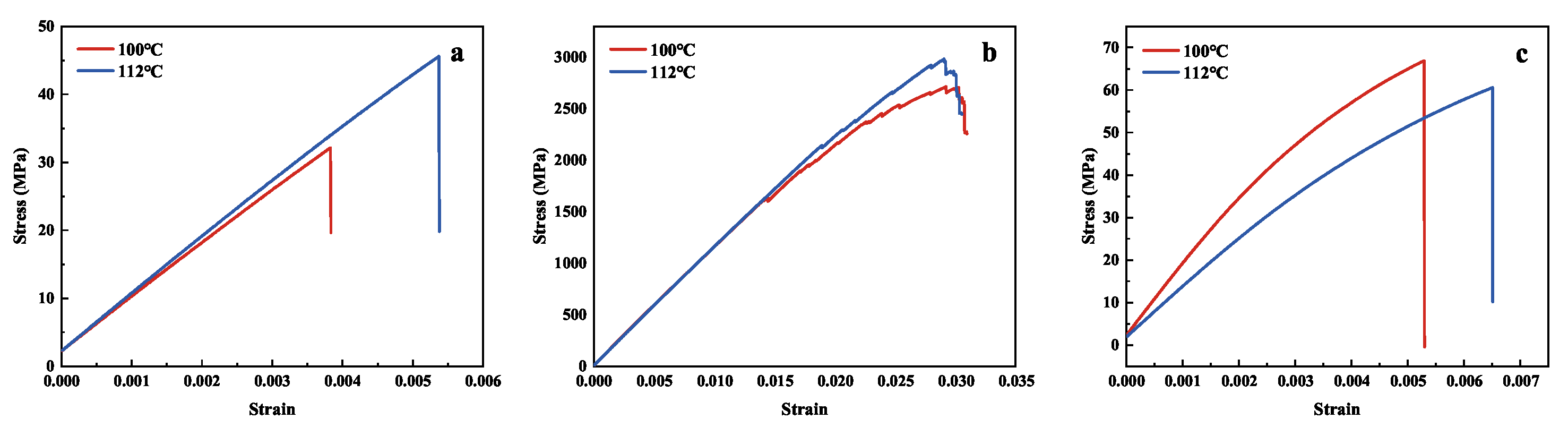

3.3. Effect of Curing Temperature on Mechanical Properties of Composites

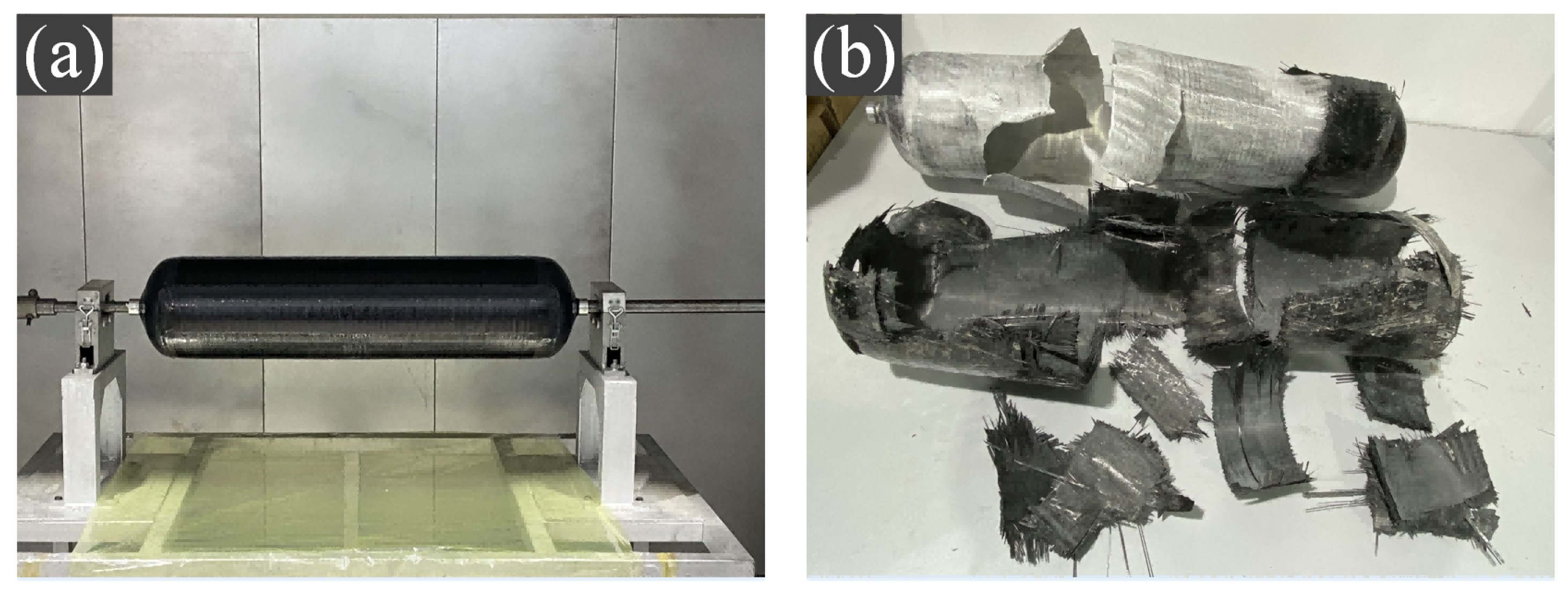

3.4. Burst Pressure Results of Composite Pressure Vessel

4. Conclusions

- (1)

- Compared to 100 °C, the tensile strength of 4251A4/B2 pure epoxy resin matrix at a 112 °C curing temperature is improved by 6.30%, and the flexural strength can still maintain the original level. It shows that the curing temperature of 112 °C positively affects the improvement of the overall properties of epoxy resin used in composites.

- (2)

- The tensile and flexural strength of the composites for winding were improved using a curing regime of 112 °C. The tensile strength of NOL rings was enhanced by 22%. The tensile strength and flexural strength of the unidirectional plates increased by 68.86% and 37.42%, respectively, in the 90° direction, and the tensile strength in the 0° direction increased by 5.82%. The application of this curing regime provides a strong guarantee for the improvement of composite materials and overall performance in hydrogen storage vessels.

- (3)

- The 35 MPa pressure vessel is cured and molded at 112 °C, and its actual burst pressure reaches 104.4 MPa, 26.93% higher than the minimum design burst pressure. At 112 °C, the resin fluidity in the pressure vessel is improved, and the interfacial bonding between the resin matrix and the fibers is enhanced, which ultimately leads to the good overall performance of the pressure vessel. It shows that the selection of the curing regime in the molding process of the pressure vessel is an essential factor in the overall mechanical properties.

- (4)

- The non-isothermal kinetic method is used to analyze the curing kinetics of 4251A4/B2 epoxy resin, and the activation energy values calculated using the Kissinger method and Ozawa method are 56.735 kJ/mol and 60.392 kJ/mol, respectively. Its n-order reaction model will be used in pressure vessel curing molding simulation.

- (5)

- The curing temperature is a crucial factor affecting the curing process. In applying 4251A4/B2 epoxy resin wet-forming composite materials and pressure vessels, the curing temperature of 112 °C is a curing parameter that cannot be ignored to improve the overall performance of the structure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nitin, M.S.; Suresh Kumar, S. Ballistic performance of synergistically toughened Kevlar/epoxy composite targets reinforced with multiwalled carbon nanotubes/graphene nanofillers. Polym. Compos. 2021, 43, 782–797. [Google Scholar] [CrossRef]

- Gieparda, W.; Rojewski, S.; Wüstenhagen, S.; Kicinska-Jakubowska, A.; Krombholz, A. Chemical modification of natural fibres to epoxy laminate for lightweight constructions. Compos. Part Appl. Sci. Manuf. 2021, 140, 106171. [Google Scholar] [CrossRef]

- Li, Q.; Li, Y.; Chen, Y.; Wu, Q.; Wang, S. An Effective Method for Preparation of Liquid Phosphoric Anhydride and Its Application in Flame Retardant Epoxy Resin. Materials 2021, 14, 2205. [Google Scholar] [CrossRef]

- Xu, Y.; Hoa, S.V. Mechanical properties of carbon fiber reinforced epoxy/clay nanocomposites. Compos. Sci. Technol. 2008, 68, 854–861. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Y.; Hu, J. Recent advances in the development of aerospace materials. Prog. Aerosp. Sci. 2018, 97, 22–34. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C.; Wang, Y. Mechanical performance evolution and life prediction of prestressed CFRP plate exposed to hygrothermal and freeze-thaw environments. Compos. Struct. 2022, 293, 115719. [Google Scholar] [CrossRef]

- Voudouris, G.; Di Maio, D.; Sever, I.A. Experimental fatigue behaviour of CFRP composites under vibration and thermal loading. Int. J. Fatigue 2020, 140, 105791. [Google Scholar] [CrossRef]

- Li, C.; Xian, G. Mechanical property evolution and life prediction of carbon fiber and pultruded carbon fiber reinforced polymer plate exposed to elevated temperatures. Polym. Compos. 2020, 41, 5143–5155. [Google Scholar] [CrossRef]

- Nebe, M.; Asijee, T.J.; Braun, C.; van Campen, J.M.J.F.; Walther, F. Experimental and analytical analysis on the stacking sequence of composite pressure vessels. Compos. Struct. 2020, 247, 112429. [Google Scholar] [CrossRef]

- Leh, D.; Saffré, P.; Francescato, P.; Arrieux, R. Multi-sequence dome lay-up simulations for hydrogen hyper-bar composite pressure vessels. Compos. Part Appl. Sci. Manuf. 2013, 52, 106–117. [Google Scholar] [CrossRef]

- Mertiny, P.; Ellyin, F.; Hothan, A. An experimental investigation on the effect of multi-angle filament winding on the strength of tubular composite structures. Compos. Sci. Technol. 2004, 64, 1–9. [Google Scholar] [CrossRef]

- Fard, M.Y.; Raji, B. Hydrostatic and Cyclic Pressure Testing of Small-Scale Composite Pipes and Vessels. J. Aerosp. Eng. 2022, 35, 1–10. [Google Scholar]

- Nebe, M.; Johman, A.; Braun, C.; Campen, J.V. The effect of stacking sequence and circumferential ply drop locations on the mechanical response of type IV composite pressure vessels subjected to internal pressure: A numerical and experimental study. Compos. Struct. 2022, 294, 115585. [Google Scholar] [CrossRef]

- Xu, J.; Yu, L.; Qiao, M.; You, B. In-situ curing of composite vessel using heating gasbag. Compos. Struct. 2015, 131, 171–182. [Google Scholar] [CrossRef]

- Saenz-Dominguez, I.; Tena, I.; Sarrionandia, M.; Torre, J.; Aurrekoetxea, J. An analytical model of through-thickness photopolymerisation of composites: Ultraviolet light transmission and curing kinetics. Compos. Part Eng. 2020, 191, 107963. [Google Scholar] [CrossRef]

- Lu, J.-H.; Youngblood, J.P. Adhesive bonding of carbon fiber reinforced composite using UV-curing epoxy resin. Compos. Part Eng. 2015, 82, 221–225. [Google Scholar] [CrossRef]

- Hu, J.; Xie, H.; Zhu, Z.; Yang, W.; Tan, W.; Zeng, K.; Yang, G. Reducing the melting point and curing temperature of aromatic cyano-based resins simultaneously through a Brϕnsted acid-base synergistic strategy. Polymer 2022, 246, 124745. [Google Scholar] [CrossRef]

- McHugh, J.; Stark, W. Determination and interpretation of changes in thermophysical properties of a carbon-fibre prepreg during cure. Polym. Test. 2016, 49, 115–120. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Q.; Gao, L.; Jia, Y. Effects of key thermophysical properties on the curing uniformity of carbon fiber reinforced resin composites. e-Polymers 2018, 18, 19–26. [Google Scholar] [CrossRef]

- Barghamadi, M. Curing studies of epoxy resin by 4,4’-diaminoazobenzene as curing agent reinforced with nanosilica and nanoclay particles along with impact resistance and thermal evaluation. Polym. Compos. 2010, 31, 1465–1473. [Google Scholar] [CrossRef]

- Ferdosian, F.; Yuan, Z.; Anderson, M.; Xu, C. Sustainable lignin-based epoxy resins cured with aromatic and aliphatic amine curing agents: Curing kinetics and thermal properties. Thermochim. Acta 2015, 618, 48–55. [Google Scholar] [CrossRef]

- Yeo, H. Curing kinetics of liquid crystalline 4,4’-diglycidyloxybiphenyl epoxy with various diamines. Polymer 2019, 168, 209–217. [Google Scholar] [CrossRef]

- Abliz, D.; Jürgens, T.; Artys, T.; Ziegmann, G. Cure kinetics and rheology modelling of boehmite (AlOOH) nanoparticle modified epoxy resin systems. Thermochim. Acta 2018, 669, 30–39. [Google Scholar] [CrossRef]

- Luo, X.; Yu, X.; Ma, Y.; Naito, K.; Zhang, Q. Preparation and cure kinetics of epoxy with nanodiamond modified with liquid crystalline epoxy. Thermochim. Acta 2018, 663, 1–8. [Google Scholar] [CrossRef]

- Nikzamir, M.; Mortezaei, M.; Jahani, M. Effect of surface area of nanosilica particles on the cure kinetics parameters of an epoxy resin system. J. Appl. Polym. Sci. 2019, 136, 47958. [Google Scholar] [CrossRef]

- Pattanaik, A.; Mukherjee, M.; Mishra, S.B. Influence of curing condition on thermo-mechanical properties of fly ash reinforced epoxy composite. Compos. Part Eng. 2019, 176, 107301. [Google Scholar] [CrossRef]

- Baghad, A.; El Mabrouk, K. The isothermal curing kinetics of a new carbon fiber/epoxy resin and the physical properties of its autoclaved composite laminates. Mater. Today Proc. 2022, 57, 922–929. [Google Scholar] [CrossRef]

- Ferdosian, F.; Zhang, Y.; Yuan, Z.; Anderson, M.; Xu, C. Curing kinetics and mechanical properties of bio-based epoxy composites comprising lignin-based epoxy resins. Eur. Polym. J. 2016, 82, 153–165. [Google Scholar] [CrossRef]

- Mphahlele, K.; Ray, S.S.; Kolesnikov, A. Cure kinetics, morphology development, and rheology of a high-performance carbon-fiber-reinforced epoxy composite. Compos. Part Eng. 2019, 176, 107300. [Google Scholar] [CrossRef]

- Cruz-Cruz, I.; Ramirez-Herrera, C.A.; Martinez-Romero, O.; Castillo-Marquez, S.A.; Jimenez-Cedeno, I.H.; Olvera-Trejo, D.; Elias-Zuniga, A. Influence of Epoxy Resin Curing Kinetics on the Mechanical Properties of Carbon Fiber Composites. Polymers 2022, 14, 1100. [Google Scholar] [CrossRef]

- Lascano, D.; Lerma-Canto, A.; Fombuena, V.; Balart, R.; Montanes, N.; Quiles-Carrillo, L. Kinetic Analysis of the Curing Process of Biobased Epoxy Resin from Epoxidized Linseed Oil by Dynamic Differential Scanning Calorimetry. Polymers 2021, 13, 1279. [Google Scholar] [CrossRef] [PubMed]

- Liang, Q.; Feng, X.-P.; Zhang, K.; Hui, X.-M.; Hou, X.; Ye, J.-R. Effect of curing pressure on the curing behavior of an epoxy system: Curing kinetics and simulation verification. Polymer 2022, 256, 125162. [Google Scholar] [CrossRef]

- Ernault, E.; Richaud, E.; Fayolle, B. Thermal oxidation of epoxies: Influence of diamine hardener. Polym. Degrad. Stab. 2016, 134, 76–86. [Google Scholar] [CrossRef] [Green Version]

- Parameswaranpillai, J.; George, A.; Pionteck, J.; Thomas, S. Investigation of Cure Reaction, Rheology, Volume Shrinkage and Thermomechanical Properties of Nano-TiO2 Filled Epoxy/DDS Composites. J. Polym. 2013, 2013, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Voto, G.; Sequeira, L.; Skordos, A.A. Formulation based predictive cure kinetics modelling of epoxy resins. Polymer 2021, 236, 124304. [Google Scholar] [CrossRef]

- Toyota, K. Products and kinetics of the cationic ring-opening polymerization of 3-glycidoxypropylmethyldimethoxysilane by lithium perchlorate. Polymer 2021, 218, 123490. [Google Scholar] [CrossRef]

- Sourour, S.; Kamal, M.R. Differential scanning calorimetry of epoxy cure: Isothermal cure kinetics. Thermochim. Acta 1976, 14, 41–59. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, J.; Chen, Y.; Ju, L.; Li, S.; Zhao, Y. Effect of no-pressure curing temperature on bending property of 2D-T700/E44 composite. Emerg. Mater. Res. 2020, 9, 695–704. [Google Scholar] [CrossRef]

- Li, C.; Zhu, R.; Huang, P.; Wang, X. Interfacial shear strength and fracture toughness between single carbon fiber and TiO2 matrix under microbond test. J. Adhes. 2019, 97, 821–839. [Google Scholar] [CrossRef]

- Man, T.C.; Karin, P.; Lin, Y.H.; Larpsuriyakul, P.; Ohtake, N. A Study on Curing Temperature and Fracture Mechanism of Carbon and Glass Fiber Reinforced Polymers Using an Electron Microscopy. Int. J. Automot. Technol. 2021, 22, 687–700. [Google Scholar] [CrossRef]

- Ismail, A.S.; Jawaid, M.; Hamid, N.H.; Yahaya, R.; Hassan, A.; Asim, M.; Supian, A.B.M. Effect of Curing Temperature on Mechanical Properties of Bio-phenolic/Epoxy Polymer Blends. J. Polym. Environ. 2021, 30, 878–885. [Google Scholar] [CrossRef]

- Alavi-Soltani, S.; Sabzevari, S.; Koushyar, H.; Minaie, B. Thermal, rheological, and mechanical properties of a polymer composite cured at different isothermal cure temperatures. J. Compos. Mater. 2011, 46, 575–587. [Google Scholar] [CrossRef]

- Koushyar, H.; Alavi-Soltani, S.; Minaie, B.; Violette, M. Effects of variation in autoclave pressure, temperature, and vacuum-application time on porosity and mechanical properties of a carbon fiber/epoxy composite. J. Compos. Mater. 2011, 46, 1985–2004. [Google Scholar] [CrossRef]

- CGH2R Draft Revision 10; Hydrogen Vehicles: On-Board Storage Systems Draft ECE Compressed Gaseous Hydrogen Regulatioin Revision 10. CENELEC: Brussels, Belgium, 2006.

- Chen, R.X. Stress equilibrium factor and the cylinder wound angle of the filament-wound case. J. Solid Rocket. Technol. 2009, 32, 677–679. (In Chinese) [Google Scholar]

- GB/T 2567-2021; Test Methods for Properties of Resin Casting Body. Standards Press of China: Beijing, China, 2021.

- GB/T 1458-2008; Test Method for Mechanical Properties of Ring of Filament-Winding Reinforced Plastics. Standards Press of China: Beijing, China, 2008.

- ASTM Standard D3039/D3039M-17; Test Method for Tensile Properties of Polymer Matrix Composite Materials. International Organization for Standardization: Geneva, Switzerland, 2017.

- ASTM Standard D3518/D3518M-18; Test Method for In-Plane Shear Response of Polymer Matrix Composite Materials by Tensile Test of a ±45° Laminate. International Organization for Standardization: Geneva, Switzerland, 2018.

- ASTM Standard D790-10; Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. International Organization for Standardization: Geneva, Switzerland, 2010.

- Cai, H.; Li, P.; Sui, G.; Yu, Y.; Li, G.; Yang, X.; Ryu, S. Curing kinetics study of epoxy resin/flexible amine toughness systems by dynamic and isothermal DSC. Thermochim. Acta 2008, 473, 101–105. [Google Scholar] [CrossRef]

- Zvetkov, V.L. Mechanistic modeling of the epoxy-amine reaction. Thermochim. Acta 2005, 435, 71–84. [Google Scholar] [CrossRef]

- Kissinger, H.E. Reaction Kinetics in Differential Thermal Analysis. Anal. Chem. 2002, 29, 1702–1706. [Google Scholar] [CrossRef]

- Ozawa, T. A New Method of Analyzing Thermogravimetric Data. Bull. Chem. Soc. Jpn. 1965, 38, 1881–1886. [Google Scholar] [CrossRef] [Green Version]

- Koga, N. Ozawa’s kinetic method for analyzing thermoanalytical curves. J. Therm. Anal. Calorim. 2013, 113, 1527–1541. [Google Scholar] [CrossRef]

- Kaelble, D.H.; Smith, T. Analysis of curing kinetics in polymer composites. J. Polym. Sci. Polym. Lett. Ed. 1974, 12, 473–475. [Google Scholar] [CrossRef]

- ISO 19881:2018; Gaseous Hydrogen-Land Vehicle Fuel Containers. International Organization for Standardization: Geneva, Switzerland, 2018.

| Density (g/mL) | Viscosity (mPa·s) | Gel Time (h) | Gel Time (s) |

|---|---|---|---|

| 1.47 | 1400–1500 | >12 | 80–120 |

| Tensile Strength (MPa) | Linear Density (g/km) | Volume Density (g/cm) | Elongation (%) | Diameter (m) |

|---|---|---|---|---|

| 4900 | 800 | 1.8 | 2.1 | 7 |

| Heating Rate (°C/min) | (°C) | (°C) | (°C) |

|---|---|---|---|

| 5 | 104.5 | 121.1 | 137.2 |

| 10 | 114.0 | 133.2 | 152.3 |

| 15 | 121.0 | 143.1 | 164.0 |

| 20 | 125.0 | 151.5 | 176.4 |

| 0 | 99.0 | 112.0 | 125.0 |

| Model | (kg/mol) | (kg/mol) | (kg/mol) | A (min) | n |

|---|---|---|---|---|---|

| 4251A4/B2 | 56.735 | 60.392 | 58.564 | 7.57 × 10 | 0.89 |

| Curing Temperature | 4251-100 | 4251-112 |

|---|---|---|

| Tensile strength (MPa) | 1852.37 | 2260.80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, J.; Liu, L.; Qin, Z.; Zhao, X.; Li, Z.; Emmanuel, U.; Feng, J. Experimental Study of Curing Temperature Effect on Mechanical Performance of Carbon Fiber Composites with Application to Filament Winding Pressure Vessel Design. Polymers 2023, 15, 982. https://doi.org/10.3390/polym15040982

Liang J, Liu L, Qin Z, Zhao X, Li Z, Emmanuel U, Feng J. Experimental Study of Curing Temperature Effect on Mechanical Performance of Carbon Fiber Composites with Application to Filament Winding Pressure Vessel Design. Polymers. 2023; 15(4):982. https://doi.org/10.3390/polym15040982

Chicago/Turabian StyleLiang, Jianguo, Lihua Liu, Zelin Qin, Xiaodong Zhao, Zhi Li, Uwayezu Emmanuel, and Jun Feng. 2023. "Experimental Study of Curing Temperature Effect on Mechanical Performance of Carbon Fiber Composites with Application to Filament Winding Pressure Vessel Design" Polymers 15, no. 4: 982. https://doi.org/10.3390/polym15040982

APA StyleLiang, J., Liu, L., Qin, Z., Zhao, X., Li, Z., Emmanuel, U., & Feng, J. (2023). Experimental Study of Curing Temperature Effect on Mechanical Performance of Carbon Fiber Composites with Application to Filament Winding Pressure Vessel Design. Polymers, 15(4), 982. https://doi.org/10.3390/polym15040982