Machine Learning in 3D and 4D Printing of Polymer Composites: A Review

Abstract

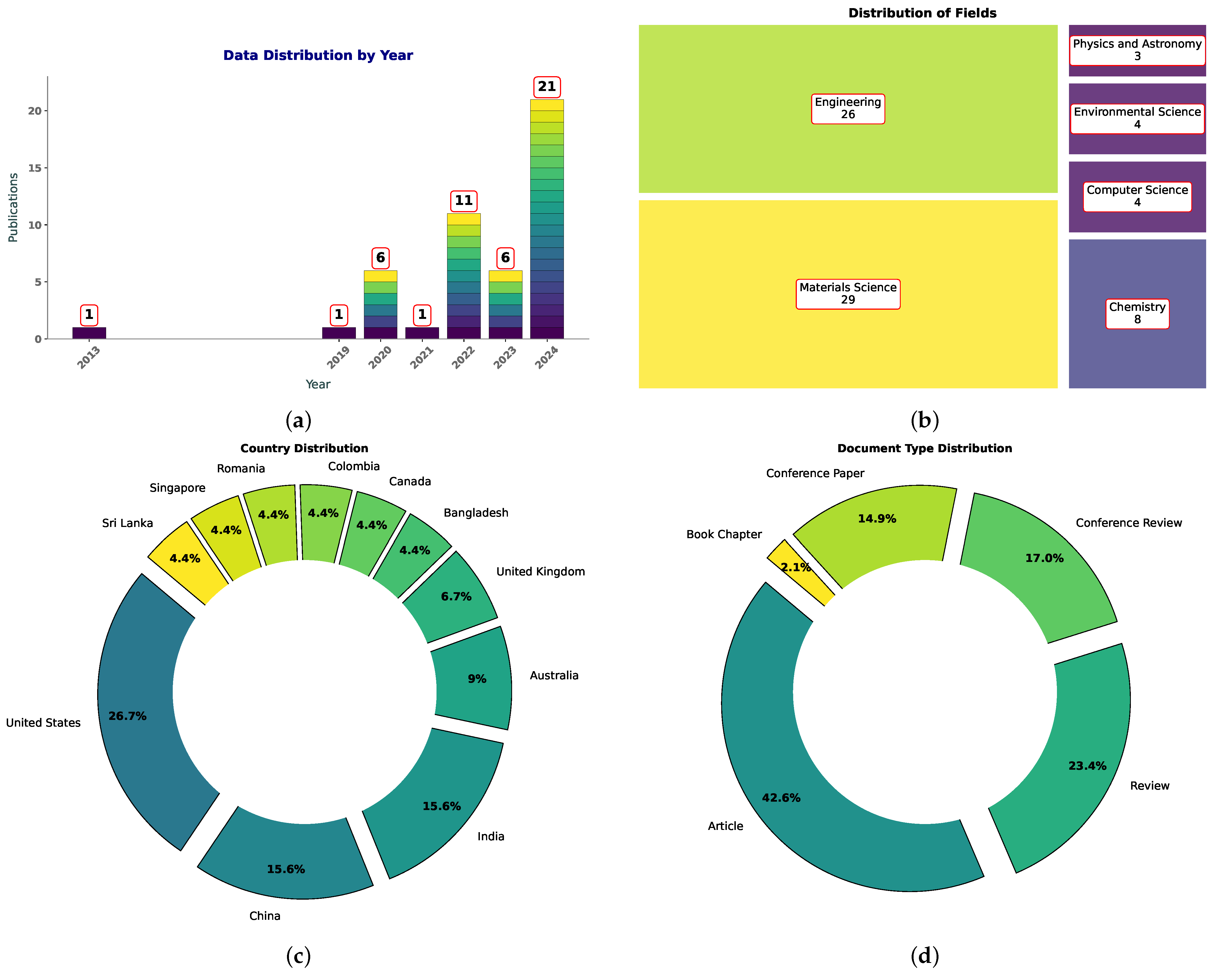

1. Introduction

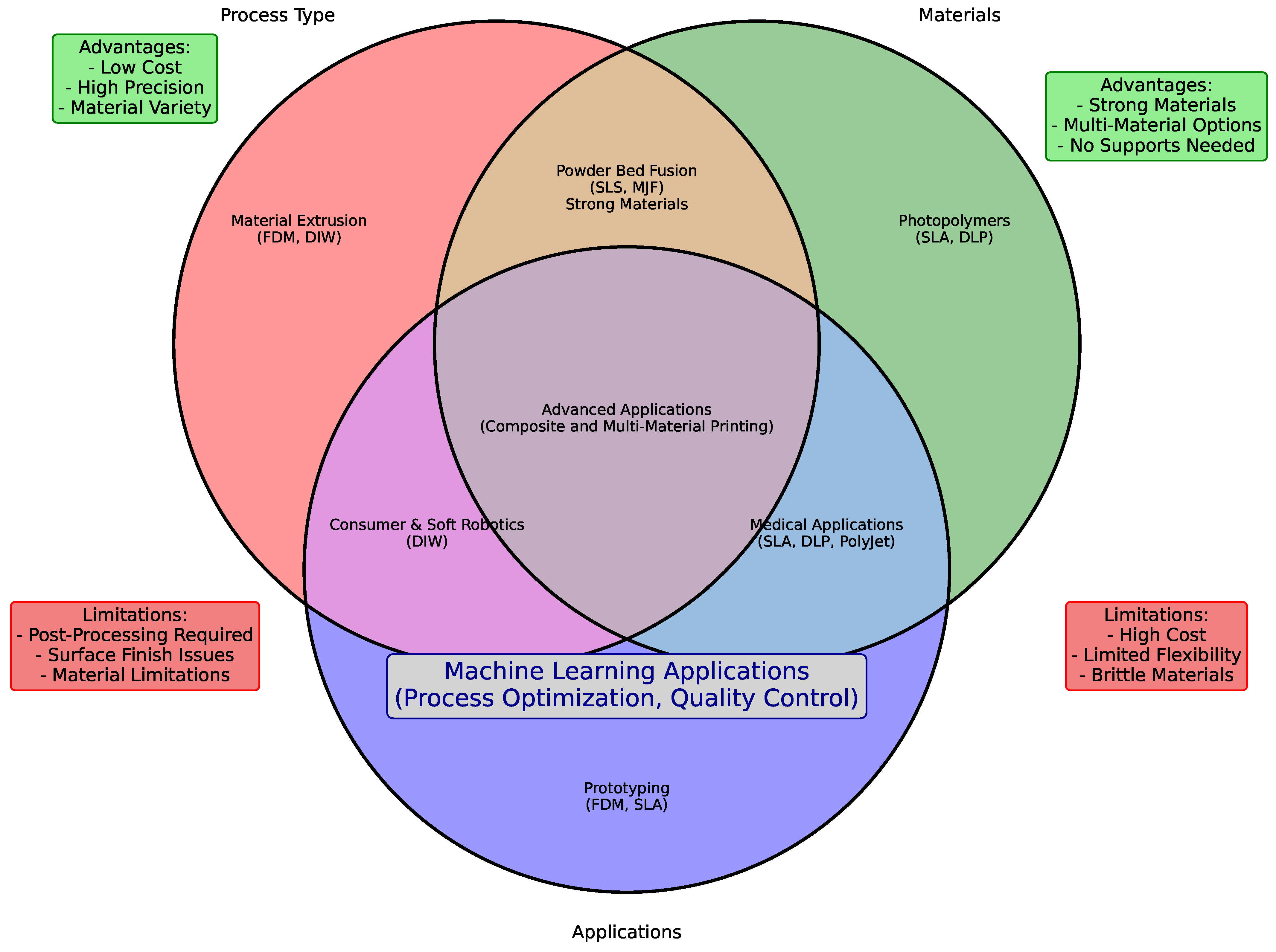

2. 3D and 4D Printing: An Overview

2.1. Material Extrusion

2.1.1. Fused Deposition Modeling

2.1.2. Fused Filament Fabrication

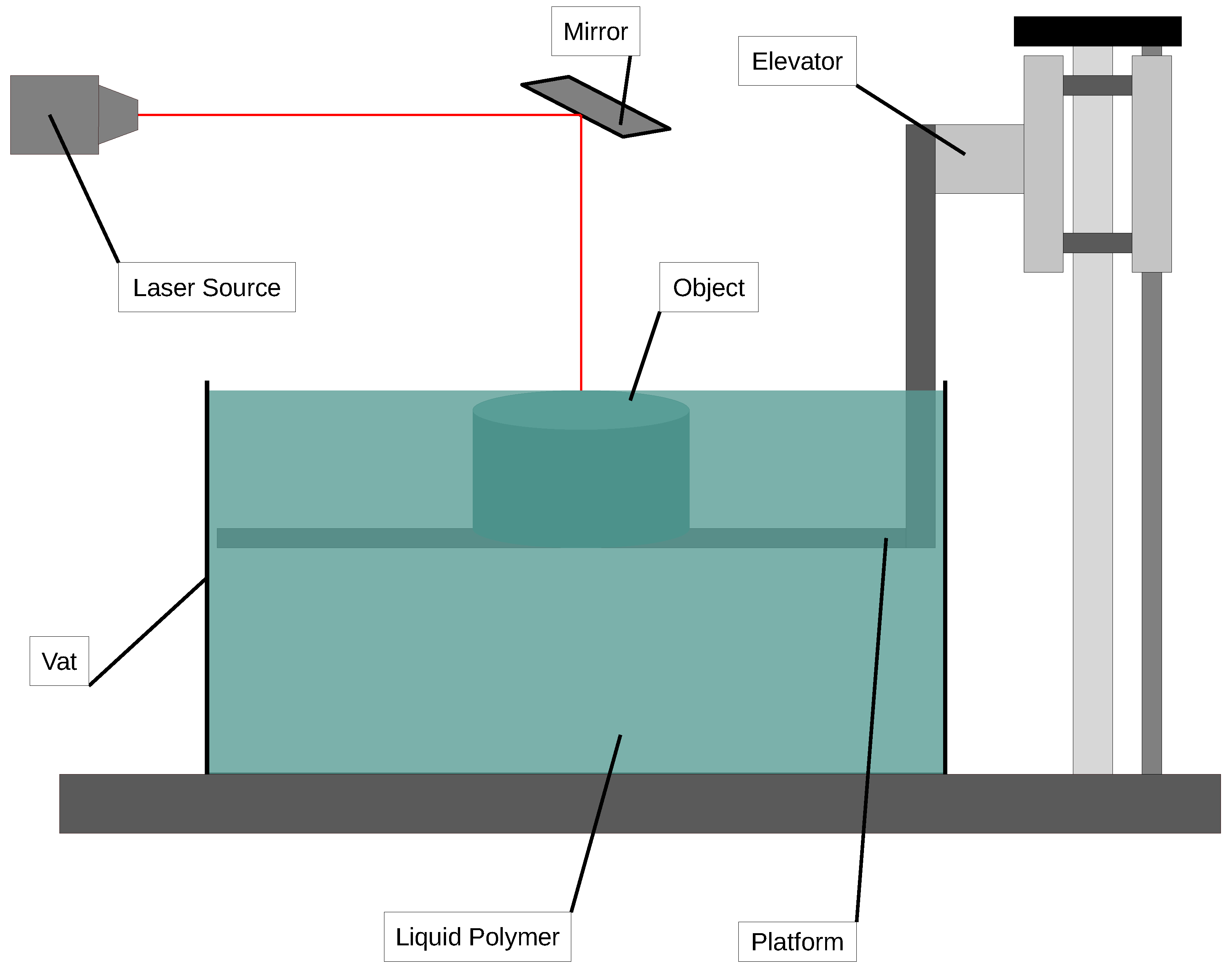

2.2. Stereolithography

2.3. Selective Laser Sintering

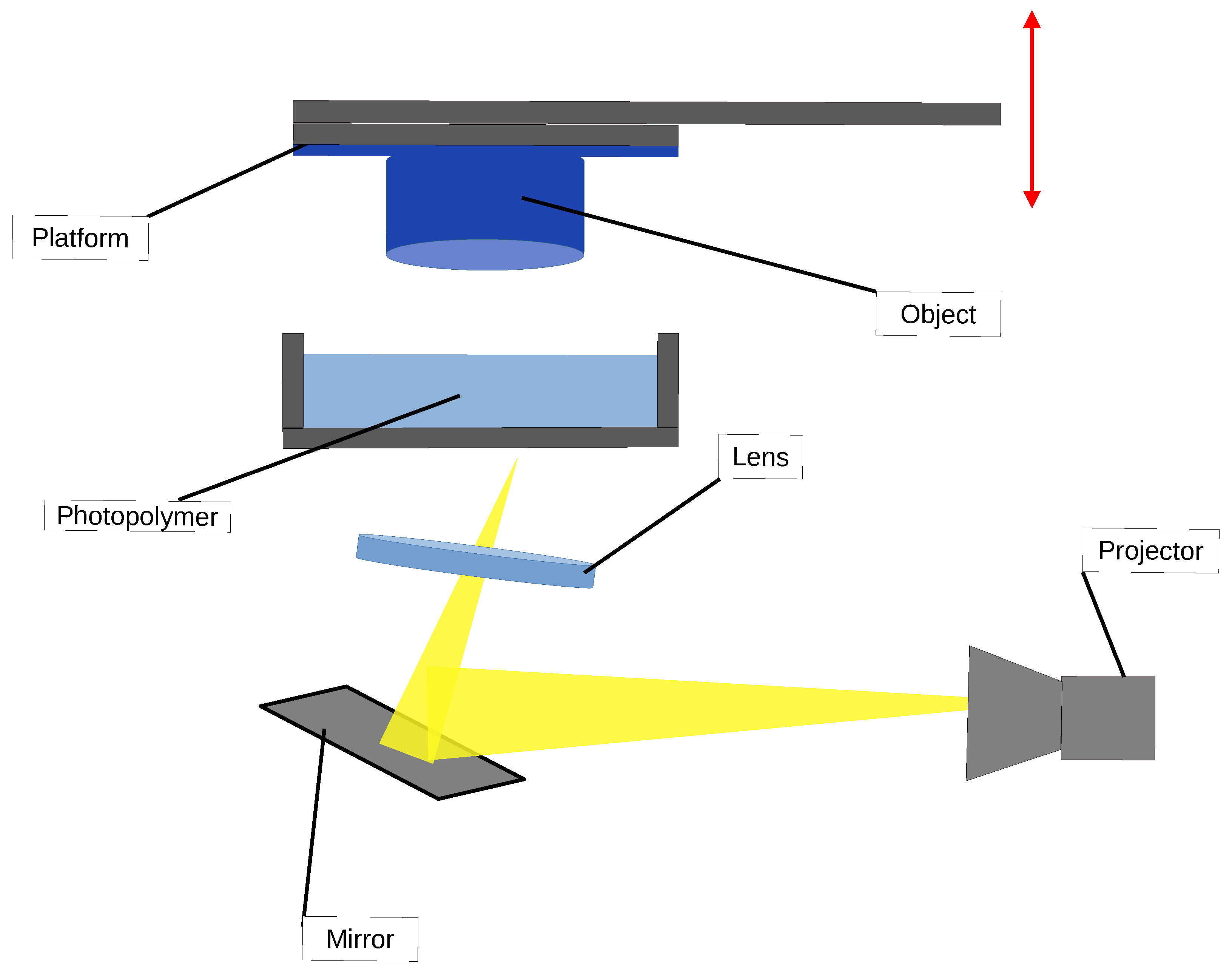

2.4. Digital Light Processing

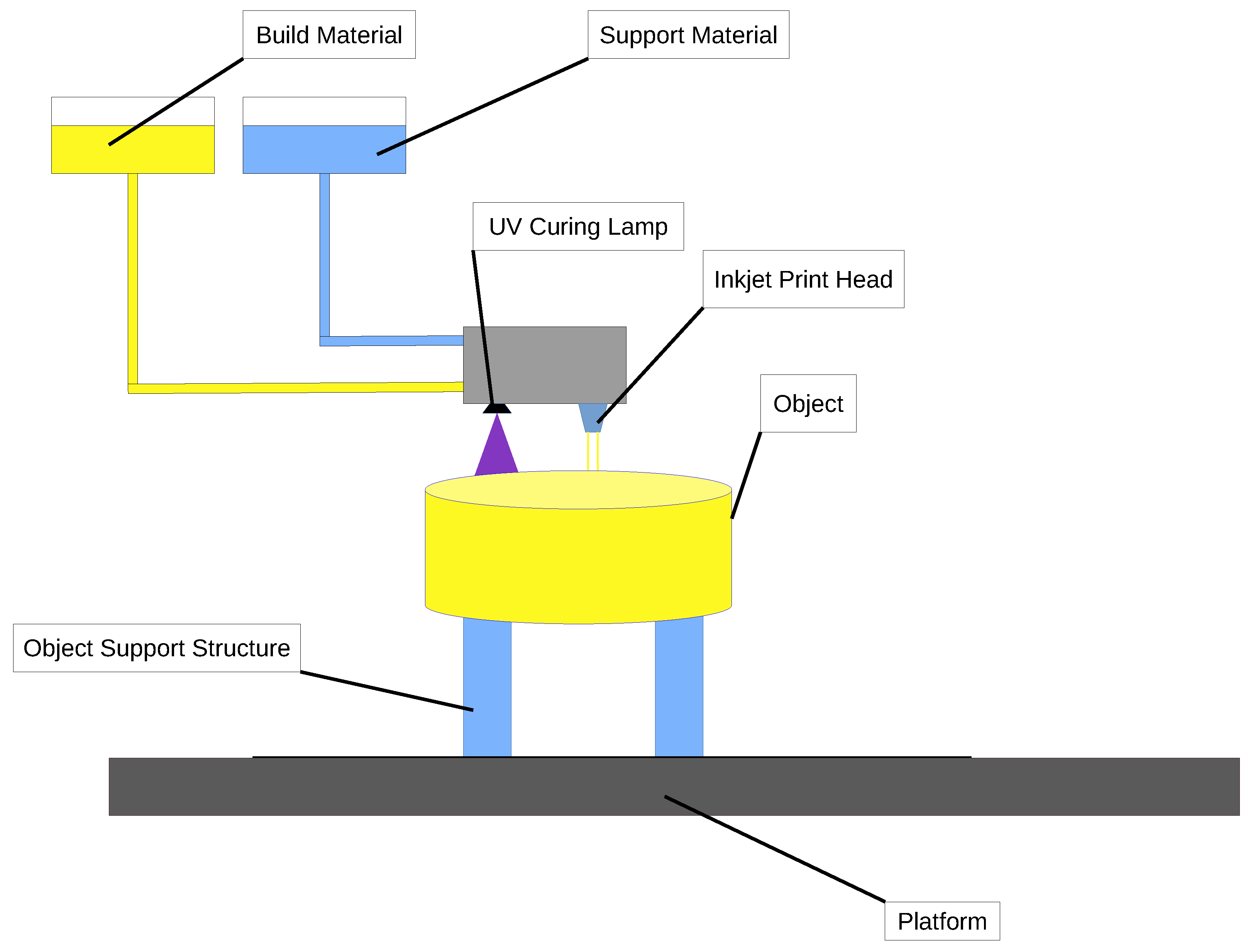

2.5. Jetting 3D Technologies

2.5.1. Multi Jet Fusion

2.5.2. PolyJet Printing

2.6. Direct Ink Writing

2.7. 4D Printing

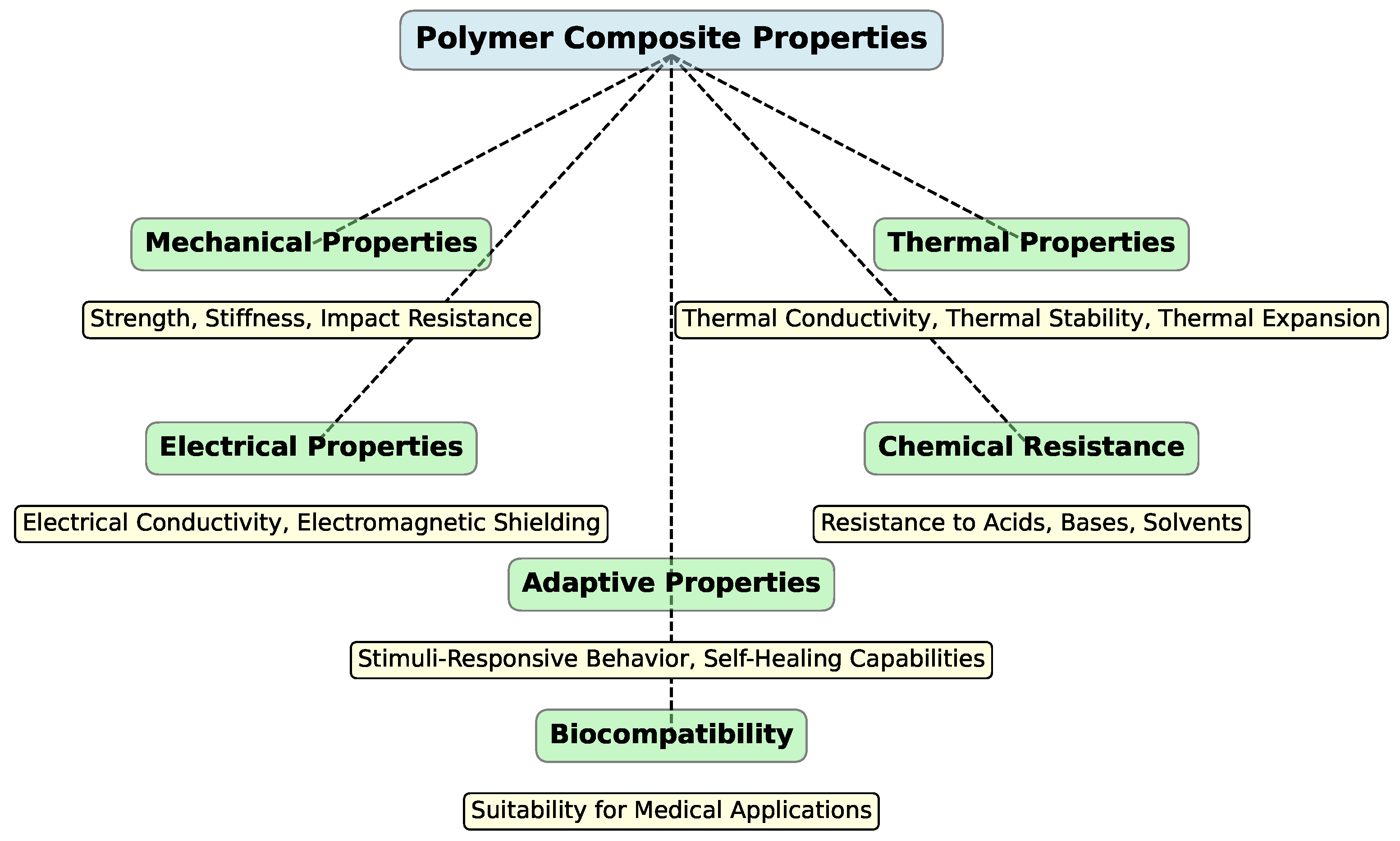

3. Properties of Polymer Composites in AM Technologies

3.1. Mechanical Properties

3.2. Thermal Properties

3.3. Electrical Properties

3.4. Adaptive Properties and 4DP

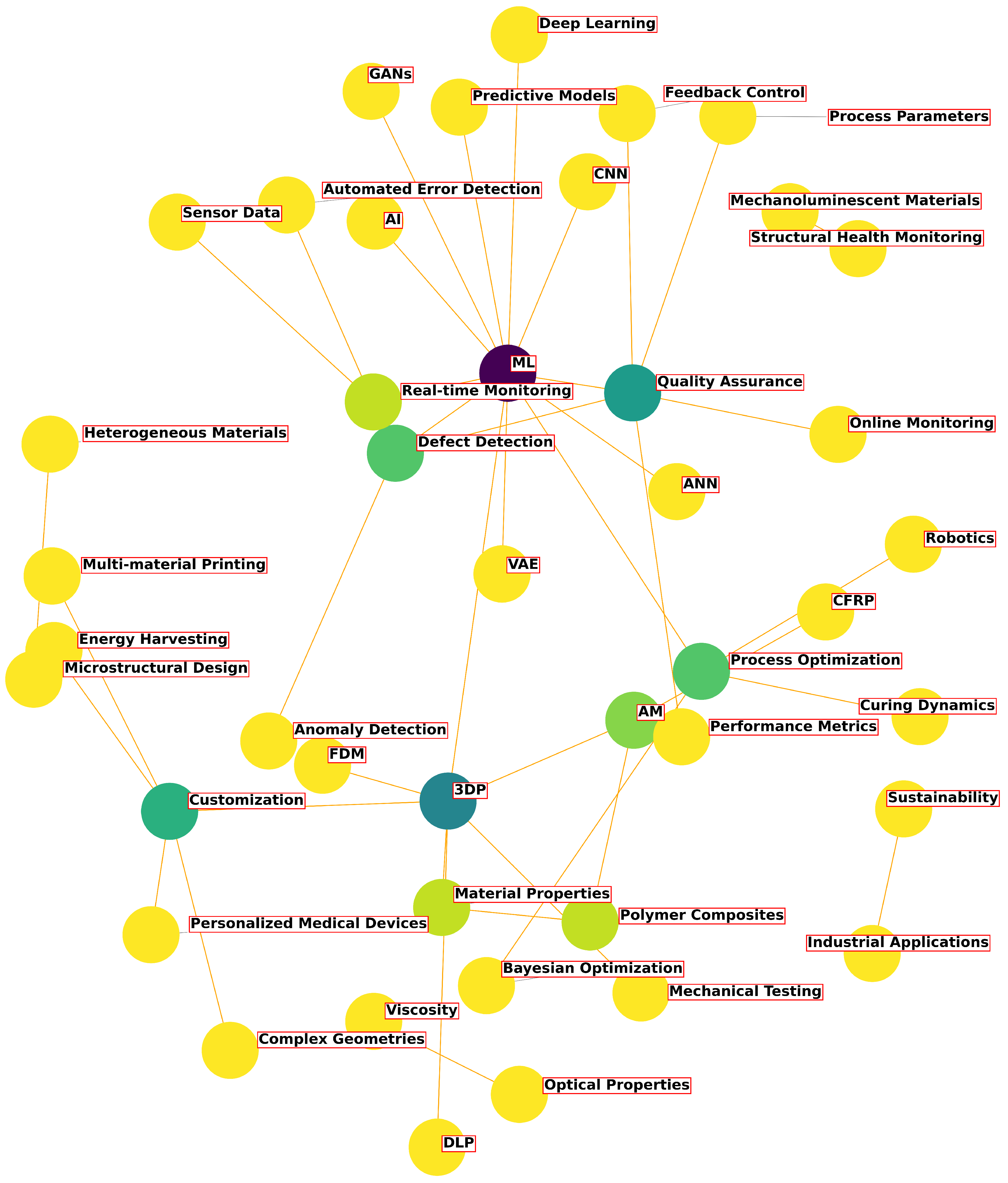

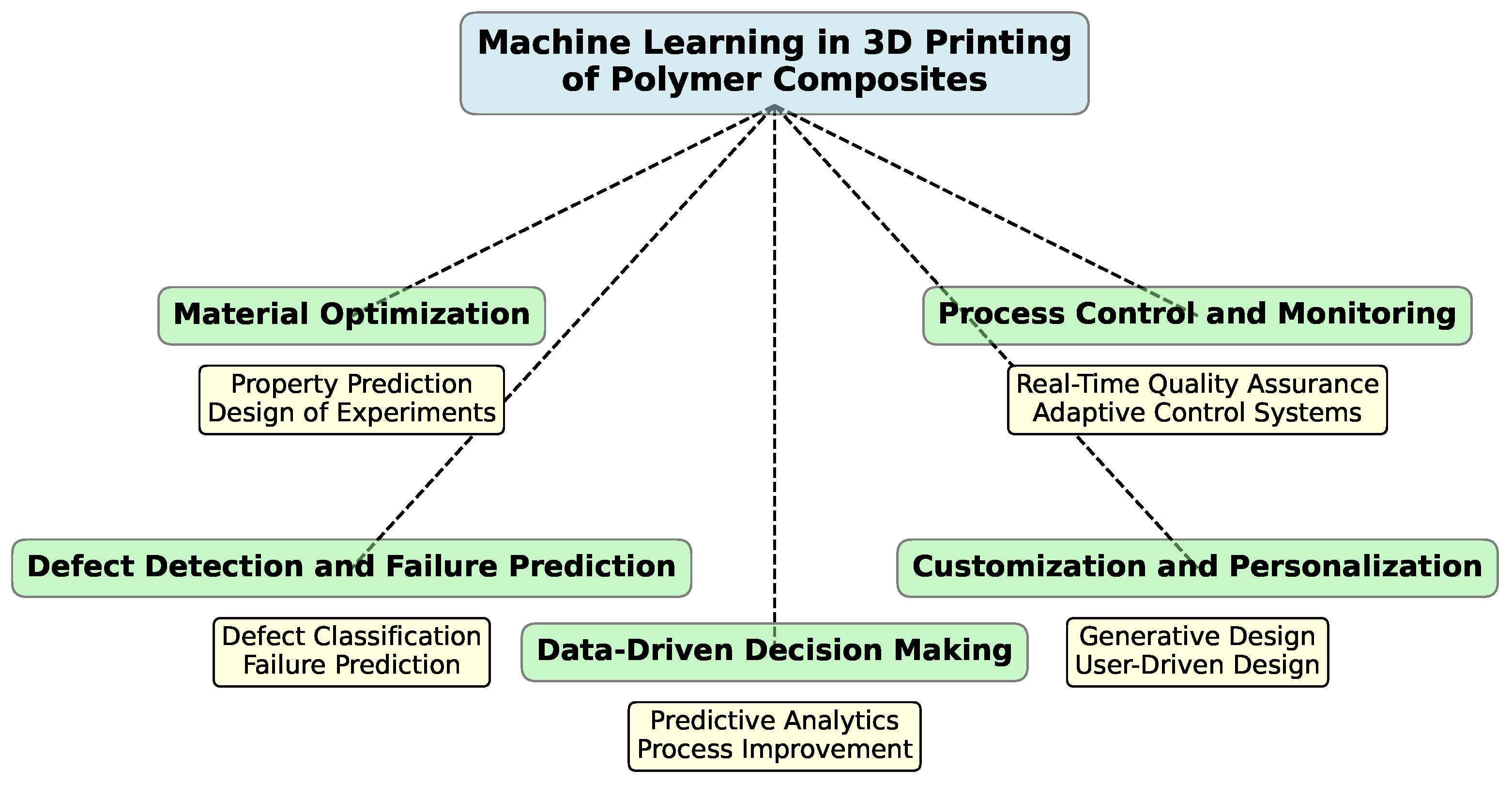

4. Application of ML in 3DP of Polymer Composites

4.1. Properties Prediction

4.2. Process Control and Monitoring

4.3. Defect Detection and Failure Prediction

4.4. Customization and Personalization

4.5. VAT Photopolymerization and ML

5. Application of ML in 4DP of Polymer Composites

6. Transformation of Polymer Composites to Ceramics and Other Materials

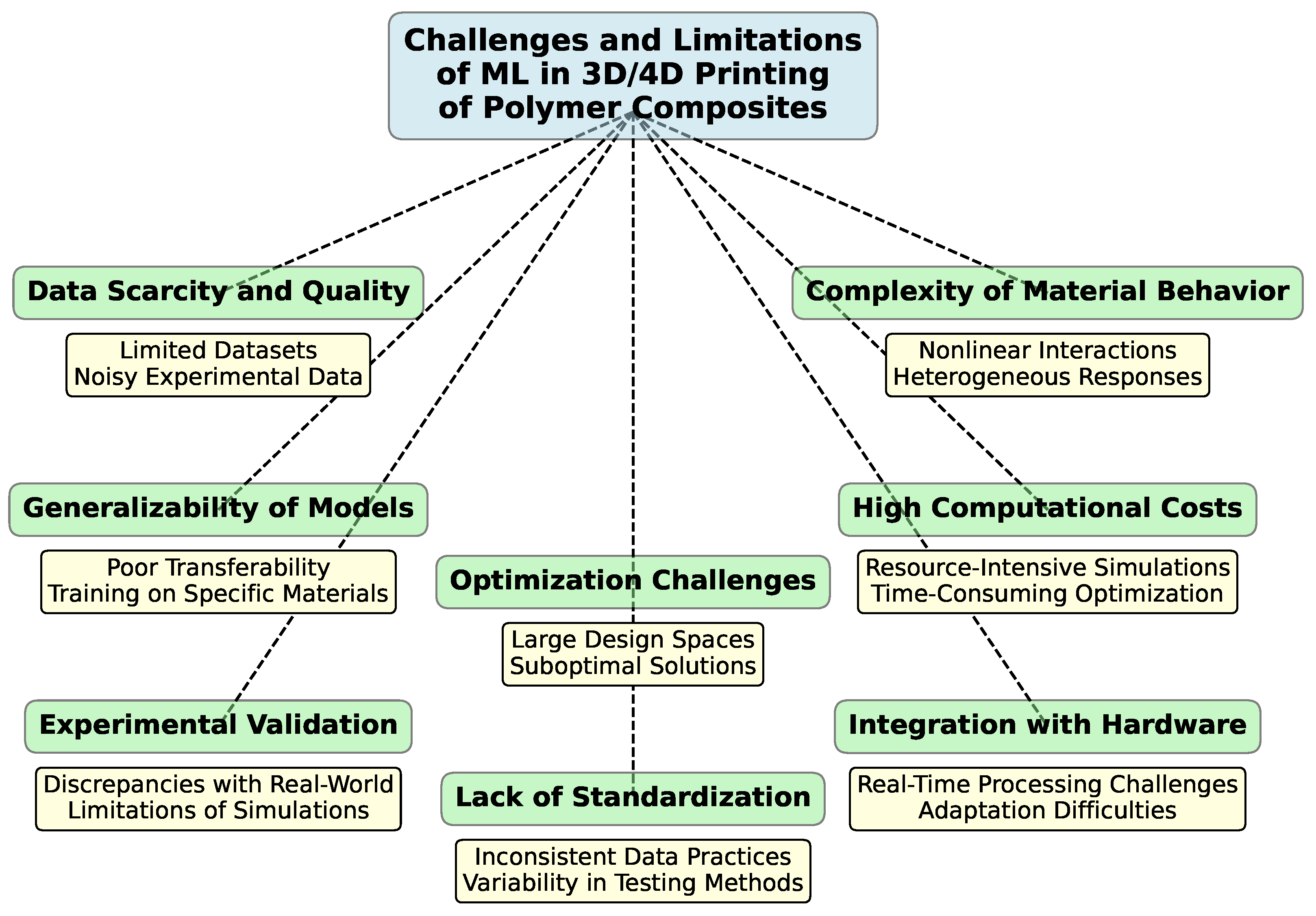

7. Challenges and Limitations

8. Future Directions

9. Conclusions

- The integration of ML in real-time monitoring systems (e.g., AI2AM technology for FDM) improves the quality and consistency of printed polymer composites. This shift to smart manufacturing aligns with Industry 4.0 principles, focusing on defect detection and parameter optimization to prevent errors and enhance efficiency.

- Techniques like the deep learning model developed by Lu et al. for detecting defects in carbon fiber-reinforced polymers (CFRPs) showcase the ability of AI to provide real-time geometric analysis and process adjustments. This automation reduces reliance on traditional methods, enhancing overall manufacturing quality.

- Systems like the self-monitoring approach by Narayanan et al. utilize deep learning to detect delamination and predict warping, demonstrating the capability for early error detection. This proactive management improves automated quality control across various manufacturing sectors.

- Jin et al. [340] achieved up to 99.5% accuracy in classifying 3D-printed parts using ML models. This level of precision benefits both large-scale manufacturers and individual users, emphasizing the competitive advantage gained through intelligent quality assurance.

- By employing laser scanning methods (as demonstrated by Lin et al. [240]) to monitor printed surfaces against CAD models, companies can achieve real-time feedback control that reduces waste and prevents unnecessary production runs, leading to more sustainable manufacturing practices.

- The Continual G-learning method for defect detection exemplifies the potential of reinforcement learning to address emerging defects in real time using historical and real-time data, showcasing an advanced adaptive quality control system that requires minimal training samples.

- Innovations like the multi-material inkjet 3DP method described by He et al. for personalizing medical devices highlight the growing trend towards customization, enabling user-defined mechanical properties and multifunctional device design.

- Xue et al.’s variational autoencoder (VAE) framework [256] for designing mechanical metamaterials demonstrates the ability of ML to efficiently customize 3D-printed parts for specific macroscopic elastic properties, fostering innovation in material science and application design.

- The reduction in printing time (up to 25%) and waiting time (47%) achieved through methods like WTP-VP, as described by Cao et al., signify a positive trend towards more environmentally friendly manufacturing processes by minimizing resource usage.

- Chen et al.’s work [21] on tool path identification in GFRP composites highlights the potential risks to intellectual property as reverse-engineering capabilities using ML can reconstruct manufacturing processes from finished products, necessitating enhanced data protection strategies.

- Recent studies highlight advancements in creating polymer-derived ceramics (PDCs) with superior mechanical properties and functionality. For example, Su et al. [274] developed a precursor-derived SiOC ceramic that has the potential for applications in high-efficiency electromagnetic interference (EMI) shielding, particularly in the aerospace and electronics sectors.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Osouli-Bostanabad, K.; Masalehdan, T.; Kapsa, R.M.; Quigley, A.; Lalatsa, A.; Bruggeman, K.F.; Franks, S.J.; Williams, R.J.; Nisbet, D.R. Traction of 3D and 4D printing in the healthcare industry: From drug delivery and analysis to regenerative medicine. ACS Biomater. Sci. Eng. 2022, 8, 2764–2797. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.S.; Khan, S.A.; Shabbir, S.; Umar, M.; Mohapatra, S.; Khuroo, T.; Naseef, P.P.; Kuruniyan, M.S.; Iqbal, Z.; Mirza, M.A. Raw materials, technology, healthcare applications, patent repository and clinical trials on 4D printing technology: An updated review. Pharmaceutics 2022, 15, 116. [Google Scholar] [CrossRef] [PubMed]

- Mahmood, A.; Perveen, F.; Chen, S.; Akram, T.; Irfan, A. Polymer Composites in 3D/4D Printing: Materials, Advances, and Prospects. Molecules 2024, 29, 319. [Google Scholar] [CrossRef] [PubMed]

- Ntouanoglou, K.; Stavropoulos, P.; Mourtzis, D. 4D printing prospects for the aerospace industry: A critical review. Procedia Manuf. 2018, 18, 120–129. [Google Scholar] [CrossRef]

- Lakkala, P.; Munnangi, S.R.; Bandari, S.; Repka, M. Additive manufacturing technologies with emphasis on stereolithography 3D printing in pharmaceutical and medical applications: A review. Int. J. Pharm. X 2023, 5, 100159. [Google Scholar] [CrossRef]

- Periyasamy, R.; Hemanth Kumar, M.; Rangappa, S.M.; Siengchin, S. A comprehensive review on natural fillers reinforced polymer composites using fused deposition modeling. Polym. Compos. 2023, 44, 3715–3747. [Google Scholar] [CrossRef]

- Luo, X.; Cheng, H.; Wu, X. Nanomaterials reinforced polymer filament for fused deposition modeling: A state-of-the-art review. Polymers 2023, 15, 2980. [Google Scholar] [CrossRef]

- Verma, N.; Awasthi, P.; Gupta, A.; Banerjee, S.S. Fused deposition modeling of polyolefins: Challenges and opportunities. Macromol. Mater. Eng. 2023, 308, 2200421. [Google Scholar] [CrossRef]

- Yadav, A.; Rohru, P.; Babbar, A.; Kumar, R.; Ranjan, N.; Chohan, J.S.; Kumar, R.; Gupta, M. Fused filament fabrication: A state-of-the-art review of the technology, materials, properties and defects. Int. J. Interact. Des. Manuf. (IJIDeM) 2023, 17, 2867–2889. [Google Scholar] [CrossRef]

- Tao, Y.; Li, P.; Zhang, J.; Wang, S.; Shi, S.Q.; Kong, F. A review of fused filament fabrication of continuous natural fiber reinforced thermoplastic composites: Techniques and materials. Polym. Compos. 2023, 44, 8200–8222. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, R.; Singh, T.; Batish, A. Fused filament fabrication: A comprehensive review. J. Thermoplast. Compos. Mater. 2023, 36, 794–814. [Google Scholar] [CrossRef]

- Credi, C.; Bernasconi, R.; Levi, M.; Magagnin, L. Self-activating metal-polymer composites for the straightforward selective metallization of 3D printed parts by stereolithography. J. Mater. Res. Technol. 2023, 22, 1855–1867. [Google Scholar] [CrossRef]

- Tamburri, E.; Montaina, L.; Pescosolido, F.; Carcione, R.; Battistoni, S. 3D Extrusion and Stereolithography Printing Methods for Producing Multifunctional Polymer Composites. Macromol. Symp. 2024, 413, 2400030. [Google Scholar] [CrossRef]

- Nugraha, A.D.; Kumar, V.V.; Gautama, J.P.; Wiranata, A.; Mangunkusumo, K.G.H.; Rasyid, M.I.; Dzanzani, R.; Muflikhun, M.A. Investigating the characteristics of nano-graphite composites additively manufactured using stereolithography. Polymers 2024, 16, 1021. [Google Scholar] [CrossRef]

- Shen, H.; Wu, W.; Hu, H.; Rui, Z.; Ye, J.; Zhang, C. Preparation of carbon black/graphene nanosheets/PP composites with 3D separated conductive networks based on selective laser sintering. Polym. Compos. 2023, 44, 3522–3534. [Google Scholar] [CrossRef]

- Schappo, H.; Giry, K.; Salmoria, G.; Damia, C.; Hotza, D. Polymer/calcium phosphate biocomposites manufactured by selective laser sintering: An overview. Prog. Addit. Manuf. 2023, 8, 285–301. [Google Scholar] [CrossRef]

- Wu, Z.; Li, Y.; Shi, C.; Lu, Z.; Su, B. A general method for fabricating polymer-based intrinsic superhydrophobic objects by a selective laser sintering 3D printing strategy. Compos. Part B Eng. 2023, 264, 110910. [Google Scholar] [CrossRef]

- Kidalov, S.; Voznyakovskii, A.; Vozniakovskii, A.; Titova, S.; Auchynnikau, Y. The effect of few-layer graphene on the complex of hardness, strength, and thermo physical properties of polymer composite materials produced by digital light processing (DLP) 3D printing. Materials 2023, 16, 1157. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, J.; Singh, V.; Xu, L.; Kabi, P.; Bele, E.; Tiwari, M.K. Digital light 3D printing of a polymer composite featuring robustness, self-healing, recyclability and tailorable mechanical properties. Addit. Manuf. 2023, 61, 103343. [Google Scholar] [CrossRef]

- Yao, J.; Hakkarainen, M. Methacrylated wood flour-reinforced “all-wood” derived resin for digital light processing (DLP) 3D printing. Compos. Commun. 2023, 38, 101506. [Google Scholar] [CrossRef]

- Chen, J.; An, R.; Tey, W.S.; Zeng, Q.; Zhao, L.; Zhou, K. In Situ Filler Addition for Homogeneous Dispersion of Carbon Nanotubes in Multi Jet Fusion–Printed Elastomer Composites. Adv. Sci. 2023, 10, 2300593. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Hou, Y.; An, R.; Tey, W.S.; Gao, M.; Chen, J.; Zhao, L.; Zhou, K. Investigation of the mechanical properties of polyimide fiber/polyamide 12 composites printed by Multi Jet Fusion. Virtual Phys. Prototyp. 2023, 18, e2246032. [Google Scholar] [CrossRef]

- Peng, Y.S. 3D Printing of Fibre-Reinforced Polymer Composites via Multi Jet Fusion; Nanyang Technological University: Singapore, 2023. [Google Scholar]

- Kozior, T.; Ehrmann, A. First proof-of-principle of polyjet 3D printing on textile fabrics. Polymers 2023, 15, 3536. [Google Scholar] [CrossRef] [PubMed]

- Andena, L.; Contino, M.; Arioli, M.; De Noni, L.; Volders, T.; Ruffoni, D. Fracture of Polyjet 3D printed materials: A preliminary investigation. In Proceedings of the 9th International Conference on Fracture of Polymers, Composites and Adhesives, Les Diablerets, Switzerland, 24–27 March 2024. [Google Scholar]

- Szczygieł, P.; Radoń-Kobus, K.; Madej, M.; Kozior, T. Tribological properties of MED610 medical material used in PolyJet matrix 3D printing technology. Tribologia 2023, 306, 65–77. [Google Scholar] [CrossRef]

- Raj, R.; Dixit, A.R. Direct ink writing of carbon-doped polymeric composite ink: A review on its requirements and applications. 3D Print. Addit. Manuf. 2023, 10, 828–854. [Google Scholar] [CrossRef]

- Liu, H.; Mei, D.; Yu, S.; Qian, S.; Wang, Y. Direct ink writing of chopped carbon fibers reinforced polymer-derived SiC composites with low shrinkage and high strength. J. Eur. Ceram. Soc. 2023, 43, 235–244. [Google Scholar] [CrossRef]

- Yang, Z.; Medora, E.; Ren, Z.; Cheng, M.; Namilae, S.; Jiang, Y. Coaxial direct ink writing of ZnO functionalized continuous carbon fiber-reinforced thermosetting composites. Compos. Sci. Technol. 2024, 256, 110782. [Google Scholar] [CrossRef]

- Shinde, S.; Mane, R.; Vardikar, A.; Dhumal, A.; Rajput, A. 4D printing: From emergence to innovation over 3D printing. Eur. Polym. J. 2023, 197, 112356. [Google Scholar] [CrossRef]

- Zeng, C.; Liu, L.; Lin, C.; Xin, X.; Liu, Y.; Leng, J. 4D printed continuous fiber reinforced shape memory polymer composites with enhanced mechanical properties and shape memory effects. Compos. Part A Appl. Sci. Manuf. 2024, 180, 108085. [Google Scholar] [CrossRef]

- Zhao, W.; Yue, C.; Liu, L.; Liu, Y.; Leng, J. Research progress of shape memory polymer and 4D printing in biomedical application. Adv. Healthc. Mater. 2023, 12, 2201975. [Google Scholar] [CrossRef]

- Yan, S.; Zhang, F.; Luo, L.; Wang, L.; Liu, Y.; Leng, J. Shape memory polymer composites: 4d printing, smart structures, and applications. Research 2023, 6, 0234. [Google Scholar] [CrossRef] [PubMed]

- Lalegani Dezaki, M.; Bodaghi, M. Sustainable 4D printing of magneto-electroactive shape memory polymer composites. Int. J. Adv. Manuf. Technol. 2023, 126, 35–48. [Google Scholar] [CrossRef]

- Abdullah, T.; Okay, O. 4D printing of body temperature-responsive hydrogels based on poly (acrylic acid) with shape-memory and self-healing abilities. ACS Appl. Bio Mater. 2023, 6, 703–711. [Google Scholar] [CrossRef] [PubMed]

- Pelluau, T.; Brossier, T.; Habib, M.; Sene, S.; Félix, G.; Larionova, J.; Blanquer, S.; Guari, Y. 4D printing nanocomposite hydrogel based on PNIPAM and Prussian blue nanoparticles using stereolithography. Macromol. Mater. Eng. 2024, 309, 2300305. [Google Scholar] [CrossRef]

- Goyal, R.; Sahu, S.; Mitra, S.; Niranjan, R.; Priyadarshini, R.; Yadav, R.; Lochab, B. Nanocellulose-Reinforced 4D Printed Hydrogels: Thermoresponsive Shape Morphing and Drug Release. ACS Appl. Polym. Mater. 2024, 6, 1348–1361. [Google Scholar] [CrossRef]

- Aufa, A.; Ismail, Z.; Hassan, M.Z. Emerging trends in 4d printing of hydrogels in the biomedical field: A review. Mater. Today Proc. 2023; in press. [Google Scholar]

- Schweizer, K.; Bhandari, S.; Lopez-Anido, R.; Korey, M.; Tekinalp, H. Recycling Large-Format 3D Printed Polymer Composite Formworks Used for Casting Precast Concrete -Technical Feasibility and Challenges. J. Compos. Constr. 2024, 28, 04024061. [Google Scholar] [CrossRef]

- Ejeromedoghene, O.; Omoniyi, A.O.; Akor, E.; Alowakennu, M.; Samson, K.A.; Abesa, S.; Zhang, Z. Progress in stimuli-responsive hydrogel composites for digital technologies. Appl. Mater. Today 2024, 37, 102088. [Google Scholar] [CrossRef]

- Kuang, X.; Yue, L.; Qi, H.J. Introduction to 4D printing: Concepts and material systems. In Additive Manufacturing Technology: Design, Optimization, and Modeling; Wiley: Hoboken, NJ, USA, 2023; pp. 1–42. [Google Scholar]

- Dixit, G.; Pandey, P.M. Experimental investigations of temperature-sensitive shape memory polymer composites for 4D printing. J. Thermoplast. Compos. Mater. 2024, 08927057241254322. [Google Scholar] [CrossRef]

- Kouka, M.A.; Abbassi, F.; Habibi, M.; Chabert, F.; Zghal, A.; Garnier, C. 4D printing of shape memory polymers, blends, and composites and their advanced applications: A comprehensive literature review. Adv. Eng. Mater. 2023, 25, 2200650. [Google Scholar] [CrossRef]

- Ma, T.; Zhang, Y.; Ruan, K.; Guo, H.; He, M.; Shi, X.; Guo, Y.; Kong, J.; Gu, J. Advances in 3D printing for polymer composites: A review. InfoMat 2024, 6, e12568. [Google Scholar] [CrossRef]

- Ghilan, A.; Chiriac, A.; Nita, L.; Rusu, A.; Neamtu, I.; Chiriac, V. Trends in 3D Printing Processes for Biomedical Field: Opportunities and Challenges. J. Polym. Environ. 2020, 28, 1345–1367. [Google Scholar] [CrossRef] [PubMed]

- Ng, W.L.; Goh, G.L.; Goh, G.D.; Ten, J.S.J.; Yeong, W.Y. Progress and opportunities for machine learning in materials and processes of additive manufacturing. Adv. Mater. 2024, 36, 2310006. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Ji, X.; Wang, W.; Zhou, L. 3D-Networks Based Polymer Composites for Multifunctional Thermal Management and Electromagnetic Protection: A Mini Review. Materials 2024, 17, 2400. [Google Scholar] [CrossRef]

- Nikooharf, M.H.; Shirinbayan, M.; Arabkoohi, M.; Bahlouli, N.; Fitoussi, J.; Benfriha, K. Machine learning in polymer additive manufacturing: A review. Int. J. Mater. Form. 2024, 17, 52. [Google Scholar] [CrossRef]

- Dananjaya, V.; Marimuthu, S.; Yang, R.C.; Grace, A.; Abeykoon, C. Synthesis, properties, applications, 3D printing and machine learning of graphene quantum dots in polymer nanocomposites. Prog. Mater. Sci. 2024, 144, 101282. [Google Scholar] [CrossRef]

- Oskolkov, A.A.; Bezukladnikov, I.I.; Trushnikov, D.N. Mathematical Model of the Layer-by-Layer FFF/FGF Polymer Extrusion Process for Use in the Algorithm of Numerical Implementation of Real-Time Thermal Cycle Control. Polymers 2023, 15, 4518. [Google Scholar] [CrossRef]

- Behseresht, S.; Park, Y.H.; Love, A.; Pastrana, O.A.V. Application of Numerical Modeling and Finite Element Analysis in Fused Filament Fabrication: A Review. Materials 2024, 17, 4185. [Google Scholar] [CrossRef]

- Bouzaglou, O.; Golan, O.; Lachman, N. Process design and parameters interaction in material extrusion 3D printing: A review. Polymers 2023, 15, 2280. [Google Scholar] [CrossRef]

- Sadaf, M.; Bragaglia, M.; Slemenik Perše, L.; Nanni, F. Advancements in metal additive manufacturing: A comprehensive review of material extrusion with highly filled polymers. J. Manuf. Mater. Process. 2024, 8, 14. [Google Scholar] [CrossRef]

- Bankapalli, N.K.; Gupta, V.; Saxena, P.; Bajpai, A.; Lahoda, C.; Polte, J. Filament fabrication and subsequent additive manufacturing, debinding, and sintering for extrusion-based metal additive manufacturing and their applications: A review. Compos. Part B Eng. 2023, 264, 110915. [Google Scholar] [CrossRef]

- Nazir, A.; Gokcekaya, O.; Billah, K.M.M.; Ertugrul, O.; Jiang, J.; Sun, J.; Hussain, S. Multi-material additive manufacturing: A systematic review of design, properties, applications, challenges, and 3D printing of materials and cellular metamaterials. Mater. Des. 2023, 226, 111661. [Google Scholar] [CrossRef]

- Memarzadeh, A.; Safaei, B.; Tabak, A.; Sahmani, S.; Kizilors, C. Advancements in additive manufacturing of polymer matrix composites: A systematic review of techniques and properties. Mater. Today Commun. 2023, 36, 106449. [Google Scholar] [CrossRef]

- Sun, X.; Mazur, M.; Cheng, C.T. A review of void reduction strategies in material extrusion-based additive manufacturing. Addit. Manuf. 2023, 67, 103463. [Google Scholar] [CrossRef]

- Samykano, M.; Kumaresan, R.; Kananathan, J.; Kadirgama, K.; Pandey, A.K. An overview of fused filament fabrication technology and the advancement in PLA-biocomposites. Int. J. Adv. Manuf. Technol. 2024, 132, 27–62. [Google Scholar] [CrossRef]

- Alqutaibi, A.Y.; Alghauli, M.A.; Aljohani, M.H.A.; Zafar, M.S. Advanced additive manufacturing in implant dentistry: 3D printing technologies, printable materials, current applications and future requirements. Bioprinting 2024, 42, e00356. [Google Scholar] [CrossRef]

- Ali, F.; Kalva, S.N.; Koc, M. Advancements in 3D printing techniques for biomedical applications: A comprehensive review of materials consideration, post processing, applications, and challenges. Discov. Mater. 2024, 4, 53. [Google Scholar] [CrossRef]

- Slepicka, M.; Borrmann, A. Fabrication Information Modeling for Closed-Loop Design and Quality Improvement in Additive Manufacturing for construction. Autom. Constr. 2024, 168, 105792. [Google Scholar] [CrossRef]

- Bănică, C.F.; Sover, A.; Anghel, D.C. Printing the Future Layer by Layer: A Comprehensive Exploration of Additive Manufacturing in the Era of Industry 4.0. Appl. Sci. 2024, 14, 9919. [Google Scholar] [CrossRef]

- Franco Urquiza, E.A. Advances in Additive Manufacturing of Polymer-Fused Deposition Modeling on Textiles: From 3D Printing to Innovative 4D Printing—A Review. Polymers 2024, 16, 700. [Google Scholar] [CrossRef]

- Subramani, R.; Kalidass, A.K.; Muneeswaran, M.D.; Lakshmipathi, B.G. Effect of fused deposition modeling process parameter in influence of mechanical property of acrylonitrile butadiene styrene polymer. Appl. Chem. Eng. 2024, 7, 3576. [Google Scholar] [CrossRef]

- Kut, P.; Pietrucha-Urbanik, K. Bibliometric Analysis of Multi-Criteria Decision-Making (MCDM) Methods in Environmental and Energy Engineering Using CiteSpace Software: Identification of Key Research Trends and Patterns of International Cooperation. Energies 2024, 17, 3941. [Google Scholar] [CrossRef]

- Alamoodi, A.; Al-Samarraay, M.S.; Albahri, O.; Deveci, M.; Albahri, A.; Yussof, S. Evaluation of energy economic optimization models using multi-criteria decision-making approach. Expert Syst. Appl. 2024, 255, 124842. [Google Scholar] [CrossRef]

- Nwanno, C.E.; Thapa, A.; Watt, J.; Simkins Bendayan, D.; Li, W. Field Emission Properties of Cu-Filled Vertically Aligned Carbon Nanotubes Grown Directly on Thin Cu Foils. Nanomaterials 2024, 14, 988. [Google Scholar] [CrossRef] [PubMed]

- Melentiev, R.; Lagerweij, A.; Lubineau, G. Multiprocess additive manufacturing via fused deposition modeling, chemical deposition, and electroplating with tough interfacial adhesion. Smart Mater. Manuf. 2024, 2, 100043. [Google Scholar] [CrossRef]

- Sandhu, H.S.; Alam, A.S.; Jeevan, K.; Yadav, A.K.; Sai, G.; Korapram, V.M. A review of the mechanical properties of 3D printed and electroplated ABS parts. AIP Conf. Proc. 2024, 2962, 020055. [Google Scholar]

- Nizam, M.; Purohit, R.; Taufik, M. Materials for 3D printing in healthcare sector: A review. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2024, 238, 939–963. [Google Scholar] [CrossRef]

- Singh, S.; Attri, R.K.; Trivedi, S. Optimization of FDM 3D Printing Process Parameters for Improving Wear Characteristics of PLA-nGr Composite using Taguchi DOE. J. Mater. Eng. Perform. 2024, 1–9. [Google Scholar] [CrossRef]

- Bahrami, M.H.; Ehteshamfar, M.V.; Adibi, H. The effect, prediction, and optimization of Fe particles on wear behavior of Fe–ABS composites fabricated by fused deposition modeling. Arab. J. Sci. Eng. 2024, 49, 2001–2016. [Google Scholar] [CrossRef]

- Çaparoğlu, Ö.F.; Ok, Y.; Çağlayan Özaydın, N. The Genetic Algorithm-Artificial Neural Networks Integration in the Optimization: An Application for Transportation Systems. In Intelligent and Fuzzy Systems; Springer: Cham, Switzerland, 2024; pp. 277–284. [Google Scholar]

- Abdel Hamid, E.; Aly, H.; El Naggar, K. Synthesis of nanogeopolymer adsorbent and its application and reusability in the removal of methylene blue from wastewater using response surface methodology (RSM). Sci. Rep. 2024, 14, 20631. [Google Scholar] [CrossRef]

- Hajjaj, M.S.; Alamoudi, R.A.; Babeer, W.A.; Rizg, W.Y.; Basalah, A.A.; Alzahrani, S.J.; Yeslam, H.E. Flexural strength, flexural modulus and microhardness of milled vs. fused deposition modeling printed Zirconia; effect of conventional vs. speed sintering. BMC Oral Health 2024, 24, 38. [Google Scholar] [CrossRef]

- Khan, W.A.; Hassan, M.; Ahmed, I.; Xiao, M.; Faraz, M.I.; Li, K.; Khan, I.; Muhammad, R.; Wu, H.; Hussain, G. Insights into flexural and impact properties of polymer based materials printed through fused filament fabrication: Progress in the last decade. Int. J. Lightweight Mater. Manuf. 2024, 7, 925–957. [Google Scholar] [CrossRef]

- Kariuki, L.W.; Ikua, B.W.; Karanja, S.K.; Ng’ang’a, S.P.; Zeidler, H. Fused filament fabrication of carbon fiber-reinforced polymer composite: Effect of process parameters on flexural properties. Eng. Rep. 2024, 6, e12807. [Google Scholar] [CrossRef]

- Kara, Y.; Lubineau, G. Enhancing structural integrity of the continuous fiber-reinforced 3D printed composites by self-reinforcing nanofiber interleaves. Compos. Commun. 2024, 51, 102042. [Google Scholar] [CrossRef]

- García-Cabezón, C.; Naranjo, J.A.; García-Hernández, C.; Berges, C.; Herranz, G.; Martín-Pedrosa, F. Using fused filament fabrication to improve the tribocorrosion behaviour of 17-4 PH SS in comparison to other metal forming techniques. Friction 2024, 12, 2325–2343. [Google Scholar] [CrossRef]

- Kalinke, C.; Crapnell, R.D.; de Oliveira, P.R.; Janegitz, B.C.; Bonacin, J.A.; Banks, C.E. How to improve sustainability in Fused Filament Fabrication (3D Printing) research? Glob. Challenges 2024, 8, 2300408. [Google Scholar] [CrossRef]

- Nath, P.C.; Sharma, R.; Mahapatra, U.; Mohanta, Y.K.; Rustagi, S.; Sharma, M.; Mahajan, S.; Nayak, P.K.; Sridhar, K. Sustainable production of cellulosic biopolymers for enhanced smart food packaging: An up-to-date review. Int. J. Biol. Macromol. 2024, 273, 133090. [Google Scholar] [CrossRef]

- Celikci, N.; Ziba, C.A.; Dolaz, M.; Tümer, M. Comparison of composite resins containing UV light-sensitive chitosan derivatives in stereolithography (SLA)-3D printers. Int. J. Biol. Macromol. 2024, 136057. [Google Scholar] [CrossRef]

- Gruhn, P.; Koske, D.; Storck, J.L.; Ehrmann, A. Three-dimensional printing by vat photopolymerization on textile fabrics: Method and mechanical properties of the textile/polymer composites. Textiles 2024, 4, 417–425. [Google Scholar] [CrossRef]

- Abdul, W.; Durgaiahsangam, H.P.; Jyosyula, S.K.R.; Khan, M.A. 3D Printing of Polymer and Polymer Matrix Composites. In Polymer Composites: Fundamentals and Applications; Springer: Singapore, 2024; pp. 281–300. [Google Scholar]

- Alshihabi, M.; Kayacan, M.Y. Effect of nanosized carbon nanotubes, Titanium Nitride and cubic Boron Nitride powders on mechanical and thermal properties of SLA 3D printed resin composites. Polym. Compos. 2024; Early View. [Google Scholar]

- Vázquez-Hernández, C.; Ramos-Galicia, L.; Velasco-Santos, C.; Bertolacci, L.; Zahid, M.; Yañez-Limón, J.M.; Perotto, G.; Martinez-Hernandez, A.L. Effect of keratin-rich fibers from rabbit hair in two polymers processed using additive manufacturing: FDM and SLA. J. Manuf. Process. 2024, 120, 1104–1114. [Google Scholar] [CrossRef]

- Wawryniuk, Z.; Brancewicz-Steinmetz, E.; Sawicki, J. Revolutionizing transportation: An overview of 3D printing in aviation, automotive, and space industries. Int. J. Adv. Manuf. Technol. 2024, 134, 3083–3105. [Google Scholar] [CrossRef]

- Nabavi, S.F.; Dalir, H. A review on laser-assisted manufacturing process of thermoset composites: A review of fundamentals, processes, scientific modelling, challenges and prospective. Opt. Laser Technol. 2025, 181, 111713. [Google Scholar] [CrossRef]

- Biswas, A.; Singh, A.K.; Das, D. Stereolithography-Based Polymer Additive Manufacturing Process for Microfluidics Devices: A Review. In Advances in Additive Manufacturing; Wiley: Hoboken, NJ, USA, 2024; pp. 237–268. [Google Scholar]

- Demoly, F.; André, J.C. 3D stereolithography of polymer matrix composites. In Additive Manufacturing of Polymer-Based Composite Materials; Elsevier: Amsterdam, The Netherlands, 2024; pp. 247–280. [Google Scholar]

- Modica, F.; Basile, V.; Fassi, I. An Experiment-Based Variable Compensation Method to Improve the Geometric Accuracy of Sub-Mm Features Fabricated by Stereolithography (SLA). J. Manuf. Mater. Process. 2024, 8, 90. [Google Scholar] [CrossRef]

- Rooney, K.; Dong, Y.; Pramanik, A.; Basak, A.K. Additive Manufacturing in Australian Small to Medium Enterprises: Vat Polymerisation Techniques, Case Study and Pathways to Industry 4.0 Competitiveness. J. Manuf. Mater. Process. 2023, 7, 168. [Google Scholar] [CrossRef]

- Ma, R.; Liu, R.; Lu, B. Approaches Used to Design Support Structures for Ceramic Additive Manufacturing: A Review. Addit. Manuf. Front. 2024, 3, 200136. [Google Scholar] [CrossRef]

- Vinay, D.; Keshavamurthy, R.; Tambrallimath, V. Enhanced mechanical properties of metal filled 3D printed polymer composites. J. Inst. Eng. (India) Ser. D 2023, 104, 181–195. [Google Scholar] [CrossRef]

- Shah, M.; Ullah, A.; Azher, K.; Ur Rehman, A.; Akturk, N.; Juan, W.; Tüfekci, C.S.; Salamci, M.U. The influence of nanoparticle dispersions on mechanical and thermal properties of polymer nanocomposites using SLA 3D printing. Crystals 2023, 13, 285. [Google Scholar] [CrossRef]

- Golhin, A.P.; Tonello, R.; Frisvad, J.R.; Grammatikos, S.; Strandlie, A. Surface roughness of as-printed polymers: A comprehensive review. Int. J. Adv. Manuf. Technol. 2023, 127, 987–1043. [Google Scholar] [CrossRef]

- Sun, Y.; Cui, J.; Feng, S.; Cui, J.; Guo, Y.; Liang, C.; Gao, W.; Lu, Z.; Liu, F.; Zhang, B. Projection Stereolithography 3D Printing High-Conductive Hydrogel for Flexible Passive Wireless Sensing. Adv. Mater. 2024, 36, 2400103. [Google Scholar] [CrossRef]

- Carvalho, S.S.; Reis, J.R.; Caldeirinha, R.F. A State-of-the-Art Review on 4D Printed Antennas and Other Adaptable Designs. IEEE Access 2024, 12, 62861–62881. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, G.; Wang, C.; Zhang, Y.; Yan, C.; Shi, Y. Thermal debinding for stereolithography additive manufacturing of advanced ceramic parts: A comprehensive review. Mater. Des. 2024, 238, 112632. [Google Scholar] [CrossRef]

- Meana, V.; Zapico, P.; Cuesta, E.; Giganto, S.; Meana, L.; Martínez-Pellitero, S. Additive Manufacturing of Ceramic Reference Spheres by Stereolithography (SLA). Appl. Sci. 2024, 14, 7530. [Google Scholar] [CrossRef]

- Kulkarni, O.; Enriquez-Cabrera, A.; Yang, X.; Foncy, J.; Nicu, L.; Molnár, G.; Salmon, L. Stereolithography 3D Printing of Stimuli-Responsive Spin Crossover@ Polymer Nanocomposites with Optimized Actuating Properties. Nanomaterials 2024, 14, 1243. [Google Scholar] [CrossRef] [PubMed]

- Ravi, P.; Patel, P. Stereolithography (SLA) in pharmaceuticals. In Additive Manufacturing in Pharmaceuticals; Springer: Singapore, 2023; pp. 97–123. [Google Scholar]

- Curti, C.; Kirby, D.J.; Russell, C.A. Systematic screening of photopolymer resins for stereolithography (SLA) 3D printing of solid oral dosage forms: Investigation of formulation factors on printability outcomes. Int. J. Pharm. 2024, 653, 123862. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Wang, R.; Wang, Q.; Wen, M.; Wang, J.; Sheng, L.; Zheng, Y.; Xi, T. A Review on 3D Printing Processes in Pharmaceutical Engineering and Tissue Engineering: Applications, Trends and Challenges. Adv. Mater. Technol. 2024, 2400620. [Google Scholar] [CrossRef]

- Nizam, M.; Purohit, R.; Taufik, M. 3D printing in healthcare: A review on drug printing, challenges and future perspectives. Mater. Today Commun. 2024, 40, 110199. [Google Scholar] [CrossRef]

- Ullah, M.; Wahab, A.; Khan, S.U.; Naeem, M.; ur Rehman, K.; Ali, H.; Ullah, A.; Khan, A.; Khan, N.R.; Rizg, W.Y.; et al. 3D printing technology: A new approach for the fabrication of personalized and customized pharmaceuticals. Eur. Polym. J. 2023, 195, 112240. [Google Scholar] [CrossRef]

- Tyagi, N.; Bhardwaj, V.; Sharma, D.; Tomar, R.; Chaudhary, V.; Khanuja, M.; Singh, M.K.; Sharma, G. 3D printing technology in the pharmaceutical and biomedical applications: A critical review. Biomed. Mater. Devices 2024, 2, 178–190. [Google Scholar] [CrossRef]

- Kulkarni, V.R.; Saha, T.; Giri, B.R.; Lu, A.; Das, S.C.; Maniruzzaman, M. Recent Advancements in Pharmaceutical 3D Printing Industry. J. Drug Deliv. Sci. Technol. 2024, 100, 106072. [Google Scholar] [CrossRef]

- Sultana, N.; Ali, A.; Waheed, A.; Aqil, M. 3D Printing in pharmaceutical manufacturing: Current status and future prospects. Mater. Today Commun. 2023, 38, 107987. [Google Scholar] [CrossRef]

- Elbadawi, M.; Basit, A.W.; Gaisford, S. Energy consumption and carbon footprint of 3D printing in pharmaceutical manufacture. Int. J. Pharm. 2023, 639, 122926. [Google Scholar] [CrossRef]

- Feng, S.; Repka, M.A. Future Prospects Including Novel Polymeric Excipients for 3D Printing of Pharmaceutical and Biomedical Applications. In 3D Printing: Emerging Technologies and Functionality of Polymeric Excipients in Drug Product Development; Springer: Cham, Switzerland, 2023; pp. 273–286. [Google Scholar]

- Rouway, M.; Nachtane, M.; Tarfaoui, M.; Sbai, S.J. 3D Printing of a Tidal Turbine Blade Using Two Methods of SLS and FFF of a Reinforced PA12 Composite: A Comparative Study. Sustain. Mar. Struct. 2024, 6, 1–19. [Google Scholar] [CrossRef]

- Tang, H.; Zhang, S.; He, L.; Yang, Z.; Liu, T. 3D printing of high-stiffness and high-strength glass fiber reinforced PEEK composites by selective laser sintering. Compos. Part A Appl. Sci. Manuf. 2024, 187, 108470. [Google Scholar] [CrossRef]

- Nobre, L.; Barros, D.; Bessa, J.; Cunha, F.; Machado, M.; Mendonça, J.P.; Luís, J.; Oliveira, M.; Machado, P.; Fernandes, C.; et al. Enhancing mechanical performance in SLS-printed PA12-slate composites through amino-silane treatment of mineral waste. Int. J. Adv. Manuf. Technol. 2024, 134, 2979–2992. [Google Scholar] [CrossRef]

- Wang, Y.; Ding, Y.; Yu, K.; Dong, G. Innovative polymer-based composite materials in additive manufacturing: A review of methods, materials, and applications. Polym. Compos. 2024; Early View. [Google Scholar]

- Daneshdoost, N.; Peloquin, J.; Gall, K. Structure-performance relationships of multi-material jetting polymeric composites designed at the voxel scale: Distribution and composition effects. J. Manuf. Process. 2024, 131, 2118–2132. [Google Scholar] [CrossRef]

- Tan, P.; Zhou, M.; Tang, C.; Zhou, K. A powder-scale multiphysics framework for powder bed fusion of fiber-reinforced polymer composites. Adv. Powder Mater. 2024, 3, 100190. [Google Scholar] [CrossRef]

- Zhang, G.; Zheng, X.; Wang, Q.; Ni, Y.; Liu, F.; Zhao, K.; Xu, L.R. Limitations of composite strength theory for predicting the ultimate strengths of layered 3D printing polymers. Compos. Part A Appl. Sci. Manuf. 2024, 185, 108288. [Google Scholar] [CrossRef]

- Gajbhiye, T.S.; Waghmare, S.; Dhande, M.; Gondane, R.; Giripunje, M.; Shelare, S.; Belkhode, P. Polymer composite additive manufacturing: Applications, challenges and opportunities. Mater. Today Proc. 2024; in press. [Google Scholar]

- Zhang, S.; Tang, H.; Tang, D.; Liu, T.; Liao, W. Effect of fabrication process on the microstructure and mechanical performance of carbon fiber reinforced PEEK composites via selective laser sintering. Compos. Sci. Technol. 2024, 246, 110396. [Google Scholar] [CrossRef]

- Colucci, G.; Lupone, F.; Bondioli, F.; Messori, M. 3D printing of PBAT-based composites filled with agro-wastes via selective laser sintering. Eur. Polym. J. 2024, 215, 113197. [Google Scholar] [CrossRef]

- Adak, N.C.; Sharia, F.; Lee, W. Laser-Assisted Additive Manufacturing Techniques for Advanced Composites. In Advances in Additive Manufacturing; Wiley: Hoboken, NJ, USA, 2024; pp. 217–235. [Google Scholar]

- Joshua, R.J.N.; Raj, S.A.; Hameed Sultan, M.T.; Łukaszewicz, A.; Józwik, J.; Oksiuta, Z.; Dziedzic, K.; Tofil, A.; Shahar, F.S. Powder Bed Fusion 3D Printing in Precision Manufacturing for Biomedical Applications: A Comprehensive Review. Materials 2024, 17, 769. [Google Scholar] [CrossRef]

- Yang, Y.; Bharech, S.; Finger, N.; Zhou, X.; Schröder, J.; Xu, B.X. Elasto-plastic residual stress analysis of selective laser sintered porous materials based on 3D-multilayer thermo-structural phase-field simulations. npj Comput. Mater. 2024, 10, 117. [Google Scholar] [CrossRef]

- Bertolini, F.; Mariani, M.; Mercadelli, E.; Baldisserri, C.; Galassi, C.; Capiani, C.; Ardito, R.; Lecis, N. 3D printing of potassium sodium niobate by binder jetting: Printing parameters optimisation and correlation to final porosity. J. Mater. Res. Technol. 2024, 29, 4597–4606. [Google Scholar] [CrossRef]

- Song, Y.; Ghafari, Y.; Asefnejad, A.; Toghraie, D. An overview of selective laser sintering 3D printing technology for biomedical and sports device applications: Processes, materials, and applications. Opt. Laser Technol. 2024, 171, 110459. [Google Scholar] [CrossRef]

- Azam, M.U.; Belyamani, I.; Schiffer, A.; Kumar, S.; Askar, K. Progress in selective laser sintering of multifunctional polymer composites for strain-and self-sensing applications. J. Mater. Res. Technol. 2024, 30, 9625–9646. [Google Scholar] [CrossRef]

- Han, S.; Li, S.; Song, X.; Zhou, Z.; Meng, Q.; Araby, S.; Abdelsalam, A.A. Carbon nanotubes/α-ZrP sheets for high mechanical performance and flame-retarding polyamides using selective laser sintering. Virtual Phys. Prototyp. 2024, 19, e2368644. [Google Scholar] [CrossRef]

- Cai, R.; Luo, X.; Xie, G.; Wang, K.; Peng, Y.; Rao, Y. Effects of the printing parameters on geometric accuracy and mechanical properties of digital light processing printed polymer. J. Mater. Sci. 2024, 59, 14807–14819. [Google Scholar] [CrossRef]

- Cortés, A.; Bañón-Veracruz, M.; Jiménez-Suárez, A.; Campo, M.; Prolongo, M.; Prolongo, S. Enhancing efficiency and sustainability of digital light processing 3D-Printing by novel two-stage processing of carbon nanotube reinforced nanocomposites. J. Mater. Res. Technol. 2024, 29, 3237–3248. [Google Scholar] [CrossRef]

- Cheng, J.; Yu, S.; Wang, R.; Ge, Q. Digital light processing based multimaterial 3D printing: Challenges, solutions and perspectives. Int. J. Extrem. Manuf. 2024, 6, 042006. [Google Scholar] [CrossRef]

- Hussain, M.I.; Xia, M.; Ren, X.; Ge, C.; Jamil, M.; Gupta, M.K. Digital light processing 3D printing of ceramic materials: A review on basic concept, challenges, and applications. Int. J. Adv. Manuf. Technol. 2024, 130, 2241–2267. [Google Scholar] [CrossRef]

- Senthooran, V.; Weng, Z.; Wu, L. Enhancing Mechanical and Thermal Properties of 3D-Printed Samples Using Mica-Epoxy Acrylate Resin Composites—Via Digital Light Processing (DLP). Polymers 2024, 16, 1148. [Google Scholar] [CrossRef]

- Magalhães, F.d.C.; Rubio, J.C.C. Mechanical Properties of Recycled Carbon Fiber-Reinforced Resin Composites 3D Printed via Digital Light Processing. J. Mater. Eng. Perform. 2024, 1–11. [Google Scholar] [CrossRef]

- Guessasma, S.; Stephant, N.; Durand, S.; Belhabib, S. Digital Light Processing Route for 3D Printing of Acrylate-Modified PLA/Lignin Blends: Microstructure and Mechanical Performance. Polymers 2024, 16, 1342. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Kim, D.H.; Kim, H.; Seung, H.M.; Song, H.C.; Kim, M. Engineering Digital Light Processing Ceramic Composites for Wide-Range Flexible Sensing Arrays. Compos. Part B Eng. 2024, 283, 111595. [Google Scholar] [CrossRef]

- Guo, A.; Li, S.; Wang, S.; Zhai, Z.; Qu, P.; Guo, S.; Kong, H.; Tang, R.; Liu, C.; Han, W.; et al. Digital light processing of multi-walled carbon nanotubes-reinforced photosensitive resin composites: Effects on microstructures and mechanical properties. J. Mater. Res. Technol. 2024, 28, 434–445. [Google Scholar] [CrossRef]

- Swetha, S.; Sahiti, T.J.; Priya, G.S.; Harshitha, K.; Anil, A. Review on digital light processing (DLP) and effect of printing parameters on quality of print. Interactions 2024, 245, 178. [Google Scholar] [CrossRef]

- Melentiev, R.; Harakály, G.; Stögerer, J.; Mitteramskogler, G.; Wagih, A.; Lubineau, G.; Grande, C.A. High-resolution metal 3D printing via digital light processing. Addit. Manuf. 2024, 85, 104156. [Google Scholar] [CrossRef]

- Wang, Y.; Su, R.; Chen, J.; Wang, W.; Zhang, X.; Xu, H.; He, R. 3D Printed Bioinspired Flexible Absorber: Toward High-Performance Electromagnetic Absorption at 75–110 GHz. ACS Appl. Mater. Interfaces 2023, 15, 53996–54005. [Google Scholar] [CrossRef]

- Khorasani, M.; MacDonald, E.; Downing, D.; Ghasemi, A.; Leary, M.; Dash, J.; Sharabian, E.G.; Almalki, A.; Brandt, M.; Bateman, S. Multi Jet Fusion (MJF) of polymeric components: A review of process, properties and opportunities. Addit. Manuf. 2024, 91, 104331. [Google Scholar] [CrossRef]

- Kafi, A.; Khorasani, M.; Downing, D.; Rashed, K.; Leary, M.; Zhang, D.; Bateman, S. Prediction of absorptivity in Multi-Jet Fusion manufactured polypropylene structures through laser flash and corrected porosity method. Int. J. Adv. Manuf. Technol. 2024, 130, 4041–4052. [Google Scholar] [CrossRef]

- Alomarah, A.; Abbas, A.T.; Faisal, B.; Peng, Z.; Ruan, D. The Effects of Manufacturing Techniques on the Mechanical Performance of an Auxetic Structure Manufactured by Fused Filament Fabrication and Multijet Fusion Processes. Adv. Eng. Mater. 2024, 26, 2302033. [Google Scholar] [CrossRef]

- Ráž, K.; Chval, Z.; Kemka, V. Parametric Production of Prostheses Using the Additive Polymer Manufacturing Technology Multi Jet Fusion. Materials 2024, 17, 2347. [Google Scholar] [CrossRef]

- Lupone, F.; Padovano, E.; Lambertini, V.G.; Sampieri, R.; Casamento, F.; Zecchi, S.; Badini, C. Selective Laser Sintering versus Multi Jet Fusion: A Comprehensive Comparison Study Based on the Properties of Glass Beads-Reinforced Polyamide 12. Adv. Eng. Mater. 2024, 26, 2301345. [Google Scholar] [CrossRef]

- Avanzini, A.; Tomasoni, M.; Xu, Z.; Berto, F.; Razavi, N. Fracture assessment of polyamide 12 (PA12) specimens fabricated via Multi Jet FusionTM in the presence of geometrical discontinuities. Eng. Fract. Mech. 2024, 303, 110118. [Google Scholar] [CrossRef]

- Seah, Y.T. Multi Jet Fusion of ZnO Nanorod-Reinforced PA12 Nanocomposites; Nanyang Technological University: Singapore, 2024. [Google Scholar]

- Tang, C.; Liu, J.; Qiao, J.; Wei, Y.; Shi, C.; Hao, W. The preparation and axial compressive properties of 3D-printed polymer lattice-reinforced cementitious composite columns. J. Build. Eng. 2024, 97, 110770. [Google Scholar] [CrossRef]

- Gao, P.; Liu, R.; Wang, M.; Zhang, H.; Gao, X.; Ma, J. Static and Fatigue Behaviors of Polyamide 12 Hinge Joint Manufactured by Multi-Jet Fusion. J. Mater. Eng. Perform. 2024, 1–12. [Google Scholar] [CrossRef]

- Kim, W.; Hwang, J.Y.; Ji, C.H. Large deflection angle resonant 1D scanning micromirror fabricated with multi jet fusion 3D printed parts. Int. J. Optomechatronics 2024, 18, 2371289. [Google Scholar] [CrossRef]

- Bochnia, J.; Kozior, T.; Szot, W.; Rudnik, M.; Zmarzły, P.; Gogolewski, D.; Szczygieł, P.; Musiałek, M. Selected Mechanical and Rheological Properties of Medical Resin MED610 in PolyJet Matrix Three-Dimensional Printing Technology in Quality Aspects. 3D Print. Addit. Manuf. 2024, 11, 299–313. [Google Scholar] [CrossRef]

- Nachimuthu, M.; PK, R. Inkjet four-dimensional printing of shape memory polymers: A review. Rapid Prototyp. J. 2023, 29, 437–446. [Google Scholar] [CrossRef]

- Xin, Y.; Zhou, X.; Bark, H.; Lee, P.S. The role of 3D printing technologies in soft grippers. Adv. Mater. 2024, 36, 2307963. [Google Scholar] [CrossRef]

- Tee, Y.L.; Tran, P.; Leary, M.; Pille, P.; Brandt, M. 3D Printing of polymer composites with material jetting: Mechanical and fractographic analysis. Addit. Manuf. 2020, 36, 101558. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Kim, J. 4D-printing—Fused deposition modeling printing and PolyJet printing with shape memory polymers composite. Fibers Polym. 2020, 21, 2364–2372. [Google Scholar] [CrossRef]

- Tee, Y.L.; Peng, C.; Pille, P.; Leary, M.; Tran, P. PolyJet 3D printing of composite materials: Experimental and modelling approach. JOM 2020, 72, 1105–1117. [Google Scholar] [CrossRef]

- Muthuram, N.; Madhav, P.S.; Vasan, D.K.; Mohan, M.E.; Prajeeth, G. A review of recent literatures in poly jet printing process. Mater. Today Proc. 2022, 68, 1906–1920. [Google Scholar] [CrossRef]

- Wu, C.; Do, T.T.; Tran, P. Mechanical properties of polyjet 3d-printed composites inspired by space-filling peano curves. Polymers 2021, 13, 3516. [Google Scholar] [CrossRef] [PubMed]

- Kozior, T.; Mamun, A.; Trabelsi, M.; Sabantina, L. Comparative analysis of polymer composites produced by FFF and PJM 3D printing and electrospinning technologies for possible filter applications. Coatings 2022, 12, 48. [Google Scholar] [CrossRef]

- Palanisamy, C.; Raman, R.; Dhanraj, P.K. Additive manufacturing: A review on mechanical properties of polyjet and FDM printed parts. Polym. Bull. 2022, 79, 7065–7116. [Google Scholar] [CrossRef]

- Conway, C.H.; McGregor, D.J.; Antonsen, T.; Wood, C.; Shao, C.; King, W.P. Geometry repeatability and prediction for personalized medical devices made using multi-jet fusion additive manufacturing. Addit. Manuf. Lett. 2024, 9, 100200. [Google Scholar] [CrossRef]

- Patpatiya, P.; Chaudhary, K.; Shastri, A.; Sharma, S. A review on polyjet 3D printing of polymers and multi-material structures. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 095440622210795. [Google Scholar] [CrossRef]

- Azpiazu-Flores, F.X.; Elfana, A.; Yang, C.C.; Morton, D.; Lin, W.S. Effect of artificial aging and different surface finishing protocols on the flexural strength and surface hardness of a photopolymer for manufacturing monolithic polychromatic complete dentures using PolyJet 3D printing. J. Prosthodont. 2024; Early View. [Google Scholar]

- Krause, M.; Marshall, A.; Catterlin, J.K.; Hornik, T.; Kartalov, E.P. Dimensional Fidelity and Orientation Effects of PolyJet Technology in 3D Printing of Negative Features for Microfluidic Applications. Micromachines 2024, 15, 389. [Google Scholar] [CrossRef]

- Aberdeen, N.J.; Forghani, K.; Sochol, R.D. Brief Paper: Geometric Determinants of Material Jetting-Enabled Bi-Material Interface Integrity Using Polyjet 3D Printing. In Proceedings of the International Manufacturing Science and Engineering Conference, Knoxville, TN, USA, 17–21 June 2024; Volume 88100, p. V001T01A007. [Google Scholar]

- Tang, T.; Joralmon, D.; Tiwari, L.; Ravishekar, R.; He, Q.; Pham, L.; Yang, Y.; Li, X. Additive manufacturing of polymer matrix composites via direct ink writing process. In Additive Manufacturing of Polymer-Based Composite Materials; Elsevier: Amsterdam, The Netherlands, 2024; pp. 203–245. [Google Scholar]

- Chen, C.T.; Chen, Z.L. Direct ink writing of polymer matrix composite with carbon for driving a flexible thermoelectric actuator of shape memory polymer. Mater. Today Commun. 2024, 38, 108303. [Google Scholar] [CrossRef]

- Sole-Gras, M.; Ren, B.; Ryder, B.J.; Ge, J.; Huang, J.; Chai, W.; Yin, J.; Fuchs, G.E.; Wang, G.; Jiang, X.; et al. Vapor-induced phase-separation-enabled versatile direct ink writing. Nat. Commun. 2024, 15, 3058. [Google Scholar] [CrossRef]

- Lin, Z.; Qiu, X.; Cai, Z.; Li, J.; Zhao, Y.; Lin, X.; Zhang, J.; Hu, X.; Bai, H. High internal phase emulsions gel ink for direct-ink-writing 3D printing of liquid metal. Nat. Commun. 2024, 15, 4806. [Google Scholar] [CrossRef] [PubMed]

- Ingram, M.; Campbell, E.; Molotnikov, A.; Feih, S.; Zhong, Y.L. Recent Advances in Multifunctional Polymer/2D Nanocomposite Development for Fused Filament Fabrication and Direct Ink Writing of Electrically and Thermally Conductive Components. Adv. Nanocomposites 2024, 1, 157–170. [Google Scholar] [CrossRef]

- Bao, X.; Meng, J.; Tan, Z.; Zhang, C.; Li, L.; Liu, T. Direct-ink-write 3D printing of highly-stretchable polyaniline gel with hierarchical conducting network for customized wearable strain sensors. Chem. Eng. J. 2024, 491, 151918. [Google Scholar] [CrossRef]

- Zu, W.; Carranza, H.E.; Bartlett, M.D. Enhancing Electrical Conductivity of Stretchable Liquid Metal–Silver Composites through Direct Ink Writing. ACS Appl. Mater. Interfaces 2024, 16, 23895–23903. [Google Scholar] [CrossRef]

- Bhardwaj, D.; Singhmar, R.; Garg, M.; Gupta, D.; Dhiman, A.; Han, S.S.; Agrawal, G. Designing advanced hydrogel inks with direct ink writing based 3D printability for engineered biostructures. Eur. Polym. J. 2024, 205, 112736. [Google Scholar] [CrossRef]

- Li, M.; Huang, S.; Willems, E.; Soete, J.; Inokoshi, M.; Van Meerbeek, B.; Vleugels, J.; Zhang, F. UV-Curing Assisted Direct Ink Writing of Dense, Crack-Free, and High-Performance Zirconia-Based Composites With Aligned Alumina Platelets. Adv. Mater. 2024, 36, 2306764. [Google Scholar] [CrossRef]

- Khecho, A.; Hewlin, R., Jr.; Joyee, E.B. Direct Ink Writing of SiC-Fe3O4-Polymer Nanocomposites for Magnetic Humidity Sensors: Rheology Characterization. In Proceedings of the International Manufacturing Science and Engineering Conference, Knoxville, TN, USA, 17–21 June 2024; Volume 88100, p. V001T02A005. [Google Scholar]

- dos Santos, V.I.; Chevalier, J.; Fredel, M.C.; Henriques, B.; Gremillard, L. Ceramics and ceramic composites for biomedical engineering applications via Direct Ink Writing: Overall scenario, advances in the improvement of mechanical and biological properties and innovations. Mater. Sci. Eng. R Rep. 2024, 161, 100841. [Google Scholar] [CrossRef]

- Li, S.; Zhang, H.; Sun, L.; Zhang, X.; Guo, M.; Liu, J.; Wang, W.; Zhao, N. 4D printing of biological macromolecules employing handheld bioprinters for in situ wound healing applications. Int. J. Biol. Macromol. 2024, 280, 135999. [Google Scholar] [CrossRef]

- Xu, P.; Zhu, L.; Zhao, Z.; Yang, Z.; Ning, J.; Xue, P.; Lu, H. Anisotropy behavior of liquid metal elastomer composites with both enhanced thermal conductivity and crack resistance by direct ink writing. Compos. Part A Appl. Sci. Manuf. 2024, 177, 107890. [Google Scholar] [CrossRef]

- Abas, M.; Jan, Z.; Rahman, K. Direct Ink Writing; CRC Press: Boca Raton, FL, USA, 2023; pp. 188–209. [Google Scholar] [CrossRef]

- Abas, M.; Rahman, K. Fabrication of flex sensors through direct ink write technique and its electrical characterization. Appl. Phys. A 2016, 122, 972. [Google Scholar] [CrossRef]

- Baniasadi, H.; Abidnejad, R.; Fazeli, M.; Lipponen, J.; Niskanen, J.; Kontturi, E.; Seppälä, J.; Rojas, O.J. Innovations in hydrogel-based manufacturing: A comprehensive review of direct ink writing technique for biomedical applications. Adv. Colloid Interface Sci. 2024, 324, 103095. [Google Scholar] [CrossRef] [PubMed]

- van Hazendonk, L.S.; Vonk, C.F.; van Grondelle, W.; Vonk, N.H.; Friedrich, H. Towards a predictive understanding of direct ink writing of graphene-based inks. Appl. Mater. Today 2024, 36, 102014. [Google Scholar] [CrossRef]

- Elumalai, D.; Hosseinnezhad, R.; Bondarenko, V.; Morawiec, J.; Vozniak, I.; Galeski, A. Shape Memory Polymer Foam Based on Nanofibrillar Composites of Polylactide/Polyamide. Molecules 2024, 29, 5045. [Google Scholar] [CrossRef]

- Brossier, T.; Habib, M.; Benkhaled, T.; Volpi, G.; Lapinte, V.; Blanquer, S. 4D printing of hydrogels based on poly(oxazoline) and poly(acrylamide) copolymers by stereolithography. Mater. Adv. 2024, 5, 2750–2758. [Google Scholar] [CrossRef]

- Sindhu, P.M.; Ranjani, M.; Kiran, M.G.; Sachin, M.S. 4D Food Printing: Transforming Culinary Creation with Time-Responsive Technology. Agrisustain-Int. J. 2023, 1, 34–41. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U.; Noroozi, R.; Zolfagharian, A.; Bodaghi, M. 4D printing of shape memory polymer composites: A review on fabrication techniques, applications, and future perspectives. J. Manuf. Process. 2022, 81, 759–797. [Google Scholar] [CrossRef]

- Qiu, W.; Xu, X.; Dong, K.; Wang, Y.; Xiong, Y. Recent advances in 4D printing of fiber-reinforced polymer composites: A review and outlook. Compos. Part B Eng. 2024, 283, 111645. [Google Scholar] [CrossRef]

- Ahmad, H.; Markina, A.; Porotnikov, M.; Ahmad, F. A review of carbon fiber materials in automotive industry. IOP Conf. Ser. Mater. Sci. Eng. 2020, 971, 032011. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, Y.; Mo, Z.; Chouw, N.; Jayaraman, K.; Xu, Z.d. A critical review on the properties of natural fibre reinforced concrete composites subjected to impact loading. J. Build. Eng. 2023, 77, 107497. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P.D. Reviewing the integrated design approach for augmenting strength and toughness at macro-and micro-scale in high-performance advanced composites. Materials 2023, 16, 5745. [Google Scholar] [CrossRef]

- Sadeghian, H.; Ayatollahi, M.R.; Khosravani, M.R.; Razavi, N. From prototyping to functional parts: A review of mechanical reinforcing procedures for polymeric parts fabricated via material extrusion. J. Manuf. Process. 2024, 130, 1–34. [Google Scholar] [CrossRef]

- Ali, Z.; Yaqoob, S.; Yu, J.; D’Amore, A. Critical review on the characterization, preparation, and enhanced mechanical, thermal, and electrical properties of carbon nanotubes and their hybrid filler polymer composites for various applications. Compos. Part Open Access 2024, 13, 100434. [Google Scholar] [CrossRef]

- Younus, M.M.; Naguib, H.M.; Fekry, M.; Elsawy, M.A. Pushing the limits of PLA by exploring the power of MWCNTs in enhancing thermal, mechanical properties, and weathering resistance. Sci. Rep. 2023, 13, 16588. [Google Scholar] [CrossRef] [PubMed]

- Kotsilkova, R.; Petrova-Doycheva, I.; Menseidov, D.; Ivanov, E.; Paddubskaya, A.; Kuzhir, P. Exploring thermal annealing and graphene-carbon nanotube additives to enhance crystallinity, thermal, electrical and tensile properties of aged poly (lactic) acid-based filament for 3D printing. Compos. Sci. Technol. 2019, 181, 107712. [Google Scholar] [CrossRef]

- De Bortoli, L.; De Farias, R.; Mezalira, D.; Schabbach, L.; Fredel, M. Functionalized carbon nanotubes for 3D-printed PLA-nanocomposites: Effects on thermal and mechanical properties. Mater. Today Commun. 2022, 31, 103402. [Google Scholar] [CrossRef]

- PARIN, F.N.; DEMIRCI, F. Durability of polymer composite materials for high-temperature applications. In Aging and Durability of FRP Composites and Nanocomposites; Elsevier: Amsterdam, The Netherlands, 2024; pp. 135–170. [Google Scholar]

- Hassine, S.; Chatti, S.; Louhichi, B.; Seibi, A. Experimental Study of the Tensile Behavior of Structures Obtained by FDM 3D Printing Process. Polymers 2024, 16, 1562. [Google Scholar] [CrossRef]

- Li, M.; Hu, Z.; Yan, B.; Wang, J.; Zhang, H.; Ye, F.; Sun, B.; Liu, J.; Li, Y.; Ding, G.; et al. A flexible resistive strain gauge with reduced temperature effect via thermal expansion anisotropic composite substrate. Microsystems Nanoeng. 2024, 10, 129. [Google Scholar] [CrossRef]

- Jia, X.; Luo, J.; Luo, Q.; Li, Q.; Pang, T. Experimental study on the effects of temperature on mechanical properties of 3D printed continuous carbon fiber reinforced polymer (C-CFRP) composites. Thin-Walled Struct. 2024, 205, 112465. [Google Scholar] [CrossRef]

- Tarhini, A.; Tehrani-Bagha, A. Advances in preparation methods and conductivity properties of graphene-based polymer composites. Appl. Compos. Mater. 2023, 30, 1737–1762. [Google Scholar] [CrossRef]

- Wagmare, R.; Harshe, R.; Pednekar, J.; Patro, T.U. Additive manufacturing of continuous fiber-reinforced polymer composites: Current trend and future directions. Prog. Addit. Manuf. 2024, 1–28. [Google Scholar] [CrossRef]

- Yan, Y.; Jiang, Y.; Ng, E.L.L.; Zhang, Y.; Owh, C.; Wang, F.; Song, Q.; Feng, T.; Zhang, B.; Li, P.; et al. Progress and opportunities in additive manufacturing of electrically conductive polymer composites. Mater. Today Adv. 2023, 17, 100333. [Google Scholar] [CrossRef]

- Yan, Y.; Han, M.; Jiang, Y.; Ng, E.L.L.; Zhang, Y.; Owh, C.; Song, Q.; Li, P.; Loh, X.J.; Chan, B.Q.Y.; et al. Electrically Conductive Polymers for Additive Manufacturing. ACS Appl. Mater. Interfaces 2024, 16, 5337–5354. [Google Scholar] [CrossRef] [PubMed]

- Bas, J.; Dutta, T.; Llamas Garro, I.; Velázquez-González, J.S.; Dubey, R.; Mishra, S.K. Embedded Sensors with 3D Printing Technology. Sensors 2024, 24, 1955. [Google Scholar] [CrossRef]

- He, X.; Zhang, B.; Liu, Q.; Chen, H.; Cheng, J.; Jian, B.; Yin, H.; Li, H.; Duan, K.; Zhang, J.; et al. Highly conductive and stretchable nanostructured ionogels for 3D printing capacitive sensors with superior performance. Nat. Commun. 2024, 15, 6431. [Google Scholar] [CrossRef]

- Carvalho, S.S.; Reis, J.R.; Mateus, A.; Caldeirinha, R.F. Exploring design approaches for 3D printed antennas. IEEE Access 2024, 12, 10718–10735. [Google Scholar] [CrossRef]

- Dontha, B.; Moulod, M.; Balbaugh, S.; Hoelzle, D.; Li, J.; Miranda, F.A.; Kiourti, A. RF characterization of a photocurable PEDOT: PSS: PEGDA conductive biomaterial for 3D-Printing implantable antennas. IEEE Trans. Antennas Propag. 2024, 72, 2825–2830. [Google Scholar] [CrossRef]

- Saghafi, M.K.; Vasantham, S.K.; Hussain, N.; Mathew, G.; Colombo, F.; Schamberger, B.; Pohl, E.; Marques, G.C.; Breitung, B.; Tanaka, M.; et al. Printed Electronic Devices and Systems for Interfacing with Single Cells up to Organoids. Adv. Funct. Mater. 2024, 34, 2308613. [Google Scholar] [CrossRef]

- Akram, S.; Ashraf, M.; Javid, A.; Abid, H.A.; Ahmad, S.; Nawab, Y.; Rasheed, A.; Xue, Z.; Nosheen, A. Recent advances in electromagnetic interference (EMI) shielding textiles: A comprehensive review. Synth. Met. 2023, 294, 117305. [Google Scholar] [CrossRef]

- Maleki, A.H.; Zolfaghari, A. Investigation of electrical, electromagnetic interference shielding and tensile properties of 3D-printed acrylonitrile butadiene styrene/carbon nanotube composites. J. Thermoplast. Compos. Mater. 2024, 37, 2409–2424. [Google Scholar] [CrossRef]

- apińska, A.; Grochowska, N.; Cieplak, K.; Płatek, P.; Wood, P.; Deuszkiewicz, P.; Dużyńska, A.; Sztorch, B.; Głowcka, J.; Przekop, R.; et al. Architecture influence on acoustic performance, EMI shielding, electrical and thermal, properties of 3D printed PLA/graphite/molybdenum disulfide composites. Mater. Des. 2024, 245, 113241. [Google Scholar] [CrossRef]

- Randis, R.; Darmadi, D.B.; Gapsari, F.; Sonief, A.A.a.; Akpan, E.D.; Ebenso, E.E. The potential of nanocomposite-based coatings for corrosion protection of metals: A review. J. Mol. Liq. 2023, 390, 123067. [Google Scholar] [CrossRef]

- Savadatti, M.B.; Kumar, K.; Jaya Christiyan, K.G.; Gajakosh, A.; Thakur, M.; Kumar, R.S.; Paulraj, R.L.; Madhusudhana, H.K. Machine Learning Applications for 3D-Printed Polymers and Their Composites. In Development, Properties, and Industrial Applications of 3D Printed Polymer Composites; IGI Global: Hershey, PA, USA, 2023; pp. 239–260. [Google Scholar] [CrossRef]

- Ng, W.L.; An, J.; Chua, C.K. Process, material, and regulatory considerations for 3D printed medical devices and tissue constructs. Engineering 2024, 36, 146–166. [Google Scholar] [CrossRef]

- Sajjad, R.; Chauhdary, S.T.; Anwar, M.T.; Zahid, A.; Khosa, A.A.; Imran, M.; Sajjad, M.H. A review of 4D printing–technologies, shape shifting, smart polymer based materials, and biomedical applications. Adv. Ind. Eng. Polym. Res. 2024, 7, 20–36. [Google Scholar] [CrossRef]

- Sun, X.H.; Zhou, K.; Demoly, F.; Zhao, R.; Qi, H. Perspective: Machine Learning in Design for 3D/4D Printing. J. Appl. Mech. 2024, 91, 030801. [Google Scholar] [CrossRef]

- Mahmood, A.; Akram, T.; Shenggui, C.; Chen, H. Revolutionizing manufacturing: A review of 4D printing materials, stimuli, and cutting-edge applications. Compos. Part B Eng. 2023, 266, 110952. [Google Scholar] [CrossRef]

- Ostolaza, M.; Arrizubieta, J.I.; Lamikiz, A.; Plaza, S.; Ortega, N. Latest developments to manufacture metal matrix composites and functionally graded materials through AM: A state-of-the-art review. Materials 2023, 16, 1746. [Google Scholar] [CrossRef]

- Wu, C.; Xu, F.; Wang, H.; Liu, H.; Yan, F.; Ma, C. Manufacturing technologies of polymer composites—A review. Polymers 2023, 15, 712. [Google Scholar] [CrossRef]

- Hamdi, Y.; Lallemand, F.; Benita, S. Drug-loaded nanocarriers for back-of-the-eye diseases-formulation limitations. J. Drug Deliv. Sci. Technol. 2015, 30, 331–341. [Google Scholar] [CrossRef]

- Elbadawi, M.; Castro, B.M.; Gavins, F.K.; Ong, J.J.; Gaisford, S.; Pérez, G.; Basit, A.W.; Cabalar, P.; Goyanes, A. M3DISEEN: A novel machine learning approach for predicting the 3D printability of medicines. Int. J. Pharm. 2020, 590, 119837. [Google Scholar] [CrossRef]

- Saleh, E. 3D and 4D printed polymer composites for electronic applications. In Processes, Applications, and Challenges; Elsevier: Amsterdam, The Netherlands, 2020; pp. 505–525. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, X.; Cole, T.; Lu, H.; Hang, J.; Li, W.; Tang, S.Y.; Boyer, C.; Davis, T.; Qiao, R. 3D-printed liquid metal polymer composites as NIR-responsive 4D printing soft robot. Nat. Commun. 2023, 14, 7815. [Google Scholar] [CrossRef]

- Peng, H.; Han, B.; Tong, T.; Jin, X.; Peng, Y.; Guo, M.; Li, B.; Ding, J.; Kong, Q.; Wang, Q. 3D printing processes in precise drug delivery for personalized medicine. Biofabrication 2024, 16, 032001. [Google Scholar] [CrossRef] [PubMed]

- Ong, J.J.; Castro, B.M.; Gaisford, S.; Cabalar, P.; Basit, A.W.; Pérez, G.; Goyanes, A. Accelerating 3D printing of pharmaceutical products using machine learning. Int. J. Pharm. X 2022, 4, 100120. [Google Scholar] [CrossRef] [PubMed]

- Peloquin, J.; Kirillova, A.; Rudin, C.; Brinson, L.; Gall, K. Prediction of tensile performance for 3D printed photopolymer gyroid lattices using structural porosity, base material properties, and machine learning. Mater. Des. 2023, 232, 112126. [Google Scholar] [CrossRef]

- Tao, H.; Ahmadianfar, I.; Goliatt, L.; Kazmi, S.S.U.H.; Yassin, M.A.; Oudah, A.Y.; Homod, R.Z.; Togun, H.; Yaseen, Z.M. PM2.5 concentration forecasting: Development of integrated multivariate variational mode decomposition with kernel Ridge regression and weighted mean of vectors optimization. Atmos. Pollut. Res. 2024, 15, 102125. [Google Scholar] [CrossRef]

- Khusheef, A.S.; Shahbazi, M.; Hashemi, R. Predicting 3D printed plastic part properties: A deep learning approach with thermographic and vibration data fusion. Expert Syst. Appl. 2024, 255, 124605. [Google Scholar] [CrossRef]

- Monticeli, F.M.; Neves, R.M.; Ornaghi, H.L., Jr.; Almeida, J.H.S., Jr. Prediction of bending properties for 3D-printed carbon fibre/epoxy composites with several processing parameters using ANN and statistical methods. Polymers 2022, 14, 3668. [Google Scholar] [CrossRef]

- Malley, S.; Reina, C.; Nacy, S.; Gilles, J.; Koohbor, B.; Youssef, G. Predictability of mechanical behavior of additively manufactured particulate composites using machine learning and data-driven approaches. Comput. Ind. 2022, 142, 103739. [Google Scholar] [CrossRef]

- G, K.; Kandasubramanian, B. Exertions of Magnetic Polymer Composites Fabricated via 3D Printing. Ind. Eng. Chem. Res. 2022, 61, 16895–16909. [Google Scholar] [CrossRef]

- Griffiths, C.; Howarth, J.; De Almeida-Rowbotham, G.; Rees, A.; Kerton, R. A design of experiments approach for the optimisation of energy and waste during the production of parts manufactured by 3D printing. J. Clean. Prod. 2016, 139, 74–85. [Google Scholar] [CrossRef]

- Kafle, A.; Luis, E.; Silwal, R.; Pan, H.M.; Shrestha, P.; Bastola, A. 3D/4D Printing of Polymers: Fused Deposition Modelling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). Polymers 2021, 13, 3101. [Google Scholar] [CrossRef]

- Sani, A.R.; Zolfagharian, A.; Kouzani, A.Z. Artificial Intelligence-Augmented Additive Manufacturing: Insights on Closed-Loop 3D Printing. Adv. Intell. Syst. 2024, 6, 2400102. [Google Scholar] [CrossRef]

- Lu, L.; Hou, J.; Yuan, S.; Yao, X.; Li, Y.; Zhu, J. Deep learning-assisted real-time defect detection and closed-loop adjustment for additive manufacturing of continuous fiber-reinforced polymer composites. Robot.-Comput.-Integr. Manuf. 2023, 79, 102431. [Google Scholar] [CrossRef]

- Narayanan, B.N.; Beigh, K.; Loughnane, G.; Powar, N. Support vector machine and convolutional neural network based approaches for defect detection in fused filament fabrication. In Proceedings of the Applications of Machine Learning, San Diego, CA, USA, 11–15 August 2019; Volume 11139, pp. 283–291. [Google Scholar]

- Jin, Z.; Zhang, Z.; Gu, G.X. Automated real-time detection and prediction of interlayer imperfections in additive manufacturing processes using artificial intelligence. Adv. Intell. Syst. 2020, 2, 1900130. [Google Scholar] [CrossRef]

- Charalampous, P.; Kostavelis, I.; Kopsacheilis, C.; Tzovaras, D. Vision-based real-time monitoring of extrusion additive manufacturing processes for automatic manufacturing error detection. Int. J. Adv. Manuf. Technol. 2021, 115, 3859–3872. [Google Scholar] [CrossRef]

- Martin Montal, J.; Pernas-Sánchez, J.; Varas, D. Experimental Characterization Framework for SLA Additive Manufacturing Materials. Polymers 2021, 13, 1147. [Google Scholar] [CrossRef]

- Lin, W.; Shen, H.; Fu, J.; Wu, S. Online quality monitoring in material extrusion additive manufacturing processes based on laser scanning technology. Precis. Eng. 2019, 60, 76–84. [Google Scholar] [CrossRef]

- Yao, H.; Yu, M.; Fu, J.; Zhu, M.; Li, Y.; Li, S.; Gan, R.; Zhou, H.; Qi, S. Shape memory polymers enable versatile magneto-active structure with 4D printability, variable stiffness, shape-morphing and effective grasping. Smart Mater. Struct. 2023, 32, 095005. [Google Scholar] [CrossRef]

- Chung, J.; Shen, B.; Law, A.C.C.; Kong, Z.J. Reinforcement learning-based defect mitigation for quality assurance of additive manufacturing. J. Manuf. Syst. 2022, 65, 822–835. [Google Scholar] [CrossRef]

- Aljazara, A.; Abu Tuhaimer, N.; Alawwad, A.; Bani-Hani, K.; Qusef, A.; Alsalhi, N.; Al-dawoodi, A. Quality of 3D Printed Objects Using Fused Deposition Modeling (FDM) Technology in Terms of Dimensional Accuracy. Int. J. Online Biomed. Eng. (iJOE) 2023, 19, 45–62. [Google Scholar] [CrossRef]

- Carrico, J.D.; Hermans, T.; Kim, K.J.; Leang, K.K. 3D-printing and machine learning control of soft ionic polymer-metal composite actuators. Sci. Rep. 2019, 9, 17482. [Google Scholar] [CrossRef]

- Omairi, A.; Ismail, Z.H. Towards machine learning for error compensation in additive manufacturing. Appl. Sci. 2021, 11, 2375. [Google Scholar] [CrossRef]

- Chen, G.L.; Yanamandra, K.; Gupta, N. Artificial neural networks framework for detection of defects in 3D-printed fiber reinforcement composites. JOM 2021, 73, 2075–2084. [Google Scholar] [CrossRef]

- Chen, G.L.; Gupta, N. Image processing and machine learning methods applied to additive manufactured composites for defect detection and toolpath reconstruction. In Machine Learning Applied to Composite Materials; Springer: Singapore, 2022; pp. 19–44. [Google Scholar]

- Goh, G.D.; Hamzah, N.M.B.; Yeong, W.Y. Anomaly detection in fused filament fabrication using machine learning. 3D Print. Addit. Manuf. 2023, 10, 428–437. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Wan, L.; Ismail, Y.; Ye, J.; Yang, D. A micromechanics and machine learning coupled approach for failure prediction of unidirectional CFRP composites under triaxial loading: A preliminary study. Compos. Struct. 2021, 267, 113876. [Google Scholar] [CrossRef]

- Shanaswara, A.; Aditya, M.; Rashyid, M.; Herianto, H.; Muflikhun, M. Optimasi Multiobjektif Parameter Proses 3D Printer Jenis Fused Deposition Modelling Menggunakan Grey Relational Analysis-Taguchi. J. Rekayasa Mesin 2023, 14, 791–810. [Google Scholar] [CrossRef]

- Pandžić, A.; Hodzic, D.; Kadric, E. Experimental Investigation on Influence of Infill Density on Tensile Mechanical Properties of Different FDM 3D Printed Materials. TEM J. 2021, 10, 1195–1201. [Google Scholar] [CrossRef]

- Wan, L.; Ullah, Z.; Yang, D.; Falzon, B.G. Probability embedded failure prediction of unidirectional composites under biaxial loadings combining machine learning and micromechanical modelling. Compos. Struct. 2023, 312, 116837. [Google Scholar] [CrossRef]

- Fontes, A.; Shadmehri, F. Data-driven failure prediction of Fiber-Reinforced Polymer composite materials. Eng. Appl. Artif. Intell. 2023, 120, 105834. [Google Scholar] [CrossRef]

- Sepasdar, R.; Karpatne, A.; Shakiba, M. A data-driven approach to full-field nonlinear stress distribution and failure pattern prediction in composites using deep learning. Comput. Methods Appl. Mech. Eng. 2022, 397, 115126. [Google Scholar] [CrossRef]

- Pandžić, A.; Hodzic, D.; Kadric, D.; Kadric, E. The Effect of Ultraviolet Radiation on Mechanical Properties of Fused Deposition Modeling 3D Printed Materials. TEM J. 2023, 12, 1921–1928. [Google Scholar] [CrossRef]

- Xue, T.; Wallin, T.J.; Menguc, Y.; Adriaenssens, S.; Chiaramonte, M. Machine learning generative models for automatic design of multi-material 3D printed composite solids. Extrem. Mech. Lett. 2020, 41, 100992. [Google Scholar] [CrossRef]

- Lee, S.; Zhang, Z.; Gu, G.X. Generative machine learning algorithm for lattice structures with superior mechanical properties. Mater. Horizons 2022, 9, 952–960. [Google Scholar] [CrossRef] [PubMed]

- Qian, C.; Tan, R.K.; Ye, W. Design of architectured composite materials with an efficient, adaptive artificial neural network-based generative design method. Acta Mater. 2022, 225, 117548. [Google Scholar] [CrossRef]

- He, Y.; Abdi, M.; Trindade, G.F.; Begines, B.; Dubern, J.F.; Prina, E.; Hook, A.L.; Choong, G.Y.; Ledesma, J.; Tuck, C.J.; et al. Exploiting generative design for 3D printing of bacterial biofilm resistant composite devices. Adv. Sci. 2021, 8, 2100249. [Google Scholar] [CrossRef]

- Hashemi, M.S.; Nguyen, K.; Kirby, L.; Song, X.; Sheidaei, A. Universal Design Methodology for Printable Microstructural Materials via a New Deep Generative Learning Model: Application to a Piezocomposite. arXiv 2024, arXiv:2402.11102. [Google Scholar]

- Garland, A.P.; White, B.C.; Jensen, S.C.; Boyce, B.L. Pragmatic generative optimization of novel structural lattice metamaterials with machine learning. Mater. Des. 2021, 203, 109632. [Google Scholar] [CrossRef]

- Sachdeva, I.; Ramesh, S.; Chadha, U.; Punugoti, H.; Selvaraj, S.K. Computational AI models in VAT photopolymerization: A review, current trends, open issues, and future opportunities. Neural Comput. Appl. 2022, 34, 17207–17229. [Google Scholar] [CrossRef]

- Nasrin, T.; Pourkamali-Anaraki, F.; Hansen, C.J.; Jensen, R.E.; Peterson, A. Predicting Printability of Highly Filled Polymer Suspensions via Vat Photopolymerization: A Classification-Based Machine Learning Approach. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4806327 (accessed on 4 November 2024).

- Jo, J.; Park, K.; Song, H.; Lee, H.; Ryu, S. Innovative 3D printing of mechanoluminescent composites: Vat photopolymerization meets machine learning. Addit. Manuf. 2024, 90, 104324. [Google Scholar] [CrossRef]

- Frumosu, F.D.; Méndez Ribó, M.; Shan, S.; Zhang, Y.; Kulahci, M. Online monitoring for error detection in vat photopolymerization. Int. J. Comput. Integr. Manuf. 2023, 36, 1313–1330. [Google Scholar] [CrossRef]

- Shan, Y.; Krishnakumar, A.; Qin, Z.; Mao, H. Smart Resin Vat: Real-Time Detecting Failures, Defects, and Curing Area in Vat Photopolymerization 3D Printing. In Proceedings of the International Manufacturing Science and Engineering Conference, West Lafayette, IN, USA, 27 June–1 July 2022; Volume 85802, p. V001T01A030. [Google Scholar]

- Cao, L.; Lu, L.; Liu, X.; Zhang, J.; Jiang, T.; Tu, C.; Chen, B. Waiting time prediction for bottom-up vat photopolymerization. Addit. Manuf. 2023, 74, 103693. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, H.; Zhao, X. In-situ interferometric curing monitoring for digital light processing based vat photopolymerization additive manufacturing. Addit. Manuf. 2024, 81, 104001. [Google Scholar] [CrossRef]

- Alli, Y.A.; Anuar, H.; Manshor, M.R.; Okafor, C.E.; Kamarulzaman, A.F.; Akçakale, N.; Nazeri, F.N.M.; Bodaghi, M.; Suhr, J.; Nasir, N.A.M. Optimization of 4D/3D printing via machine learning: A systematic review. Hybrid Adv. 2024, 6, 100242. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, Y.; Suo, S.; Guo, J.; Rao, W.F. Predicting 4D hardness property from 3D datasets for performance-tunable material extrusion additive manufacturing. Mater. Today Commun. 2024, 38, 108216. [Google Scholar] [CrossRef]

- Sun, X.; Yue, L.; Yu, L.; Shao, H.; Peng, X.; Zhou, K.; Demoly, F.; Zhao, R.; Qi, H.J. Machine Learning-Evolutionary Algorithm Enabled Design for 4D-Printed Active Composite Structures. Adv. Funct. Mater. 2022, 32, 2109805. [Google Scholar] [CrossRef]

- Forte, C.T.; Montgomery, S.M.; Yue, L.; Hamel, C.M.; Qi, H.J. Grayscale digital light processing gradient printing for stress concentration reduction and material toughness enhancement. J. Appl. Mech. 2023, 90, 071003. [Google Scholar] [CrossRef]

- Hamel, C.M.; Roach, D.J.; Long, K.N.; Demoly, F.; Dunn, M.L.; Qi, H.J. Machine-learning based design of active composite structures for 4D printing. Smart Mater. Struct. 2019, 28, 065005. [Google Scholar] [CrossRef]

- Su, R.; Chen, J.; Zhang, X.; Wang, W.; He, R.; Xu, H.; Li, Y. 3D printed SiOC architecture towards terahertz electromagnetic interference shielding and absorption. Chem. Eng. J. 2024, 498, 155689. [Google Scholar] [CrossRef]

- Lyu, S.; Zhao, T.; Wang, Y.; Han, H.; Li, T.; Zhang, C.; Li, D.; Wang, J.K.; Huang, J.; Yu, P.; et al. Ti3C2Tx-coated diatom frustules-derived porous SiO2 composites with high EMI shielding and mechanical properties. Ceram. Int. 2022, 48, 22845–22853. [Google Scholar] [CrossRef]

- Wang, W.; Gao, X.; Li, Z.; Shen, C.; Ren, X.; He, R. High performance Csf/SiC ceramic matrix composites fabricated by material extrusion 3D printing and precursor infiltration and pyrolysis. Ceram. Int. 2024, 50, 44511–44520. [Google Scholar] [CrossRef]

- Sarvestani, H.Y.; Lacelle, T.; Sohrabi-Kashani, A.; Shashoua, A.; Karamzadeh, V.; Ravanbakhsh, H.; Robitaille, A.; Lavoie, H.; Paquet, C.; Jakubinek, M.; et al. 3D-printed polymer-derived ceramics with tunable cellular architectures. Appl. Mater. Today 2024, 39, 102327. [Google Scholar] [CrossRef]

- Jiang, L.; Long, C.; Xiong, S.; Wang, X.; Mo, Y.; Zeng, J.; Liu, Z.; Liu, C.; Chen, Z. 4D printing of shape-programmable polymer-derived ceramics via two-stage folding-assisted pyrolysis strategy. Virtual Phys. Prototyp. 2024, 19, e2406408. [Google Scholar] [CrossRef]

- Zhu, N.; Hou, Y.; Zhang, L.; Wen, G. Preparation of h-BN/SiCO ceramic matrix composites with high thermal conductivity and strength by vat photopolymerization 3D printing. J. Eur. Ceram. Soc. 2024, 44, 5885–5895. [Google Scholar] [CrossRef]

- Young, J.C.; Brinckmann, S.A.; Fox, A.; Fertig III, R.S.; Lynch, S.P.; Frick, C.P. On enhancing the manufacturability and conversion of additively manufactured polymer-derived ceramics. J. Eur. Ceram. Soc. 2024, 44, 116691. [Google Scholar] [CrossRef]

- Bobrin, V.A.; Hackbarth, H.G.; Bonsu, J.O.; Yao, Y.; Bedford, N.M.; Kundu, D.; Zhang, J.; Corrigan, N.; Boyer, C. Microphase Separation 3D Printing of Binary Inorganic Polymer Precursors to Prepare Nanostructured Carbon-Ceramic Multimaterials. Adv. Mater. Technol. 2024, 9, 2400337. [Google Scholar] [CrossRef]

- Wang, K.; Yin, J.; Chen, X.; Liu, X.; Huang, Z. Microstructure and properties of liquid phase sintered SiC ceramics fabricated via selective laser printing and precursor impregnation and pyrolysis. Ceram. Int. 2024, 50, 4315–4322. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, T.; Huang, G. State-of-the-art research progress and challenge of the printing techniques, potential applications for advanced ceramic materials 3D printing. Mater. Today Commun. 2024, 40, 110001. [Google Scholar] [CrossRef]

- Phan, B.K.; Shen, K.H.; Gurnani, R.; Tran, H.; Lively, R.; Ramprasad, R. Gas permeability, diffusivity, and solubility in polymers: Simulation-experiment data fusion and multi-task machine learning. npj Comput. Mater. 2024, 10, 186. [Google Scholar] [CrossRef]

- Ricci, E.; De Angelis, M.G. A perspective on data-driven screening and discovery of polymer membranes for gas separation, from the molecular structure to the industrial performance. Rev. Chem. Eng. 2024, 40, 567–600. [Google Scholar] [CrossRef]

- Zhang, Q.; Han, S.; Abed, A.M.; Basem, A.; El-Sharkawy, M.R.; Salah, B.; Mahariq, I. Enhancing battery pack safety against cone impact using machine learning techniques and Gaussian noise. Process. Saf. Environ. Prot. 2024, 191, 448–465. [Google Scholar] [CrossRef]

- Hippalgaonkar, K.; Li, Q.; Wang, X.; Fisher III, J.W.; Kirkpatrick, J.; Buonassisi, T. Knowledge-integrated machine learning for materials: Lessons from gameplaying and robotics. Nat. Rev. Mater. 2023, 8, 241–260. [Google Scholar] [CrossRef]

- Osterberg, M.; Henn, K.A.; Farooq, M.; Valle-Delgado, J.J. Biobased nanomaterials—The role of interfacial interactions for advanced materials. Chem. Rev. 2023, 123, 2200–2241. [Google Scholar] [CrossRef] [PubMed]

- Khalid, M.Y.; Arif, Z.U.; Tariq, A.; Hossain, M.; Umer, R.; Bodaghi, M. 3D printing of active mechanical metamaterials: A critical review. Mater. Des. 2024, 246, 113305. [Google Scholar] [CrossRef]

- Zhou, X.; Ren, L.; Song, Z.; Li, G.; Zhang, J.; Li, B.; Wu, Q.; Li, W.; Ren, L.; Liu, Q. Advances in 3D/4D printing of mechanical metamaterials: From manufacturing to applications. Compos. Part B Eng. 2023, 254, 110585. [Google Scholar] [CrossRef]

- Rodríguez, S.E.; Calius, E.; Khatibi, A.; Orifici, A.; Das, R. Mechanical metamaterial systems as transformation mechanisms. Extrem. Mech. Lett. 2023, 61, 101985. [Google Scholar] [CrossRef]

- Chen, Y.; Ebrahimifakhar, A.; Hu, Y.; Yuill, D.P. Generalizability of machine learning-based fault classification for residential air-conditioners. Energy Build. 2023, 295, 113263. [Google Scholar] [CrossRef]

- Li, K.; DeCost, B.; Choudhary, K.; Greenwood, M.; Hattrick-Simpers, J. A critical examination of robustness and generalizability of machine learning prediction of materials properties. npj Comput. Mater. 2023, 9, 55. [Google Scholar] [CrossRef]

- Nasrin, T.; Pourkamali-Anaraki, F.; Peterson, A.M. Application of machine learning in polymer additive manufacturing: A review. J. Polym. Sci. 2024, 62, 2639–2669. [Google Scholar] [CrossRef]

- Manshor, M.R.; Alli, Y.A.; Anuar, H.; Ejeromedoghene, O.; Omotola, E.O.; Suhr, J. 4D printing: Historical evolution, computational insights and emerging applications. Mater. Sci. Eng. B 2023, 295, 116567. [Google Scholar] [CrossRef]

- Nath, D.; Ankit; Neog, D.R.; Gautam, S.S. Application of machine learning and deep learning in finite element analysis: A comprehensive review. Arch. Comput. Methods Eng. 2024, 31, 2945–2984. [Google Scholar] [CrossRef]

- Belkebir, H.; Prod’hon, R.; Foufou, S.; Gomes, S.; Demoly, F. Towards a Multi-view and Multi-representation CAD Models System for Computational Design of Multi-material 4D Printed Structures. In IFIP International Conference on Product Lifecycle Management; Springer: Cham, Switzerland, 2023; pp. 287–297. [Google Scholar]

- Athinarayanarao, D.; Prod’hon, R.; Chamoret, D.; Qi, H.J.; Bodaghi, M.; André, J.C.; Demoly, F. Computational design for 4D printing of topology optimized multi-material active composites. npj Comput. Mater. 2023, 9, 1. [Google Scholar] [CrossRef]

- Khanam, R.; Hussain, M.; Hill, R.; Allen, P. A comprehensive review of convolutional neural networks for defect detection in industrial applications. IEEE Access 2024, 12, 94250–94295. [Google Scholar] [CrossRef]

- Kumar, S.; Gopi, T.; Harikeerthana, N.; Gupta, M.K.; Gaur, V.; Krolczyk, G.M.; Wu, C. Machine learning techniques in additive manufacturing: A state of the art review on design, processes and production control. J. Intell. Manuf. 2023, 34, 21–55. [Google Scholar] [CrossRef]