Bio-Sourced, High-Performance Carbon Fiber Reinforced Itaconic Acid-Based Epoxy Composites with High Hygrothermal Stability and Durability

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

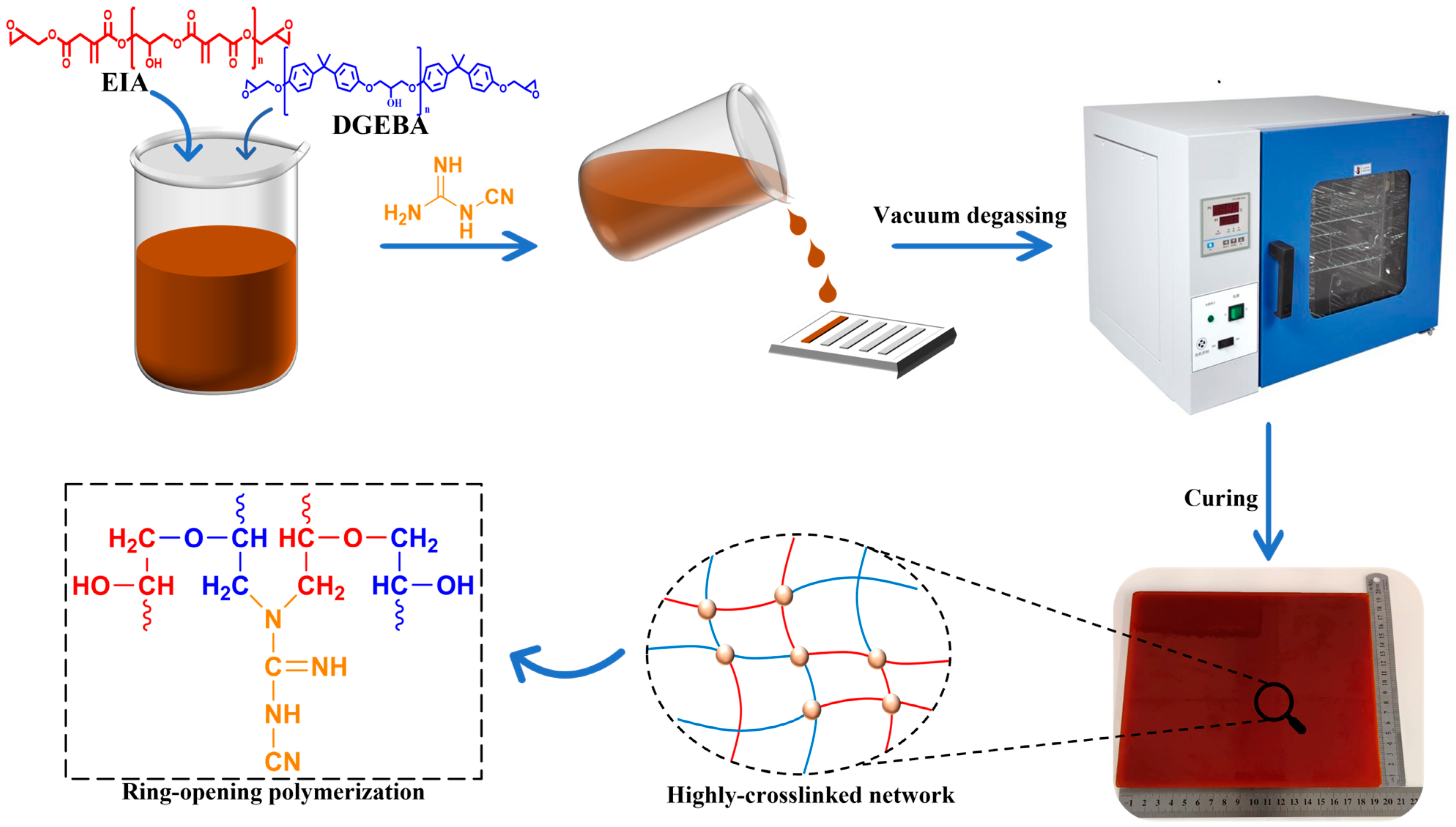

2.2. Preparation of the Cured Epoxy Resin

2.3. Preparation of Carbon Fiber Composite Laminates

2.4. Hygrothermal Aging

2.5. Characterization

3. Results and Discussion

3.1. Moisture Uptake Behavior

3.2. FT-IR Analysis of Composites before and after Hygrothermal Aging

3.3. Mechanical Properties of the CFRP Composite

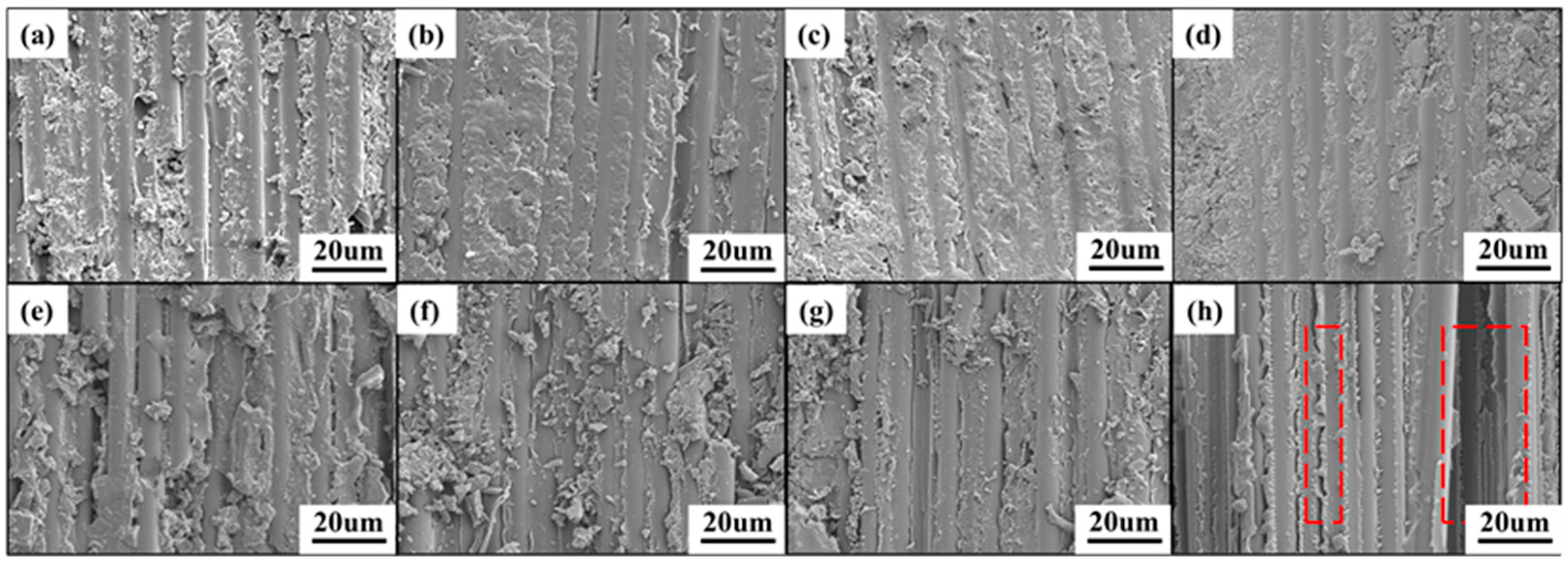

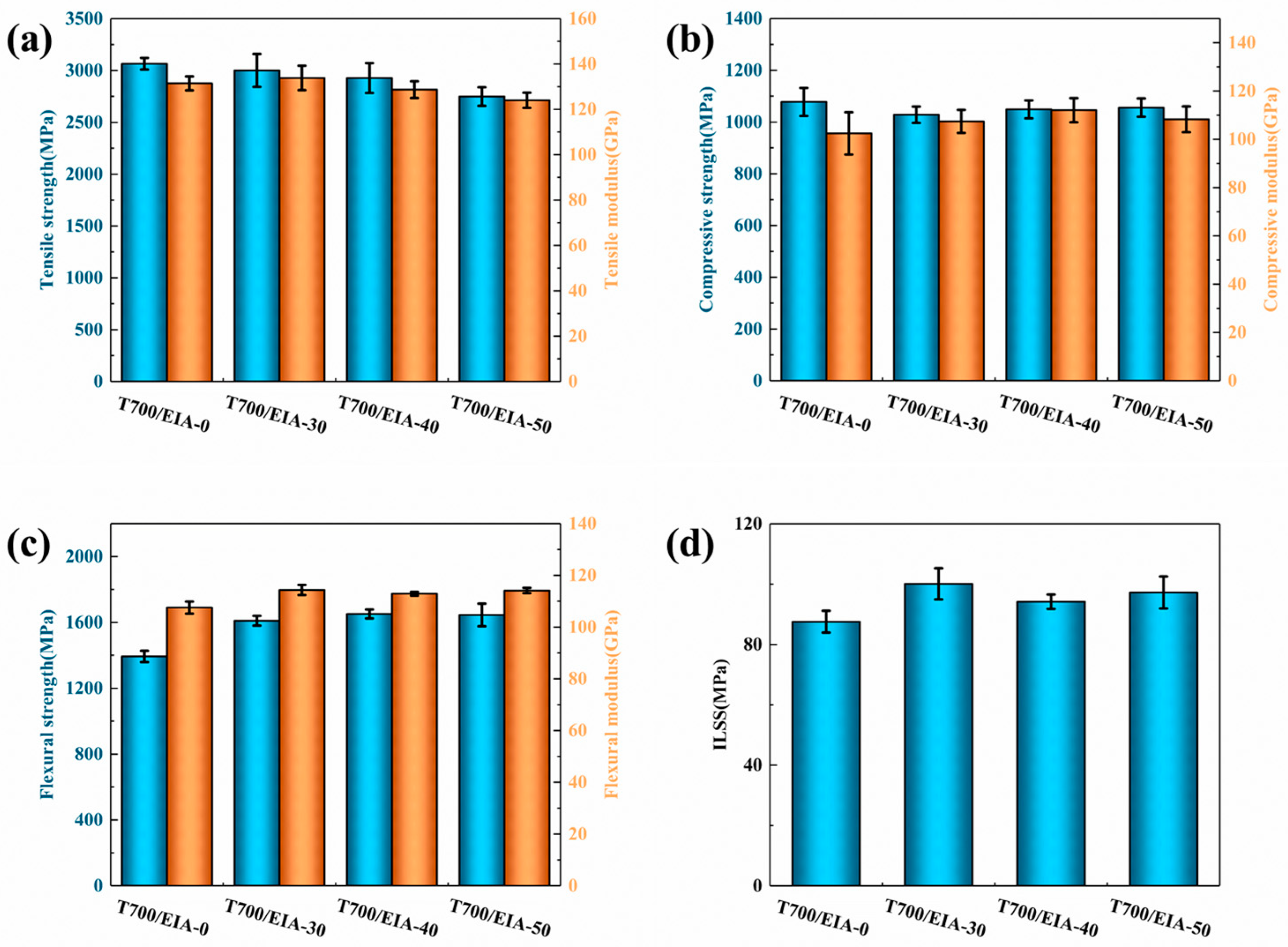

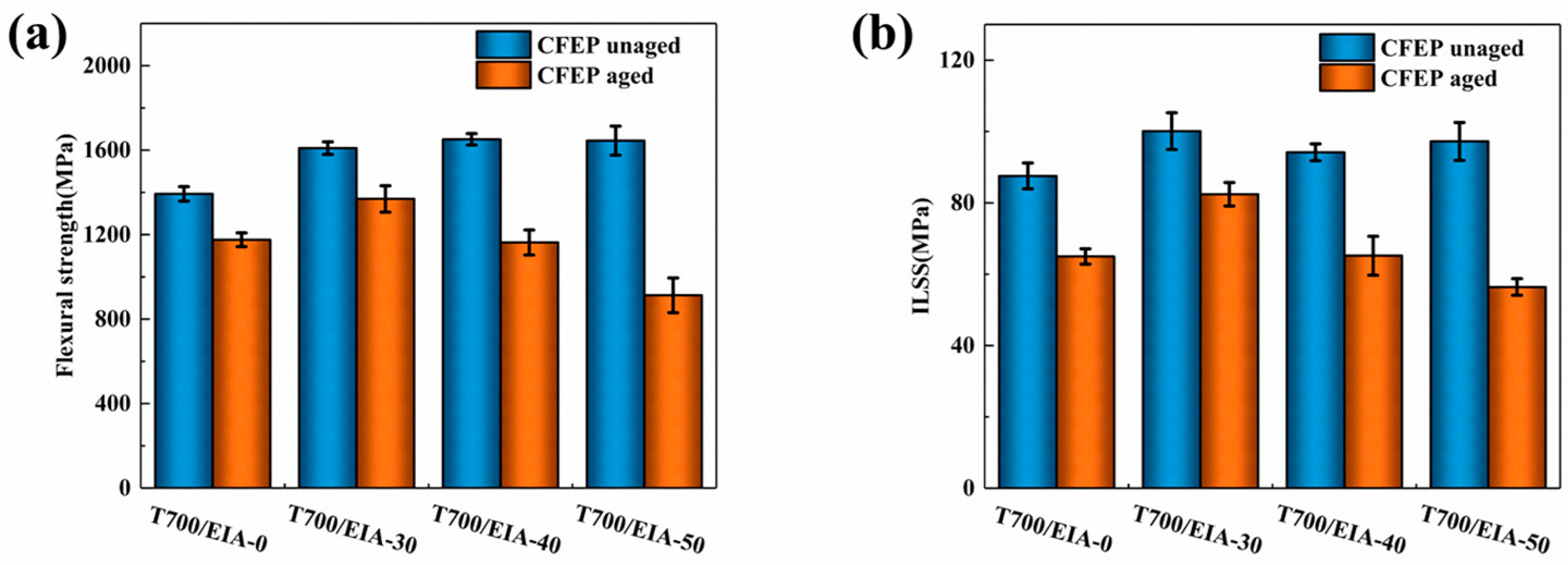

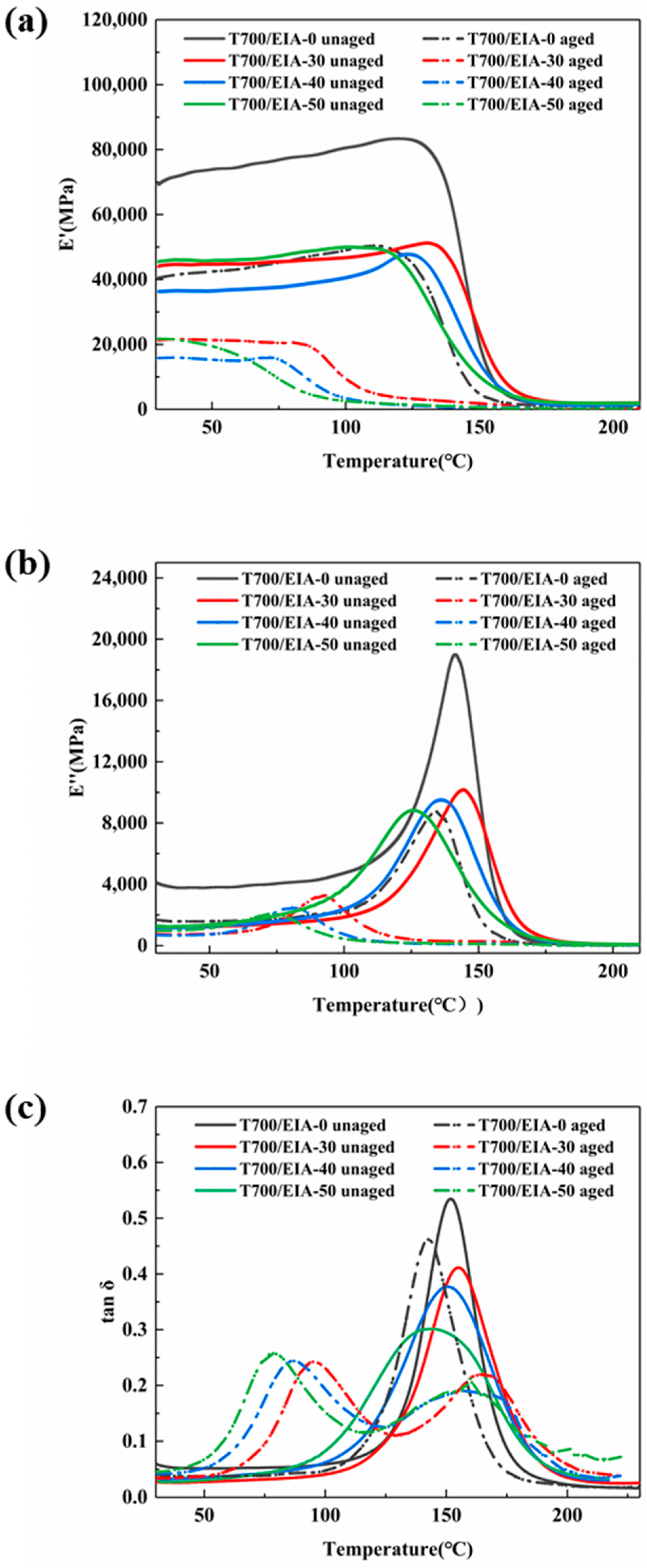

3.4. Thermodynamic Properties of Composites

3.5. Thermal Degradation Behavior of the Composites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Mazzon, E.; Habas-Ulloa, A.; Habas, J.-P. Lightweight rigid foams from highly reactive epoxy resins derived from vegetable oil for automotive applications. Eur. Polym. J. 2015, 68, 546–557. [Google Scholar] [CrossRef]

- Diez-Barcenilla, G.; Salvador, A.A.; Zubieta, K.G.; Zuza, E. Epoxy matrix composites from waste for manufacturing tools for energy efficient moulding process. Clean Technol. Environ. Policy 2022, 24, 1793–1810. [Google Scholar] [CrossRef]

- Stefan, W.; Petra, V.; Peter, M.; Nerea, M. Investigations on thermoforming of carbon fiber reinforced epoxy vitrimer composites. Compos. Part A Appl. Sci. Manuf. 2021, 154, 106791. [Google Scholar] [CrossRef]

- Carter, J.T.; Emmerson, G.T.; Faro, C.L.; McGrail, P.T.; Moore, D.R. The development of a low temperature cure modified epoxy resin system for aerospace composites. Compos. Part A Appl. Sci. Manuf. 2003, 34, 83–91. [Google Scholar] [CrossRef]

- Mordor Intelligence Research & Advisory. Epoxy Resin Market Size & Share Analysis—Growth Trends & Forecasts (2024–2029). Available online: https://www.mordorintelligence.com/industry-reports/global-epoxy-resin-market-industry (accessed on 31 May 2024).

- Ďurovcová, I.; Kyzek, S.; Fabová, J.; Makuková, J.; Gálová, E.; Ševčovičová, A. Genotoxic potential of bisphenol A: A review. Environ. Pollut. 2022, 306, 119346. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Chen, T.; Wang, X.; Zheng, Y.; Zheng, J.; Song, G.; Liu, S. Recent Progress on Moisture Absorption Aging of Plant Fiber Reinforced Polymer Composites. Polymers 2023, 15, 4121. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, F.C.; Kirwan, K.; Lehane, D.; Coles, S.R. Epoxy resin blends and composites from waste vegetable oil. Eur. Polym. J. 2017, 89, 449–460. [Google Scholar] [CrossRef]

- Marriam, F.; Irshad, A.; Umer, I.; Asghar, M.A.; Atif, M. Vegetable oils as bio-based precursors for epoxies. Sustain. Chem. Pharm. 2023, 31, 100935. [Google Scholar] [CrossRef]

- Nikafshar, S.; Wang, J.; Dunne, K.; Sangthonganotai, P.; Nejad, M. Choosing the Right Lignin to Fully Replace Bisphenol A in Epoxy Resin Formulation. ChemSusChem 2021, 14, 1184–1195. [Google Scholar] [CrossRef]

- Nicastro, K.H.; Kloxin, C.J.; Epps, T.H., III. Potential Lignin-Derived Alternatives to Bisphenol A in Diamine-Hardened Epoxy Resins. ACS Sustain. Chem. Eng. 2018, 6, 14812–14819. [Google Scholar] [CrossRef]

- Mantzaridis, C.; Brocas, A.-L.; Llevot, A.; Cendejas, G.; Auvergne, R.; Caillol, S.; Carlotti, S.; Cramail, H. Rosin acid oligomers as precursors of DGEBA-free epoxy resins. Green Chem. 2013, 15, 3091–3098. [Google Scholar] [CrossRef]

- Wang, H.; Liu, B.; Liu, X.; Zhang, J.; Xian, M. Synthesis of biobased epoxy and curing agents using rosin and the study of cure reactions. Green Chem. 2008, 10, 1190–1196. [Google Scholar] [CrossRef]

- Tserpes, K.; Tzatzadakis, V.; Katsiropoulos, C. Effect of hygrothermal ageing on the interlaminar shear strength of carbon fiber-reinforced rosin-based epoxy bio-composites. Compos. Struct. 2019, 226, 111211. [Google Scholar] [CrossRef]

- Mora, A.-S.; Decostanzi, M.; David, G.; Caillol, S. Cardanol-Based Epoxy Monomers for High Thermal Properties Thermosets. Eur. J. Lipid Sci. Technol. 2019, 121, 1800421. [Google Scholar] [CrossRef]

- Kinaci, E.; Can, E.; Scala, J.J.L.; Palmese, G.R. Influence of Epoxidized Cardanol Functionality and Reactivity on Network Formation and Properties. Polymers 2020, 12, 1956. [Google Scholar] [CrossRef] [PubMed]

- Eid, N.; Ameduri, B.; Boutevin, B. Synthesis and Properties of Furan Derivatives for Epoxy Resins. ACS Sustain. Chem. Eng. 2021, 9, 8018–8031. [Google Scholar] [CrossRef]

- Xu, J.; Liu, X.; Fu, S. Bio-based epoxy resin from gallic acid and its thermosets toughened with renewable tannic acid derivatives. J. Mater. Sci. 2022, 57, 9493–9507. [Google Scholar] [CrossRef]

- Hou, G.; Li, N.; Han, H.; Run, M.; Gao, J. Preparation and thermal properties of bio-based gallic acid epoxy/carbon nanotubes composites by cationic ring-opening reaction. Polym. Compos. 2016, 37, 3093–3102. [Google Scholar] [CrossRef]

- Hong, J.; Radojcic, D.; Ionescu, M.; Petrović, Z.; Eastwood, E. Advanced Materials from Corn: Isosorbide-Based Epoxy Resins. Polym. Chem. 2014, 5, 5360–5368. [Google Scholar] [CrossRef]

- Ma, S.; Liu, X.; Jiang, Y.; Tang, Z.; Zhang, C.; Zhu, J. Bio-based epoxy resin from itaconic acid and its thermosets cured with anhydride and comonomers. Green Chem. 2013, 15, 245–254. [Google Scholar] [CrossRef]

- Ramon, E.; Sguazzo, C.; Moreira, P. A Review of Recent Research on Bio-Based Epoxy Systems for Engineering Applications and Potentialities in the Aviation Sector. Aerospace 2018, 5, 110. [Google Scholar] [CrossRef]

- Deng, L.; Wang, Z.; Qu, B.; Liu, Y.; Qiu, W.; Qi, S. A Comparative Study on the Properties of Rosin-Based Epoxy Resins with Different Flexible Chains. Polymers 2023, 15, 4246. [Google Scholar] [CrossRef] [PubMed]

- Kathalewar, M.; Sabnis, A. Epoxy resin from cardanol as partial replacement of bisphenol-A-based epoxy for coating application. J. Coat. Technol. Res. 2014, 11, 601–618. [Google Scholar] [CrossRef]

- Dutta, K.; Karak, N. Bisphenol-A free bio-based gallic acid amide epoxy thermosets. J. Appl. Polym. Sci. 2023, 140, e54306. [Google Scholar] [CrossRef]

- Łukaszczyk, J.; Janicki, B.; Kaczmarek, M. Synthesis and properties of isosorbide based epoxy resin. Eur. Polym. J. 2011, 47, 1601–1606. [Google Scholar] [CrossRef]

- Saha, B.C.; Kennedy, G.J.; Qureshi, N.; Bowman, M.J. Production of itaconic acid from pentose sugars by Aspergillus terreus. Biotechnol. Prog. 2017, 33, 1059–1067. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.; Song, C.W.; Shin, J.H.; Lee, S.Y. Biorefineries for the production of top building block chemicals and their derivatives. Metab. Eng. 2015, 28, 223–239. [Google Scholar] [CrossRef] [PubMed]

- Diankristanti, P.A.; Ng, I.S. Microbial itaconic acid bioproduction towards sustainable development: Insights, challenges, and prospects. Bioresour. Technol. 2023, 384, 129280. [Google Scholar] [CrossRef] [PubMed]

- Rebolledo-Leiva, R.; Moreira, M.T.; González-García, S. Environmental assessment of the production of itaconic acid from wheat straw under a biorefinery approach. Bioresour. Technol. 2022, 345, 126481. [Google Scholar] [CrossRef]

- Magalhães, A.I.; de Carvalho, J.C.; Medina, J.D.C.; Soccol, C.R. Downstream process development in biotechnological itaconic acid manufacturing. Appl. Microbiol. Biotechnol. 2017, 101, 1–12. [Google Scholar] [CrossRef]

- Ma, S.; Liu, X.; Fan, L.; Jiang, Y.; Cao, L.; Tang, Z.; Zhu, J. Synthesis and Properties of a Bio-Based Epoxy Resin with High Epoxy Value and Low Viscosity. ChemSusChem 2014, 7, 555–562. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; Liu, X.; Jiang, Y.; Fan, L.; Feng, J.; Zhu, J. Synthesis and properties of phosphorus-containing bio-based epoxy resin from itaconic acid. Sci. China-Chem. 2014, 57, 379–388. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, B.; Ma, S.; Yu, T.; Xu, X.; Li, Q.; Wang, S.; Han, Y.; Yu, Z.; Zhu, J. Catalyst-free malleable, degradable, bio-based epoxy thermosets and its application in recyclable carbon fiber composites. Compos. Part B Eng. 2021, 211, 108654. [Google Scholar] [CrossRef]

- Almudaihesh, F.; Holford, K.; Pullin, R.; Eaton, M. The influence of water absorption on unidirectional and 2D woven CFRP composites and their mechanical performance. Compos. Part B Eng. 2020, 182, 107626. [Google Scholar] [CrossRef]

- Wong, T.C.; Broutman, L.J. Water in epoxy resins Part II. Diffusion mechanism. Polym. Eng. Sci. 1985, 25, 529–534. [Google Scholar] [CrossRef]

- Zhou, J.; Lucas, J.P. Hygrothermal effects of epoxy resin. Part I: The nature of water in epoxy. Polymer 1999, 40, 5505–5512. [Google Scholar] [CrossRef]

- Mijović, J.; Zhang, H. Local Dynamics and Molecular Origin of Polymer Network−Water Interactions as Studied by Broadband Dielectric Relaxation Spectroscopy, FTIR, and Molecular Simulations. Macromolecules 2003, 36, 1279–1288. [Google Scholar] [CrossRef]

- Korkees, F.; Alston, S.; Arnold, C. Directional diffusion of moisture into unidirectional carbon fiber/epoxy Composites: Experiments and modeling. Polym. Compos. 2018, 39, E2305–E2315. [Google Scholar] [CrossRef]

- Bone, J.E.; Sims, G.D.; Maxwell, A.S.; Frenz, S.; Ogin, S.L.; Foreman, C.; Dorey, R.A. On the relationship between moisture uptake and mechanical property changes in a carbon fibre/epoxy composite. J. Compos. Mater. 2022, 56, 2189–2199. [Google Scholar] [CrossRef]

- Beura, S.; Chakraverty, A.P.; Pati, S.N.; Pradhan, D.D.; Thatoi, D.N.; Mohanty, U.K. Effect of salinity and strain rate on sea water aged GFRP composite for marine applications. Mater. Today Commun. 2023, 34, 105056. [Google Scholar] [CrossRef]

- Shi, Z.; Zou, C.; Zhou, F.; Zhao, J. Analysis of the Mechanical Properties and Damage Mechanism of Carbon Fiber/Epoxy Composites under UV Aging. Materials 2022, 15, 2919. [Google Scholar] [CrossRef] [PubMed]

- Aslan, A.; Salur, E.; Düzcükoğlu, H.; Sinan Şahin, Ö.; Ekrem, M. The effects of harsh aging environments on the properties of neat and MWCNT reinforced epoxy resins. Constr. Build. Mater. 2021, 272, 121929. [Google Scholar] [CrossRef]

- Shen, M.; Almallahi, R.; Rizvi, Z.; Gonzalez-Martinez, E.; Yang, G.; Robertson, M.L. Accelerated hydrolytic degradation of ester-containing biobased epoxy resins. Polym. Chem. 2019, 10, 3217–3229. [Google Scholar] [CrossRef]

- ASTM D5229/D5229M; Standard Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D3039; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D6641; Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM D7264; Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D2344; Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates. ASTM International: West Conshohocken, PA, USA, 2022.

- Korkees, F. Moisture absorption behavior and diffusion characteristics of continuous carbon fiber reinforced epoxy composites: A review. Polym.-Plast. Technol. Mater. 2023, 62, 1789–1822. [Google Scholar] [CrossRef]

- Zhavoronok, E.S.; Senchikhin, I.N.; Roldughin, V.I. Physical aging and relaxation processes in epoxy systems. Polym. Sci. Ser. A 2017, 59, 159–192. [Google Scholar] [CrossRef]

- McConnell, B.K.; Pethrick, R.A. Dielectric studies of water absorption and desorption in epoxy resins: Influence of cure process on behaviour. Polym. Int. 2008, 57, 689–699. [Google Scholar] [CrossRef]

- Li, K.; Wang, K.; Zhan, M.-S.; Xu, W. The change of thermal–mechanical properties and chemical structure of ambient cured DGEBA/TEPA under accelerated thermo-oxidative aging. Polym. Degrad. Stab. 2013, 98, 2340–2346. [Google Scholar] [CrossRef]

- Kumar, S.; Samal, S.K.; Mohanty, S.; Nayak, S.K. Curing kinetics of bio-based epoxy resin-toughened DGEBA epoxy resin blend: Synthesis and characterization. J. Therm. Anal. Calorim. 2019, 137, 1567–1578. [Google Scholar] [CrossRef]

- Behera, A.; Vishwakarma, A.; Thawre, M.M.; Ballal, A. Effect of hygrothermal aging on static behavior of quasi-isotropic CFRP composite laminate. Compos. Commun. 2020, 17, 51–55. [Google Scholar] [CrossRef]

- Xian, G.; Karbhari, V.M. DMTA based investigation of hygrothermal ageing of an epoxy system used in rehabilitation. J. Appl. Polym. Sci. 2007, 104, 1084–1094. [Google Scholar] [CrossRef]

- Xian, G.; Karbhari, V.M. Segmental relaxation of water-aged ambient cured epoxy. Polym. Degrad. Stab. 2007, 92, 1650–1659. [Google Scholar] [CrossRef]

| Sample | EIA (wt%) | DGEBA (wt%) | E-20 (wt%) | DICY (wt%) | GLOC-500 (wt%) |

|---|---|---|---|---|---|

| EIA-0 | 0 | 70 | 20 | 8 | 2 |

| EIA-30 | 30 | 50 | 20 | 8 | 2 |

| EIA-40 | 40 | 40 | 20 | 8 | 2 |

| EIA-50 | 50 | 30 | 20 | 8 | 2 |

| Sample | Tensile Strength/MPa | Compressive Strength/MPa | Flexural Strength/MPa | Retention Rate of Flexural Strength/% | ILSS/MPa | Retention Rate of ILSS/% | |

|---|---|---|---|---|---|---|---|

| T700/EIA-0 | Unaged | 3064.70 | 1077.79 | 1393.22 | 100 | 87.54 | 100 |

| aged | - | - | 1175.89 | 84.40 | 64.98 | 74.23 | |

| T700/EIA-30 | Unaged | 3000.74 | 1077.79 | 1609.67 | 100 | 100.11 | 100 |

| aged | - | - | 1369.23 | 85.06 | 82.42 | 82.33 | |

| T700/EIA-40 | Unaged | 2927.52 | 1048.90 | 1651.34 | 100 | 94.17 | 100 |

| aged | - | - | 1162.78 | 70.41 | 65.17 | 69.20 | |

| T700/EIA-50 | Unaged | 2748.62 | 1055.77 | 1644.89 | 100 | 97.24 | 100 |

| aged | - | - | 912.53 | 55.48 | 56.41 | 58.01 | |

| Sample | Initial Storage Modulus/GPa | Initial Loss Modulus/GPa | Tg/°C | Td5%/°C | |

|---|---|---|---|---|---|

| T700/EIA-0 | Unaged | 69.27 | 4.12 | 151.91 | 318.62 |

| aged | 40.56 | 1.68 | 142.57 | 319.87 | |

| T700/EIA-30 | Unaged | 44.05 | 1.20 | 155.12 | 322.18 |

| aged | 21.59 | 0.72 | 94.88 | 322.62 | |

| T700/EIA-40 | Unaged | 36.29 | 1.17 | 150.44 | 305.63 |

| aged | 15.81 | 0.68 | 86.77 | 308.81 | |

| T700/EIA-50 | Unaged | 45.48 | 1.28 | 143.63 | 293.73 |

| aged | 21.60 | 0.97 | 80.98 | 300.55 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, K.; Fang, Y.; Wang, Z.; Ni, N.; Liu, Z.; Kim, S.; An, Z.; Lyu, Z.; Xu, Y.; Yang, X. Bio-Sourced, High-Performance Carbon Fiber Reinforced Itaconic Acid-Based Epoxy Composites with High Hygrothermal Stability and Durability. Polymers 2024, 16, 1649. https://doi.org/10.3390/polym16121649

Xiao K, Fang Y, Wang Z, Ni N, Liu Z, Kim S, An Z, Lyu Z, Xu Y, Yang X. Bio-Sourced, High-Performance Carbon Fiber Reinforced Itaconic Acid-Based Epoxy Composites with High Hygrothermal Stability and Durability. Polymers. 2024; 16(12):1649. https://doi.org/10.3390/polym16121649

Chicago/Turabian StyleXiao, Kaixuan, Yuan Fang, Zhaodi Wang, Nannan Ni, Ziqian Liu, Soochan Kim, Zongfu An, Zhiyi Lyu, Yahong Xu, and Xin Yang. 2024. "Bio-Sourced, High-Performance Carbon Fiber Reinforced Itaconic Acid-Based Epoxy Composites with High Hygrothermal Stability and Durability" Polymers 16, no. 12: 1649. https://doi.org/10.3390/polym16121649

APA StyleXiao, K., Fang, Y., Wang, Z., Ni, N., Liu, Z., Kim, S., An, Z., Lyu, Z., Xu, Y., & Yang, X. (2024). Bio-Sourced, High-Performance Carbon Fiber Reinforced Itaconic Acid-Based Epoxy Composites with High Hygrothermal Stability and Durability. Polymers, 16(12), 1649. https://doi.org/10.3390/polym16121649