Towards Tough Thermoplastic Adhesive Tape by Microstructuring the Tape Using Tailored Defects

Abstract

:1. Introduction

2. Methods

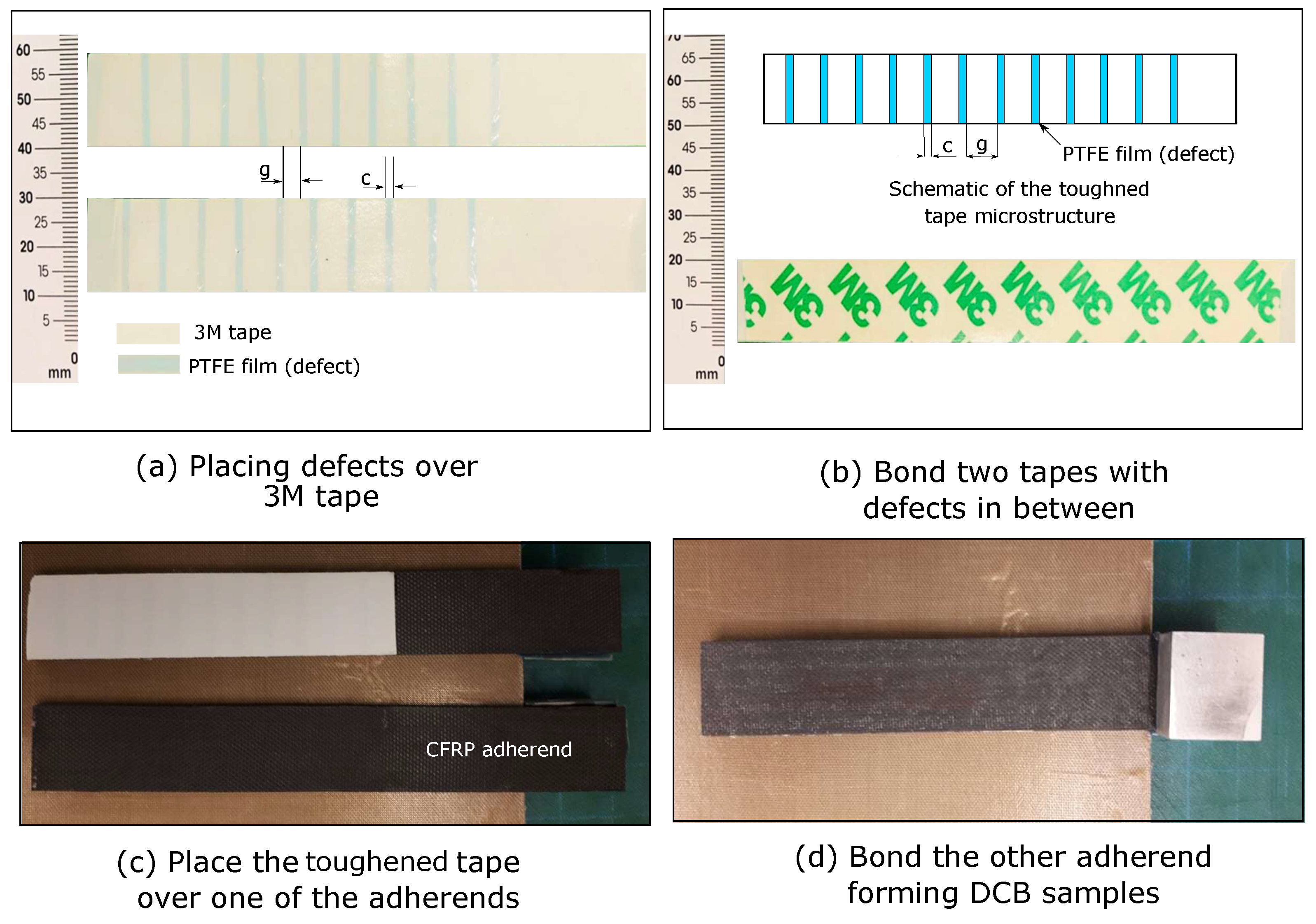

2.1. Manufacturing Toughened Thermoplastic Adhesive Tape

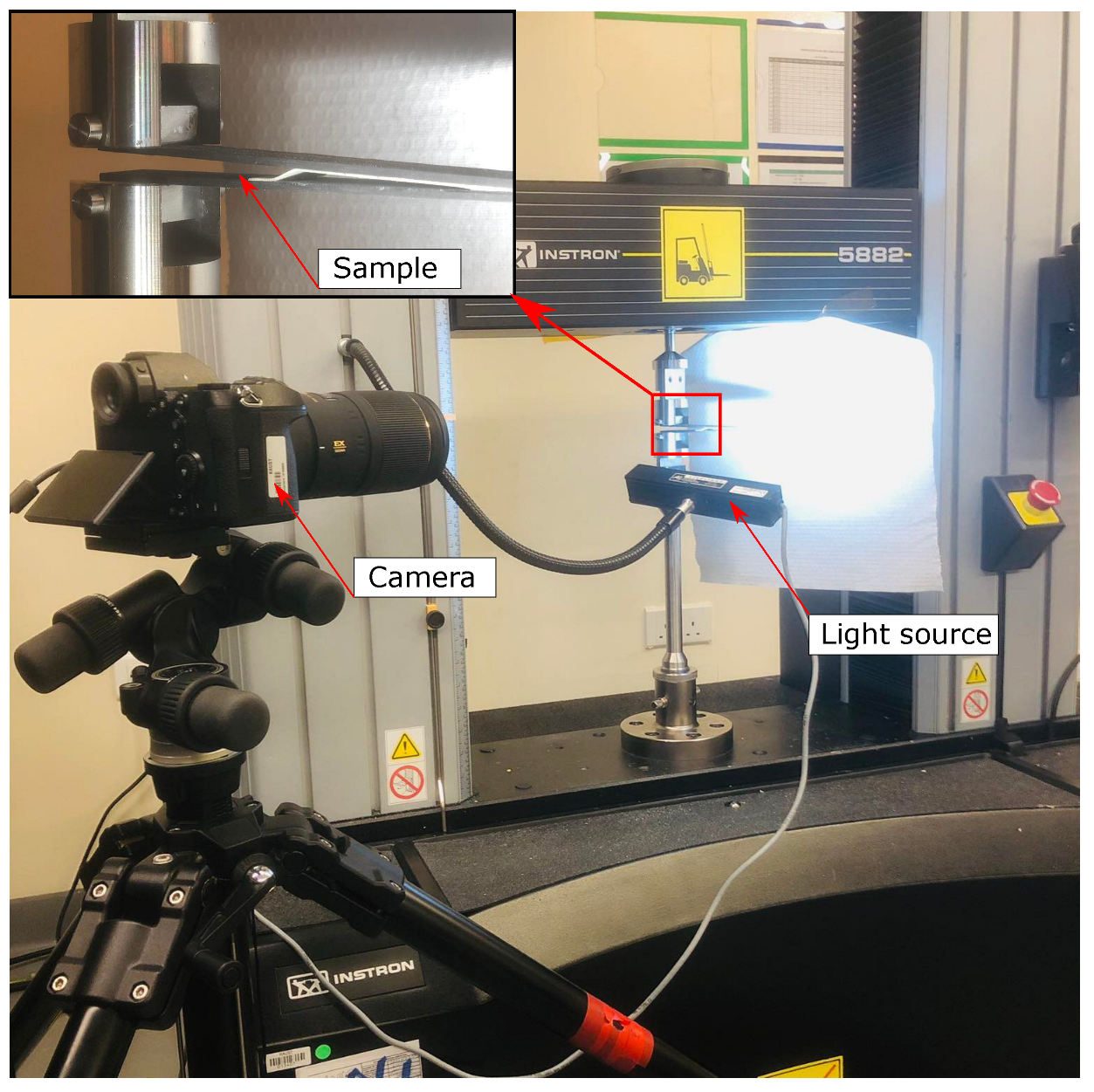

2.2. Experimental Tests

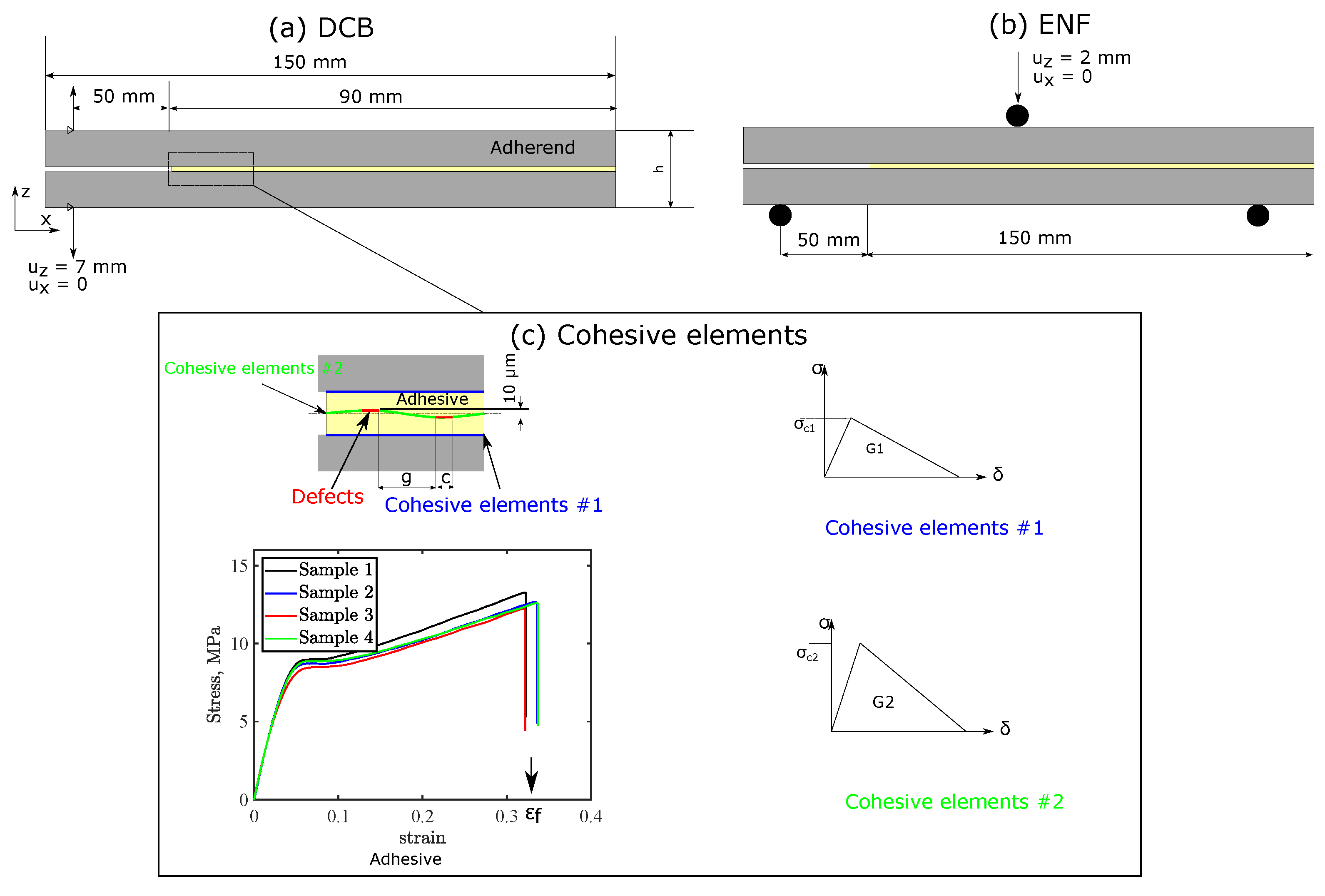

2.3. Finite Element Modeling of DCB and ENF Tests

2.4. Data Reduction Methods for Mode I and II Fracture Toughness

2.5. Characterizing Cohesive Laws for Interfaces

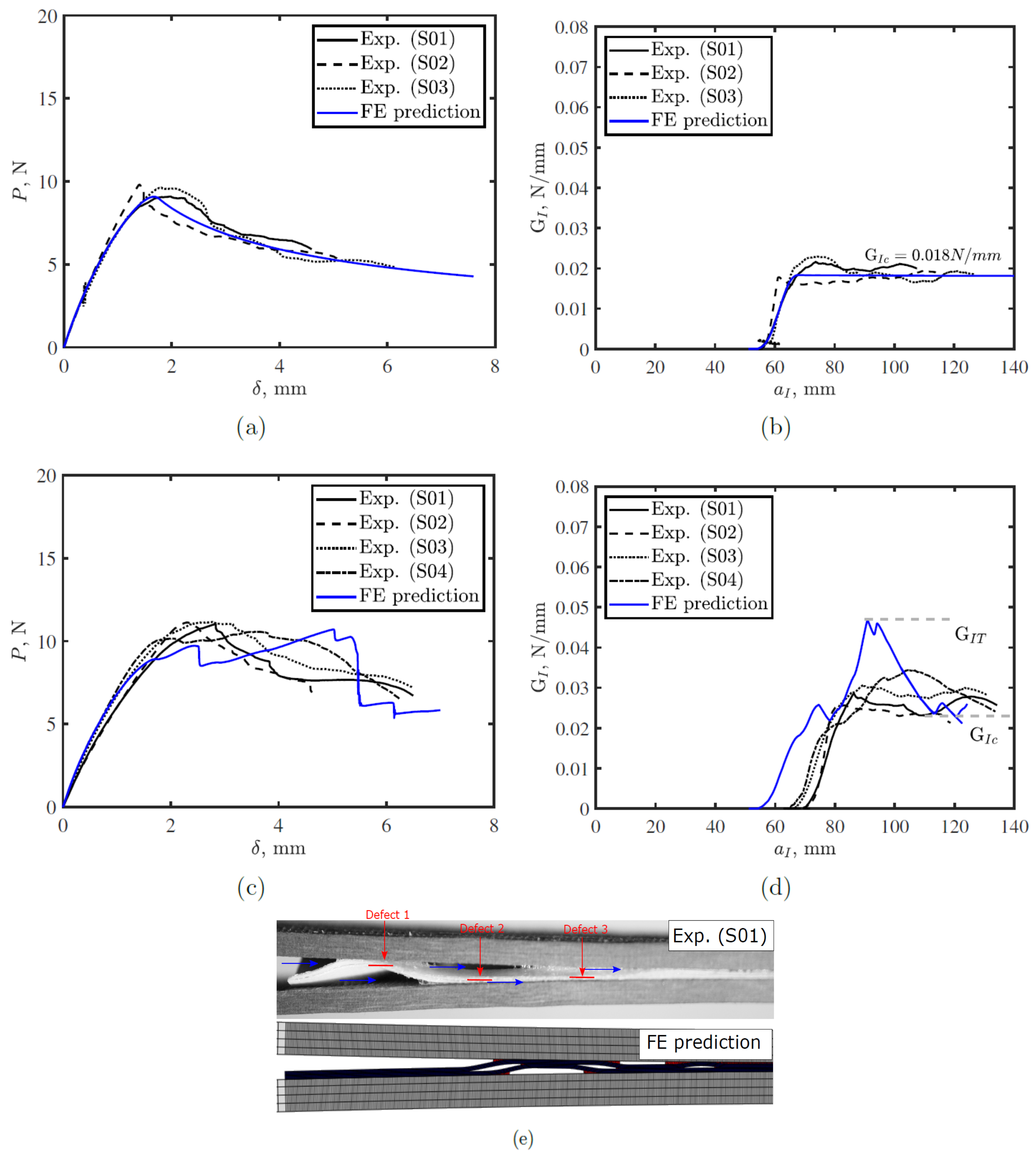

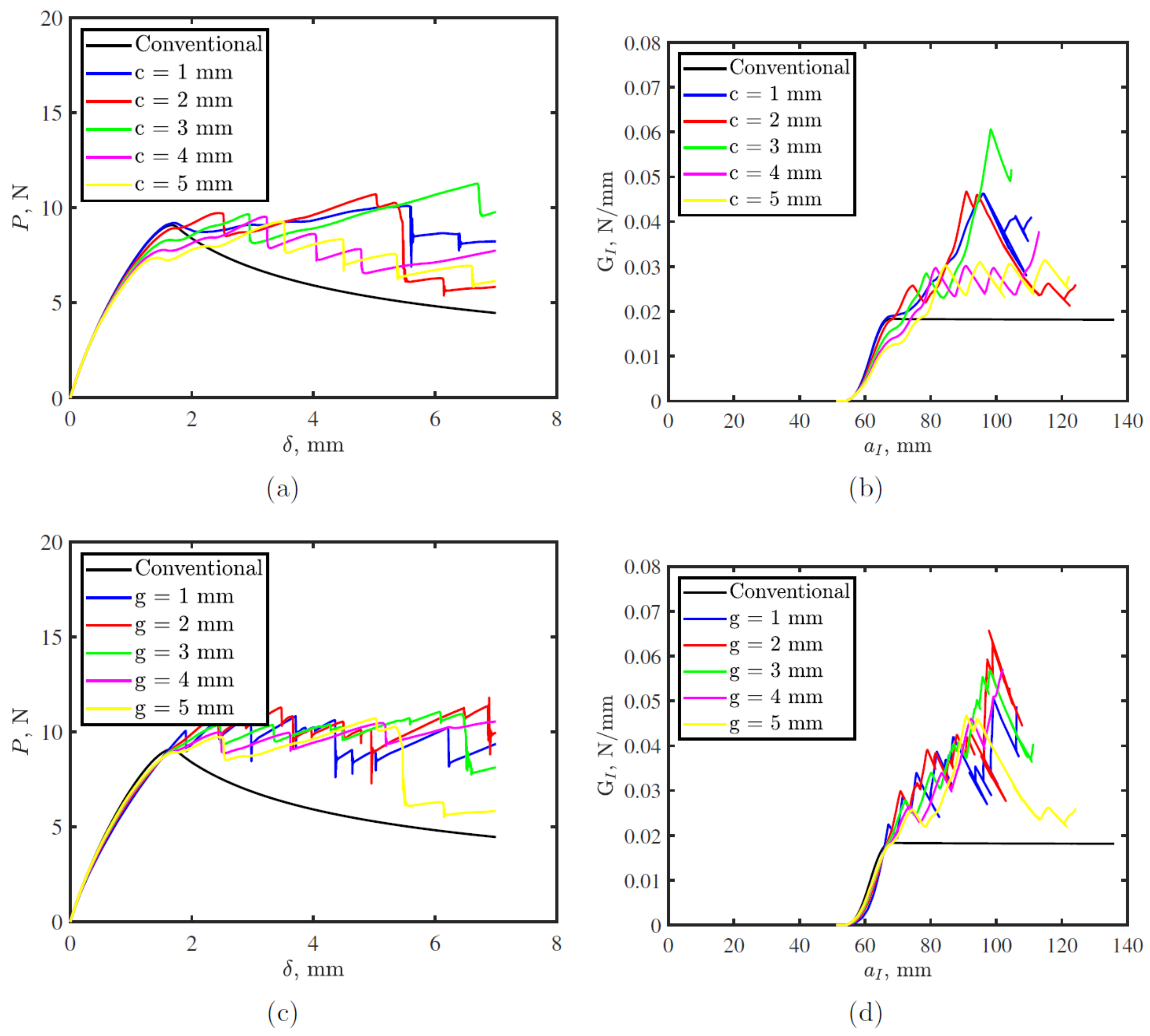

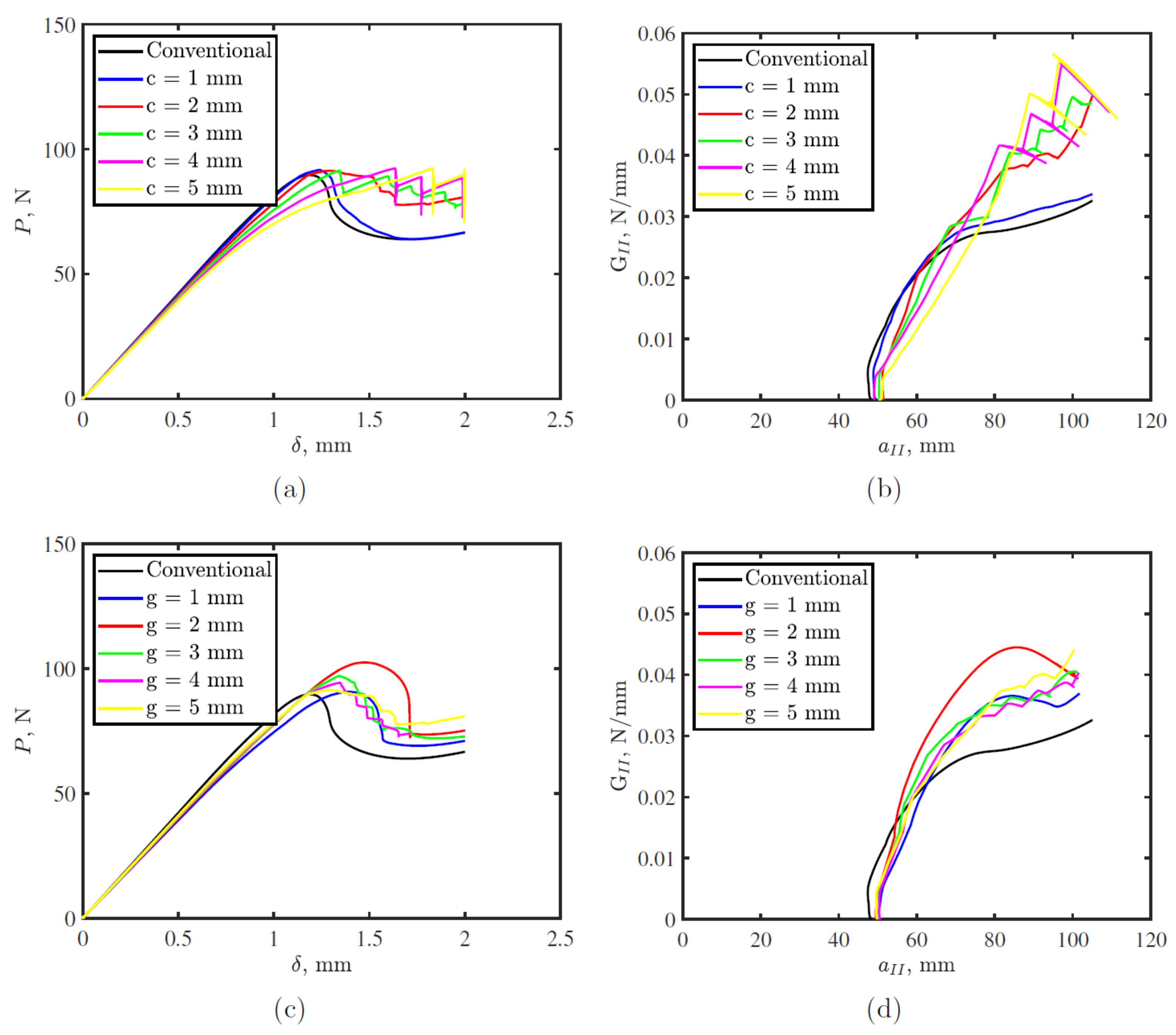

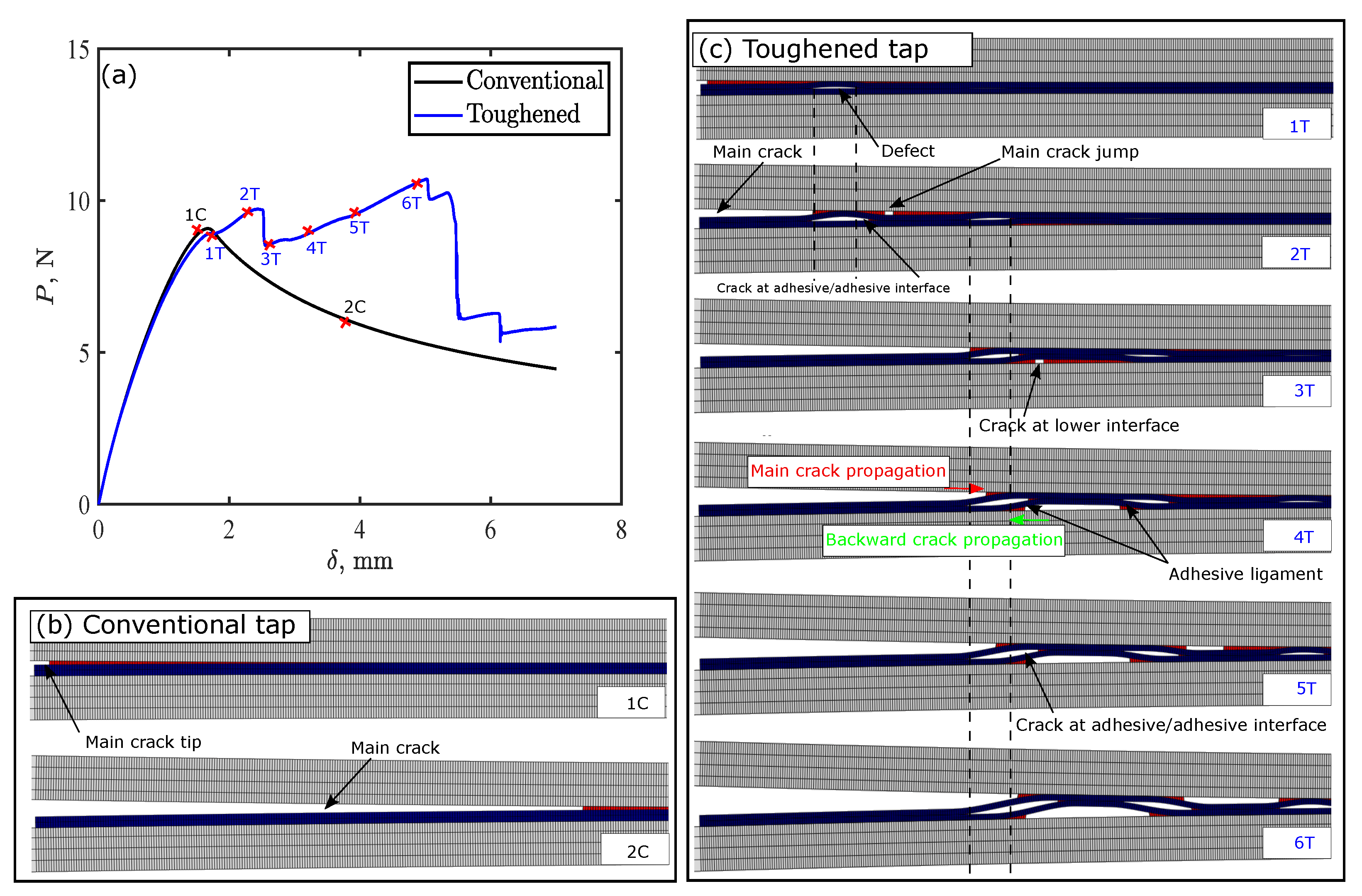

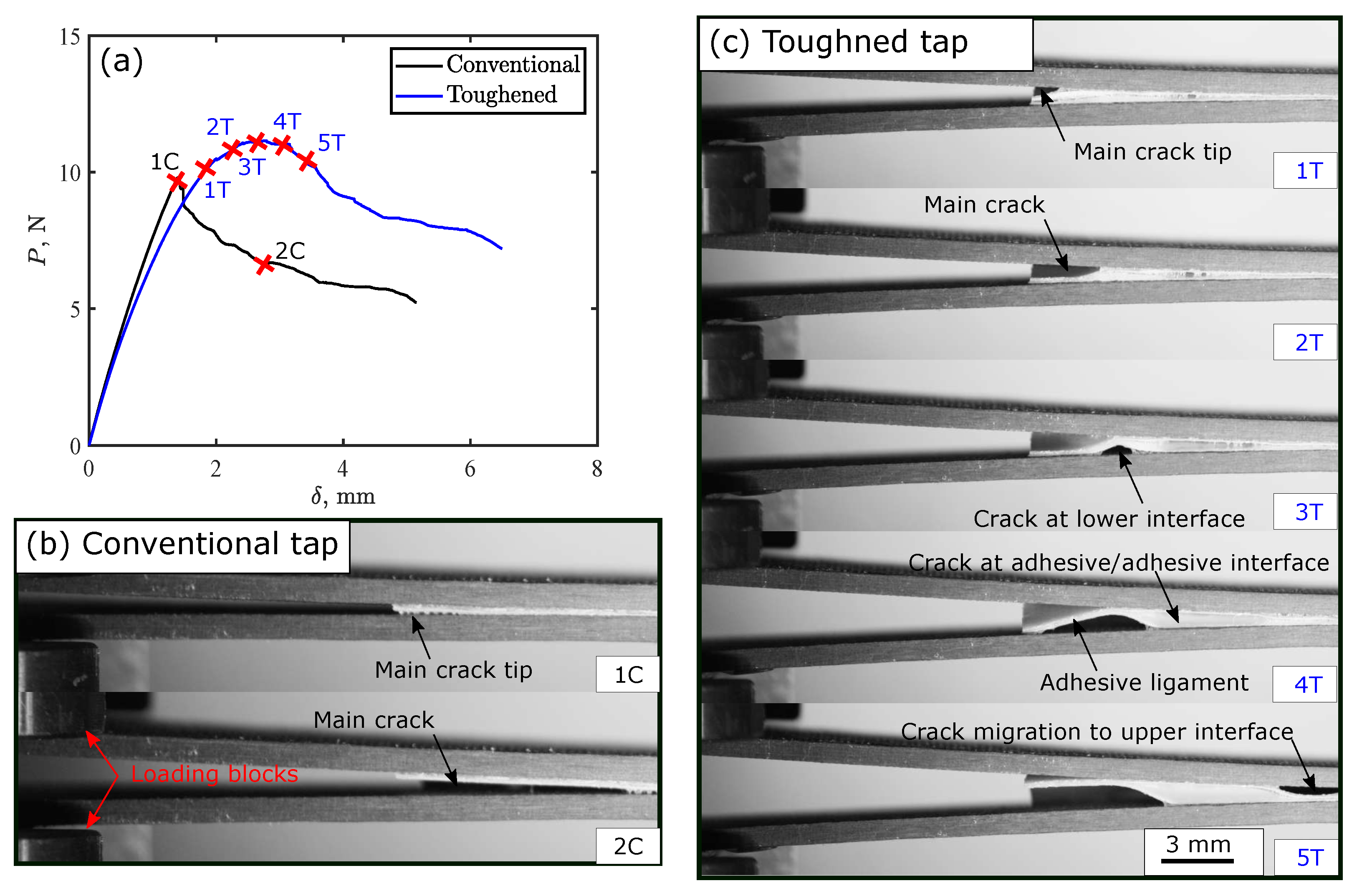

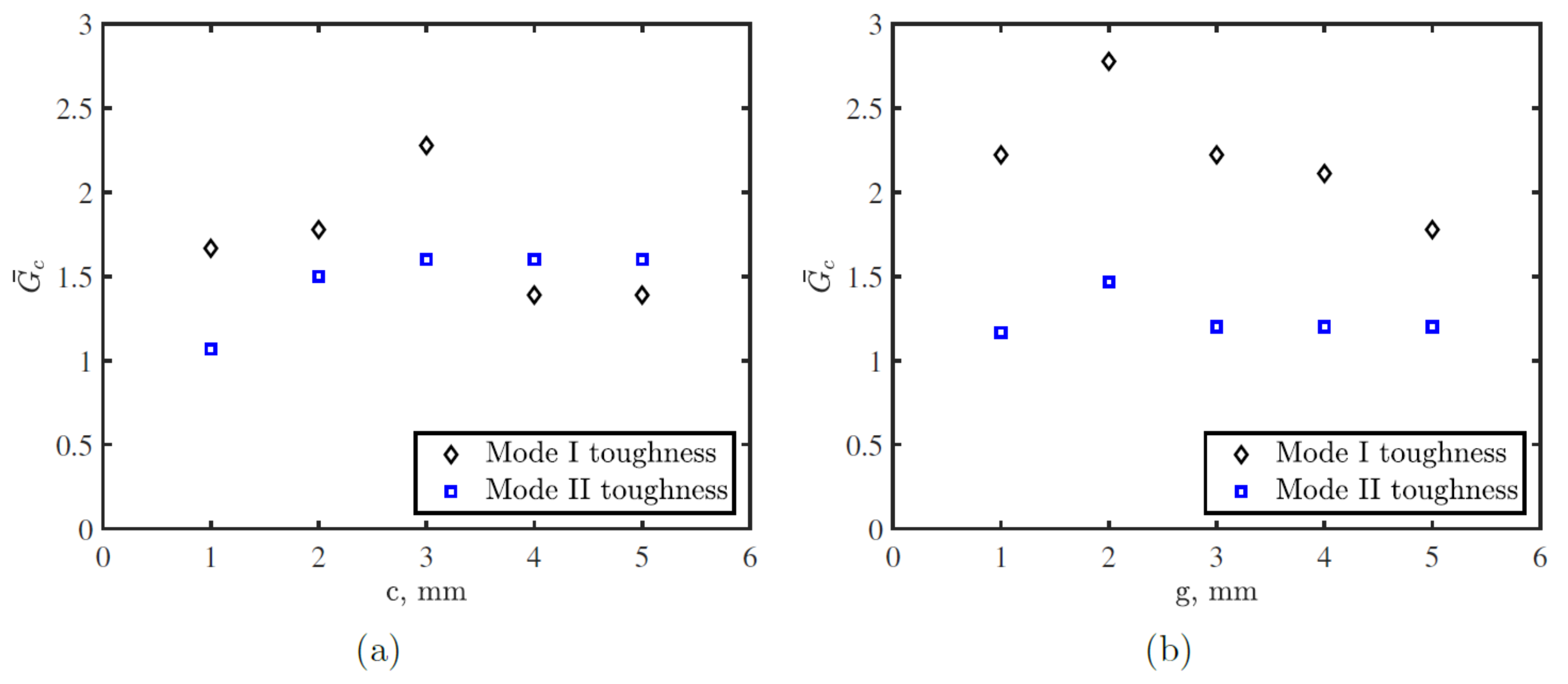

3. Results

4. Discussion

4.1. Toughening Mechanisms

4.2. Toughened Tape Microstructure Effects on Toughness

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Matthews, F.; Kilty, P.; Godwin, E. A review of the strength of joints in fibre-reinforced plastics. Part 2. Adhesively bonded joints. Composites 1982, 13, 29–37. [Google Scholar] [CrossRef]

- Jucienė, M.; Dobilaitė, V. Impact of climatic effects and various surfaces on the tack of adhesive tapes for building & construction. J. Build. Eng. 2021, 42, 102825. [Google Scholar]

- Fufa, S.M.; Labonnote, N.; Frank, S.; Rüther, P.; Jelle, B.P. Durability evaluation of adhesive tapes for building applications. Constr. Build. Mater. 2018, 161, 528–538. [Google Scholar] [CrossRef]

- McNichol, L.; Lund, C.; Rosen, T.; Gray, M. Medical adhesives and patient safety: State of the scienceconsensus statements for the assessment, prevention, and treatment of adhesive-related skin injuries. J. Wound Ostomy Cont. Nurs. 2013, 40, 365–380. [Google Scholar] [CrossRef]

- Ageorges, C.; Ye, L.; Hou, M. Advances in fusion bonding techniques for joining thermoplastic matrix composites: A review. Compos. Part A Appl. Sci. Manuf. 2001, 32, 839–857. [Google Scholar] [CrossRef]

- Beckermann, G.W.; Pickering, K.L. Mode I and Mode II interlaminar fracture toughness of composite laminates interleaved with electrospun nanofibre veils. Compos. Part A Appl. Sci. Manuf. 2015, 72, 11–21. [Google Scholar] [CrossRef]

- Narducci, F.; Lee, K.Y.; Pinho, S. Interface micro-texturing for interlaminar toughness tailoring: A film-casting technique. Compos. Sci. Technol. 2018, 156, 203–214. [Google Scholar] [CrossRef]

- Jain, L.K.; Dransfield, K.A.; Mai, Y.W. On the effects of stitching in CFRPs-II. Mode II delamination toughness. Compos. Sci. Technol. 1998, 58, 829–837. [Google Scholar] [CrossRef]

- Mouritz, A.P.; Cox, B. A mechanistic approach to the properties of stitched laminates. Compos. Part A Appl. Sci. Manuf. 2000, 31, 1–27. [Google Scholar] [CrossRef]

- Chang, P.; Mouritz, A.; Cox, B. Properties and failure mechanisms of pinned composite lap joints in monotonic and cyclic tension. Compos. Sci. Technol. 2006, 66, 2163–2176. [Google Scholar] [CrossRef]

- Mouritz, A.P. Review of z-pinned composite laminates. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2383–2397. [Google Scholar] [CrossRef]

- Fischer, F.; Kreling, S.; Jäschke, P.; Frauenhofer, M.; Kracht, D.; Dilger, K. Laser surface pre-treatment of CFRP for adhesive bonding in consideration of the absorption behaviour. J. Adhes. 2012, 88, 350–363. [Google Scholar] [CrossRef]

- Kanerva, M.; Saarela, O. The peel ply surface treatment for adhesive bonding of composites: A review. Int. J. Adhes. Adhes. 2013, 43, 60–69. [Google Scholar] [CrossRef]

- Leena, K.; Athira, K.; Bhuvaneswari, S.; Suraj, S.; Rao, V.L. Effect of surface pre-treatment on surface characteristics and adhesive bond strength of aluminium alloy. Int. J. Adhes. Adhes. 2016, 70, 265–270. [Google Scholar] [CrossRef]

- Tao, R.; Li, X.; Yudhanto, A.; Alfano, M.; Lubineau, G. Laser-based interfacial patterning enables toughening of CFRP/epoxy joints through bridging of adhesive ligaments. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106094–106099. [Google Scholar] [CrossRef]

- Wagih, A.; Tao, R.; Yudhanto, A.; Lubineau, G. Improving mode II fracture toughness of secondary bonded joints using laser patterning of adherends. Compos. Part A Appl. Sci. Manuf. 2020, 134, 105892–105898. [Google Scholar] [CrossRef] [Green Version]

- Hashem, M.; Wagih, A.; Lubineau, G. Laser-based pretreatment of composite T-joints for improved pull-off strength and toughness. Compos. Struct. 2022, 291, 115545. [Google Scholar] [CrossRef]

- Yudhanto, A.; Almulhim, M.; Kamal, F.; Tao, R.; Fatta, L.; Alfano, M.; Lubineau, G. Enhancement of fracture toughness in secondary bonded CFRP using hybrid thermoplastic/thermoset bondline architecture. Compos. Sci. Technol. 2020, 199, 108346. [Google Scholar] [CrossRef]

- Wagih, A.; Lubineau, G. Enhanced mode II fracture toughness of secondary bonded joints using tailored sacrificial cracks inside the adhesive. Compos. Sci. Technol. 2021, 204, 108605. [Google Scholar] [CrossRef]

- Wagih, A.; Tao, R.; Lubineau, G. Bio-inspired adhesive joint with improved interlaminar fracture toughness. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106530. [Google Scholar] [CrossRef]

- Wagih, A.; Hashem, M.; Lubineau, G. Simultaneous strengthening and toughening of composite T-joints by microstructuring the adhesive bondline. Compos. Part A Appl. Sci. Manuf. 2022, 162, 107134. [Google Scholar] [CrossRef]

- Mapari, S.; Mestry, S.; Mhaske, S. Developments in pressure-sensitive adhesives: A review. Polym. Bull. 2021, 78, 4075–4108. [Google Scholar] [CrossRef]

- Langmans, J.; Desta, T.Z.; Alderweireldt, L.; Roels, S. Durability of self-adhesive tapes for exterior air barrier applications: A laboratory investigation. Int. J. Vent. 2017, 16, 30–41. [Google Scholar] [CrossRef]

- Jacobs V, W.P.; Daniel Dolan, J.; Dillard, D.A.; Ohanehi, D.C. An evaluation of acrylic pressure sensitive adhesive tapes for bonding wood in building construction applications. J. Adhes. Sci. Technol. 2012, 26, 1349–1381. [Google Scholar] [CrossRef]

- Schalau, G.; Bobenrieth, A.; Huber, R.O.; Nartker, L.S.; Thomas, X. Silicone adhesives in medical applications. In Applied Adhesive Bonding in Science and Technology; IntechOpen: London, UK, 2018. [Google Scholar]

- Petrie, E.M. Handbook of Adhesives and Sealants; McGraw-Hill Education: New York, NY, USA, 2007. [Google Scholar]

- Song, K.; Dávila, C.G.; Rose, C.A. Guidelines and parameter selection for the simulation of progressive delamination. In Proceedings of the 2008 Abaqus User’s Conference, Newport, RI, USA, 19–22 May 2008; Available online: https://ntrs.nasa.gov/api/citations/20080020385/downloads/20080020385.pdf (accessed on 2 November 2022).

- Turon, A.; Davila, C.G.; Camanho, P.P.; Costa, J. An engineering solution for mesh size effects in the simulation of delamination using cohesive zone models. Eng. Fract. Mech. 2007, 74, 1665–1682. [Google Scholar] [CrossRef]

- Hashemi, S.; Kinloch, A.J.; Williams, J. The analysis of interlaminar fracture in uniaxial fibre-polymer composites. Proc. R. Soc. Lond. A Math. Phys. Sci. 1990, 427, 173–199. [Google Scholar]

- Kanninen, M. A dynamic analysis of unstable crack propagation and arrest in the DCB test specimen. Int. J. Fract. 1974, 10, 415–430. [Google Scholar] [CrossRef]

- Williams, J. End corrections for orthotropic DCB specimens. Compos. Sci. Technol. 1989, 35, 367–376. [Google Scholar] [CrossRef]

- Davies, P.; Sims, G.; Blackman, B.; Brunner, A.; Kageyama, K.; Hojo, M.; Tanaka, K.; Murri, G.; Rousseau, C.; Gieseke, B.; et al. Comparison of test configurations for the determination of GIIc of unidirectional carbon/epoxy composites, an international round robin. Plast Rubber Compos. 1999, 28, 432–437. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wagih, A.; Mahmoud, H.A.; Tao, R.; Lubineau, G. Towards Tough Thermoplastic Adhesive Tape by Microstructuring the Tape Using Tailored Defects. Polymers 2023, 15, 259. https://doi.org/10.3390/polym15020259

Wagih A, Mahmoud HA, Tao R, Lubineau G. Towards Tough Thermoplastic Adhesive Tape by Microstructuring the Tape Using Tailored Defects. Polymers. 2023; 15(2):259. https://doi.org/10.3390/polym15020259

Chicago/Turabian StyleWagih, Ahmed, Hassan A. Mahmoud, Ran Tao, and Gilles Lubineau. 2023. "Towards Tough Thermoplastic Adhesive Tape by Microstructuring the Tape Using Tailored Defects" Polymers 15, no. 2: 259. https://doi.org/10.3390/polym15020259

APA StyleWagih, A., Mahmoud, H. A., Tao, R., & Lubineau, G. (2023). Towards Tough Thermoplastic Adhesive Tape by Microstructuring the Tape Using Tailored Defects. Polymers, 15(2), 259. https://doi.org/10.3390/polym15020259