Mechanical Properties and Synergistic Interfacial Interactions of ZnO Nanorod-Reinforced Polyamide–Imide Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Instrumentation

2.3. Synthesis of ZnO Nanorods

2.4. Preparation of Thin Films of ZnO Nanorods Reinforced PAI Composites

2.5. Mechanical Property Measurements

2.6. Hypervelocity Impact Testing

3. Results

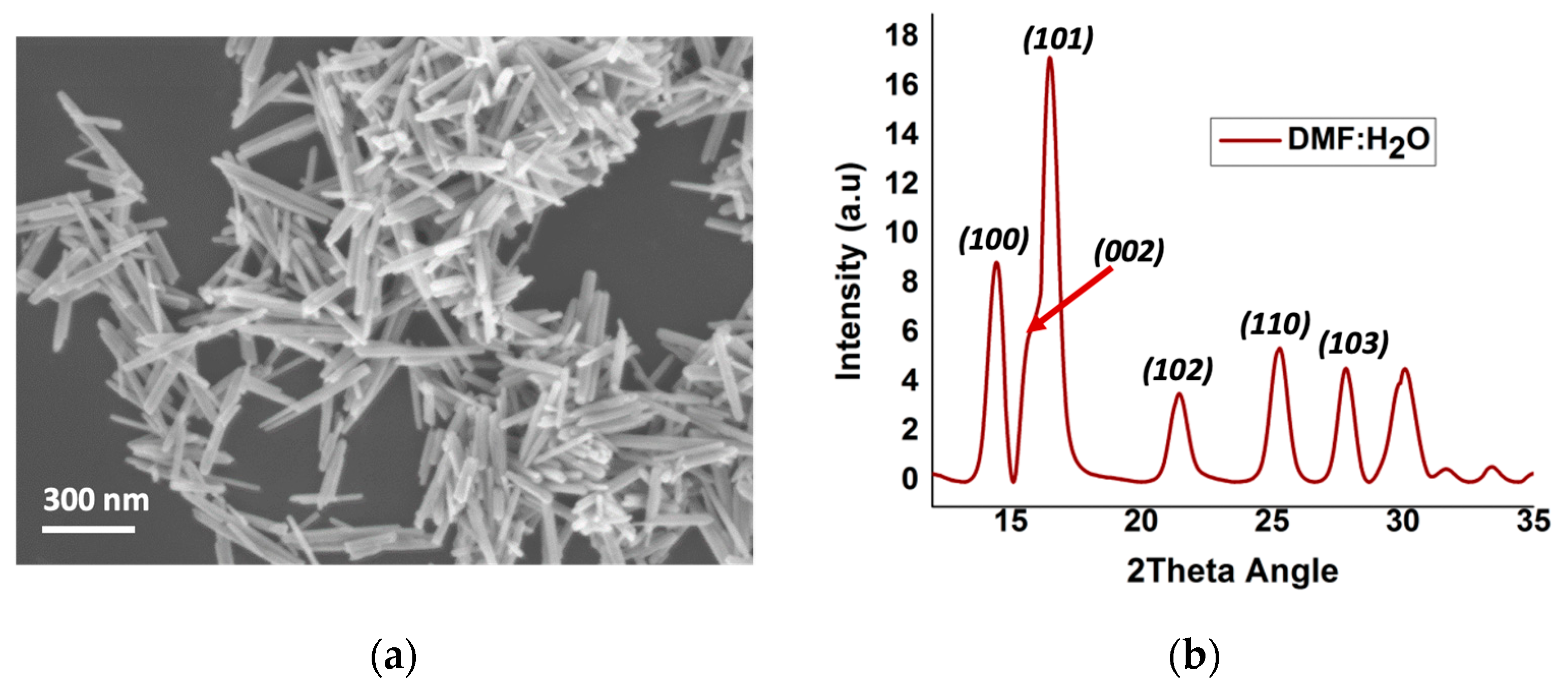

3.1. Morphology and Crsystallinity of ZnO Nanorods

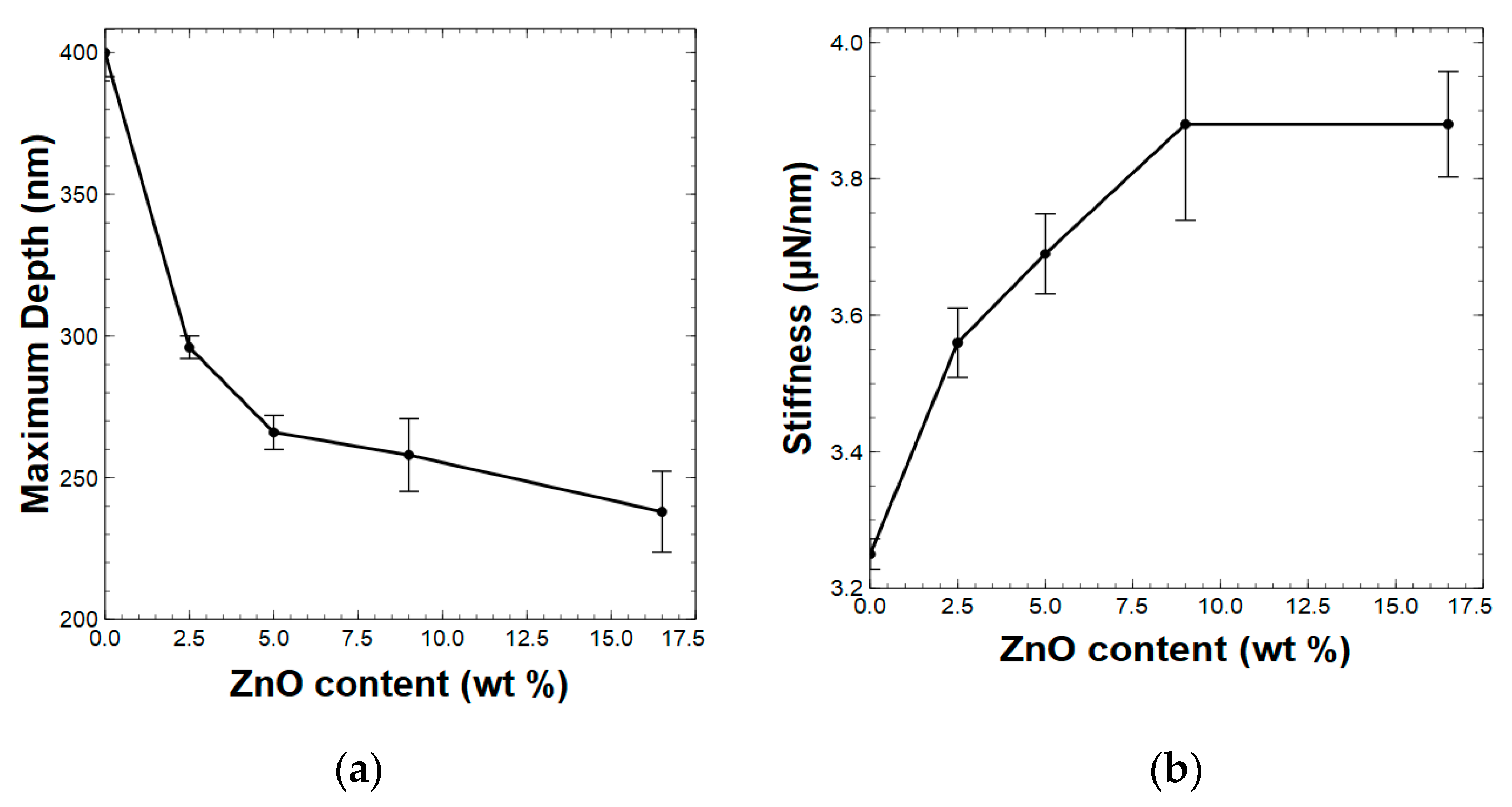

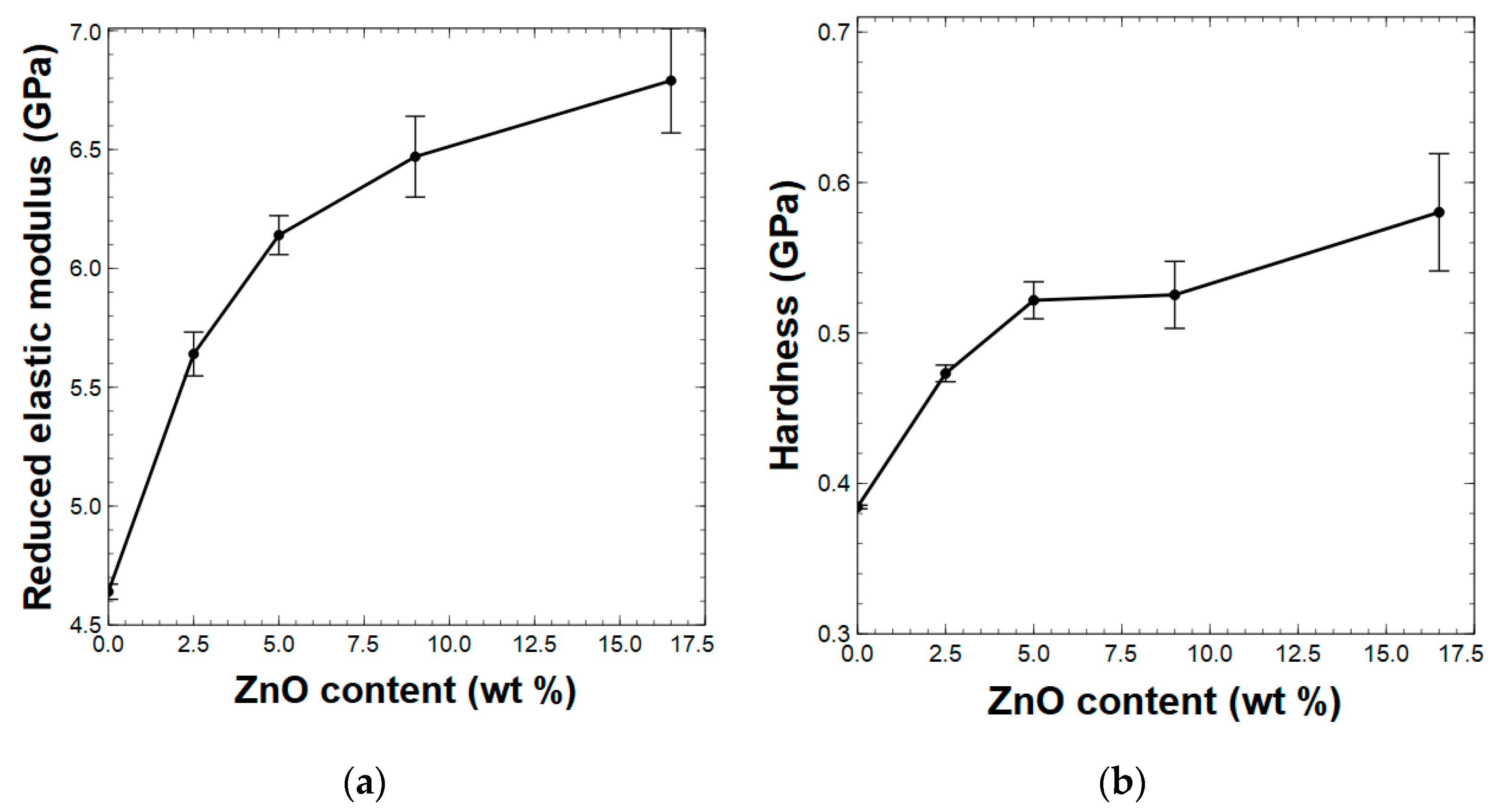

3.2. Dynamic Mechanical Properties of PAI Composites

3.3. Morphologies of PAI Composites

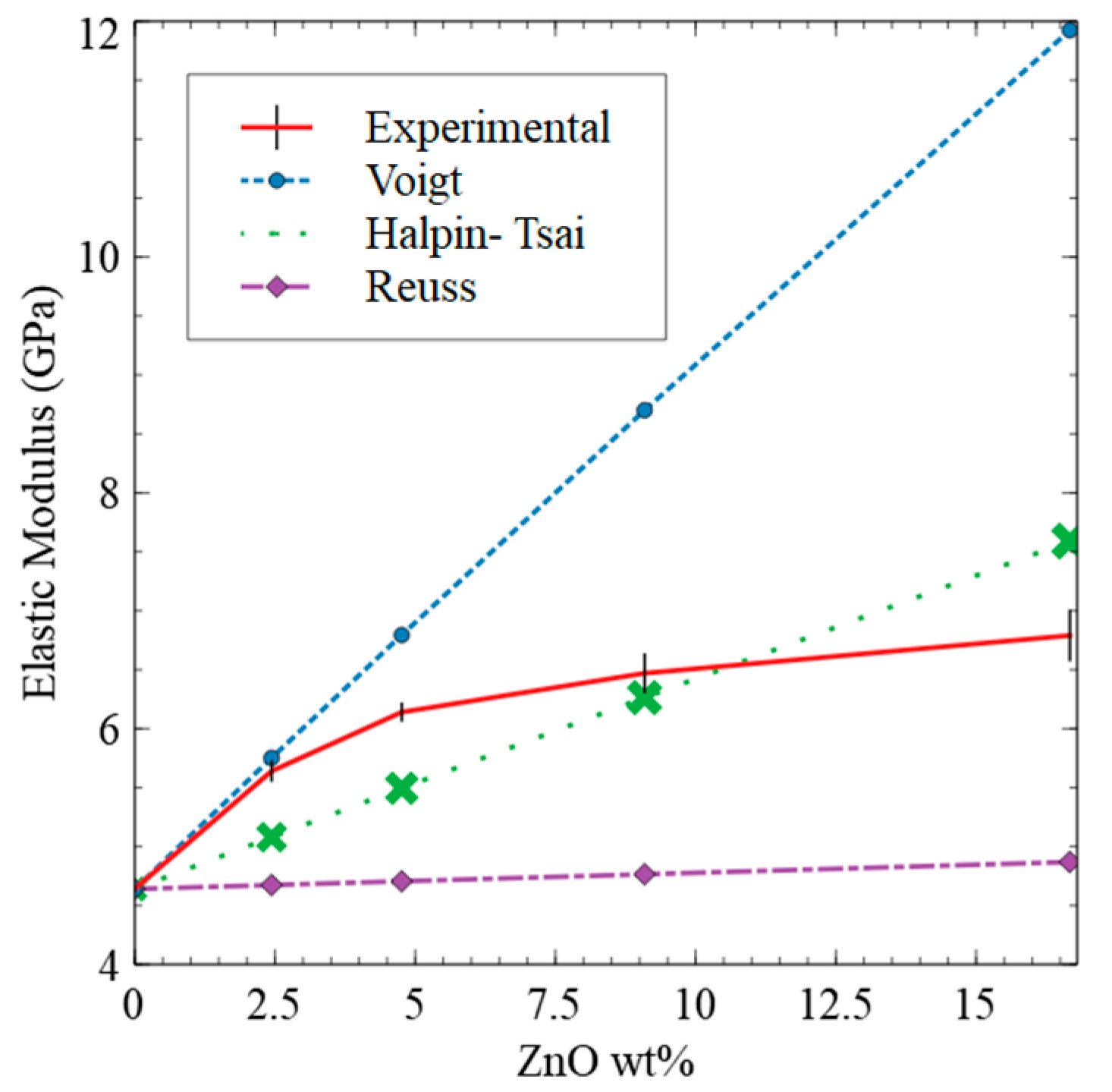

3.4. Rule of Mixture and Modified Rule of Mixture Model

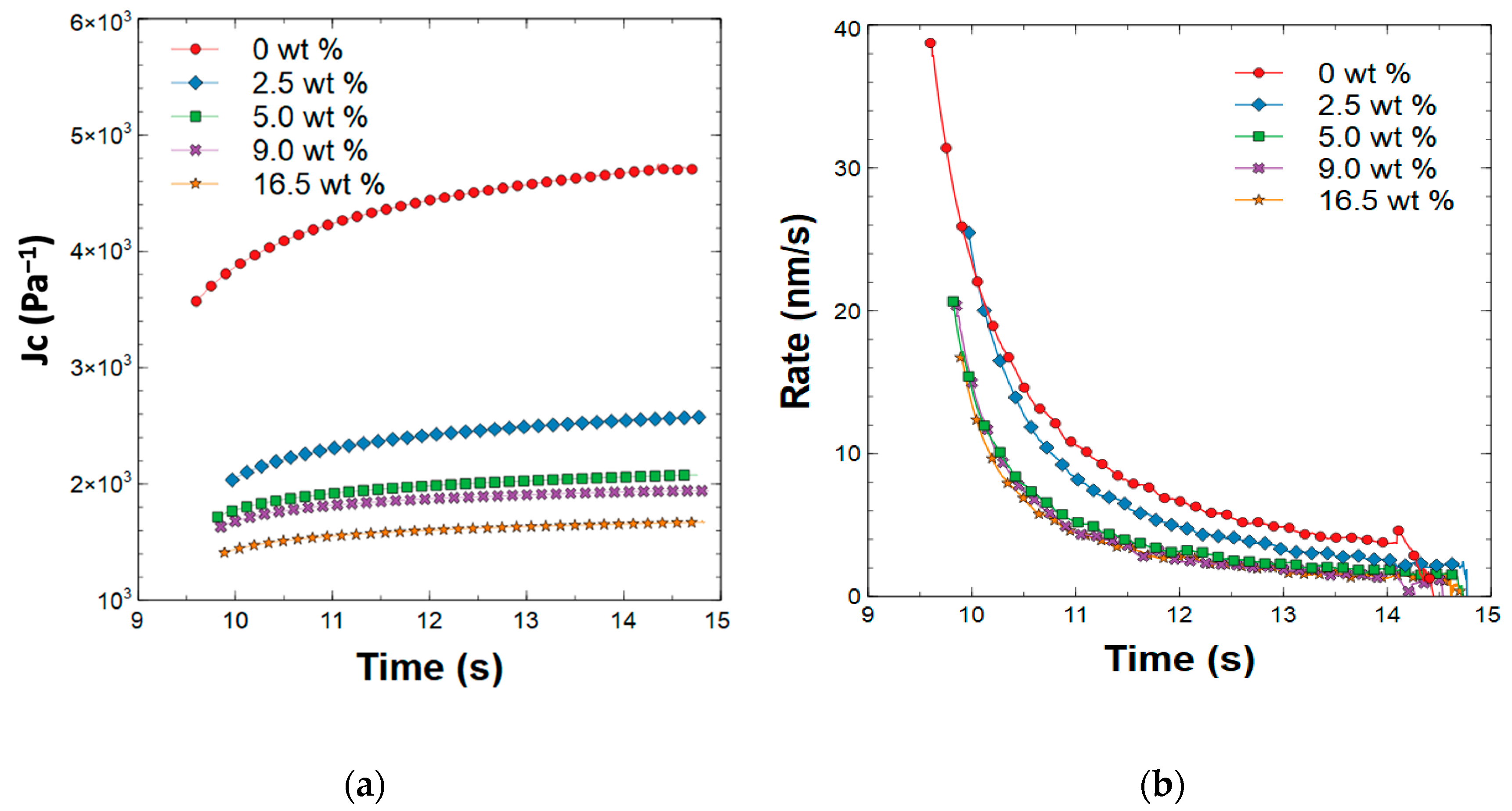

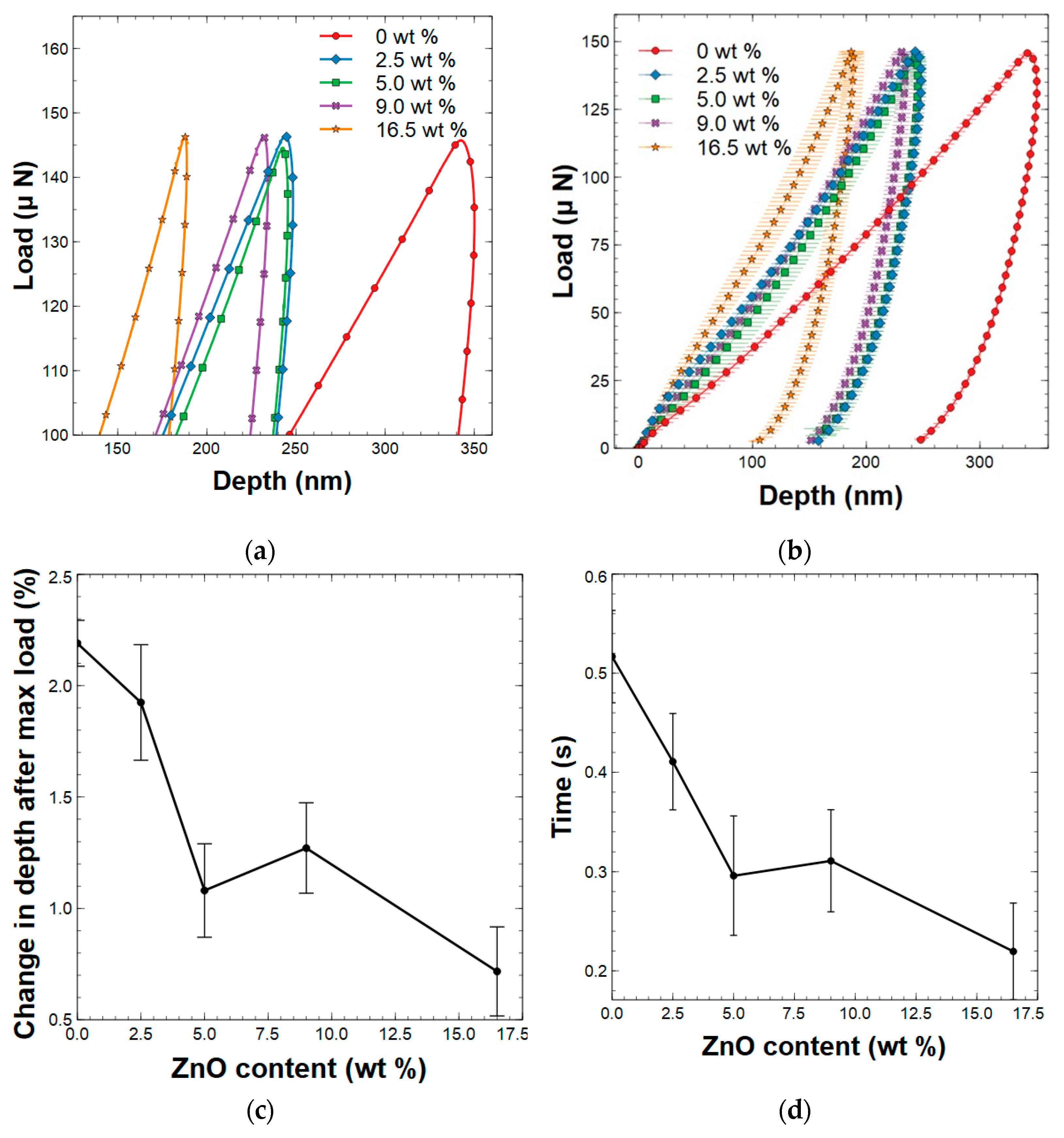

3.5. Viscoelastic Properties of PAI Composites

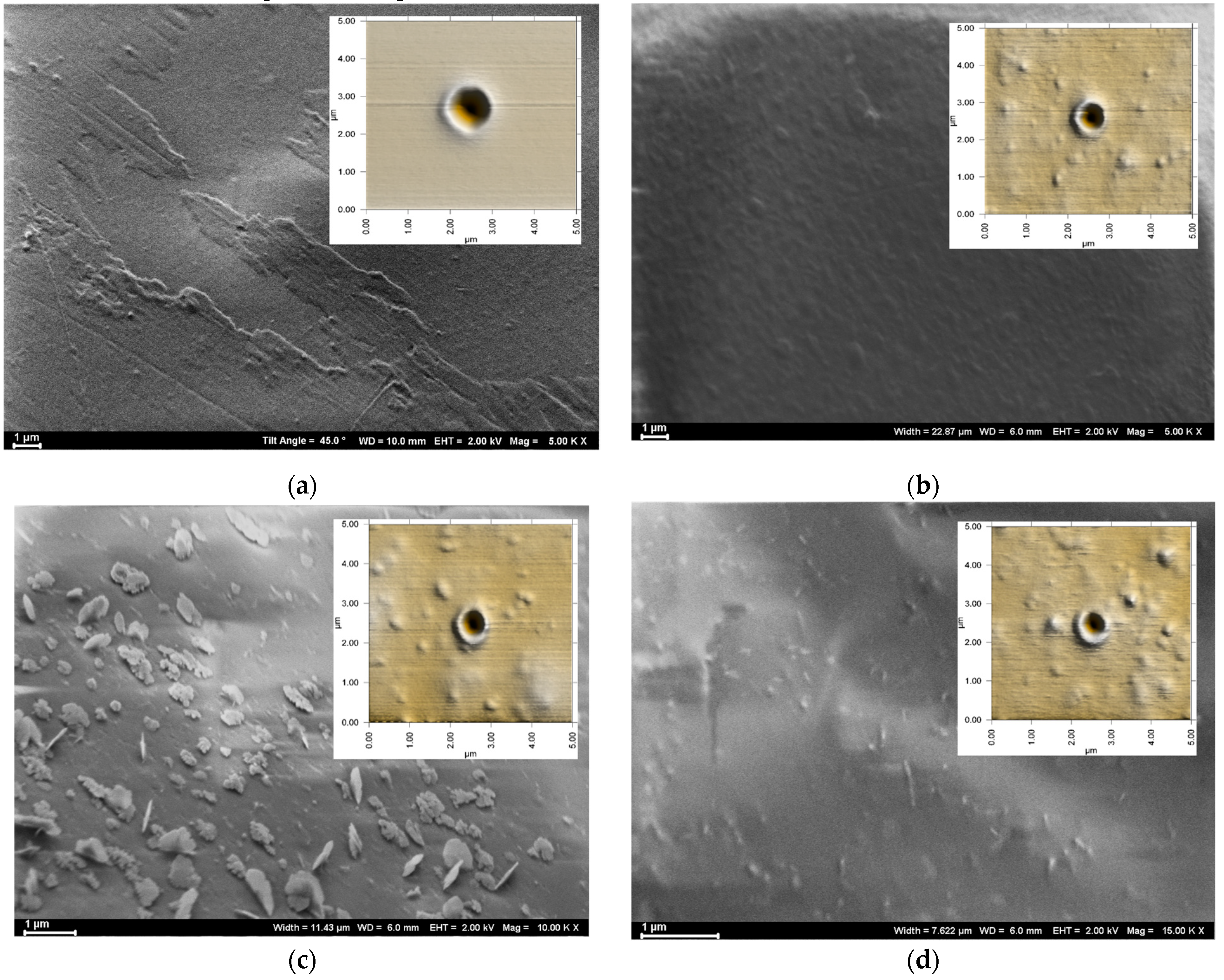

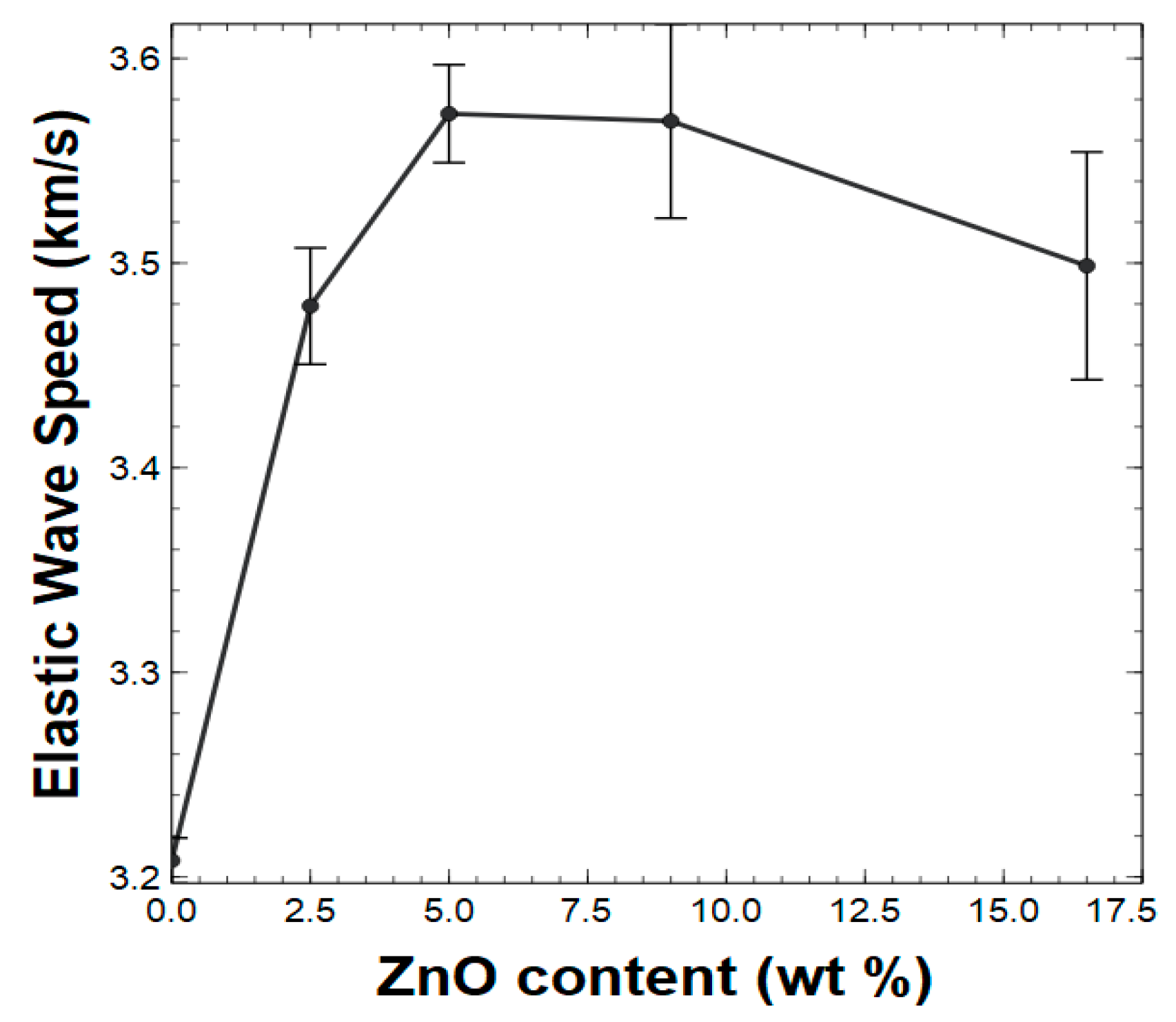

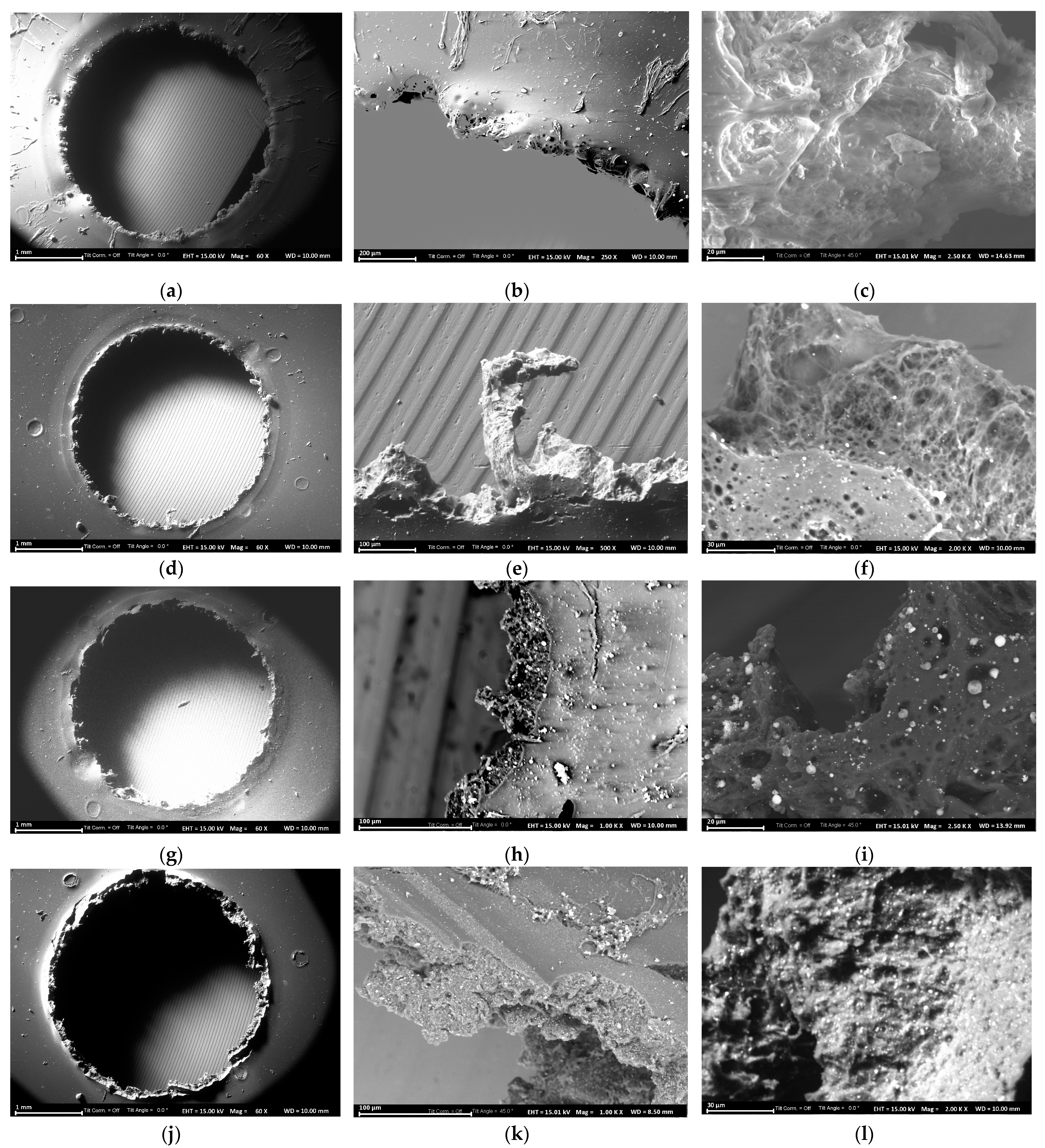

3.6. Evaluation of the Hypervelocity Impact’s Damage to the Composites

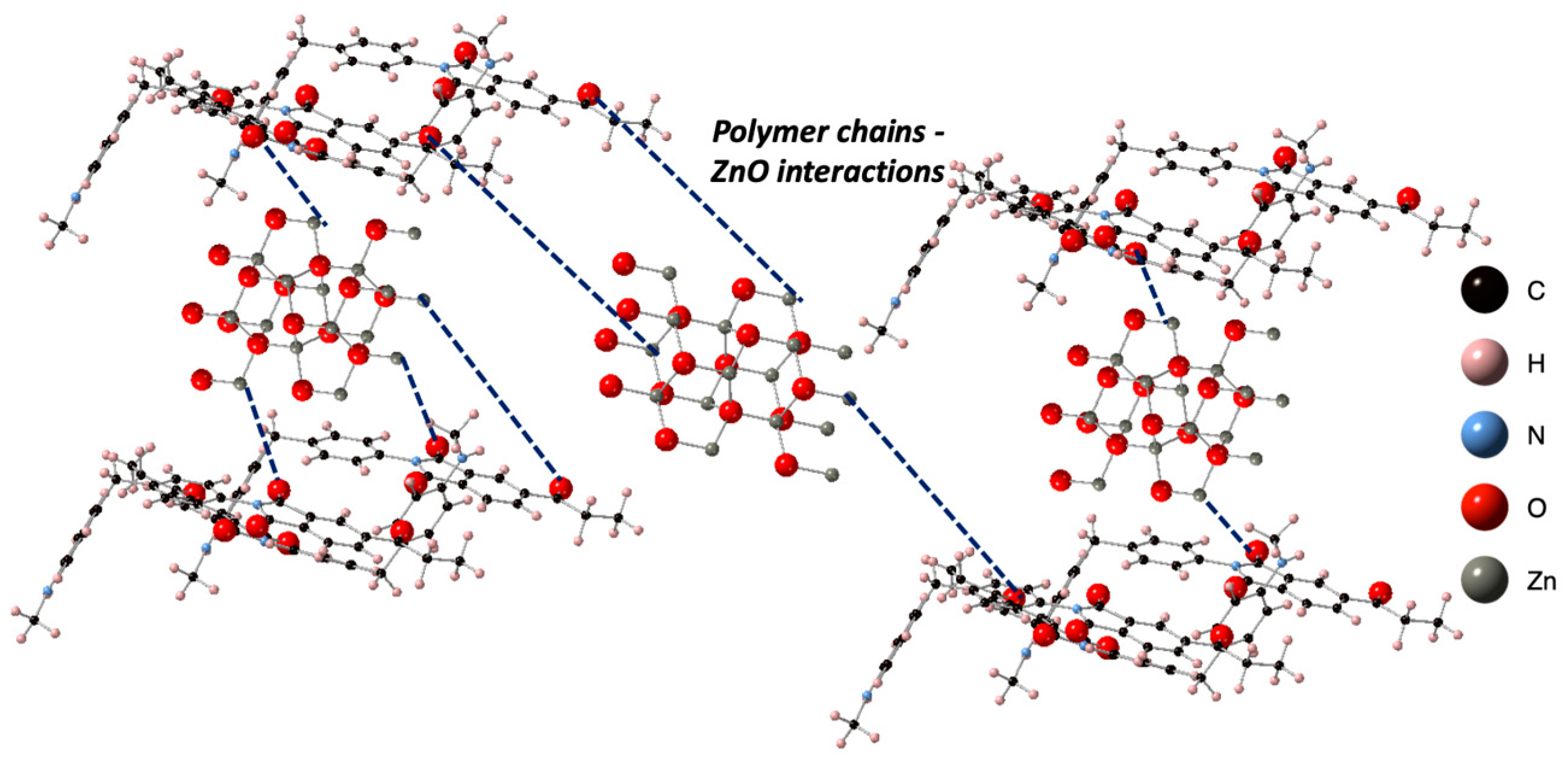

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jancar, J.; Douglas, J.F.; Starr, F.W.; Kumar, S.K.; Cassagnau, P.; Lesser, A.J.; Sternstein, S.S.; Buehler, M.J. Current Issues in Research on Structure–Property Relationships in Polymer Nanocomposites. Polymer 2010, 51, 3321–3343. [Google Scholar] [CrossRef]

- Jancar, J.; Hoy, R.S.; Lesser, A.J.; Jancarova, E.; Zidek, J. Effect of Particle Size, Temperature, and Deformation Rate on the Plastic Flow and Strain Hardening Response of PMMA Composites. Macromolecules 2013, 46, 9409–9426. [Google Scholar] [CrossRef]

- Jancar, J.; Hoy, R.S.; Jancarova, E.; Zidek, J. Effect of Temperature, Strain Rate and Particle Size on the Yield Stresses and Post-Yield Strain Softening of PMMA and Its Composites. Polymer 2015, 63, 196–207. [Google Scholar] [CrossRef]

- Jancar, J. Review of the Role of the Interphase in the Control of Composite Performance on Micro- and Nano-Length Scales. J. Mater. Sci. 2008, 43, 6747–6757. [Google Scholar] [CrossRef]

- Hashemi, A.; Jouault, N.; Williams, G.A.; Zhao, D.; Cheng, K.J.; Kysar, J.W.; Guan, Z.; Kumar, S.K. Enhanced Glassy State Mechanical Properties of Polymer Nanocomposites via Supramolecular Interactions. Nano Lett. 2015, 15, 5465–5471. [Google Scholar] [CrossRef]

- Cordero, Z.C.; Huskins, E.L.; Park, M.; Livers, S.; Frary, M.; Schuster, B.E.; Schuh, C.A. Powder-Route Synthesis and Mechanical Testing of Ultrafine Grain Tungsten Alloys. Metall. Mater. Trans. A 2014, 45, 3609–3618. [Google Scholar] [CrossRef]

- Miracle, D. Metal Matrix Composites—From Science to Technological Significance. Compos. Sci. Technol. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Cho, J.; Boccaccini, A.R.; Shaffer, M.S.P. Ceramic Matrix Composites Containing Carbon Nanotubes. J. Mater. Sci. 2009, 44, 1934–1951. [Google Scholar] [CrossRef]

- Laurenzi, S.; de Zanet, G.; Santonicola, M.G. Numerical Investigation of Radiation Shielding Properties of Polyethylene-Based Nanocomposite Materials in Different Space Environments. Acta Astronaut. 2020, 170, 530–538. [Google Scholar] [CrossRef]

- Lei, X.-F.; Qiao, M.-T.; Tian, L.-D.; Yao, P.; Ma, Y.; Zhang, H.-P.; Zhang, Q.-Y. Improved Space Survivability of Polyhedral Oligomeric Silsesquioxane (POSS) Polyimides Fabricated via Novel POSS-Diamine. Corros. Sci. 2015, 90, 223–238. [Google Scholar] [CrossRef]

- Georgiev, A.; Dimov, D.; Spassova, E.; Assa, J.; Dineff, P.; Danev, G. High Performance Polymers—Polyimides Based—From Chemistry to Applications; InTech: London, UK, 2012. [Google Scholar]

- Meador, M.A.B.; Vivod, S.L. Polyimide Synthesis. In Encyclopedia of Polymeric Nanomaterials; Kobayashi, S., Müllen, K., Eds.; Springer: Berlin/Heidelberg, Germany, 2021; pp. 1–11. [Google Scholar]

- Verker, R.; Grossman, E.; Gouzman, I.; Eliaz, N. Residual Stress Effect on Degradation of Polyimide under Simulated Hypervelocity Space Debris and Atomic Oxygen. Polymer 2007, 48, 19–24. [Google Scholar] [CrossRef]

- Clemenson, P.I.; Pandiman, D.; Pearson, J.T.; Lavery, A.J. Synthesis and Characterization of New Water-Soluble Precursors of Polyimides. Polym. Eng. Sci. 1997, 37, 966–977. [Google Scholar] [CrossRef]

- Progar, D.J.; Pike, R.A. Adhesive Evaluation of Water-Soluble LARC-TPI. Int. J. Adhes. Adhes. 1988, 8, 25–32. [Google Scholar] [CrossRef]

- Maekawa, Y.; Miwa, T.; Horie, K.; Yamashita, T. Solution Properties of Polyamic Acids and Their Amine Salts. React. Funct. Polym. 1996, 30, 71–73. [Google Scholar] [CrossRef]

- Thipperudrappa, S.; Ullal Kini, A.; Hiremath, A. Influence of Zinc Oxide Nanoparticles on the Mechanical and Thermal Responses of Glass Fiber-reinforced Epoxy Nanocomposites. Polym. Compos. 2020, 41, 174–181. [Google Scholar] [CrossRef]

- Bindu, P.; Thomas, S. Viscoelastic Behavior and Reinforcement Mechanism in Rubber Nanocomposites in the Vicinity of Spherical Nanoparticles. J. Phys. Chem. B 2013, 117, 12632–12648. [Google Scholar] [CrossRef]

- Shahbazi, R.; Javadpour, J.; Khavandi, A.R. Effect of Nanosized Reinforcement Particles on Mechanical Properties of High Density Polyethylene–Hydroxyapatite Composites. Adv. Appl. Ceram. 2006, 105, 253–257. [Google Scholar] [CrossRef]

- Wacharawichanant, S.; Thongyai, S.; Phutthaphan, A.; Eiamsam-ang, C. Effect of Particle Sizes of Zinc Oxide on Mechanical, Thermal and Morphological Properties of Polyoxymethylene/Zinc Oxide Nanocomposites. Polym. Test. 2008, 27, 971–976. [Google Scholar] [CrossRef]

- Sun, Y.; Shi, C.; Liu, Z.; Wen, D. Theoretical Research Progress in High-Velocity/Hypervelocity Impact on Semi-Infinite Targets. Shock Vib. 2015, 2015, 265321. [Google Scholar] [CrossRef]

- Herrmann, W.; Wilbeck, J.S. Review of Hypervelocity Penetration Theories. Int. J. Impact Eng. 1987, 5, 307–322. [Google Scholar] [CrossRef]

- Smith, J.A.; Lacy, J.M.; Lévesque, D.; Monchalin, J.-P.; Lord, M. Use of the Hugoniot Elastic Limit in Laser Shockwave Experiments to Relate Velocity Measurements. In AIP Conference Proceedings; AIP Publishing LLCAIP Publishing: Melville, NY, USA, 2016; Volume 1706, p. 080005. [Google Scholar] [CrossRef]

- Baghdadi, Y.N.; Youssef, L.; Bouhadir, K.; Harb, M.; Mustapha, S.; Patra, D.; Tehrani-Bagha, A.R. The Effects of Modified Zinc Oxide Nanoparticles on the Mechanical/Thermal Properties of Epoxy Resin. J. Appl. Polym. Sci. 2020, 137, 49330. [Google Scholar] [CrossRef]

- Holdsworth, S. Creep-Ductility of High Temperature Steels: A Review. Metals 2019, 9, 342. [Google Scholar] [CrossRef]

- Davis, K.; Yarbrough, R.; Froeschle, M.; White, J.; Rathnayake, H. Band Gap Engineered Zinc Oxide Nanostructures: Via a Sol-Gel Synthesis of Solvent Driven Shape-Controlled Crystal Growth. RSC Adv. 2019, 9, 14638–14648. [Google Scholar] [CrossRef]

- El-Naggar, M.E.; Hassabo, A.G.; Mohamed, A.L.; Shaheen, T.I. Surface Modification of SiO2 Coated ZnO Nanoparticles for Multifunctional Cotton Fabrics. J. Colloid Interface Sci. 2017, 498, 413–422. [Google Scholar] [CrossRef]

- Stan, G.; Ciobanu, C.V.; Parthangal, P.M.; Cook, R.F. Diameter-Dependent Radial and Tangential Elastic Moduli of ZnO Nanowires. Nano Lett. 2007, 7, 3691–3697. [Google Scholar] [CrossRef]

- Liu, B.; Feng, X.; Zhang, S.-M. The Effective Young’s Modulus of Composites beyond the Voigt Estimation Due to the Poisson Effect. Compos. Sci. Technol. 2009, 69, 2198–2204. [Google Scholar] [CrossRef]

- Solvay Specialty Polymers Torlon® 4203 Polyamide-Imide (PAI). Available online: http://www.matweb.com/search/datasheet_print.aspx?matguid=d6b32d3ff6444b76_a21c4e47b1602a02 (accessed on 17 October 2020).

- Tripathi, S.; Agarwal, R.; Singh, D. Size Dependent Elastic and Thermophysical_Properties of Zinc Oxide Nanowires: Semiconductor Materials Characterisation for_High Temperature Applications. Johns. Matthey Technol. Rev. 2019, 63, 166–176. [Google Scholar] [CrossRef]

- Ondreas, F.; Lepcio, P.; Zboncak, M.; Zarybnicka, K.; Govaert, L.E.; Jancar, J. Effect of Nanoparticle Organization on Molecular Mobility and Mechanical Properties of Polymer Nanocomposites. Macromolecules 2019, 52, 6250–6259. [Google Scholar] [CrossRef]

- Sarvestani, A.S.; Picu, C.R. Network Model for the Viscoelastic Behavior of Polymer Nanocomposites. Polymer 2004, 45, 7779–7790. [Google Scholar] [CrossRef]

- Sarvestani, A.S.; Picu, C.R. A Frictional Molecular Model for the Viscoelasticity of Entangled Polymer Nanocomposites. Rheol. Acta 2005, 45, 132–141. [Google Scholar] [CrossRef]

- Picu, C.R.; Sarvestani, A.S.; Palade, L.I. Molecular Constitutive Model for Entangled Polymer Nanocomposites. Mater. Plast. 2012, 49, 133–142. [Google Scholar]

- Yang, J.; Zhang, Z.; Friedrich, K.; Schlarb, A.K. Creep Resistant Polymer Nanocomposites Reinforced with Multiwalled Carbon Nanotubes. Macromol. Rapid Commun. 2007, 28, 955–961. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kesler, D.; Ariyawansa, B.P.; Rathnayake, H. Mechanical Properties and Synergistic Interfacial Interactions of ZnO Nanorod-Reinforced Polyamide–Imide Composites. Polymers 2023, 15, 1522. https://doi.org/10.3390/polym15061522

Kesler D, Ariyawansa BP, Rathnayake H. Mechanical Properties and Synergistic Interfacial Interactions of ZnO Nanorod-Reinforced Polyamide–Imide Composites. Polymers. 2023; 15(6):1522. https://doi.org/10.3390/polym15061522

Chicago/Turabian StyleKesler, Dallas, Bhanuka P. Ariyawansa, and Hemali Rathnayake. 2023. "Mechanical Properties and Synergistic Interfacial Interactions of ZnO Nanorod-Reinforced Polyamide–Imide Composites" Polymers 15, no. 6: 1522. https://doi.org/10.3390/polym15061522

APA StyleKesler, D., Ariyawansa, B. P., & Rathnayake, H. (2023). Mechanical Properties and Synergistic Interfacial Interactions of ZnO Nanorod-Reinforced Polyamide–Imide Composites. Polymers, 15(6), 1522. https://doi.org/10.3390/polym15061522