Effects of Polymer–Curing Agent Ratio on Rheological, Mechanical Properties and Chemical Characterization of Epoxy-Modified Cement Composite Grouting Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

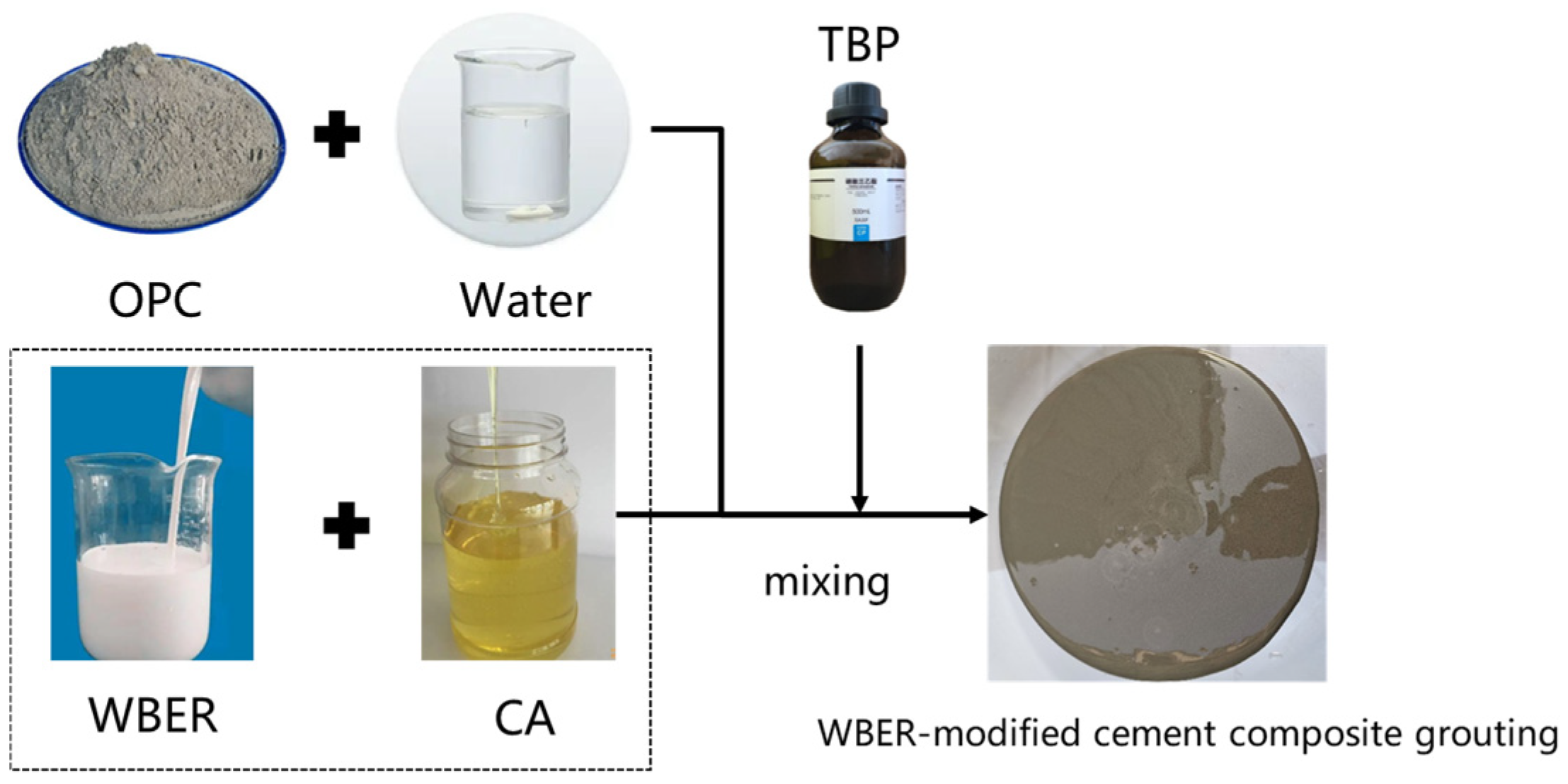

2.2. Preparation of WBER-Modified Cement-Based Paste

2.3. Experimental Approaches

2.3.1. Fluidity and Rheological Properties

2.3.2. Grain Size Distribution and Zeta Potential

2.3.3. Bleeding Ratio and Setting Time

2.3.4. X-ray Diffraction (XRD) and Fourier-Transform Infrared Spectroscopy (FT-IR)

2.3.5. Scanning Electron Microscopy (SEM) and Confocal Laser Scanning Microscopy (CLSM)

2.3.6. Mechanical Properties

3. Results and Discussion

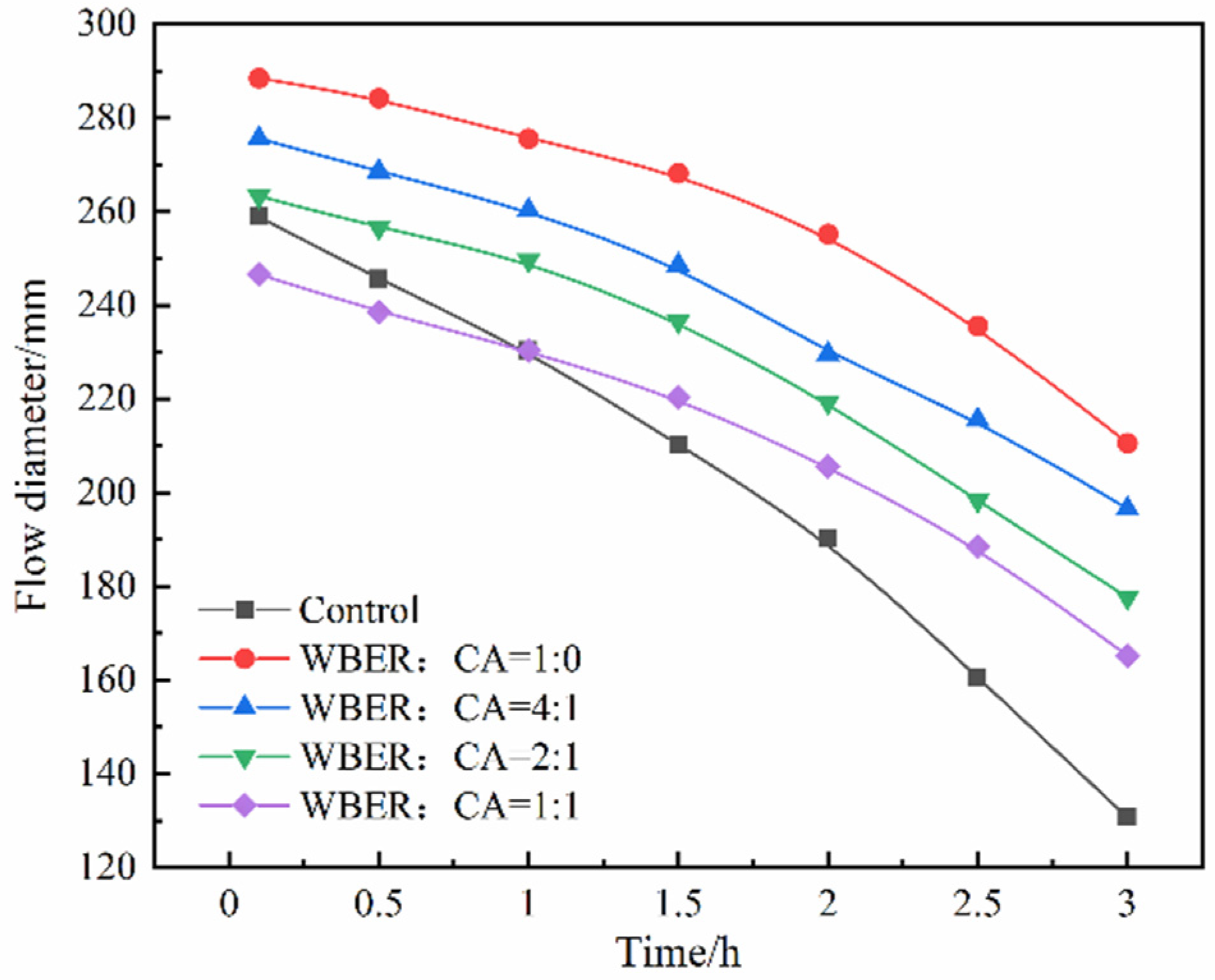

3.1. Fluidity and Rheological Properties of Epoxy-Modified Composite Grouting

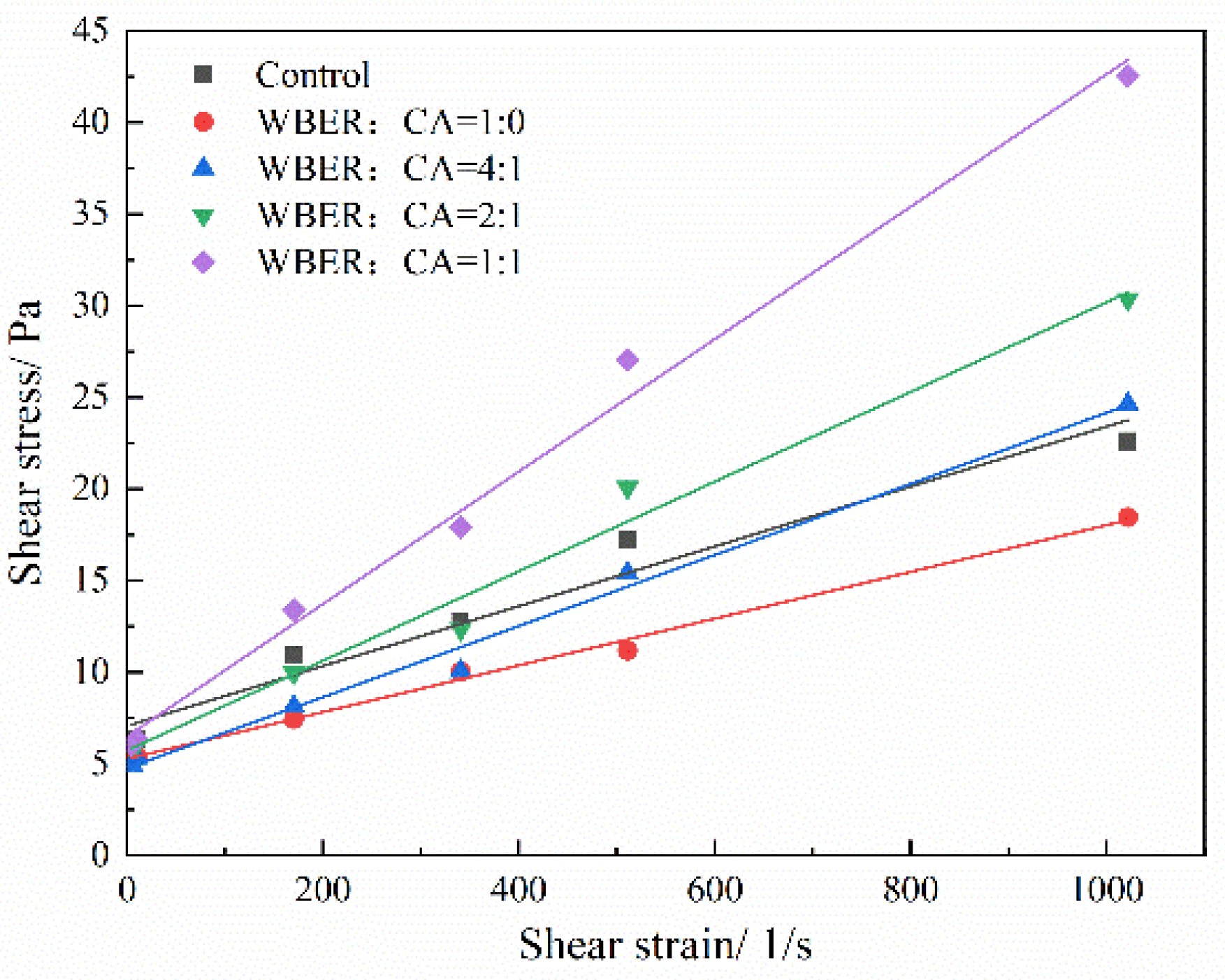

3.1.1. Rheological Curve

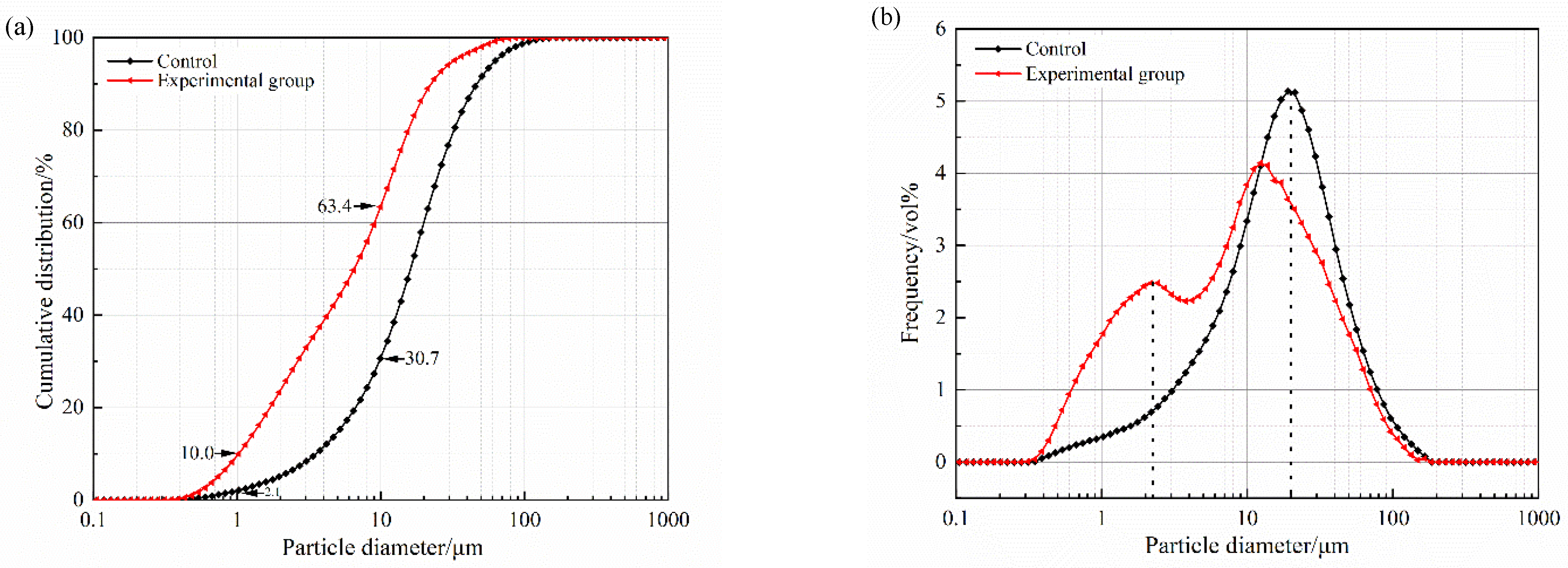

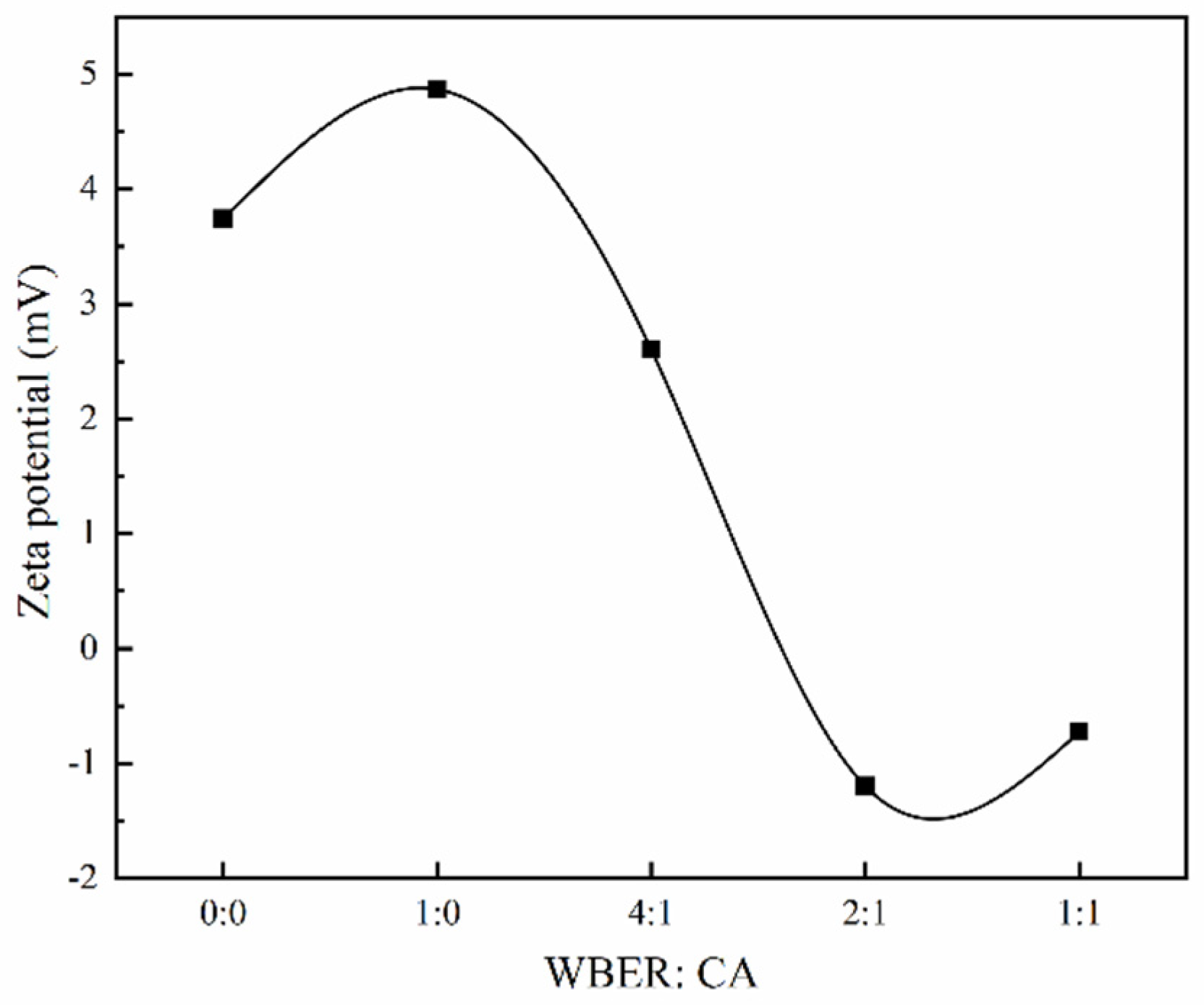

3.1.2. Zeta Potential and Grain Size Distribution

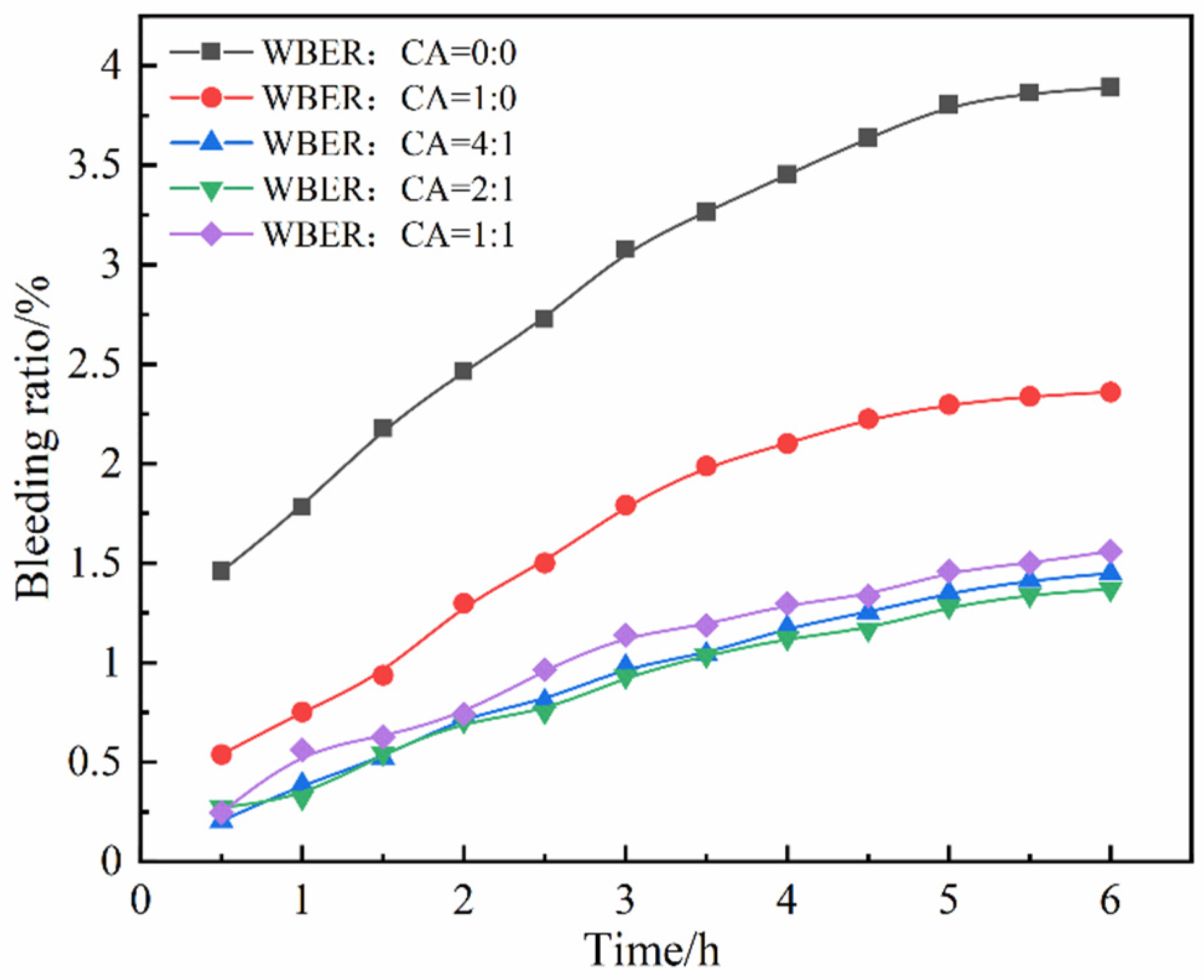

3.1.3. Setting Time and Bleeding Ratio

3.2. Chemical Characterization of Epoxy-Modified Composite Paste

3.2.1. Fourier-Transform Infrared Spectroscopy (FT-IR)

3.2.2. X-ray Diffraction (XRD)

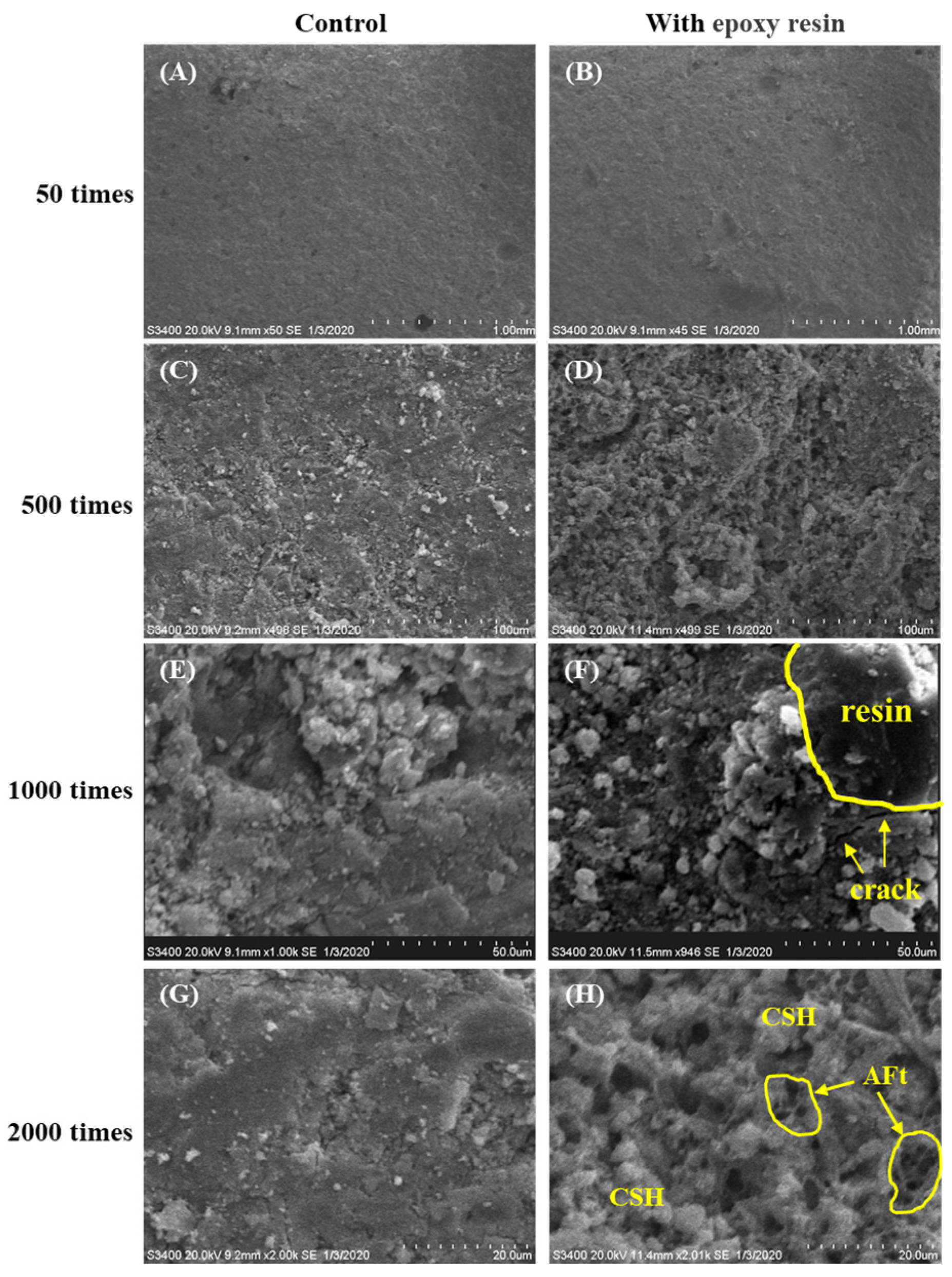

3.2.3. Scanning Electron Microscopy (SEM)

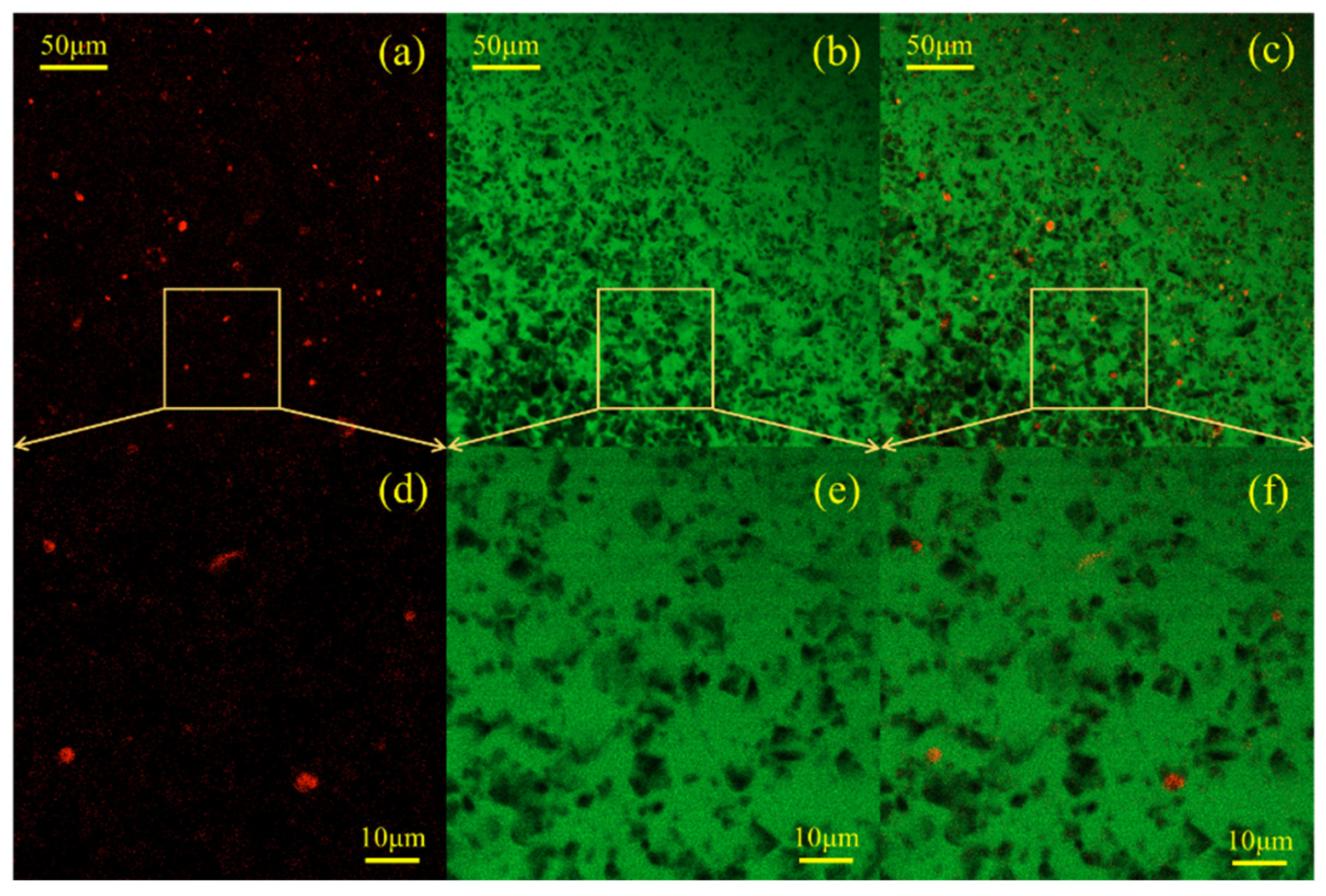

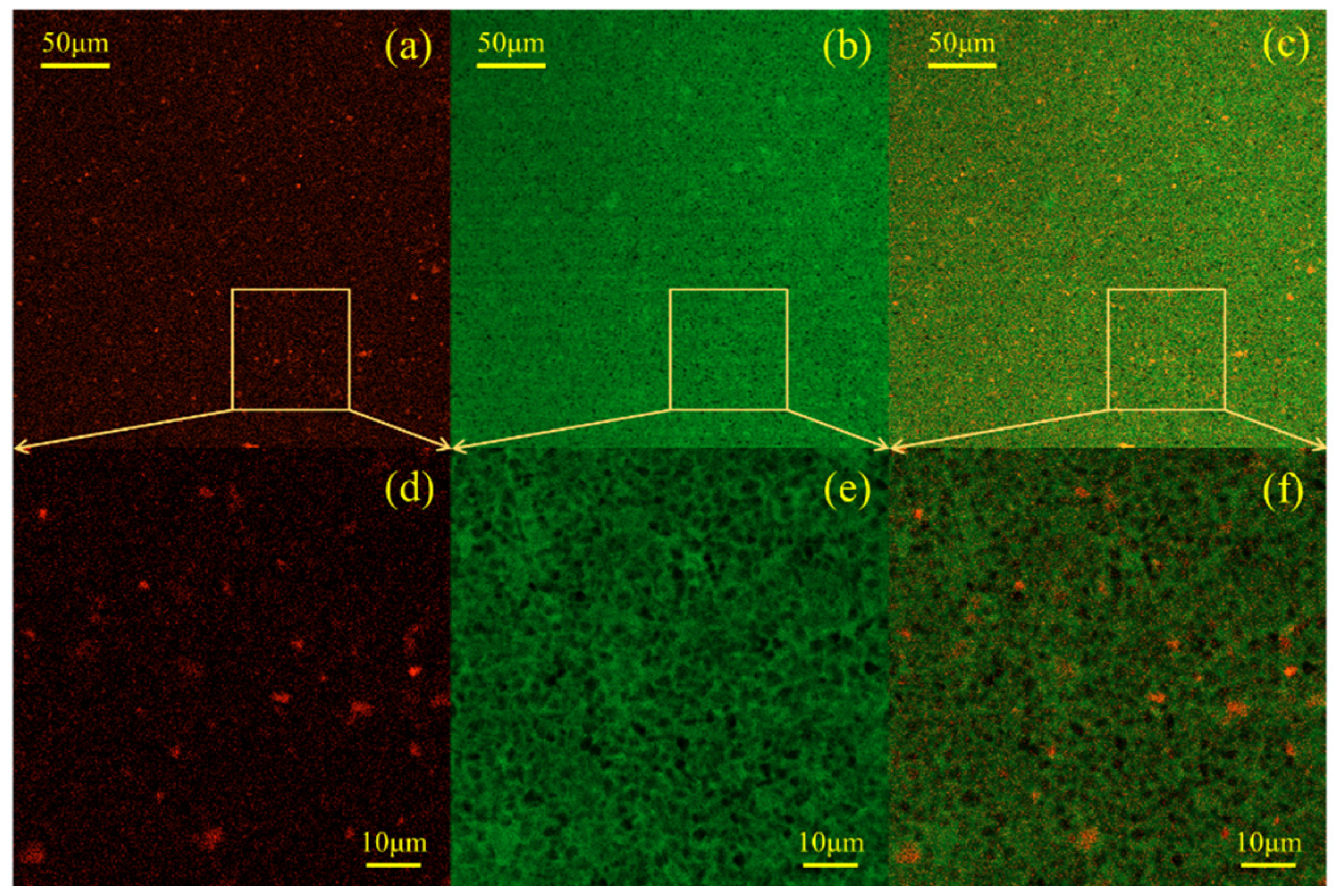

3.2.4. Confocal Laser Scanning Microscopy (CLSM)

3.3. Mechanical Properties of WBER-Modified Composite Grouting

3.3.1. Uniaxial Compressive Strength

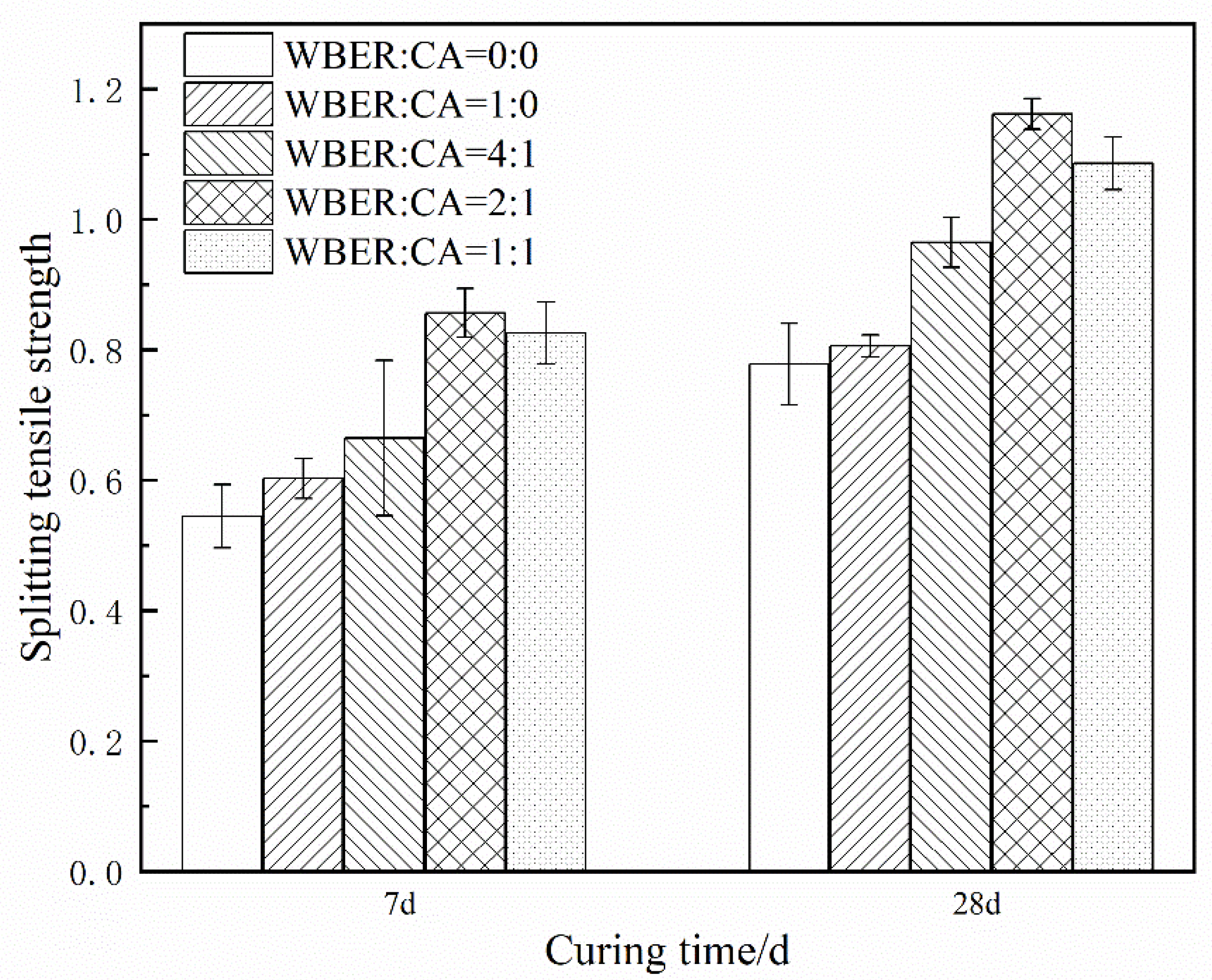

3.3.2. Splitting Tensile Strength

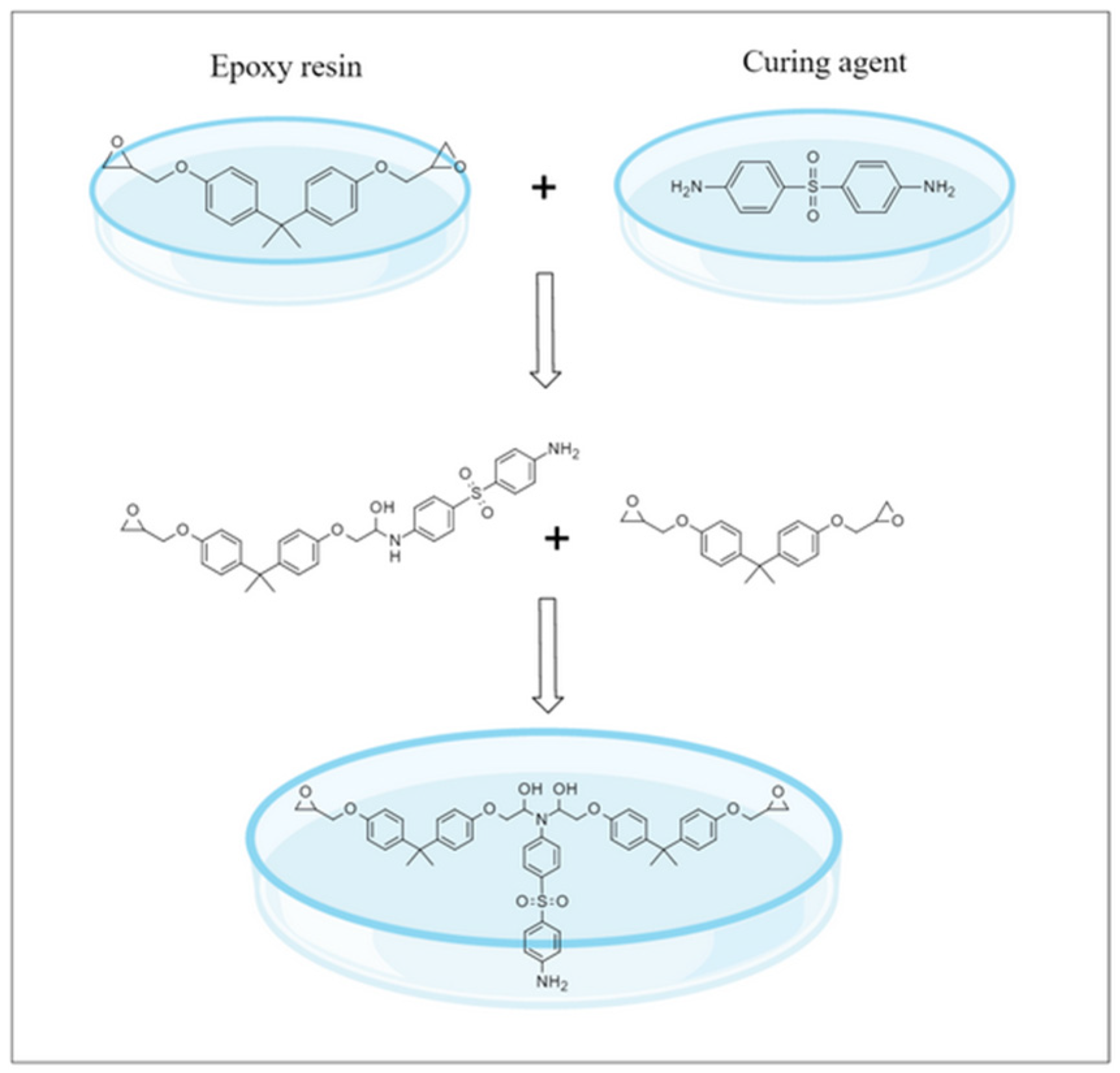

3.4. The Modification Mechanism of WBER-Modified Cement

4. Conclusions

- WBER-modified grout exhibits Bingham fluid characteristics, with WBER enhancing the fluidity of cement paste and prolonging its stability after water addition, effectively mitigating rapid fluidity loss.

- The addition of WBER modifies the particle size distribution of the cement paste, resulting in a decrease in mean particle size and a more uniform grain size distribution. The contrasting zeta potentials between WBER and the cement particles lead to an initial increase in the suspension’s zeta potential, which diminishes as the CA content rises.

- Incorporation of WBER alone diminishes the uniaxial compressive strength of the hardened grout. However, the composite’s strength is significantly improved with the addition of CA, reaching an optimal WBER/CA ratio of approximately 2:1, corresponding to a 38.88% strength enhancement. The splitting tensile strength is markedly affected by WBER, with the optimal epoxy-to-curing agent ratio of 2:1 yielding a 48.7% increase.

- WBER promotes the cement hydration process, leading to an augmentation in the yield of calcium hydroxide within the hydration products, while concurrently diminishing the concentration of calcium carbonate. The core reaction between WBER and cement is the reaction between free Ca2+ and -OH, with Ca2+ as the node to form a complex network structure as a product of crosslinking. The reaction products adhere to cement particles, thereby establishing a robust composite of organic and inorganic phases.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Xi, J.; Hehua, Z.; Zhiguo, Y.; Fengshou, Z.; Fei, Y.; Peinan, L.; Xuehui, Z.; Zhiren, D.; Yun, B.; Baoshan, H. A state-of-art review on development and progress of backfill grouting materials for shield tunneling. Dev. Built Environ. 2023, 16, 100250. [Google Scholar]

- Min, F.L.; Zhu, W.; Lin, C.; Guo, X.J. Opening the Excavation Chamber of the Large-Diameter Size Slurry Shield: A Case Study in Nanjing Yangtze River Tunnel in China. Tunn. Undergr. Space Technol. 2015, 46, 18–27. [Google Scholar] [CrossRef]

- Wang, Z.W.; Liu, Q.S.; Wang, Y.X. Thermo-mechanical FDEM model for thermal cracking of rock and granular materials. Powder Technol. 2021, 393, 807–823. [Google Scholar] [CrossRef]

- Hong, K. Typical Underwater Tunnels in the Mainland of China and Related Tunneling Technologies. Eng. J. 2017, 3, 871–879. [Google Scholar] [CrossRef]

- Sharghi, M.; Chakeri, H.; Ozcelik, Y. Investigation into the effects of two component grout properties on surface settlements. Tunn. Undergr. Space Technol. 2017, 63, 205–216. [Google Scholar] [CrossRef]

- Yang, C.; Shen, S.L.; Hou, D.W.; Liao, S.M.; Yuan, D.J. Material properties of the seal gasket for shield tunnels: A review. Constr. Build. Mater. 2018, 191, 877–890. [Google Scholar] [CrossRef]

- Aboulayt, A.; Souayfan, F.; Roziere, E.; Jaafri, R.; Loukili, A. Alkali-activated grouts based on slag-fly ash mixtures: From early-age characterization to long-term phase composition. Constr. Build. Mater. 2020, 260, 120510. [Google Scholar] [CrossRef]

- Tuyan, M.; Zhang, L.V.; Nehdi, M.L. Development of sustainable alkali-activated slag grout for preplaced aggregate concrete. J. Clean. Prod. 2020, 263, 120227. [Google Scholar]

- Dong, Q.; Wang, G.; Chen, X.; Tan, J.; Gu, X. Recycling of steel slag aggregate in Portland cement concrete: An overview. J. Clean. Prod. 2020, 282, 124447. [Google Scholar] [CrossRef]

- Khan, M.I.; Sutanto, M.H.; Napiah, M.B.; Khan, K.; Rafiq, W. Design optimization and statistical modeling of cementitious grout containing irradiated plastic waste and silica fume using response surface methodology. Constr. Build. Mater. 2020, 271, 121504. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, S.; Li, L.; Han, J.; Lin, C. A preliminary study of the properties of potassium phosphate magnesium cement-based grouts admixed with metakaolin, sodium silicate and bentonite. Constr. Build. Mater. 2020, 262, 119893. [Google Scholar] [CrossRef]

- Lv, J.; Zhou, T.; Du, Q.; Wu, H. Experimental investigation on properties of gypsum-quicklime-soil grout material in the reparation of earthen site cracks. Constr. Build. Mater. 2017, 157, 253–262. [Google Scholar] [CrossRef]

- Vavricuk, A.; Bokan-Bosiljkov, V.; Kramar, S. The influence of metakaolin on the properties of natural hydraulic lime-based grouts for historic masonry repair. Constr. Build. Mater. 2018, 172, 706–716. [Google Scholar] [CrossRef]

- Sha, F.; Li, S.; Liu, R.; Li, Z.; Zhang, Q. Experimental study on performance of cement-based grouts admixed with fly ash, bentonite, superplasticizer and water glass. Constr. Build. Mater. 2018, 161, 282–291. [Google Scholar] [CrossRef]

- Zhang, G.; Qiu, D.; Wang, S.; Wang, P. Effects of plastic expansive agent on the fluidity, mechanical strength, dimensional stability and hydration of high performance cementitious grouts. Constr. Build. Mater. 2020, 243, 118204. [Google Scholar] [CrossRef]

- Sonebi, M. Rheological properties of grouts with viscosity modifying agents as diutan gum and welan gum incorporating pulverised fly ash. Cem. Concr. Res. 2006, 36, 1609–1618. [Google Scholar] [CrossRef]

- Li, H.; Ni, D.; Li, L.; Dong, B.; Gu, L. Insight into the role of polyacrylamide polymer powder on the cracking in plastic period of cement mortar. Constr. Build. Mater. 2020, 260, 119914. [Google Scholar] [CrossRef]

- Tarannum, N. Preparation and applications of hydrophobic multicomponent based redispersible polymer powder: A review. Constr. Build. Mater. 2020, 247, 118579. [Google Scholar] [CrossRef]

- Lin, C.; Wang, X.; Nie, L. Comprehensive Geophysical Investigation and Analysis of Lining Leakage for Water-Rich Rock Tunnels: A Case Study of Kaiyuan Tunnel, Jinan, China. Geotech. Geol. Eng. 2020, 38, 3449–3468. [Google Scholar] [CrossRef]

- Deng, X.; Zhu, X.P.; Chen, H.L.; Wang, D.P.; Yin, W. Mechanical Properties of Polyester Fiber and SBR Latex Compound-Modified Mortar for Tunnel Grouting. Electron. J. Geotech. Eng. 2016, 21, 1365–1374. [Google Scholar]

- Martins, Z.; Lily, P.; Martin, A.; Bernhard, K.; Urs, S.; Christoph, G. Asphalt recycling in polymer modified pavement: A test section and recommendations. Constr. Build. Mater. 2023, 409, 134005. [Google Scholar]

- Debbarma, K.; Saha, S.; Sarkar, P.P. Application of vinyl acrylic co-polymer on subgrade and sub base pavement stabilization. Mater. Today Proc. 2023. [CrossRef]

- Mohammed, A.S.; Mahmood, W.I.; Ghafor, K.; Fuad, M. TGA, rheological properties with maximum shear stress and compressive strength of cement-based grout modified with polycarboxylate polymers. Constr. Build. Mater. 2019, 235, 117534. [Google Scholar] [CrossRef]

- Thai, C.K.; Lee, S.H.; Keo, S.A.; Yune, C.Y. Effect of acrylate-cement grout on the unconfined compressive strength of silty sand. KSCE J. Civ. Eng. 2019, 23, 2495–2502. [Google Scholar]

- Ali, A. The effect of polymer-cement stabilization on the unconfined compressive strength of liquefiable soils. Int. J. Polym. Sci. 2013, 2013, 155–171. [Google Scholar]

- Jiapei, D.; Yuhuan, B.; Zhonghou, S.; Xuechao, C. A novel fluid for use in oil and gas well construction to prevent the oil and gas leak from the wellbore. Constr. Build. Mater. 2019, 217, 626–637. [Google Scholar]

- Zhang, Z.Q.; Peiyu, L.; Yan, Y. Hydration kinetics of the epoxy resin-modified cement at different temperatures. Constr. Build. Mater. 2017, 150, 287–294. [Google Scholar] [CrossRef]

- Hsieh, T.H.; Kinloch, A.J.; Masania, K.; Taylor, A.C.; Sprenger, S. The mechanisms and mechanics of the toughening of epoxy polymers modified with silica nanoparticles. Polymer 2010, 51, 6284–6294. [Google Scholar] [CrossRef]

- El-Hawary, M.M.; Abdul-Jaleel, A. Durability assessment of epoxy modified concrete. Constr. Build. Mater. 2010, 24, 1523–1528. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Q. Investigation on fundamental properties and chemical characterization of water-soluble epoxy resin modified cement grout. Constr. Build. Mater. 2021, 299, 123877. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.A.; Sapidis, G.; Papastergiadis, E. Fundamental properties of epoxy resin-modified cement grouts. Constr. Build. Mater. 2016, 125, 184–195. [Google Scholar] [CrossRef]

- Wang, L.; Tian, Z.; Ma, G.; Zhang, M. Interlayer bonding improvement of 3D printed concrete with polymer modified mortar: Experiments and molecular dynamics studies. Cem. Concr. Compos. 2020, 110, 103571. [Google Scholar] [CrossRef]

- Schober, K.-U. Strengthening of timber floors with concrete-type adhesives. Proc. Inst. Civ. Eng. Struct. Build 2020, 173, 320–325. [Google Scholar] [CrossRef]

- Adeyi, A.J.; Adeyi, O.; Oke, O.E.; Ajayi, O.K.; Otolorin, J.A.; Akinyemi, O.; Areghan, S.E.; Isola, B.F.; Owoloja, A.O.; Gbadamosi, B. Nauclea latifolia herb root waste reinforced epoxy polymer composite: The study of effects, modelling, certainty and sensitivity analysis. Clean. Mater. 2023, 7, 100167. [Google Scholar] [CrossRef]

- Ohama, Y.; Takahashi, S. Effects of accelerated curing conditions on strength properties of epoxy-modified mortars without hardener. In Brittle Matrix Composites; Woodhead Publishing: Sawston, UK, 2003; pp. 533–541. [Google Scholar]

- Bhutta, M.A.R. Effects of polymer–cement ratio and accelerated curing on flexural behavior of hardener-free epoxy-modified mortar panels. Mater. Struct. 2009, 43, 429–439. [Google Scholar] [CrossRef]

- Ariffin, N.F.; Hussin, M.W.; Sam, A.R.M.; Bhutta, M.A.R.; Abd Khalid, N.H.; Mirza, J. Strength properties and molecular composition of epoxy-modified mortars. Constr. Build. Mater. 2015, 94, 315–322. [Google Scholar] [CrossRef]

- Wan-Ki, K.; Deuck-Mo, K.; Hwa-Sung, R.; Won-Jun, P.; Sung-Min, H. Properties of hardener-free epoxy-modified mortars utilizing pyrolysis tar replacement. Constr. Build. Mater. 2017, 144, 598–607. [Google Scholar]

- GB/T 1346-2011; Test Methods for Water Requirement of Normal Consistency, Setting Time and Soundness of the Portland Cement. National Standards of People’s Republic of China: Beijing, China, 2011.

- ASTM C942-2015; Standard Test Method for Compressive Strength of Grouts for Preplaced-Aggregate Concrete in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2015.

- Betioli, A.M.; Gleize, P.J.P.; John, V.M.; Pileggi, R.G. Effect of EVA on the fresh properties of cement paste. Cem. Concr. Compos. 2012, 34, 255–260. [Google Scholar] [CrossRef]

- Li, S.; Sha, F.; Liu, R.; Zhang, Q.; Li, Z. Investigation on fundamental properties of microfine cement and cement-slag grouts. Constr. Build. Mater. 2017, 153, 965–974. [Google Scholar] [CrossRef]

- Magnus, E.; Friedrich, M.; Vorschulze, C. Variations in the Rheology and Penetrability of Cement-Based Grouts—An Experimental Study. Cem. Concr. Res. 2004, 34, 1111–1119. [Google Scholar]

- Labbez, C.; Jonsson, B.; Pochard, I.; Nonat, A.; Cabane, B. Surface Charge Density and Electrokinetic Potential of Highly Charged Minerals: Experiments and Monte Carlo Simulations on Calcium Silicate Hydrate. J. Phys. Chem. B 2006, 110, 9219–9230. [Google Scholar] [CrossRef]

- Lowke, D.; Gehlen, C. The zeta potential of cement and additions in cementitious suspensions with high solid fraction. Cem. Concr. Res. 2017, 95, 195–204. [Google Scholar] [CrossRef]

- Natarajan, S.; Pillai, N.N.; Murugan, S. Experimental investigations on the properties of epoxy-resin-bonded cement concrete containing sea sand for use in unreinforced concrete applications. Materials 2019, 12, 645. [Google Scholar] [CrossRef]

- Bernard, E.; Lothenbach, B.; Le Goff, F.; Pochard, I.; Dauzères, A. Effect of magnesium on calcium silicate hydrate (C-S-H). Cem. Concr. Res. 2017, 97, 61–72. [Google Scholar] [CrossRef]

- Hidalgo, A.; Domingo, C.; Garcia, C.; Petit, S.; Andrade, C.; Alonso, C. Microstructural changes induced in portland cement-based materials due to natural and supercritical carbonation. J. Mater. Sci. 2008, 43, 3101–3111. [Google Scholar] [CrossRef]

- Wang, M.; Wang, R.M.; Zheng, S.R.; Farhan, S.; Yao, H.; Jiang, H. Research on the Chemical Mechanism in the Polyacrylate Latex Modified Cement System. Cem. Concr. Res. 2015, 76, 62–69. [Google Scholar] [CrossRef]

- Wang, M.; Wang, R.; Yao, H.; Farhan, S.; Zheng, S.; Wang, Z.; Du, C.; Jiang, H. Research on the mechanism of polymer latex modified cement. Constr. Build. Mater. 2016, 111, 710–718. [Google Scholar] [CrossRef]

- Qu, X.; Zhao, X. Influence of SBR latex and HPMC on the cement hydration at early age. Case Stud. Constr. Mat. 2017, 6, 213–218. [Google Scholar] [CrossRef]

- Ohama, Y. Polymer-based admixtures. Cem. Concr. Compos. 1998, 20, 189–212. [Google Scholar] [CrossRef]

| Item | Epoxy Resin | Curing Agent |

|---|---|---|

| Appearance | Milky white | Light yellow |

| Solid content | 50 ± 2 | 44 ± 2 |

| Epoxide (active hydrogen) equivalent | 220~280 | 260 ± 60 |

| Viscosity mpa·s/24 °C | 100~450 | >2000 |

| pH value | 2~7 | 8~11 |

| Specific gravity | 1.01~1.08 | 1.00~1.08 |

| Molecular Formula | Molecular Weight | Melting Point | Boiling Point | Water Solubility | Refractive Index | Flash Point | Density |

|---|---|---|---|---|---|---|---|

| C12H27O4P | 266.31 | −79 °C | 289 °C | 0.6 g/100 mL | 1.423~1.425 | 146 °C | 0.979 |

| WBER/CA | Yield Stress (τ0, Pa) | Plastic Viscosity (η, Pa·s) | Correlation Coefficient (R2) |

|---|---|---|---|

| 0:0 | 6.60 | 17.70 | 0.99 |

| 1:0 | 5.61 | 12.74 | 0.99 |

| 4:1 | 4.68 | 18.94 | 0.99 |

| 2:1 | 5.55 | 24.01 | 0.99 |

| 1:1 | 6.48 | 35.68 | 0.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Wu, J. Effects of Polymer–Curing Agent Ratio on Rheological, Mechanical Properties and Chemical Characterization of Epoxy-Modified Cement Composite Grouting Materials. Polymers 2024, 16, 2665. https://doi.org/10.3390/polym16182665

Wang Y, Wu J. Effects of Polymer–Curing Agent Ratio on Rheological, Mechanical Properties and Chemical Characterization of Epoxy-Modified Cement Composite Grouting Materials. Polymers. 2024; 16(18):2665. https://doi.org/10.3390/polym16182665

Chicago/Turabian StyleWang, Yuxuan, and Jiehao Wu. 2024. "Effects of Polymer–Curing Agent Ratio on Rheological, Mechanical Properties and Chemical Characterization of Epoxy-Modified Cement Composite Grouting Materials" Polymers 16, no. 18: 2665. https://doi.org/10.3390/polym16182665

APA StyleWang, Y., & Wu, J. (2024). Effects of Polymer–Curing Agent Ratio on Rheological, Mechanical Properties and Chemical Characterization of Epoxy-Modified Cement Composite Grouting Materials. Polymers, 16(18), 2665. https://doi.org/10.3390/polym16182665