Effect of Liquid Glass-Modified Lignin Waste on the Flammability Properties of Biopolyurethane Foam Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of bioPUR Foam Composites

2.3. Methods

3. Results and Discussion

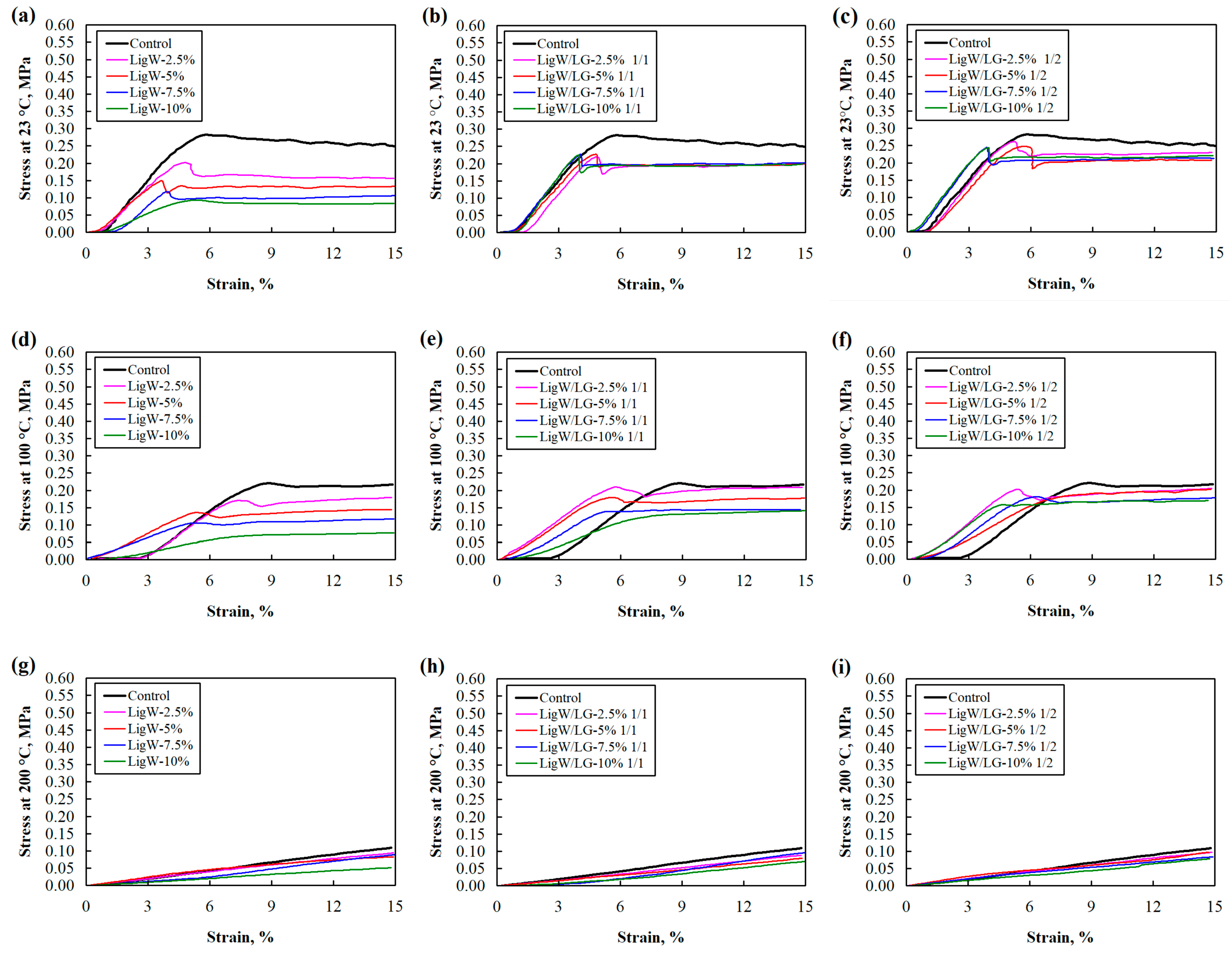

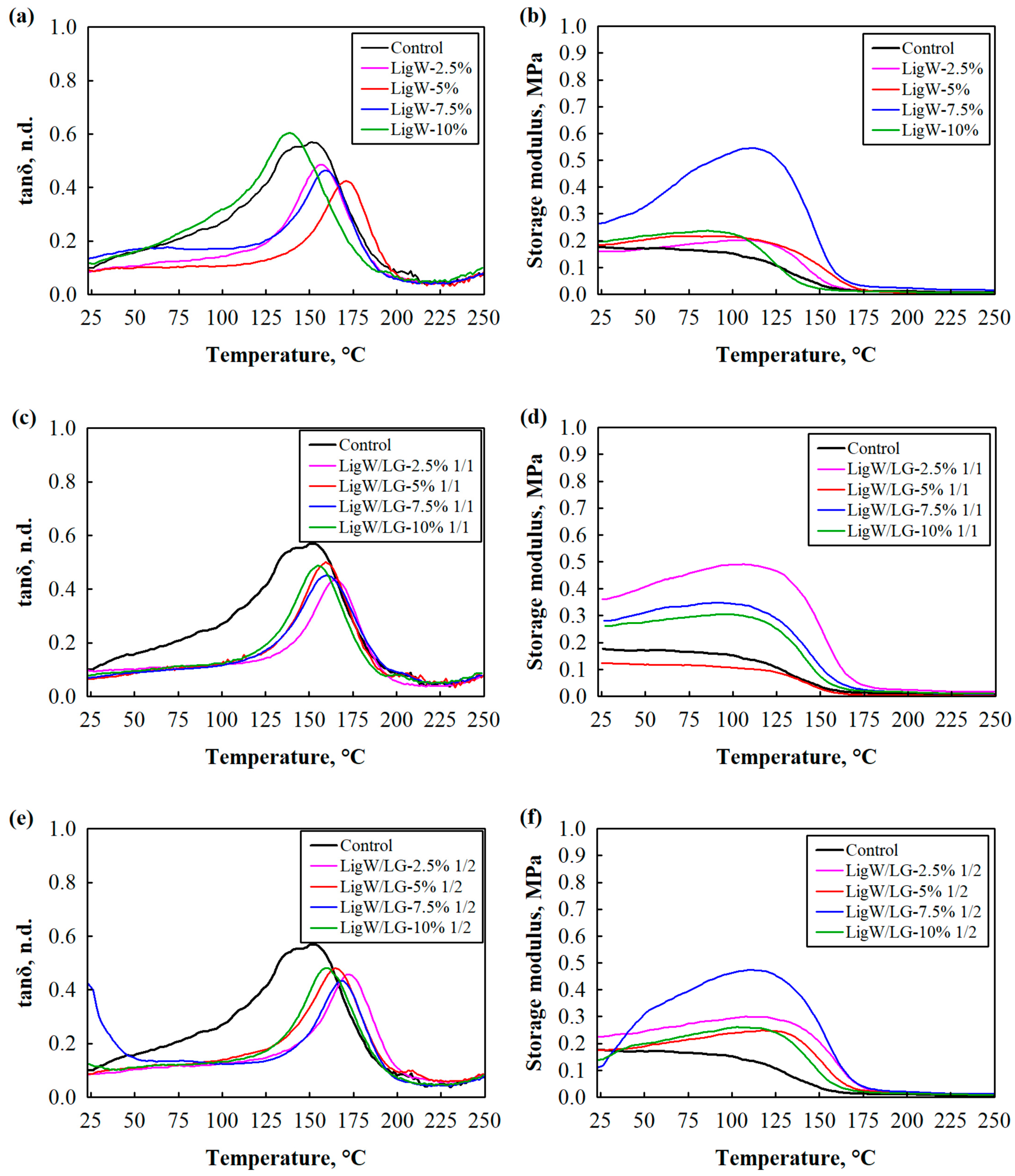

3.1. Physical and Thermo-Mechanical Properties of bioPUR Foam Composites

3.2. Thermal Stability of bioPUR Foam Composites

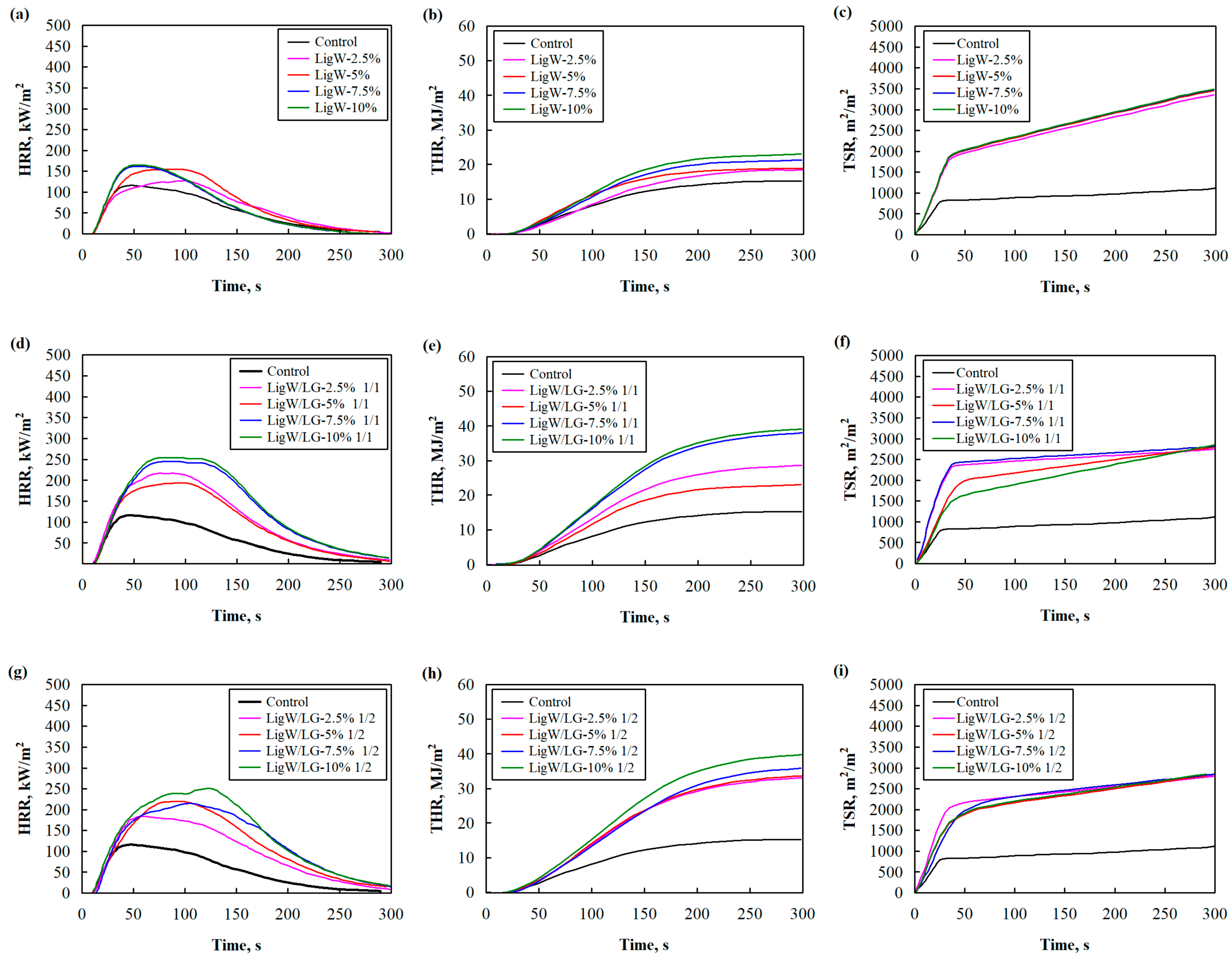

3.3. Ignitability and Flammability of bioPUR Foam Composites

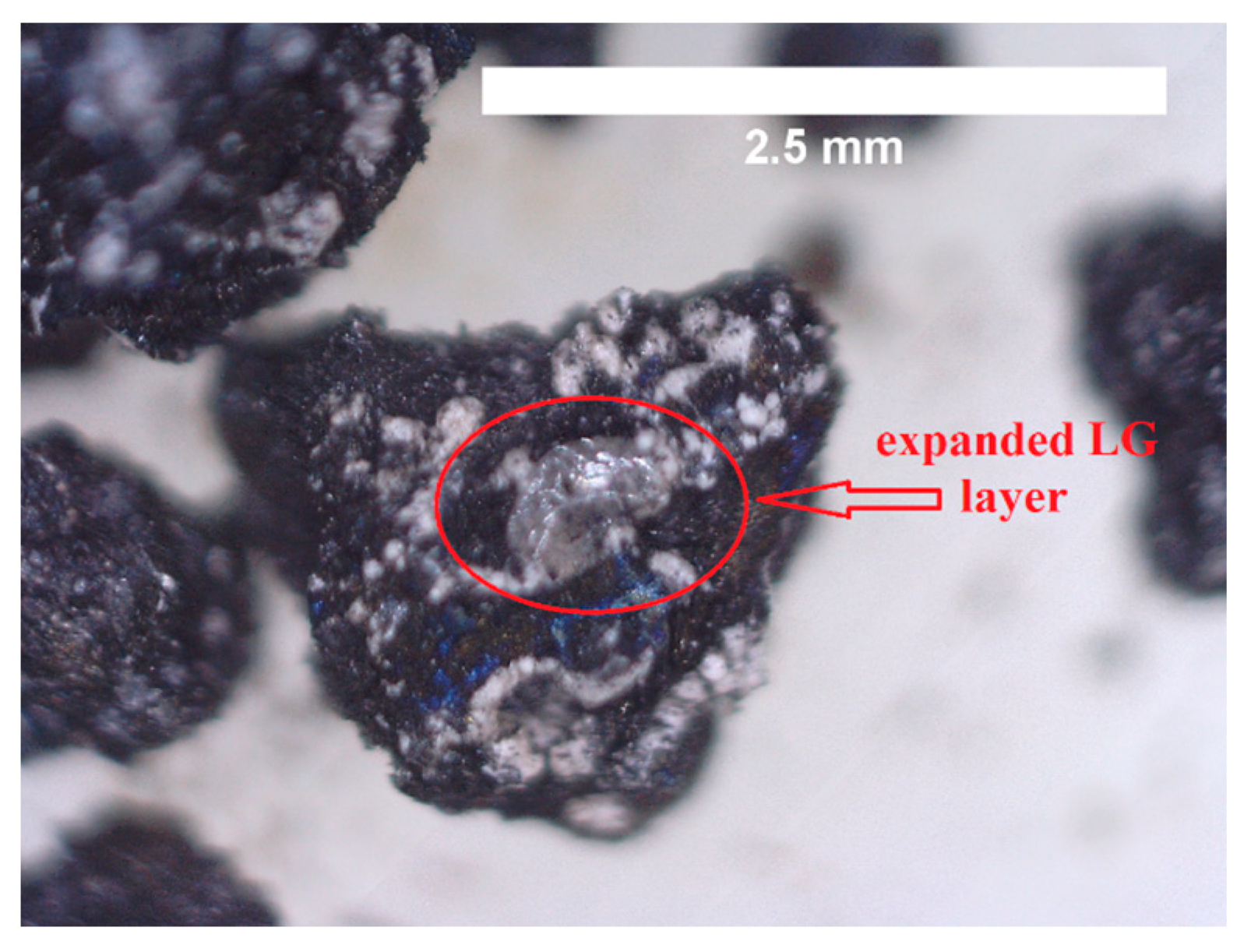

3.4. Microstructural Analysis of Char Residues From

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ma, Z.; Zhang, J.; Maluk, C.; Yu, Y.; Seraji, S.M.; Yu, B.; Wang, H.; Song, P. A Lava-Inspired Micro/Nano-Structured Ceramifiable Organic-Inorganic Hybrid Fire-Extinguishing Coating. Matter 2022, 5, 911–932. [Google Scholar] [CrossRef]

- Chen, X.L.; Zeng, F.R.; Li, W.X.; Zhang, L.; Deng, C.; Tan, Y.; Chen, M.J.; Huang, S.C.; Liu, B.W.; Wang, Y.Z.; et al. Durable Flame-Retardant, Smoke-Suppressant, and Thermal-Insulating Biomass Polyurethane Foam Enabled by a Green Bio-Based System. J. Mater. Sci. Technol. 2023, 162, 179–188. [Google Scholar] [CrossRef]

- Zygmunt-Kowalska, B.; Zakrzewska, P.; Szajding, A.; Handke, B.; Kuźnia, M. Polyurethane Foams Reinforced with Microspheres—Assessment of the Application in Construction as a Thermal Insulation Material. Thermochim. Acta 2023, 726, 179556. [Google Scholar] [CrossRef]

- Beverte, I.; Cabulis, U.; Andersons, J.; Kirpluks, M.; Skruls, V.; Cabulis, P. Anisotropy and Mechanical Properties of Nanoclay Filled, Medium-Density Rigid Polyurethane Foams Produced in a Sealed Mold, from Renewable Resources. Polymers 2023, 15, 2582. [Google Scholar] [CrossRef]

- Kowalczyk, Ł.; Korol, J.; Chmielnicki, B.; Laska, A.; Chuchala, D.; Hejna, A. One More Step towards a Circular Economy for Thermal Insulation Materials—Development of Composites Highly Filled with Waste Polyurethane (PU) Foam for Potential Use in the Building Industry. Materials 2023, 16, 782. [Google Scholar] [CrossRef]

- Gurunathan, T.; Arukula, R. High Performance Polyurethane Dispersion Synthesized from Plant Oil Renewable Resources: A Challenge in the Green Materials. Polym. Degrad. Stab. 2018, 150, 122–132. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, Y.; Zhu, M.; Zhao, J.; Cai, D.; Cao, H. Valorization of Lignin for Renewable Non-Isocyanate Polyurethanes: A State-of-the-Art Review. Mater. Today Sustain. 2023, 22, 100367. [Google Scholar] [CrossRef]

- Guo, W.; Sun, S.; Wang, P.; Chen, H.; Zheng, J.; Lin, X.; Qin, Y.; Qiu, X. Successive Organic Solvent Fractionation and Homogenization of Technical Lignin for Polyurethane Foam with High Mechanical Performance. Int. J. Biol. Macromol. 2022, 221, 913–922. [Google Scholar] [CrossRef]

- Sun, N.; Di, M.; Liu, Y. Lignin-Containing Polyurethane Elastomers with Enhanced Mechanical Properties via Hydrogen Bond Interactions. Int. J. Biol. Macromol. 2021, 184, 1–8. [Google Scholar] [CrossRef]

- Luo, S.; Gao, L.; Guo, W. Effect of Incorporation of Lignin as Bio-Polyol on the Performance of Rigid Lightweight Wood–Polyurethane Composite Foams. J. Wood Sci. 2020, 66, 23. [Google Scholar] [CrossRef]

- Vieira, F.R.; Gama, N.V.; Evtuguin, D.V.; Amorim, C.O.; Amaral, V.S.; Pinto, P.C.O.R.; Barros-Timmons, A. Bio-Based Polyurethane Foams from Kraft Lignin with Improved Fire Resistance. Polymers 2023, 15, 1074. [Google Scholar] [CrossRef] [PubMed]

- Kairytė, A.; Šeputytė-Jucikė, J.; Członka, S.; Vėjelis, S.; Vaitkus, S. Impact of Different Ratios of Lignin Waste and Liquid Glass on the Performance Characteristics of Biopolyurethane Foams. Polymers 2023, 15, 818. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; He, H.; Liu, T.; Wei, R.; Cao, X.; Sun, Q.; Venkatesh, S.; Yuen, R.K.K.; Roy, V.A.L.; Li, R.K.Y. Synergetic Enhancement on Flame Retardancy by Melamine Phosphate Modified Lignin in Rice Husk Ash Filled P34HB Biocomposites. Compos. Sci. Technol. 2018, 168, 246–254. [Google Scholar] [CrossRef]

- Han, J.; Liang, G.; Gu, A.; Ye, J.; Zhang, Z.; Yuan, L. A Novel Inorganic-Organic Hybridized Intumescent Flame Retardant and its Super Flame Retarding Cyanate Ester Resins. J. Mater. Chem. A. 2013, 1, 2169–2182. [Google Scholar] [CrossRef]

- Qi, F.; Tang, M.; Wang, N.; Liu, N.; Chen, X.; Zhang, Z.; Zhang, K.; Lu, X. Efficient Organic–Inorganic Intumescent Interfacial Flame Retardants to Prepare Flame Retarded Polypropylene with Excellent Performance. RSC Adv. 2017, 7, 31696–31706. [Google Scholar] [CrossRef]

- Chen, S.N.; Li, P.K.; Hsieh, T.H.; Ho, K.S.; Hong, Y.M. Enhancements on Flame Resistance by Inorganic Silicate-Based Intumescent Coating Materials. Materials 2021, 14, 6628. [Google Scholar] [CrossRef]

- Kumar, S.P.; Takamori, S.; Araki, H.; Kuroda, S. Flame Retardancy of Clay–Sodium Silicate Composite Coatings on Wood for Construction Purposes. RSC Adv. 2015, 5, 34109–34116. [Google Scholar] [CrossRef]

- EN ISO 29470:2020; Thermal Insulating Products for Building Applications—Determination of the Apparent Density. European Standardization Committee: Brussels, Belgium, 2020.

- EN ISO 29469:2023; Thermal Insulating Products for Building Applications—Determination of Compression Behaviour. European Standardization Committee: Brussels, Belgium, 2023.

- EN ISO 16535:2019; Thermal Insulating Products for Building Applications—Determination of Long-Term Water Absorption by Immersion. European Standardization Committee: Brussels, Belgium, 2019.

- ISO 5660-1:2015; Reaction-to-Fire Tests—Heat Release, Smoke Production and Mass Loss Rate—Part 1: Heat Release Rate (Cone Calorimeter Method) and Smoke Production Rate (Dynamic Measurement). International Standardization Committee: Geneva, Switzerland, 2015.

- ISO 11925-2:2020; Reaction to Fire Tests—Ignitability of Products Subjected to Direct Impingement of Flame—Part 2: Single-Flame Source Test. International Standardization Committee: Geneva, Switzerland, 2020.

- Duarte, A.P.C.; Mazzuca, P.; Lopo de Carvalho, J.M.; Tiago, C.; Firmo, J.P.; Correia, J.R. Determination of the Temperature-Dependent Thermophysical Properties of Polymeric Foams using Numerical Inverse Analysis. Constr. Build. Mater. 2023, 394, 131980. [Google Scholar] [CrossRef]

- Sharma, C.; Kumar, S.; Unni, A.R.; Aswal, V.K.; Rath, S.K.; Harikrishnan, G. Foam Stability and Polymer Phase Morphology of Flexible Polyurethane Foams Synthesized from Castor Oil. J. Appl. Polym. Sci. 2014, 131, 40668. [Google Scholar] [CrossRef]

- Kharbas, H.A.; Ellingham, T.; Manitiu, M.; Scholz, G.; Turng, L.S. Effect of a Cross-Linking Agent on the Foamability of Microcellular Injection Molded Thermoplastic Polyurethane. J. Cell. Plast. 2017, 53, 407–423. [Google Scholar] [CrossRef]

- Bartczak, P.; Wysokowski, M.; Szylińczuk, K.; Odalanowska, M.; Jesionowski, T.; Borysiak, S. Green Synthesis of Chitin/Lignin-Based Polyurethane Composites. Ind. Crops Prod. 2023, 204, 117237. [Google Scholar] [CrossRef]

- Głowacz-Czerwonka, D.; Zakrzewska, P.; Oleksy, M.; Pielichowska, K.; Kuźnia, M.; Telejko, T. The Influence of Biowaste-Based Fillers on the Mechanical and Fire Properties of Rigid Polyurethane Foams. Sustain. Mater. Technol. 2023, 36, e00610. [Google Scholar] [CrossRef]

- Luo, X.; Mohanty, A.; Misra, M. Lignin as a Reactive Reinforcing Filler for Water-Blown Rigid Biofoam Composites from Soy Oil-Based Polyurethane. Ind. Crops Prod. 2013, 47, 13–19. [Google Scholar] [CrossRef]

- Acosta, A.P.; Otoni, C.G.; Missio, A.L.; Amico, S.C.; Delucis, R.A. Rigid Polyurethane Biofoams Filled with Chemically Compatible Fruit Peels. Polymers 2022, 14, 4526. [Google Scholar] [CrossRef] [PubMed]

- Horak, Z.; Dvorak, K.; Zarybnicka, L.; Vojackova, H.; Dvorakova, J.; Vilimek, M. Experimental Measurements of Mechanical Properties of PUR Foam Used for Testing Medical Devices and Instruments Depending on Temperature, Density and Strain Rate. Materials 2020, 13, 4560. [Google Scholar] [CrossRef]

- Liang, Y.; Gao, A.; Sun, Y.; Tian, F.; Sun, W.; Lu, W.; He, Z. Mechanism Confirmation of Organofunctional Silanes Modified Sodium Silicate/Polyurethane Composites for Remarkably Enhanced Mechanical Properties. Sci. Rep. 2021, 11, 9407. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Zhang, C.; Deng, Y.; Zhang, P. A Review of Research on the Effect of Temperature on the Properties of Polyurethane Foams. Polymers 2022, 14, 4586. [Google Scholar] [CrossRef] [PubMed]

- Anwar, M.F.; Yu, L.J.; Lim, Y.M.; Tarawneh, M.A.; Se Yong, E.N.; Lai, N.Y.G. Water Absorption Properties of Polyurethane Foam Reinforced with Paper Pulp. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Oliaie, H.; Haddadi-Asl, V.; Mirhosseini, M.M.; Jouibari, I.S.; Mohebi, S.; Shams, A. Role of Sequence of Feeding on the Properties of Polyurethane Nanocomposite Containing Halloysite Nanotubes. Des. Monomers Polym. 2019, 22, 199–212. [Google Scholar] [CrossRef]

- Ma, S.; Xiao, Y.; Zhou, F.; Schartel, B.; Chan, Y.Y.; Korobeinichev, O.P.; Trubachev, S.A.; Hu, W.; Ma, C.; Hu, Y. Effects of Novel Phosphorus-Nitrogen-Containing DOPO Derivative Salts on Mechanical Properties, Thermal Stability and Flame Retardancy of Flexible Polyurethane Foam. Polym. Degrad. Stab. 2020, 177, 109160. [Google Scholar] [CrossRef]

- Kamairudin, N.; Abdullah, L.C.; Hoong, S.S.; Biak, D.R.A.; Ariffin, H. Preparation and Effect of Methyl-Oleate-Based Polyol on the Properties of Rigid Polyurethane Foams as Potential Thermal Insulation Material. Polymers 2023, 15, 3028. [Google Scholar] [CrossRef]

- Modesti, M.; Lorenzetti, A.; Besco, S.; Hrelja, D.; Semenzatto, S.; Bertani, R.; Michelin, R.A. Synergism Between Flame Retardant and Modified Layered Silicate on Thermal Stability and Fire Behaviour of Polyurethane Nanocomposite Foams. Polym. Degrad. Stab. 2008, 93, 2166–2171. [Google Scholar] [CrossRef]

- Ridho, M.R.; Agustiany, E.A.; Dn, M.R.; Madyaratri, E.W.; Ghozali, M.; Restu, W.K.; Falah, F.; Lubis, M.A.R.; Syamani, F.A.; Nurhamiyah, Y.; et al. Lignin as Green Filler in Polymer Composites: Development Methods, Characteristics, and Potential Applications. Adv. Mater. Sci. Eng. 2022, 2022, 136341. [Google Scholar] [CrossRef]

- Zhang, D.; Zeng, J.; Liu, W.; Qiu, X.; Qian, Y.; Zhang, H.; Yang, Y.; Liu, M.; Yang, D. Pristine Lignin as a Flame Retardant in Flexible PU Foam. Green Chem. 2021, 23, 5972–5980. [Google Scholar] [CrossRef]

- Widsten, P.; Tamminen, T.; Paajanen, A.; Hakkarainen, T.; Liitiä, T. Modified and Unmodified Technical Lignins as Flame Retardants for Polypropylene. Holzforschung 2021, 75, 584–590. [Google Scholar] [CrossRef]

- Podkościelna, B.; Wnuczek, K.; Goliszek, M.; Klepka, T.; Dziuba, K. Flammability Tests and Investigations of Properties of Lignin-Containing Polymer Composites Based on Acrylates. Molecules 2020, 25, 5947. [Google Scholar] [CrossRef] [PubMed]

- Aydoğan, B.; Usta, N. Cone Calorimeter Evaluation on Fire Resistance of Rigid Polyurethane Foams Filled with Nanoclay/Intumescent Flame Retardant Materials. Res. Eng. Struct. Mater. 2018, 4, 71–77. [Google Scholar] [CrossRef]

- Carretier, V.; Delcroix, J.; Pucci, M.F.; Rublon, P.; Lopez-Cuesta, J.-M. Influence of Sepiolite and Lignin as Potential Synergists on Flame Retardant Systems in Polylactide (PLA) and Polyurethane Elastomer (PUE). Materials 2020, 13, 2450. [Google Scholar] [CrossRef]

- Barczewski, M.; Kurańska, M.; Sałasińska, K.; Aniśko, J.; Szulc, J.; Szafraniak-Wiza, I.; Prociak, A.; Polaczek, K.; Uram, K.; Surmacz, K.; et al. Comprehensive Analysis of the Influence of Expanded Vermiculite on the Foaming Process and Selected Properties of Composite Rigid Polyurethane Foams. Polymers 2022, 14, 4967. [Google Scholar] [CrossRef]

- Zhu, H.; Xu, S. Preparation of Flame-Retardant Rigid Polyurethane Foams by Combining Modified Melamine–Formaldehyde Resin and PhosphorusFlame Retardants. ACS Omega 2020, 5, 9658–9667. [Google Scholar] [CrossRef]

- Zemła, M.; Prociak, A.; Michałowski, S.; Cabulis, U.; Kirpluks, M.; Simakovs, K. Thermal Insulating Rigid Polyurethane Foams with Bio-Polyol from Rapeseed Oil Modified by Phosphorus Additive and Reactive Flame Retardants. Mol. Sci. 2022, 23, 12386. [Google Scholar] [CrossRef]

- Wypych, G. Handbook of Fillers, 4th ed.; ChemTec Publishing: Toronto, ON, Canada, 2016; ISBN 978-18-9519-891-1. [Google Scholar]

- Phan, H.T.Q.; Nguyen, B.T.; Pham, L.H.; Pham, C.T.; Do, T.V.V.; Hoang, C.N.; Nguyen, N.N.; Kim, J.; Hoang, D.Q. Excellent Fireproof Characteristics and High Thermal Stability of Rice Husk-Filled Polyurethane with Halogen-Free Flame Retardant. Polymers 2019, 11, 1587. [Google Scholar] [CrossRef] [PubMed]

- Strąkowska, A.; Członka, S.; Kairytė, A. Rigid Polyurethane Foams Reinforced with POSS-Impregnated Sugar Beet Pulp Filler. Materials 2020, 13, 5493. [Google Scholar] [CrossRef] [PubMed]

- De Luca Bossa, F.; Santillo, C.; Verdolotti, L.; Campaner, P.; Minigher, A.; Boggioni, L.; Losio, S.; Coccia, F.; Iannace, S.; Lama, G.C. Greener Nanocomposite Polyurethane Foam Based on Sustainable Polyol and Natural Fillers: Investigation of Chemico-Physical and Mechanical Properties. Materials 2020, 13, 211. [Google Scholar] [CrossRef] [PubMed]

- Zieleniewska, M.; Szczepkowski, L.; Krzyżowska, M.; Leszczyński, M.K.; Ryszkowska, J. Rigid Polyurethane Foam Composites with Vegetable Filler for Application in the Cosmetics Industry. Polimery 2016, 61, 807–814. [Google Scholar] [CrossRef]

- Członka, S.; Kairytė, A.; Miedzińska, K.; Strąkowska, A. Polyurethane Composites Reinforced with Walnut Shell Filler Treated with Perlite, Montmorillonite and Halloysite. Int. J. Mol. Sci. 2021, 22, 7304. [Google Scholar] [CrossRef]

- Gondaliya, A.; Nejad, M. Lignin as a Partial Polyol Replacement in Polyurethane Flexible Foam. Molecules 2021, 26, 2302. [Google Scholar] [CrossRef]

- Dong, F.; Wang, Y.; Wang, S.; Shaghaleh, H.; Sun, P.; Huang, X.; Xu, X.; Wang, S.; Liu, H. Flame Retarded Polyurethane Foam Conffered by a Bio-Based Nitrogen-Phosphorus-Containing Flame Retardant. React. Funct. Polym. 2021, 168, 105057. [Google Scholar] [CrossRef]

| Lignin Waste, wt.% | Compressive Strength, kPa, at Different Temperatures | Tensile Strength, kPa, at Different Temperatures | Apparent Density 1, kg/m3 | Water Absorption, vol.% | ||||

|---|---|---|---|---|---|---|---|---|

| 23 °C 1 | 100 °C | 200 °C | 23 °C 1 | 100 °C | 200 °C | |||

| 0 | 282 ± 5 | 220 ± 7 | 75 ± 5 | 231 ± 4 | 175 ± 5 | 104 ± 6 | 42 ± 2 | 4.2 ± 0.2 |

| bioPUR foam with LigW | ||||||||

| 2.5 | 206 ± 7 | 172 ± 6 | 66 ± 6 | 190 ± 5 | 133 ± 6 | 107 ± 5 | 38 ± 3 | 5.0 ± 0.4 |

| 5 | 150 ± 6 | 142 ± 8 | 66 ± 5 | 207 ± 6 | 144 ± 5 | 78 ± 5 | 36 ± 2 | 5.0 ± 0.3 |

| 7.5 | 113 ± 8 | 107 ± 5 | 56 ± 5 | 243 ± 3 | 137 ± 4 | 78 ± 6 | 35 ± 2 | 5.3 ± 0.3 |

| 10 | 95 ± 4 | 75 ± 6 | 36 ± 6 | 243 ± 4 | 117 ± 5 | 54 ± 4 | 33 ± 2 | 5.5 ± 0.3 |

| bioPUR foam with LigW/LG ratio 1/1 | ||||||||

| 2.5 | 235 ± 9 | 210 ± 8 | 60 ± 4 | 208 ± 5 | 137 ± 4 | 77 ± 4 | 42 ± 3 | 4.3 ± 0.3 |

| 5 | 230 ± 8 | 179 ± 8 | 52 ± 7 | 282 ± 6 | 132 ± 5 | 72 ± 6 | 42 ± 3 | 4.5 ± 0.2 |

| 7.5 | 228 ± 5 | 146 ± 6 | 54 ± 6 | 284 ± 5 | 117 ± 6 | 63 ± 3 | 45 ± 2 | 4.5 ± 0.2 |

| 10 | 225 ± 6 | 134 ± 7 | 42 ± 5 | 286 ± 7 | 101 ± 3 | 50 ± 3 | 46 ± 2 | 4.7 ± 0.3 |

| bioPUR foam with LigW/LG ratio 1/2 | ||||||||

| 2.5 | 260 ± 7 | 202 ± 6 | 67 ± 6 | 298 ± 6 | 198 ± 5 | 138 ± 6 | 43 ± 4 | 4.4 ± 0.2 |

| 5 | 247 ± 7 | 196 ± 7 | 65 ± 5 | 302 ± 6 | 167 ± 4 | 107 ± 4 | 44 ± 2 | 4.3 ± 0.2 |

| 7.5 | 241 ± 4 | 170 ± 5 | 59 ± 5 | 290 ± 4 | 141 ± 4 | 68 ± 5 | 46 ± 3 | 4.5 ± 0.3 |

| 10 | 244 ± 9 | 167 ± 8 | 49 ± 7 | 300 ± 5 | 130 ± 6 | 63 ± 3 | 46 ± 2 | 4.6 ± 0.2 |

| Lignin Waste, wt.% | Tg, °C | Storage Modulus, MPa | |

|---|---|---|---|

| at 23 °C | at 100 °C | ||

| 0 | 145 | 0.18 | 0.15 |

| bioPUR foam with LigW | |||

| 2.5 | 158 | 0.16 | 0.20 |

| 5 | 172 | 0.18 | 0.21 |

| 7.5 | 161 | 0.27 | 0.53 |

| 10 | 140 | 0.20 | 0.23 |

| bioPUR foam with LigW/LG ratio 1/1 | |||

| 2.5 | 167 | 0.36 | 0.49 |

| 5 | 161 | 0.12 | 0.11 |

| 7.5 | 161 | 0.28 | 0.34 |

| 10 | 157 | 0.26 | 0.30 |

| bioPUR foam with LigW/LG ratio 1/2 | |||

| 2.5 | 175 | 0.23 | 0.29 |

| 5 | 167 | 0.18 | 0.24 |

| 7.5 | 169 | 0.11 | 0.46 |

| 10 | 162 | 0.14 | 0.26 |

| Lignin Waste, wt.% | T5wt.%, °C | T50wt.%, °C | Tmax Stages, °C | Char Yield at 900 °C, wt.% | |||

|---|---|---|---|---|---|---|---|

| 1st | 2nd | 3rd | 4th | ||||

| 0 | 240 | 468 | 221 | 324 | 464 | 660 | 1.68 |

| bioPUR foam with LigW | |||||||

| 2.5 | 216 | 478 | 212 | 324 | - | 650 | 1.60 |

| 5 | 221 | 487 | 216 | 324 | - | 627 | 1.62 |

| 7.5 | 216 | 482 | 212 | 319 | - | 615 | 2.49 |

| 10 | 216 | 487 | 216 | 319 | - | 608 | 2.51 |

| bioPUR foam with LigW/LG ratio 1/1 | |||||||

| 2.5 | 235 | 502 | 216 | 326 | - | 663 | 3.68 |

| 5 | 235 | 505 | 221 | 324 | - | 650 | 3.76 |

| 7.5 | 232 | 506 | 228 | 319 | - | 598 | 5.24 |

| 10 | 230 | 506 | 221 | 314 | - | 585 | 5.29 |

| bioPUR foam with LigW/LG ratio 1/2 | |||||||

| 2.5 | 254 | 511 | 228 | 322 | - | 647 | 2.45 |

| 5 | 254 | 506 | 227 | 319 | - | 650 | 2.68 |

| 7.5 | 228 | 503 | 218 | 317 | - | 623 | 4.30 |

| 10 | 227 | 502 | 212 | 314 | - | 596 | 5.98 |

| Lignin Waste, wt.% | Time for Flame to Reach 150 mm Height, s | Height of Flame Damaged Area, mm | Time of Self-Extinguishment after Flame Source Removal, s |

|---|---|---|---|

| 0 | 6 ± 2 | 138 ± 4 | - |

| bioPUR foam with LigW | |||

| 2.5 | 11 ± 2 | 109 ± 2 | - |

| 5 | 10 ± 2 | 125 ± 3 | - |

| 7.5 | 10 ± 3 | 130 ± 5 | - |

| 10 | 9 ± 2 | 140 ± 3 | - |

| bioPUR foam with LigW/LG ratio 1/1 | |||

| 2.5 | 10 ± 2 | 122 ± 2 | 5 ± 2 |

| 5 | 10 ± 3 | 120 ± 3 | 5 ± 2 |

| 7.5 | 10 ± 2 | 117 ± 2 | 4 ± 2 |

| 10 | 14 ± 3 | 115 ± 4 | 4 ± 2 |

| bioPUR foam with LigW/LG ratio 1/2 | |||

| 2.5 | 11 ± 2 | 119 ± 2 | 4 ± 2 |

| 5 | 12 ± 2 | 116 ± 3 | 4 ± 2 |

| 7.5 | 11 ± 2 | 109 ± 4 | 3 ± 2 |

| 10 | 13 ± 3 | 98 ± 2 | 3 ± 2 |

| Lignin Waste, wt.% | pHRR, kW/m2 | THR, MJ/m2 | TSR, m2/m2 | CO2Y, kg/kg | COY, kg/kg | COY/CO2Y, n. d. | Ignition Time, s | LOI, % |

|---|---|---|---|---|---|---|---|---|

| 0 | 82 | 13.6 | 1141 | 3.67 | 0.18 | 0.05 | 3 | 19.8 |

| bioPUR foam with LigW | ||||||||

| 2.5 | 89 | 17.1 | 3422 | 3.88 | 0.32 | 0.08 | 3 | 21.0 |

| 5 | 102 | 17.7 | 3462 | 4.01 | 0.28 | 0.07 | 3 | 21.4 |

| 7.5 | 116 | 18.3 | 3479 | 4.12 | 0.34 | 0.08 | 3 | 21.6 |

| 10 | 125 | 19.7 | 3488 | 4.22 | 0.36 | 0.09 | 3 | 21.6 |

| bioPUR foam with LigW/LG ratio 1/1 | ||||||||

| 2.5 | 159 | 25.8 | 2745 | 4.14 | 0.24 | 0.06 | 2 | 22.4 |

| 5 | 133 | 25.7 | 2789 | 4.26 | 0.29 | 0.07 | 3 | 22.4 |

| 7.5 | 184 | 31.7 | 2820 | 4.39 | 0.28 | 0.06 | 5 | 22.6 |

| 10 | 190 | 32.7 | 2843 | 4.53 | 0.32 | 0.07 | 5 | 22.8 |

| bioPUR foam with LigW/LG ratio 1/2 | ||||||||

| 2.5 | 150 | 29.5 | 2815 | 4.38 | 0.22 | 0.05 | 3 | 23.1 |

| 5 | 152 | 29.9 | 2832 | 4.54 | 0.25 | 0.06 | 3 | 23.3 |

| 7.5 | 159 | 32.3 | 2855 | 4.69 | 0.28 | 0.06 | 6 | 23.4 |

| 10 | 173 | 36.8 | 2874 | 4.72 | 0.28 | 0.06 | 6 | 23.4 |

| Waste Filler | Waste Filler Amount, wt.% | Results | Reference |

|---|---|---|---|

| Sunflower husk | 5–15 | Thermal stability at higher temperatures decreased by 4–13 °C, time to ignition (TTI) increased by 5 s, pHRR decreased by a maximum of 6 kW/m2, and LOI did not change significantly | [27] |

| Rice husk | 5–15 | Thermal stability at higher temperatures increased by 5–21 °C, TTI increased by a maximum of 10 s, pHRR decreased by a maximum of 5 kW/m2, and LOI did not change significantly | [48] |

| Buckwheat husk | 5–15 | Thermal stability at higher temperatures increased by 2–5 °C, TTI increased by a maximum of 8 s, pHRR decreased by a maximum of 12 kW/m2, and LOI did not change significantly | [49] |

| Rice husk with aluminium hydroxide | 5 | LOI increased by 4%, thermal stability at higher temperatures increased by 173 °C, and pHRR decreased by 73 kW/m2 | [48] |

| Rice husk with aluminium diethylphosphinate | 5 | LOI increased by 3%, thermal stability at higher temperatures increased by 132 °C, and pHRR increased by 3 kW/m2 | [48] |

| POSS-impregnated sugar beet pulp | 1–5 | Thermal stability at higher temperatures increased by a maximum of 11 °C, pHRR decreased by a maximum of 105 kW/m2, TSR decreased by a maximum of 400 m2/m2, LOI increased by 1%, and CO2Y and COY decreased by a maximum of 0.05 kg/kg | [49] |

| Walnut shells | 5 | Thermal stability at higher temperatures increased by 5 °C | [50] |

| Hazelnut shells | 4–25 | Thermal stability at higher temperatures decreased by 9 °C | [51] |

| Walnut shells treated with perlite, montmorillonite, and halloysite | 2 | Thermal stability at higher temperatures increased by 15 °C for walnut shells/perlite, 7 °C for walnut shells/montmorillonite, and 19 °C for walnut shells/halloysite. TTI increased by 4 s for walnut shells/perlite, 3 s for walnut shells/montmorillonite, and 4 s for walnut shells/halloysite. pHRR decreased by 29 kW/m2 for walnut shells/perlite, 32 kW/m2 for walnut shells/montmorillonite, and 31 kW/m2 for walnut shells/halloysite. TSR decreased by 187 m2/m2 for walnut shells/perlite, 242 m2/m2 for walnut shells/montmorillonite, and 356 m2/m2 for walnut shells/halloysite. COY did not change significantly. CO2Y decreased by 0.08 kg/kg for walnut shells/perlite and walnut shells/montmorillonite, and by 0.09 kg/kg for walnut shells/halloysite | [52] |

| Organosolv and kraft lignin from various sources | 20 | Thermal stability at higher temperatures increased by a maximum of 25 °C | [53] |

| Lignin Amount, wt.% | The Main Elements, % | ||||

|---|---|---|---|---|---|

| C | N | O | Na | Si | |

| bioPUR with LigW | |||||

| 5 | 80.30 | 6.01 | 11.63 | 0.4 | 1.82 |

| 10 | 84.27 | 4.58 | 9.23 | 0 | 1.92 |

| bioPUR with LigW/LG ratio 1/1 | |||||

| 5 | 80.65 | 7.04 | 9.21 | 0.29 | 2.81 |

| 10 | 78.71 | 5.12 | 13.12 | 0.04 | 3.01 |

| bioPUR with LigW/LG ratio 1/2 | |||||

| 5 | 63.29 | 8.75 | 17.59 | 6.90 | 3.47 |

| 10 | 60.99 | 6.24 | 19.27 | 7.83 | 5.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kairytė, A.; Makowska, S.; Rybiński, P.; Strzelec, K.; Kremensas, A.; Šeputytė-Jucikė, J.; Vaitkus, S. Effect of Liquid Glass-Modified Lignin Waste on the Flammability Properties of Biopolyurethane Foam Composites. Polymers 2024, 16, 205. https://doi.org/10.3390/polym16020205

Kairytė A, Makowska S, Rybiński P, Strzelec K, Kremensas A, Šeputytė-Jucikė J, Vaitkus S. Effect of Liquid Glass-Modified Lignin Waste on the Flammability Properties of Biopolyurethane Foam Composites. Polymers. 2024; 16(2):205. https://doi.org/10.3390/polym16020205

Chicago/Turabian StyleKairytė, Agnė, Sylwia Makowska, Przemysław Rybiński, Krzysztof Strzelec, Arūnas Kremensas, Jurga Šeputytė-Jucikė, and Saulius Vaitkus. 2024. "Effect of Liquid Glass-Modified Lignin Waste on the Flammability Properties of Biopolyurethane Foam Composites" Polymers 16, no. 2: 205. https://doi.org/10.3390/polym16020205

APA StyleKairytė, A., Makowska, S., Rybiński, P., Strzelec, K., Kremensas, A., Šeputytė-Jucikė, J., & Vaitkus, S. (2024). Effect of Liquid Glass-Modified Lignin Waste on the Flammability Properties of Biopolyurethane Foam Composites. Polymers, 16(2), 205. https://doi.org/10.3390/polym16020205