Evaluation of Fatigue Damage Monitoring of Single-Lap Composite Adhesive Joint Using Conductivity

Abstract

:1. Introduction

2. Materials and Methods

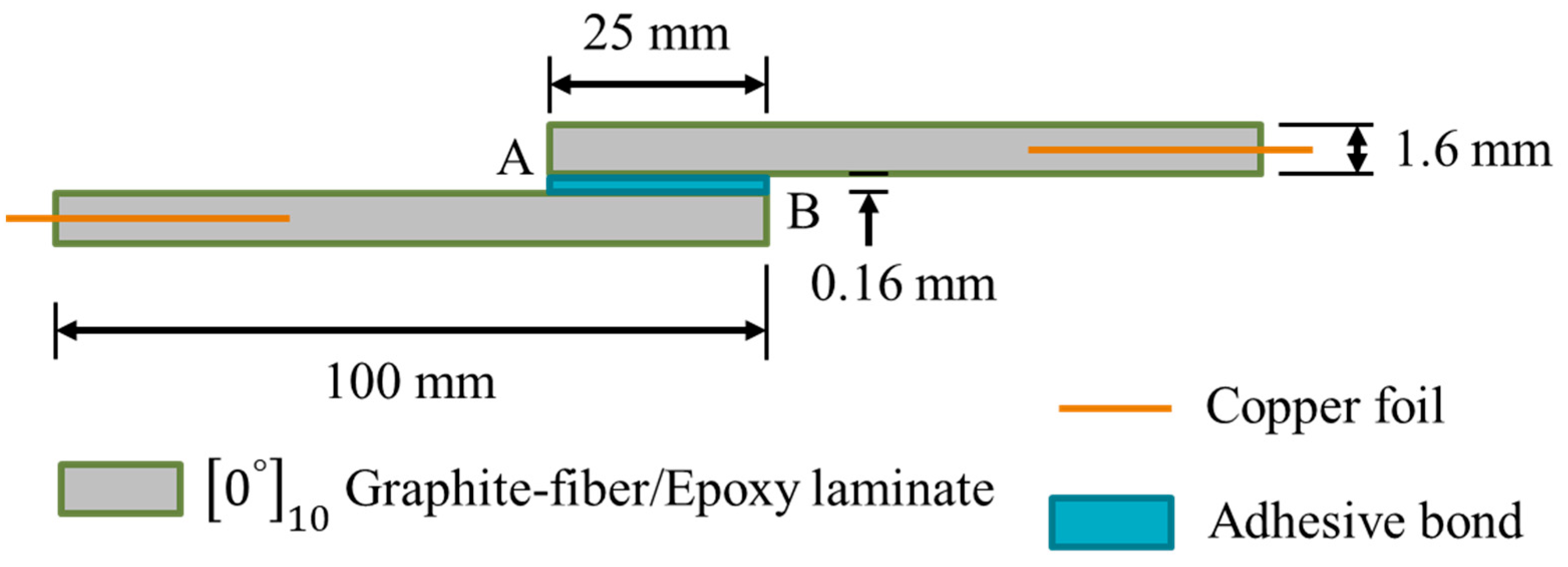

2.1. Lap-Joint Specimen Preparation

2.2. Conductivity Measurement

2.3. Mechanical Testing

2.4. Liquid Fluorescent Penetrant Treatment

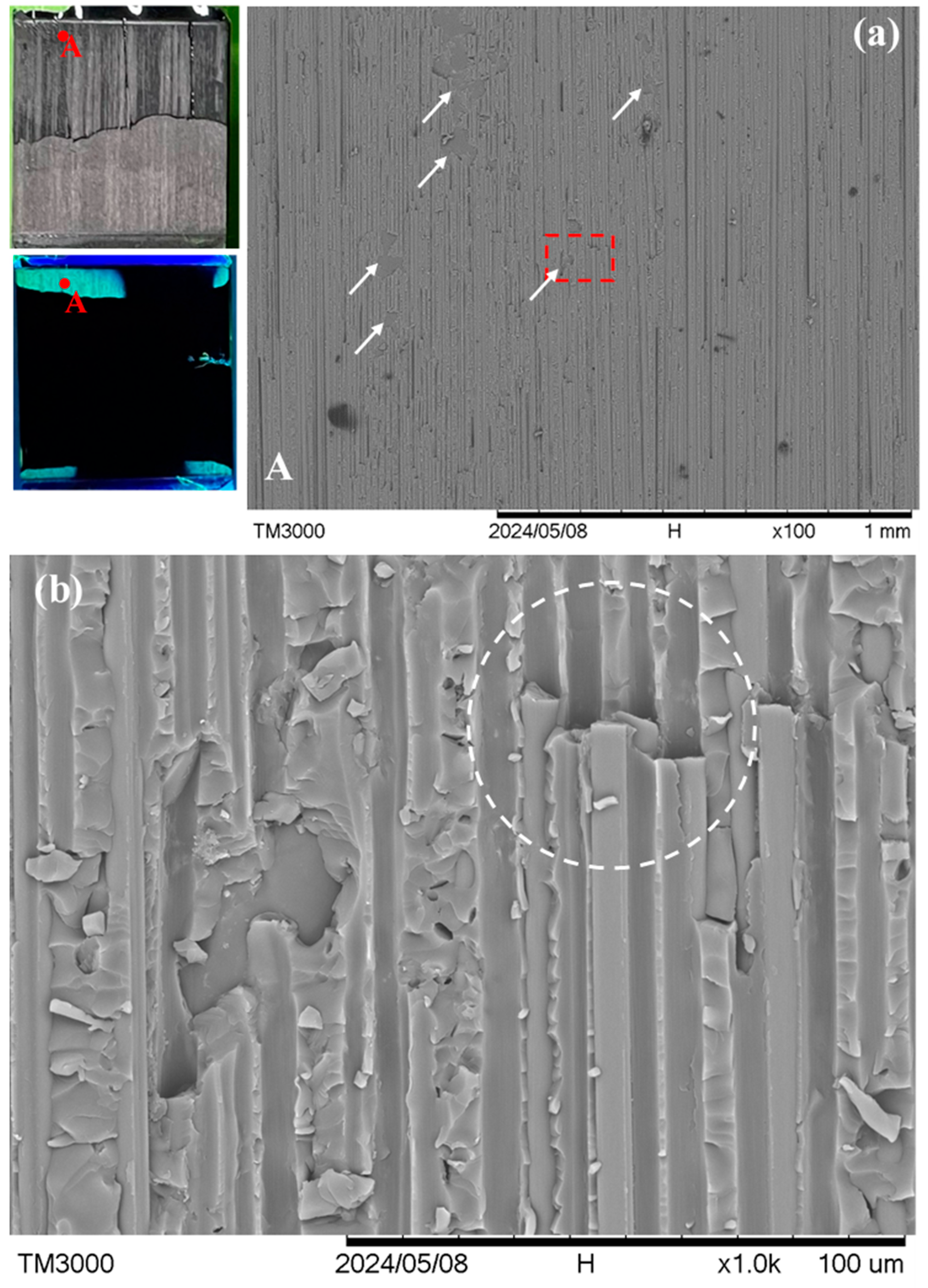

2.5. Fractographic Observation

3. Results

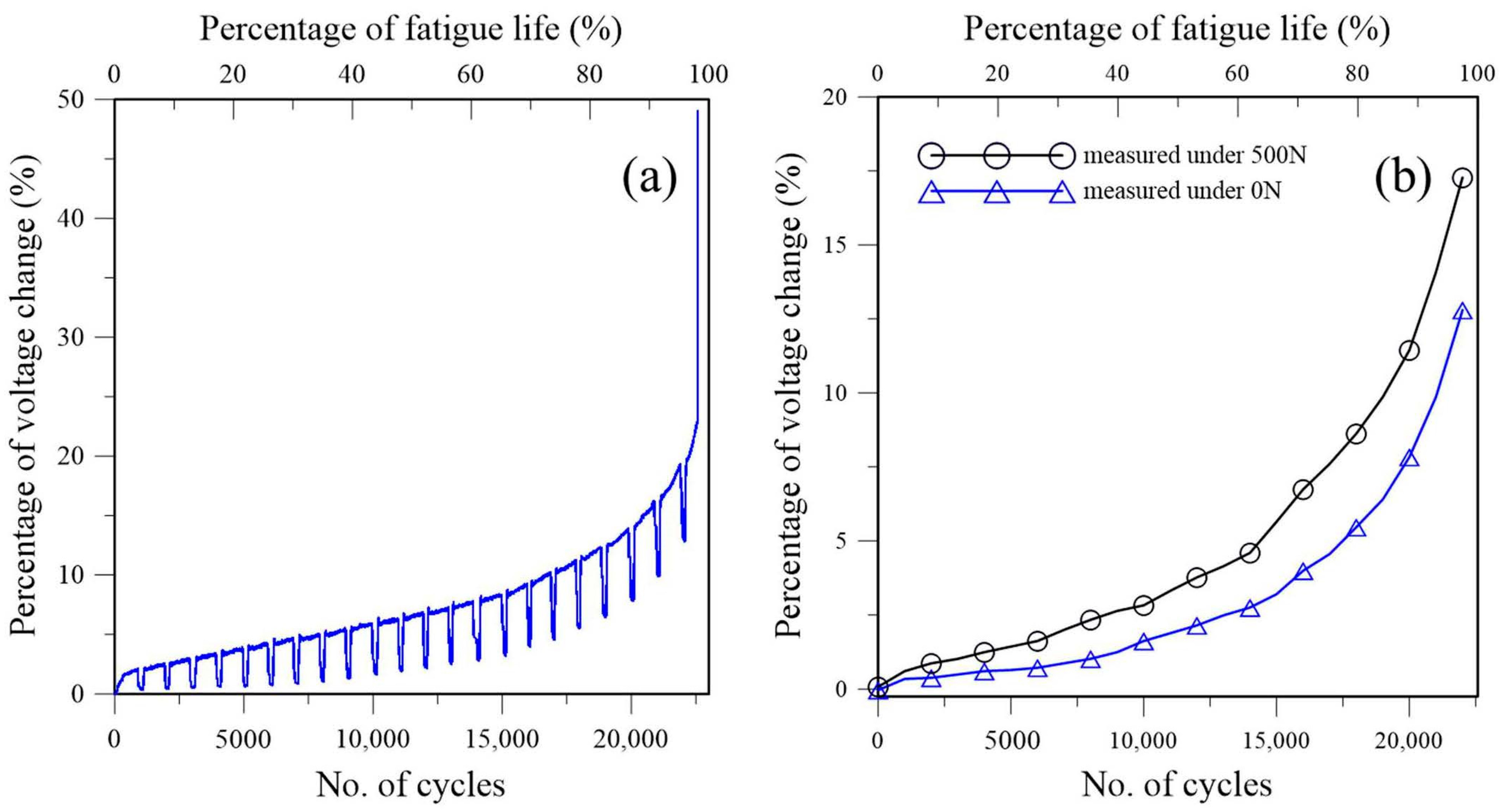

3.1. Voltage Drop across the Adhesive Joint during Fatigue Testing

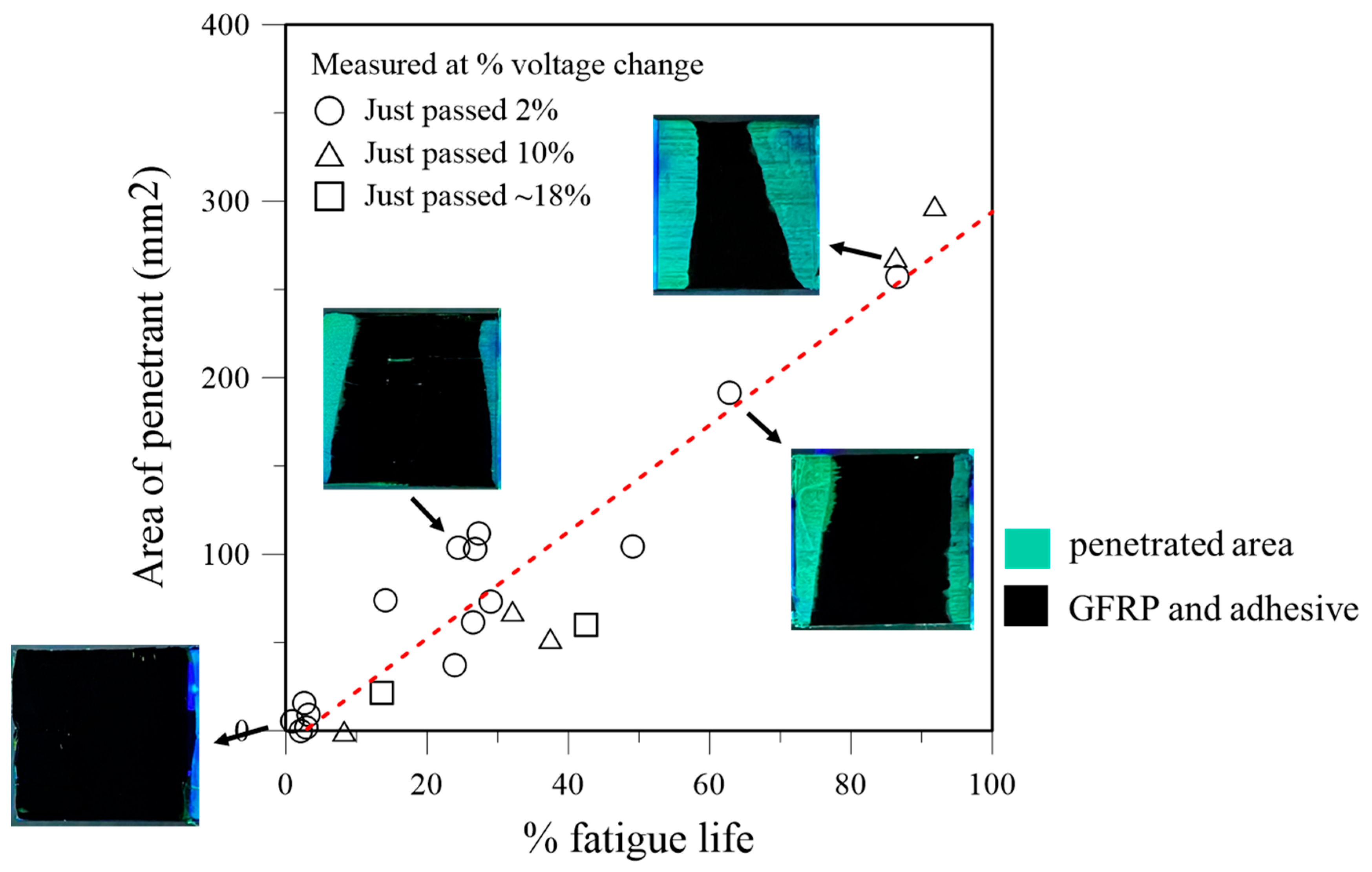

3.2. Relationship between Fatigue Life, Debonded Area, and Percentage Voltage Change

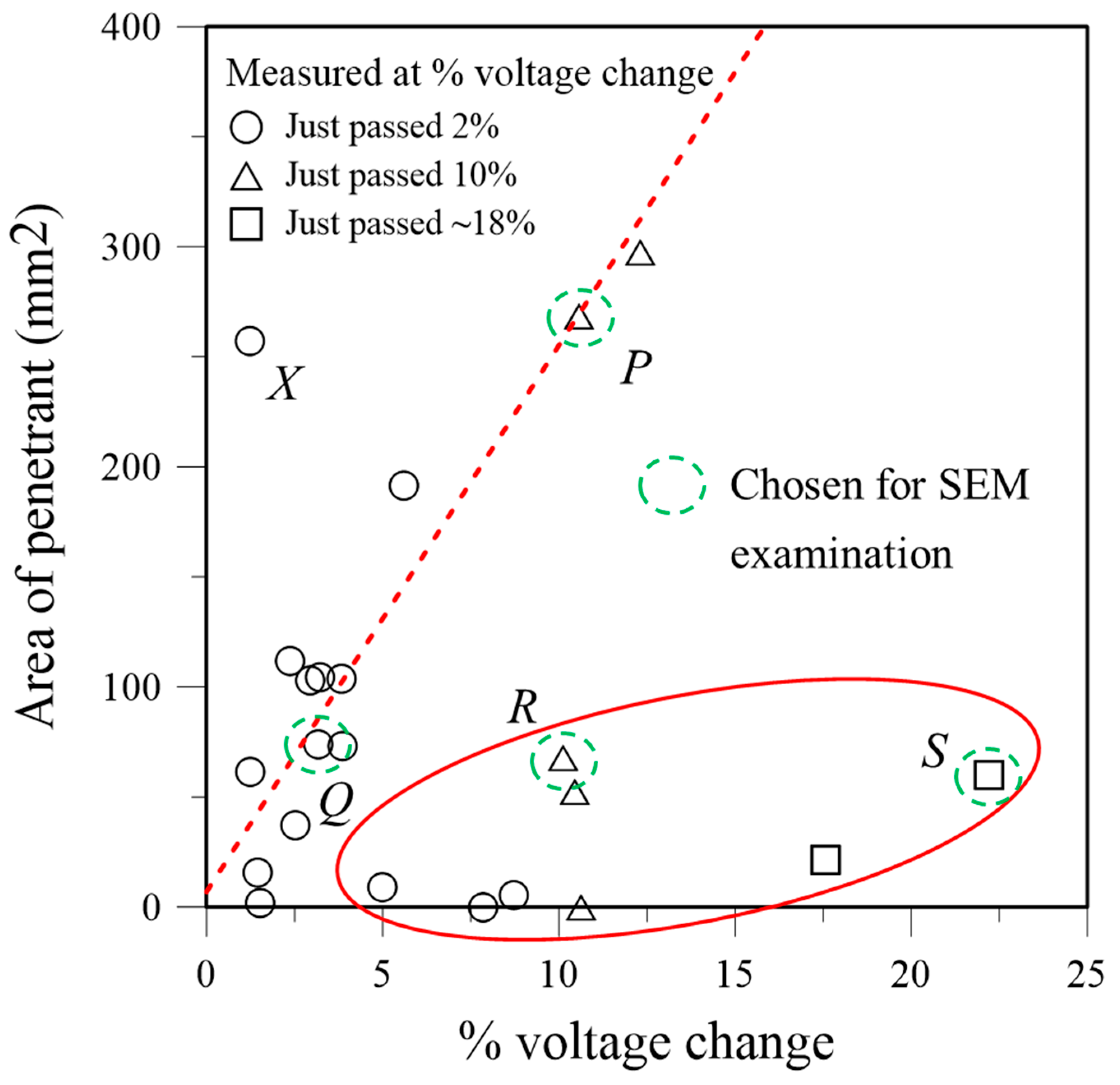

3.3. Fractographic Observation of Damages in the Specimens

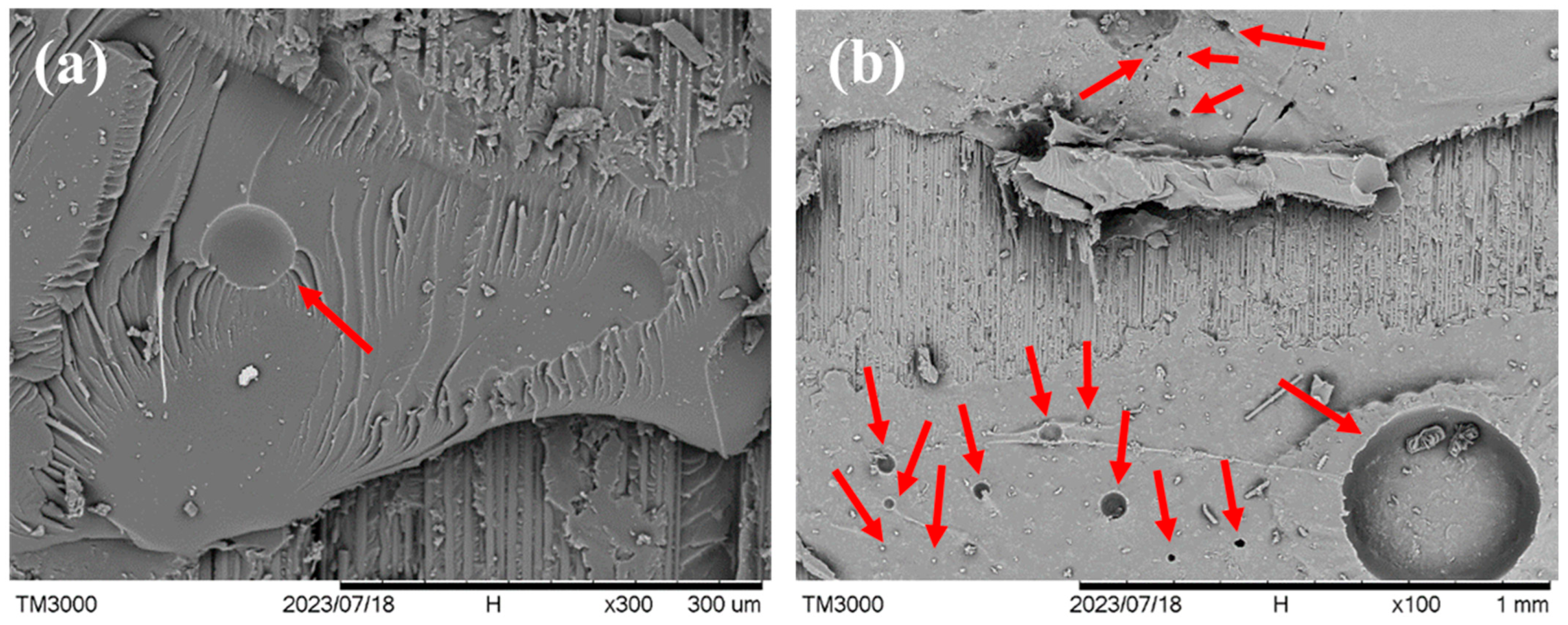

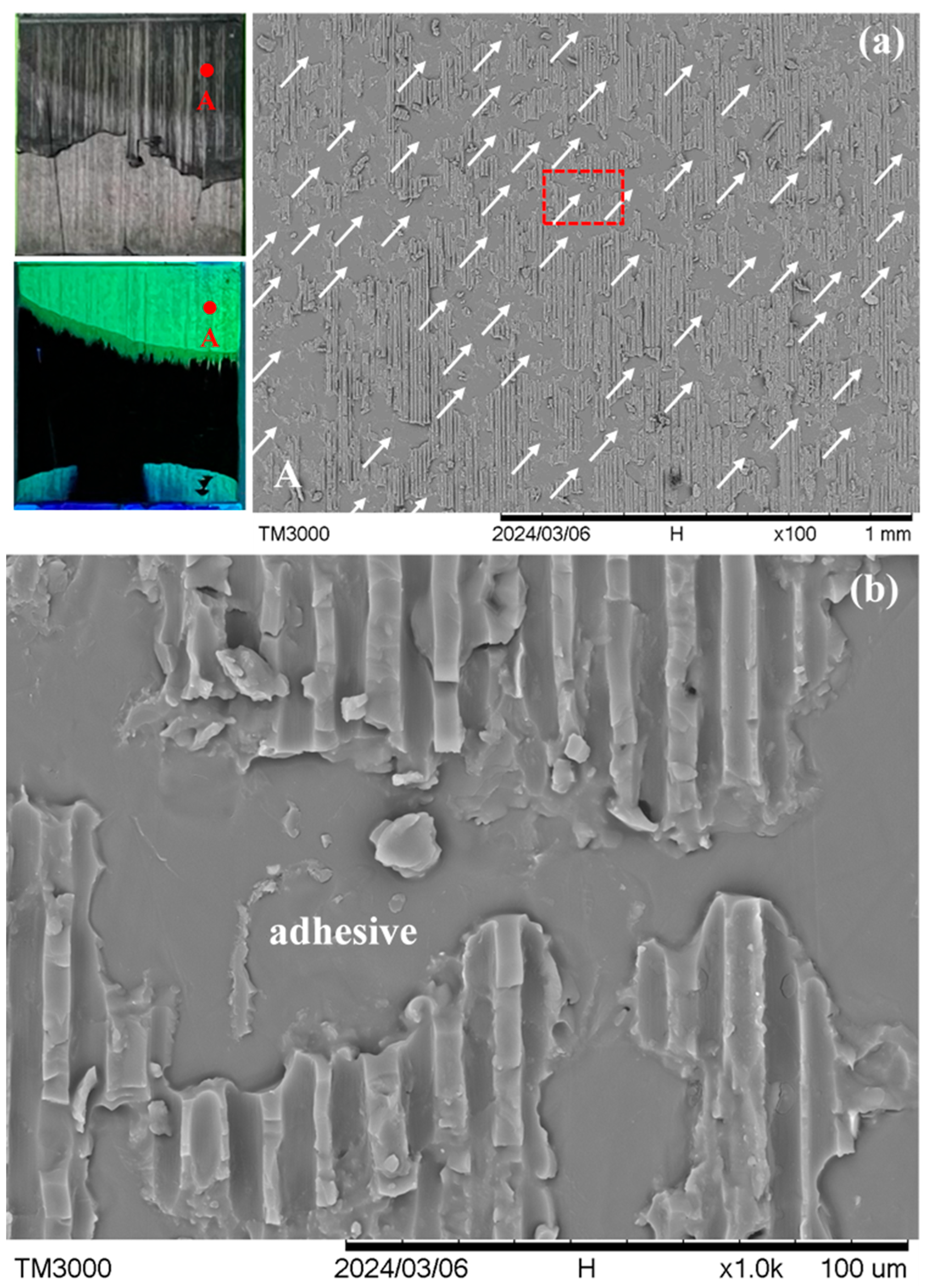

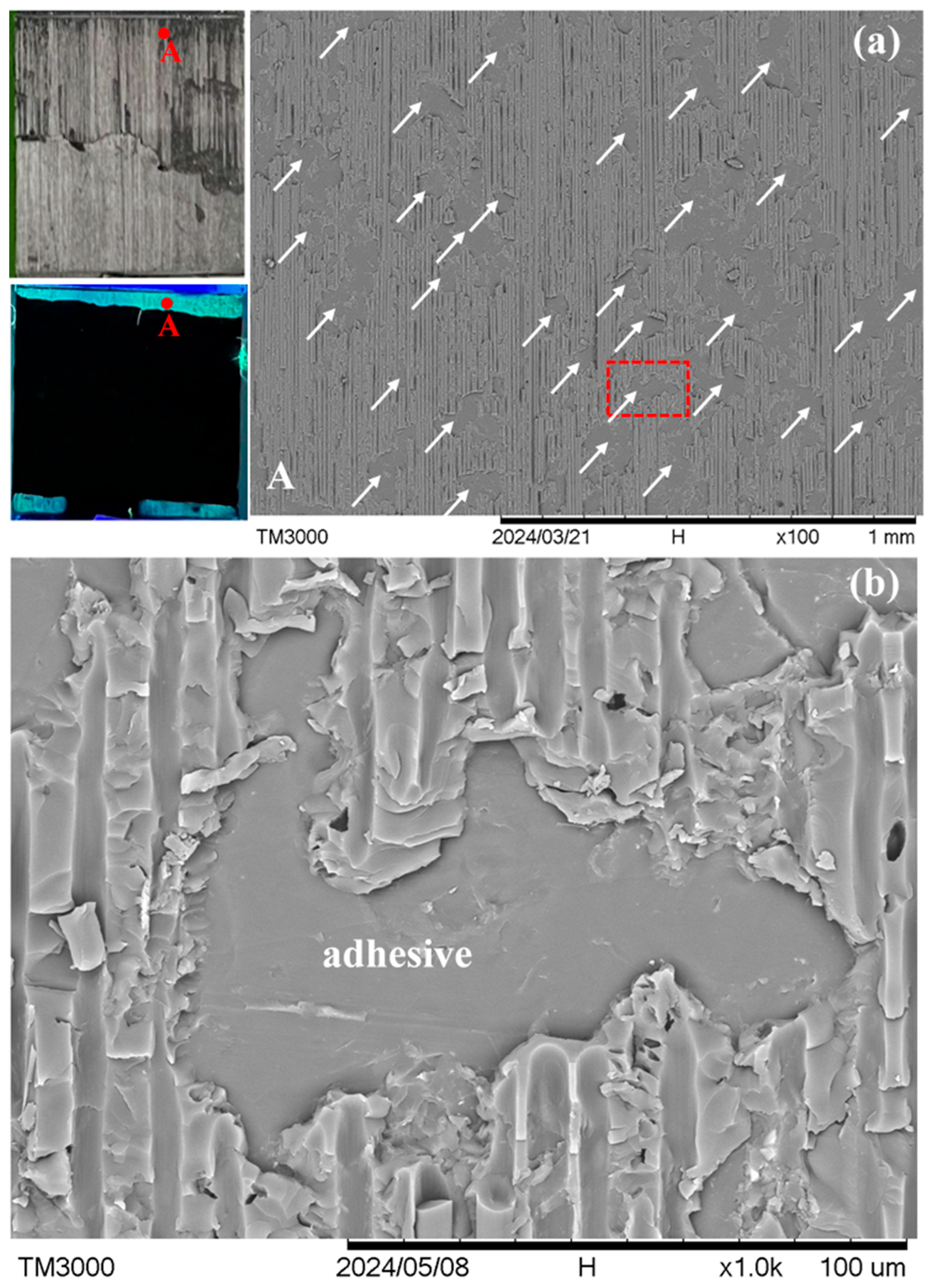

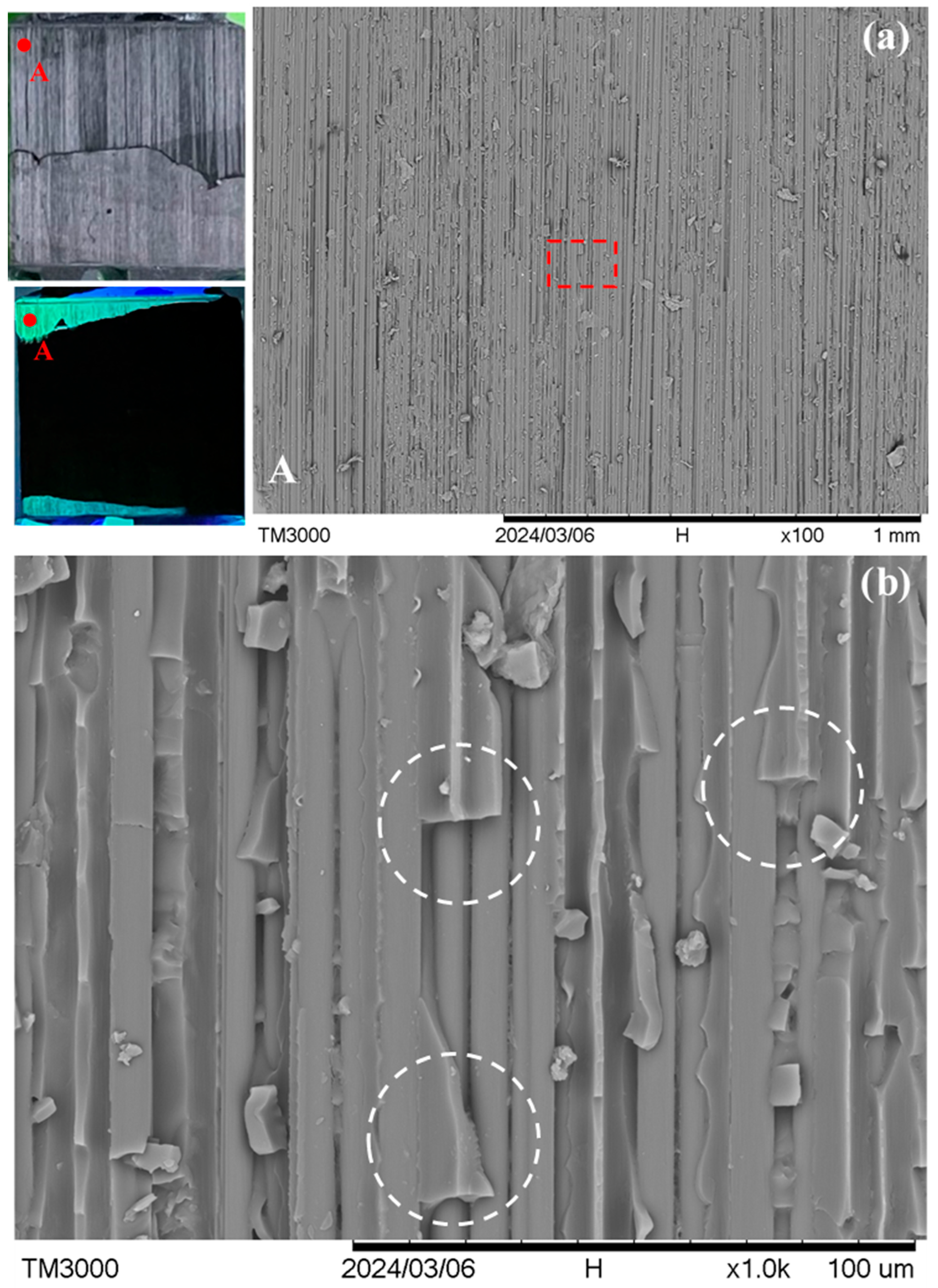

4. Conclusions

- The percentage voltage change monotonically increased from 0% to 49% with fatigue loading cycles. The percentage voltage changes measured at 500 N are higher than that at 0 N, with the difference initially at 0.11% and increasing to 4.48% as it approached the end of the fatigue life.

- The debonded area is roughly directly proportional to the fatigue life expended. A debonded area of 200 mm2, out of the total joint area of 625 mm2, roughly corresponds to 70% expended life.

- The percentage voltage change does not have a unique correlation with the debonded area. Two different trends existed. In one trend, the percentage voltage change correlated linearly with the debonded area. Specimens in this trend are fractured partly by interfacial debonding and partly by the peel-off of fiber from the outermost lamina of the composite adherend. In another trend, considerable voltage changes occurred with small debonded areas. The major fatigue fracture mechanism for specimens in this latter trend is intra- or inter-laminar debonding inside the adherend.

- As there is no unique correlation between the debonded area and the percentage voltage change, the latter is not a valid quantifying parameter for the fatigue life expended in the current composite lap-joint specimens.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Casavola, C.; Palano, F.; De Cillis, F.; Tati, A.; Terzi, R.; Luprano, V. Analysis of CFRP Joints by Means of T-Pull Mechanical Test and Ultrasonic Defects Detection. Materials 2018, 11, 620. [Google Scholar] [CrossRef] [PubMed]

- Jasiuniene, E.; Mazeika, L.; Samaitis, V.; Cicenas, V.; Mattsson, D. Ultrasonic non-destructive testing of complex titanium/carbon fibre composite joints. Ultrasonics 2019, 95, 13–21. [Google Scholar] [CrossRef]

- Yilmaz, B.; Ba, A.; Jasiūnienė, E.; Bui, H.-K.; Berthiau, G. Evaluation of Bonding Quality with Advanced Nondestructive Testing (NDT) and Data Fusion. Sensors 2020, 20, 5127. [Google Scholar] [CrossRef]

- Yu, X.; Fan, Z.; Puliyakote, S.; Castaings, M. Remote monitoring of bond line defects between a composite panel and a stiffener using distributed piezoelectric sensors. Smart Mater. Struct. 2018, 27, 035014. [Google Scholar] [CrossRef]

- Ochôa, P.; Villegas, I.F.; Groves, R.M.; Benedictus, R. Diagnostic of manufacturing defects in ultrasonically welded thermoplastic composite joints using ultrasonic guided waves. NDT E Int. 2019, 107, 102126. [Google Scholar] [CrossRef]

- Mohd Tahir, M.F.; Echtermeyer, A.T. Phased Array Ultrasonic Testing on Thick Glass Fiber Reinforced Thermoplastic Composite Pipe Implementing the Classical Time-Corrected Gain Method. J. Nondestr. Eval. 2024, 43, 74. [Google Scholar] [CrossRef]

- de Almeida, P.D.; Pereira, G.R. Phased array inspection of glass fiber reinforced polymers pipeline joints. J. Mater. Res. Technol. 2019, 8, 4736–4740. [Google Scholar] [CrossRef]

- Nagy, P.B. Ultrasonic detection of kissing bonds at adhesive interfaces. J. Adhes. Sci. Technol. 1991, 5, 619–630. [Google Scholar] [CrossRef]

- Yılmaz, B.; Jasiūnienė, E. Advanced ultrasonic NDT for weak bond detection in composite-adhesive bonded structures. Int. J. Adhes. Adhes. 2020, 102, 102675. [Google Scholar] [CrossRef]

- Liu, T.; Pei, C.; Cheng, X.; Zhou, H.; Xiao, P.; Chen, Z. Adhesive debonding inspection with a small EMAT in resonant mode. NDT E Int. 2018, 98, 110–116. [Google Scholar] [CrossRef]

- Roth, W.; Giurgiutiu, V. Structural health monitoring of an adhesive disbond through electromechanical impedance spectroscopy. Int. J. Adhes. Adhes. 2017, 73, 109–117. [Google Scholar] [CrossRef]

- Medeiros, R.d.; Souza, G.; Marques, D.; Flor, F.; Tita, V. Vibration-based structural monitoring of bi-clamped metal-composite bonded joint: Experimental and numerical analyses. J. Adhes. 2021, 97, 891–917. [Google Scholar] [CrossRef]

- Dugnani, R.; Chang, F.-K. Analytical model of lap-joint adhesive with embedded piezoelectric transducer for weak bond detection. J. Intell. Mater. Syst. Struct. 2017, 28, 124–140. [Google Scholar] [CrossRef]

- Dugnani, R.; Zhuang, Y.; Kopsaftopoulos, F.; Chang, F.-K. Adhesive bond-line degradation detection via a cross-correlation electromechanical impedance–based approach. Struct. Health Monit. 2016, 15, 650–667. [Google Scholar] [CrossRef]

- Grammatikos, S.; Kordatos, E.; Matikas, T.; Paipetis, A. Real-time debonding monitoring of composite repaired materials via electrical, acoustic, and thermographic methods. J. Mater. Eng. Perform. 2014, 23, 169–180. [Google Scholar] [CrossRef]

- Martens, U.; Schröder, K.-U. Evaluation of infrared thermography methods for analysing the damage behaviour of adhesively bonded repair solutions. Compos. Struct. 2020, 240, 111991. [Google Scholar] [CrossRef]

- Shin, P.H.; Webb, S.C.; Peters, K.J. Pulsed phase thermography imaging of fatigue-loaded composite adhesively bonded joints. NDT E Int. 2016, 79, 7–16. [Google Scholar] [CrossRef]

- Kryukov, I.; Böhm, S. Prospects and limitations of eddy current shearography for non-destructive testing of adhesively bonded structural joints. J. Adhes. 2019, 95, 874–886. [Google Scholar] [CrossRef]

- Kryukov, I.; Thiede, H.; Böhm, S. Quality assurance for structural adhesively bonded joints by eddy current shearography. Weld World 2017, 61, 581–588. [Google Scholar] [CrossRef]

- Davis, M.J.; McGregor, A. Assessing adhesive bond failures: Mixed-mode bond failures explained. In Proceedings of the ISASI Australian Safety Seminar, Canberra, Australia, 4–6 June 2010; Available online: http://www.adhesionassociates.com/papers/56%20Assessing%20Adhesive%20Bond%20Failures%20-%20Mixed-Mode%20Bond%20Failures%20Explained.pdf (accessed on 1 June 2024).

- Baker, A.A.; Wang, J. Chapter Six—Adhesively Bonded Repair/Reinforcement of Metallic Airframe Components: Materials, Processes, Design and Proposed Through-Life Management; Jones, R., Baker, A.A., Matthews, N., Champagne, V., Eds.; Aircraft Sustainment and Repair, Butterworth-Heinemann: Oxford, UK, 2018; pp. 191–252. [Google Scholar] [CrossRef]

- Sadeghi, M.Z.; Weiland, J.; Preisler, A.; Zimmermann, J.; Schiebahn, A.; Reisgen, U.; Schröder, K.U. Damage detection in adhesively bonded single lap joints by using backface strain: Proposing a new position for backface strain gauges. Int. J. Adhes. Adhes. 2020, 97, 102494. [Google Scholar] [CrossRef]

- Sadeghi, M.Z.; Weiland, J.; Zimmermann, J.; Schiebahn, A.; Reisgen, U.; Schröder, K.U. Experimental and FE investigations on the influential parameters in positioning and measurement of strain gauges in adhesively bonded single lap joints. Procedia Struct. Integr. 2020, 28, 1590–1600. [Google Scholar] [CrossRef]

- Augustin, T.; Karsten, J.; Kötter, B.; Fiedler, B. Health monitoring of scarfed CFRP joints under cyclic loading via electrical resistance measurements using carbon nanotube modified adhesive films. Compos. Part A Appl. Sci. Manuf. 2018, 105, 150–155. [Google Scholar] [CrossRef]

- Dengg, A.; Kralovec, C.; Schagerl, M. Damage monitoring of pinned hybrid composite-titanium joints using direct current electrical resistance measurement. Compos. Struct. 2024, 334, 117972. [Google Scholar] [CrossRef]

- Grefe, H.; Weiser, D.; Kandula, M.W.; Dilger, K. Deformation measurement within adhesive bonds of aluminium and CFRP using advanced fibre optic sensors. Manuf. Rev. 2020, 7, 14. [Google Scholar] [CrossRef]

- Young, S.; Penumadu, D.; Foster, D.; Maeser, H.; Balijepalli, B.; Reese, J.; Bank, D.; Dahl, J.; Blanchard, P. Smart Adhesive Joint with High-Definition Fiber-Optic Sensing for Automotive Applications. Sensors 2020, 20, 614. [Google Scholar] [CrossRef] [PubMed]

- Jaiswal, P.R.; Kumar, R.I.; Saeedifar, M.; Saleh, M.; Luyckx, G.; De Waele, W. Deformation and damage evolution of a full-scale adhesive joint between a steel bracket and a sandwich panel for naval application. Proc. Inst. Mech. Engr. Part C J. Mech. Eng. Sci. 2021, 235, 571–584. [Google Scholar] [CrossRef]

- Zeng, H.; Yan, R.; Xu, L.; Gui, S. Application study on fiber Bragg grating sensors in damage monitoring of sandwich composite joints. J. Sandw. Struct. Mater. 2020, 22, 1542–1563. [Google Scholar] [CrossRef]

- Webb, S.; Shin, P.; Peters, K.; Zikry, M.; Stan, N.; Chadderdon, S.; Selfridge, R.; Schultz, S. Characterization of fatigue damage in adhesively bonded lap joints through dynamic, full-spectral interrogation of fiber Bragg grating sensors: 1. Experiments. Smart Mater. Struct. 2013, 23, 025016. [Google Scholar] [CrossRef]

- Karpenko, O.; Khomenko, A.; Koricho, E.; Haq, M.; Udpa, L. Monitoring of fatigue damage in composite lap-joints using guided waves and FBG sensors. In Proceedings of the AIP Conference Proceedings 1706, 42nd Annual Review of Progress in Quantitative Nondestructive Evaluation, Minneapolis, MN, USA, 26–31 July 2015; Chimenti, D.E., Bond, L.J., Eds.; AIP Publishing: Melville, NY, USA, 2016; p. 120005. [Google Scholar] [CrossRef]

- Shin, C.-S.; Lin, T.-C. Adhesive Joint Integrity Monitoring Using the Full Spectral Response of Fiber Bragg Grating Sensors. Polymers 2021, 13, 2954. [Google Scholar] [CrossRef]

- Shin, C.-S.; Lin, T.-C. Hygrothermal Damage Monitoring of Composite Adhesive Joint Using the Full Spectral Response of Fiber Bragg Grating Sensors. Polymers 2022, 14, 368. [Google Scholar] [CrossRef]

- Andrew, J.J.; Arumugam, V.; Ramesh, C. Acoustic emission characterization of local bending behavior for adhesively bonded hybrid external patch repaired glass/epoxy composite laminates. Struct. Health Monit. 2019, 18, 739–756. [Google Scholar] [CrossRef]

- Shin, C.S.; Chiang, C.C. Deformation monitoring by using optical fiber grating sensor. J. Chin. Inst. Eng. 2005, 28, 985–992. [Google Scholar] [CrossRef]

- Wen, S.; Wang, S.; Chung, D. Piezoresistivity in continuous carbon fiber polymer-matrix and cement-matrix composites. J. Mater. Sci. 2000, 35, 3669–3675. [Google Scholar] [CrossRef]

- Zhang, J.; Zhuang, R.; Liu, J.; Mäder, E.; Heinrich, G.; Gao, S. Functional interphases with multi-walled carbon nanotubes in glass fibre/epoxy composites. Carbon 2010, 48, 2273–2281. [Google Scholar] [CrossRef]

- Park, J.-M.; Kwon, D.-J.; Wang, Z.-J.; DeVries, K.L. Review of self-sensing of damage and interfacial evaluation using electrical resistance measurements in nano/micro carbon materials-reinforced composites. Adv. Compos. Mater. 2015, 24, 197–219. [Google Scholar] [CrossRef]

- Wang, Z.-J.; Kwon, D.-J.; Gu, G.-Y.; Kim, H.-S.; Kim, D.-S.; Lee, C.-S.; DeVries, K.L.; Park, J.-M. Mechanical and interfacial evaluation of CNT/polypropylene composites and monitoring of damage using electrical resistance measurements. Compos. Sci. Technol. 2013, 81, 69–75. [Google Scholar] [CrossRef]

- Bilotti, E.; Zhang, H.; Deng, H.; Zhang, R.; Fu, Q.; Peijs, T. Controlling the dynamic percolation of carbon nanotube based conductive polymer composites by addition of secondary nanofillers: The effect on electrical conductivity and tuneable sensing behaviour. Compos. Sci. Technol. 2013, 74, 85–90. [Google Scholar] [CrossRef]

- Hao, B.; Ma, Q.; Yang, S.; Mäder, E.; Ma, P.-C. Comparative study on monitoring structural damage in fiber-reinforced polymers using glass fibers with carbon nanotubes and graphene coating. Compos. Sci. Technol. 2016, 129, 38–45. [Google Scholar] [CrossRef]

- Pramanik, P.; Khastgir, D.; De, S.; Saha, T. Pressure-sensitive electrically conductive nitrile rubber composites filled with particulate carbon black and short carbon fibre. J. Mater. Sci. 1990, 25, 3848–3853. [Google Scholar] [CrossRef]

- Sánchez-Romate, X.F.; García, C.; Rams, J.; Sánchez, M.; Ureña, A. Structural health monitoring of a CFRP structural bonded repair by using a carbon nanotube modified adhesive film. Compos. Struct. 2021, 270, 114091. [Google Scholar] [CrossRef]

- Sánchez-Romate, X.F.; Coca, Á.; Jiménez-Suárez, A.; Sánchez, M.; Ureña, A. Crack sensing mechanisms of Mode-II and skin-stringer joints between dissimilar materials by using carbon nanotubes. Compos. Sci. Technol. 2021, 201, 108553. [Google Scholar] [CrossRef]

- Sánchez-Romate, X.F.; Sbarufatti, C.; Sánchez, M.; Bernasconi, A.; Scaccabarozzi, D.; Libonati, F.; Cinquemani, S.; Güemes, A.; Ureña, A. Fatigue crack growth identification in bonded joints by using carbon nanotube doped adhesive films. Smart Mater. Struct. 2020, 29, 035032. [Google Scholar] [CrossRef]

- Li, W.; Frederick, H.; Palardy, G. Multifunctional films for thermoplastic composite joints: Ultrasonic welding and damage detection under tension loading. Compos. Part A Appl. Sci. Manuf. 2021, 141, 106221. [Google Scholar] [CrossRef]

- Mactabi, R.; Rosca, I.D.; Hoa, S.V. Monitoring the integrity of adhesive joints during fatigue loading using carbon nanotubes. Compos. Sci. Technol. 2013, 78, 1–9. [Google Scholar] [CrossRef]

- Kim, C.-H.; Choi, J.-H.; Kweon, J.-H. Defect detection in adhesive joints using the impedance method. Compos. Struct. 2015, 120, 183–188. [Google Scholar] [CrossRef]

- Kang, M.-H.; Choi, J.-H.; Kweon, J.-H. Fatigue life evaluation and crack detection of the adhesive joint with carbon nanotubes. Compos. Struct. 2014, 108, 417–422. [Google Scholar] [CrossRef]

- Ladani, R.B.; Wu, S.; Zhang, J.; Ghorbani, K.; Kinloch, A.J.; Mouritz, A.P.; Wang, C.H. Using carbon nanofibre sensors for in-situ detection and monitoring of disbonds in bonded composite joints. Procedia Eng. 2017, 188, 362–368. [Google Scholar] [CrossRef]

- Bregar, T.; An, D.; Gharavian, S.; Burda, M.; Durazo-Cardenas, I.; Thakur, V.K.; Ayre, D.; Słoma, M.; Hardiman, M.; McCarthy, C. Carbon nanotube embedded adhesives for real-time monitoring of adhesion failure in high performance adhesively bonded joints. Sci. Rep. 2020, 10, 16833. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Faller, L.-M.; Farahani, M.; Zangl, H. Structural health monitoring of adhesive joints under pure mode I loading using the electrical impedance measurement. Eng. Fract. Mech. 2021, 245, 107585. [Google Scholar] [CrossRef]

- Li, W.; Palardy, G. Mechanical and electrical properties of MWCNT/PP films and structural health monitoring of GF/PP joints. In Proceedings of the SPE Automotive Composites Conference & Exhibition, Novi, MI, USA, 2–4 November 2021; Available online: https://speautomotive.com/wp-content/uploads/2021/10/MechanicalElectrical-Properties-of-MWCNTPP-Films-for-Structural-Health-Monitoring-of-GFPP-Joints.pdf (accessed on 1 June 2024).

- Kumar, S.; Falzon, B.G.; Hawkins, S.C. Ultrasensitive embedded sensor for composite joints based on a highly aligned carbon nanotube web. Carbon 2019, 149, 380–389. [Google Scholar] [CrossRef]

- Bekas, D.G.; Sharif-Khodaei, Z.; Baltzis, D.; Aliabadi, M.F.; Paipetis, A.S. Quality assessment and damage detection in nanomodified adhesively-bonded composite joints using inkjet-printed interdigital sensors. Compos. Struct. 2019, 211, 557–563. [Google Scholar] [CrossRef]

- Lee, B.M.; Loh, K.J. A 2D percolation-based model for characterizing the piezoresistivity of carbon nanotube-based films. J. Mater. Sci. 2015, 50, 2973–2983. [Google Scholar] [CrossRef]

- Li, C.; Chou, T. Modeling of damage sensing in fiber composites using carbon nanotube networks. Comp. Sci. Technol. 2008, 68, 3373–3379. [Google Scholar] [CrossRef]

- Hu, N.; Karube, Y.; Arai, M.; Watanabe, T.; Yan, C.; Li, Y.; Liu, Y.; Fukunaga, H. Investigation on sensitivity of a polymer/carbon nanotube composite strain sensor. Carbon 2010, 48, 680–687. [Google Scholar] [CrossRef]

- Hu, N.; Karube, Y.; Yan, C.; Masuda, Z.; Fukunaga, H. Tunneling effect in a polymer/carbon nanotube nanocomposite strain sensor. Acta Mater. 2008, 56, 2929–2936. [Google Scholar] [CrossRef]

- Stampfer, C.; Helbling, T.; Jungen, A.; Hierold, C. Piezoresistance of Single-Walled Carbon Nanotubes. In Proceedings of the Transducers & Eurosensors ’07, The 14th International Conference on Solid-State Sensors, Actuators and Microsystems, Lyon, France, 10–14 June 2007; pp. 1565–1568. [Google Scholar] [CrossRef]

- Yang, L.; Anantram, M.P.; Han, J.; Lu, J. Bandgap change of carbon nanotubes: Effect of small uniaxial and torsional strain. Phys. Rev. B 1999, 60, 13874–13878. [Google Scholar] [CrossRef]

- D5868-01; Standard Test Method for Lap Shear Adhesion for Fiber Reinforced Plastic (FRP) Bonding. ASTM International: West Conshohocken, PA, USA, 2014.

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Gonçalves, J.P.M.; de Moura, M.F.S.F.; de Castro, P.M.S.T. A three-dimensional finite element model for stress analysis of adhesive joints. Int. J. Adhes. Adhes. 2002, 22, 357–365. [Google Scholar] [CrossRef]

- Shin, C.-S.; Chen, L.-W. Damage Monitoring of Composite Adhesive Joint Integrity Using Conductivity and Fiber Bragg Grating. Polymers 2023, 15, 1575. [Google Scholar] [CrossRef]

- ASTM D638-22; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D3418-21; Standard Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential Scanning Calorimetry. ASTM International: West Conshohocken, PA, USA, 2021.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, C.-S.; Huang, S.-H. Evaluation of Fatigue Damage Monitoring of Single-Lap Composite Adhesive Joint Using Conductivity. Polymers 2024, 16, 2374. https://doi.org/10.3390/polym16162374

Shin C-S, Huang S-H. Evaluation of Fatigue Damage Monitoring of Single-Lap Composite Adhesive Joint Using Conductivity. Polymers. 2024; 16(16):2374. https://doi.org/10.3390/polym16162374

Chicago/Turabian StyleShin, Chow-Shing, and Shun-Hsuan Huang. 2024. "Evaluation of Fatigue Damage Monitoring of Single-Lap Composite Adhesive Joint Using Conductivity" Polymers 16, no. 16: 2374. https://doi.org/10.3390/polym16162374

APA StyleShin, C.-S., & Huang, S.-H. (2024). Evaluation of Fatigue Damage Monitoring of Single-Lap Composite Adhesive Joint Using Conductivity. Polymers, 16(16), 2374. https://doi.org/10.3390/polym16162374