Sound Absorption Performance and Mechanical Properties of the 3D-Printed Bio-Degradable Panels

Abstract

:1. Introduction

2. Materials and Methods

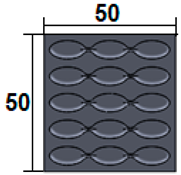

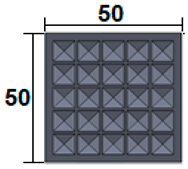

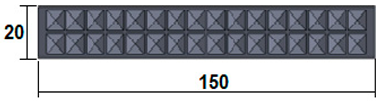

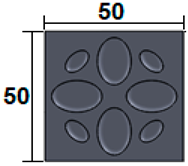

2.1. Design of the Panels

2.2. Materials Properties

2.3. Manufacturing Process of the 3D-Printed Panels

2.4. Acoustic Testing

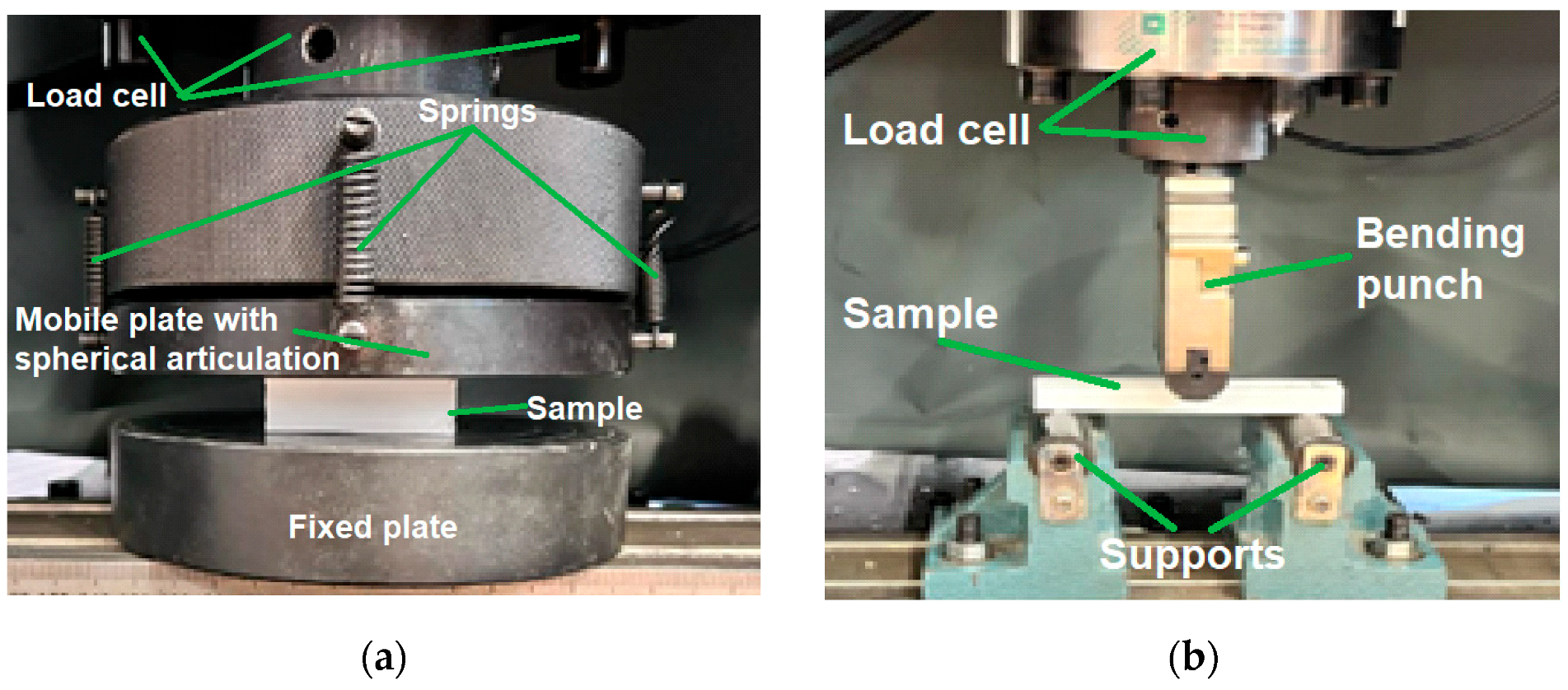

2.5. Mechanical Testing

2.6. Microscopic Analysis

3. Results and Discussion

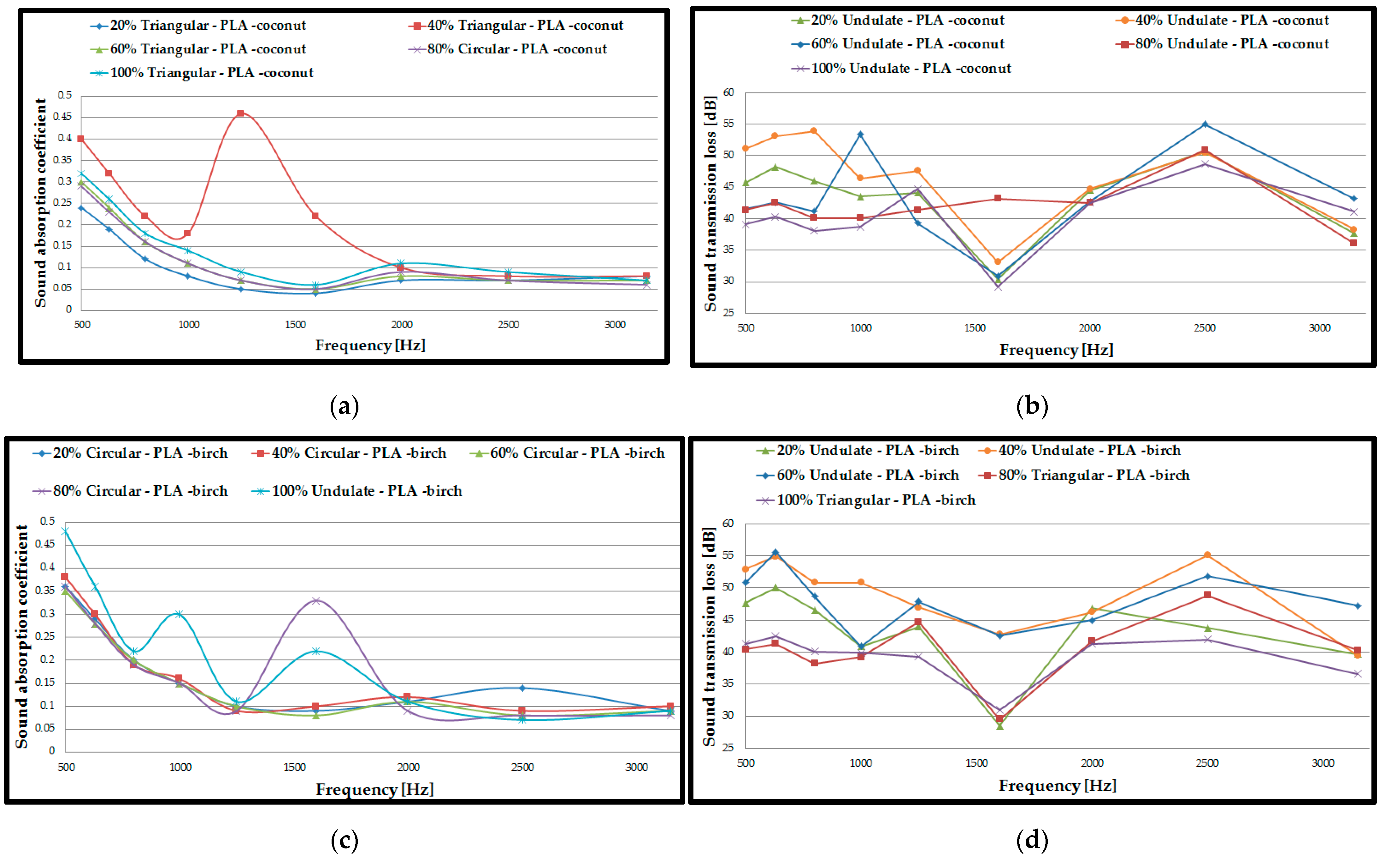

3.1. The Effect of Filling Density on the Acoustic Performance of 3D-Printed Double Panels

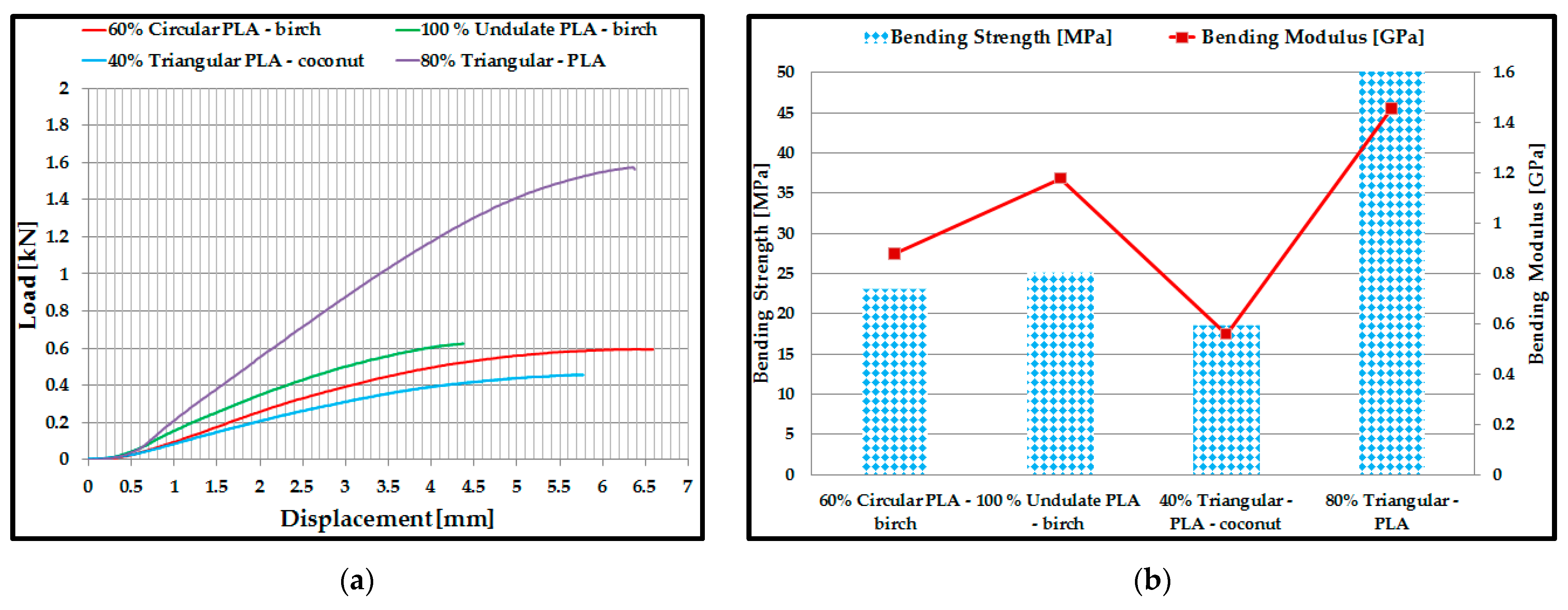

3.2. Mechanical Performance of 3D-Printed Double Panels

3.3. Microscopic Analysis of 3D-Printed Double Panels

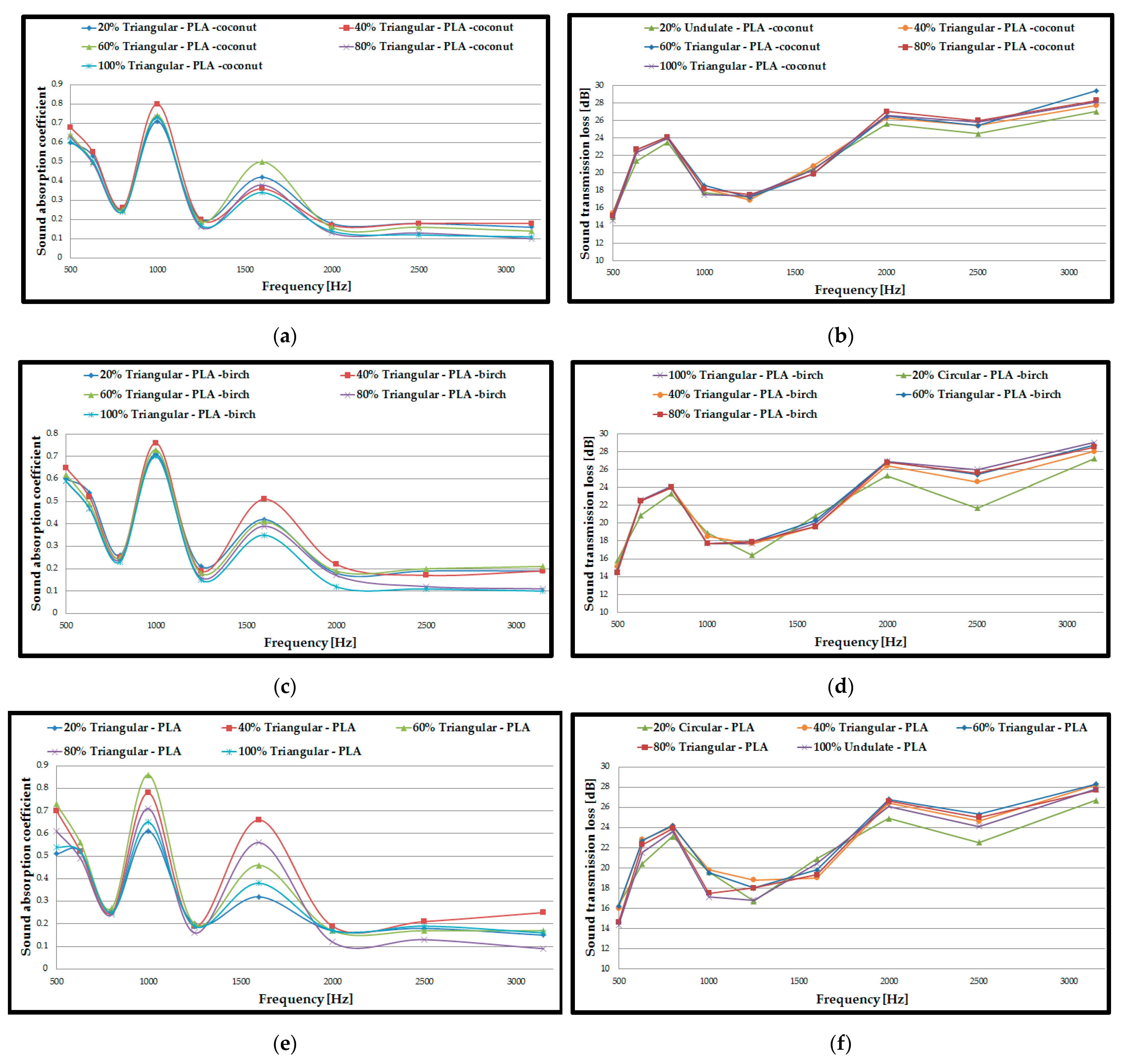

3.4. Acoustic Analysis of 3D-Printed Single Panels

3.5. Acoustic Analysis of 3D-Printed Single Panels with Drilled Holes

3.6. Acoustic Analysis of 3D-Printed Single Panels with Holes

4. Conclusions

- -

- For very good sound absorption properties, the configuration with 40% infill, triangular–PLA with coconut ground particles and 8 mm thickness is recommended.

- -

- The physical–mechanical properties of the material (PLA with ground coconut particles) ensure their use for obtaining protective sound-absorbing panels (near highways or heavily trafficked roads, various casings or covers of engines).

- -

- Transmission loss coefficient (STL) decreases with panel thickness.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sleinus, D.; Sinka, M.; Korjakins, A.; Obuka, V.; Nikolajeva, V.; Brencis, R.; Savicka, E. Properties of Sound Absorption Composite Materials Developed Using Flax Fiber, Sphagnum Moss, Vermiculite, and Sapropel. Materials 2023, 16, 1060. [Google Scholar] [CrossRef] [PubMed]

- Gliscinska, E.; Perez de Amezaga, J.; Michalak, M.; Krucinska, I. Green Sound-Absorbing Composite Materials of Various Structure and Profiling. Coatings 2021, 11, 407. [Google Scholar] [CrossRef]

- Zhang, J.; Shen, Y.; Jiang, B.; Li, Y. Sound Absorption Characterization of Natural Materials and Sandwich Structure Composites. Aerospace 2018, 5, 75. [Google Scholar] [CrossRef]

- Bratu, M.; Dumitrescu, O.; Vasile, O.; Constantin, A.; Muntean, M. Research on the sound-absorbing properties of new composite materials with some wastes. Rom. J. Mater. 2014, 44, 160–168. [Google Scholar]

- Tiuc, A.E.; Nemes, O.; Vermeșan, H.; Gavrea, D.R.T.; Vasile, O. New sound absorbing materials obtained from waste rigid polyurethane foam. Mater. Plast. 2019, 56, 1021–1027. [Google Scholar] [CrossRef]

- Tiuc, A.-E.; Borlea (Mureșan), S.I.; Nemeș, O.; Vermeșan, H.; Vasile, O.; Popa, F.; Pințoi, R. New Composite Materials Made from Rigid/Flexible Polyurethane Foams with Fir Sawdust: Acoustic and Thermal Behavior. Polymers 2022, 14, 3643. [Google Scholar] [CrossRef] [PubMed]

- Yang, T.; Hu, L.; Xiong, X.; Petrů, M.; Noman, M.T.; Mishra, R.; Militký, J. Sound Absorption Properties of Natural Fibers: A Review. Sustainability 2020, 12, 8477. [Google Scholar] [CrossRef]

- Mamtaz, H.; Fouladi, M.H.; Al-Atabi, M.; Namasivayam, S.N. Acoustic absorption of natural fiber composites. J. Eng. 2016, 2016, 5836107. [Google Scholar] [CrossRef]

- Taban, E.; Tajpoor, A.; Faridan, M.; Samaei, S.E.; Beheshti, M.H. Acoustic Absorption Characterization and Prediction of Natural Coir Fibers. Acoust. Aust. 2019, 47, 67–77. [Google Scholar] [CrossRef]

- Sujon, A.S.; Islam, A.; Nadimpalli, V.K. Damping and sound absorption properties of polymer matrix composites: A review. Polym. Test. 2021, 104, 107388. [Google Scholar] [CrossRef]

- Rubino, C.; Bonet Aracil, M.; Gisbert-Payá, J.; Liuzzi, S.; Stefanizzi, P.; Zamorano Cantó, M.; Martellotta, F. Composite Eco-Friendly Sound Absorbing Materials Made of Recycled Textile Waste and Biopolymers. Materials 2019, 12, 4020. [Google Scholar] [CrossRef] [PubMed]

- Pakdel, E.; Kashi, S.; Baum, T.; Usman, K.A.S.; Razal, J.M.; Varley, R.; Wang, X.G. Carbon fibre waste recycling into hybrid nonwovens for electromagnetic interference shielding and sound absorption. J. Clean. Prod. 2021, 315, 128196. [Google Scholar] [CrossRef]

- Kim, B.S.; Cho, S.J.; Min, D.K.; Park, J. Experimental study for improving sound absorption of a composite helical-shaped porous structure using carbon fiber. Compos. Struct. 2016, 145, 242–247. [Google Scholar] [CrossRef]

- Wang, D.-W.; Wen, Z.-H.; Glorieux, C.; Ma, L. Sound Absorption of Face-Centered Cubic Sandwich Structure with Micro-Perforations. Mater. Des. 2020, 186, 108344. [Google Scholar] [CrossRef]

- Sui, N.; Yan, X.; Huang, T.Y.; Xu, J.; Yuan, F.G.; Jing, Y. A lightweight yet sound-proof honeycomb acoustic metamaterial. Appl. Phys. Lett. 2015, 106, 171905. [Google Scholar] [CrossRef]

- Arunkumar, M.P.; Jagadeesh, M.; Pitchaimani, J.; Gangadharan, K.V.; Babu, M.L. Sound radiation and transmission loss characteristics of a honeycomb sandwich panel with composite facings: Effect of inherent material damping. J. Sound Vib. 2016, 383, 221–232. [Google Scholar] [CrossRef]

- Isaac, C.W.; Pawelczyk, M.; Wrona, S. Comparative Study of Sound Transmission Losses of Sandwich Composite Double Panel Walls. Appl. Sci. 2020, 10, 1543. [Google Scholar] [CrossRef]

- Li, X.; Peng, Y.; He, Y.; Zhang, C.; Zhang, D.; Liu, Y. Research Progress on Sound Absorption of Electrospun Fibrous Composite Materials. Nanomaterials 2022, 12, 1123. [Google Scholar] [CrossRef]

- Lee, H.M.; Luo, W.; Xie, J.; Wen, G.; Lee, H.P. Studies on the sound absorption and transimission loss performances of wood-based natural and waste materials. Acta Mech. Sin. 2021, 37, 861–873. [Google Scholar] [CrossRef]

- Shen, X.; Bai, P.; Yang, X.; Zhang, X.; To, S. Low Frequency Sound Absorption by Optimal Combination Structure of Porous Metal and Microperforated Panel. Appl. Sci. 2019, 9, 1507. [Google Scholar] [CrossRef]

- Durbaca, I.; Sporea, N.; Vasile, O. Assessment of the Acoustic Absorption Characteristics of Layered Composite Structures Obtained from Plates with Lignocellulosic Coatings (I). Mater. Plast. 2020, 57, 8–14. [Google Scholar] [CrossRef]

- Zhang, Z.; Denayer, H.; Claeys, C.; Desmet, W.; Deckers, E. Angle-dependent reflection, transmission and absorption coefficients measurement using a 2D waveguide. Appl. Acoust. 2021, 177, 107946. [Google Scholar] [CrossRef]

- Yang, G.; Huang, Q.; Yang, M.; Huang, Y. Sound Transmission Loss of Metamaterial Honeycomb Core Sandwich Plate Elastically Connected with Periodic Subwavelength Arrays of Shunted Piezoelectric Patches. Materials 2022, 15, 3923. [Google Scholar] [CrossRef] [PubMed]

- Cao, L.; Fu, Q.; Si, Y.; Ding, B.; Yu, J. Porous materials for sound absorption. Compos. Commun. 2018, 10, 25–35. [Google Scholar] [CrossRef]

- Soltani, P.; Taban, E.; Faridan, M.; Samaei, S.E.; Amininasab, S. Experimental and computational investigation of sound absorption performance of sustainable porous material: Yucca Gloriosa fiber. Appl. Acoust. 2020, 157, 106999. [Google Scholar] [CrossRef]

- Rastegar, N.; Ershad-Langroudi, A.; Parsimehr, H.; Moradi, G. Sound-absorbing porous materials: A review on polyurethane-based foams. Iran. Polym. J. 2022, 31, 83–105. [Google Scholar] [CrossRef]

- Miki, Y. Acoustical properties of porous materials. Modifications of Delany-Bazley models. J. Acoust. Soc. Jpn. 1990, 11, 19–24. [Google Scholar] [CrossRef]

- Sailesh, R.; Yuvaraj, L.; Doddamani, M.; Mailan Chinnapandi, L.B.; Pitchaimani, J. Sound absorption and transmission loss characteristics of 3D printed bio-degradable material with graded spherical perforations. Appl. Acoust. 2022, 186, 108457. [Google Scholar] [CrossRef]

- Sailesh, R.; Yuvaraj, L.; Pitchaimani, J.; Doddamani, M.; Mailan Chinnapandi, L.B. Acoustic Behaviour of 3D Printed Bio-Degradable Micro-Perforated Panels with Varying Perforation Cross-Sections. Appl. Acoust. 2021, 174, 107769. [Google Scholar] [CrossRef]

- Monkova, K.; Vasina, M.; Monka, P.P.; Kozak, D.; Vanca, J. Effect of the Pore Shape and Size of 3D-Printed Open-Porous ABS Materials on Sound Absorption Performance. Materials 2020, 13, 4474. [Google Scholar] [CrossRef]

- Vasina, M.; Monkova, K.; Monka, P.P.; Kozak, D.; Tkac, J. Study of the Sound Absorption Properties of 3D-Printed Open-Porous ABS Material Structures. Polymers 2020, 12, 1062. [Google Scholar] [CrossRef]

- Zielinski, T.G.; Dauchez, N.; Boutin, T.; Leturia, M.; Wilkinson, A.; Chevillotte, F.; Becot, F.-X.; Venegas, R. Taking advantage of a 3D printing imperfection in the development of sound-absorbing materials. Appl. Acoust. 2022, 197, 108941. [Google Scholar] [CrossRef]

- Errico, F.; Ichchou, M.; de Rosa, S.; Franco, F.; Bareille, O. Investigations about periodic design for broadband increased sound transmission loss of sandwich panels using 3D-printed models. Mech. Syst. Signal Process. 2020, 136, 106432. [Google Scholar] [CrossRef]

- Boulvert, J.; Costa-Baptista, J.; Cavalieri, T.; Perna, M.; Fotsing, E.R.; Romero-García, V.; Gabard, G.; Ross, A.; Mardjono, J.; Groby, J.-P. Acoustic modeling of micro-lattices obtained by additive manufacturing. Appl. Acoust. 2020, 164, 107244. [Google Scholar] [CrossRef]

- Amaya-Amaya, V.; de Icaza-Herrera, M.; Martínez-Hernández, A.L.; Martínez-Barrera, G.; Velasco-Santos, C. Experimental approximation of the sound absorption coefficient (∝) for 3D printed reentrant auxetic structures of poly lactic acid reinforced with chicken keratin materials. Mater. Lett. 2021, 283, 128757. [Google Scholar] [CrossRef]

- Gao, N.; Hou, H. Sound absorption characteristic of micro-helix metamaterial by 3D printing. Theor. Appl. Mech. Lett. 2018, 8, 63–67. [Google Scholar] [CrossRef]

- Yang, W.; Bai, X.; Zhu, W.; Kiran, R.; An, J.; Chua, C.K.; Zhou, K. 3D Printing of Polymeric Multi-Layer Micro-Perforated Panels for Tunable Wideband Sound Absorption. Polymers 2020, 12, 360. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Zhan, J.; Fard, M.; Davy, J. Acoustic properties of multilayer sound absorbers with a 3D printed micro-perforated panel. Appl. Acoust. 2017, 121, 25–32. [Google Scholar] [CrossRef]

- Liu, Z.Q.; Zhan, J.X.; Fard, M.; Davy, J.L. Acoustic properties of a porous polycarbonate material produced by additive manufacturing. Mater. Lett. 2016, 181, 296–299. [Google Scholar] [CrossRef]

- Jiang, C.; Moreau, D.; Doolan, C. Acoustic Absorption of Porous Materials Produced by Additive Manufacturing with Varying Geometries. In Proceedings of the ACOUSTICS 2017, Perth, Australia, 19–22 November 2017. [Google Scholar]

- Liu, Z.Q.; Zhan, J.X.; Fard, M.; Davy, J.L. Acoustic measurement of a 3D printed micro-perforated panel combined with a porous material. Measurement 2017, 104, 233–236. [Google Scholar] [CrossRef]

- Opiela, K.C.; Zieliński, T.G.; Attenborough, K. Limitations on validating slitted sound absorber designs through budget additive manufacturing. Mater. Des. 2022, 218, 110703. [Google Scholar] [CrossRef]

- Sekar, V.; Eh Noum, S.Y.; Sivanesan, S.; Putra, A.; Kassim, D.H.; Wong, Y.S.; Chin, K.C. Effect of Perforation Volume on Acoustic Absorption of the 3D Printed Micro-Perforated Panels Made of Polylactic Acid Reinforced with Wood Fibers. J. Phys. Conf. Ser. 2021, 2120, 012039. [Google Scholar] [CrossRef]

- ISO 10534-2 (1998-11); Acoustics—Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes—Part 2: Transfer-Function Method. International Organization for Standardization (ISO): Geneva, Switzerland, 1998.

- E1050; Standard Test Method for Impedance and Absorption of Acoustical Materials Using a Tube, Two Microphone and a Digital Frequency Analysis System. ASTM International: West Conshohocken, PA, USA, 2010.

- MIL-STD-401B; Military Standard: Sandwich Constructions and Core Materials, General Test Methods. U.S. Department of Defense: Washington, VA, USA, 1967.

- ASTM C393/C393M-2011; Standard Test Method for Core Shear Properties of Sandwich Constructions by Beam Flexure. American Society for Testing and Materials: West Conshohocken, PA, USA, 2011.

- EasyWood PLA Material, Formfutura. Available online: https://formfutura.com/shop/product/easywood-2804?category=465 (accessed on 26 May 2023).

- Premium PLA. Available online: https://formfutura.com/product/premium-pla/ (accessed on 26 May 2023).

- Ilyas, R.A.; Sapuan, S.M.; Harussani, M.M.; Hakimi, M.Y.A.Y.; Haziq, M.Z.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Ishak, M.R.; Razman, M.R.; Nurazzi, N.M.; et al. Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications. Polymers 2021, 13, 1326. [Google Scholar] [CrossRef] [PubMed]

- Bergaliyeva, S.; Sales, D.L.; Delgado, F.J.; Bolegenova, S.; Molina, S.I. Manufacture and Characterization of Polylactic Acid Filaments Recycled from Real Waste for 3D Printing. Polymers 2023, 15, 2165. [Google Scholar] [CrossRef] [PubMed]

- Krapež Tomec, D.; Kariž, M. Use of Wood in Additive Manufacturing: Review and Future Prospects. Polymers 2022, 14, 1174. [Google Scholar] [CrossRef] [PubMed]

- Koruk, H.; Ozcan, A.C.; Genc, G.; Sanliturk, K.Y. Jute and Luffa Fiber-Reinforced Biocomposites: Effects of Sample Thickness and Fiber/Resin Ratio on Sound Absorption and Transmission Loss Performance. J. Nat. Fibers 2021, 19, 6239–6254. [Google Scholar] [CrossRef]

- Sekar, V.; Eh Noum, S.Y.; Sivanesan, S.; Putra, A.; Chin Vui Sheng, D.D.; Kassim, D.H. Effect of Thickness and Infill Density on Acoustic Performance of 3D Printed Panels Made of Natural Fiber Reinforced Composites. J. Nat. Fibers 2021, 13, 7132–7140. [Google Scholar] [CrossRef]

- Bakhtiari, H.; Aamir, M.; Tolouei-Rad, M. Effect of 3D Printing Parameters on the Fatigue Properties of Parts Manufactured by Fused Filament Fabrication: A Review. Appl. Sci. 2023, 13, 904. [Google Scholar] [CrossRef]

- Gonabadi, H.; Yadav, A.; Bull, S.J. The effect of processing parameters on the mechanical characteristics of PLA produced by a 3D FFF printer. Int. J. Adv. Manuf. Technol. 2020, 111, 695–709. [Google Scholar] [CrossRef]

- Gao, W.; Hou, Y.; Shang, F.; Zhang, J. 3D Printed Structures for Ultrasound Attenuation in Underwater Environment. 3D Print. Addit. Manuf. 2022. ahead of print. [Google Scholar] [CrossRef]

- Müller, M.; Jirků, P.; Šleger, V.; Mishra, R.K.; Hromasová, M.; Novotný, J. Effect of Infill Density in FDM 3D Printing on Low-Cycle Stress of Bamboo-Filled PLA-Based Material. Polymers 2022, 14, 4930. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Gao, Y.; Jiang, J.; Gu, H.; Lv, S.; Ni, H.; Wang, X.; Jia, C. Study on effects of FFF 3D printing parameters on mechanical properties of polylactic acid. IOP Conf. Ser. Mater. Sci. Eng. 2019, 688, 2019. [Google Scholar]

- Lupone, F.; Padovano, E.; Venezia, C.; Badini, C. Experimental Characterization and Modeling of 3D Printed Continuous Carbon Fibers Composites with Different Fiber Orientation Produced by FFF Process. Polymers 2022, 14, 426. [Google Scholar] [CrossRef]

- Naveed, N. Investigating the Material Properties and Microstructural Changes of Fused Filament Fabricated PLA and Tough-PLA Parts. Polymers 2021, 13, 1487. [Google Scholar] [CrossRef] [PubMed]

- Tao, Y.; Kong, F.; Li, Z.; Zhang, J.; Zhao, X.; Yin, Q.; Xing, D.; Li, P. A Review on Voids of 3D Printed Parts by Fused Filament Fabrication. J. Mater. Res. Technol. 2021, 15, 4860–4879. [Google Scholar] [CrossRef]

- Gómez Escobar, V.; Moreno González, C.; Rey Gozalo, G. Analysis of the Influence of Thickness and Density on Acoustic Absorption of Materials Made from Used Cigarette Butts. Materials 2021, 14, 4524. [Google Scholar] [CrossRef] [PubMed]

- Hassan, T.; Jamshaid, H.; Mishra, R.; Khan, M.Q.; Petru, M.; Tichy, M.; Muller, M. Factors Affecting Acoustic Properties of Natural-Fiber-Based Materials and Composites: A Review. Textiles 2021, 1, 55–85. [Google Scholar] [CrossRef]

- Yuvaraj, L.; Jeyanthi, S. Acoustic performance of countersunk micro-perforated panel in multilayer porous material. Build. Acoust. 2020, 27, 3–20. [Google Scholar] [CrossRef]

- Arjunan, A.; Baroutaji, A.; Latif, A. Acoustic behaviour of 3D printed titanium perforated panels. Results Eng. 2021, 11, 100252. [Google Scholar] [CrossRef]

- Park, S.H. Acoustic properties of micro-perforated panel absorbers backed by Helmholtz resonators for the improvement of low-frequency sound absorption. J. Sound Vib. 2013, 332, 4895–4911. [Google Scholar] [CrossRef]

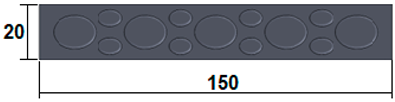

| Acoustic Test Specimens | ||||

|---|---|---|---|---|

| Double panel | Single panel | Panels with drilling holes (Drill gage) | 3D-printed panels with holes | |

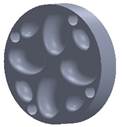

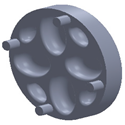

| Circular profile |   |  |  | |

| Triangular profile |   |  |  |  |

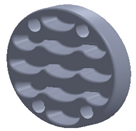

| Corrugated profile |   |  |  | |

| Compression Test Specimens | Three-Point Bending Test Specimens | |||

|---|---|---|---|---|

| Circular profile | Section view |  | Section view |  |

| Triangular profile | Section view |  | Section view |  |

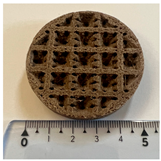

| Corrugated profile | Section view |  | Section view |  |

| Parameter | Value | ||

|---|---|---|---|

| PLA Coconut | PLA Birch | PLA | |

| Filament diameter | 2.85 [mm] | 2.85 [mm] | 2.85 [mm] |

| Layer height | 0.2 [mm] | 0.2 [mm] | 0.2 [mm] |

| Infill density | 20; 40; 60; 80; 100 [%] | 20; 40; 60; 80; 100 [%] | 20; 40; 60; 80; 100 [%] |

| Print speed | 50 [mm/s] | 50 [mm/s] | 40 [mm/s] |

| Travel speed | 120 [mm/s] | 120 [mm/s] | 120 [mm/s] |

| Printing temperature | 240 [°C] | 240 [°C] | 240 [°C] |

| Building plate temperature | 50 [°C] | 50 [°C] | 60 [°C] |

| Infill pattern | cubic | cubic | cubic |

| Hotend | 0.4 [mm] | 0.4 [mm] | 0.4 [mm] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaharia, S.-M.; Pop, M.A.; Cosnita, M.; Croitoru, C.; Matei, S.; Spîrchez, C. Sound Absorption Performance and Mechanical Properties of the 3D-Printed Bio-Degradable Panels. Polymers 2023, 15, 3695. https://doi.org/10.3390/polym15183695

Zaharia S-M, Pop MA, Cosnita M, Croitoru C, Matei S, Spîrchez C. Sound Absorption Performance and Mechanical Properties of the 3D-Printed Bio-Degradable Panels. Polymers. 2023; 15(18):3695. https://doi.org/10.3390/polym15183695

Chicago/Turabian StyleZaharia, Sebastian-Marian, Mihai Alin Pop, Mihaela Cosnita, Cătălin Croitoru, Simona Matei, and Cosmin Spîrchez. 2023. "Sound Absorption Performance and Mechanical Properties of the 3D-Printed Bio-Degradable Panels" Polymers 15, no. 18: 3695. https://doi.org/10.3390/polym15183695

APA StyleZaharia, S.-M., Pop, M. A., Cosnita, M., Croitoru, C., Matei, S., & Spîrchez, C. (2023). Sound Absorption Performance and Mechanical Properties of the 3D-Printed Bio-Degradable Panels. Polymers, 15(18), 3695. https://doi.org/10.3390/polym15183695