Mechanical and Insulation Performance of Rigid Polyurethane Foam Reinforced with Lignin-Containing Nanocellulose Fibrils

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Lignin-Containing Nanocellulose Fibrils (LCNF) Preparation

2.3. Polyol Preparation

2.4. Preparation of RPUF

2.5. Characterization

2.5.1. Polyol Characterization

2.5.2. Physical Properties of RPUF

2.5.3. Gel Content of RPUF

2.5.4. Fourier Transform Infrared Spectroscopy

2.5.5. Scanning Electron Microscopy

2.5.6. Laser Confocal Microscopy

2.5.7. Mechanical Tests

2.5.8. Thermal Tests

2.5.9. Statistical Analysis

3. Results and Discussion

3.1. Polyols

3.2. Influence of LCNF on RPUF Properties

3.2.1. Chemical Structure of RPUF

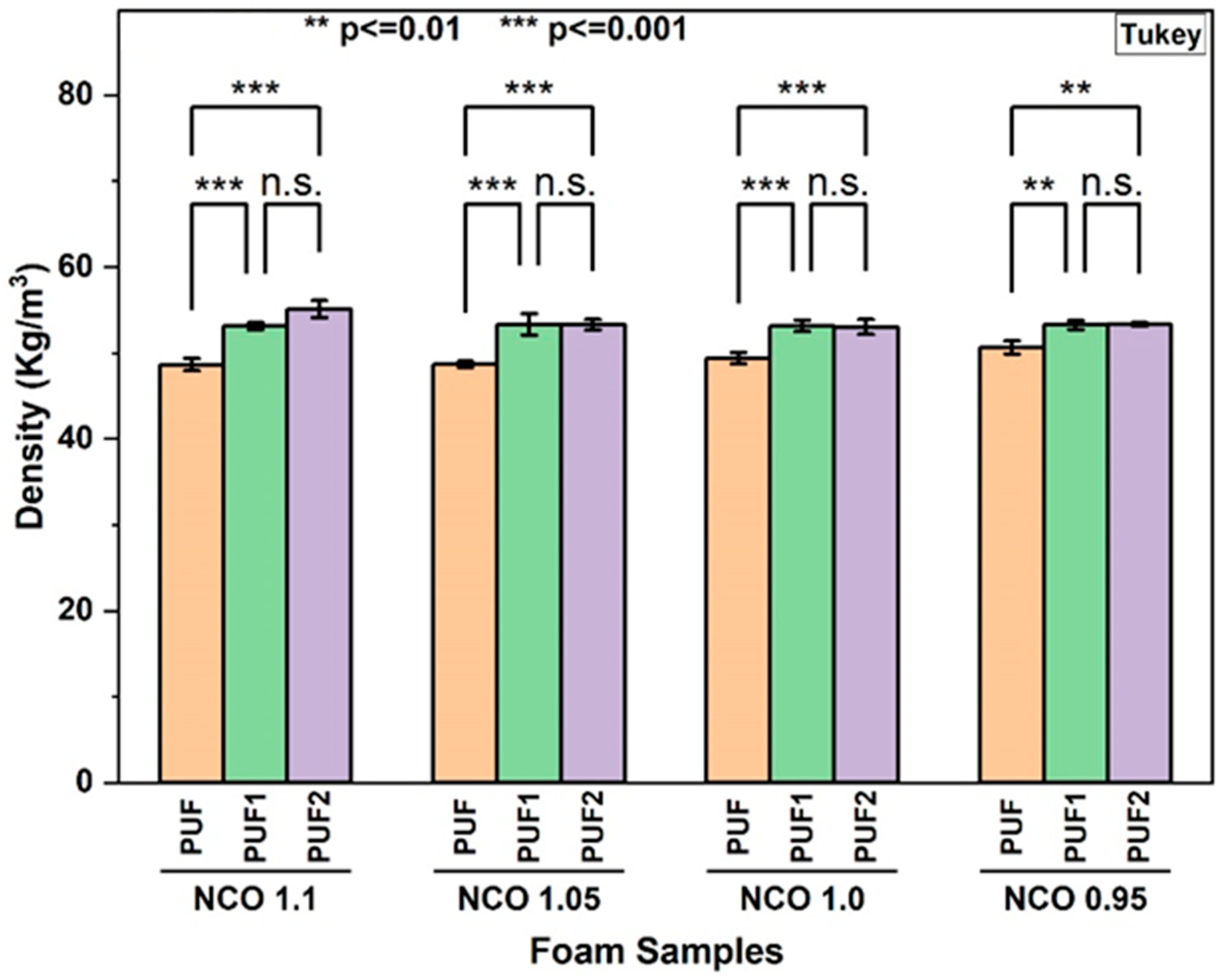

3.2.2. Density of RPUF

3.2.3. Cell Morphology of RPUF

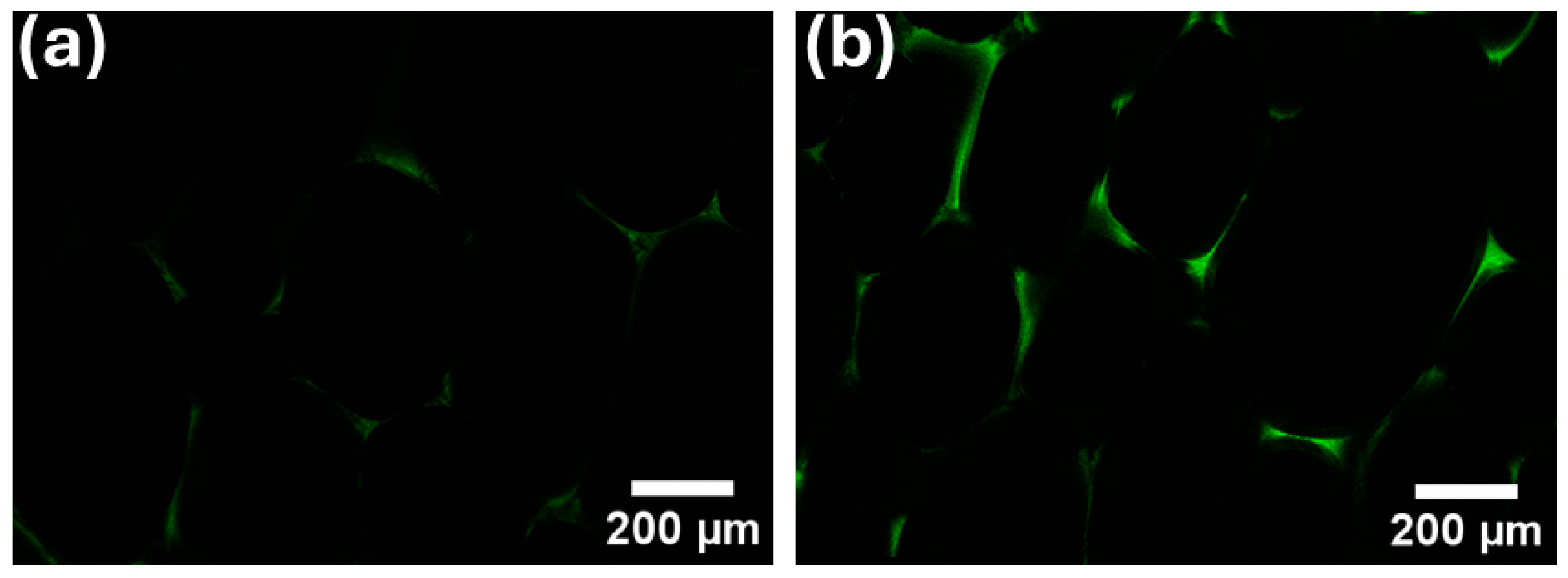

3.2.4. Confocal Microscope Characterization of RPUF

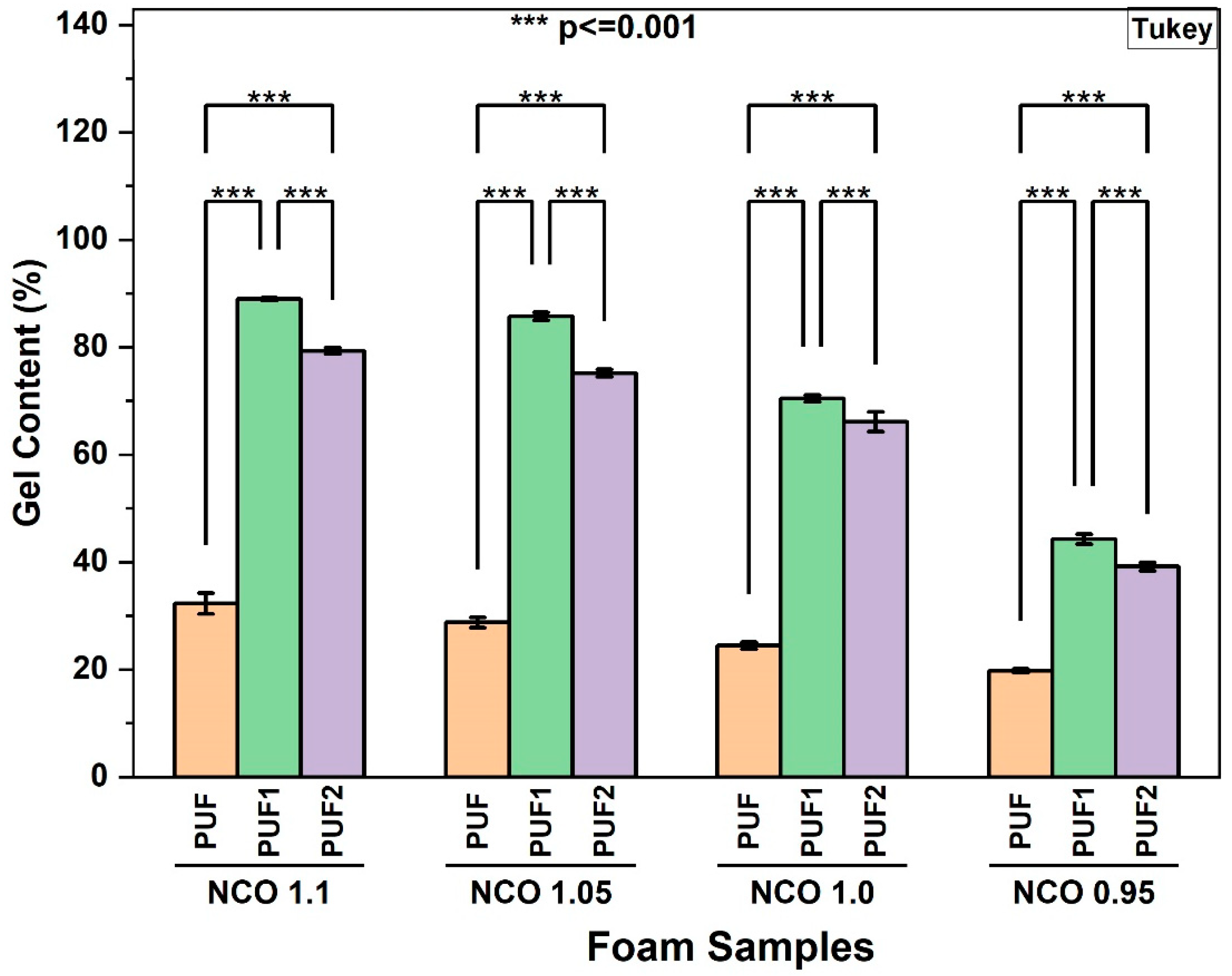

3.2.5. Gel Content of RPUF

3.2.6. Compressive Strength and Modulus of RPUF

3.2.7. Thermal Conductivity of RPUF

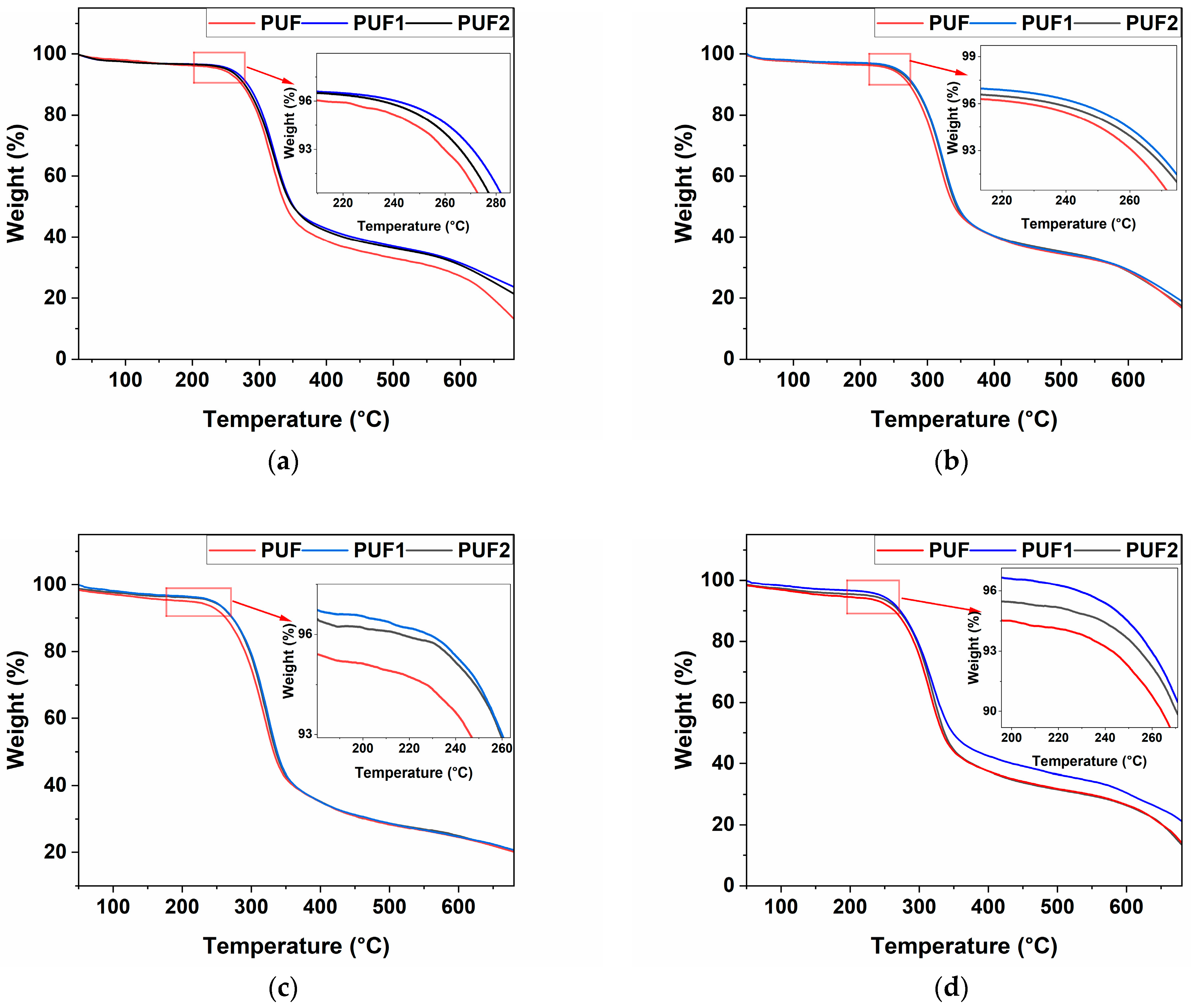

3.2.8. Thermal Stability of RPUF

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Szycher, M. Szycher’s Handbook of Polyurethanes, 2nd ed.; CRC Press/Taylor & Francis: Boca Raton, FL, USA, 2013; ISBN 978-1-4398-3958-4. [Google Scholar]

- Engels, H.-W.; Pirkl, H.-G.; Albers, R.; Albach, R.W.; Krause, J.; Hoffmann, A.; Casselmann, H.; Dormish, J. Polyurethanes: Versatile Materials and Sustainable Problem Solvers for Today’s Challenges. Angew. Chem. (Int. Ed.) 2013, 52, 9422–9441. [Google Scholar] [CrossRef] [PubMed]

- Haridevan, H.; Evans, D.A.C.; Ragauskas, A.J.; Martin, D.J.; Annamalai, P.K. Valorisation of Technical Lignin in Rigid Polyurethane Foam: A Critical Evaluation on Trends, Guidelines and Future Perspectives. Green Chem. 2021, 23, 8725–8753. [Google Scholar] [CrossRef]

- Peyrton, J.; Avérous, L. Structure-Properties Relationships of Cellular Materials from Biobased Polyurethane Foams. Mater. Sci. Eng. R Rep. 2021, 145, 100608. [Google Scholar] [CrossRef]

- Blattmann, H.; Fleischer, M.; Bähr, M.; Mülhaupt, R. Isocyanate-and Phosgene-free Routes to Polyfunctional Cyclic Carbonates and Green Polyurethanes by Fixation of Carbon Dioxide. Macromol. Rapid Commun. 2014, 35, 1238–1254. [Google Scholar] [CrossRef] [PubMed]

- Prociak, A.; Malewska, E.; Bąk, S. Influence of Isocyanate Index on Selected Properties of Flexible Polyurethane Foams Modified with Various Bio-Components. J. Renew. Mater. 2016, 4, 78. [Google Scholar] [CrossRef]

- Gomez-Lopez, A.; Elizalde, F.; Calvo, I.; Sardon, H. Trends in Non-Isocyanate Polyurethane (NIPU) Development. Chem. Commun. 2021, 57, 12254–12265. [Google Scholar] [CrossRef]

- Lee, Y.J.; Park, C.K.; Kim, S.H. Fabrication of Castor-Oil/Polycaprolactone Based Bio-Polyurethane Foam Reinforced with Nanocellulose. Polym. Compos. 2018, 39, 2004–2011. [Google Scholar] [CrossRef]

- Stanzione, M.; Oliviero, M.; Cocca, M.; Errico, M.E.; Gentile, G.; Avella, M.; Lavorgna, M.; Buonocore, G.G.; Verdolotti, L. Tuning of Polyurethane Foam Mechanical and Thermal Properties Using Ball-Milled Cellulose. Carbohydr. Polym. 2020, 231, 115772. [Google Scholar] [CrossRef] [PubMed]

- Faruk, O.; Sain, M.; Farnood, R.; Pan, Y.F.; Xiao, H.N. Development of Lignin and Nanocellulose Enhanced Bio PU Foams for Automotive Parts. J. Polym. Environ. 2014, 22, 279–288. [Google Scholar] [CrossRef]

- Ghasemi, S.; Amini, E.N.; Tajvidi, M.; Kiziltas, A.; Mielewski, D.F.; Gardner, D.J. Flexible Polyurethane Foams Reinforced with Organic and Inorganic Nanofillers. J. Appl. Polym. Sci. 2021, 138, 49983. [Google Scholar] [CrossRef]

- Xue, B.-L.; Wen, J.-L.; Sun, R.-C. Lignin-Based Rigid Polyurethane Foam Reinforced with Pulp Fiber: Synthesis and Characterization. ACS Sustain. Chem. Eng. 2014, 2, 1474–1480. [Google Scholar] [CrossRef]

- Cordero, A.I.; Amalvy, J.I.; Fortunati, E.; Kenny, J.M.; Chiacchiarelli, L.M. The Role of Nanocrystalline Cellulose on the Microstructure of Foamed Castor-Oil Polyurethane Nanocomposites. Carbohydr. Polym. 2015, 134, 110–118. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Park, J.; Minn, K.S.; Youn, J.R.; Song, Y.S. Eco-Friendly Nanocellulose Embedded Polymer Composite Foam for Flame Retardancy Improvement. Macromol. Res. 2020, 28, 165–171. [Google Scholar] [CrossRef]

- Guo, W.; Wang, X.; Zhang, P.; Liu, J.; Song, L.; Hu, Y. Nano-Fibrillated Cellulose-Hydroxyapatite Based Composite Foams with Excellent Fire Resistance. Carbohydr. Polym. 2018, 195, 71–78. [Google Scholar] [CrossRef] [PubMed]

- Leng, W.; Li, J.; Cai, Z. Synthesis and Characterization of Cellulose Nanofibril-Reinforced Polyurethane Foam. Polymers 2017, 9, 597. [Google Scholar] [CrossRef] [PubMed]

- Leng, W.; Pan, B. Thermal Insulating and Mechanical Properties of Cellulose Nanofibrils Modified Polyurethane Foam Composite as Structural Insulated Material. Forests 2019, 10, 200. [Google Scholar] [CrossRef]

- Haridevan, H.; Evans, D.A.C.; Martin, D.J.; Annamalai, P.K. Dispersion Engineering of Cellulose Nanofibres in Polyols: For Controlled Microstructure of High-Performance Polyurethane Foam. Mater. Adv. 2024, 5, 1540–1551. [Google Scholar] [CrossRef]

- Septevani, A.A.; Evans, D.A.C.; Annamalai, P.K.; Martin, D.J. The Use of Cellulose Nanocrystals to Enhance the Thermal Insulation Properties and Sustainability of Rigid Polyurethane Foam. Ind. Crops Prod. 2017, 107, 114–121. [Google Scholar] [CrossRef]

- Septevani, A.A.; Evans, D.A.C.; Martin, D.J.; Annamalai, P.K. Hybrid Polyether-Palm Oil Polyester Polyol Based Rigid Polyurethane Foam Reinforced with Cellulose Nanocrystal. Ind. Crops Prod. 2018, 112, 378–388. [Google Scholar] [CrossRef]

- Gimenez, R.B.; Leonardi, L.; Cerrutti, P.; Amalvy, J.; Chiacchiarelli, L.M. Improved Specific Thermomechanical Properties of Polyurethane Nanocomposite Foams Based on Castor Oil and Bacterial Nanocellulose. J. Appl. Polym. Sci. 2017, 134, 44982. [Google Scholar] [CrossRef]

- Chiacchiarelli, L.M.; Cerrutti, P.; Flores-Johnson, E.A. Compressive Behavior of Rigid Polyurethane Foams Nanostructured with Bacterial Nanocellulose at Low and Intermediate Strain Rates. J. Appl. Polym. Sci. 2020, 137, 48701. [Google Scholar] [CrossRef]

- Haridevan, H.; McLaggan, M.S.; Evans, D.A.C.; Martin, D.J.; Seaby, T.; Zhang, Z.Y.; Annamalai, P.K. Dispersion Methodology for Technical Lignin into Polyester Polyol for High-Performance Polyurethane Insulation Foam. ACS Appl. Polym. Mater. 2021, 3, 3528–3537. [Google Scholar] [CrossRef]

- Phanthong, P.; Reubroycharoen, P.; Hao, X.; Xu, G.; Abudula, A.; Guan, G. Nanocellulose: Extraction and Application. Carbon Resour. Convers. 2018, 1, 32–43. [Google Scholar] [CrossRef]

- Tanguy, N.R.; Wu, H.; Nair, S.S.; Lian, K.; Yan, N. Lignin Cellulose Nanofibrils as an Electrochemically Functional Component for High-Performance and Flexible Supercapacitor Electrodes. ChemSusChem 2021, 14, 1057–1067. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Du, H.; Zheng, T.; Liu, W.; Zhang, M.; Liu, H.; Zhang, X.; Si, C. Lignin-Containing Cellulose Nanomaterials: Preparation and Applications. Green Chem. 2021, 23, 9723–9746. [Google Scholar] [CrossRef]

- Tanguy, N.R.; Rana, M.; Khan, A.A.; Zhang, X.; Tratnik, N.; Chen, H.; Ban, D.; Yan, N. Natural Lignocellulosic Nanofibrils as Tribonegative Materials for Self-Powered Wireless Electronics. Nano Energy 2022, 98, 107337. [Google Scholar] [CrossRef]

- Wang, Z.; Gnanasekar, P.; Sudhakaran Nair, S.; Farnood, R.; Yi, S.; Yan, N. Biobased Epoxy Synthesized from a Vanillin Derivative and Its Reinforcement Using Lignin-Containing Cellulose Nanofibrils. ACS Sustain. Chem. Eng. 2020, 8, 11215–11223. [Google Scholar] [CrossRef]

- Zhang, C.W.; Nair, S.S.; Chen, H.; Yan, N.; Farnood, R.; Li, F.Y. Thermally Stable, Enhanced Water Barrier, High Strength Starch Bio-Composite Reinforced with Lignin Containing Cellulose Nanofibrils. Carbohydr. Polym. 2020, 230, 115626. [Google Scholar] [CrossRef] [PubMed]

- Nair, S.S.; Chen, H.; Peng, Y.; Huang, Y.; Yan, N. Polylactic Acid Biocomposites Reinforced with Nanocellulose Fibrils with High Lignin Content for Improved Mechanical, Thermal, and Barrier Properties. ACS Sustain. Chem. Eng. 2018, 6, 10058–10068. [Google Scholar] [CrossRef]

- Peng, Y.; Nair, S.S.; Chen, H.; Yan, N.; Cao, J. Effects of Lignin Content on Mechanical and Thermal Properties of Polypropylene Composites Reinforced with Micro Particles of Spray Dried Cellulose Nanofibrils. ACS Sustain. Chem. Eng. 2018, 6, 11078–11086. [Google Scholar] [CrossRef]

- Nair, S.S.; Kuo, P.-Y.; Chen, H.; Yan, N. Investigating the Effect of Lignin on the Mechanical, Thermal, and Barrier Properties of Cellulose Nanofibril Reinforced Epoxy Composite. Ind. Crops Prod. 2017, 100, 208–217. [Google Scholar] [CrossRef]

- Trifol, J.; Marin Quintero, D.C.; Moriana, R. Pine Cone Biorefinery: Integral Valorization of Residual Biomass into Lignocellulose Nanofibrils (LCNF)-Reinforced Composites for Packaging. ACS Sustain. Chem. Eng. 2021, 9, 2180–2190. [Google Scholar] [CrossRef]

- Chen, H.; Nair, S.S.; Chauhan, P.; Yan, N. Lignin Containing Cellulose Nanofibril Application in PMDI Wood Adhesives for Drastically Improved Gap-Filling Properties with Robust Bondline Interfaces. Chem. Eng. J. 2019, 360, 393–401. [Google Scholar] [CrossRef]

- Chen, H.; Gnanasekar, P.; Nair, S.S.; Xu, W.; Chauhan, P.; Yan, N. Lignin as a Key Component in Lignin-Containing Cellulose Nanofibrils for Enhancing the Performance of Polymeric Diphenylmethane Diisocyanate Wood Adhesives. ACS Sustain. Chem. Eng. 2020, 8, 17165–17176. [Google Scholar] [CrossRef]

- Nair, S.S.; Yan, N. Effect of High Residual Lignin on the Thermal Stability of Nanofibrils and Its Enhanced Mechanical Performance in Aqueous Environments. Cellulose 2015, 22, 3137–3150. [Google Scholar] [CrossRef]

- D’Souza, J.; Camargo, R.; Yan, N. Polyurethane Foams Made from Liquefied Bark-Based Polyols. J. Appl. Polym. Sci. 2014, 131, 40599. [Google Scholar] [CrossRef]

- Hayati, A.N.; Evans, D.A.C.; Laycock, B.; Martin, D.J.; Annamalai, P.K. A Simple Methodology for Improving the Performance and Sustainability of Rigid Polyurethane Foam by Incorporating Industrial Lignin. Ind. Crops Prod. 2018, 117, 149–158. [Google Scholar] [CrossRef]

- ASTM D4274-23; Standard Test Methods for Testing Polyurethane Raw Materials: Determination of Hydroxyl Numbers of Polyols. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM D1622-20; Standard Test Method for Apparent Density of Rigid Cellular Plastics. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D6226-21; Standard Test Method for Open Cell Content of Rigid Cellular Plastics. ASTM International: West Conshohocken, PA, USA, 2021.

- Ma, X.; Li, S.; Wang, F.; Wu, J.; Chao, Y.; Chen, X.; Chen, P.; Zhu, J.; Yan, N.; Chen, J. Catalyst-Free Synthesis of Covalent Adaptable Network (CAN) Polyurethanes from Lignin with Editable Shape Memory Properties. ChemSusChem 2023, 16, e202202071. [Google Scholar] [CrossRef] [PubMed]

- Levchik, G.F.; Si, K.; Levchik, S.V.; Camino, G.; Wilkie, C.A. The Correlation between Cross-Linking and Thermal Stability: Cross-Linked Polystyrenes and Polymethacrylates. Polym. Degrad. Stab. 1999, 65, 395–403. [Google Scholar] [CrossRef]

- Zhao, Y.; Yan, N.; Feng, M. Polyurethane Foams Derived from Liquefied Mountain Pine Beetle-infested Barks. J. Appl. Polym. Sci. 2012, 123, 2849–2858. [Google Scholar] [CrossRef]

- Luo, Y.; Fan, J.; Budarin, V.L.; Hu, C.; Clark, J.H.; Matharu, A.; Melo, E.M. de Toward a Zero-Waste Biorefinery: Confocal Microscopy as a Tool for the Analysis of Lignocellulosic Biomass. ACS Sustain. Chem. Eng. 2018, 6, 13185–13191. [Google Scholar] [CrossRef]

- Singh, S.; Simmons, B.A.; Vogel, K.P. Visualization of Biomass Solubilization and Cellulose Regeneration during Ionic Liquid Pretreatment of Switchgrass. Biotechnol. Bioeng. 2009, 104, 68–75. [Google Scholar] [CrossRef]

- ASTM D1621-16; Standard Test Method for Compressive Properties of Rigid Cellular Plastics. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C518-10; Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus. ASTM International: West Conshohocken, PA, USA, 2015.

- Asano, Y.; Hatakeyama, H.; Hatakeyama, T. Thermal and Mechanical Properties of Sodium Lignosulfonate-Based Rigid Polyurethane Foams Prepared with Three Kinds of Polyols. Sen’i Gakkaishi 2003, 59, 465–470. [Google Scholar] [CrossRef]

- Haridevan, H.; Chaleat, C.; Pooley, L.; Evans, D.A.C.; Halley, P.J.; Martin, D.J.; Annamalai, P.K. Processing and Rheological Properties of Polyol/Cellulose Nanofibre Dispersions for Polyurethanes. Polymer 2022, 255, 125130. [Google Scholar] [CrossRef]

- Ionescu, M. Chemistry and Technology of Polyols for Polyurethanes; iSmithers Rapra Publishing: Shawbury, UK, 2005; ISBN 1859575013. [Google Scholar]

- Amran, U.A.; Salleh, K.M.; Zakaria, S.; Roslan, R.; Chia, C.H.; Jaafar, S.N.S.; Sajab, M.S.; Mostapha, M. Production of Rigid Polyurethane Foams Using Polyol from Liquefied Oil Palm Biomass: Variation of Isocyanate Indexes. Polymers 2021, 13, 3072. [Google Scholar] [CrossRef] [PubMed]

- Ivdre, A.; Abolins, A.; Sevastyanova, I.; Kirpluks, M.; Cabulis, U.; Merijs-Meri, R. Rigid Polyurethane Foams with Various Isocyanate Indices Based on Polyols from Rapeseed Oil and Waste PET. Polymers 2020, 12, 738. [Google Scholar] [CrossRef]

- Mosiewicki, M.A.; Rojek, P.; Michałowski, S.; Aranguren, M.I.; Prociak, A. Rapeseed Oil-based Polyurethane Foams Modified with Glycerol and Cellulose Micro/Nanocrystals. J. Appl. Polym. Sci. 2015, 132, 41602. [Google Scholar] [CrossRef]

- Modesti, M.; Lorenzetti, A.; Besco, S. Influence of Nanofillers on Thermal Insulating Properties of Polyurethane Nanocomposites Foams. Polym. Eng. Sci. 2007, 47, 1351–1358. [Google Scholar] [CrossRef]

- Kim, S.H.; Kim, B.K.; Lim, H. Effect of Isocyanate Index on the Properties of Rigid Polyurethane Foams Blown by HFC 365mfc. Macromol. Res. 2008, 16, 467–472. [Google Scholar] [CrossRef]

- Quienne, B.; Cuminet, F.; Pinaud, J.; Semsarilar, M.; Cot, D.; Ladmiral, V.; Caillol, S. Upcycling Biobased Polyurethane Foams into Thermosets: Toward the Closing of the Loop. ACS Sustain. Chem. Eng. 2022, 10, 7041–7049. [Google Scholar] [CrossRef]

- Kim, J.-M.; Kim, J.-H.; Ahn, J.-H.; Kim, J.-D.; Park, S.; Park, K.H.; Lee, J.-M. Synthesis of Nanoparticle-Enhanced Polyurethane Foams and Evaluation of Mechanical Characteristics. Compos. Part B Eng. 2018, 136, 28–38. [Google Scholar] [CrossRef]

- Li, Y.; Ragauskas, A.J. Ethanol Organosolv Lignin-Based Rigid Polyurethane Foam Reinforced with Cellulose Nanowhiskers. RSC Adv. 2012, 2, 3347–3351. [Google Scholar] [CrossRef]

- Shawyer, M.; Pizzali, A.F.M. The Use of Ice on Small Fishing Vessels; Food & Agriculture Organization: Rome, Italy, 2003; ISBN 9251050104. [Google Scholar]

| Sample | NCO Index | Closed Cell Content (%) | Average Cell Size (µm) |

|---|---|---|---|

| PUF | 1.1 | 90.4 ± 0.6 | 397.6 ± 66 |

| 1.05 | 89.9 ± 0.9 | 377.8 ± 41 | |

| 1.0 | 90.1 ± 2.7 | 385.6 ± 48 | |

| 0.95 | 89.5 ± 1.2 | 389.6 ± 79 | |

| PUF1 | 1.1 | 90.1 ± 1.6 | 274.1 ± 61 |

| 1.05 | 90.4 ± 0.6 | 265.2 ± 56 | |

| 1.0 | 90.3 ± 2.1 | 280.5 ± 46 | |

| 0.95 | 89.7 ± 1.2 | 280.1 ± 58 | |

| PUF2 | 1.1 | 87.6 ± 1.9 | 332.1 ± 82 |

| 1.05 | 88.4 ±0.4 | 322.5 ± 62 | |

| 1.0 | 87.5 ± 0.5 | 312.9 ± 75 | |

| 0.95 | 86.9 ± 1.3 | 346.7 ± 90 |

| Sample | T5% (°C) | Tm (°C) | Residue (%) |

|---|---|---|---|

| PUF/1.1 | 242.5 | 318.3 | 13.2 |

| PUF1/1.1 | 256.8 | 324.1 | 22.2 |

| PUF2/1.1 | 251.5 | 322.4 | 19.4 |

| PUF/1.05 | 240.5 | 314.3 | 14.0 |

| PUF1/1.05 | 255.8 | 322.4 | 16.7 |

| PUF2/1.05 | 251.0 | 322.1 | 15.1 |

| PUF/1.0 | 218.9 | 316.1 | 9.8 |

| PUF1/1.0 | 245.2 | 322.0 | 18.9 |

| PUF2/1.0 | 242.1 | 320.4 | 9.9 |

| PUF/0.95 | 205.4 | 311.1 | 19.4 |

| PUF1/0.95 | 244.3 | 316.8 | 20.0 |

| PUF2/0.95 | 224.5 | 316.6 | 19.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bello, K.O.; Yan, N. Mechanical and Insulation Performance of Rigid Polyurethane Foam Reinforced with Lignin-Containing Nanocellulose Fibrils. Polymers 2024, 16, 2119. https://doi.org/10.3390/polym16152119

Bello KO, Yan N. Mechanical and Insulation Performance of Rigid Polyurethane Foam Reinforced with Lignin-Containing Nanocellulose Fibrils. Polymers. 2024; 16(15):2119. https://doi.org/10.3390/polym16152119

Chicago/Turabian StyleBello, Kabirat O., and Ning Yan. 2024. "Mechanical and Insulation Performance of Rigid Polyurethane Foam Reinforced with Lignin-Containing Nanocellulose Fibrils" Polymers 16, no. 15: 2119. https://doi.org/10.3390/polym16152119

APA StyleBello, K. O., & Yan, N. (2024). Mechanical and Insulation Performance of Rigid Polyurethane Foam Reinforced with Lignin-Containing Nanocellulose Fibrils. Polymers, 16(15), 2119. https://doi.org/10.3390/polym16152119