Fatigue Behaviour of High-Performance Green Epoxy Biocomposite Laminates Reinforced by Optimized Long Sisal Fibers

Abstract

1. Introduction

2. Biocomposite Materials

2.1. Green Epoxy Matrix

2.2. Natural Reinforcement

2.3. Manufacturing of the Biocomposites

3. Experimental Test Methods

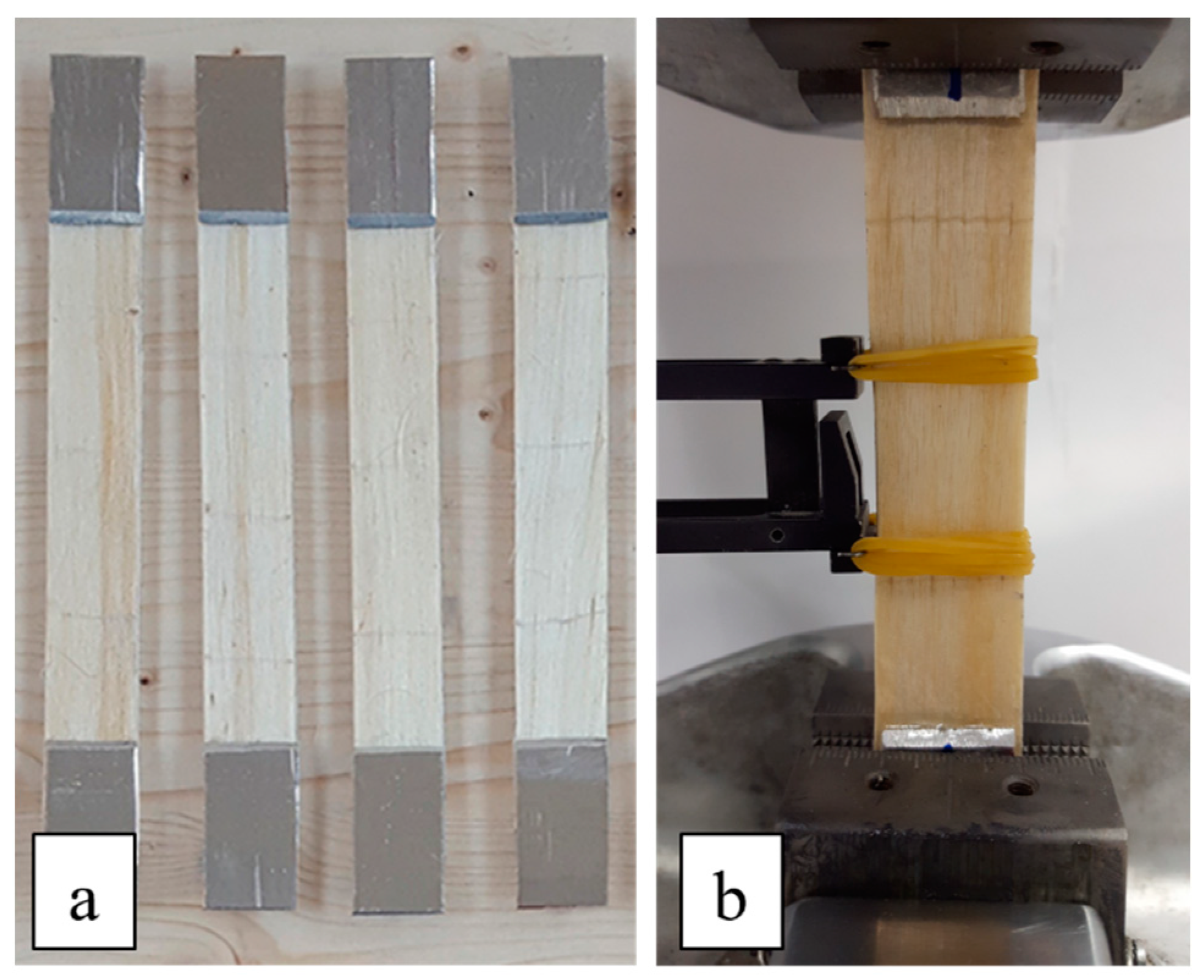

3.1. Static Tensile Tests

3.2. Fatigue Tests

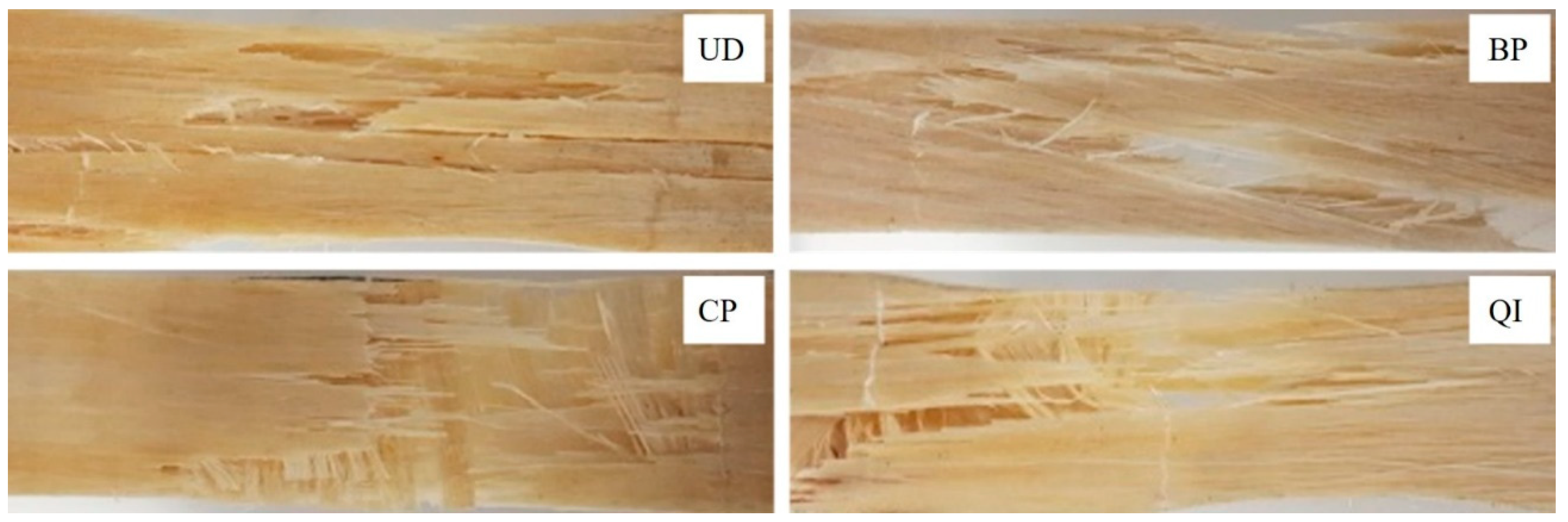

4. Analysis of Results and Damage Evaluation

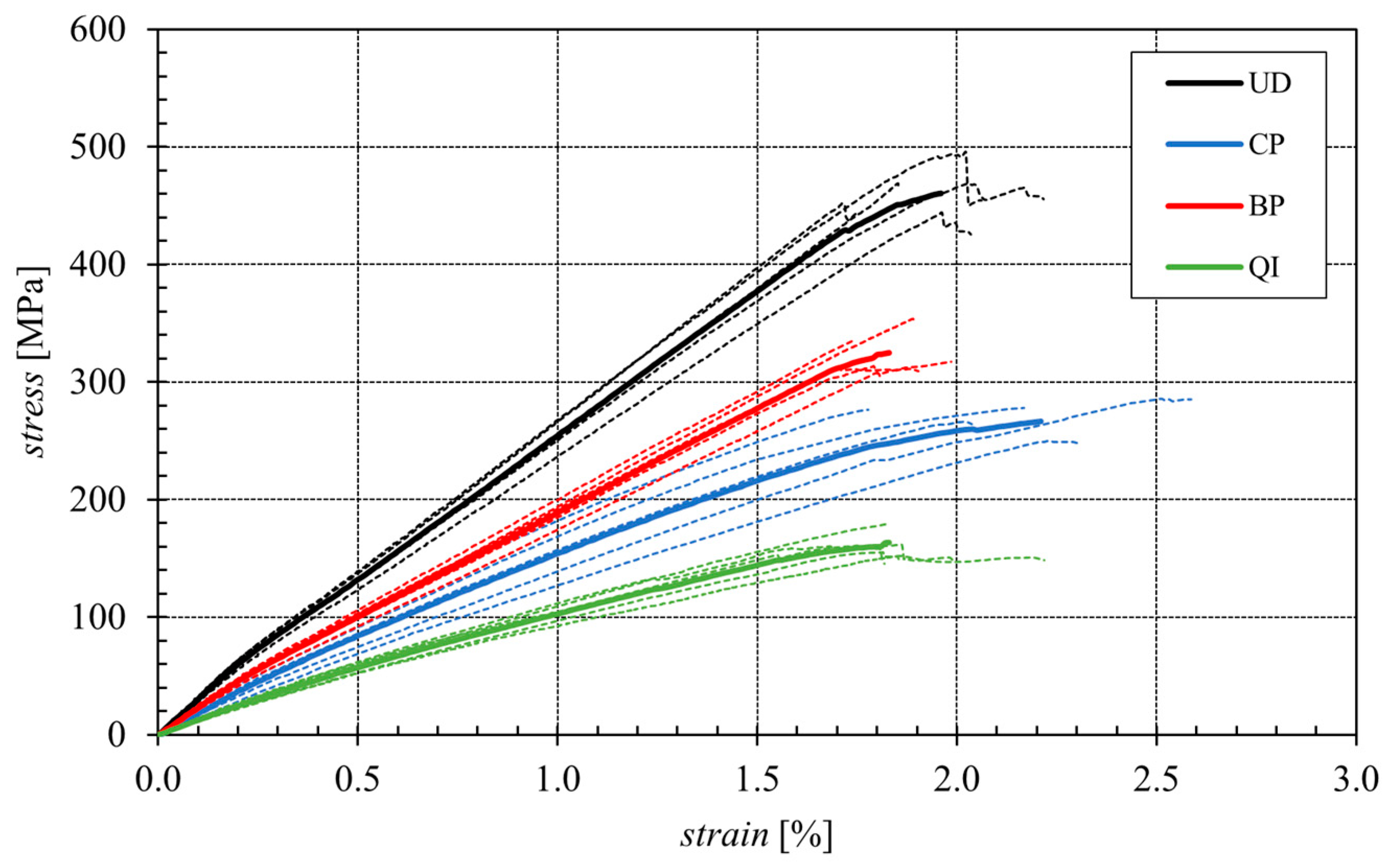

4.1. Static Mechanical Properties

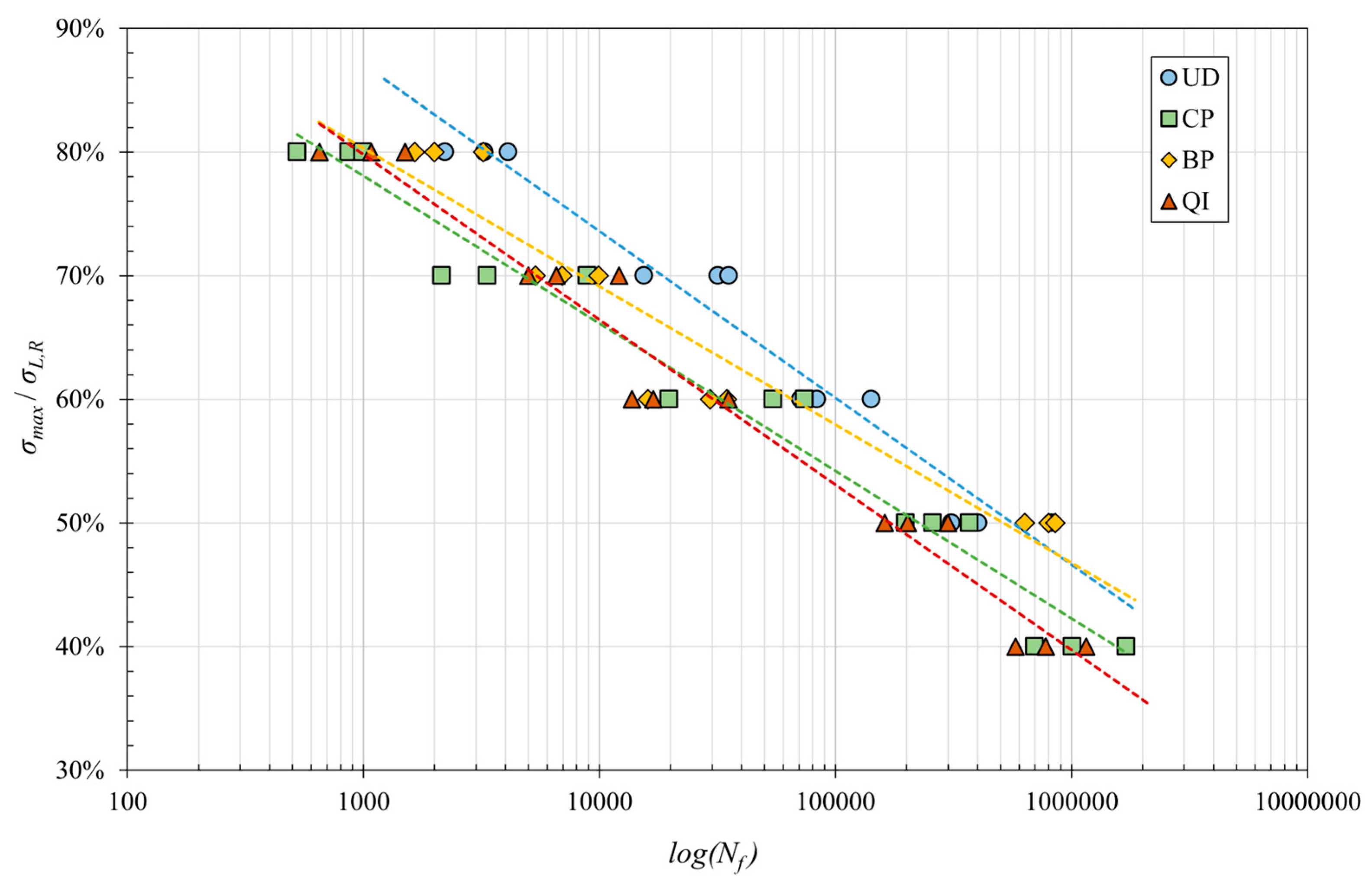

4.2. Fatigue Life

5. Comparison with Other Natural and Synthetic Fiber Composites

6. Conclusions

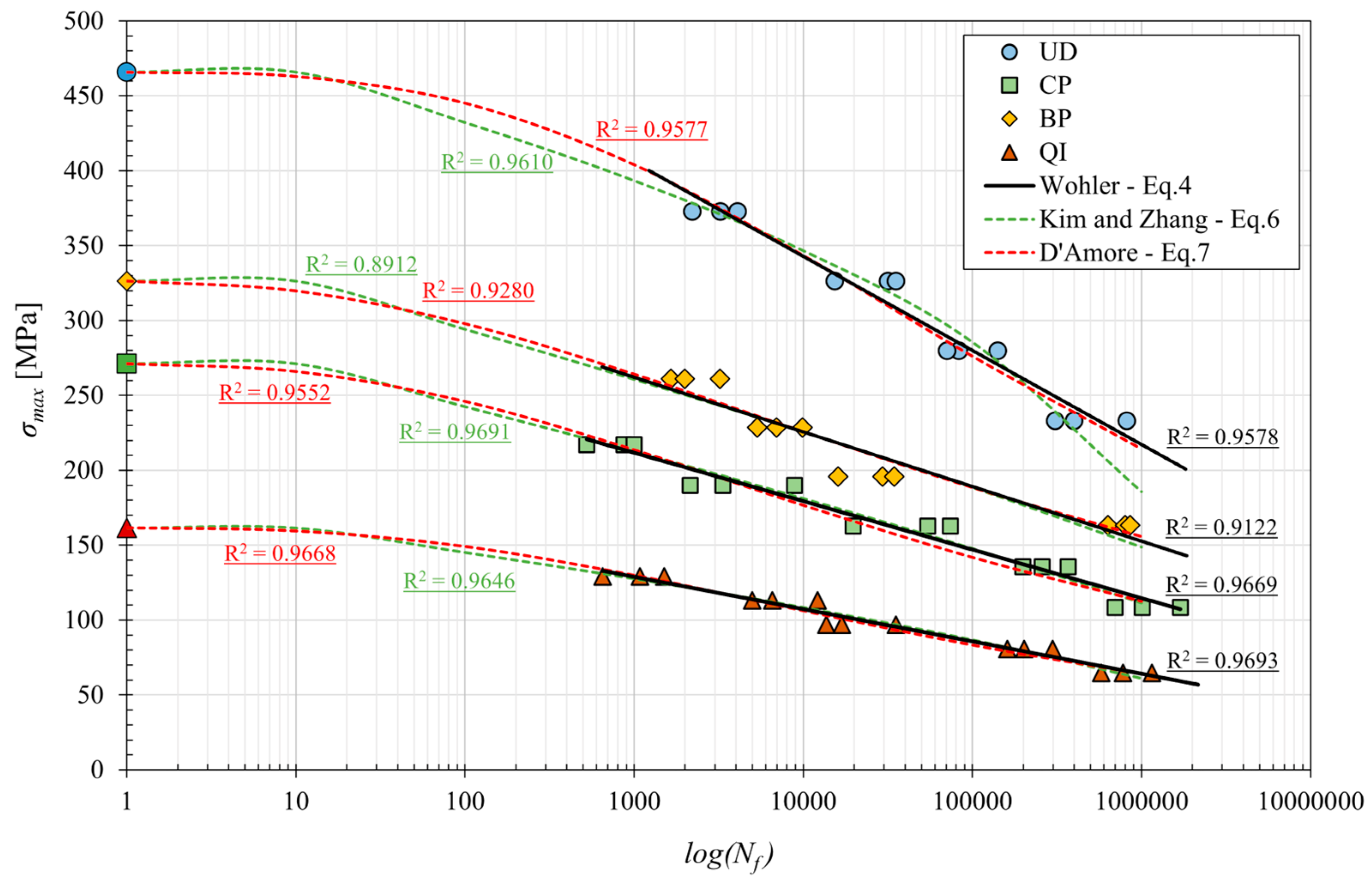

- The laminates exhibit a good fatigue performance, with fatigue ratios close to 0.5 for unidirectional and angle-ply (±7.5°) laminates and close to 0.4 for cross-ply and quasi-isotropic laminates. Interestingly, the absolute fatigue strength values at 106 cycles are equal to about 220 MPa, 150 MPa, 115 MPa and 65 MPa, respectively, for unidirectional, braided-ply, cross-ply and quasi-isotropic lay-up.

- Such fatigue performances are comparable to those of ordinary structural steels and are better than those of different aluminum alloys; consequently, the UD laminates can be used to advantageously replace steel and aluminum in structural applications related to components subject to both static and fatigue loading.

- Unlike described in the literature in relation to synthetic fiber composites, although the braided-ply layup exhibits the best relative fatigue behavior (negligible damage until 85% of the fatigue life), it does not provide the best absolute fatigue strength due to the significant relative reduction in the static strength.

- Interestingly, the fatigue strength of 150 MPa of cross-ply laminate indicates that such lay-up can be widely exploited in the design of structural and semi-structural mechanical components subject to biaxial fatigue loading, as does the fatigue strength of 65 MPa of the quasi-isotropic laminate, which is about 4–5 times the fatigue strength of the matrix alone, indicating that such laminates (or equivalent random discontinuous fiber configurations, the so-called MAT) can be advantageously used to replace plastics in the presence of generic fatigue loading.

- Appropriate models for predicting fatigue behavior at high and low numbers of cycles have been proposed.

- The comparison with both natural fiber and synthetic fiber composites reported in the literature has highlighted that at “low cycles number” fatigue the analyzed biocomposites exhibit better performance than all the comparable composites reported in the literature, also including high-cost and high-environmental impact carbon composites. Such an advantage is preserved up to about 3 105 cycles for all other composites, and it is lost for higher fatigue cycles with respect to high-cost and high-stiffness natural fiber biocomposites.

- The fatigue performances of the analyzed biocomposites are always superior to those of the common fiberglass; such a result confirms previous results that have already been reported in the literature by the same authors, which show in detail that the proposed high-performance biocomposites can be advantageously used to replace common fiberglass in order to increase the use of green materials.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pickering, K.L.; Aruan Efendy, M.G.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Ahmad, F.; Choi, H.S.; Park, M.K. A review: Natural fiber composites selection in view of mechanical, light weight, and economic properties. Macromol. Mater. Eng. 2015, 300, 10–24. [Google Scholar] [CrossRef]

- Koronis, G.; Silva, A.; Fontul, M. Green composites: A review of adequate materials for automotive applications. Compos. Part B Eng. 2013, 44, 120–127. [Google Scholar] [CrossRef]

- Campilho, R. Natural Fiber Composites, 1st ed.; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar] [CrossRef]

- Mahboob, Z.; Bougherara, H. Fatigue of flax-epoxy and other plant fibre composites: Critical review and analysis. Compos. Part A Appl. Sci. Manuf. 2018, 109, 440–462. [Google Scholar] [CrossRef]

- Liang, S.; Gning, P.B.; Guillaumat, L. Properties evolution of flax/epoxy composites under fatigue loading. Int. J. Fatigue 2014, 63, 36–45. [Google Scholar] [CrossRef]

- Liang, S.; Gning, P.B.; Guillaumat, L. A comparative study of fatigue behaviour of flax/epoxy and glass/epoxy composites. Compos. Sci. Technol. 2012, 72, 535–543. [Google Scholar] [CrossRef]

- El Sawi, I.; Fawaz, Z.; Zitoune, R.; Bougherara, H. An investigation of the damage mechanisms and fatigue life diagrams of flax fiber-reinforced polymer laminates. J. Mater. Sci. 2014, 49, 2338–2346. [Google Scholar] [CrossRef]

- Bensadoun, F.; Vallons, K.A.M.; Lessard, L.B.; Verpoest, I.; Van Vuure, A.W. Fatigue behaviour assessment of flax-epoxy composites. Compos. Part A Appl. Sci. Manuf. 2016, 82, 253–266. [Google Scholar] [CrossRef]

- Gassan, J. A study of fibre and interface parameters affecting the fatigue behaviour of natural fibre composites. Compos.–Part A Appl. Sci. Manuf. 2002, 33, 369–374. [Google Scholar] [CrossRef]

- De Vasconcellos, D.S.; Touchard, F.; Chocinski-Arnault, L. Tension-tension fatigue behaviour of woven hemp fibre reinforced epoxy composite: A multi-instrumented damage analysis. Int. J. Fatigue 2014, 59, 159–169. [Google Scholar] [CrossRef]

- Yuanjian, T.; Isaac, D.H. Impact and fatigue behaviour of hemp fibre composites. Compos. Sci. Technol. 2007, 67, 3300–3307. [Google Scholar] [CrossRef]

- Shahzad, A.; Isaac, D.H. Fatigue Properties of Hemp and Glass Fiber Composites. Polym. Compos. 2014, 35, 1926–1934. [Google Scholar] [CrossRef]

- Fotouh, A.; Wolodko, J.D.; Lipsett, M.G. Fatigue of natural fiber thermoplastic composites. Compos. Part B Eng. 2014, 62, 175–182. [Google Scholar] [CrossRef]

- Towo, A.N.; Ansell, M.P. Fatigue of sisal fibre reinforced composites: Constant-life diagrams and hysteresis loop capture. Compos. Sci. Technol. 2008, 68, 915–924. [Google Scholar] [CrossRef]

- Shah, D.U. Damage in biocomposites: Stiffness evolution of aligned plant fibre composites during monotonic and cyclic fatigue loading. Compos. Part A Appl. Sci. Manuf. 2016, 83, 160–168. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J.; Clifford, M.J.; Licence, P. Fatigue life evaluation of aligned plant fibre composites through S-N curves and constant-life diagrams. Compos. Sci. Technol. 2013, 74, 139–149. [Google Scholar] [CrossRef]

- Katunin, A.; Wachla, D.; Santos, P.; Reis, P.N.B. Fatigue life assessment of hybrid bio-composites based on self-heating temperature. Compos. Struct. 2023, 304, 116456. [Google Scholar] [CrossRef]

- Guo, R.; Xian, G.; Li, C.; Hong, B. Effect of fiber hybrid mode on the tension–tension fatigue performance for the pultruded carbon/glass fiber reinforced polymer composite rod. Eng. Fract. Mech. 2022, 260, 108208. [Google Scholar] [CrossRef]

- Xian, G.; Zhou, P.; Bai, Y.; Wang, J.; Li, C.; Dong, S.; Guo, R.; Li, J.; Du, H.; Zhong, J. Design, preparation and mechanical properties of novel glass fiber reinforced polypropylene bending bars. Constr. Build. Mater. 2024, 429, 136455. [Google Scholar] [CrossRef]

- Wilt, J.; GangaRao, H.; Liang, R.; Mostoller, J. Structural responses of FRP sheet piles under cantilever loading. Sustain. Struct. 2023, 3, 8–9. [Google Scholar] [CrossRef]

- Zuccarello, B.; Militello, C.; Bongiorno, F. Influence of the anisotropy of sisal fibers on the mechanical properties of high performance unidirectional biocomposite lamina and micromechanical models. Compos. Part A Appl. Sci. Manuf. 2021, 143, 106320. [Google Scholar] [CrossRef]

- Zuccarello, B.; Bongiorno, F.; Militello, C. Basalt Fiber Hybridization Effects on High-Performance Sisal-Reinforced Biocomposites. Polymer 2022, 14, 1457. [Google Scholar] [CrossRef] [PubMed]

- Zuccarello, B.; Zingales, M. Toward high performance renewable agave reinforced biocomposites: Optimization of fiber performance and fiber-matrix adhesion analysis. Compos. Part B Eng. 2017, 122, 109–120. [Google Scholar] [CrossRef]

- Bongiorno, F.; Militello, C.; Zuccarello, B. Mode I translaminar fracture toughness of high performance laminated biocomposites reinforced by sisal fibers: Accurate measurement approach and lay-up effects. Compos. Sci. Technol. 2022, 217, 109089. [Google Scholar] [CrossRef]

- Militello, C.; Bongiorno, F.; Epasto, G.; Zuccarello, B. Low-velocity impact behaviour of green epoxy biocomposite laminates reinforced by sisal fibers. Compos. Struct. 2020, 253, 112744. [Google Scholar] [CrossRef]

- Zuccarello, B.; Marannano, G.; Mancino, A. Optimal manufacturing and mechanical characterization of high performance biocomposites reinforced by sisal fibers. Compos. Struct. 2018, 194, 575–583. [Google Scholar] [CrossRef]

- Zuccarello, B.; Militello, C.; Bongiorno, F. Environmental aging effects on high-performance biocomposites reinforced by sisal fibers. Polym. Degrad. Stab. 2023, 211, 110319. [Google Scholar] [CrossRef]

- Zuccarello, B.; Bartoli, M.; Bongiorno, F.; Militello, C.; Tagliaferro, A.; Pantano, A. New concept in bioderived composites: Biochar as toughening agent for improving performances and durability of agave-based epoxy biocomposites. Polymers 2021, 13, 198. [Google Scholar] [CrossRef]

- Pantano, A.; Militello, C.; Bongiorno, F.; Zuccarello, B. Analysis of the parameters affecting the stiffness of short sisal fiber biocomposites manufactured by compression-molding. Polymers 2022, 14, 154. [Google Scholar] [CrossRef]

- Pantano, A.; Bongiorno, F.; Marannano, G.; Zuccarello, B. Enhancement of Static and Fatigue Strength of Short Sisal Fiber Biocomposites by Low Fraction Nanotubes. Appl. Compos. Mater. 2021, 28, 91–112. [Google Scholar] [CrossRef]

- ASTM D 3822; Standard Test Method for Tensile Properties of Single Textile Fibers. ASTM International: West Conshohocken, PA, USA, 2001.

- Agarwal, B.D.; Broutman, L.J.; Chandrashekhara, K. Analysis and Performance of Fiber Composites; John Wiley & Sons: New York, NY, USA; New Delhi, India, 1998. [Google Scholar] [CrossRef]

- Barbero, E.J. Introduction to Composite Materials Design; Taylo & Francis Group: New York, NY, USA, 1999. [Google Scholar]

- ASTM D 3039; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2014.

- Plumtree, A.; Melo, M.; Dahl, J. Damage evolution in a [±45]2S CFRP laminate under block loading conditions. Int. J. Fatigue 2010, 32, 139–145. [Google Scholar] [CrossRef]

- Ye, L. On fatigue damage accumulation and material degradation in composite materials. Compos. Sci. Technol. 1989, 36, 339–350. [Google Scholar] [CrossRef]

- Kim, H.S.; Huang, S. S-n curve characterisation for composite materials and prediction of remaining fatigue life using damage function. J. Compos. Sci. 2021, 5, 76. [Google Scholar] [CrossRef]

- D’Amore, A.; Caprino, G.; Stupak, P.; Zhou, J.; Nicolais, L. Effect of stress ratio on the flexural fatigue behaviour of continuous strand mat reinforced plastics. Sci. Eng. Compos. Mater. 1996, 5, 1–8. [Google Scholar] [CrossRef]

- Mandell, J.F.; Reed, R.M.; Samborsky, D.D. Fatigue of Fiberglass Wind Turbine Blade Materials. American Society of Mechanical Engineers, Solar Energy Division. 1992. Available online: https://www.osti.gov/biblio/10105798 (accessed on 1 August 1992).

- Kawai, M.; Yajima, S.; Hachinohr, E.A.; Takano, Y. Off-Axis Fatigue Behavior of Unidirectional Carbon Fiber Reinforced Composites at Room and High Temperatures. J. Compos. Mater. 2001, 35, 545–576. [Google Scholar] [CrossRef]

| Laminate | Acronimus | Lay-up |

|---|---|---|

| Unidirectional | UD | [0]16 |

| Cross-ply | CP | [(0/90)4]s |

| Braided-ply | BP | [(±7.5)4]s |

| Quasi-isotropic | QI | [(0/±45/90)2]s |

| Laminate | ||||

|---|---|---|---|---|

| UD | BP | CP | QI | |

| Ultimate Tensile Strength σL,R [MPa] SD of the Ultimate Tensile Strength [MPa] | 465.8 17.7 | 326.4 15.9 | 271.2 25.7 | 161.5 9.3 |

| Young’s modulus EL [GPa] SD of the Young’s modulus [GPa] | 26.4 1.08 | 20.1 0.94 | 16.9 2.41 | 11.4 0.84 |

| Failure Strain εL,R [%] SD of the Failure Strain [%] | 1.9 0.11 | 1.8 0.10 | 2.2 0.24 | 1.8 0.06 |

| Lay-up | σL,R [MPa] | σF [MPa] | Fatigue Ratio | a [MPa] | b [MPa] | a’ | b’ |

|---|---|---|---|---|---|---|---|

| UD | 465.8 | 217.2 | 0.47 | 594.1 | −62.8 | 1.275 | −0.134 |

| CP | 271.2 | 114.7 | 0.42 | 308.8 | −32.3 | 1.139 | −0.119 |

| BP | 326.4 | 152.7 | 0.47 | 371.6 | −36.5 | 1.138 | −0.112 |

| QI | 161.5 | 64.2 | 0.4 | 193.7 | −21.6 | 1.198 | −0.133 |

| Kim and Zhang | D’Amore et al. | |||

|---|---|---|---|---|

| Lay-up | α | β | α’ | β’ |

| UD | 2.292 | −1.697 | 0.0067 | 2.9423 |

| CP | 0.7121 | −0.343 | 0.0217 | 2.3878 |

| BP | 0.7448 | −0.352 | 0.0228 | 2.2210 |

| QI | 2.3420 | −0.624 | 0.0149 | 2.6401 |

| Laminate | Lay-up | Vf [%] | σL,R [MPa] | σF (106 Cycles) [MPa] | Fatigue Ratio | Refs. |

|---|---|---|---|---|---|---|

| Sisal fiber biocomposites (from present work) | ||||||

| sisal/green epoxy | [0]16 | 70 | 465.8 | 217.2 | 0.466 | current work |

| sisal/green epoxy | [0/90]4S | 70 | 271.2 | 114.7 | 0.423 | current work |

| sisal/green epoxy | [±7.5]4S | 70 | 326.4 | 152.7 | 0.468 | current work |

| sisal/green epoxy | [0/±45/90]2S | 70 | 161.5 | 64.2 | 0.398 | current work |

| Other natural fiber composites (from literature) | ||||||

| flax/polyester | [0]4 | 27 | 263.3 | 114.6 | 0.485 | [17] |

| flax/epoxy | [0]12 | 43 | 318.0 | 115.2 | 0.632 | [6,7] |

| flax/epoxy | [0/90]3S | 43 | 170.0 | 51.2 | 0.301 | [6,7] |

| flax/epoxy | [±45]3S | 43 | 79.0 | 41.1 | 0.520 | [6,7] |

| hemp/poliester | [0]4 | 36 | 171.3 | 83.1 | 0.485 | [17] |

| hemp/epoxy | [0/90]7 | 36 | 113.0 | 41.5 | 0.367 | [11] |

| hemp/epoxy | [±45]7 | 36 | 66.0 | 31.7 | 0.480 | [11] |

| juta/poliester | [0]4 | 32 | 175.1 | 85.3 | 0.487 | [17] |

| Synthetic fiber composites (from literature) | ||||||

| glass/epoxy | [0]5 | 30 | 570.0 | 205.1 | 0.360 | [40] |

| glass/epoxy | [0/90]3S | 43 | 380.0 | 111.6 | 0.294 | [6,7] |

| glass/epoxy | [±45]3S | 43 | 103.0 | 42.8 | 0.415 | [6,7] |

| carbon/epoxy | [0]12 | 64 | 1934.0 | 1150.0 | 0.595 | [41] |

| carbon/epoxy | [±45]2S | 58 | 188.7 | 101.7 | 0.539 | [36] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zuccarello, B.; Militello, C.; Bongiorno, F. Fatigue Behaviour of High-Performance Green Epoxy Biocomposite Laminates Reinforced by Optimized Long Sisal Fibers. Polymers 2024, 16, 2630. https://doi.org/10.3390/polym16182630

Zuccarello B, Militello C, Bongiorno F. Fatigue Behaviour of High-Performance Green Epoxy Biocomposite Laminates Reinforced by Optimized Long Sisal Fibers. Polymers. 2024; 16(18):2630. https://doi.org/10.3390/polym16182630

Chicago/Turabian StyleZuccarello, B., C. Militello, and F. Bongiorno. 2024. "Fatigue Behaviour of High-Performance Green Epoxy Biocomposite Laminates Reinforced by Optimized Long Sisal Fibers" Polymers 16, no. 18: 2630. https://doi.org/10.3390/polym16182630

APA StyleZuccarello, B., Militello, C., & Bongiorno, F. (2024). Fatigue Behaviour of High-Performance Green Epoxy Biocomposite Laminates Reinforced by Optimized Long Sisal Fibers. Polymers, 16(18), 2630. https://doi.org/10.3390/polym16182630