Vibration Welding of PLA/PHBV Blend Composites with Nanocrystalline Cellulose

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Preliminary Tests

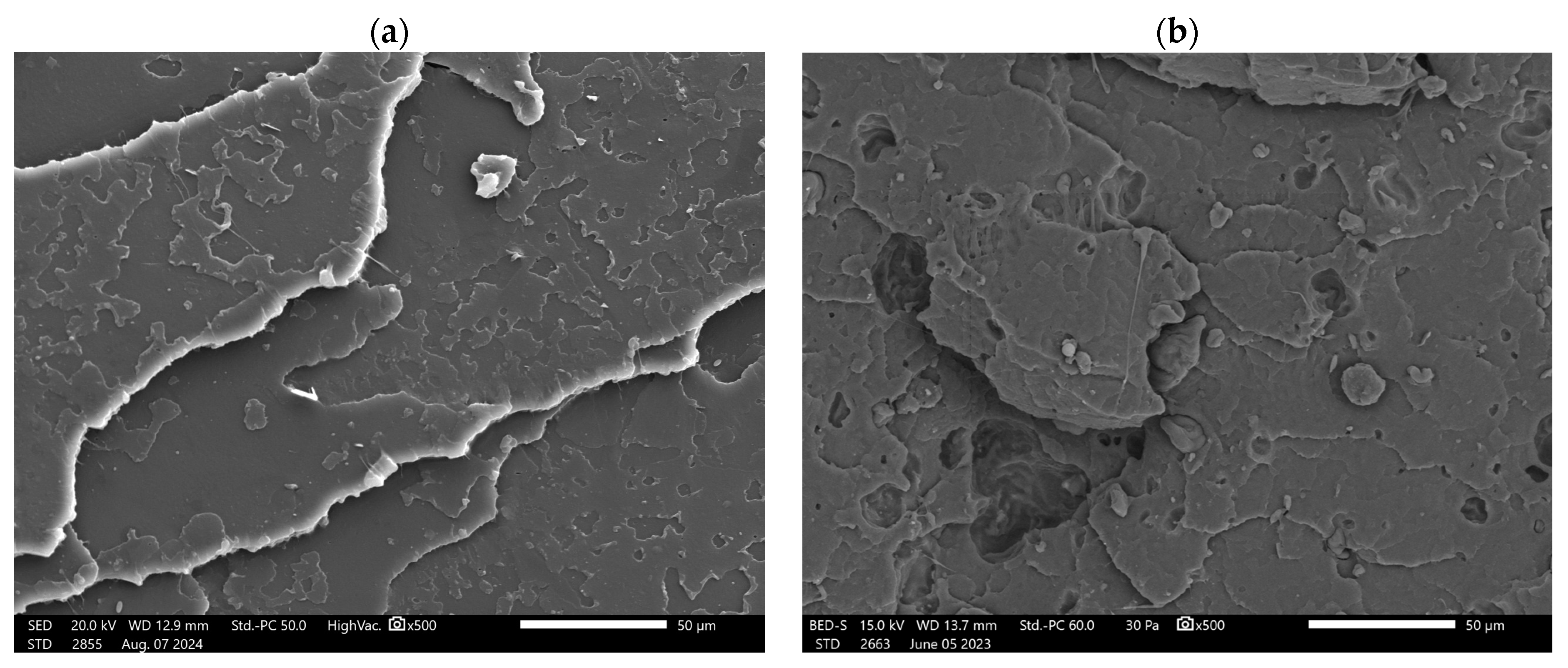

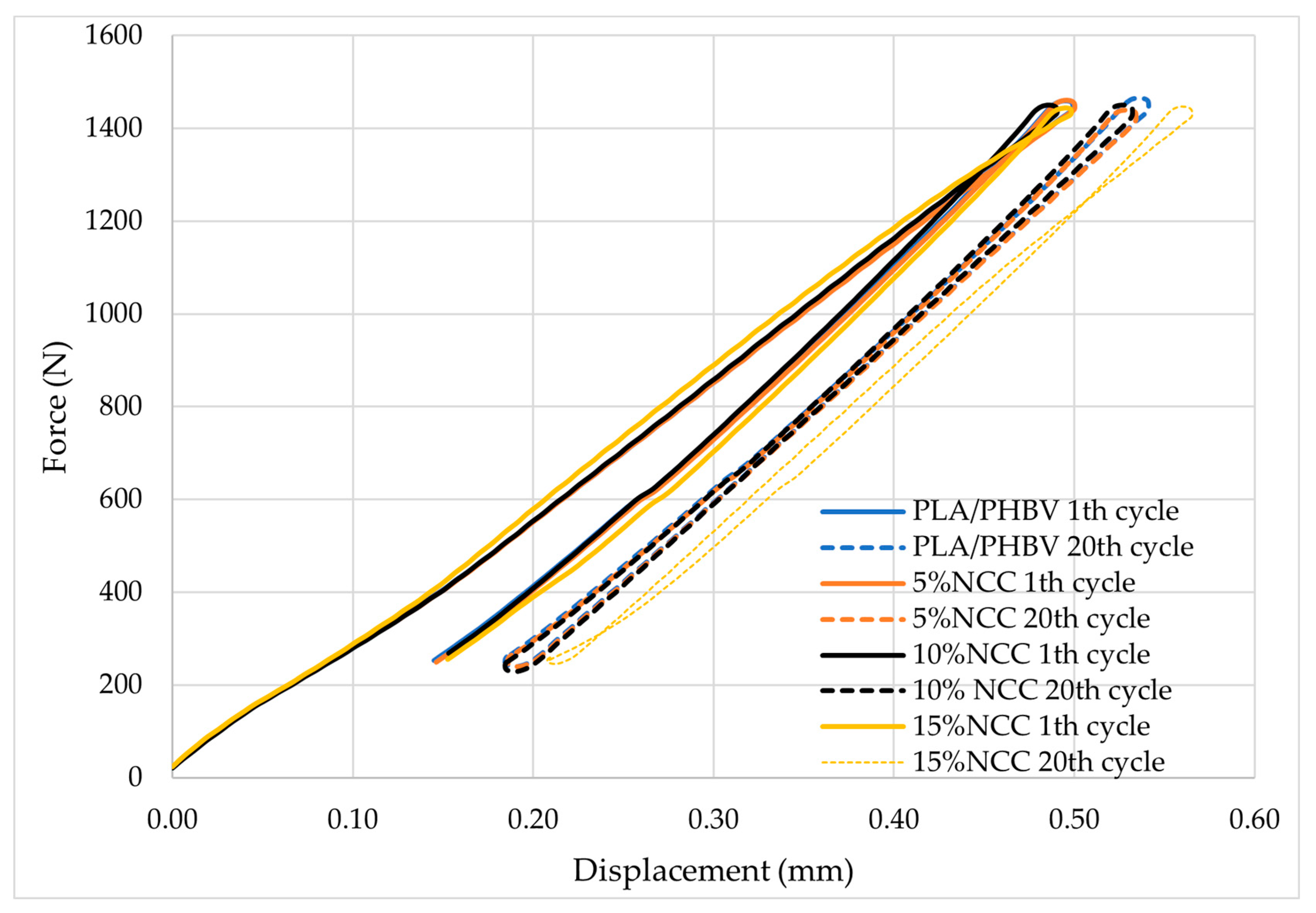

3.2. Structure Analysis

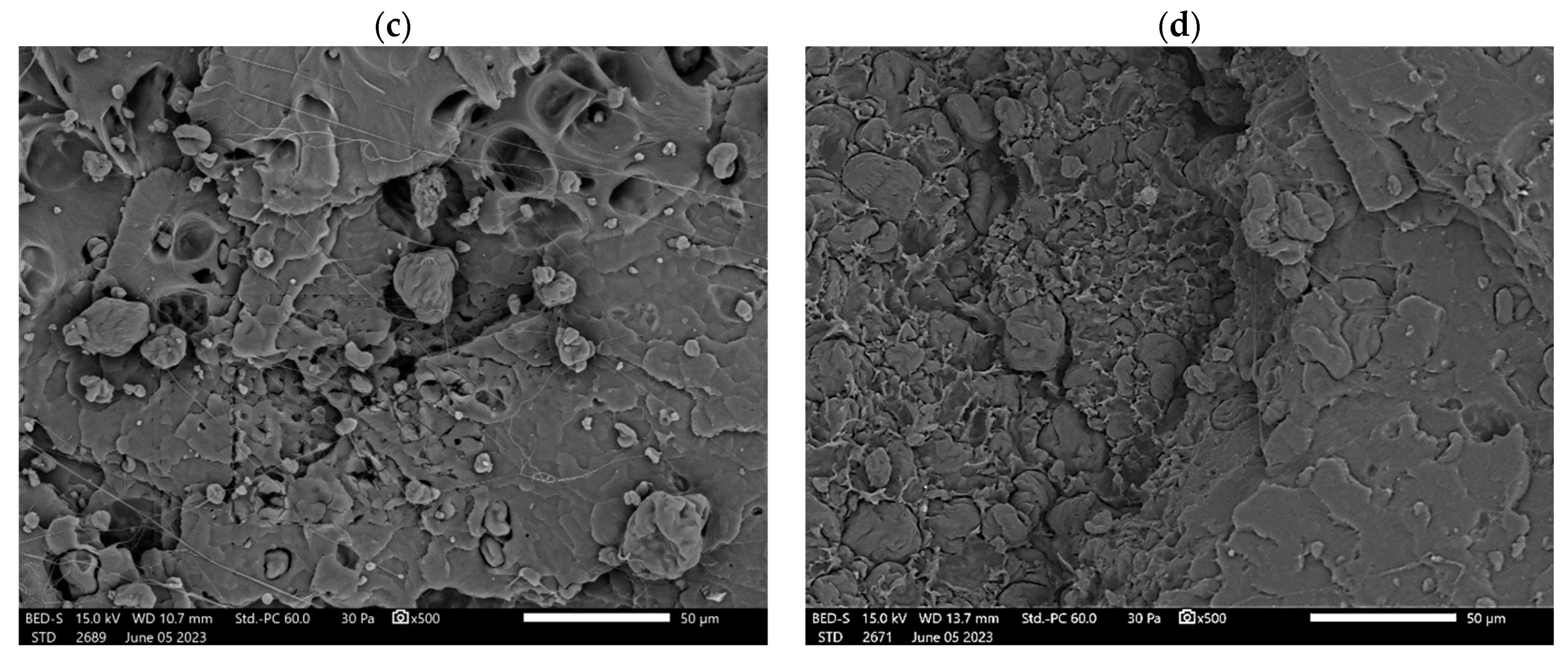

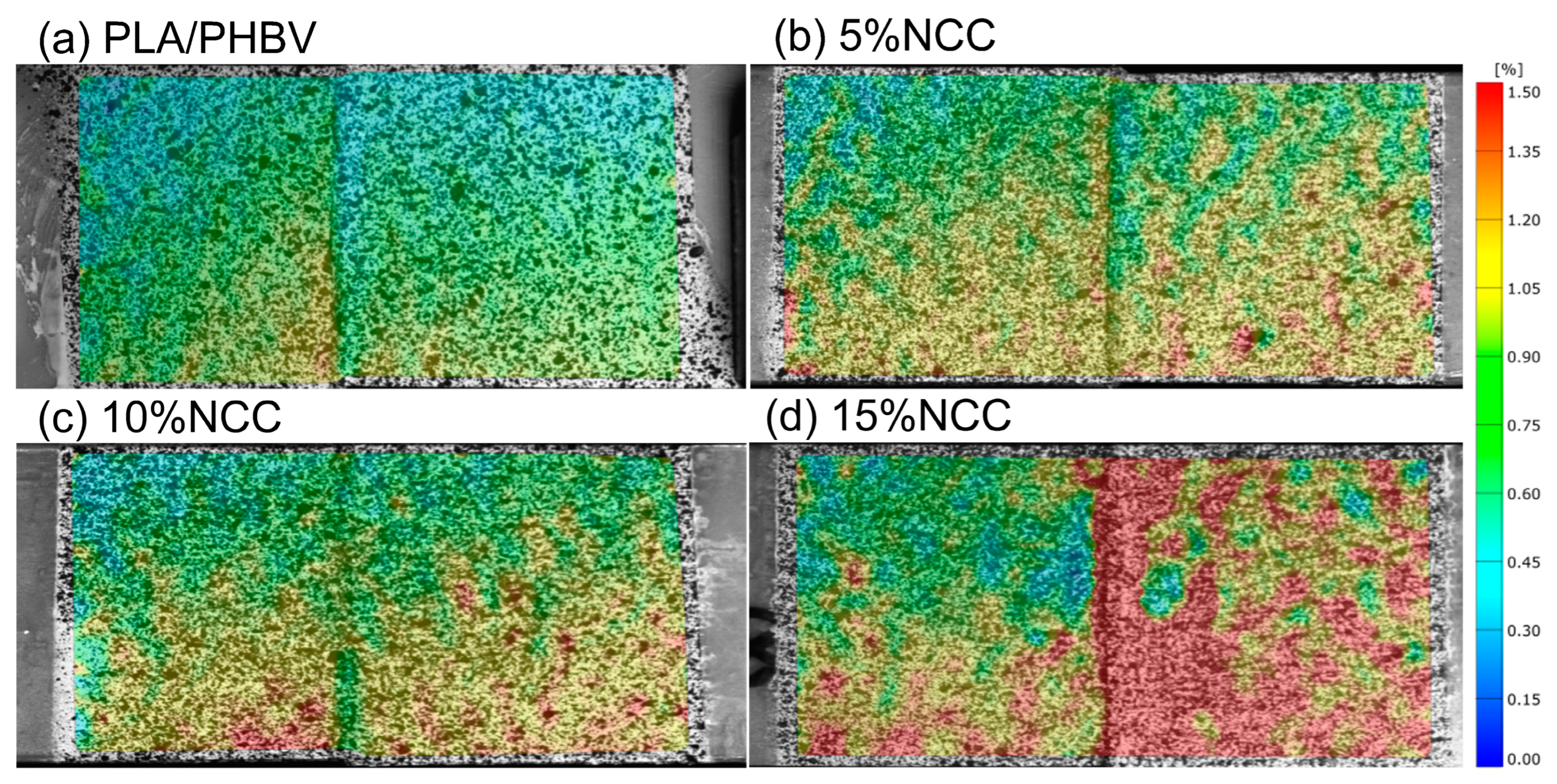

3.3. Mechanical Analysis

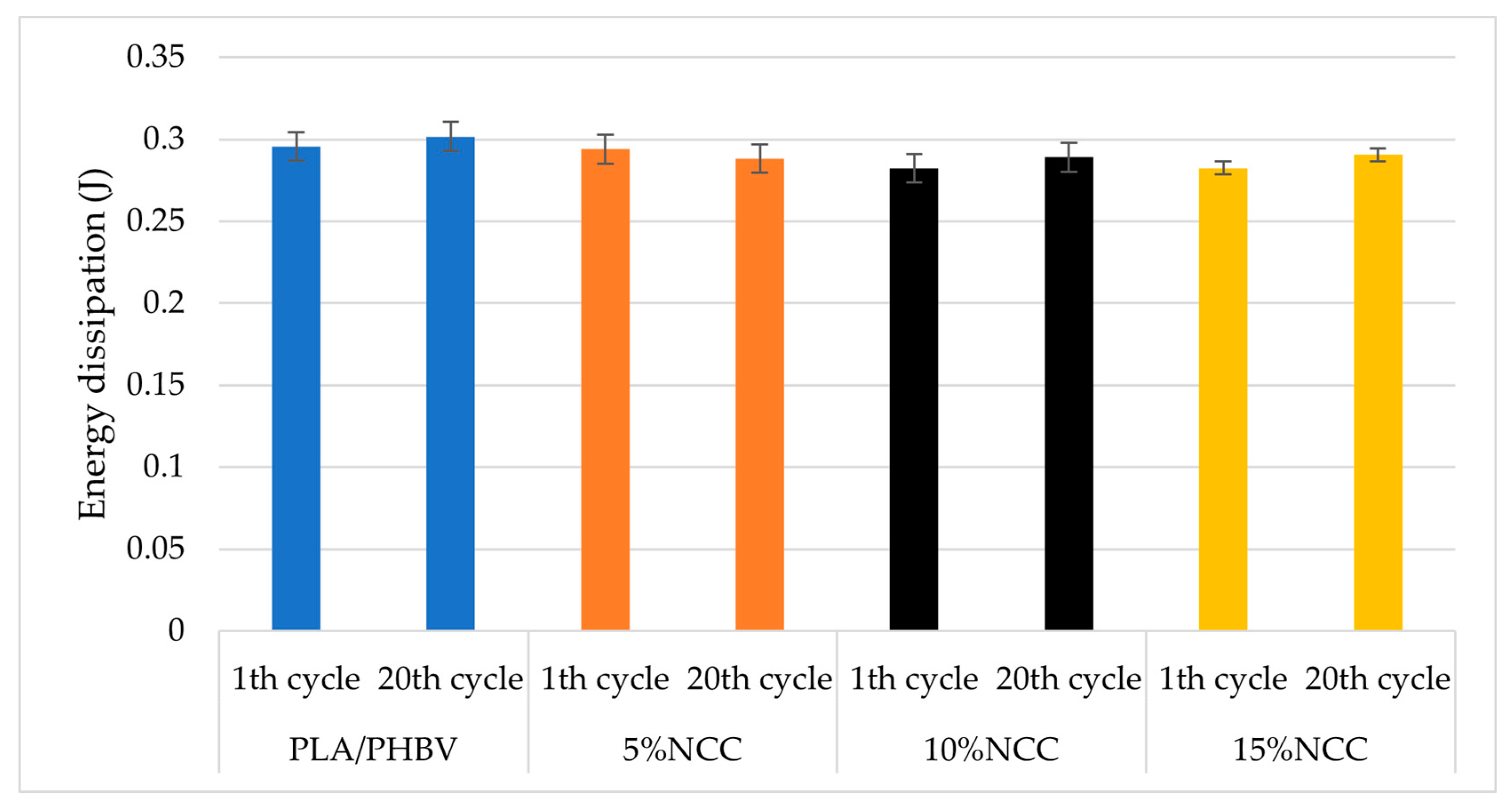

3.4. Energy Dissipation

3.5. Degradation Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Krawczak, P.; Maffezzoli, A. Editorial: Advanced Thermoplastic Composites and Manufacturing Processes. Front. Mater. 2020, 7, 166. [Google Scholar] [CrossRef]

- Chen, L.; Deng, T.; Zhou, H.; Huang, Z.; Peng, X.; Zhou, H. A Numerical Simulation Method for the One-Step Compression-Stamping Process of Continuous Fiber Reinforced Thermoplastic Composites. Polymers 2021, 13, 3237. [Google Scholar] [CrossRef]

- Yildiz Zeyrek, B.; Aydoğan, B.; Dilekcan, E.; Öztürk, F. Recycle Potential of Thermoplastic Composites. Ömer Halisdemir Üniversitesi Mühendislik Bilim. Derg. 2023, 12, 919–925. [Google Scholar] [CrossRef]

- Bodaghi, M.; Park, C.H.; Krawczak, P. Reactive Processing of Acrylic-Based Thermoplastic Composites: A Mini-Review. Front. Mater. 2022, 9, 931338. [Google Scholar] [CrossRef]

- Çobanoğlu, M.; Ece, R.E.; Öztürk, F. Thermoforming process parameter optimization of thermoplastic PEKK/CF and PPS. Eskişehir Tech. Univ. J. Sci. Technol. A-Appl. Sci. Eng. 2021, 22, 50–57. [Google Scholar] [CrossRef]

- Reulier, M.; Perrin, R.; Avérous, L. Biocomposites Based on Chemically Modified Cellulose Fibers with Renewable Fatty-Acid-Based Thermoplastic Systems: Effect of Different Fiber Treatments. J. Appl. Polym. Sci. 2016, 133, 43878. [Google Scholar] [CrossRef]

- Behera, A.K.; Avancha, S.; Sen, R.; Adhikari, B. Development and Characterization of Plasticized Starch-Based Biocomposites with Soy Pulp as Reinforcement Filler. J. Appl. Polym. Sci. 2013, 127, 4681–4687. [Google Scholar] [CrossRef]

- Choudhury, M.R.; Debnath, K. A Review of the Research and Advances in Electromagnetic Joining of Fiber-Reinforced Thermoplastic Composites. Polym. Eng. Sci. 2019, 59, 1965–1985. [Google Scholar] [CrossRef]

- Sun, H.; Kosukegawa, H.; Takagi, T.; Uchimoto, T.; Hashimoto, M.; Takeshita, N. Electromagnetic Pulse-Induced Acoustic Testing and the Pulsed Guided Wave Propagation in Composite/Metal Adhesive Bonding Specimens. Compos. Sci. Technol. 2021, 201, 108499. [Google Scholar] [CrossRef]

- Meyer, S.P.; Wunderling, C.; Zaeh, M.F. Influence of the Laser-Based Surface Modification on the Bond Strength for Friction Press Joining of Aluminum and Polyethylene: Analysis of the Temperature Profile and the Surface Texture as a Way to Characterize the Friction Press Joining Process. Prod. Eng. 2019, 13, 721–730. [Google Scholar] [CrossRef]

- Villegas, I.F. Ultrasonic Welding of Thermoplastic Composites. Front. Mater. 2019, 6, 291. [Google Scholar] [CrossRef]

- Dal Conte, U.F.; F Villegas, I.; Tachon, J. Ultrasonic Plastic Welding of CF/PA6 Composites to Aluminium: Process and Mechanical Performance of Welded Joints. J. Compos. Mater. 2019, 53, 2607–2621. [Google Scholar] [CrossRef]

- Patham, B.; Foss Peter, H. Thermoplastic Vibration Welding: Review of Process Phenomenology and Processing–Structure–Property Interrelationships. Polym. Eng. Sci. 2010, 51, 1420–1428. [Google Scholar] [CrossRef]

- Jandali, G.; Mallick, P.K. Vibration Welding of Continuous-Fiber Thermoplastic Matrix Composites. J. Thermoplast. Compos. Mater. 2004, 17, 343–358. [Google Scholar] [CrossRef]

- Bates, P.; Couzens, D.; Kendall, J. Vibration Welding of Continuously Reinforced Thermoplastic Composites. J. Thermoplast. Compos. Mater. 2001, 14, 344–354. [Google Scholar] [CrossRef]

- Villegas, I.F.; Moser, L.; Yousefpour, A.; Mitschang, P.; Bersee, H.E.N. Process and Performance Evaluation of Ultrasonic, Induction and Resistance Welding of Advanced Thermoplastic Composites. J. Thermoplast. Compos. Mater. 2013, 26, 1007–1024. [Google Scholar] [CrossRef]

- Zhao, X.; Lawal, T.; Rodrigues, M.; Geib, T.; Vodovotz, Y. Value-Added Use of Invasive Plant-Derived Fibers as Phbv Fillers for Biocomposite Development. Polymers 2021, 13, 1975. [Google Scholar] [CrossRef]

- Zhao, H.; Cui, Z.; Sun, X.; Turng, L.; Peng, X. Morphology and Properties of Injection Molded Solid and Microcellular Polylactic Acid/Polyhydroxybutyrate-Valerate (Pla/Phbv) Blends. Ind. Eng. Chem. Res. 2013, 52, 2569–2581. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, C.; Zhang, H.; Deng, B. Blends of Polylactide and Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) with Low Content of Hydroxyvalerate Unit: Morphology, Structure, and Property. J. Appl. Polym. Sci. 2015, 132, 42689. [Google Scholar] [CrossRef]

- Qiang, T.; Wang, J.; Wolcott, M. Facile Fabrication of 100% Bio-Based and Degradable Ternary Cellulose/Phbv/Pla Composites. Materials 2018, 11, 330. [Google Scholar] [CrossRef]

- Lacoste, C.; Gallard, B.; Lopez-Cuesta, J.; Kalaoglu-Altan, O.; Clerck, K. Development of Bionanocomposites Based on Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate)/Polylactide Blends Reinforced with Cloisite 30b. J. Funct. Biomater. 2020, 11, 64. [Google Scholar] [CrossRef] [PubMed]

- Gasmi, S.; Hassan, M.; Luyt, A. Crystallization and Dielectric Behaviour of Pla and Phbv in Pla/Phbv Blends and Pla/Phbv/TiO2 Nanocomposites. Express Polym. Lett. 2019, 13, 199–212. [Google Scholar] [CrossRef]

- Brütting, C.; Dreier, J.; Bonten, C.; Altstädt, V.; Ruckdäschel, H. Sustainable Immiscible Polylactic Acid (Pla) and Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) (Phbv) Blends: Crystallization and Foaming Behavior. ACS Sustain. Chem. Eng. 2023, 11, 6676–6687. [Google Scholar] [CrossRef]

- International Standard ASTM G154-23; Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Materials. ASTM International: Conshohocken, PA, USA, 2023.

- Pathma, B.; Foss Peter, H. Estimation of Melt Film Variables During the Steady- State Penetration Phase of Thermoplastic Vibration Welding Using a Generalized Newtonian Fluid Model. Polym. Eng. Sci. 2012, 52, 581–597. [Google Scholar] [CrossRef]

- Leisen, C.; Seefried, A.; Drummer, D. Post-crosslinking Behavior of Radiation Crosslinked Polyamide 66 during Vibration Welding. Polym. Eng. Sci. 2016, 56, 735–742. [Google Scholar] [CrossRef]

- Liu, J.; Cao, B.; Yang, J. Effects of Vibration Amplitude on Microstructure Evolution and Mechanical Strength of Ultrasonic Spot Welded Cu/Al Joints. Metals 2017, 7, 471. [Google Scholar] [CrossRef]

- Liu, S.-J.; I-Ta, C. Optimizing the Weld Strength of Ultrasonically Welded Nylon Composites. J. Compos. Mater. 2002, 36, 611–624. [Google Scholar] [CrossRef]

- Ao, S.S.; Zhang, W.; Li, C.J.; Oliveira, J.P.; Zeng, Z.; Luo, Z. Variable-Parameter NiTi Ultrasonic Spot Welding with Cu Interlayer. Mater. Manuf. Process. 2021, 36, 599–607. [Google Scholar] [CrossRef]

- Benatar, A.; Eswaran, R.V.; Nayar, S.K. Ultrasonic Welding of Thermoplastics in the Near-field. Polym. Eng. Sci. 1989, 29, 1689–1698. [Google Scholar] [CrossRef]

- Tucker, B.; Bates, P.J.; Tucker, R.; Sidiropolous, V. Improving Vibration Weld Joint Strength through Process and Equipment Modifications. Sci. Technol. Weld. Join. 2004, 9, 443–450. [Google Scholar] [CrossRef]

- Bates, P.J.; Macdonald, J.J.; Wang, C.Y. Vibration Welding Nylon 66—Part I Experimental Study P.J. J. Thermoplast. Compos. Mater. 2003, 16, 101–119. [Google Scholar] [CrossRef]

- Lin, L.; Schlarb, A.K.; Gall, K. Improved Weld Strength of Vibration Welded Polyoxymethylene/Multiwalled Carbon Nanotubes Hybrid Nanocomposites. Polym. Eng. Sci. 2016, 56, 636–642. [Google Scholar] [CrossRef]

- Tsang, K.Y.; DuQuesnay, D.L.; Bates, P.J. Fatigue Properties of Vibration-Welded Nylon 6 and Nylon 66 Reinforced with Glass Fibres. Compos. B Eng. 2008, 39, 396–404. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A. Effects of Fiber Orientation and Anisotropy on Tensile Strength and Elastic Modulus of Short Fiber Reinforced Polymer Composites Composites Part B: Engineering. Composites Part B 2014, 72, 116–129. [Google Scholar] [CrossRef]

- Conceição, M.N.; dos Santos, M.C.C.; Mancipe, J.M.A.; Pereira, P.S.C.; Ribeiro, R.C.C.; Thiré, R.M.S.M.; Bastos, D.C. A Biodegradable Composite of Poly (3-Hydroxybutyrate-Co-3-Hydroxyvalerate) (PHBV) with Short Cellulose Fiber for Packaging. Mater. Res. 2023, 26, e20220615. [Google Scholar] [CrossRef]

- Mukherjee, T.; Kao, N.; Gupta, R.K.; Quazi, N.; Bhattacharya, S. Evaluating the State of Dispersion on Cellulosic Biopolymer by Rheology. J. Appl. Polym. Sci. 2016, 133, 43200. [Google Scholar] [CrossRef]

- Peterson, A.; Mehandzhiyski, A.Y.; Svenningsson, L.; Ziolkowska, A.; Kádár, R.; Lund, A.; Sandblad, L.; Evenäs, L.; Lo Re, G.; Zozoulenko, I.; et al. A Combined Theoretical and Experimental Study of the Polymer Matrix-Mediated Stress Transfer in a Cellulose Nanocomposite. Macromolecules 2021, 54, 3507–3516. [Google Scholar] [CrossRef]

- Yousefian, H.; Rodrigue, D. Effect of Nanocrystalline Cellulose on Morphological, Thermal, and Mechanical Properties of Nylon 6 Composites. Polym. Compos. 2014, 37, 1473–1479. [Google Scholar] [CrossRef]

- Khan, R.; Beck, S.; Dussault, D.; Salmieri, S.; Bouchard, J.; Lacroix, M. Mechanical and Barrier Properties of Nanocrystalline Cellulose Reinforced Poly(Caprolactone) Composites: Effect of Gamma Radiation. J. Appl. Polym. Sci. 2013, 129, 3038–3046. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, Y.; Wang, X.; Rodrigue, D. Reinforcement of Lignin-Based Phenol-Formaldehyde Adhesive with Nano-Crystalline Cellulose (Ncc): Curing Behavior and Bonding Property of Plywood. Mater. Sci. Appl. 2015, 6, 567–575. [Google Scholar] [CrossRef]

- Rashid, E.; Julkapli, N.; Yehya, W. Reinforcement Effect of Nanocellulose on Thermal Stability of Nitrile Butadiene Rubber (Nbr) Composites. J. Appl. Polym. Sci. 2018, 135, 46594. [Google Scholar] [CrossRef]

- Al-Haik, M.; Aldajah, S.; Siddique, W.; Kabir, M.; Haik, Y. Mechanical and Thermal Characterization of Polypropylene-Reinforced Nanocrystalline Cellulose Nanocomposites. J. Thermoplast. Compos. Mater. 2020, 35, 680–691. [Google Scholar] [CrossRef]

- Pal, K.; Panwar, V.; Friedrich, S.; Gehde, M. An Investigation on Vibration Welding of Amorphous and Semicrystalline Polymers. Mater. Manuf. Process. 2016, 31, 372–378. [Google Scholar] [CrossRef]

- Zhang, X.; Li, S.; Li, J.; Fu, B.; Di, J.; Xu, L.; Zhu, X. Reinforcing Effect of Nanocrystalline Cellulose and Office Waste Paper Fibers on Mechanical and Thermal Properties of Poly (Lactic Acid) Composites. J. Appl. Polym. Sci. 2021, 138, 50462. [Google Scholar] [CrossRef]

- Szebényi, G.; Hliva, V. Detection of Delamination in Polymer Composites by Digital Image Correlation-Experimental Test. Polymers 2019, 11, 523. [Google Scholar] [CrossRef]

- Aravind, T.; Ashraf, M.S.; AS, R.; Ahalya, N.; Rawat, M.S.; Uma, B.; Sharma, R.; Subbiah, R.; Sida, S. Study of Progress on Nanocrystalline Cellulose and Natural Fiber Reinforcement Biocomposites. J. Nanomater. 2022, 2022, 6519480. [Google Scholar] [CrossRef]

- Cerbu, C.; Ursache, S.; Botis, M.F.; Hadăr, A. Simulation of the Hybrid Carbon-Aramid Composite Materials Based on Mechanical Characterization by Digital Image Correlation Method. Polymers 2021, 13, 4184. [Google Scholar] [CrossRef]

- Najafi, M.; Khalili, S.M.R.; Eslami-Farsani, R. Hybridization Effect of Basalt and Carbon Fibers on Impact and Flexural Properties of Phenolic Composites. Iran. Polym. J. (Engl. Ed.) 2014, 23, 767–773. [Google Scholar] [CrossRef]

- Rahman, M.Z.; Jayaraman, K.; Mace, B.R. Impact Energy Absorption of Flax Fiber-reinforced Polypropylene Composites. Polym. Compos. 2017, 39, 4165–4175. [Google Scholar] [CrossRef]

- Cheon, J.; Im, Y. Energy Absorption in Polymer Composites for Automotive Crashworthiness. J. Compos. Mater. 2002, 36, 813. [Google Scholar]

- Cieszyński, T.; Topoliński, T. Badania Zmęczeniowe Kompozytów Polimerowych Przy Sterowaniu Energią Dyssypacji. Czas. Tech. Mech.-WPK Mech. 2006, 103, 115–119. [Google Scholar]

- Porebska, R.; Rybak, A.; Kozub, B.; Sekula, R. Polymer Matrix Influence on Stability of Wood Polymer Composites. Polym. Adv. Technol. 2015, 26, 1076–1082. [Google Scholar] [CrossRef]

- Mazurkiewicz, S.; Porębska, R. Energia Dyssypacji w Kompozytach Polimerowych. Czas. Tech. Mech.-WPK 2009, 106, 245–248. [Google Scholar]

- Mazur, K.; Kuciel, S. Mechanical and Hydrothermal Aging Behaviour of Polyhydroxybutyrate-Co-Valerate (PHBV) Composites Reinforced by Natural Fibres. Molecules 2019, 24, 3538. [Google Scholar] [CrossRef]

- Nakai, K.; Yokoyama, T. Effects of Strain Rate on the Stress-Strain Hysteresis Loops of Several Polymers in Compression. Abstr. ATEM Int. Conf. Adv. Technol. Exp. Mech. Asian Conf. Exp. Mech. 2007, 2007, OS13-2-4. [Google Scholar] [CrossRef]

- Li, L.; Reynaud, P.; Fantozzi, G. Effects of Interface Bonding Properties on Cyclic Tensile Behavior of Unidirectional C/Si3N4 and SiC/Si3N4 Composites. Int. J. Appl. Ceram. Technol. 2018, 15, 1124–1137. [Google Scholar] [CrossRef]

- Ferreira, F.V.; Pinheiro, I.F.; Gouveia, R.F.; Thim, G.P.; Lona, L.M.F. Functionalized Cellulose Nanocrystals as Reinforcement in Biodegradable Polymer Nanocomposites. Polym. Compos. 2018, 39, E9–E29. [Google Scholar] [CrossRef]

- Lin, N.; Yu, J.; Chang, P.; Li, J.; Huang, J. Poly(Butylene Succinate)-Based Biocomposites Filled With Polysaccharide Nanocrystals: Structure and Properties. Polym. Compos. 2011, 32, 472–482113. [Google Scholar] [CrossRef]

- Nurhamiyah, Y.; Chen, B. Structure and Properties of Biobased Polyamide 36,9/Cellulose Nanocomposites. RSC Sustain. 2023, 1, 2254–2260. [Google Scholar] [CrossRef]

- Colli-Gongora, P.E.; Moo-Tun, N.M.; Herrera-Franco, P.J.; Valadez-Gonzalez, A. Assessing the Effect of Cellulose Nanocrystal Content on the Biodegradation Kinetics of Multiscale Polylactic Acid Composites under Controlled Thermophilic Composting Conditions. Polymers 2023, 15, 3093. [Google Scholar] [CrossRef]

- Mirabolghasemi, S.M.; Najafi, M.; Azizi, A.; Haji Bagherian, M. Physico-Mechanical Properties of Polylactic Acid Bio-Nanocomposites Filled by Hybrid Nanoparticles. Polym. Polym. Compos. 2021, 29, S1510–S1519. [Google Scholar] [CrossRef]

| Designation | Description | Density, (g/cm3) |

|---|---|---|

| PLA/PHBV | PLA/PHBV blend containing 90% PLA and 10% PHBV as the base material | 1.25 |

| 5%NCC | PLA/PHBV blend with 5 wt% NCC | 1.26 |

| 10%NCC | PLA/PHBV blend with 10 wt% NCC | 1.27 |

| 15%NCC | PLA/PHBV blend with 15 wt% NCC | 1.28 |

| Cycle | Function | Intensity (W/m2/nm) | Temp. (°C) | Time (min) |

| UV light | 1.55 | 60 | 8:00 | |

| Water spraying | - | - | 0:15 | |

| Condensation | - | 50 | 3:45 |

| Index | Vibration Welding Parameters | Max Force, (N) | ||

|---|---|---|---|---|

| Vibration Amplitude a, (mm) | Welding Time tz, (s) | Pressure p, (atm) | ||

| PLA/PHBV_1 | 1.0 | 6.5 | 1.0 | 640 ± 258 |

| PLA/PHBV_2 | 1.0 | 3.0 | 1.0 | 2874 ± 125 |

| PLA/PHBV_3 | 1.2 | 4.5 | 1.0 | 2157 ± 352 |

| 5%NNC_1 | 1.0 | 6.5 | 1.0 | 2011 ± 147 |

| 5%NNC_2 | 1.0 | 4.5 | 1.0 | 1590 ± 156 |

| 5%NNC_3 | 1.6 | 3.0 | 1.0 | 2894 ± 65 |

| 10%NNC_1 | 1.0 | 5.0 | 1.5 | 1552 ± 24 |

| 10%NNC_2 | 1.2 | 4.0 | 1.5 | 3030 ± 48 |

| 10%NNC_3 | 1.6 | 5.0 | 1.0 | 3705 ± 25 |

| 15%NNC_1 | 1.2 | 4.5 | 1.0 | 2357 ± 158 |

| 15%NNC_2 | 1.6 | 3.0 | 1.0 | 2830 ± 235 |

| 15%NNC_3 | 1.6 | 5.0 | 1.5 | 3787 ± 46 |

| Index | Vibration Welding Parameters | Max Force, (N) | ||

|---|---|---|---|---|

| Vibration Amplitude a, (mm) | Welding Time tz, (s) | Pressure p, (atm) | ||

| PLA/PHBV | 1.0 | 3.0 | 1.0 | 2874 ± 125 |

| 5%NNC | 1.6 | 3.0 | 1.0 | 2894 ± 65 |

| 10%NNC | 1.6 | 5.0 | 1.0 | 3705 ± 25 |

| 15%NNC | 1.6 | 5.0 | 1.5 | 3787 ± 46 |

| Material | Condition | Young’s Modulus (MPa) | Tensile Strength (MPa) |

|---|---|---|---|

| PLA/PHBV | conditioned | 4899 ± 119 | 61.1 ± 1.1 |

| aged | - | - | |

| 5%NNC | conditioned | 7319 ± 846 | 63.4 ± 2.4 |

| aged | 3265 ± 987 | 9.3 ± 1.3 | |

| 10%NNC | conditioned | 8777 ± 622 | 63.7 ± 3.6 |

| aged | 4786 ± 1223 | 13.0 ± 3.4 | |

| 15%NNC | conditioned | 9097 ± 580 | 64.8 ± 5.1 |

| aged | 4947 ± 1233 | 14.7 ± 3.7 | |

| aged * | 1136 ± 852 | 4.7 ± 2.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bazan, P.; Kozub, B.; Rochman, A.; Melnychuk, M.; Majewska, P.; Mroczka, K. Vibration Welding of PLA/PHBV Blend Composites with Nanocrystalline Cellulose. Polymers 2024, 16, 3495. https://doi.org/10.3390/polym16243495

Bazan P, Kozub B, Rochman A, Melnychuk M, Majewska P, Mroczka K. Vibration Welding of PLA/PHBV Blend Composites with Nanocrystalline Cellulose. Polymers. 2024; 16(24):3495. https://doi.org/10.3390/polym16243495

Chicago/Turabian StyleBazan, Patrycja, Barbara Kozub, Arif Rochman, Mykola Melnychuk, Paulina Majewska, and Krzysztof Mroczka. 2024. "Vibration Welding of PLA/PHBV Blend Composites with Nanocrystalline Cellulose" Polymers 16, no. 24: 3495. https://doi.org/10.3390/polym16243495

APA StyleBazan, P., Kozub, B., Rochman, A., Melnychuk, M., Majewska, P., & Mroczka, K. (2024). Vibration Welding of PLA/PHBV Blend Composites with Nanocrystalline Cellulose. Polymers, 16(24), 3495. https://doi.org/10.3390/polym16243495