PPyNT/NR/NBR Composites with Excellent Microwave Absorbing Performance in X-Band

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of PPyNT

2.3. Fabrication of PPyNT/NR/NBR Composites

2.4. Characterization

3. Results and Discussion

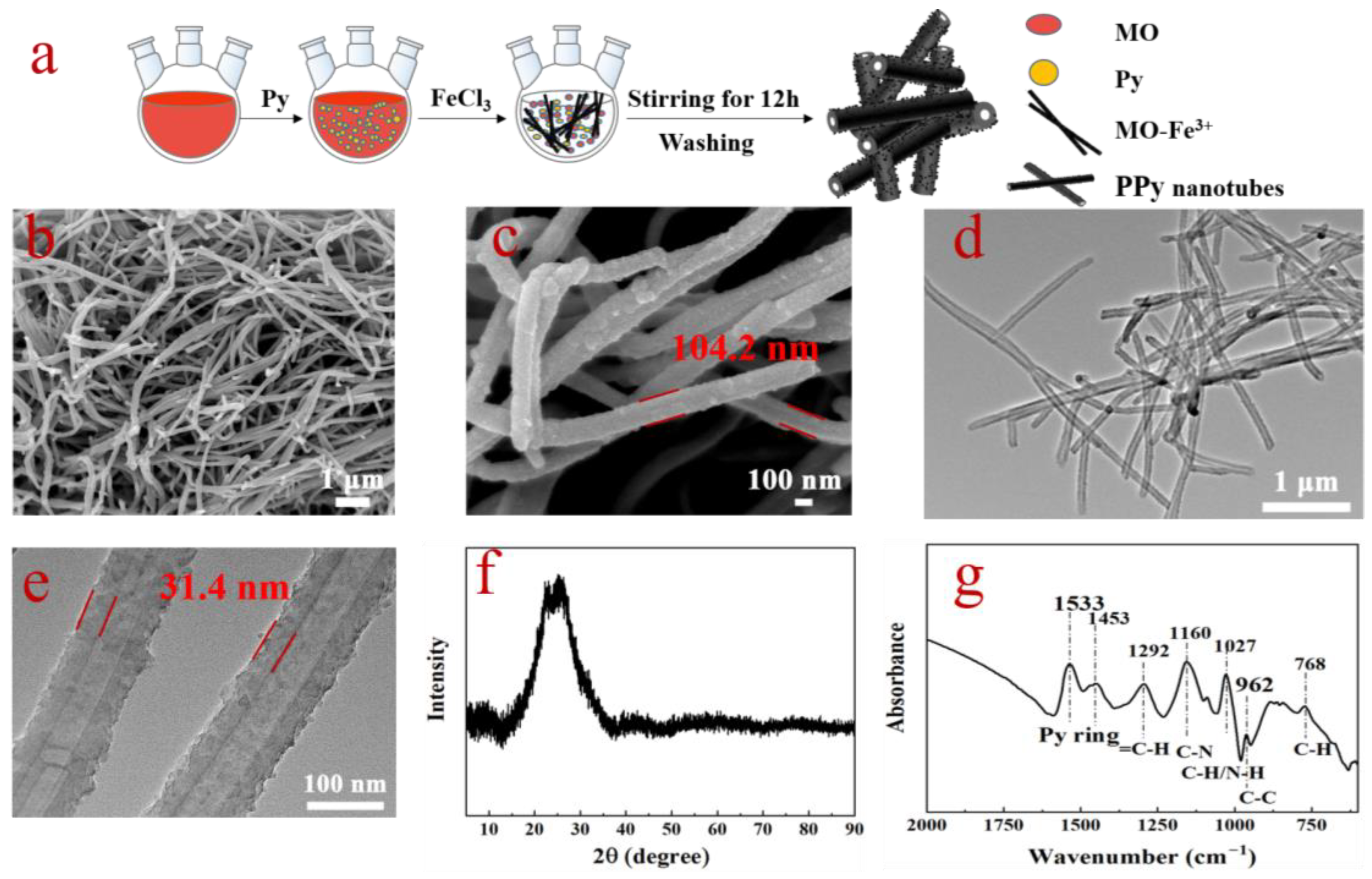

3.1. Morphology and Structure of PPyNT

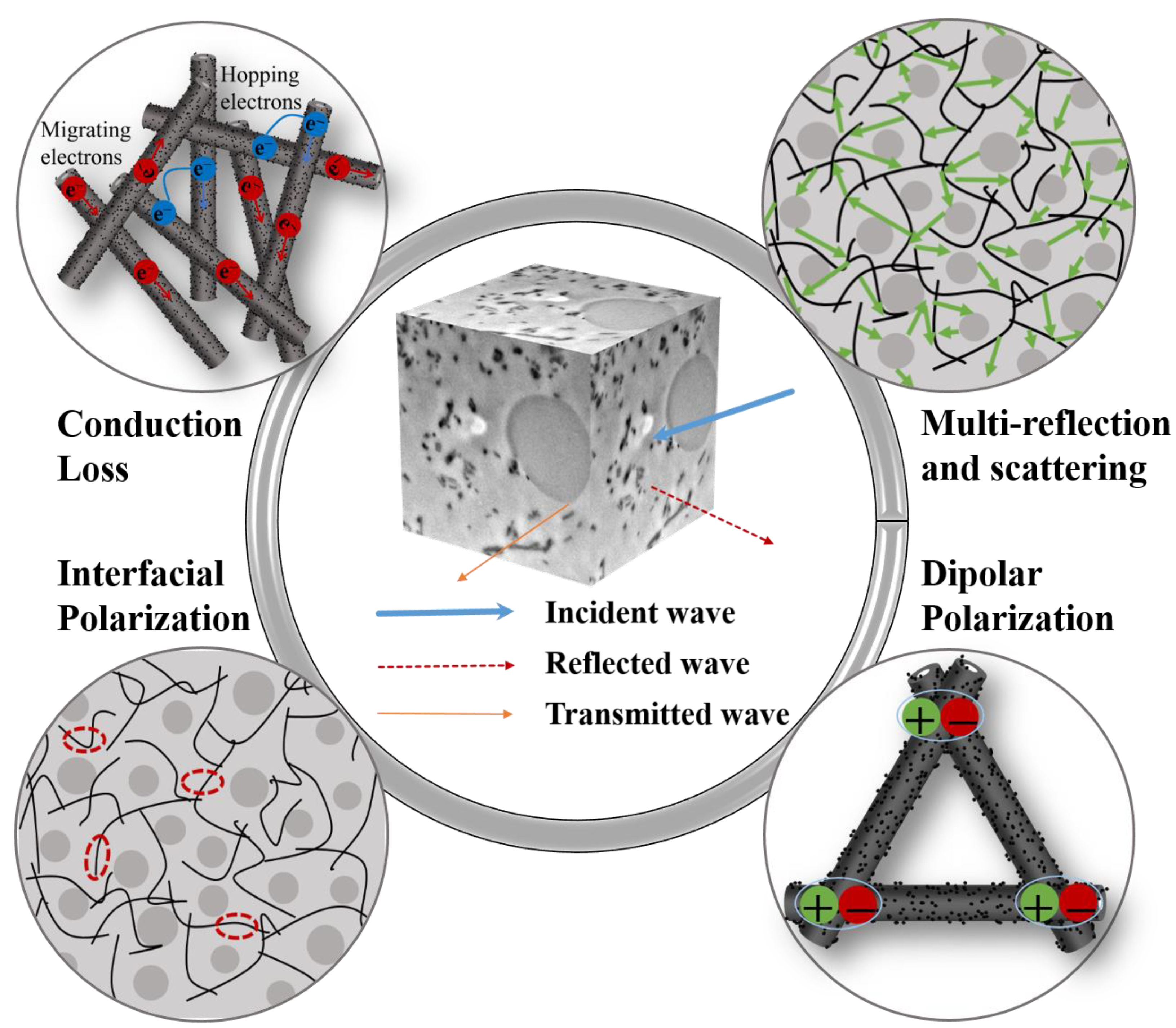

3.2. MA Performance of PPyNT/NR/NBR Composites

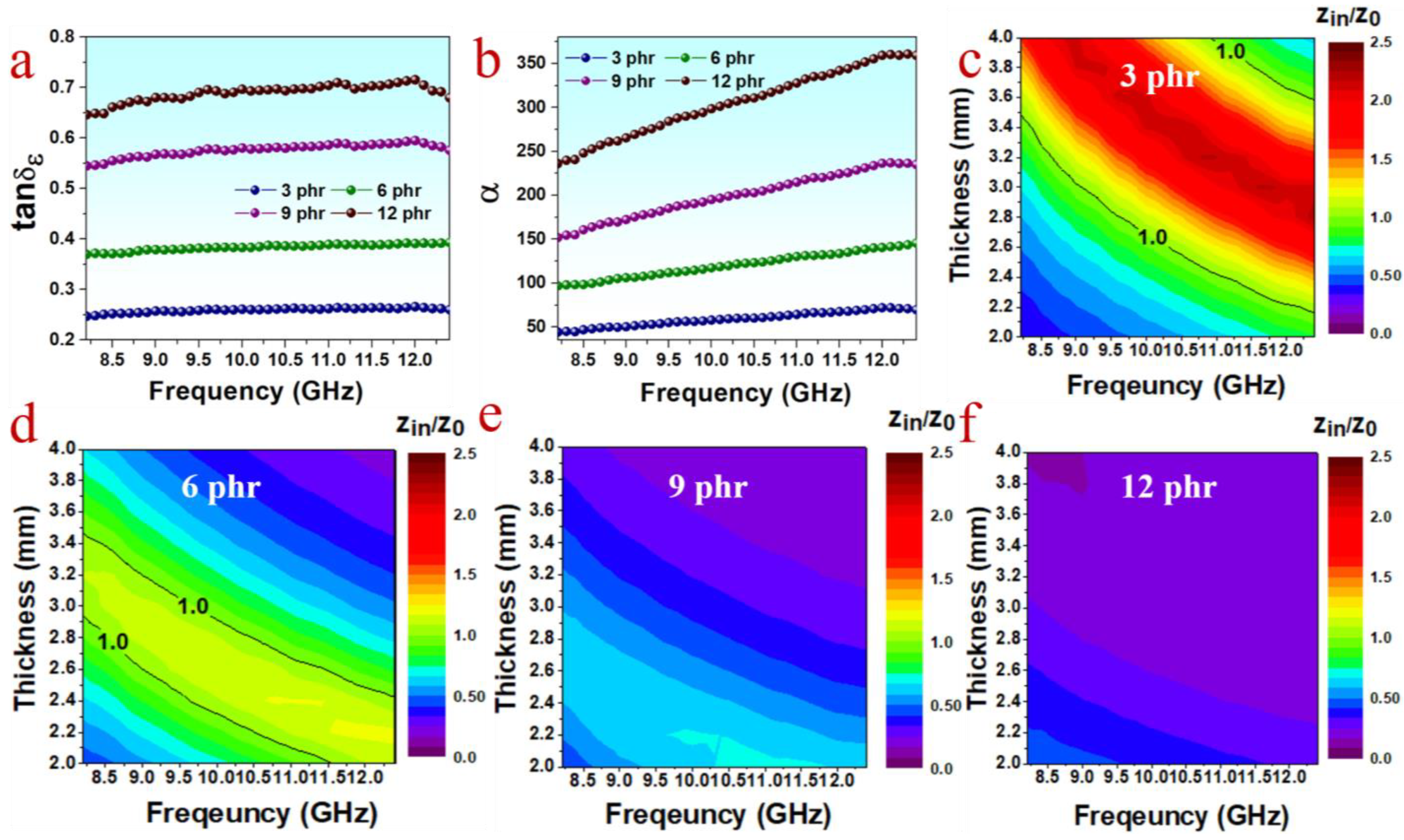

3.2.1. Optimization of PPyNT Content

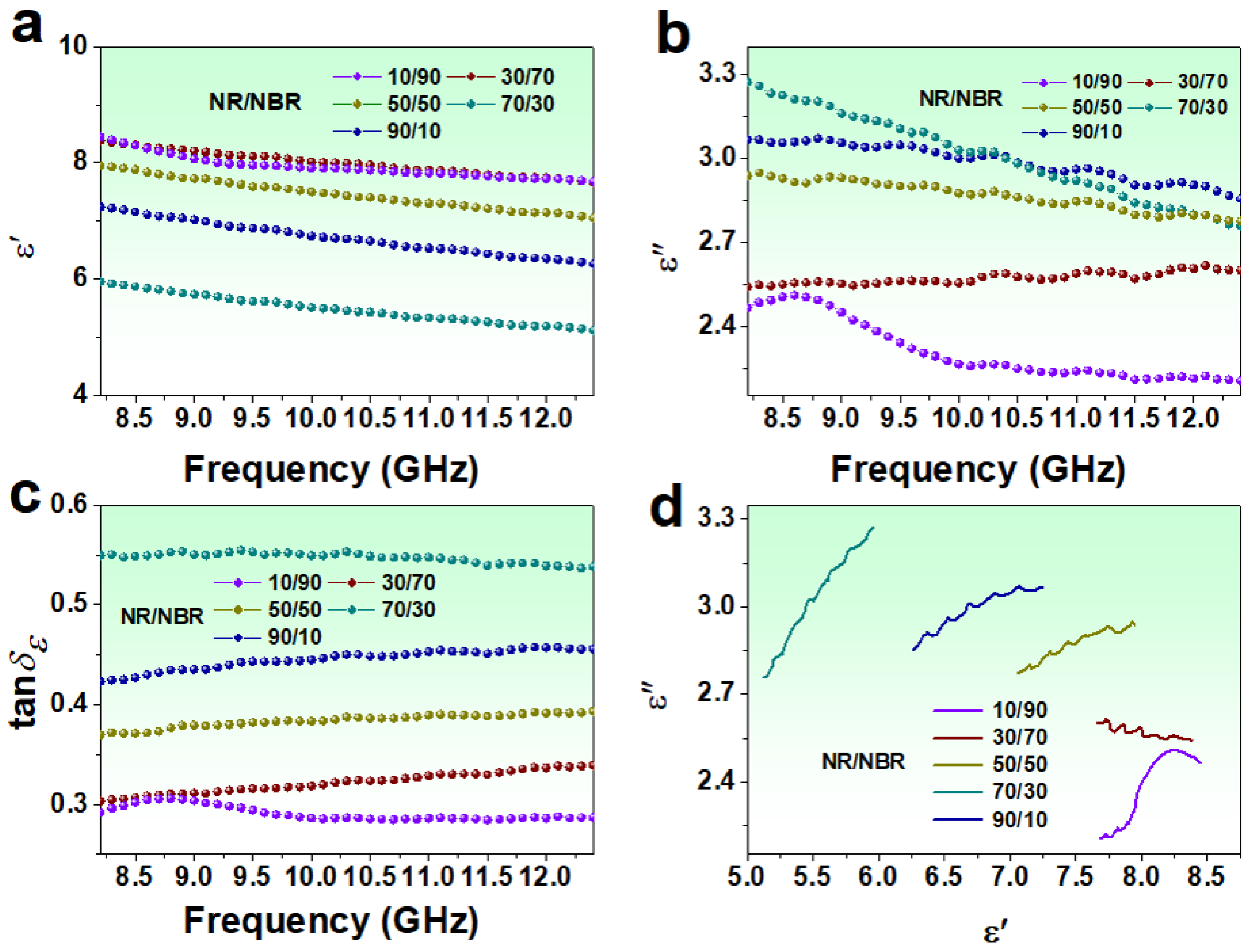

3.2.2. Optimization of the NR/NBR Blend Ratio

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Saini, L.; Jani, R.K.; Janu, Y.; Kumar, M.; Patra, M.K.; Dixit, A. Gamma radiation induced microwave absorption properties of Ultra-thin barium titanate (BaTiO3) ceramic tiles over X-Band (8.2–12.4 GHz). Ceram. Int. 2021, 47, 22397–22403. [Google Scholar] [CrossRef]

- Kruzelak, J.; Kvasnicakova, A.; Usak, E.; Usakova, M.; Dosoudil, R.; Hudec, I. Rubber magnets based on NBR and lithium ferrite with the ability to absorb electromagnetic radiation. Polym. Adv. Technol. 2020, 31, 1624–1633. [Google Scholar] [CrossRef]

- Hu, J.; Liang, C.; Li, J.; Liang, Y.; Li, S.; Li, G.; Wang, Z.; Dong, D. Flexible reduced graphene oxide@Fe3O4/silicone rubber composites for enhanced microwave absorption. Appl. Surf. Sci. 2021, 570, 151270. [Google Scholar] [CrossRef]

- Singh, V.K.; Shukla, A.; Patra, M.K.; Saini, L.; Jani, R.K.; Vadera, S.R.; Kumar, N. Microwave absorbing properties of a thermally reduced graphene oxide/nitrile butadiene rubber composite. Carbon 2012, 50, 2202–2208. [Google Scholar] [CrossRef]

- Vinayasree, S.; Soloman, M.A.; Sunny, V.; Mohanan, P.; Kurian, P.; Anantharaman, M.R. A microwave absorber based on strontium ferrite–carbon black–nitrile rubber for S and X-band applications. Compos. Sci. Technol. 2013, 82, 69–75. [Google Scholar] [CrossRef]

- Zhai, Y.; Zhang, Y.; Ren, W. Electromagnetic characteristic and microwave absorbing performance of different carbon-based hydrogenated acrylonitrile–butadiene rubber composites. Mater. Chem. Phys. 2012, 133, 176–181. [Google Scholar] [CrossRef]

- Chen, C.; Pu, N.; Liu, Y.; Chen, L.; Wu, C.; Cheng, T.; Lin, M.; Ger, M.; Gong, Y.; Peng, Y.; et al. Microwave absorption properties of holey graphene/silicone rubber composites. Compos. B Eng. 2018, 135, 119–128. [Google Scholar] [CrossRef]

- Li, L.; Wang, Z.; Zhao, P.; Luo, Y.; Liao, L.; Xu, K.; Li, P.; Wang, Z.; Peng, Z. Thermodynamics favoured preferential location of nanoparticles in co-continuous rubber blend toward improved electromagnetic properties. Eur. Polym. J. 2017, 92, 275–286. [Google Scholar] [CrossRef]

- Geng, H.; Zhao, P.; Mei, J.; Chen, Y.; Yu, R.; Zhao, Y.; Ding, A.; Peng, Z.; Liao, L.; Liao, J. Improved microwave absorbing performance of natural rubber composite with multi-walled carbon nanotubes and molybdenum disulfide hybrids. Polym. Adv. Technol. 2020, 31, 2752–2762. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Das, T.K.; Ganguly, S.; Paul, S.; Nath, K.; Katheria, A.; Ghosh, T.; Nath Chowdhury, S.; Das, N.C. Carbon nanotubes and carbon nanofibers based co-continuous thermoplastic elastomeric blend composites for efficient microwave shielding and thermal management. Compos. Part A Appl. Sci. Manuf. 2022, 161, 107118. [Google Scholar] [CrossRef]

- Saini, L.; Gupta, V.; Patra, M.K.; Jani, R.K.; Shukla, A.; Kumar, N.; Dixit, A. Impedance engineered microwave absorption properties of Fe-Ni/C core-shell enabled rubber composites for X-band stealth applications. J. Alloys Compd. 2021, 869, 159360. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, C.; Ma, Y.; Zhao, H.; Sui, J.; Liu, J.; Sun, C. Elastic composites fabricating for electromagnetic interference shielding based on MWCNTs and Fe3O4 unique distribution in immiscible NR/NBR blends. Polym. Eng. Sci. 2022, 62, 2019–2030. [Google Scholar] [CrossRef]

- Sultana, S.M.N.; Pawar, S.P.; Sundararaj, U. Effect of Processing Techniques on EMI SE of Immiscible PS/PMMA Blends Containing MWCNT: Enhanced Intertube and Interphase Scattering. Ind. Eng. Chem. Res. 2019, 58, 11576–11584. [Google Scholar] [CrossRef]

- Zhao, P.; Li, L.; Luo, Y.; Lv, Z.; Xu, K.; Li, S.; Zhong, J.; Wang, Z.; Peng, Z. Effect of blend ratio on the morphology and electromagnetic properties of nanoparticles incorporated natural rubber blends. Compos. B Eng. 2016, 99, 216–223. [Google Scholar] [CrossRef]

- Sun, M.; Xu, C.; Li, J.; Xing, L.; Zhou, T.; Wu, F.; Shang, Y.; Xie, A. Protonic doping brings tuneable dielectric and electromagnetic attenuated properties for polypyrrole nanofibers. Chem. Eng. J. 2020, 381, 122615. [Google Scholar] [CrossRef]

- Xie, A.; Wu, F.; Jiang, W.; Zhang, K.; Sun, M.; Wang, M. Chiral induced synthesis of helical polypyrrole (PPy) nano-structures: A lightweight and high-performance material against electromagnetic pollution. J. Mater. Chem. C 2017, 5, 2175–2181. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, X.; Huang, J.; Chen, S.; Zhang, Y.; Dong, C.; Chen, G.; Wang, L.; Guan, H. Enhanced microwave absorption of biomass carbon/nickel/polypyrrole (C/Ni/PPy) ternary composites through the synergistic effects. J. Alloys Compd. 2022, 890, 161887. [Google Scholar] [CrossRef]

- Upadhyay, J.; Kumar, A. Structural, thermal and dielectric studies of polypyrrole nanotubes synthesized by reactive self degrade template method. Mater. Sci. Eng. B 2013, 178, 982–989. [Google Scholar] [CrossRef]

- Yang, X.; Zhu, Z.; Dai, T.; Lu, Y. Facile Fabrication of Functional Polypyrrole Nanotubes via a Reactive Self-Degraded Template. Macromol. Rapid Commun. 2005, 26, 1736–1740. [Google Scholar] [CrossRef]

- Liu, M.; Yang, X.; Shao, W.; Wu, T.; Ji, R.; Fan, B.; Tong, G. Superior microwave absorbing properties of O, S, N codoped carbon planar helixes via carbonization of polypyrrole spiral nanowires. Carbon 2021, 174, 625–637. [Google Scholar] [CrossRef]

- Zhu, Q.; Li, E.; Liu, X.; Song, W.; Li, Y.; Wang, X.; Liu, C. Epoxy coating with in-situ synthesis of polypyrrole functionalized graphene oxide for enhanced anticorrosive performance. Prog. Org. Coat. 2020, 140, 105488. [Google Scholar] [CrossRef]

- Sharika, T.; Abraham, J.; ArifP, M.; George, S.C.; Kalarikkal, N.; Thomas, S. Excellent electromagnetic shield derived from MWCNT reinforced NR/PP blend nanocomposites with tailored microstructural properties. Compos. B Eng. 2019, 173, 106798. [Google Scholar] [CrossRef]

- Qin, M.; Zhang, L.; Wu, H. Dielectric Loss Mechanism in Electromagnetic Wave Absorbing Materials. Adv. Sci. (Weinh) 2022, 9, e2105553. [Google Scholar] [CrossRef]

- Tan, Y.; Li, J.; Tang, X.; Yue, T.; Wang, M. Effect of phase morphology and distribution of multi-walled carbon nanotubes on microwave shielding of poly(l-lactide)/poly(ε-caprolactone) composites. Compos. Part A Appl. Sci. Manuf. 2020, 137, 106008. [Google Scholar] [CrossRef]

- Han, T.; Nagarajan, S.; Zhao, H.; Sun, C.; Wen, S.; Zhao, S.; Zhao, S.; Zhang, L. Novel reinforcement behavior in nanofilled natural rubber (NR)/butadiene-acrylonitrile rubber (NBR) blends: Filling-polymer network and supernanosphere. Polymer 2020, 186, 122005. [Google Scholar] [CrossRef]

- Veena, M.G.; Renukappa, N.M.; Shivakumar, K.N.; Seetharamu, S. Dielectric properties of nanosilica filled epoxy nanocomposites. Sādhanā 2016, 41, 407–414. [Google Scholar] [CrossRef] [Green Version]

- Lei, L.; Yao, Z.; Zhou, J.; Wei, B.; Fan, H. 3D printing of carbon black/polypropylene composites with excellent microwave absorption performance. Compos. Sci. Technol. 2020, 200, 108479. [Google Scholar] [CrossRef]

- Yuan, J.; Yao, S.; Sylvestre, A.; Bai, J. Biphasic Polymer Blends Containing Carbon Nanotubes: Heterogeneous Nanotube Distribution and Its Influence on the Dielectric Properties. J. Phys. Chem. C 2012, 116, 2051–2058. [Google Scholar] [CrossRef]

- Lin, X.; Cheng, S.; Wu, F.; Li, Y.; Zhuang, Q.; Dong, W.; Xie, A. Connecting of conjugate microporous polymer nanoparticles by polypyrrole via sulfonic acid doping to form conductive nanocomposites for excellent microwaves absorption. Compos. Sci. Technol. 2022, 221, 109350. [Google Scholar] [CrossRef]

- Chen, L.; Liu, F.; Sui, J.; Waterhouse, G.I.N.; Zhang, Z.; Yu, L. Carbon doped with binary heteroatoms (N,X–C, where X = P, B, or S) derived from polypyrrole for enhanced electromagnetic wave absorption at microwave frequencies. Ceram. Int. 2023, 49, 4252–4263. [Google Scholar] [CrossRef]

- Wu, G.; Cheng, Y.; Yang, Z.; Jia, Z.; Wu, H.; Yang, L.; Li, H.; Guo, P.; Lv, H. Design of carbon sphere/magnetic quantum dots with tunable phase compositions and boost dielectric loss behavior. Chem. Eng. J. 2018, 333, 519–528. [Google Scholar] [CrossRef]

- Shi, Y.; Yu, L.; Li, K.; Li, S.; Dong, Y.; Zhu, Y.; Fu, Y.; Meng, F. Well-matched impedance of polypyrrole-loaded cotton non-woven fabric/polydimethylsiloxane composite for extraordinary microwave absorption. Compos. Sci. Technol. 2020, 197, 108246. [Google Scholar] [CrossRef]

- Wen, B.; Cao, M.; Hou, Z.; Song, W.; Zhang, L.; Lu, M.; Jin, H.; Fang, X.; Wang, W.; Yuan, J. Temperature dependent microwave attenuation behavior for carbon-nanotube/silica composites. Carbon 2013, 65, 124–139. [Google Scholar] [CrossRef]

- Ran, K.; Wang, W.; Hou, X.; Huang, Y.; Zhang, Z.; He, D.; Fang, Y.; Wang, S.; Zhao, R.; Xue, W. Oxygen plasma modulates the interfacial impedance of microwave reduced graphene oxide for enhanced microwave absorption. J. Alloys Compd. 2022, 924, 166568. [Google Scholar] [CrossRef]

- Flaifel, M.H.; Ahmad, S.H.; Abdullah, M.H.; Rasid, R.; Shaari, A.H.; El-Saleh, A.A.; Appadu, S. Preparation, thermal, magnetic and microwave absorption properties of thermoplastic natural rubber matrix impregnated with NiZn ferrite nanoparticles. Compos. Sci. Technol. 2014, 96, 103–108. [Google Scholar] [CrossRef]

| Sample | RLmin dB | EAB GHz | Thickness mm | Filler Loading (wt.%) | Ref. |

|---|---|---|---|---|---|

| Fe-Ni/C/NBR | −8~−10 | 0 | 1.5 | 70 | [11] |

| CBSrF/NBR | −16 | 1.5 | 5 | 20.73 | [5] |

| CB/NR | >−5 | 0 | 5 | 14.2 | [8] |

| CCB/NR/ENR (70/30) | >−10 | 0 | 5.5 | 30 | [14] |

| MWCNT/HNBR | −21.3 | Not mentioned | 2 | 8.26 | [6] |

| rGO@Fe3O4/SR | −22.5 | 2.1 | 1.5 | 50 | [3] |

| NiZn/TPNR | −38.3 | Not mentioned | 7 | 12 | [35] |

| RGO/NR | −57 | 3.8 | 3 | 10 | [4] |

| PPyNT/NR/NBR (90/10) | −56.67 | 3.7 | 2.9 | 5.24 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Wang, A.; Feng, X.; Dong, H.; Zhuang, T.; Sui, J.; Zhao, S.; Sun, C. PPyNT/NR/NBR Composites with Excellent Microwave Absorbing Performance in X-Band. Polymers 2023, 15, 1866. https://doi.org/10.3390/polym15081866

Yang H, Wang A, Feng X, Dong H, Zhuang T, Sui J, Zhao S, Sun C. PPyNT/NR/NBR Composites with Excellent Microwave Absorbing Performance in X-Band. Polymers. 2023; 15(8):1866. https://doi.org/10.3390/polym15081866

Chicago/Turabian StyleYang, Huiru, Aiping Wang, Xincong Feng, Hailing Dong, Tao Zhuang, Jing Sui, Shugao Zhao, and Chong Sun. 2023. "PPyNT/NR/NBR Composites with Excellent Microwave Absorbing Performance in X-Band" Polymers 15, no. 8: 1866. https://doi.org/10.3390/polym15081866