Additive Manufacturing of Head Surrogates for Evaluation of Protection in Sports

Abstract

:1. Introduction

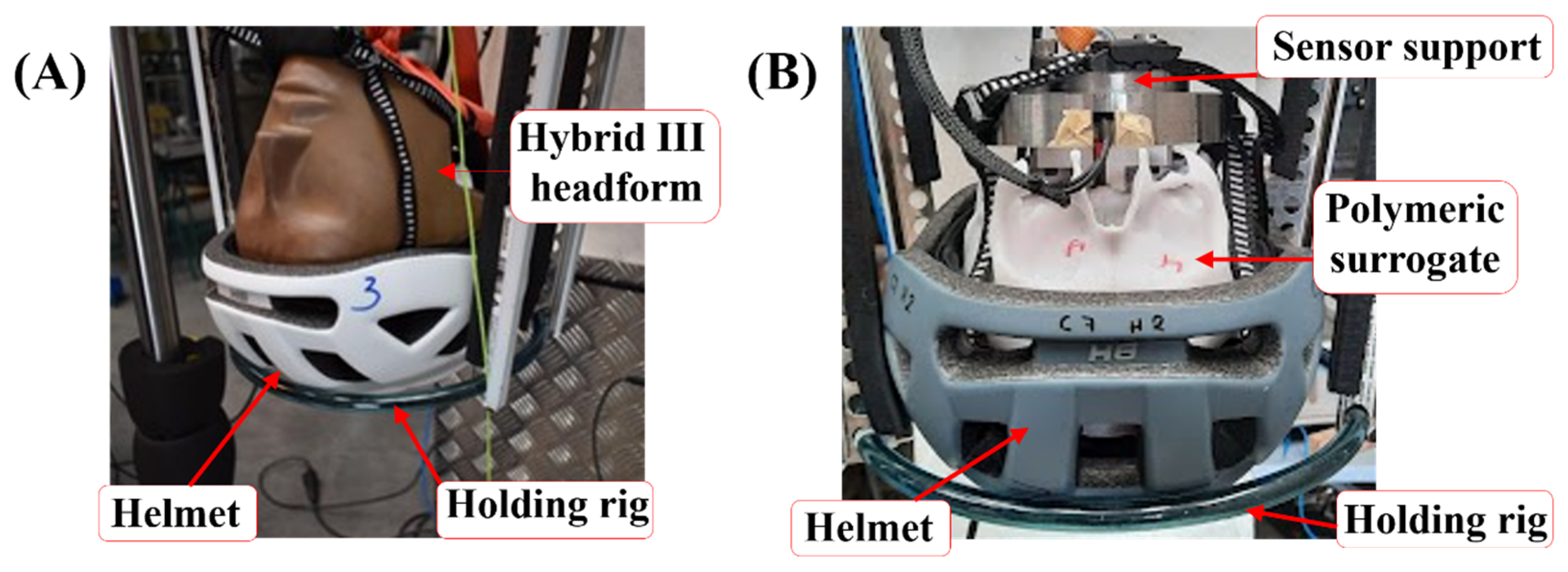

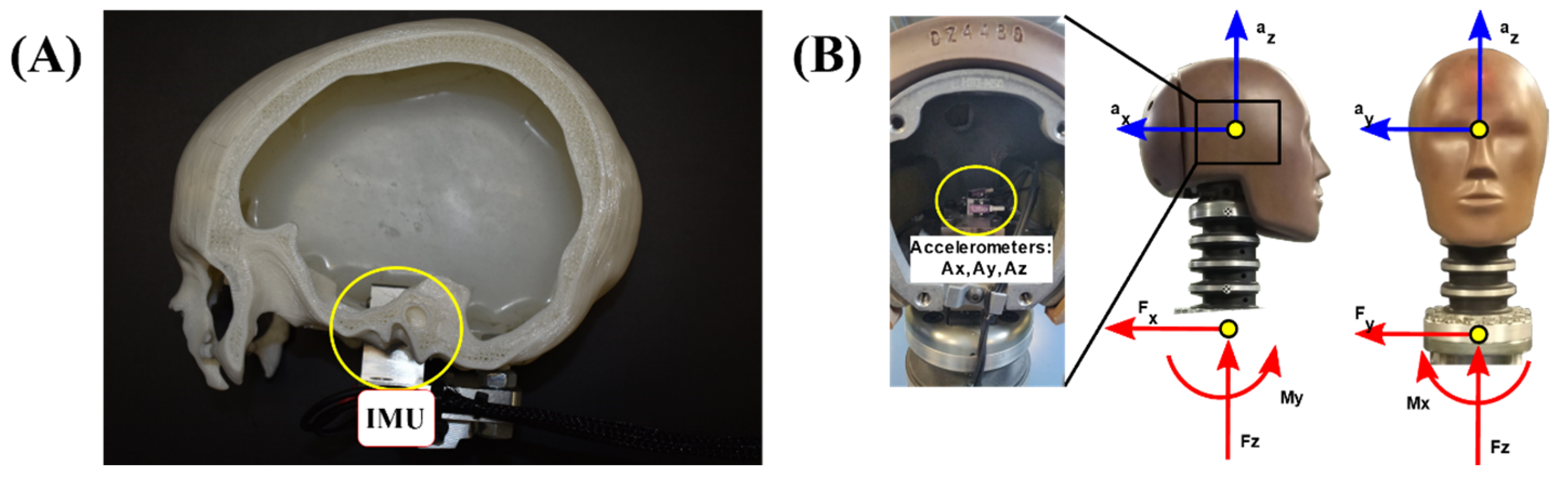

2. Materials and Methods

2.1. Skull Surrogate Design and Manufacturing

2.2. Brain Mass Surrogate

2.3. Demonstrator

2.4. Signal Acquisition and Processing

3. Results and Discussion

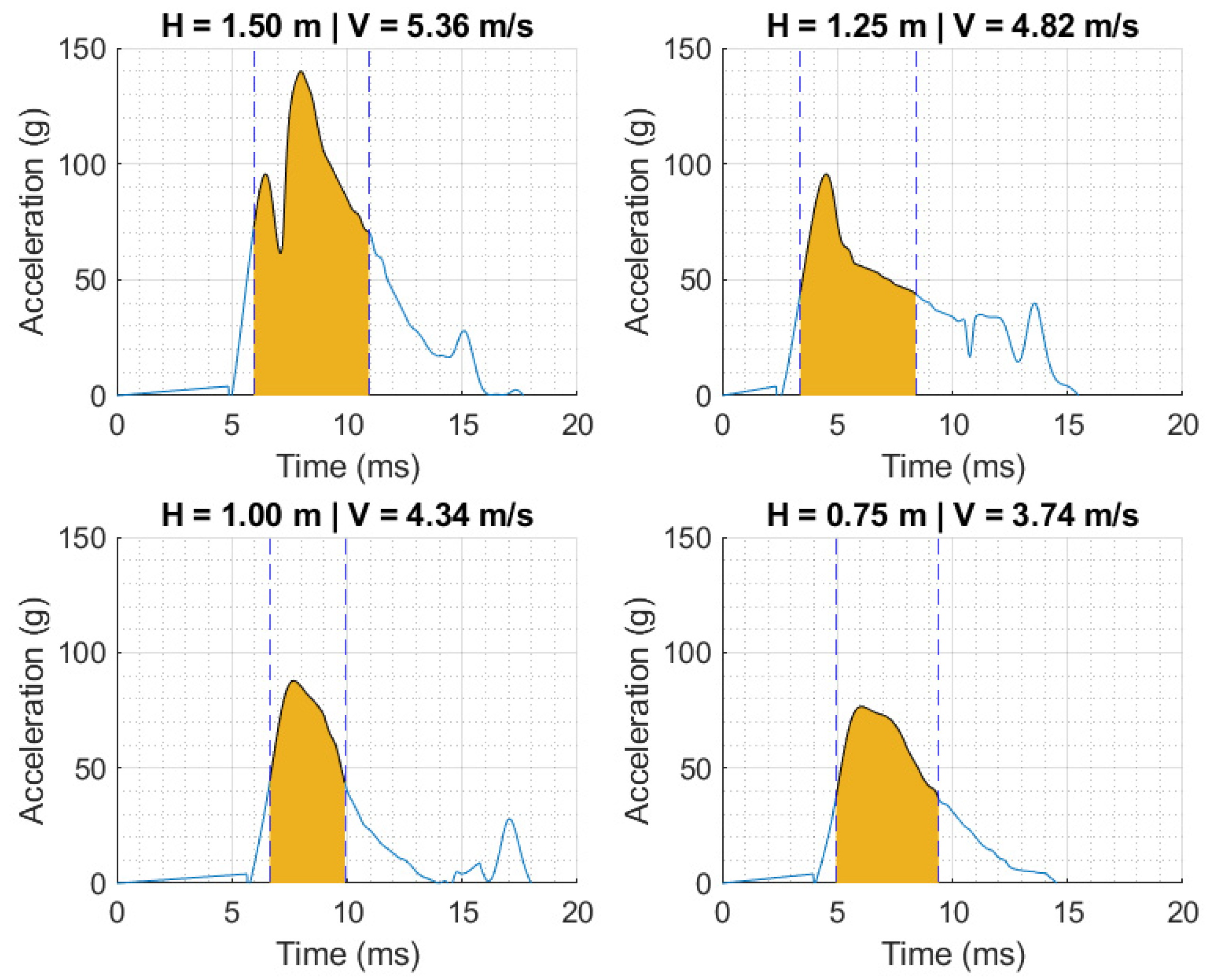

3.1. Acceleration–Time Histories

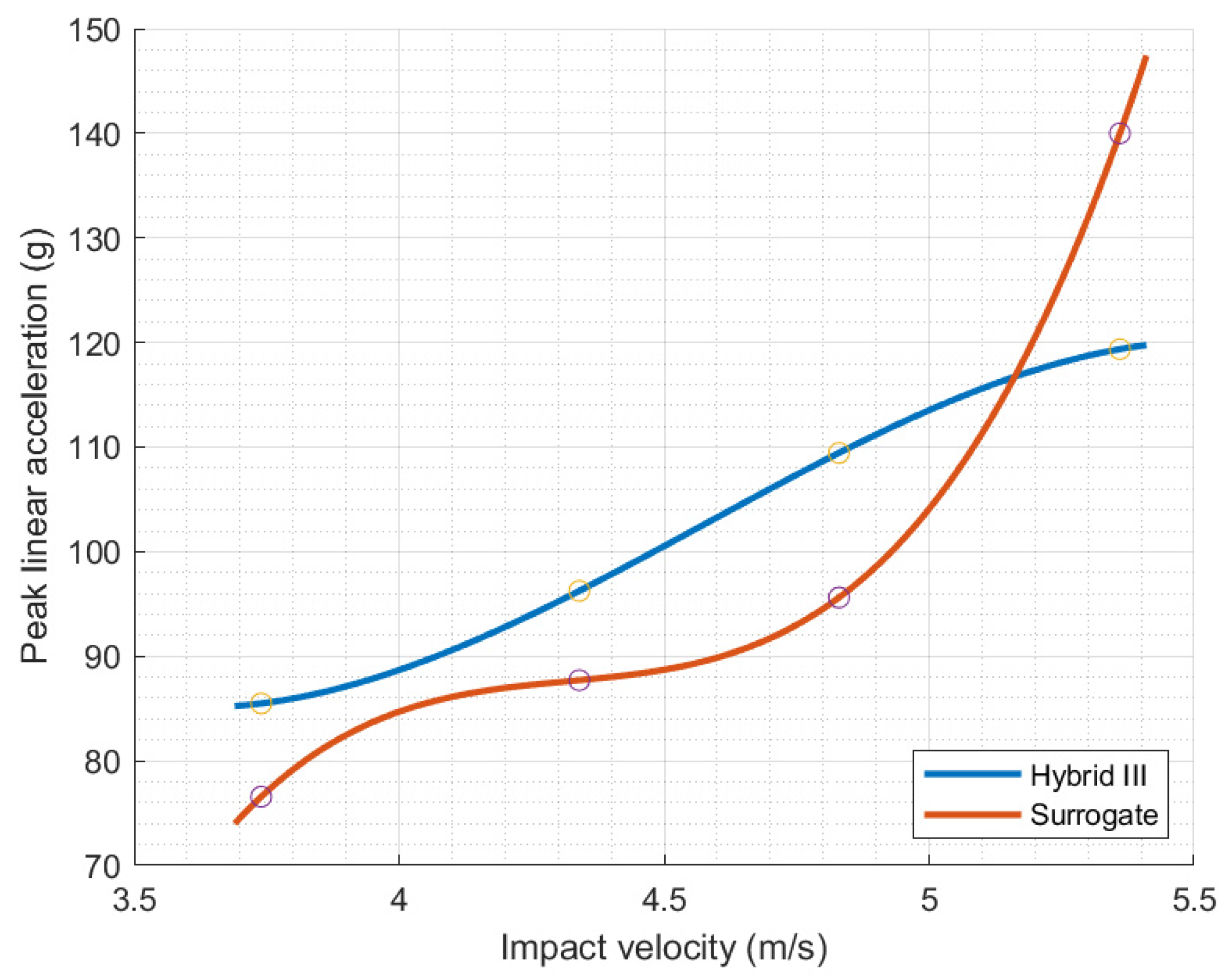

3.2. Peak Linear Acceleration and Head Injury Criterion

4. Conclusions

- The skull surrogates were developed using AM techniques, highlighting the viability of these methodologies for readily fabricating experimental constructs required for assessing sports protection equipment. AM is suitable for overcoming the challenges stemming from complex geometries and material properties.

- The proposed 3D-printed surrogate is agnostic to the specific anatomical features and can be easily adapted to analyze the performance of other sports gear while accounting for variability caused by gender, age, and other physiological parameters.

- The performance of the developed surrogates was compared to the standardized Hybrid II head form, showing reasonable agreement in the overall acceleration–time histories and the extracted impact efficacy metrics (i.e., peak linear acceleration and HIC). These results analogize and validate the two substitutes of the human head considered herein.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Smith, D.H.; Meaney, D.F.; Shull, W.H. Diffuse axonal injury in head trauma. J. Head Trauma Rehabil. 2003, 18, 307–316. [Google Scholar] [CrossRef] [PubMed]

- Ling, H.; Hardy, J.; Zetterberg, H. Neurological consequences of traumatic brain injuries in sports. Mol. Cell. Neurosci. 2015, 66, 114–122. [Google Scholar] [CrossRef] [PubMed]

- Bourdet, N.; Deck, C.; Carreira, R.P.; Willinger, R. Head impact conditions in the case of cyclist falls. Proc. Inst. Mech. Eng. Part P J. Sports Eng. Technol. 2012, 226, 282–289. [Google Scholar] [CrossRef]

- Singh, G.; Chanda, A. Mechanical properties of whole-body soft human tissues: A review. Biomed. Mater. 2021, 16, 062004. [Google Scholar] [CrossRef] [PubMed]

- Kneubuehl, B.P. Wound Ballistics: Basics; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Hubbard, R.P.; McLeod, D.G. Definition and development of a crash dummy head. In SAE Transactions; SAE: Warrendale, PA, USA, 1974; pp. 3836–3851. [Google Scholar]

- Versace, J. A Review of the Severity Index. In SAE Technical Papers; SAE: Warrendale, PA, USA, 1971. [Google Scholar] [CrossRef]

- Germanetti, F.; Fiumarella, D.; Belingardi, G.; Scattina, A. Injury Criteria for Vehicle Safety Assessment: A Review with a Focus Using Human Body Models. Vehicles 2022, 4, 1080–1095. [Google Scholar] [CrossRef]

- Kang, J.; Nusholtz, G.; Agaram, V. Hybrid III Dummy Neck Issues. In SAE Technical Papers; SAE: Warrendale, PA, USA, 2005. [Google Scholar] [CrossRef]

- Pellman, E.J.; Viano, D.C. Concussion in professional football: Summary of the research conducted by the National Football League’s Committee on Mild Traumatic Brain Injury. Neurosurg. Focus 2006, 21, E12. [Google Scholar] [CrossRef] [PubMed]

- Pellman, E.J.; Viano, D.C.; Casson, I.R.; Tucker, A.M.; Waeckerle, J.F.; Powell, J.W.; Feuer, H. Concussion in professional football: Repeat injuries—Part 4. Neurosurgery 2004, 55, 860–876. [Google Scholar] [CrossRef]

- Viano, D.C.; Pellman, E.J. Concussion in professional football: Biomechanics of the striking player—Part 8. Neurosurgery 2005, 56, 266–278. [Google Scholar] [CrossRef]

- Viano, D.C.; Casson, I.R.; Pellman, E.J. Concussion in professional football: Biomechanics of the struck player—Part 14. Neurosurgery 2007, 61, 313–327. [Google Scholar] [CrossRef]

- Pellman, E.J.; Viano, D.C.; Withnall, C.; Shewchenko, N.; Bir, C.A.; Halstead, P.D. Concussion in professional football: Helmet testing to assess impact performance—Part 11. Neurosurgery 2006, 58, 78–95. [Google Scholar] [CrossRef]

- Zhang, J.; Yoganandan, N.; Pintar, F.A. Dynamic biomechanics of the human head in lateral impacts. Ann. Adv. Automot. Med. 2009, 53, 249. Available online: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3256796/ (accessed on 7 February 2024).

- Merkle, A.C.; Wing, I.D.; Roberts, J.C. Human surrogate head response to dynamic overpressure loading in protected and unprotected conditions. In Proceedings of the 26th Southern Biomedical Engineering Conference SBEC 2010, College Park, MD, USA, 30 April–2 May 2010; pp. 22–25. [Google Scholar] [CrossRef]

- Banton, R.; Piehler, T.; Zander, N.; Benjamin, R.; Mrozek, R.; Duckworth, J.; Petel, O. Experimental and numerical investigation of blast wave impact on a surrogate head model. Shock Waves 2021, 31, 481–498. [Google Scholar] [CrossRef]

- Kerwin, J.; Yücesoy, A.; Vidhate, S.; Dávila-Montero, B.M.; Van Orman, J.L.; Pence, T.J.; Tartis, M.; Mejía-Alvarez, R.; Willis, A.M. Sulcal Cavitation in Linear Head Acceleration: Possible Correlation with Chronic Traumatic Encephalopathy. Front. Neurol. 2022, 13, 832370. [Google Scholar] [CrossRef] [PubMed]

- UNE-EN 1078:2012; Cascos Para Ciclistas y Para Usuarios de Monopatines y Patines de Ruedas. 2012. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0049481 (accessed on 7 February 2024).

- F1447 Standard Specification for Helmets Used in Recreational Bicycling or Roller Skating. Available online: https://www.astm.org/f1447-18.html (accessed on 7 February 2024).

- Cripton, P.A.; Dressler, D.M.; Stuart, C.A.; Dennison, C.R.; Richards, D. Bicycle helmets are highly effective at preventing head injury during head impact: Head-form accelerations and injury criteria for helmeted and unhelmeted impacts. Accid. Anal. Prev. 2014, 70, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Rush, G.A.; Prabhu, R.; Rush, G.A.; Williams, L.N.; Horstemeyer, M.F. Modified Drop Tower Impact Tests for American Football Helmets. JoVE J. Vis. Exp. 2017, 2017, e53929. [Google Scholar] [CrossRef] [PubMed]

- Bland, M.L.; Zuby, D.S.; Mueller, B.C.; Rowson, S. Differences in the protective capabilities of bicycle helmets in real-world and standard-specified impact scenarios. Traffic Inj. Prev. 2018, 19, S158–S163. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.Z.; Pan, C.S.; Wimer, B.M. Evaluation of the shock absorption performance of construction helmets under repeated top impacts. Eng. Fail. Anal. 2019, 96, 330–339. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Li, P.; Wang, Z. Buckling-regulated origami materials with synergy of deployable and undeployable features. Int. J. Mech. Sci. 2023, 247, 108167. [Google Scholar] [CrossRef]

- Motherway, J.A.; Verschueren, P.; Van Der Perre, G.; Sloten, J.V.; Gilchrist, M.D. The Mechanical Properties of Cranial Bone. IFMBE Proc. 2010, 31, 776–779. [Google Scholar] [CrossRef]

- Rammohan, A.V.; Lee, T.; Tan, V.B.C. A Novel Morphological Model of Trabecular Bone Based on the Gyroid. Int. J. Appl. Mech. 2015, 7, 1550048. [Google Scholar] [CrossRef]

- Vafaeefar, M.; Moerman, K.M.; Kavousi, M.; Vaughan, T.J. A morphological, topological and mechanical investigation of gyroid, spinodoid and dual-lattice algorithms as structural models of trabecular bone. J. Mech. Behav. Biomed. Mater. 2023, 138, 105584. [Google Scholar] [CrossRef] [PubMed]

- UNE-EN ISO/ASTM 52900:2022; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. 2022. Available online: https://www.normadoc.com/spanish/une-en-iso-astm-52900-2022-4242978.html (accessed on 21 May 2024).

- Mantecón, R.; Marco, M.; Muñoz-Sanchez, A.; Youssef, G.; Díaz-Álvarez, J.; Miguélez, H. Additive Manufacturing and Mechanical Characterization of PLA-Based Skull Surrogates. Polymers 2022, 15, 58. [Google Scholar] [CrossRef] [PubMed]

- Elsayed, Y.; Vincensi, A.; Lekakou, C.; Geng, T.; Saaj, C.M.; Ranzani, T.; Cianchetti, M.; Menciassi, A. Finite Element Analysis and Design Optimization of a Pneumatically Actuating Silicone Module for Robotic Surgery Applications. Soft Robot. 2014, 1, 255–262. [Google Scholar] [CrossRef]

- J211/1_202208; Instrumentation for Impact Test, Part 1—Electronic Instrumentation—SAE International. 2022. Available online: https://www.sae.org/standards/content/j211/1_202208/ (accessed on 29 April 2024).

| Drop Height | Impact Velocity | Peak Linear Acceleration | HIC |

|---|---|---|---|

| 1.50 m | 5.36 m/s | 119 g | 522 |

| 1.25 m | 4.82 m/s | 109 g | 425 |

| 1.00 m | 4.34 m/s | 96 g | 320 |

| 0.75 m | 3.74 m/s | 85 g | 286 |

| Drop Height | Impact Velocity | Peak Linear Acceleration | HIC |

|---|---|---|---|

| 1.50 m | 5.33 m/s | 140 g | 478 |

| 1.25 m | 4.82 m/s | 95 g | 151 |

| 1.00 m | 4.31 m/s | 88 g | 144 |

| 0.75 m | 3.74 m/s | 76 g | 133 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mantecón, R.; Valverde-Marcos, B.; Rubio, I.; Youssef, G.; Loya, J.A.; Díaz-Álvarez, J.; Miguélez, M.H. Additive Manufacturing of Head Surrogates for Evaluation of Protection in Sports. Polymers 2024, 16, 1753. https://doi.org/10.3390/polym16121753

Mantecón R, Valverde-Marcos B, Rubio I, Youssef G, Loya JA, Díaz-Álvarez J, Miguélez MH. Additive Manufacturing of Head Surrogates for Evaluation of Protection in Sports. Polymers. 2024; 16(12):1753. https://doi.org/10.3390/polym16121753

Chicago/Turabian StyleMantecón, Ramiro, Borja Valverde-Marcos, Ignacio Rubio, George Youssef, José Antonio Loya, José Díaz-Álvarez, and María Henar Miguélez. 2024. "Additive Manufacturing of Head Surrogates for Evaluation of Protection in Sports" Polymers 16, no. 12: 1753. https://doi.org/10.3390/polym16121753