Laser-Sintering of Cyclic Olefine Copolymer for Low Dielectric Loss Applications

Abstract

:1. Introduction

2. State of the Art

3. Materials and Methods

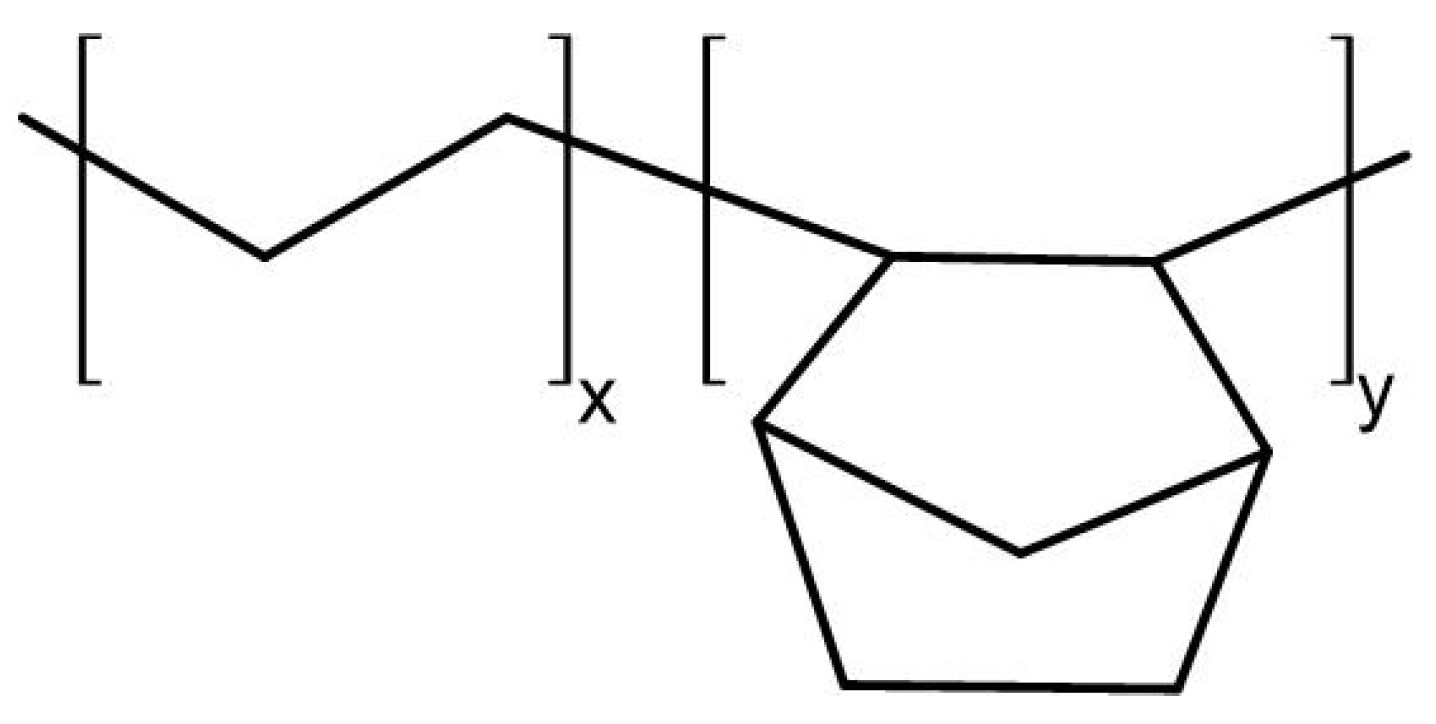

3.1. Material

3.2. Part Generation

3.3. Methods

3.3.1. Material Analysis

3.3.2. Part Analysis

4. Results

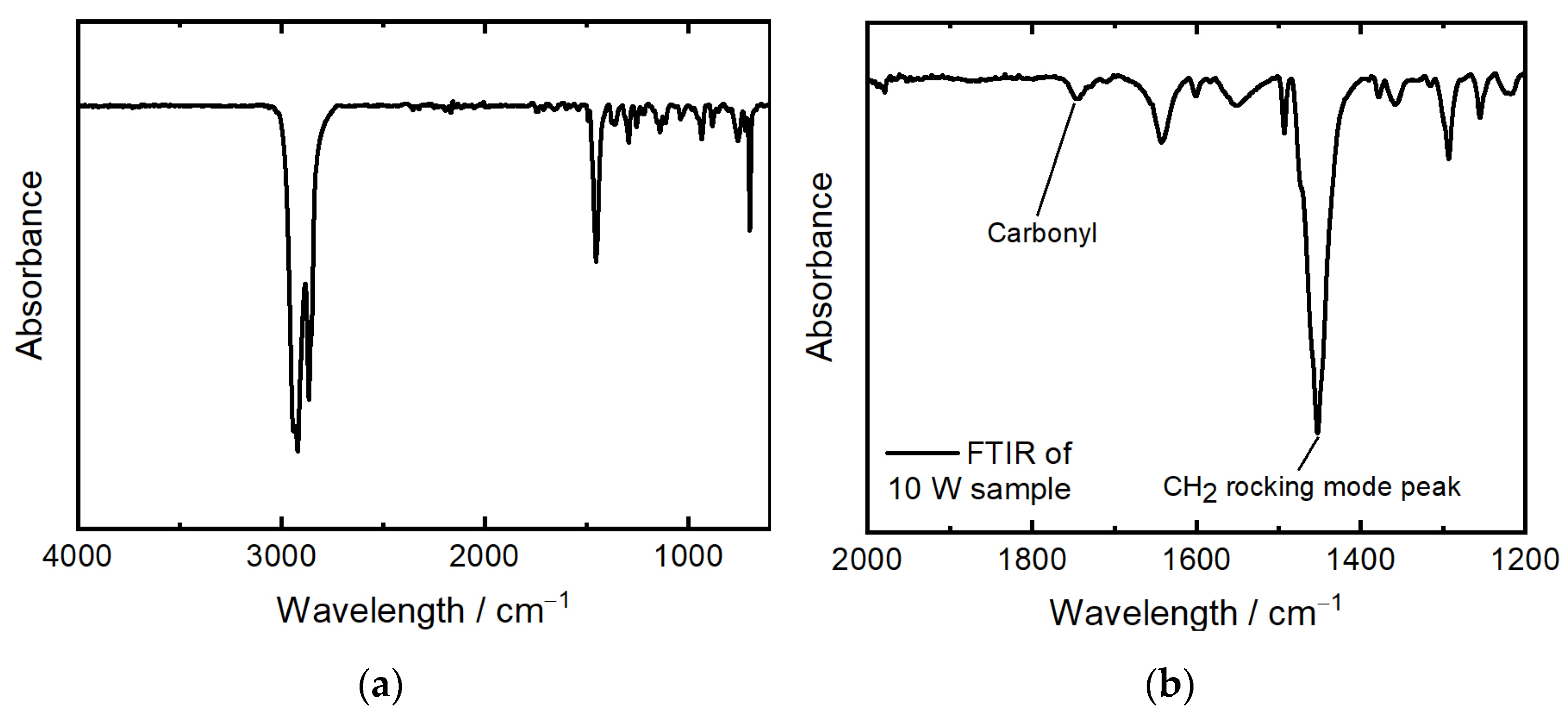

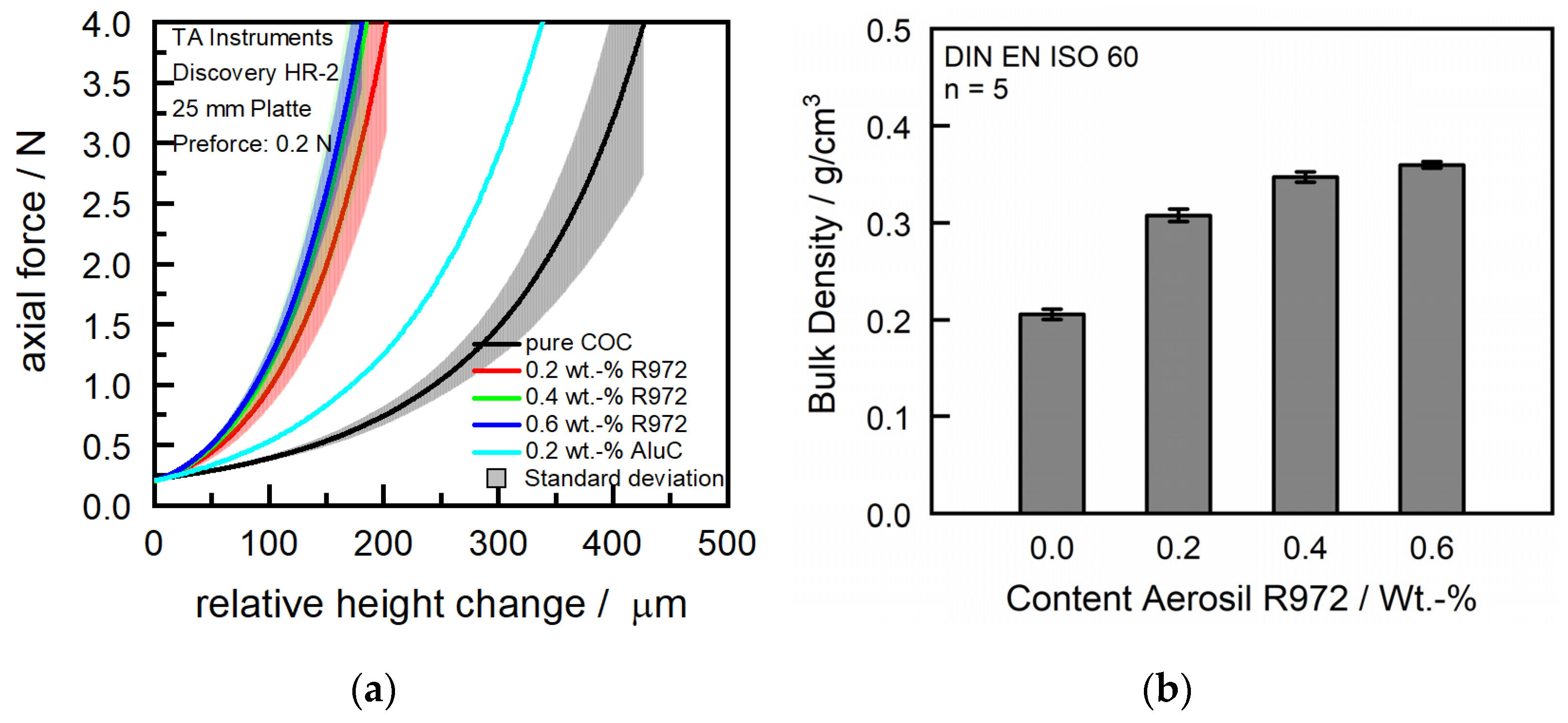

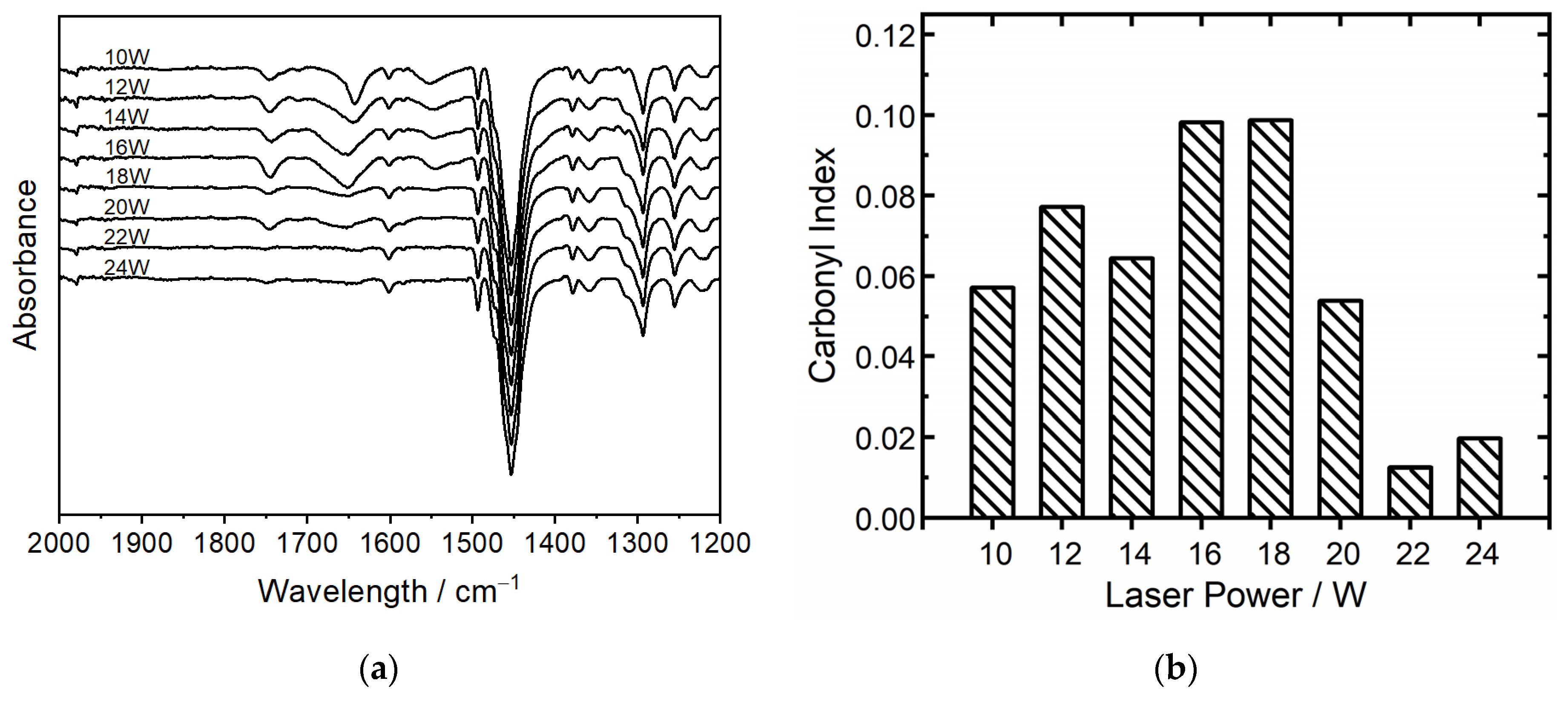

4.1. Material and Particle Properties

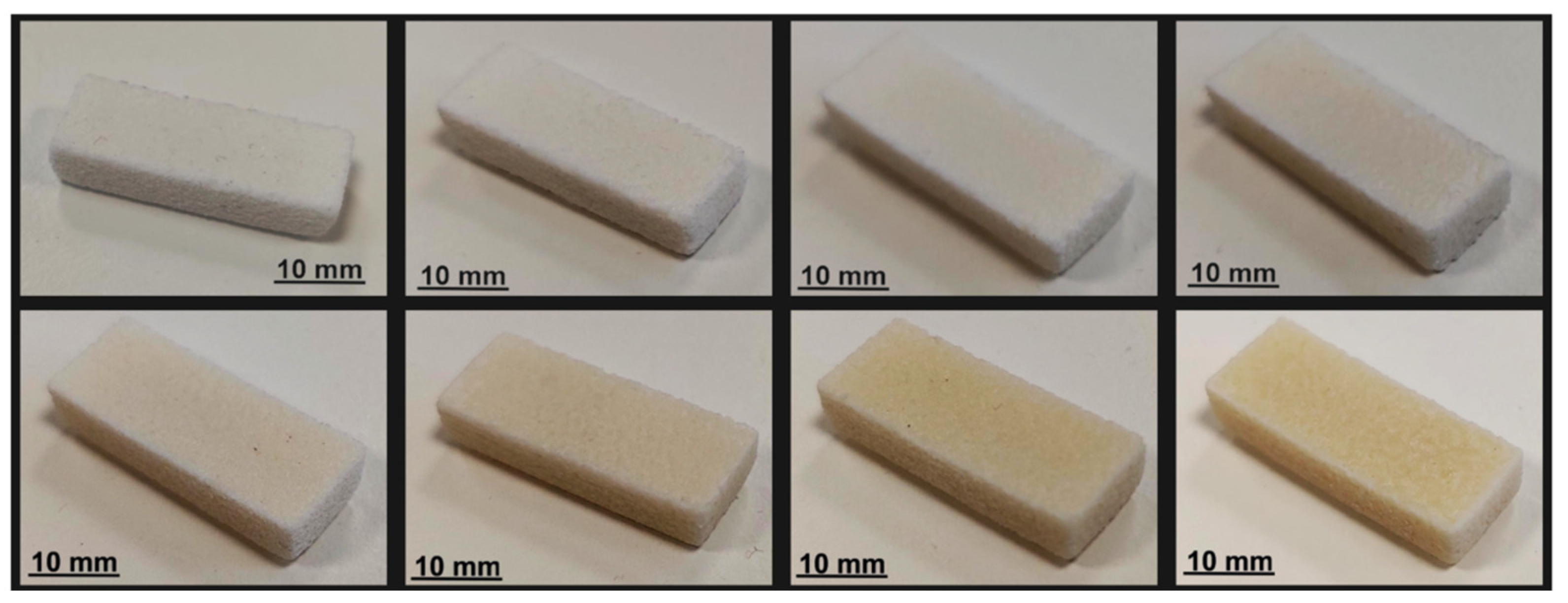

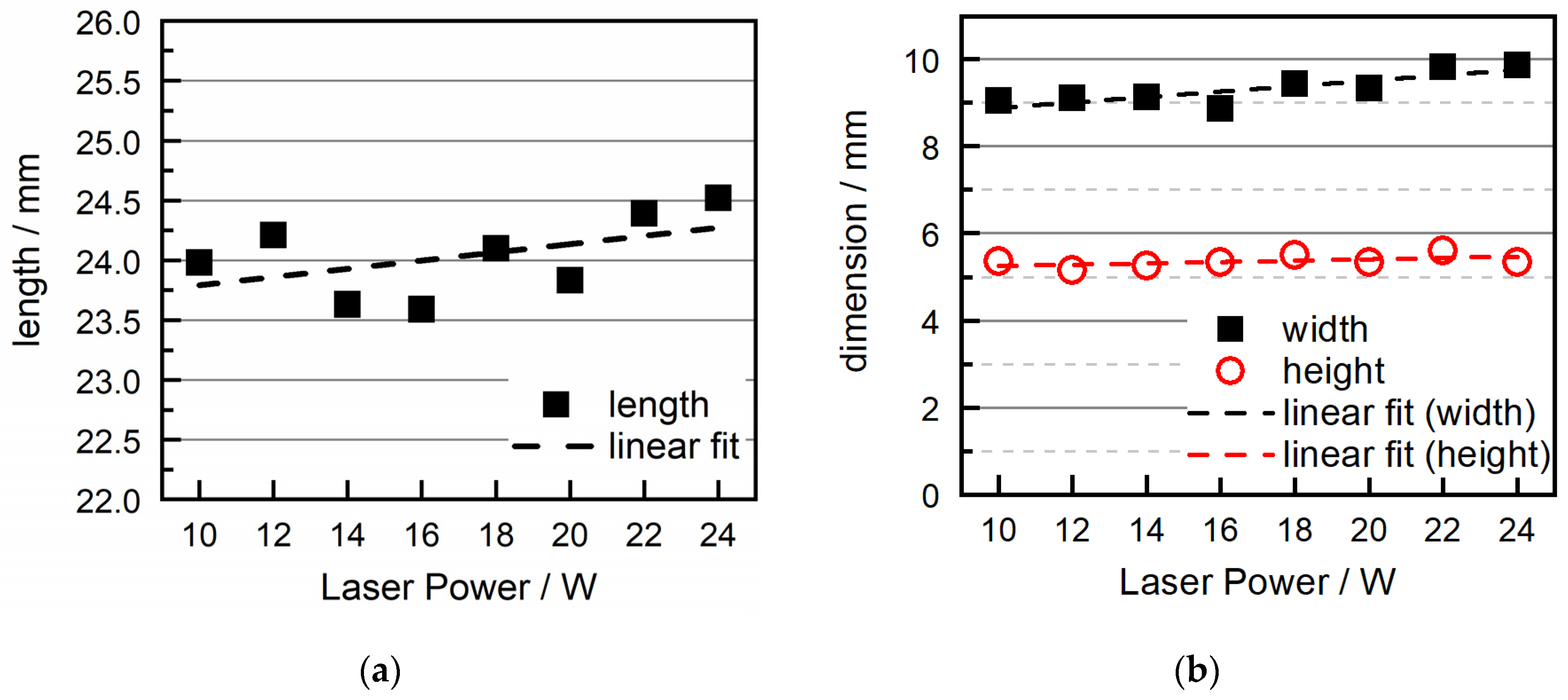

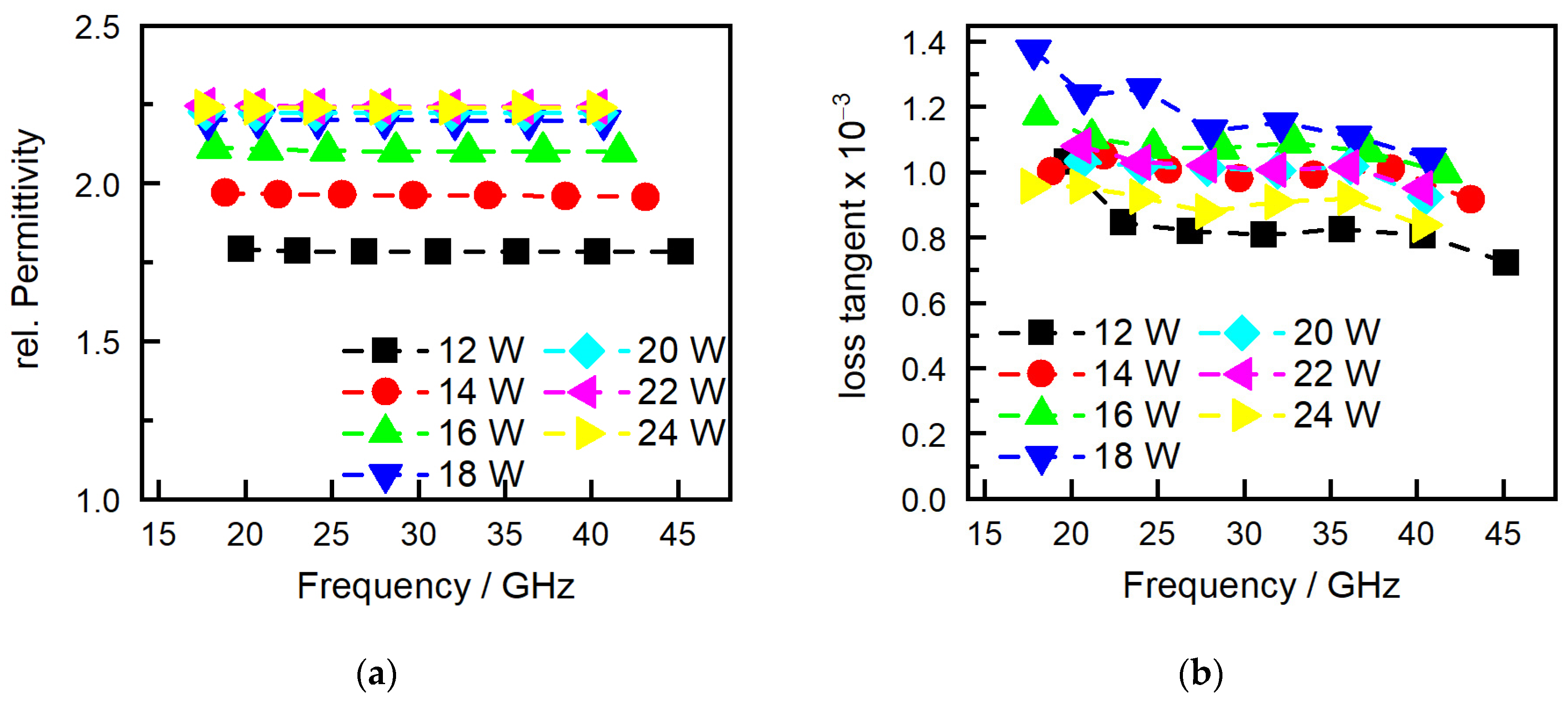

4.2. Part Properties

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Goodridge, R.D.; Tuck, C.J.; Hague, R.J.M. Laser sintering of polyamides and other polymers. Prog. Mater. Sci. 2012, 57, 229–267. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Leu, M.C.; Nakagawa, T. Progress in Additive Manufacturing and Rapid Prototyping. Cirp Ann. 1998, 47, 525–540. [Google Scholar] [CrossRef]

- Stansbury, J.W.; Idacavage, M.J. 3D printing with polymers: Challenges among expanding options and opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef] [PubMed]

- Greiner, S.; Jaksch, A.; Cholewa, S.; Drummer, D. Development of material-adapted processing strategies for laser sintering of polyamide 12. Adv. Ind. Eng. Polym. Res. 2021, 4, 251–263. [Google Scholar] [CrossRef]

- Schmid, M.; Wegener, K. Additive Manufacturing: Polymers Applicable for Laser Sintering (LS). Procedia Eng. 2016, 149, 457–464. [Google Scholar] [CrossRef]

- Tonello, R.; Conradsen, K.; Pedersen, D.B.; Frisvad, J.R. Surface Roughness and Grain Size Variation When 3D Printing Polyamide 11 Parts Using Selective Laser Sintering. Polymers 2023, 15, 2967. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Xu, X.; Zhao, Z.; Wang, M.; Zhang, J. Study in performance and morphology of polyamide 12 produced by selective laser sintering technology. Rapid Prototyp. J. 2018, 24, 813–820. [Google Scholar] [CrossRef]

- Jibing, C.; Junsheng, C.; Junsheng, Y.; Yiping, W. Selective laser sintering of acrylonitrile butadiene styrene polymer and post-processing enhancement: An experimental study. Iran. Polym. J. 2023, 32, 1537–1550. [Google Scholar] [CrossRef]

- Khazaee, S.; Kiani, A.; Badrossamay, M.; Foroozmehr, E. Selective Laser Sintering of Polystyrene: Preserving Mechanical Properties without Post-processing. J. Mater. Eng. Perform. 2021, 30, 3068–3078. [Google Scholar] [CrossRef]

- Leite, J.L.; Salmoria, G.V.; Paggi, R.A.; Ahrens, C.H.; Pouzada, A.S. A study on morphological properties of laser sintered functionally graded blends of amorphous thermoplastics. Int. J. Mater. Prod. Technol. 2010, 39, 205. [Google Scholar] [CrossRef]

- Ho, H.C.H.; Gibson, I.; Cheung, W.L. Effects of energy density on morphology and properties of selective laser sintered polycarbonate. J. Mater. Process. Technol. 1999, 89–90, 204–210. [Google Scholar] [CrossRef]

- Shi, Y.; Chen, J.; Wang, Y.; Li, Z.; Huang, S. Study of the selective laser sintering of polycarbonate and postprocess for parts reinforcement. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2007, 221, 37–42. [Google Scholar] [CrossRef]

- Salmoria, G.V.; Leite, J.L.; Lopes, C.N.; Machado, R.A.F.; Lago, A. The manufacturing of PMMA/PS blends by selective laser sintering. In Virtual and Rapid Manufacturing; Taylor & Francis: London, UK, 2007; pp. 305–313. [Google Scholar]

- Velu, R.; Singamneni, S. Evaluation of the influences of process parameters while selective laser sintering PMMA powders. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 229, 603–613. [Google Scholar] [CrossRef]

- Han, W.; Kong, L.; Xu, M. Advances in selective laser sintering of polymers. Int. J. Extrem. Manuf. 2022, 4, 42002. [Google Scholar] [CrossRef]

- Gao, H.; Chen, G.F.R.; Xing, P.; Choi, J.W.; Low, H.Y.; Tan, D.T.H. High-Resolution 3D Printed Photonic Waveguide Devices. Adv. Opt. Mater. 2020, 8, 2000613. [Google Scholar] [CrossRef]

- Le Sage, G.P. 3D Printed Waveguide Slot Array Antennas. IEEE Access 2016, 4, 1258–1265. [Google Scholar] [CrossRef]

- Lomakin, K.; Sippel, M.; Ullmann, I.; Helmreich, K.; Gold, G. 3D Printed Helix Antenna for 77GHz. In Proceedings of the 2020 14th European Conference on Antennas and Propagation (EuCAP), Copenhagen, Denmark, 15–20 March 2020; IEEE: New York, NY, USA, 2020; pp. 1–4, ISBN 978-88-31299-00-8. [Google Scholar]

- Wang, L.; Yang, J.; Cheng, W.; Zou, J.; Zhao, D. Progress on Polymer Composites With Low Dielectric Constant and Low Dielectric Loss for High-Frequency Signal Transmission. Front. Mater. 2021, 8, 774843. [Google Scholar] [CrossRef]

- Ahmad, Z. Polymer Dielectric Materials. In Dielectric Material; Silaghi, M.A., Ed.; InTechOpen Limited: London, UK, 2012; ISBN 978-953-51-0764-4. [Google Scholar]

- Hwang, J.-H.; Markondeya Raj, P.; Abothu, I.R.; Yoon, C.; Iyer, M.; Jung, H.-M.; Hong, J.-K.; Tummala, R. Temperature dependence of the dielectric properties of polymer composite based RF capacitors. Microelectron. Eng. 2008, 85, 553–558. [Google Scholar] [CrossRef]

- Wang, Q.; Che, J.; Wu, W.; Hu, Z.; Liu, X.; Ren, T.; Chen, Y.; Zhang, J. Contributing Factors of Dielectric Properties for Polymer Matrix Composites. Polymers 2023, 15, 590. [Google Scholar] [CrossRef]

- Vanskeviče, I.; Kinka, M.; Banys, J.; Macutkevič, J.; Schaefer, S.; Selskis, A.; Fierro, V.; Celzard, A. Dielectric and Ultrasonic Properties of PDMS/TiO2 Nanocomposites. Polymers 2024, 16, 603. [Google Scholar] [CrossRef]

- Küchler, F.; Färber, R.; Franck, C.M. Humidity and Temperature Effects on the Dielectric Properties of PET Film. In Proceedings of the 2020 IEEE Electrical Insulation Conference (EIC), Knoxville, TN, USA, 22 June–3 July 2020; pp. 179–183. [Google Scholar]

- DIN EN ISO 11357-1:2023-06; Dynamische Differenzkalorimetrie. Deutsches Institut für Normung e.V.: Berlin, Germany, 2023.

- DIN EN ISO 11358-1:2022-07; Kunststoffe-Thermogravimetrie (TG) von Polymeren. Deutsches Institut für Normung e.V.: Berlin, Germany, 2022.

- Hesse, N.; Winzer, B.; Peukert, W.; Schmidt, J. Towards a generally applicable methodology for the characterization of particle properties relevant to processing in powder bed fusion of polymers—From single particle to bulk solid behavior. Addit. Manuf. 2021, 41, 101957. [Google Scholar] [CrossRef]

- DIN EN ISO 60:2023-12; Kunststoffe-Bestimmung der Scheinbaren Dichte von Formmassen, die durch einen Gegebenen Trichter Abfließen Können (Schüttdichte). Deutsches Institut für Normung e.V.: Berlin, Germany, 2023.

- DIN EN ISO 1183-3:2000-05; Kunststoffe-Bestimmung der Dichte von nicht Verschäumten Kunststoffen-Teil 3: Gas-Pyknometer-Verfahren. Deutsches Institut für Normung e.V.: Berlin, Germany, 2000.

- Gutiérrez-Villarreal, M.H.; Zavala-Betancourt, S.A. Thermo-Oxidative Stability of Cyclic Olefin Copolymers in the Presence of Fe, Co and Mn Stearates as Pro-Degradant Additives. Polym.-Plast. Technol. Eng. 2014, 53, 1804–1810. [Google Scholar] [CrossRef]

- Sharma, N.; Chang, L.P.; Chu, Y.L.; Ismail, H.; Ishiaku, U.S.; Mohd Ishak, Z.A. A study on the effect of pro-oxidant on the thermo-oxidative degradation behaviour of sago starch filled polyethylene. Polym. Degrad. Stab. 2001, 71, 381–393. [Google Scholar] [CrossRef]

- Jaksch, A.; Cholewa, S.; Drummer, D. Thin-Walled Part Properties in Powder Bed Fusion of Polymers—A Comparative Study on Temperature Development and Part Performance Depending on Part Thickness and Orientation. J. Manuf. Mater. Process. 2023, 7, 96. [Google Scholar] [CrossRef]

- Schmid, M.; Amado, F.; Levy, G.; Wegener, K. Flowability of Powders for Selective Laser Sintering (SLS) investigated by Round Robin Test. In High Value Manufacturing: Advanced Research in Virtual and Rapid Prototyping, Proceedings of the 6th International Conference on Advanced Research in Virtual and Rapid Prototyping, Leiria, Portugal, 1–5 October 2013; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Ruggi, D.; Lupo, M.; Sofia, D.; Barrès, C.; Barletta, D.; Poletto, M. Flow properties of polymeric powders for selective laser sintering. Powder Technol. 2020, 370, 288–297. [Google Scholar] [CrossRef]

- Suraci, S.V.; Fabiani, D.; Mazzocchetti, L.; Giorgini, L. Degradation Assessment of Polyethylene-Based Material Through Electrical and Chemical-Physical Analyses. Energies 2020, 13, 650. [Google Scholar] [CrossRef]

- Wan, D.; Qi, F.; Zhou, Q.; Zhou, H.; Zhao, M.; Duan, X. Effect of Thermal Aging on Threshold Field Strength and Relative Permittivity of Cross-Linked Polyethylene with Different Cross-Linking Agent Contents. J. Electr. Eng. Technol. 2021, 16, 2885–2892. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Levy, G.; Schindel, R.; Craeghs, T.; Yasa, E. Consolidation of polymer powders by selective laser sintering. In Proceedings of the 3rd International Conference on Polymers and Moulds Innovations, Ghent, Belgium, 17–19 September 2008; pp. 15–30. [Google Scholar]

- Caulfield, B.; McHugh, P.E.; Lohfeld, S. Dependence of mechanical properties of polyamide components on build parameters in the SLS process. J. Mater. Process. Technol. 2007, 182, 477–488. [Google Scholar] [CrossRef]

- Hu, H.; Sinha, S.; Meisel, N.; Bilén, S.G. Permittivity of 3D-Printed Nylon Substrates with Different Infill Patterns and Densities for Design of Microwave Components. Designs 2020, 4, 39. [Google Scholar] [CrossRef]

- Gugumus, F. Thermooxidative degradation of polyolefins in the solid state: Part 5. Kinetics of functional group formation in PE-HD and PE-LLD. Polym. Degrad. Stab. 1997, 55, 21–43. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| TBuildchamber | 180 °C |

| TChamber | 100 °C |

| hLayer | 120 µm |

| dHatch | 0.2 mm |

| vScan | 1000 mm/s |

| vRecoating | 100 mm/s |

| VRecoater | 100 mm/s |

| Sample Number | Energy Density [J/mm3] |

|---|---|

| 1 | 0.42 |

| 2 | 0.5 |

| 3 | 0.58 |

| 4 | 0.67 |

| 5 | 0.75 |

| 6 | 0.83 |

| 7 | 0.92 |

| 8 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romeis, M.; Ehrngruber, M.; Drummer, D. Laser-Sintering of Cyclic Olefine Copolymer for Low Dielectric Loss Applications. Polymers 2024, 16, 1751. https://doi.org/10.3390/polym16121751

Romeis M, Ehrngruber M, Drummer D. Laser-Sintering of Cyclic Olefine Copolymer for Low Dielectric Loss Applications. Polymers. 2024; 16(12):1751. https://doi.org/10.3390/polym16121751

Chicago/Turabian StyleRomeis, Manuel, Michael Ehrngruber, and Dietmar Drummer. 2024. "Laser-Sintering of Cyclic Olefine Copolymer for Low Dielectric Loss Applications" Polymers 16, no. 12: 1751. https://doi.org/10.3390/polym16121751

APA StyleRomeis, M., Ehrngruber, M., & Drummer, D. (2024). Laser-Sintering of Cyclic Olefine Copolymer for Low Dielectric Loss Applications. Polymers, 16(12), 1751. https://doi.org/10.3390/polym16121751