The Hypervelocity Impact Behavior and Energy Absorption Evaluation of Fabric

Abstract

:1. Introduction

2. Material and Hypervelocity Impact Experiment

2.1. Materials

2.2. Experimental Configuration

2.3. HVI Experiments

3. Results and Discussion

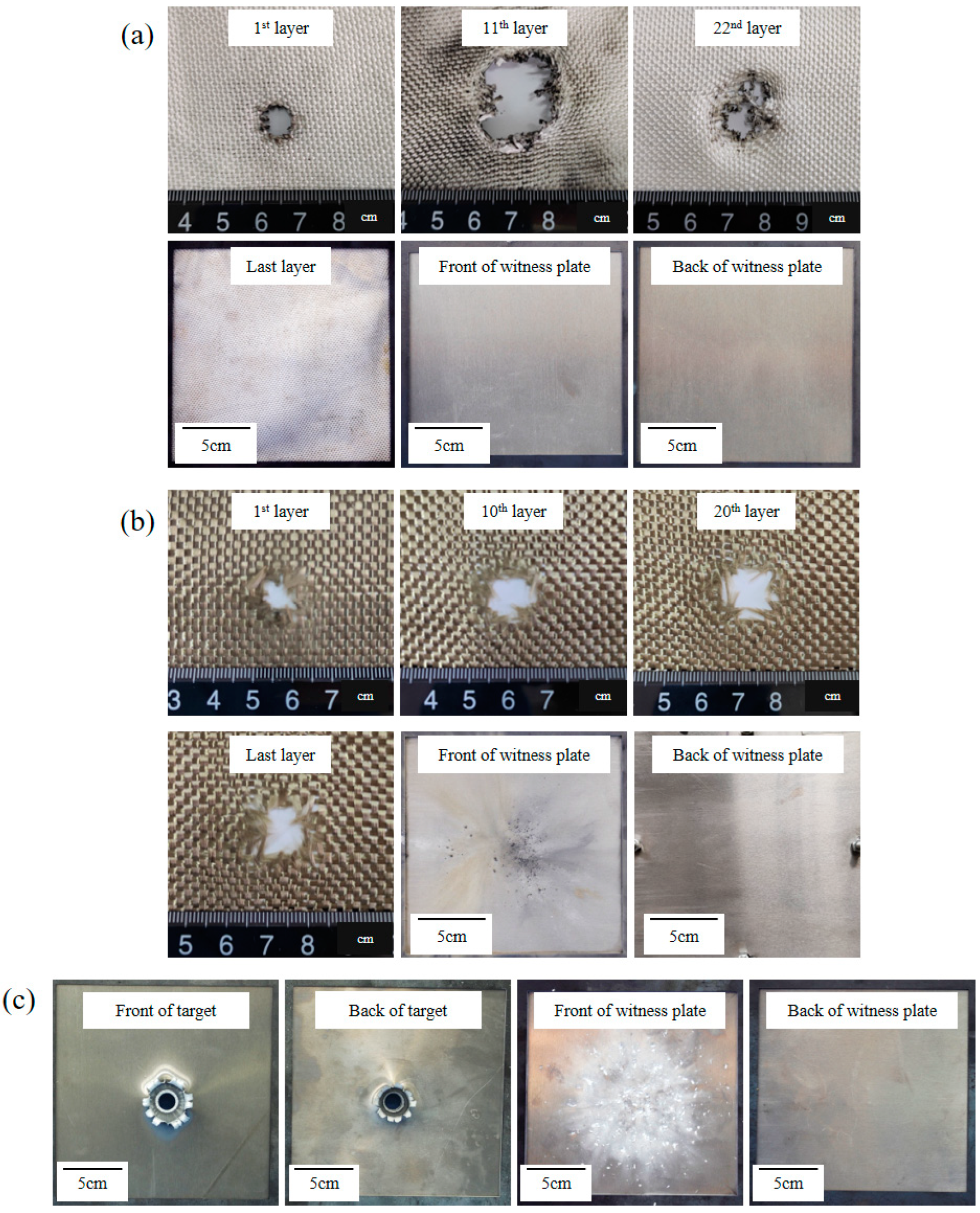

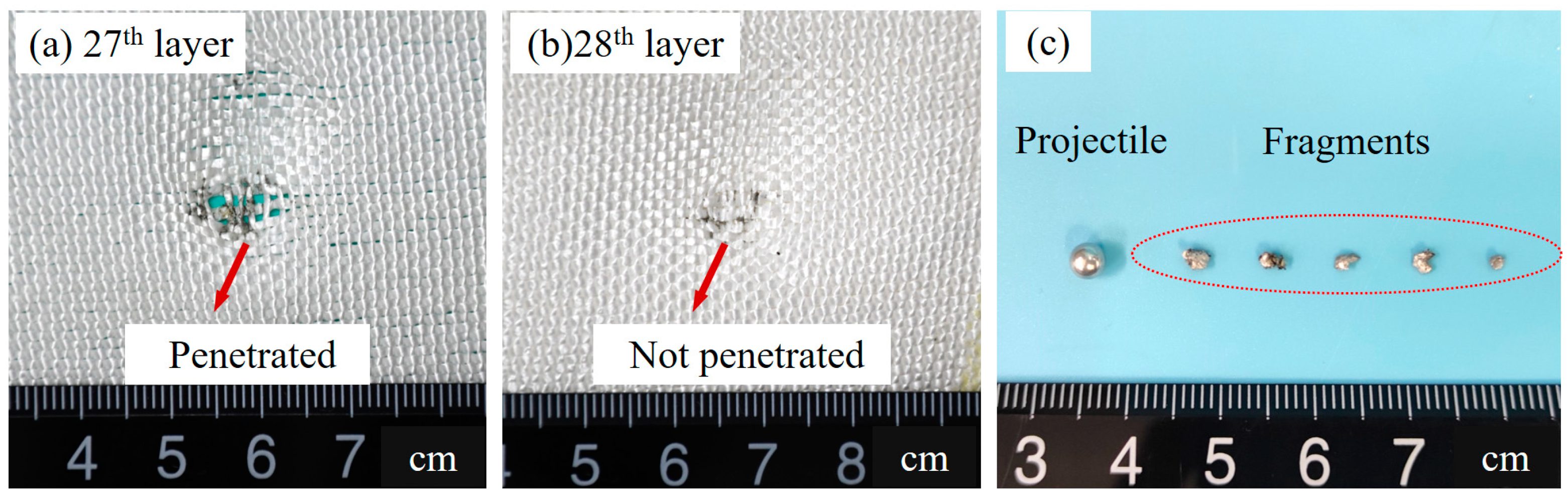

3.1. Shielding Performance Analysis

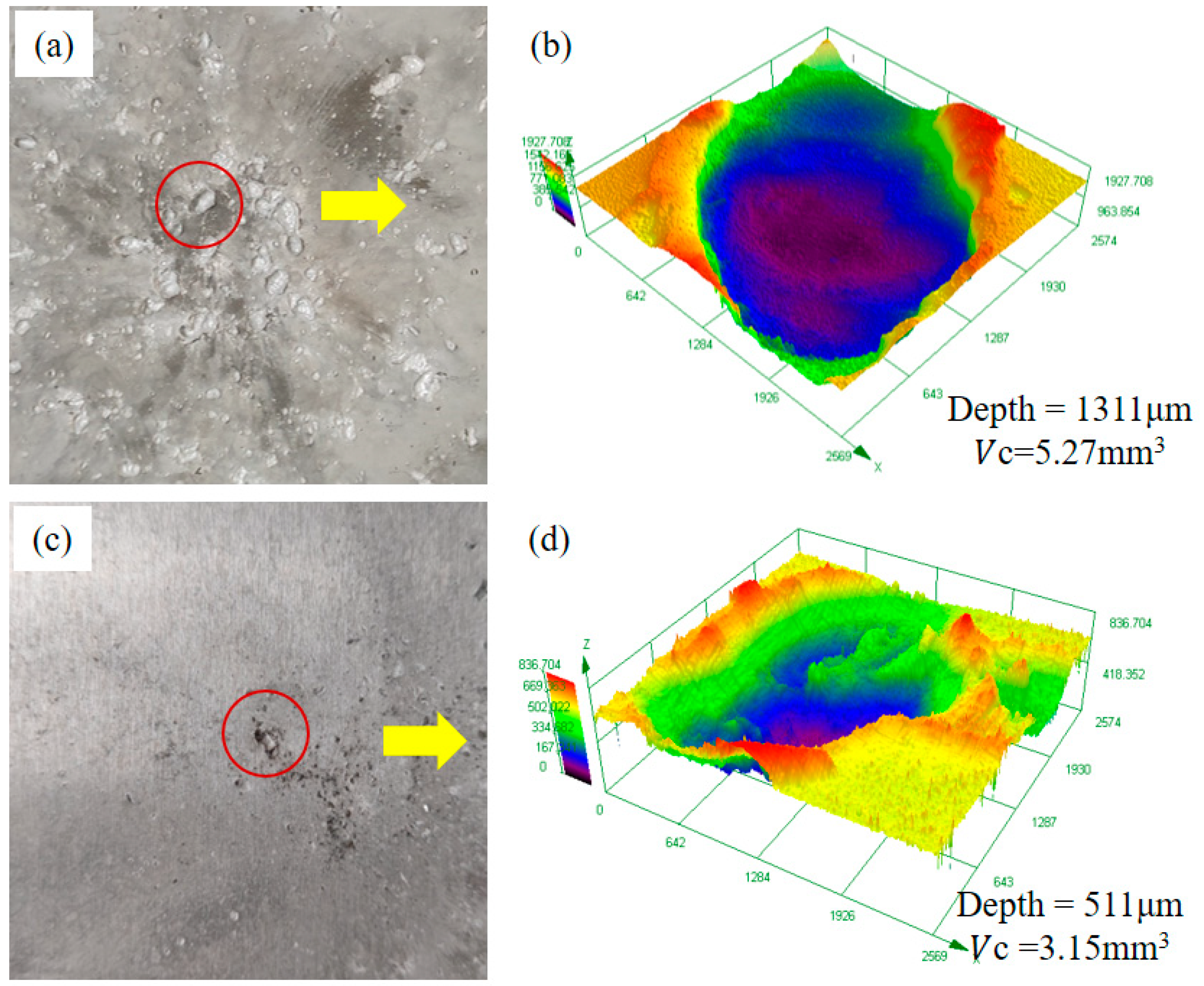

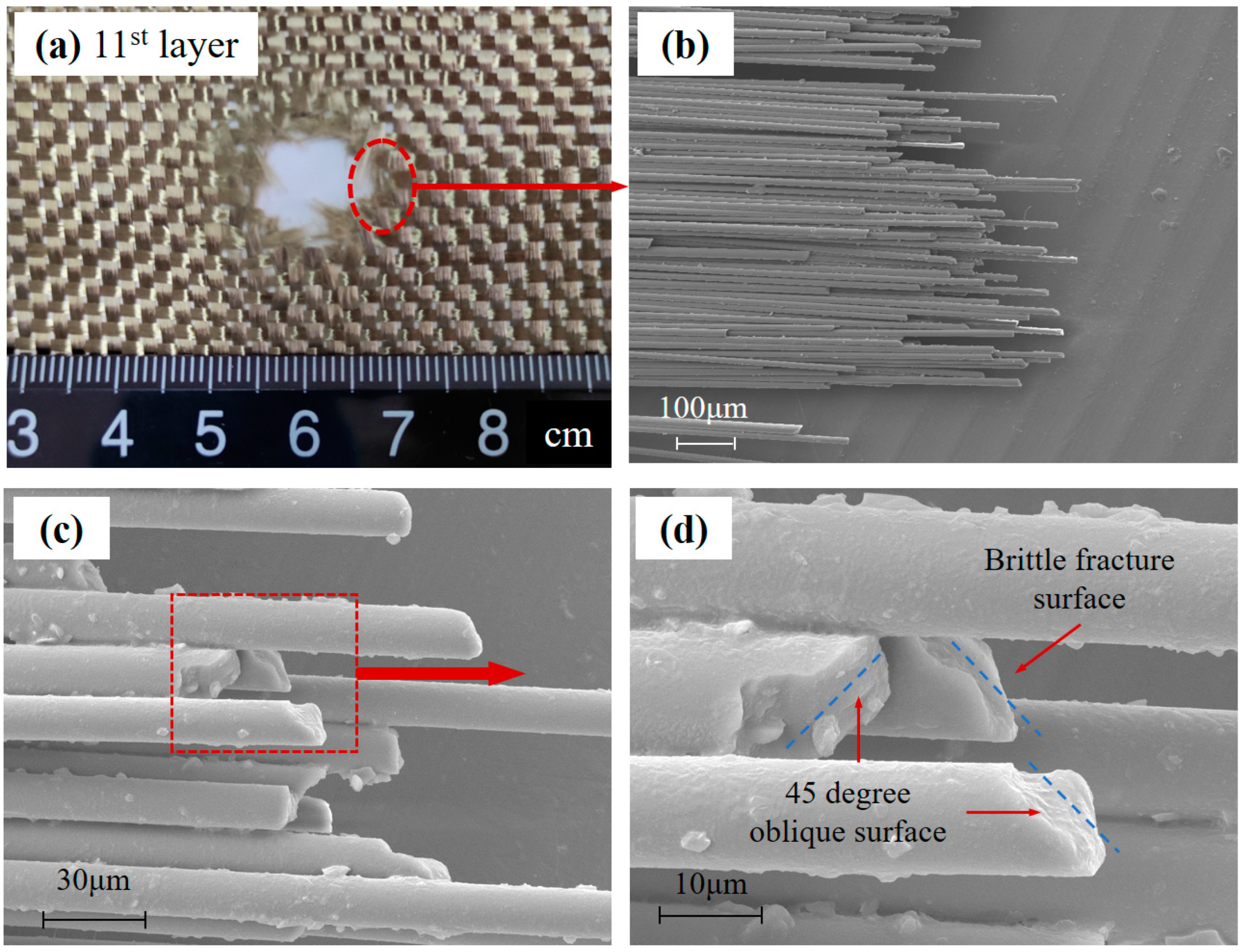

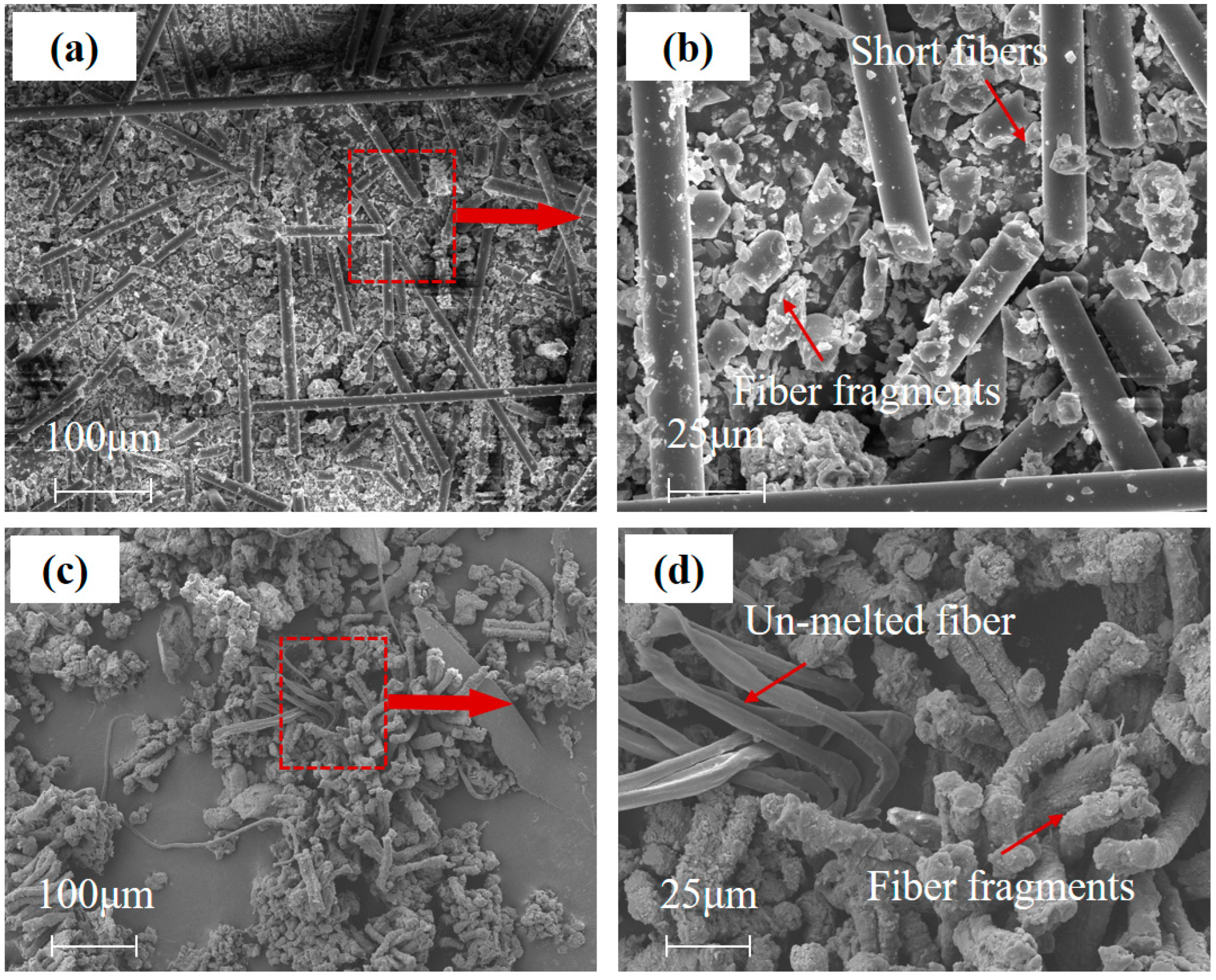

3.2. Microstructural Damage Analysis

4. Conclusions

- Basalt and UHMWPE fiber show different fracture failure modes after HVI with Al projectile. Microstructural damage analysis shows that UHMWPE fiber exhibits ductile fracture and apparent bulk softening/melting of the material, while the Basalt fiber exhibits a typical brittle fracture mode.

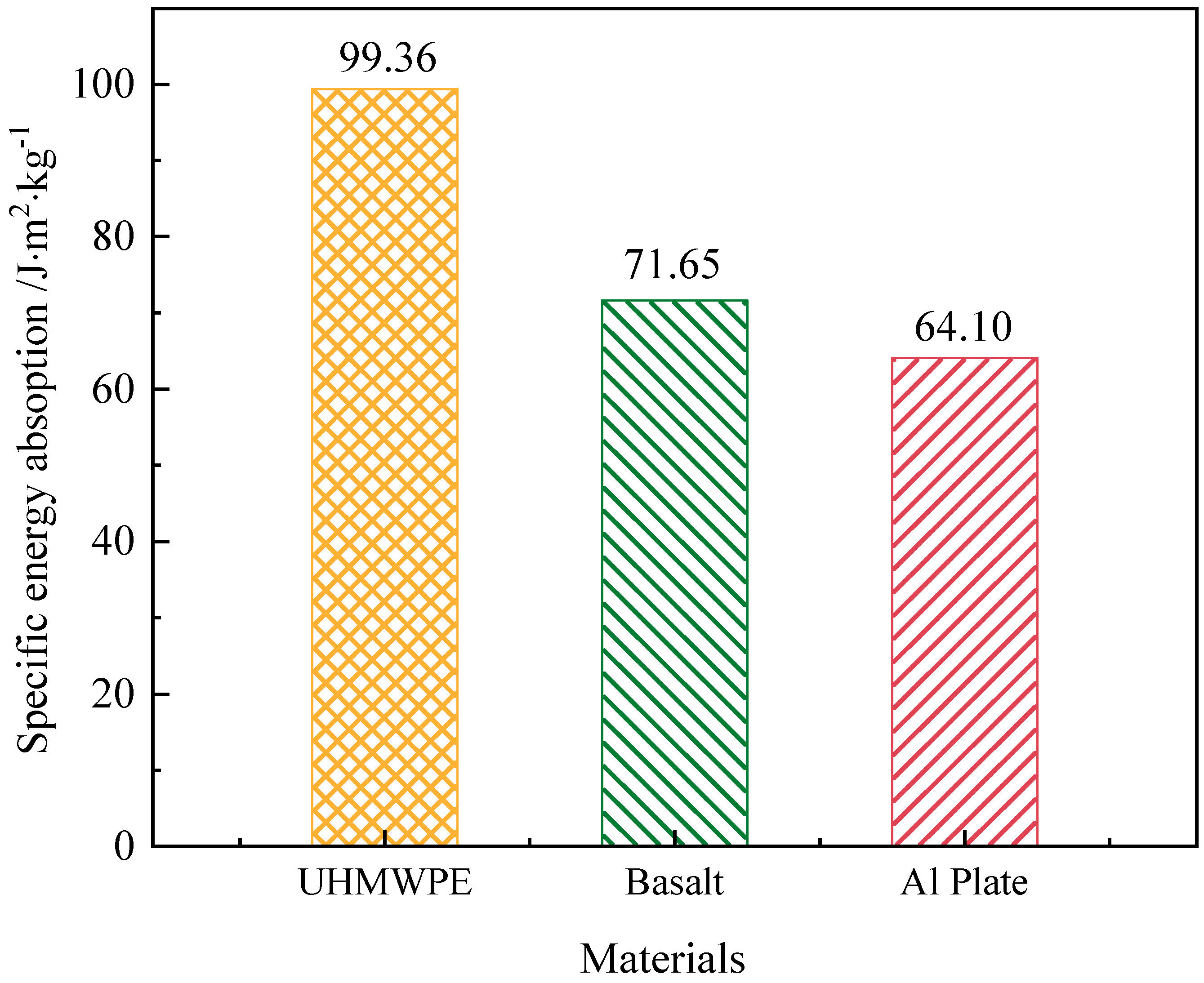

- The UHMWPE fabric target exhibited superior energy absorption efficiency and shielding performance than Basalt fabric and Al plates, while the areal density, projectile size and velocity were similar in the HVI experiments.

- In summary, the HVI experimental results combined with microstructural damage analysis of fiber materials suggest that ductile fractures with large-scale plastic deformation and apparent thermal softening/melting of fiber are significant energy absorption behavior, which could improve the energy absorption efficiency and the shielding performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Christiansen, E.L.; Kerr, J.H. Mesh double-bumper shield: A low-weight alternative for spacecraft meteoroid and orbital debris protection. Int. J. Impact Eng. 1993, 14, 169–180. [Google Scholar] [CrossRef]

- Maclay, T.; Culp, R.; Bareiss, L.; Gillespie, T.; Kustas, F. Topographically modified bumper concepts for spacecraft shielding. Int. J. Impact Eng. 1993, 14, 479–489. [Google Scholar] [CrossRef]

- Christiansen, E.L.; Crews, J.L.; Williamsen, J.E.; Robinson, J.H.; Nolen, A.M. Enhanced meteoroid and orbital debris shielding. Int. J. Impact Eng. 1995, 17, 217–228. [Google Scholar] [CrossRef] [Green Version]

- Destefanis, R.; Faraud, M.; Trucchi, M. Columbus debris shielding experiments and ballistic limit curves. Int. J. Impact Eng. 1999, 23 Pt 1, 181–192. [Google Scholar] [CrossRef]

- Ke, F.-W.; Huang, J.; Wen, X.-Z.; Ma, Z.-X.; Liu, S. Test study on the performance of shielding configuration with stuffed layer under hypervelocity impact. Acta Astronaut. 2016, 127, 553–560. [Google Scholar] [CrossRef]

- Fa-Wei, K.; Jie, H.; Xue-Zhong, W.; Xin, L.; Jing, L.; Qing, L.; Sen, L. Study on shield configuration stuffed with the integrated fabric layer and its bracing structure. Int. J. Impact Eng. 2018, 121, 191–202. [Google Scholar] [CrossRef]

- Ke, F.-W.; Huang, J.; Wen, X.-Z.; Song, Q.; Luo, Q.; Liu, S. The influences of aramid fibre and its compound with ceramic on shielding performance of stuffed layer. Acta Astronaut. 2018, 151, 928–941. [Google Scholar] [CrossRef]

- Putzar, R.; Zheng, S.; An, J.; Hovland, S. A stuffed Whipple shield for the Chinese space station. Int. J. Impact Eng. 2019, 132, 103304. [Google Scholar] [CrossRef]

- Cour-Palais, B.G.; Crews, J.L. A multi-shock concept for spacecraft shielding. Int. J. Impact Eng. 1990, 10, 135–146. [Google Scholar] [CrossRef]

- Christiansen, E.; Kerr, J.; De la Fuente, H.; Schneider, W. Flexible and deployable meteoroid/debris shielding for spacecraft. Int. J. Impact Eng. 1999, 23, 125–136. [Google Scholar] [CrossRef]

- Tanaka, M.; Moritaka, Y.; Akahoshi, Y.; Nakamura, R.; Yamori, A.; Sasaki, S. Development of a lightweight space debris shield using high strength fibers. Int. J. Impact Eng. 2001, 26, 761–772. [Google Scholar] [CrossRef]

- Miller, J.; Christiansen, E.; Davis, B.; Lear, D.; Liou, J.-C. Multi-shock Shield Performance At 14MJ for Catalogued Debris. Procedia Eng. 2015, 103, 405–412. [Google Scholar] [CrossRef] [Green Version]

- Rudolph, M.; Schäfer, F.; Destefanis, R.; Faraud, M.; Lambert, M. Fragmentation of hypervelocity aluminum projectiles on fabrics. Acta Astronaut. 2012, 76, 42–50. [Google Scholar] [CrossRef]

- Buslov, E.; Komarov, I.; Selivanov, V.; Titov, V.; Tovarnova, N.; Feldstein, V. Protection of inflatable modules of orbital stations against impacts of particles of space debris. Acta Astronaut. 2019, 163, 54–61. [Google Scholar] [CrossRef]

- Seedhouse, E. Bigelow Aerospace: Colonizing Space One Module at a Time; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Cha, J.-H.; Kim, Y.; Kumar, S.K.S.; Choi, C.; Kim, C.-G. Ultra-high-molecular-weight polyethylene as a hypervelocity impact shielding material for space structures. Acta Astronaut. 2019, 168, 182–190. [Google Scholar] [CrossRef]

- Zhao, S.; Song, Z.; Espinosa, H.D. Modelling and Analyses of Fiber Fabric and Fabric-Reinforced Polymers under Hypervelocity Impact Using Smooth Particle Hydrodynamics. Int. J. Impact Eng. 2020, 144, 103586. [Google Scholar] [CrossRef]

- Moon, J.B.; Park, Y.; Son, G.; Kim, C.-G. Computational analysis of a sandwich shield with free boundary inserted fabric at high velocity impact. Adv. Compos. Mater. 2016, 26, 197–218. [Google Scholar] [CrossRef]

- Moon, J.-B.; Yoon, S.H.; Kim, C.-G. High velocity impact test of a hybrid sandwich composite shield with unrestrained boundary fabric. Compos. Struct. 2016, 153, 60–68. [Google Scholar] [CrossRef]

- Kim, Y.; Park, Y.; Cha, J.; Ankem, V.A.; Kim, C.-G. Behavior of Shear Thickening Fluid (STF) impregnated fabric composite rear wall under hypervelocity impact. Compos. Struct. 2018, 204, 52–62. [Google Scholar] [CrossRef]

- Kim, Y.; Choi, C.; Kumar, S.K.S.; Kim, C.-G. Hypervelocity impact on flexible curable composites and pure fabric layer bumpers for inflatable space structures. Compos. Struct. 2017, 176, 1061–1072. [Google Scholar] [CrossRef]

- Gongshun, G.; Baojun, P.; Wei, Z.; Yue, H. Crater distribution on the rear wall of AL-Whipple shield by hypervelocity impacts of AL-spheres. Int. J. Impact Eng. 2008, 35, 1541–1546. [Google Scholar] [CrossRef]

- Sockalingam, S.; Chowdhury, S.C.; Gillespie, J.W.J.; Keefe, M. Recent advances in modeling and experiments of Kevlar ballistic fibrils, fibers, yarns and flexible woven textile fabrics—A review. Text. Res. J. 2016, 87, 984–1010. [Google Scholar] [CrossRef]

- Shah, K.; Sockalingam, S. Effect of transverse compression on the residual tensile strength of ultrahigh molecular weight polyethylene (Dyneema® SK-76) yarns. Def. Technol. 2019, 16, 35–42. [Google Scholar] [CrossRef]

- McDaniel, P.B.; Deitzel, J.M.; Gillespie, J.W. Structural hierarchy and surface morphology of highly drawn ultra high molecular weight polyethylene fibers studied by atomic force microscopy and wide angle X-ray diffraction. Polymer 2015, 69, 148–158. [Google Scholar] [CrossRef]

- Dong, H.; Wang, Z.; O’Connor, T.C.; Azoug, A.; Robbins, M.O.; Nguyen, T.D. Micromechanical models for the stiffness and strength of UHMWPE macrofibrils. J. Mech. Phys. Solids 2018, 116, 70–98. [Google Scholar] [CrossRef]

- Wei, B.; Cao, H.; Song, S. Tensile behavior contrast of basalt and glass fibers after chemical treatment. Mater. Des. 2010, 31, 4244–4250. [Google Scholar] [CrossRef]

- Xing, D.; Chang, C.; Xi, X.-Y.; Hao, B.; Zheng, Q.; Gutnikov, S.I.; Lazoryak, B.I.; Ma, P.-C. Morphologies and mechanical properties of basalt fibre processed at elevated temperature. J. Non-Cryst. Solids 2022, 582, 121439. [Google Scholar] [CrossRef]

- Yao, X.; Wen, L.; Yu, Z.; Guo, W.; Huang, F.; Qiang, Y.; Jin, Y. Study on corrosion behavior and mechanism of 5A06 aluminum alloy in N2O4 medium. J. Alloys Compd. 2023, 931, 167544. [Google Scholar] [CrossRef]

- Park, Y.; Kim, Y.; Baluch, A.H.; Kim, C.-G. Empirical study of the high velocity impact energy absorption characteristics of shear thickening fluid (STF) impregnated Kevlar fabric. Int. J. Impact Eng. 2014, 72, 67–74. [Google Scholar] [CrossRef]

- Tanaka, K.; Nishida, M.; Ogawa, H.; Akahori, M.; Aikawa, F. Hypervelocity crater formation in aluminum alloys at low temperatures. Int. J. Impact Eng. 2008, 35, 1821–1826. [Google Scholar] [CrossRef]

- Cheng, M.; Chen, W.; Weerasooriya, T. Experimental investigation of the transverse mechanical properties of a single Kevlar® KM2 fiber. Int. J. Solids Struct. 2004, 41, 6215–6232. [Google Scholar] [CrossRef]

- McDaniel, P.B.; Deitzel, J.M.; Gregory, D.; Polakovic, T.; Gillespie, J.W. Single fiber peel test to assess ultra high molecular weight polyethylene fiber mesostructure interactions. J. Appl. Polym. Sci. 2018, 135, 46156. [Google Scholar] [CrossRef]

- Deitzel, J.M.; McDaniel, P.; Gillespie, J.W. High performance polyethylene fibers. In Structure and Properties of High-Performance Fibers; Woodhead Publishing: Sawston, UK, 2017; pp. 167–185. [Google Scholar]

| Material | Density (g/cm3) | Tensile Strength (MPa) | Young’s Modulus (GPa) | Breaking Elongation (%) | Melting Temperature (°C) | 1-Layer AD (g/cm2) | Number of Layers | Total AD (g/m2) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Basalt | 2.65 | 3800 | 93~110 | 3.1 | 1050 | 339.8 | 32 | 10,873.6 | [8] |

| 5A06 | 2.64 | 339 | 71 | 25 | 660 | 2727.0 | 4 | 10,908.0 | [22] |

| UHMWPE | 0.96 | 2470 | 99 | 3.7 | 120 | 302.8 | 35 | 10,598.0 | test |

| Experimental | Bumper Material | Vproj/(km/s) | Penetration | Maximum Depth of Impact Crater (mm) | Impact Crater Volume (mm3) |

|---|---|---|---|---|---|

| S1 | Basalt | 4.190 | Yes | 511 | 5.19 |

| S2 | 5A06 | 4.266 | Yes | 1311 | 71.76 |

| S3 | UHMWPE | 4.250 | No | 0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Yu, D.; Cui, J.; Shi, Z.; Song, D.; Miao, C. The Hypervelocity Impact Behavior and Energy Absorption Evaluation of Fabric. Polymers 2023, 15, 1547. https://doi.org/10.3390/polym15061547

Xu H, Yu D, Cui J, Shi Z, Song D, Miao C. The Hypervelocity Impact Behavior and Energy Absorption Evaluation of Fabric. Polymers. 2023; 15(6):1547. https://doi.org/10.3390/polym15061547

Chicago/Turabian StyleXu, Huadong, Dong Yu, Jiaxin Cui, Zhixin Shi, Di Song, and Changqing Miao. 2023. "The Hypervelocity Impact Behavior and Energy Absorption Evaluation of Fabric" Polymers 15, no. 6: 1547. https://doi.org/10.3390/polym15061547

APA StyleXu, H., Yu, D., Cui, J., Shi, Z., Song, D., & Miao, C. (2023). The Hypervelocity Impact Behavior and Energy Absorption Evaluation of Fabric. Polymers, 15(6), 1547. https://doi.org/10.3390/polym15061547