Fabrication of Mildew-Resistant Wood with Multi-Functional Properties Based on In Situ Growth of Metal–Organic Frameworks

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

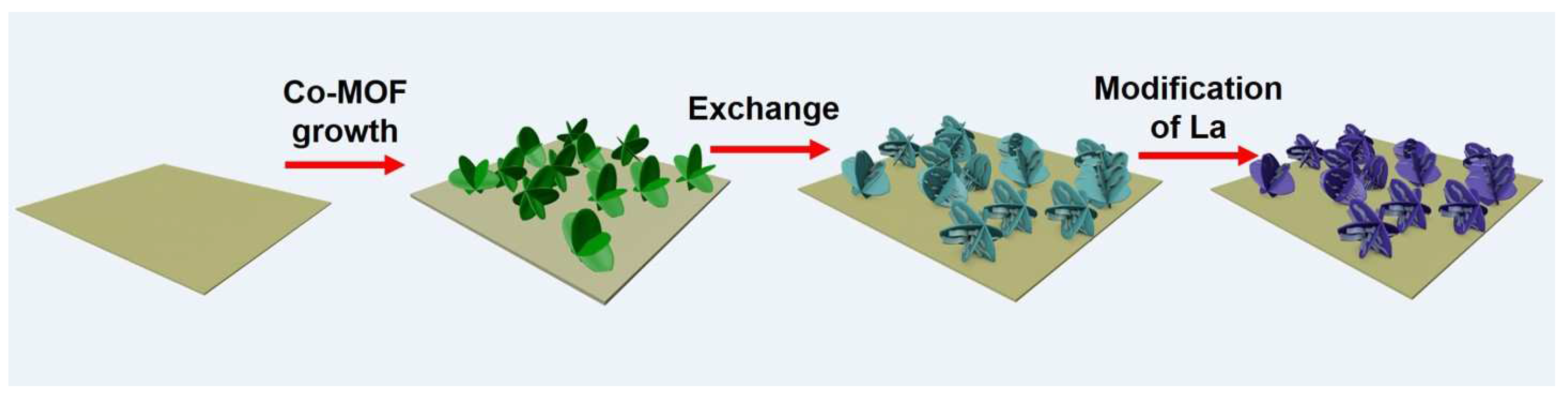

2.2. Fabrication Process of Superhydrophobic Surfaces on Balsa Wood

2.3. Characterization

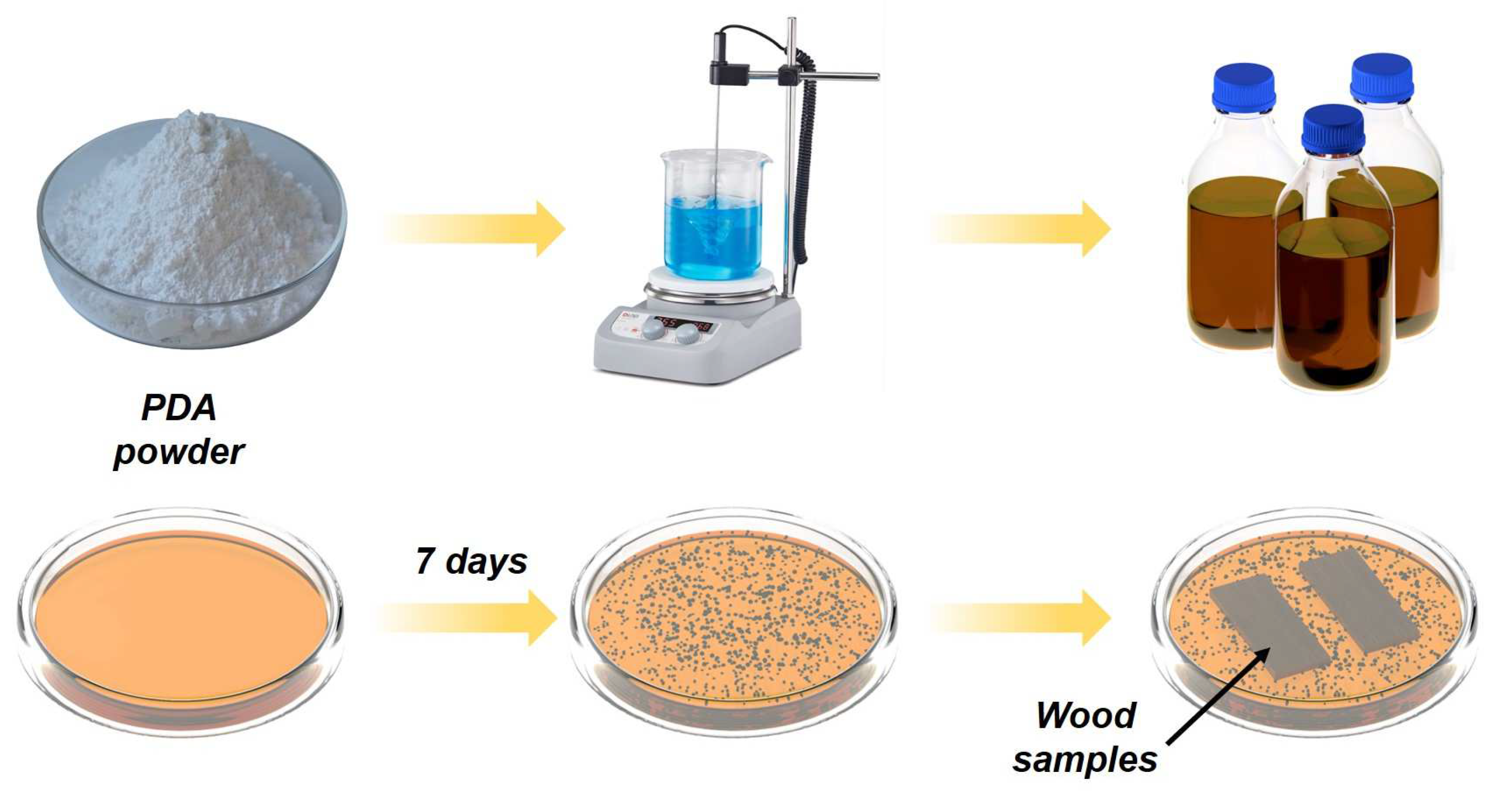

2.4. Anti-Mildew Test

3. Results

3.1. Microstructure Characterization

3.2. XRD and XPS Analyses

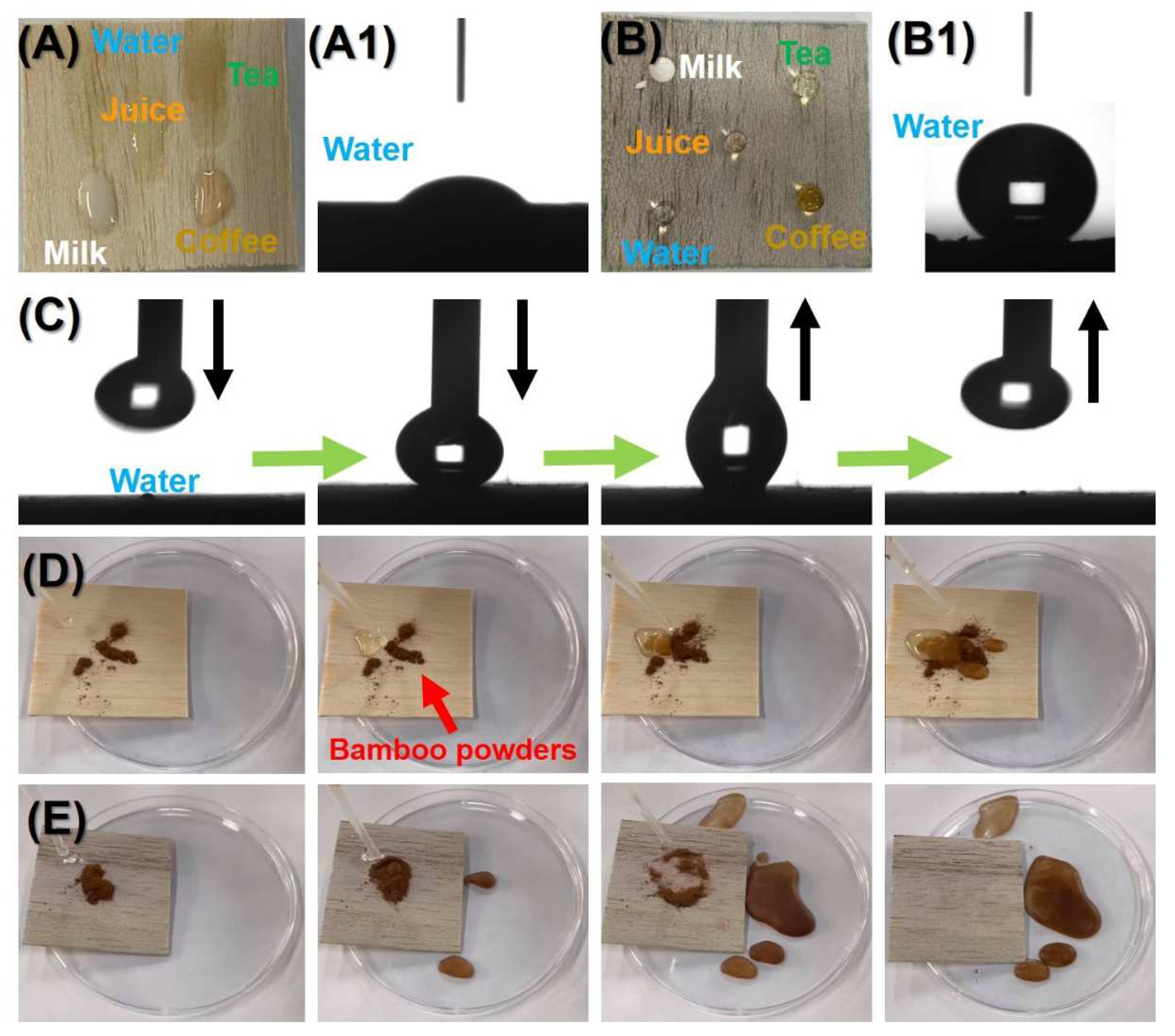

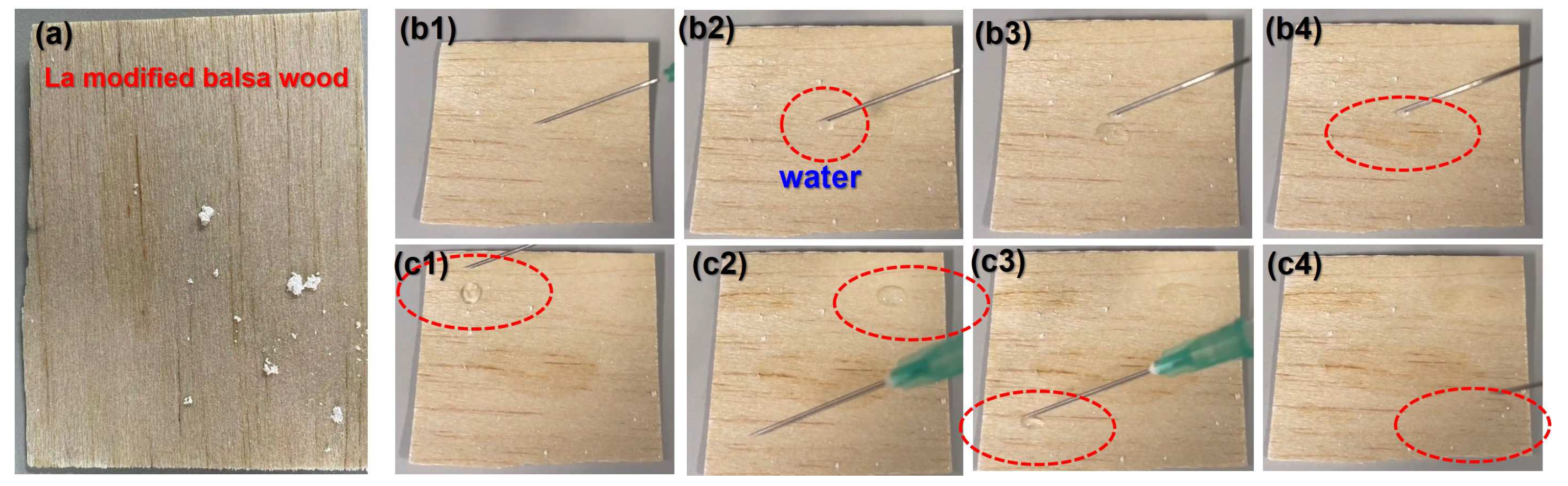

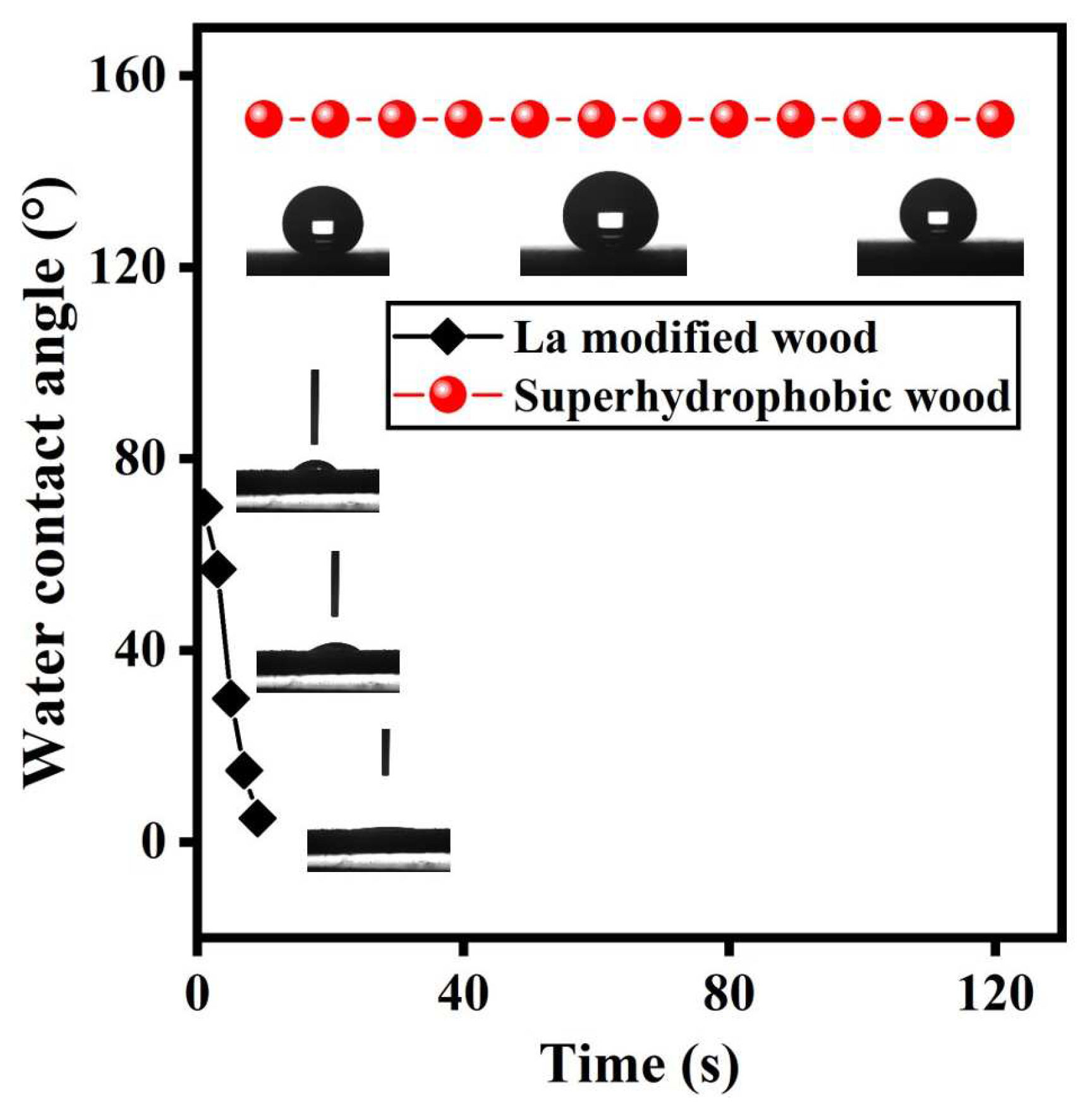

3.3. Wettability and Self-Cleaning Performance of the Wood Samples

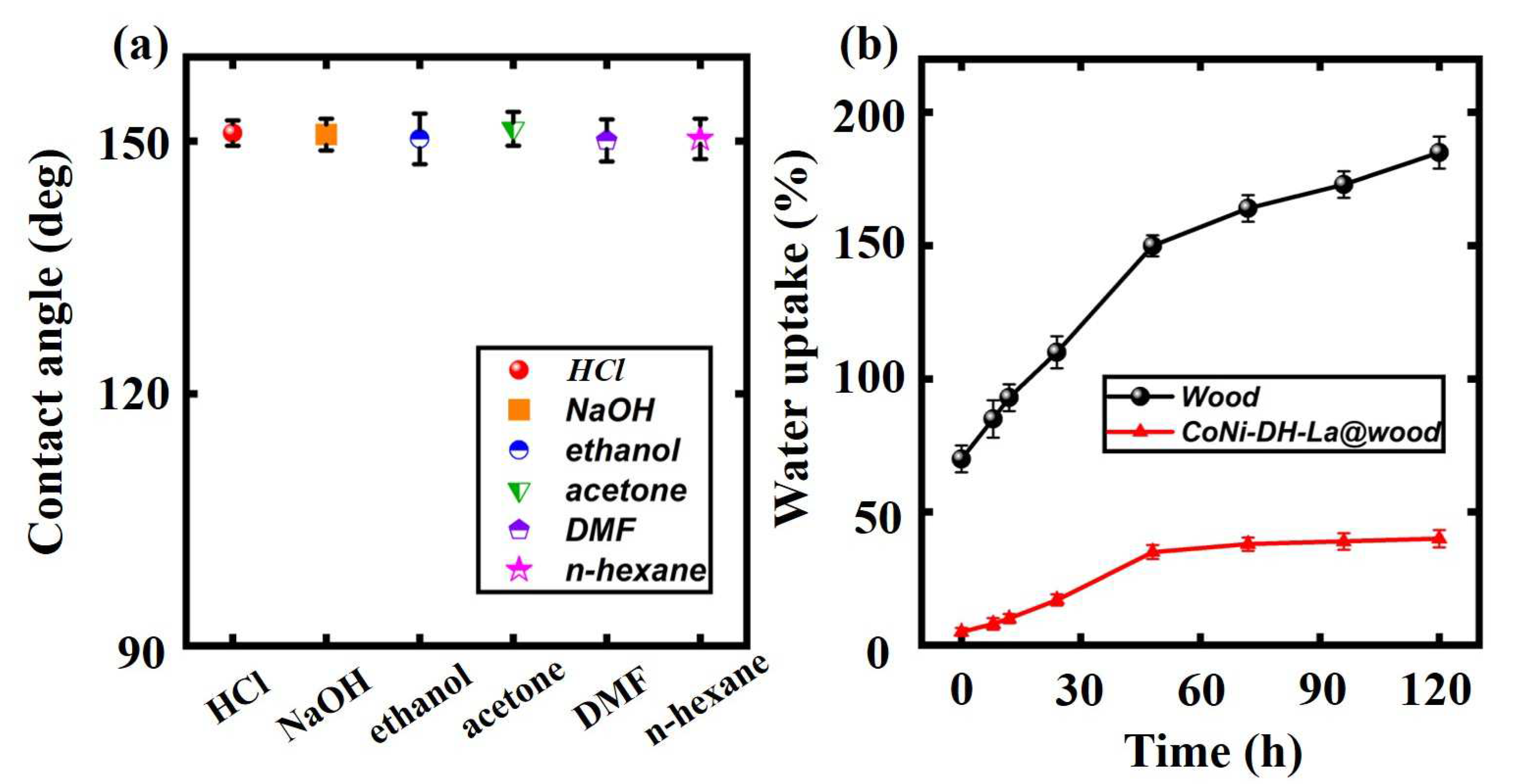

3.4. Durability and Stability of the Wood Samples

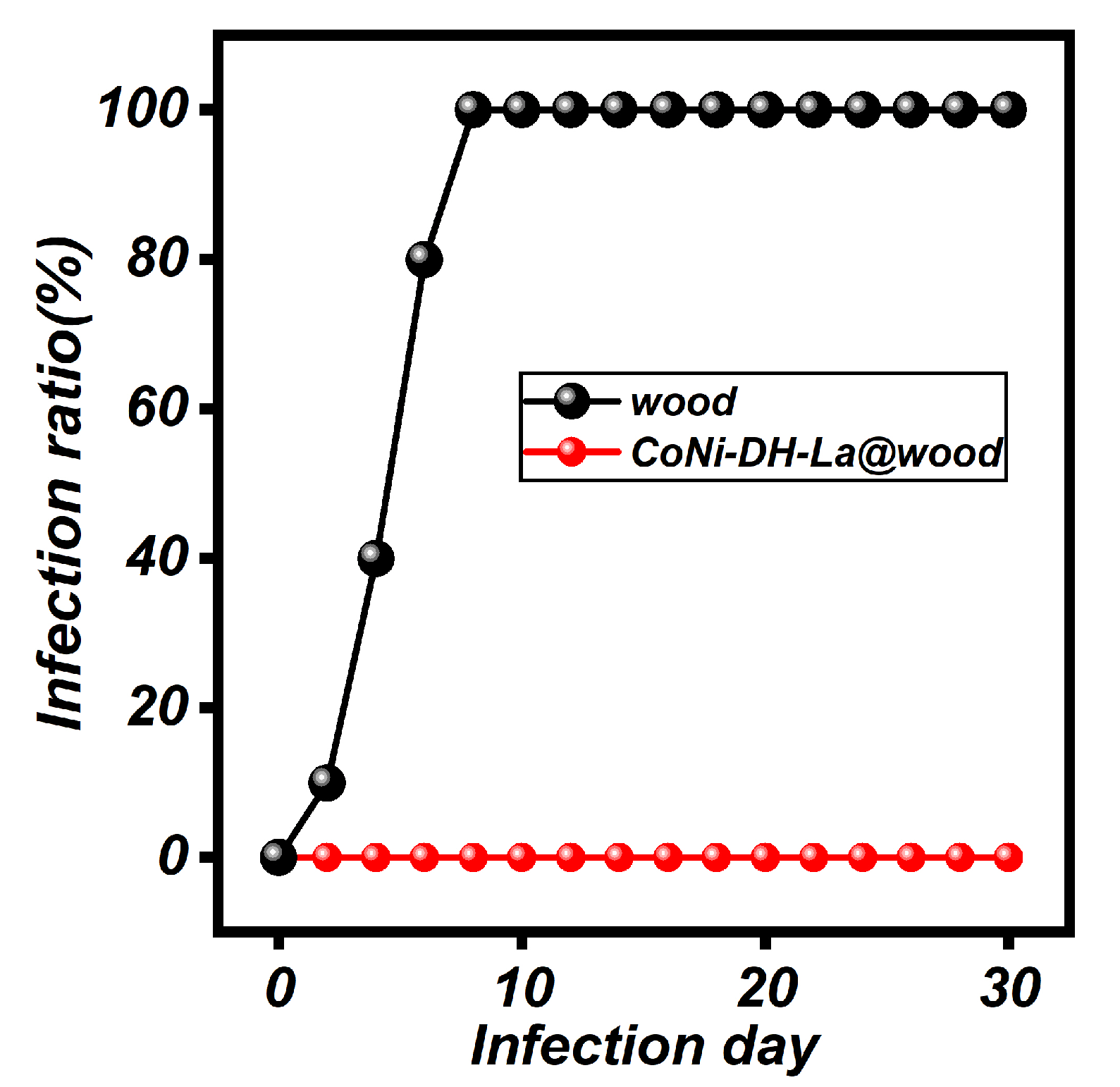

3.5. Mildew Resistance Performance of the Wood Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ghiasi, F.; Golmakani, M.T.; Eskandari, M.H.; Hosseini, S.M.H. A New Approach in the Hydrophobic Modification of Polysaccharide-Based Edible Films Using Structured Oil Nanoparticles. Ind. Crops Prod. 2020, 154, 112679. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.; Fei, B.; Xu, X.; Lian, C.; Chen, H. The Mechanical Properties and Thermal Conductivity of Bamboo with Freeze–Thaw Treatment. J Wood Sci. 2021, 67, 66. [Google Scholar] [CrossRef]

- Chen, K.; Yu, H.; Peng, H.; Jiang, J.; Lyu, J.; Zhan, T. Enhancement of the Weathering Resistance of Heat-Treated Wood: Surface Deposition of Zn Nanoparticles by Electrochemical Activation. ACS Sustain. Chem. Eng. 2022, 10, 15211–15222. [Google Scholar] [CrossRef]

- Chen, K.; Tan, Y.; Sun, F.; Zhu, J.; Peng, H.; Jiang, J.; Lyu, J.; Zhan, T. Influence of Electrochemically Deposited TiO2 on the Anti-Weathering Properties of Heat-Treated Wood. Wood Mater. Sci. Eng. 2022, 18, 1–9. [Google Scholar] [CrossRef]

- Lian, C.; Liu, R.; Luo, J.; Yang, F.; Zhang, S.; Fei, B. The Morphological Characteristics and Classification of Vascular Parenchyma Cells in Bamboo, Phyllostachys Edulis (Carr.) J. Houz. Holzforsch. 2020, 74, 829–838. [Google Scholar] [CrossRef]

- Piao, X.; Duan, X.; Xie, M.; Jin, C.; Wang, Z. Exploration and Preparation of Multifunctional Bamboo Based on a Green Wax-Based Composite System. Eng. Asp. 2022, 643, 127913. [Google Scholar] [CrossRef]

- Liu, X.; Gu, W.; Wang, K.; Zhang, W.; Xia, C.; Shi, S.Q.; Li, J. Thiol-Branched Graphene Oxide and Polydopamine-Induced Nanofibrillated Cellulose to Strengthen Protein-Based Nanocomposite Films. Cellulose 2019, 26, 7223–7236. [Google Scholar] [CrossRef]

- Lu, Y.; Yue, Y.; Ding, Q.; Mei, C.; Xu, X.; Wu, Q.; Xiao, H.; Han, J. Self-Recovery, Fatigue-Resistant, and Multifunctional Sensor Assembled by a Nanocellulose/Carbon Nanotube Nanocomplex-Mediated Hydrogel. ACS Appl. Mater. Interfaces 2021, 13, 50281–50297. [Google Scholar] [CrossRef]

- Piao, X.; Zhao, Z.; Guo, H.; Wang, Z.; Jin, C. Improved Properties of Bamboo by Thermal Treatment with Wood Wax Oil. Eng. Asp. 2022, 643, 128807. [Google Scholar] [CrossRef]

- Pineda, H.; Hu, Y.; Semple, K.; Chen, M.; Dai, C. Computer Simulation of the Mat Formation of Bamboo Scrimber Composites. Compos. Part. A Appl. Sci. Manuf. 2021, 149, 106542. [Google Scholar] [CrossRef]

- Wagih, A.; Hasani, M.; Hall, S.A.; Theliander, H. Micro/Nano-Structural Evolution in Spruce Wood during Soda Pulping. Holzforschung 2021, 75, 754–764. [Google Scholar] [CrossRef]

- Gauss, C.; Kadivar, M.; Harries, K.A.; Savastano, H., Jr. Chemical Modification of Dendrocalamus Asper Bamboo with Citric Acid and Boron Compounds: Effects on the Physical-Chemical, Mechanical and Thermal Properties. J. Clean. Prod. 2021, 279, 123871. [Google Scholar] [CrossRef]

- Yang, K.; Li, X.; Wu, Y.; Zheng, X. A Simple, Effective and Inhibitor-free Thermal Treatment for Enhancing Mold-proof Property of Bamboo Scrimber. Eur. J. Wood Prod. 2021, 79, 1049–1055. [Google Scholar] [CrossRef]

- Karlinasari, L.; Adzkia, U.; Sudarsono, A.S.; Larasatie, P.; Amin, Y.; Nugroho, N. Surface Characteristics and Acoustical Properties of Bamboo Particle Board Coated with Polyurethane Varnish. Forests 2021, 12, 1285. [Google Scholar] [CrossRef]

- Ma, R.; Chen, Y.; Wu, Z.; Bao, M.; Xiao, Z.; Sun, F.; Li, J. Nanostructured WO3·xH2O Deposition Effects on the Antimicrobial Activities of Nano TiO2-Coated Bamboo. Vacuum 2022, 204, 111397. [Google Scholar] [CrossRef]

- Ma, X.; Xiong, Y.; Liu, Y.; Han, J.; Duan, G.; Chen, Y.; He, S.; Mei, C.; Jiang, S.; Zhang, K. When MOFs Meet Wood: From Opportunities toward Applications. Chem 2022, 8, 2342–2361. [Google Scholar] [CrossRef]

- Ma, X.; Guo, H.; Zhang, C.; Chen, D.; Tian, Z.; Wang, Y.; Chen, Y.; Wang, S.; Han, J.; Lou, Z.; et al. ZIF-67/Wood Derived Self-Supported Carbon Composites for Electromagnetic Interference Shielding and Sound and Heat Insulation. Inorg. Chem. Front. 2022, 9, 6305–6316. [Google Scholar] [CrossRef]

- Guo, H.; Wang, F.; Luo, H.; Lou, Z.; Ji, Y.; Liu, X.; Shen, B.; Peng, Y.; Liu, K.; Jiang, S. Flexible TaC/C Electrospun Non–Woven Fabrics with Multiple Spatial-Scale Conductive Frameworks for Efficient Electromagnetic Interference Shielding. Composites Part A Appl. Sci. Manuf. 2021, 151, 106662. [Google Scholar] [CrossRef]

- Kayan, A. Recent Studies on Single Site Metal Alkoxide Complexes as Catalysts for Ring Opening Polymerization of Cyclic Compounds. Catal. Surv. Asia 2020, 24, 87–103. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhu, W.; Li, Z.; Feng, Y.; Qi, W.; Li, S.; Wang, X.; Chen, M. Enhancement of Wood Coating Properties by Adding Silica Sol to UV-Curable Waterborne Acrylics. Forests 2023, 14, 335. [Google Scholar] [CrossRef]

- Zhu, W.; Wu, Y.; Zhang, Y. Fabrication and Characterization of Superhydrophobicity ZnO Nanoparticles with Two Morphologies by Using Stearic Acid. Mater. Res. Express 2019, 6, 1150d1. [Google Scholar] [CrossRef]

- Zhu, W.; Kim, D.; Han, M.; Jang, J.; Choi, H.; Kwon, G.; Jeon, Y.; Yeol Ryu, D.; Lim, S.-H.; You, J.; et al. Fibrous Cellulose Nanoarchitectonics on N-Doped Carbon-Based Metal-Free Catalytic Nanofilter for Highly Efficient Advanced Oxidation Process. Chem. Eng. J. 2023, 460, 141593. [Google Scholar] [CrossRef]

- Shi, J.; Zhong, T.; Xu, X.; Wu, J.; Zou, Y.; Fei, B.; Xia, C.; Chen, H. Eco-Friendly and Special-Shaped Bamboo Binderless Fiberboards Fabricated by Self-Bonding Technology: Effect of Bamboo Fibers with Different Sizes. Ind. Crops Prod. 2023, 194, 116300. [Google Scholar] [CrossRef]

- Deng, L.; Chen, F.; Ren, X.; Jiang, Z. An Environmentally Friendly and Efficient Method to Improve the Acoustic Vibration Performance of Bamboo for Musical Instruments: Nitrogen-Protected Heat Treatment. Ind. Crops Prod. 2022, 188, 115554. [Google Scholar] [CrossRef]

- Wu, K.-T. The Effect of High-Temperature Drying on the Antisplitting Properties of Makino Bamboo Culm (Phyllostachys Makinoi Hay.). Wood Sci. Technol. 1992, 26, 271–277. [Google Scholar] [CrossRef]

- Luan, Y.; Liu, L.; Ma, Y.; Yang, Y.; Jiang, M.; Semple, K.; Dai, C.; Fei, B.; Fang, C. An Integrated Hydrothermal Process of Bamboo Flattening, Densification and Drying: Mechanical Properties and Strengthening Mechanisms. Mater. Des. 2023, 226, 111610. [Google Scholar] [CrossRef]

- Yue, J.; Yu, J.; Jiang, S.; Chen, Y. Biomass Carbon Materials with Porous Array Structures Derived from Soybean Dregs for Effective Electromagnetic Wave Absorption. Diam. Relat. Mater. 2022, 126, 109054. [Google Scholar] [CrossRef]

- Wu, J.; Cui, Z.; Yu, Y.; Han, H.; Tian, D.; Hu, J.; Qu, J.; Cai, Y.; Luo, J.; Li, J. A 3D Smart Wood Membrane with High Flux and Efficiency for Separation of Stabilized Oil/Water Emulsions. J. Hazard. Mater. 2023, 441, 129900. [Google Scholar] [CrossRef]

- Cai, Y.; Dong, Y.; Wang, K.; Tian, D.; Qu, J.; Hu, J.; Lee, J.; Li, J.; Kim, K.-H. A Polydimethylsiloxane-Based Sponge for Water Purification and Interfacial Solar Steam Generation. J. Colloid. Interface Sci. 2023, 629, 895–907. [Google Scholar] [CrossRef]

- Yang, F.; Qu, J.; Zheng, Y.; Cai, Y.; Yang, X.; Li, C.M.; Hu, J. Recent Advances in High-Crystalline Conjugated Organic Polymeric Materials for Photocatalytic CO 2 Conversion. Nanoscale 2022, 14, 15217–15241. [Google Scholar] [CrossRef]

- Wei, Y.; Hu, C.; Dai, Z.; Zhang, Y.; Zhang, W.; Lin, X. Highly Anisotropic MXene@Wood Composites for Tunable Electromagnetic Interference Shielding. Compos. Part. A Appl. Sci. Manuf. 2023, 168, 107476. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Z.; Song, L.; Feng, Y.; Yao, J. Chinese Ink Enabled Wood Evaporator for Continuous Water Desalination. Desalination 2020, 496, 114727. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, K.; Ahn, J.; Wang, F.; Sun, Y.; Lee, J.; Young Cheong, J.; Ma, C.; Zhao, H.; Duan, G.; et al. Morph-Genetic Bamboo-Reinforced Hydrogel Complex for Bio-Mimetic Actuator. Chem. Eng. J. 2023, 463, 142391. [Google Scholar] [CrossRef]

- Luan, Y.; Ma, Y.-F.; Liu, L.-T.; Fei, B.-H.; Fang, C.-H. A Novel Bamboo Engineering Material with Uniform Density, High Strength, and High Utilization Rate. Ind. Crops Prod. 2022, 184, 115045. [Google Scholar] [CrossRef]

- Chen, Q.; Wei, P.; Tang, T.; Fang, C.; Fei, B. Quantitative Visualization of Weak Layers in Bamboo at the Cellular and Subcellular Levels. ACS Appl. Bio Mater. 2020, 3, 7087–7094. [Google Scholar] [CrossRef] [PubMed]

- Kaur, P.J.; Kardam, V.; Pant, K.K.; Naik, S.N.; Satya, S. Characterization of Commercially Important Asian Bamboo Species. Eur. J. Wood Prod. 2016, 74, 137–139. [Google Scholar] [CrossRef]

- Wu, Z.; Huang, D.; Wei, Y.; Wang, X.; Wang, X.; Wei, Q.; Niu, M.; Lin, M.; Rao, J.; Xie, Y. Mesoporous Aluminosilicate Improves Mildew Resistance of Bamboo Scrimber with Anti-Mildew Agents. J. Clean. Prod. 2019, 209, 273–282. [Google Scholar] [CrossRef]

- Guan, M.; Li, X.; Xu, X.; Fu, R. Anti-Mold and Hydrophobicity of Cutinized Bamboo Prepared via Different Annealing Processes. Ind. Crops Prod. 2022, 187, 115399. [Google Scholar] [CrossRef]

- Wei, Y.; Jiang, S.; Li, C.; Li, J.; Li, X.; Li, J.; Fang, Z. Organic-Inorganic Hybrid Network to Enhance the Electrostatic Shielding of Multifunctional Soybean Meal-Based Adhesive. Ind. Crops Prod. 2022, 189, 115850. [Google Scholar] [CrossRef]

- Wei, Y.; Jiang, S.; Li, X.; Li, J.; Dong, Y.; Shi, S.Q.; Li, J.; Fang, Z. “Green” Flexible Electronics: Biodegradable and Mechanically Strong Soy Protein-Based Nanocomposite Films for Human Motion Monitoring. ACS Appl. Mater. Interfaces 2021, 13, 37617–37627. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, X.; Zhang, T.; Li, J.; Wang, W.; Yuan, T.; Li, Y. Fabrication of Mildew-Resistant Wood with Multi-Functional Properties Based on In Situ Growth of Metal–Organic Frameworks. Polymers 2024, 16, 313. https://doi.org/10.3390/polym16030313

Liang X, Zhang T, Li J, Wang W, Yuan T, Li Y. Fabrication of Mildew-Resistant Wood with Multi-Functional Properties Based on In Situ Growth of Metal–Organic Frameworks. Polymers. 2024; 16(3):313. https://doi.org/10.3390/polym16030313

Chicago/Turabian StyleLiang, Xingyu, Tao Zhang, Junting Li, Wei Wang, Tiancheng Yuan, and Yanjun Li. 2024. "Fabrication of Mildew-Resistant Wood with Multi-Functional Properties Based on In Situ Growth of Metal–Organic Frameworks" Polymers 16, no. 3: 313. https://doi.org/10.3390/polym16030313