Functionalization Methods of Starch and Its Derivatives: From Old Limitations to New Possibilities

Abstract

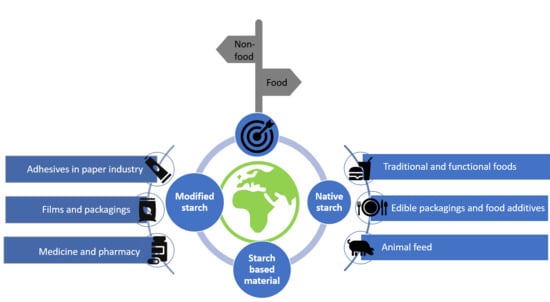

1. Introduction

2. Structure of Starch

3. Properties of Starch

4. Physical, Chemical, and Dual Modification of Starch

4.1. Development of New Resistant Starch and Pyrodextrins

4.1.1. Resistant Starch

- RS1—physically inaccessible starch mainly due to physical barriers formed by cell walls and protein matrices [82];

- RS2—starch that forms compact granules that resist digestive enzymes [83];

- RS3—retrograded starch formed during cooking and the subsequent cooling of starch or starchy products [84];

- RS4—chemically modified starch, i.e., starches which have been etherized, esterified, or cross-bonded with chemicals [85];

- RS5—natural or manufactured starch–lipid complexes [86].

4.1.2. Pyrodextrins

4.2. Progress in Synthesis of Amphiphilic Derivatives of Maltodextrin

4.3. Functionalization of Starch by Improving Its Hydrophobicity

4.3.1. Use of Lipases as Biocatalysts in Starch Esterification Reactions

| Type of Starch | Esterifying Agent | Enzyme | Solvent | Pretreatment | DS Max | Ref. |

|---|---|---|---|---|---|---|

| Corn starch | Palmitic acid | Novozym 435 (lipase B from Candida antarctica) | DMF/DMSO | - | 0.0072 | [228] |

| Corn starch | Palmitic acid | Novozym 435 | Solvent-free system | 9% aqueous NaOH/urea solution | 1.04 | [228] |

| Tapioca starch | Rosin acid | Novozym 435 | DMSO | Aqueous NaOH/urea solution | 0.106 | [229] |

| Tapioca starch | Rosin acid | Novozym 435 | DMSO | Aqueous NaOH/urea solution | 0.092 | [232] |

| Waxy corn starch | OSA—octenyl succinic anhydride | Novozym 435 | Water | Heating in distilled water (20–45%, w/w) | 0.0195 | [233] |

| Waxy corn starch | OSA—octenyl succinic anhydride | Novozym 435 | Water | Enzymatically treated native starch (β-amylase (300 U/g dry weight of starch) and transglucosidase (50 U/g dry weight of starch) | 0.0197 | [234] |

| Corn starch | Lauric acid | Lipase extracted from porcine pancreas | water | - | 0.0151 | [235] |

| High-amylose maize starch | Methyl palmitate | Candida rugosa lipase (E.C. 3.1.1.3.) (nominal activity: 739 U/mg enzyme) from Candida rugosa, type VII | Ionic liquids: 1-Butyl-3-methyl-imidazolium acetic ([BMIM]Ac) and 1-butyl-3-methyl-imidazolium tetraflouroborate ([BMIM] BF4) | Dissolution of dried starch in IL mixtures (1-butyl-3-methyl-imidazolium acetic ([BMIM]Ac) and 1-butyl-3-methyl-imidazolium tetraflouroborate ([BMIM]BF4)) and heating for 2 h at 120 °C | 0.144 | [231] |

| Potato starch | Oleic acid | Immobilized lipase from Thermomyces lanuginosus | 1-butyl-3-methylimidazolium chloride ([BMIM]Cl) | Pre-gelatinization in 1-butyl-3-methylimidazolium chloride ([BMIM]Cl) | 0.22 | [236] |

| Potato starch | Hydrolysates of high-oleic vegetable oils (pure and waste rapeseed oil) | Immobilized lipase from Thermomyces lanuginosus | 1-butyl-3-methylimidazolium chloride ([BMIM]Cl) | Pre-gelatinization in 1-butyl-3-methylimidazolium chloride ([BMIM]Cl) | 1.36 | [237] |

4.3.2. Use of Microwave Radiation in Starch Esterification Reactions

| Type of Starch | Esterifying Agent | Enzyme | Solvent | Pretreatment | DS Max | Ref. |

|---|---|---|---|---|---|---|

| Corn starches with different amylose/amylopectin ratios | Maleic (solid) and acetic (liquid) anhydrides | - | - | - | 0.274 | [239] |

| Corn starch | Citric acid | - | Distilled water | Enzymatic debranching of starch using pullulanase | - | [245] |

| Maize starch | Oleic acid | Non-commercial CaCO3-immobilized lipase from Staphylococcus aureus (SAL3) | Solvent free | Heating in distilled water (20–45%, w/w) | 2.86 | [246] |

| Corn starch | Oleic acid | Lipase of Rhizopus oryzae NRRL 3562 | Phosphate buffer (10 mM, pH 7); novel ionic liquid-type imidazolium cationic surfactants ((C16MIM)Br2, [C16-3-C16IM]Br2, and [C16-12-C16IM]Br2) | - | 2.75 | [247] |

| Maize starch | Acetic acid, lauric acid, and stearic acid | Commercial hog pancreas lipase (Sigma–Aldrich) with activity of 15–35 units/mg | DMSO, DMF | - | 0.514 | [248] |

| Potato starch | The acetic anhydride and glacial acetic acid (1:1 in volume) | - | Deionized water | Microwave pretreated | 0.073 | [242] |

4.4. Recent Developments in Selective Starch Oxidation

4.4.1. TEMPO-Mediated Oxidation of Starch

4.4.2. Dialdehyde Starch Preparation by Using Sodium Periodate

4.4.3. Hydroxyl Peroxide (H2O2) for Starch Oxidation

4.4.4. Physical and Chemical Combined Methods for Starch Oxidation

4.4.5. Electrochemical Methods for Starch Oxidation

5. Summary and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Das, A.; Ringu, T.; Ghosh, S.; Pramanik, N. A comprehensive review on recent advances in preparation, physicochemical characterization, and bioengineering applications of biopolymers. Polym. Bull. 2023, 80, 7247–7312. [Google Scholar] [CrossRef] [PubMed]

- Baranwal, J.; Barse, B.; Fais, A.; Delogu, G.L.; Kumar, A. Biopolymer: A Sustainable Material for Food and Medical Applications. Polymers 2022, 14, 983. [Google Scholar] [CrossRef] [PubMed]

- Globe Newswire. Available online: https://www.globenewswire.com/en/news-release/2023/02/28/2617539/28124/en/Starch-Global-Market-to-Reach-199-8-Million-Metric-Tons-by-2030-Use-of-Starch-as-a-Fat-Replacer-Drives-Growth.html (accessed on 14 December 2023).

- Maximize Market Research Pvt. Ltd. Available online: https://www.maximizemarketresearch.com/market-report/global-starch-market/112948/ (accessed on 14 December 2023).

- Tegge, G. Skrobia i Jej Pochodne; PTTZ Odział Malopolski: Krakow, Poland, 2010. (In Polish) [Google Scholar]

- Pérez, S.; Bertoft, E. The molecular structures of starch components and their contribution to the architecture of starch granules: A comprehensive review. Starch Stärke 2010, 62, 389–420. [Google Scholar] [CrossRef]

- Vamadevan, V.; Bertoft, E. Structure-function relationships of starch components. Starch Stärke 2014, 67, 55–68. [Google Scholar] [CrossRef]

- Bertoft, E.; Piyachomkwan, K.; Chatakanonda, P.; Sriroth, K. Internal unit chain composition in amylopectins. Carbohydr. Polym. 2008, 74, 527–543. [Google Scholar] [CrossRef]

- Robyt, J.F. Starch: Structure, Properties, Chemistry and Enzymology. In Glycoscience; Springer: Berlin/Heidelberg, Germany, 2008; pp. 1437–1472. [Google Scholar]

- Alcázar-Alay, S.C.; Meireles, M.A.A. Physicochemical properties, modifications and applications of starches from different botanical sources. Food Sci. Technol. 2015, 35, 215–236. [Google Scholar] [CrossRef]

- Hoover, R. Composition, molecular structure, and physicochemical properties of tuber and root starches: A review. Carbohydr. Polym. 2001, 45, 253–267. [Google Scholar] [CrossRef]

- Yusuph, M.; Tester, R.F.; Ansell, R.; Snape, C.E. Composition and properties of starches extracted from tubers of different potato varieties grown under the same environmental conditions. Food Chem. 2003, 82, 283–289. [Google Scholar] [CrossRef]

- Srichuwong, S.; Sunarti, T.C.; Mishima, T.; Isono, N.; Hisamatsu, M. Starches from different botanical sources I: Contribution of amylopectin fine structure to thermal properties and enzyme digestibility. Carbohydr. Polym. 2005, 60, 529–538. [Google Scholar] [CrossRef]

- Mitrus, M.; Wojtowicz, A.; Moscicki, L. Biodegradable Polymers and Their Practical Utility. In Thermoplastic Starch: A Green Material for Various Industries; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2009; pp. 1–33. [Google Scholar]

- Matsushima, R. Morphological Variations of Starch Grains. In Starch; Springer: Tokyo, Japan, 2015. [Google Scholar] [CrossRef]

- Bertoft, E. Understanding Starch Structure: Recent Progress. Agronomy 2017, 7, 56. [Google Scholar] [CrossRef]

- Kong, L.; Lee, C.; Kim, S.; Ziegler, G. Characterization of Starch Polymorphic Structures Using Vibrational Sum Frequency Generation Spectroscopy. J. Phys. Chem. B 2014, 118, 1775–1783. [Google Scholar] [CrossRef]

- Bashir, K.; Aggarwal, M. Physicochemical, structural and functional properties of native and irradiated starch: A review. J. Food. Sci. Technol. 2019, 56, 513–523. [Google Scholar] [CrossRef]

- Ai, Y.; Jane, J. Understanding Starch Structure and Functionality. In Woodhead Publishing Series in Food Science, Technology and Nutrition, Starch in Food; Woodhead Publishing: Sawston, UK, 2018; pp. 151–178. [Google Scholar]

- Carlstedt, J.; Wojtasz, J.; Fyhr, P.; Kocherbitov, V. Understanding starch gelatinization: The phase diagram approach. Carbohyd. Polym. 2015, 129, 62–69. [Google Scholar] [CrossRef]

- Ai, Y.; Jane, J. Gelatinization and rheological properties of starch. Starch Starke 2015, 67, 213–224. [Google Scholar] [CrossRef]

- Singh, S.; Singh, N.; Isono, N.; Noda, T. Relationship of granule size distribution and amylopectin structure with pasting, thermal, and retrogradation properties in wheat starch. J. Agric. Food Chem. 2010, 58, 1180–1188. [Google Scholar] [CrossRef]

- Singh, N.; Singh, J.; Kaur, L.; Sodhi, N.S.; Gill, B.S. Morphological, thermal and rheological properties of starches from different botanical sources. Food Chem. 2003, 81, 219–231. [Google Scholar] [CrossRef]

- Gao, J.; Luo, Z.G.; Luo, F.X. Ionic liquids as solvents for dissolution of corn starch and homogeneous synthesis of fatty-acid starch esters without catalysts. Carbohyd. Polym. 2012, 89, 1215–1221. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Picchioni, F. Modification of starch: A review on the application of “green” solvents and controlled functionalization. Carbohyd. Polym. 2020, 241, 116350. [Google Scholar] [CrossRef]

- El Seoud, O.A.; Koschella, A.; Fidale, L.C.; Dorn, S.; Heinze, T. Applications of ionic liquids in carbohydrate chemistry: A window of opportunities. Biomacromolecules 2007, 8, 2629–2647. [Google Scholar] [CrossRef]

- Ptak, S.; Zarski, A.; Kapusniak, J. The Importance of Ionic Liquids in the Modification of Starch and Processing of Starch-Based Materials. Materials 2020, 13, 4479. [Google Scholar] [CrossRef] [PubMed]

- Wilpiszewska, K.; Spychaj, T. Ionic liquids: Media for starch dissolution, plasticization and modification. Carbohyd. Polym. 2011, 86, 424–428. [Google Scholar] [CrossRef]

- Pawłowska, B.; Telesiński, A.; Biczak, R. Phytotoxicity of ionic liquids. Chemosphere 2019, 237, 124436. [Google Scholar] [CrossRef]

- Gonçalves, A.R.P.; Paredes, X.; Cristino, A.F.; Santos, F.J.V.; Queirós, C.S.G.P. Ionic Liquids-A Review of Their Toxicity to Living Organisms. Int. J. Mol. Sci. 2021, 22, 5612. [Google Scholar] [CrossRef]

- Kaar, J.L.; Jesionowski, A.M.; Berberich, J.A.; Moulton, R.; Russell, A.J. Impact of ionic liquid physical properties on lipase activity and stability. J. Am. Chem. Soc. 2003, 125, 4125–4131. [Google Scholar] [CrossRef]

- Muljana, H.; Picchioni, F.; Heeres, H.J.; Janssen, L.P.B.M. Supercritical carbon dioxide (scCO2) induced gelatinization of potato starch. Carbohyd. Polym. 2009, 78, 511–519. [Google Scholar] [CrossRef]

- Zaidul, I.S.M.; Noda, T.; Sharif, K.M.; Karim, A.A.; Smith, R.L. Reduction of gelatinization temperatures of starch blend suspensions with supercritical CO2 treatment. J. Supercrit. Fluids 2014, 95, 499–505. [Google Scholar] [CrossRef]

- Muljana, H.; van der Knoop, S.; Keijzer, D.; Picchioni, F.; Janssen, L.P.B.M.; Heeres, H.J. Synthesis of fatty acid starch esters in supercritical carbon dioxide. Carbohyd. Polym. 2010, 82, 346–354. [Google Scholar] [CrossRef]

- Muljana, H.; Picchioni, F.; Knez, Z.; Heeres, H.J.; Janssen, L.P.B.M. Insights in starch acetylation in sub- and supercritical CO2. Carbohyd. Res. 2011, 346, 1224–1231. [Google Scholar] [CrossRef] [PubMed]

- Salimi, K.; Yilmaz, M.; Rzayev, Z.M.; Piskin, E. Controlled graft copolymerization of lactic acid onto starch in a supercritical carbon dioxide medium. Carbohyd. Polym. 2014, 114, 149–156. [Google Scholar] [CrossRef]

- Ayoub, A.; Rizvi, S.S.H. Properties of supercritical fluid extrusion-based crosslinked starch extrudates. J. Appl. Polym. Sci. 2008, 107, 3663–3671. [Google Scholar] [CrossRef]

- Ayoub, A.; Rizvi, S.S.H. Reactive supercritical fluid extrusion for development of moisture resistant starch-based foams. J. Appl. Polym. Sci. 2011, 120, 2242–2250. [Google Scholar] [CrossRef]

- Manoi, K.; Rizvi, S.S.H. Physicochemical characteristics of phosphorylated cross-linked starch produced by reactive supercritical fluid extrusion. Carbohyd. Polym. 2010, 81, 687–694. [Google Scholar] [CrossRef]

- Flieger, J.; Flieger, M. Ionic Liquids Toxicity-Benefits and Threats. Int. J. Mol. Sci. 2020, 21, 6267. [Google Scholar] [CrossRef]

- Hu, X.-P.; Zhang, B.; Jin, Z.-Y.; Xu, X.-M.; Chen, H.-Q. Effect of high hydrostatic pressure and retrogradation treatments on structural and physicochemical properties of waxy wheat starch. Food Chem. 2017, 232, 560–565. [Google Scholar] [CrossRef]

- La Fuente, C.I.; de Souza, A.T.; Tadini, C.C.; Augusto, P.E.D. Ozonation of cassava starch to produce biodegradable films. Int. J. Biol. Macromol. 2019, 141, 713–720. [Google Scholar] [CrossRef] [PubMed]

- Sifuentes-Nieves, I.; Neira-Velázquez, G.; Hernández-Hernández, E.; Barriga-Castro, E.; Gallardo-Vega, C.; Velazquez, G.; Mendez-Montealvo, G. Influence of gelatinization process and HMDSO plasma treatment on the chemical changes and water vapor permeability of corn starch films. Int. J. Biol. Macromol. 2019, 135, 196–202. [Google Scholar] [CrossRef] [PubMed]

- Sifuentes-Nieves, I.; Velazquez, G.; Flores-Silva, P.C.; Hernández-Hernández, E.; Neira-Velázquez, G.; Gallardo-Vega, C.; Mendez- Montealvo, G. HMDSO plasma treatment as alternative to modify structural properties of granular starch. Int. J. Biol. Macromol. 2020, 144, 682–689. [Google Scholar] [CrossRef]

- Wu, Z.; Qiao, D.; Zhao, S.; Lin, Q.; Zhang, B.; Xie, F. Nonthermal physical modification of starch: An overview of recent research into structure and property alterations. Int. J. Biol. Macromol. 2022, 203, 153–175. [Google Scholar] [CrossRef] [PubMed]

- Ismailoglu, S.O.; Basman, A. Effects of infrared heat-moisture treatment on physicochemical properties of corn starch. Starch Starke 2015, 67, 528–539. [Google Scholar] [CrossRef]

- Ismailoglu, S.O.; Basman, A. Physicochemical properties of infrared heat moisture treated wheat starch. Starch-Starke 2016, 68, 67–75. [Google Scholar] [CrossRef]

- Yan, X.; Wu, Z.Z.; Li, M.Y.; Yin, F.; Ren, K.X.; Tao, H. The combined effects of extrusion and heat-moisture treatment on the physicochemical properties and digestibility of corn starch. Int. J. Biol. Macromol. 2019, 134, 1108–1112. [Google Scholar] [CrossRef] [PubMed]

- Devi, R.; Sit, N. Effect of single and dual steps annealing in combination with hydroxypropylation on physicochemical, functional and rheological properties of barley starch. Int. J. Biol. Macromol. 2019, 129, 1006–1014. [Google Scholar] [CrossRef] [PubMed]

- Maior, L.O.; Almeida, V.S.; Barretti, B.R.V.; Ito, V.C.; Beninca, C.; Demiate, I.M.; Lacerda, L.G. Combination of organic acid and heat–moisture treatment: Impact on the thermal, structural, pasting properties and digestibility of maize starch. J. Therm. Anal. Calorim. 2020, 143, 265–273. [Google Scholar] [CrossRef]

- Reyes, I.; Hernandez-Jaimes, C.; Meraz, M.; Vernon-Carter, E.J.; Alvarez-Ramirez, J. Effect of combined heat-moisture/lactic acid treatment on the physicochemical and in vitro digestibility properties of corn starch. Starch Starke 2021, 73, 2000147. [Google Scholar] [CrossRef]

- Yassaroh, Y.; Nurhaini, F.F.; Woortman, A.J.J.; Loos, K. Physicochemical properties of heat-moisture treated, sodium stearate complexed starch: The effect of sodium stearate concentration. Carbohyd. Polym. 2021, 269, 118263. [Google Scholar] [CrossRef]

- Fonseca, L.M.; El Halal, S.L.M.; Dias, A.R.G.; da Rosa Zavareze, E. Physical modification of starch by heat-moisture treatment and annealing and their applications: A review. Carbohyd. Polym. 2021, 274, 118665. [Google Scholar] [CrossRef] [PubMed]

- García-Guzmán, L.; Cabrera-Barjas, G.; Soria-Hernández, C.G.; Castaño, J.; Guadarrama-Lezama, A.Y.; Rodríguez Llamazares, S. Progress in Starch-Based Materials for Food Packaging Applications. Polysaccharides 2022, 3, 136–177. [Google Scholar] [CrossRef]

- Ghosh, S.; Sinha, J.K.; Ghosh, S.; Vashisth, K.; Han, S.; Bhaskar, R. Microplastics as an Emerging Threat to the Global Environment and Human Health. Sustainability 2023, 15, 10821. [Google Scholar] [CrossRef]

- Zarski, A.; Bajer, K.; Kapuśniak, J. Review of the Most Important Methods of Improving the Processing Properties of Starch toward Non-Food Applications. Polymers 2021, 13, 832. [Google Scholar] [CrossRef]

- Muñoz-Gimena, P.F.; Oliver-Cuenca, V.; Peponi, L.; López, D. A Review on Reinforcements and Additives in Starch-Based Composites for Food Packaging. Polymers 2023, 15, 2972. [Google Scholar] [CrossRef]

- Le Corre, D.; Bras, J.; Dufresne, A. Starch nanoparticles: A review. Biomacromolecules 2010, 11, 1139–1153. [Google Scholar] [CrossRef] [PubMed]

- Dufresne, A.; Castaño, J. Polysaccharide nanomaterial reinforced starch nanocomposites: A review. Starch Stärke 2017, 69, 1500307. [Google Scholar] [CrossRef]

- Wang, W.; Jin, X.; Zhu, Y.; Zhu, C.; Yang, J.; Wang, H.; Lin, T. Effect of vapor-phase glutaraldehyde crosslinking on electrospun starch fibers. Carbohydr. Polym. 2016, 140, 356–361. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Samanta, A.; Srivastava, R.K.; Hakkarainen, M. Starch-Derived Nanographene Oxide Paves the Way for Electrospinnable and Bioactive Starch Scaffolds for Bone Tissue Engineering. Biomacromolecules 2017, 18, 1582–1591. [Google Scholar] [CrossRef]

- Komur, B.; Bayrak, F.; Ekren, N.; Eroglu, M.; Oktar, F.N.; Sinirlioglu, Z.; Yucel, S.; Guler, O.; Gunduz, O. Starch/PCL composite nanofibers by coaxial electrospinning technique for biomedical applications. Biomed. Eng. Online 2017, 16, 40. [Google Scholar] [CrossRef] [PubMed]

- Noh, G.J.; Lim, S.A.; Lee, E.S. pH-responsive squeezing polysaccharidic nanogels for efficient docetaxel delivery. Polym. Adv. Technol. 2019, 30, 2067–2074. [Google Scholar] [CrossRef]

- Liang, T.; Hou, J.; Qu, M.; Zhao, M.; Raj, I. High-viscosity α—Starch nanogel particles to enhance oil recovery. RSC Adv. 2020, 10, 8275–8285. [Google Scholar] [CrossRef]

- Ying, X.; Shan, C.; Jiang, K.; Chen, Z.; Du, Y. Intracellular pH-sensitive delivery CaCO3 nanoparticles templated by hydrophobic modified starch micelles. RSC Adv. 2014, 4, 10841–10844. [Google Scholar] [CrossRef]

- Liu, W.; Li, Y.; Goff, H.D.; Nsor-Atindana, J.; Ma, J.; Zhong, F. Interfacial activity and self-assembly behavior of dissolved and granular octenyl succinate anhydride starches. Langmuir 2019, 35, 4702–4709. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Z.; Huang, L. pH and thermo dual-responsive starch-g-P(DEAEMA-co-PEGMA): Synthesis via SET-LRP, selfassembly and drug release behaviors. React. Funct. Polym. 2019, 141, 165–171. [Google Scholar] [CrossRef]

- Kumari, A.; Yadav, S.K.; Yadav, S.C. Biodegradable polymeric nanoparticles based drug delivery systems. Colloids Surf. B Biointerfaces 2010, 75, 1–18. [Google Scholar] [CrossRef]

- Chen, Y.F.; Kaur, L.; Singh, J. Chemical Modification of Starch. In Starch in Food, 2nd ed.; Sjoo, M., Nilsson, L., Eds.; Woodhead Publishing: Sawston, UK, 2018; pp. 283–321. [Google Scholar]

- Amaraweera, S.M.; Gunathilake, C.; Gunawardene, O.H.P.; Fernando, N.M.L.; Wanninayaka, D.B.; Dassanayake, R.S.; Rajapaksha, S.M.; Manamperi, A.; Fernando, C.A.N.; Kulatunga, A.K.; et al. Development of Starch-Based Materials Using Current Modification Techniques and Their Applications: A Review. Molecules 2021, 26, 6880. [Google Scholar] [CrossRef]

- Shokri, Z.; Seidi, F.; Reza Saeb, M.; Jin, Y.; Li, C.; Xiao, H. Elucidating the impact of enzymatic modifications on the structure, properties, and applications of cellulose, chitosan, starch and their derivatives: A review. Mater. Today Chem. 2022, 24, 100780. [Google Scholar] [CrossRef]

- Tomasik, P.; Schilling, C.H. Chemical modification of starch. Adv. Carbohydr. Chem. Biochem. 2004, 59, 175–204. [Google Scholar]

- Wang, L.; Qu, L.; Wu, Y.; Men, Y.; Liu, Z. Synthesis of regioselective starch based macroinitiators at molecular level. Starch Starke 2017, 69, 1700043. [Google Scholar] [CrossRef]

- Tan, W.; Li, Q.; Gao, Z.; Qiu, S.; Dong, F.; Guo, Z. Design, synthesis of novel starch derivative bearing 1,2,3-triazolium and pyridinium and evaluation of its antifungal activity. Carbohyd. Polym. 2017, 157, 236–243. [Google Scholar] [CrossRef]

- Brownlee, I.A.; Gill, S.; Wilcox, M.D.; Pearson, J.P.; Chater, P.I. Starch digestion in the upper gastrointestinal tract of humans. Starke 2018, 70, 1700111. [Google Scholar] [CrossRef]

- Birt, D.F.; Boylston, T.; Hendrich, S.; Jane, J.L.; Hollis, J.; Li, L.; McClelland, J.; Moore, S.; Phillips, G.J.; Rowling, M.; et al. Resistant starch: Promise for improving human health. Adv. Nutr. 2013, 4, 587–601. [Google Scholar] [CrossRef] [PubMed]

- Cerqueira, F.M.; Photenhauer, A.L.; Pollet, R.M.; Brown, H.A. Starch Digestion by Gut Bacteria: Crowdsourcing for Carbs. Trends Microbiol. 2019, 28, 95–108. [Google Scholar] [CrossRef]

- Fuller, S.; Beck, E.; Salman, H.; Tapsell, L. New Horizons for the Study of Dietary Fiber and Health: A Review. Plant Foods Hum. Nutr. 2016, 71, 1–12. [Google Scholar] [CrossRef]

- Dhingra, D.; Michael, M.; Rajput, H.; Patil, R.T. Dietary fibre in foods: A review. J. Food Sci. Technol. 2012, 49, 255–266. [Google Scholar] [CrossRef]

- Granato, D.; Barba, F.J.; Kovačević, D.B.; Lorenzo, J.M.; Cruz, A.G.; Putnik, P. Functional Foods: Product Development, Technological Trends, Efficacy Testing, and Safety. Annu. Rev. Food Sci. Technol. 2020, 11, 93–118. [Google Scholar] [CrossRef]

- Gibson, G.; Hutkins, R.; Sanders, M.E.; Prescott, S.L.; Reimer, R.A.; Salminen, S.J.; Scott, K.; Stanton, C.; Swanson, K.S.; Cani, P.D.; et al. Expert consensus document: The International Scientific Association for Probiotics and Prebiotics (ISAPP) consensus statement on the definition and scope of prebiotics. Nat. Rev. Gastroenterol. Hepatol. 2017, 14, 491–502. [Google Scholar] [CrossRef] [PubMed]

- Kraithong, S.; Wang, S.; Junejo, S.A.; Fu, X.; Theppawong, A.; Zhang, B.; Huang, Q. Type 1 resistant starch: Nutritional properties and industry applications. Food Hydrocoll. 2022, 125, 107369. [Google Scholar] [CrossRef]

- Bendiks, Z.A.; Knudsen, K.E.B.; Keenan, M.J.; Marco, M.L. Conserved and variable responses of the gut microbiome to resistant starch type 2. Nutr. Res. 2020, 77, 12–28. [Google Scholar] [CrossRef] [PubMed]

- Lockyer, S.; Nugent, A.P. Health effects of resistant starch. Nutr. Bull. 2017, 42, 10–41. [Google Scholar] [CrossRef]

- Raigond, P.; Ezekiel, R.; Raigond, B. Resistant starch in food: A review. J. Sci. Food Agric. 2015, 95, 1968–1978. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez, T.J.; Tovar, J. Update of the concept of type 5 resistant starch (RS5): Self-assembled starch V-type complexes. Trends Food Sci. Technol. 2021, 109, 711–724. [Google Scholar] [CrossRef]

- Ze, X.; Duncan, S.H.; Louis, P.; Flint, H.J. Ruminococcus bromii is a keystone species for the degradation of resistant starch in the human colon. ISME J. 2012, 6, 1535–1543. [Google Scholar] [CrossRef] [PubMed]

- Deehan, E.C.; Yang, C.; Perez-Muñoz, M.E.; Nguyen, N.K.; Cheng, C.C.; Triador, L.; Zhang, Z.; Bakal, J.A.; Walter, J. Precision Microbiome Modulation with Discrete Dietary Fiber Structures Directs Short-Chain Fatty Acid Production. Cell Host Microbe 2020, 27, 389–404.e6. [Google Scholar] [CrossRef]

- Do, M.H.; Seo, Y.S.; Park, H.-Y. Polysaccharides: Bowel health and gut microbiota. Crit. Rev. Food Sci. 2020, 61, 1212–1224. [Google Scholar] [CrossRef] [PubMed]

- Jaiturong, P.; Laosirisathian, N.; Sirithunyalug, B.; Eitssayeam, C.; Sirilun, S.; Chaiyana, W.; Sirithunyalug, J. Physicochemical and prebiotic properties of resistant starch from Musa sapientum Linn., ABB group, cv. Kluai Namwa Luang. Heliyon 2020, 6, e05789. [Google Scholar] [CrossRef] [PubMed]

- Noor, N.; Gani, A.; Jhan, F.; Jenno, J.L.H.; Dar, M.A. Resistant starch type 2 from lotus stem: Ultrasonic effect on physical and nutraceutical properties. Ultrason. Sonochem. 2021, 76, 105655. [Google Scholar] [CrossRef] [PubMed]

- Chang, D.; Hu, X.; Ma, Z. Pea-Resistant Starch with Different Multi-scale Structural Features Attenuates the Obesity-Related Physiological Changes in High-Fat Diet Mice. J. Agric. Food Chem. 2022, 70, 11377–11390. [Google Scholar] [CrossRef] [PubMed]

- Cheng, F.; Ren, Y.; Warkentin, T.D.; Ai, Y. Heat-Moisture Treatment to Modify Structure and Functionality and Reduce Digestibility of Wrinkled and Round Pea Starches. Carbohydr. Polym. 2024, 324, 121506. [Google Scholar] [CrossRef] [PubMed]

- Rashid, R.S.A.; Mohamed, A.M.D.; Achudan, S.N.; Mittis, P. Physicochemical properties of resistant starch type III from sago starch at different palm stages. Mater. Today Proc. 2020, 31, 150–154. [Google Scholar] [CrossRef]

- Thakur, M.; Rai, A.K.; Mishra, B.B.; Singh, S.P. Novel insight into valorization of potato peel biomass into type III resistant starch and maltooligosaccharide molecules. Environ. Technol. Innov. 2021, 24, 101827. [Google Scholar] [CrossRef]

- Khan, A.; Siddiqui, S.; Rahman, U.U.; Ali, H.; Saba, M.; Azhar, F.A.; Rehman, M.M.U.; Shah, A.A.; Badshah, M.; Hasan, F.; et al. Physicochemical properties of enzymatically prepared resistant starch from maize flour and its use in cookies formulation. Int. J. Food Prop. 2020, 23, 549–569. [Google Scholar] [CrossRef]

- Khan, A.; Rahman, U.U.; Siddiqui, S.; Irfan, M.; Shah, A.A.; Badshah, M.; Hasan, F.; Khan, S. Preparation and characterization of resistant starch type III from enzymatically hydrolyzed maize flour. Mol. Biol. Rep. 2019, 46, 4565–4580. [Google Scholar] [CrossRef]

- Li, L.; Yuan, T.Z.; Ai, Y. Development, structure and in vitro digestibility of type 3 resistant starch from acid-thinned and debranched pea and normal maize starches. Food Chem. 2020, 318, 126485. [Google Scholar] [CrossRef]

- Klostermann, C.E.; Buwalda, P.L.; Leemhuis, H.; de Vos, P.; Schols, H.A.; Bitter, J.H. Digestibility of resistant starch type 3 is affected by crystal type, molecular weight and molecular weight distribution. Carbohyd. Polym. 2021, 265, 118069. [Google Scholar] [CrossRef]

- Silva Lagos, L.; Klostermann, C.E.; López-Velázquez, G.; Fernández-Lainez, C.; Leemhuis, H.; Oudhuis, A.A.C.M.L.; Buwalda, P.; Schols, H.A.; de Vos, P. Crystal Type, Chain Length and Polydispersity Impact the Resistant Starch Type 3 Immunomodulatory Capacity via Toll-like Receptors. Carbohyd. Polym. 2024, 324, 121490. [Google Scholar] [CrossRef] [PubMed]

- Yan, X.; Diao, M.; Yu, Y.; Gao, F.; Wang, E.; Wang, Z.; Zhang, T.; Zhao, P. Characterization of resistant starch nanoparticles prepared via debranching and nanoprecipitation. Food Chem. 2022, 369, 130824. [Google Scholar] [CrossRef] [PubMed]

- Zi-Ni, T.; Rosma, A.; Napisah, H.; Karim, A.A.; Liong, M.-T. Characteristics of Metroxylon sagu Resistant Starch Type III as Prebiotic Substance. J. Food Sci. 2015, 80, H875–H882. [Google Scholar] [CrossRef] [PubMed]

- Ratnaningsih, N.; Suparmo; Harmayani, E.; Marsono, Y. Physicochemical properties, in vitro starch digestibility, and estimated glycemic index of resistant starch from cowpea (Vigna unguiculata) starch by autoclaving-cooling cycles. Int. J. Biol. Macromol. 2020, 142, 191–200. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Chung, H.-J.; Kim, J.-Y.; Lim, S.-T. In vitro analyses of resistant starch in retrograded waxy and normal corn starches. Int. J. Biol. Macromol. 2013, 55, 113–117. [Google Scholar] [CrossRef] [PubMed]

- Shen, R.-L.; Zhang, W.-J.; Dong, J.-L. Preparation, structural characteristics and digestibility of resistant starches from highland barley, oats and buckwheat starches. J. Food Nutr. Res. 2016, 55, 303–312. [Google Scholar]

- Adra, H.J.; Zhi, J.; Luo, K.; Kim, Y.R. Facile Preparation of Highly Uniform Type 3 Resistant Starch Nanoparticles. Carbohydr. Polym. 2022, 294, 119842. [Google Scholar] [CrossRef]

- Thakur, M.; Sharma, N.; Rai, A.K.; Singh, S.P. A novel cold-active type I pullulanase from a hot-spring metagenome for effective debranching and production of resistant starch. Bioresour. Technol. 2021, 320, 124288. [Google Scholar] [CrossRef]

- Simons, C.W.; Hall, C.; Vatansever, S. Production of resistant starch (RS3) from edible bean starches. J. Food Process Preserv. 2018, 42, e13587. [Google Scholar] [CrossRef]

- Giuberti, G.; Gallo, A. In vitro evaluation of fermentation characteristics of type 3 resistant starch. Heliyon 2020, 6, e03145. [Google Scholar] [CrossRef] [PubMed]

- Masatcioglu, T.M.; Sumer, Z.; Koksel, H. An innovative approach for significantly increasing enzyme resistant starch type 3 content in high amylose starches by using extrusion cooking. J. Cereal Sci. 2017, 74, 95–102. [Google Scholar] [CrossRef]

- Khawas, P.; Deka, S.C. Effect of modified resistant starch of culinary banana on physicochemical, functional, morphological, diffraction, and thermal properties. Int. J. Food Prop. 2017, 20, 133–150. [Google Scholar] [CrossRef]

- Chang, R.; Lu, H.; Bian, X.; Tian, Y.; Jin, Z. Ultrasound assisted annealing production of resistant starches type 3 from fractionated debranched starch: Structural characterization and in-vitro digestibility. Food Hydrocoll. 2021, 110, 106141. [Google Scholar] [CrossRef]

- Zeng, H.; Chen, P.; Chen, C.; Huang, C.; Lin, S.; Zheng, B.; Zhang, Y. Structural properties and prebiotic activities of fractionated lotus seed resistant starches. Food Chem. 2018, 251, 33–40. [Google Scholar] [CrossRef] [PubMed]

- Sari, P.M.; Uttapap, D.; Wandee, Y.; Kotatha, D.; Udchumpisai, W.; Puttanlek, C.; Rungsardthong, V. Powder structure and gelation behaviour of debranched cassava starches prepared with and without incubation. Int. J. Food Sci. Technol. 2022, 57, 6445–6458. [Google Scholar] [CrossRef]

- Faridah, D.N.; Frista, S.R.; Dias, I.; Ahmad, A.F.; Anuraga, J.; Putri, A.M. Verification of autoclaving-cooling treatment to increase the resistant starch contents in food starches based on meta-analysis result. Front. Nutr. 2022, 9, 904700. [Google Scholar] [CrossRef]

- Li, Y.; Xu, J.; Zhang, L.; Ding, Z.; Gu, Z.; Shi, G. Investigation of debranching pattern of a thermostable isoamylase and its application for the production of resistant starch. Carbohyd Res. 2017, 446–447, 93–100. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Zheng, B.; Lu, X.; Zhuang, W. The in vitro effects of retrograded starch (resistant starch type 3) from lotus seed starch on the proliferation of Bifidobacterium adolescentis. Food Funct. 2013, 4, 1609–1616. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, S.; Huang, Z.; Yuan, Y.; Miao, S.; Zhang, Y.; Zeng, H.; Zheng, B.; Deng, K. Difference in the adhesion of Bifidobacterium breve to lotus seed resistant starch is attributable to its structural performance conferred by the preparation method. Int. J. Biol. Macromol. 2022, 195, 309–316. [Google Scholar] [CrossRef]

- Shah, A.; Masoodi, F.A.; Gani, A.; Ashwar, B.A. In-vitro digestibility, rheology, structure, and functionality of RS3 from oat starch. Food Chem. 2016, 212, 749–758. [Google Scholar] [CrossRef]

- Wu, C.; Zhou, X.; Wei, B.; Tian, Y.; Xu, X.; Jin, Z. Effects of α-maltotriohydrolase hydrolysis prior to debranching on the structure and digestibility of normal maize starch. Starch Stärke 2017, 69, 1600078. [Google Scholar] [CrossRef]

- Suárez-Diéguez, T.; Pérez-Moreno, F.; Ariza-Ortega, J.A.; López-Rodríguez, G.; Nieto, J.A. Obtention and characterization of resistant starch from creole faba bean (Vicia faba L. creole) as a promising functional ingredient. LWT 2021, 145, 111247. [Google Scholar] [CrossRef]

- Villas-Boas, F.; Facchinatto, W.M.; Colnago, L.A.; Volanti, D.P.; Franco, C.M.L. Effect of amylolysis on the formation, the molecular, crystalline and thermal characteristics and the digestibility of retrograded starches. Int. J. Biol. Macromol. 2020, 163, 1333–1343. [Google Scholar] [CrossRef] [PubMed]

- Shaikh, F.; Ali, T.M.; Mustafa, G.; Hasnain, A. Structural, functional and digestibility characteristics of sorghum and corn starch extrudates (RS3) as affected by cold storage time. Int. J. Biol. Macromol. 2020, 164, 3048–3054. [Google Scholar] [CrossRef] [PubMed]

- You, Q.; Zhang, X.; Fang, X.; Yin, X.; Luo, C.; Wan, M. Ultrasonic-Assisted Preparation and Characterization of RS3 from Pea Starch. Food Bioprocess. Technol. 2019, 12, 1244–1249. [Google Scholar] [CrossRef]

- Liao, H.-J.; Hung, C.-C. Chemical composition and in vitro starch digestibility of green banana (cv. Giant Cavendish) flour and its derived autoclaved/debranched powder. LWT Food Sci. Technol. 2015, 64, 639–644. [Google Scholar] [CrossRef]

- Gong, M.; Li, X.; Xiong, L.; Sun, Q. Retrogradation property of starch nanoparticles prepared by pullulanase and recrystallization. Starch Stärke 2016, 68, 230–238. [Google Scholar] [CrossRef]

- Zięba, T.; Kapelko, M.; Szumny, A. Effect of preparation method on the properties of potato starch acetates with an equal degree of substitution. Carbohyd. Polym. 2013, 94, 193–198. [Google Scholar] [CrossRef]

- Zięba, T.; Kapelko-Żeberska, M.; Gryszkin, A.; Wilczak, A.; Raszewski, B.; Spychaj, R. Effect of the Botanical Origin on Properties of RS3/4 Type Resistant Starch. Polymers 2019, 11, 81. [Google Scholar] [CrossRef]

- Kapelko, M.; Zięba, T.; Gryszkin, A.; Styczyńska, M.; Wilczak, A. Properties of retrograded and acetylated starch produced via starch extrusion or starch hydrolysis with pullulanase. Carbohydr. Polym. 2013, 97, 551–557. [Google Scholar] [CrossRef]

- Kapelko, M.; Zięba, T.; Michalski, A.; Gryszkin, A. Effect of cross-linking degree on selected properties of retrograded starch adipate. Food Chem. 2015, 167, 124–130. [Google Scholar] [CrossRef] [PubMed]

- Kapelko-Żeberska, M.; Zięba, T.; Spychaj, R.; Gryszkin, A. Acetylated adipate of retrograded starch as RS 3/4 type resistant starch. Food Chem. 2015, 188, 365–369. [Google Scholar] [CrossRef]

- Kapelko-Żeberska, M.; Zięba, T.; Spychaj, R.; Gryszkin, A. Selected Rheological Properties of RS3/4 Type Resistant Starch. Pol. J. Food Nutr. Sci. 2017, 67, 293–299. [Google Scholar] [CrossRef]

- Remya, R.; Jyothi, A.N.; Sreekumar, J. Comparative study of RS4 type resistant starches derived from cassava and potato starches via octenyl succinylation. Starch Stärke 2017, 69, 1600264. [Google Scholar] [CrossRef]

- Remya, R.; Jyothi, A.N.; Sreekumar, J. Morphological, structural and digestibility properties of RS4 enriched octenyl succinylated sweet potato, banana and lentil starches. Food Hydrocoll. 2018, 82, 219–229. [Google Scholar] [CrossRef]

- Carolina, A.; Ilmi, F. Production of Indonesian Canna edulis Type IV resistant starch through acetylation modification. Int. Food Res. J. 2016, 23, 491–497. [Google Scholar]

- Escobar-Puentes, A.; Rincón, S.; García-Gurrola, A.; Zepeda, A.; Calvo-López, A.D.; Martínez-Bustos, F. Development of a Third-Generation Snack with Type 4 Resistant Sorghum Starch: Physicochemical and Sensorial Properties. Food Biosci. 2019, 32, 100474. [Google Scholar] [CrossRef]

- Shi, M.; Gu, F.; Wu, J.; Yu, S.; Gao, Q. Preparation, physicochemical properties, and in vitro digestibility of cross-linked resistant starch from pea starch. Starch Stärke 2013, 65, 947–953. [Google Scholar] [CrossRef]

- Yu, M.; Shin, M. Improving gel formation of rice starch added with cross-linked resistant starch prepared from rice starch. Starch Stärke 2015, 67, 829–837. [Google Scholar] [CrossRef]

- Remya, R.; Jyothi, A.N.; Sreekumar, J. Effect of Chemical Modification with Citric Acid on the Physicochemical Properties and Resistant Starch Formation in Different Starches. Carbohydr. Polym. 2018, 202, 29–38. [Google Scholar] [CrossRef]

- Falsafi, S.R.; Maghsoudlou, Y.; Aalami, M.; Jafari, S.M.; Raeisi, M. Physicochemical and Morphological Properties of Resistant Starch Type 4 Prepared under Ultrasound and Conventional Conditions and Their In-Vitro and In-Vivo Digestibilities. Ultrason. Sonochem. 2019, 53, 110–119. [Google Scholar] [CrossRef]

- Calvo-López, A.D.; Martínez-Bustos, F. Optimization of Extrusion Process of Directly Expanded Snacks Based on Potato Starch in a Single Step for the Formation of Type IV Resistant Starch. Plant Foods Hum. Nutr. 2017, 72, 243–249. [Google Scholar] [CrossRef] [PubMed]

- Jeong, O.; Shin, M. Preparation and Stability of Resistant Starch Nanoparticles, Using Acid Hydrolysis and Cross-Linking of Waxy Rice Starch. Food Chem. 2018, 256, 77–84. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Wang, F.; Wang, J.; Wang, R.; Strappe, P.; Zheng, B.; Zhou, Z.; Chen, L. Manipulation of the Internal Structure of Starch by Propionyl Treatment and Its Diverse Influence on Digestion and in Vitro Fermentation Characteristics. Carbohydr. Polym. 2021, 270, 118390. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Wang, F.; Wang, J.; Wang, A.; Yao, X.; Strappe, P.; Zhou, Z.; Wu, Q.; Guo, T. Starch Acylation of Different Short-Chain Fatty Acids and Its Corresponding Influence on Gut Microbiome and Diabetic Indexes. Food Chem. 2022, 389, 133089. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Hu, A.; Li, J.; Liu, G.; Wang, M.; Zheng, J. Comparison of Physicochemical Properties and Digestibility of Sweet Potato Starch after Two Modifications of Microwave Alone and Microwave-Assisted L-Malic Acid. Int. J. Biol. Macromol. 2022, 210, 614–621. [Google Scholar] [CrossRef] [PubMed]

- Cao, C.; Wei, D.; Xuan, F.; Deng, C.; Hu, J.; Zhou, Y. Comparative Study on the Structure and Physicochemical of Waxy Rice Starch by Phosphorylation, Lactylation and Dual-Modified. Food Sci. Technol. 2022, 42, e18622. [Google Scholar] [CrossRef]

- Hedayati, S.; Niakousari, M. Microstructure, Pasting and Textural Properties of Wheat Starch-Corn Starch Citrate Composites. Food Hydrocoll. 2018, 81, 1–5. [Google Scholar] [CrossRef]

- Hong, J.; An, D.; Zeng, X.A.; Han, Z.; Zheng, X.; Cai, M.; Bian, K.; Aadil, R.M. Behaviors of Large A-Type and Small B-Type Wheat Starch Granules Esterified by Conventional and Pulsed Electric Fields Assisted Methods. Int. J. Biol. Macromol. 2020, 155, 516–523. [Google Scholar] [CrossRef]

- Oltramari, K.; Madrona, G.S.; Neto, A.M.; de Morais, G.R.; Baesso, M.L.; Bergamasco, R.; de Moraes, F.F. Citrate esterified cassava starch: Preparation, physicochemical characterisation, and application in dairy beverages. Starch Stärke 2017, 69, 1700044. [Google Scholar] [CrossRef]

- Zhong, C.; Xiong, Y.; Lu, H.; Luo, S.; Wu, J.; Ye, J.; Liu, C. Preparation and Characterization of Rice Starch Citrates by Superheated Steam: A New Strategy of Producing Resistant Starch. LWT 2022, 154, 112890. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, J.; Kong, J.; Wang, R.; Liu, M.; Strappe, P.; Blanchard, C.; Zhou, Z. Citrate esterification of debranched waxy maize starch: Structural, physicochemical and amylolysis properties. Food Hydrocoll. 2020, 104, 105704. [Google Scholar] [CrossRef]

- Ashwar, B.A.; Gani, A.; Shah, A.; Masoodi, F.A. Physicochemical Properties, in-Vitro Digestibility and Structural Elucidation of RS4 from Rice Starch. Int. J. Biol. Macromol. 2017, 105, 471–477. [Google Scholar] [CrossRef] [PubMed]

- Shah, A.; Masoodi, F.A.; Gani, A.; Ashwar, B.A. Physicochemical, Rheological and Structural Characterization of Acetylated Oat Starches. LWT 2017, 80, 19–26. [Google Scholar] [CrossRef]

- Ashwar, B.A.; Gani, A.; Shah, A.; Masoodi, F.A. Production of RS4 from rice by acetylation: Physico-chemical, thermal, and structural characterization. Starch Stärke 2017, 69, 1600052. [Google Scholar] [CrossRef]

- Dong, H.; Vasanthan, T. Amylase Resistance of Corn, Faba Bean, and Field Pea Starches as Influenced by Three Different Phosphorylation (Cross-Linking) Techniques. Food Hydrocoll. 2020, 101, 105506. [Google Scholar] [CrossRef]

- Tian, S.-Q.; Wang, Z.-L.; Wang, X.-W.; Zhao, R.-Y. Development and digestion of resistant malate starch produced by L-malic acid treatment. RSC Adv. 2016, 6, 96182–96189. [Google Scholar] [CrossRef]

- Wang, R.; Li, M.; Liu, J.; Wang, F.; Wang, J.; Zhou, Z. Dual Modification Manipulates Rice Starch Characteristics Following Debranching and Propionate Esterification. Food Hydrocoll. 2021, 119, 106833. [Google Scholar] [CrossRef]

- Okumus, B.N.; Tacer-Caba, Z.; Kahraman, K.; Nilufer-Erdil, D. Resistant Starch Type V Formation in Brown Lentil (Lens Culinaris Medikus) Starch with Different Lipids/Fatty Acids. Food Chem. 2018, 240, 550–558. [Google Scholar] [CrossRef]

- Krishnan, V.; Mondal, D.; Bollinedi, H.; Srivastava, S.; SV, R.; Madhavan, L.; Thomas, B.; R, A.T.; Singh, A.; Singh, A.K.; et al. Cooking Fat Types Alter the Inherent Glycaemic Response of Niche Rice Varieties through Resistant Starch (RS) Formation. Int. J. Biol. Macromol. 2020, 162, 1668–1681. [Google Scholar] [CrossRef]

- Chumsri, P.; Panpipat, W.; Cheong, L.-Z.; Chaijan, M. Formation of Intermediate Amylose Rice Starch–Lipid Complex Assisted by Ultrasonication. Foods 2022, 11, 2430. [Google Scholar] [CrossRef]

- Kang, X.; Jia, S.; Gao, W.; Wang, B.; Zhang, X.; Tian, Y.; Sun, Q.; Atef, M.; Cui, B.; Abd El-Aty, A.M. The Formation of Starch-Lipid Complexes by Microwave Heating. Food Chem. 2022, 382, 132319. [Google Scholar] [CrossRef]

- Raza, H.; Liang, Q.; Ameer, K.; Ma, H.; Ren, X. Dual-Frequency Power Ultrasound Effects on the Complexing Index, Physicochemical Properties, and Digestion Mechanism of Arrowhead Starch-Lipid Complexes. Ultrason. Sonochem. 2022, 84, 105978. [Google Scholar] [CrossRef]

- Li, X.; Gao, X.; Lu, J.; Mao, X.; Wang, Y.; Feng, D.; Cao, J.; Huang, L.; Gao, W. Complex Formation, Physicochemical Properties of Different Concentration of Palmitic Acid Yam (Dioscorea Pposita Thunb.) Starch Preparation Mixtures. LWT 2019, 101, 130–137. [Google Scholar] [CrossRef]

- Reddy, C.K.; Choi, S.M.; Lee, D.J.; Lim, S.T. Complex Formation between Starch and Stearic Acid: Effect of Enzymatic Debranching for Starch. Food Chem. 2018, 244, 136–142. [Google Scholar] [CrossRef]

- Chen, J.; Xiao, J.; Wang, Z.; Cheng, H.; Zhang, Y.; Lin, B.; Qin, L.; Bai, Y. Effects of Reaction Condition on Glycosidic Linkage Structure, Physical–Chemical Properties and in Vitro Digestibility of Pyrodextrins Prepared from Native Waxy Maize Starch. Food Chem. 2020, 320, 126491. [Google Scholar] [CrossRef] [PubMed]

- Trithavisup, K.; Shi, Y.C.; Krusong, K.; Tananuwong, K. Molecular Structure and Properties of Cassava-Based Resistant Maltodextrins. Food Chem. 2022, 369, 130876. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Ji, J.; Yang, L.; Lei, N.; Wang, J.; Sun, B. Structural and Physicochemical Property Changes during Pyroconversion of Native Maize Starch. Carbohydr. Polym. 2020, 245, 116560. [Google Scholar] [CrossRef] [PubMed]

- Weil, W.; Weil, R.C.; Keawsompong, S.; Sriroth, K.; Seib, P.A.; Shi, Y.C. Pyrodextrins from Waxy and Normal Tapioca Starches: Molecular Structure and in Vitro Digestibility. Carbohydr. Polym. 2021, 252, 117140. [Google Scholar] [CrossRef] [PubMed]

- Nunes, F.M.; Lopes, E.S.; Moreira, A.S.P.; Simões, J.; Coimbra, M.A.; Domingues, R.M. Formation of Type 4 Resistant Starch and Maltodextrins from Amylose and Amylopectin upon Dry Heating: A Model Study. Carbohydr. Polym. 2016, 141, 253–262. [Google Scholar] [CrossRef] [PubMed]

- Kapusniak, K.; Lubas, K.; Wojcik, M.; Rosicka-Kaczmarek, J.; Pavlyuk, V.; Kluziak, K.; Gonçalves, I.; Lopes, J.; Coimbra, M.A.; Kapusniak, J. Effect of Continuous and Discontinuous Microwave-Assisted Heating on Starch-Derived Dietary Fiber Production. Molecules 2021, 26, 5619. [Google Scholar] [CrossRef] [PubMed]

- Toraya-Avilés, R.; Segura-Campos, M.; Chel-Guerrero, L.; Betancur-Ancona, D. Some Nutritional Characteristics of Enzymatically Resistant Maltodextrin from Cassava (Manihot esculenta Crantz) Starch. Plant Foods Hum. Nutr. 2017, 72, 149–155. [Google Scholar] [CrossRef] [PubMed]

- Kapusniak, K.; Nebesny, E. Enzyme-resistant dextrins from potato starch for potential application in the beverage industry. Carbohydr. Polym. 2017, 172, 152–158. [Google Scholar] [CrossRef]

- Alvani, K.; Qi, X.; Tester, R.F. Use of carbohydrates, including dextrins, for oral delivery. Starch Stärke 2011, 63, 424–431. [Google Scholar] [CrossRef]

- Bai, Y.; Shi, Y.C. Chemical Structures in Pyrodextrin Determined by Nuclear Magnetic Resonance Spectroscopy. Carbohydr. Polym. 2016, 151, 426–433. [Google Scholar] [CrossRef] [PubMed]

- Olvera-Hernández, V.; Betancur-Ancona, D.; Chel-Guerrero, L.A.; Ble-Castillo, J.L.; Castellanos-Ruelas, A.F. Morphological and Physicochemical Changes in Great Dwarf Banana (Musa cavendish AAA) Starch Modified by Pyrodextrinization and Enzymatic Hydrolysis. Starch Stärke 2018, 70, 1700122. [Google Scholar] [CrossRef]

- Olvera Hernandez, V.; Ble Castillo, J.L.; Betancur Ancona, D.; Acevedo Fernandez, J.J.; Castellanos Ruelas, A.; Chel Guerrero, L. Effects of modified banana (Musa cavendish) starch on glycemic control and blood pressure in rats with high sucrose diet. Nutr. Hosp. 2018, 35, 588–595. [Google Scholar] [CrossRef]

- Ekaette, I.; Saldaña, M.D.A. Ultrasound-Assisted Modification of Rutin to Nanocrystals and Its Application in Barley Starch Pyrodextrinization. Food Chem. 2021, 344, 128626. [Google Scholar] [CrossRef]

- de Souza Oliveira, E.; Lovera, M.; Rios Pires, V.; da Silva Mendes, F.R.; Lima Peixoto Maia, N.V.; Viana Rodrigues, J.P.; Rocha Bastos, M.D.; Cheng, H.N.; Biswas, A.; de Azevedo Moreira, R.; et al. Effect of acid catalyst on pyroconversion of breadfruit (Artocarpus altilis) starch: Physicochemical and structural properties. J. Food Process Preserv. 2022, 46, e16408. [Google Scholar] [CrossRef]

- Trithavisup, K.; Krusong, K.; Tananuwong, K. In-Depth Study of the Changes in Properties and Molecular Structure of Cassava Starch during Resistant Dextrin Preparation. Food Chem. 2019, 297, 124996. [Google Scholar] [CrossRef]

- Toraya-Avilés, R.; Segura-Campos, M.; Chel-Guerrero, L.; Betancur-Ancona, D. Effects of pyroconversion and enzymatic hydrolysis on indigestible starch content and physicochemical properties of cassava (Manihot esculenta) starch. Starch Stärke 2017, 69, 1600267. [Google Scholar] [CrossRef]

- Lin, C.L.; Lin, J.H.; Zeng, H.M.; Wu, Y.H.; Chang, Y.H. Indigestible Pyrodextrins Prepared from Corn Starch in the Presence of Glacial Acetic Acid. Carbohydr. Polym. 2018, 188, 68–75. [Google Scholar] [CrossRef] [PubMed]

- Mao, H.; Li, J.; Chen, Z.; Yan, S.; Li, H.; Wen, Y.; Wang, J. Molecular Structure of Different Prepared Pyrodextrins and the Inhibitory Effects on Starch Retrogradation. Food Res. Int. 2021, 143, 110305. [Google Scholar] [CrossRef] [PubMed]

- Mao, H.; Chen, Z.; Li, J.; Zhai, X.; Li, H.; Wen, Y.; Wang, J.; Sun, B. Structural Comparisons of Pyrodextrins during Thermal Degradation Process: The Role of Hydrochloric Acid. Food Chem. 2021, 349, 129174. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, J.J.; Chen, Y.; Wei, N.; Hou, Y.; Bai, W.; Hu, S.Q. Effect of Water-Soluble Dietary Fiber Resistant Dextrin on Flour and Bread Qualities. Food Chem. 2020, 317, 126452. [Google Scholar] [CrossRef]

- Weil, W.; Weil, R.C.; Keawsompong, S.; Sriroth, K.; Seib, P.A.; Shi, Y.C. Pyrodextrin from Waxy and Normal Tapioca Starches: Physicochemical Properties. Food Hydrocoll. 2020, 104, 105745. [Google Scholar] [CrossRef]

- Kapusniak (Jochym), K.; Wojcik, M.; Wrobel, K.; Rosicka-Kaczmarek, J.; Kapusniak, J. Assessment of physicochemical and thermal properties of soluble dextrin fiber from potato starch for use in fruit mousses. J. Sci. Food Agric. 2021, 101, 4125–4133. [Google Scholar] [CrossRef]

- Kapusniak, K.; Ptak, S.; Zarski, A.; Nebesny, E.; Kapusniak, J. Unconventional method for preparation of soluble fibres from starch. Agro Food Ind. Hi Tech 2014, 25, 45–49. [Google Scholar]

- Kapusniak, J.; Kapusniak, K.; Ptak, S.; Barczynska, R.; Zarski, A. Products of thermolysis of potato starch treated with hydrochloric and citric acids as potential prebiotics. Qual. Assur. Saf. Crop. 2014, 6, 347–356. [Google Scholar] [CrossRef]

- Barczynska, R.; Slizewska, K.; Jochym, K.; Kapusniak, J.; Libudzisz, Z. The Tartaric Acid-Modified Enzyme-Resistant Dextrin from Potato Starch as Potential Prebiotic. J. Funct. Foods 2012, 4, 954–962. [Google Scholar] [CrossRef]

- Slizewska, K.; Barczynska, R.; Kapusniak, J.; Jochym, K. The Effect of Tartaric Acid-modified Enzyme-resistant Dextrin from Potato Starch on Growth and Metabolism of Intestinal Bacteria. J. Plant Pathol. Microb. 2015, 6, 269. [Google Scholar] [CrossRef]

- Jochym, K.; Kapusniak, J.; Barczynska, R.; Śliżewska, K. New starch preparations resistant to enzymatic digestion. J. Sci. Food Agric. 2012, 92, 886–891. [Google Scholar] [CrossRef] [PubMed]

- Lam, N.D.; Quynh, T.M.; Diep, T.B.; Binh, P.T.; Lam, T.D. Effect of gamma irradiation and pyrolysis on indigestible fraction, physicochemical properties, and molecular structure of rice starch. J. Food Process Preserv. 2021, 45, e15880. [Google Scholar] [CrossRef]

- Gómez Pamies, L.C.; Lataza Rovaletti, M.M.; Martinez Amezaga, N.M.J.; Benítez, E.I. The Impact of Pirodextrin Addition to Improve Physicochemical Parameters of Sorghum Beer. LWT 2021, 149, 112040. [Google Scholar] [CrossRef]

- Bai, Y.; Cai, L.; Doutch, J.; Gilbert, E.P.; Shi, Y.-C. Structural Changes from Native Waxy Maize Starch Granules to Cold-Water-Soluble Pyrodextrin during Thermal Treatment. J. Agric. Food Chem. 2014, 62, 4186–4194. [Google Scholar] [CrossRef]

- Cao, Y.; Chen, X.; Sun, Y.; Shi, J.; Xu, X.; Shi, Y.-C. Hypoglycemic Effects of Pyrodextrins with Different Molecular Weights and Digestibilities in Mice with Diet-Induced Obesity. J. Agric. Food Chem. 2018, 66, 2988–2995. [Google Scholar] [CrossRef]

- Han, X.; Kang, J.; Bai, Y.; Xue, M.; Shi, Y.C. Structure of Pyrodextrin in Relation to Its Retrogradation Properties. Food Chem. 2018, 242, 169–173. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Kang, J.; Shi, Y.C. Changes in Molecular Size and Shape of Waxy Maize Starch during Dextrinization. Food Chem. 2021, 348, 128983. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Shi, J.; Shi, Y.C. Dissolution of Waxy Maize Pyrodextrin Granules in Mixtures of Glycerol and Water, Separating Loss of Crystallinity from Loss of Birefringence. Carbohydr. Polym. 2022, 281, 119062. [Google Scholar] [CrossRef]

- Lovera, M.; de Castro, G.M.C.; da Rocha Pires, N.; Bastos, M.D.S.R.; Holanda-Araújo, M.L.; Laurentin, A.; de Azevedo Moreira, R.; de Oliveira, H.D. Pyrodextrinization of Yam (Dioscorea Sp.) Starch Isolated from Tubers Grown in Brazil and Physicochemical Characterization of Yellow Pyrodextrins. Carbohydr. Polym. 2020, 242, 116382. [Google Scholar] [CrossRef] [PubMed]

- Udomrati, S.; Ikeda, S.; Gohtani, S. The effect of tapioca maltodextrins on the stability of oil-in-water emulsions. Starke 2011, 63, 347–353. [Google Scholar] [CrossRef]

- Klinkesorn, U.; Sophanodora, P.; Chinachoti, P.; McClements, D. Stability and rheology of corn oil-in-water emulsions containing maltodextrin. Food Res. Int. 2004, 37, 851–859. [Google Scholar] [CrossRef]

- D’hulst, A.; Verkebe, N. Chiral separation by capillary electrophoresis with oligosaccharides. J. Chromatogr. A. 1992, 608, 275–287. [Google Scholar] [CrossRef] [PubMed]

- Sun, P.; Yang, H.J.; Wang, Y.-Q.; Liu, K.-Z.; Xu, Y.-W. Lipase-catalyzed synthesis and characterization of stearic acid dextrin ester. Res. Health Nutr. 2013, 1, 7–11. [Google Scholar]

- Dokic, P.; Jakovljenic, J.; Dokic-Baucal, L. Molecular characteristics of maltodextrins and rheological behaviour of diluted and concentrated solutions. Colloids Surf. A Physicochem. Eng. Asp. 1998, 141, 435–440. [Google Scholar] [CrossRef]

- Dokic-Baucal, L.; Dokic, P.; Jakovljevic, J. Influence of different maltodextrins on properties of O/W emulsions. Food Hydrocoll. 2004, 18, 233–239. [Google Scholar] [CrossRef]

- Biswas, A.; Shogren, R.; Willet, J. Ionic liquid as a solvent and catalyst for acylation of maltodextrin. Ind. Crops Prod. 2009, 30, 172–175. [Google Scholar] [CrossRef]

- Udomrati, S.; Gohtani, S. Enzymatic esterification of tapioca maltodextrin fatty acid ester. Carbohydr. Polym. 2014, 99, 379–384. [Google Scholar] [CrossRef]

- Udomrati, S.; Khalid, N.; Gohtani, S.; Nakajima, M.; Neves, M.A.; Uemura, K.; Kobayashi, I. Effect of esterified oligosaccharides on the formation and stability of oil-in-water emulsions. Carbohydr. Polym. 2016, 143, 44–50. [Google Scholar] [CrossRef]

- Dickinson, E. Hydrocolloids at interfaces and the influence on the properties of dispersed systems. Food Hydrocoll. 2003, 17, 25–39. [Google Scholar] [CrossRef]

- Schirle-Keller, J.P.X. Flavour interaction with fat replacers and aspartame. Diss. Abstr. Int. B 1996, 56, 6483–6484. [Google Scholar]

- Sadtler, V.M.; Imbert, P.; Dellacherie, E. Ostwald ripening of oil-in-water emulsions stabilized by phenoxy-substituted dextrans. J. Colloid Interface Sci. 2002, 254, 355–361. [Google Scholar] [CrossRef]

- van den Broek, L.A.M.; Boeriu, C.G. Enzymatic synthesis of oligo- and polysaccharide fatty acid esters. Carbohydr. Polym. 2013, 93, 65–72. [Google Scholar] [CrossRef]

- Kaewprapan, K.; Baros, F.; Maie, E.; Inprakhon, P.; Durand, A. Macromolecular surfactants synthesized by lipase-catalyzed transesterification of dextran with vinyl decanoate. Carbohydr. Polym. 2012, 88, 313–320. [Google Scholar] [CrossRef]

- Neta, N.S.; Teixeira, J.A.; Rodrigues, L.R. Sugar Ester Surfactants: Enzymatic Synthesis and Applications in Food Industry. Crit. Rev. Food Sci. Nutr. 2014, 55, 595–610. [Google Scholar] [CrossRef] [PubMed]

- Chang, S.W.; Shaw, J.F. Biocatalysis for the production of carbohydrate esters. New Biotechnol. 2009, 26, 109–116. [Google Scholar] [CrossRef] [PubMed]

- Udomrati, S.; Gohtani, S. Tapioca maltodextrin fatty acid ester as a potential stabilizer for Tween 80-stabilized oil-in-water emulsions. Food Hydrocoll. 2015, 44, 23–31. [Google Scholar] [CrossRef]

- Udomrati, S.; Nopparat, C.; Gohtani, S.; Vipa, S.; Supakchon, K. Emulsion stabilization mechanism of combination of esterified maltodextrin and Tween 80 in oil-in-water emulsions. Food Sci. Biotechnol. 2020, 29, 387–392. [Google Scholar] [CrossRef] [PubMed]

- Roczkowska, M.; Ptak, S.; Siemion, P.; Kapusniak, J. Biocatalysed esterification of potato maltodextrin in the presence of fungal lipase. In Proceedings of the 11th International Conference on Polysaccharides-Glycoscience, Czech Chemical Society, Novotneho Lavka 5, Prague, Czech Republic, 22–24 October 2015. [Google Scholar]

- Roczkowska, M.; Kapusniak, J. Modified maltodextrins as ecological surfactants for food purposes. In Proceedings of the XLIII Scientific Session of the Committee on Food and Nutrition Sciences of the Polish Academy of Sciences Food for the Future, Publishing House of the Wroclaw University of Environmental and Life Sciences, Wroclaw, Poland, 4–5 July 2017. [Google Scholar]

- Park, N.; Walsh, M. Physical and emulsion stabilizing properties of maltodextrin fatty acid polymers produced by lipase-catalyzed reactions in ethanol. Carbohydr. Polym. 2019, 226, 115309. [Google Scholar] [CrossRef]

- Pantoa, T.; Shompoosang, S.; Ploypetchara, T.; Gohtani, S.; Udomrati, S. Surface-active properties and anti-microbial activities of esterified maltodextrins. Starch Stärke 2019, 71, 1800265. [Google Scholar] [CrossRef]

- Park, N.; Walsh, M. Microbial inhibitory properties of maltodextrin fatty acid esters against food-related microorganisms. LWT Food Sci. Technol. 2021, 147, 111664. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, H.; Hao, T.; Li, S. In vitro antibacterial activities and mechanism of sugar fatty acid esters against five food-related bacteria. Food Chem. 2015, 187, 370–377. [Google Scholar] [CrossRef]

- Ma, Y.; Hou, C.J.; Wu, H.X.; Fa, H.B.; Li, J.J.; Shen, C.H.; Li, D.; Huo, D.Q. Synthesis of maltodextrin-grafted-cinnamic acid and evaluation on its ability to stabilize anthocyanins via microencapsulation. J. Microencapsul. 2016, 33, 554–562. [Google Scholar] [CrossRef]

- Ma, Y.; Hou, C.J.; Fa, H.B.; Huo, D.Q.; Yang, M. Synthesis and antioxidant property of hydroxycinnamoyl maltodextrin derivatives. Int. J. Food Sci. Technol. 2016, 51, 2450–2459. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Q.; Fan, X.; Xu, J.; Zhang, Y.; Yuan, J.; Jin, H.; Cavaco-Paulo, A. Synthesis and characterization of starch-poly (methyl acrylate) graft copolymers using horseradish peroxidase. Carbohydr. Polym. 2016, 136, 1010–1016. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Xin, J.; Shi, J.; Wu, W.; Xia, C. A kinetic study of starch palmitate synthesis by immobilized lipase-catalyzed esterification in solvent free system. J. Mol. Catal. B Enzym. 2014, 101, 73–79. [Google Scholar] [CrossRef]

- Xin, J.Y.; Wang, Y.; Liu, T.; Lin, K.; Chang, L.; Xia, C.G. Biosysthesis of corn starch palmitate by lipase Novozym 435. Int. J. Mol. Sci. 2012, 13, 7226–7236. [Google Scholar] [CrossRef] [PubMed]

- Lin, R.; Li, H.; Long, H.; Su, J.; Huang, W.; Wang, S. Optimization of lipase-catalyzed rosin acid starch synthesis by response surface methodology. J. Mol. Catal. B Enzym. 2014, 105, 104–110. [Google Scholar] [CrossRef]

- Varavinit, S.; Chaokasem, N.; Shobsngob, S. Studies of flavor encapsulation by agents produced from modified sago and tapioca starches. Starch Stärke 2001, 53, 281–287. [Google Scholar] [CrossRef]

- Lu, X.; Luo, Z.; Yu, S.; Fu, X. Lipase-catalyzed synthesis of starch palmitate in mixed ionic liquids. J. Agric. Food Chem. 2012, 60, 9273–9279. [Google Scholar] [CrossRef]

- Lin, R.; Li, H.; Long, H.; Su, J.; Huang, W. Structure and characteristics of lipase-catalyzed rosin acid starch. Food Hydrocoll. 2015, 43, 352–359. [Google Scholar] [CrossRef]

- Xu, J.; Zhou, C.W.; Wang, R.Z.; Yang, L.; Du, S.S.; Wang, F.P.; Ruan, H.; He, G.Q. Lipase-coupling esterification of starch with octenyl succinic anhydride. Carbohydr. Polym. 2012, 87, 2137–2144. [Google Scholar] [CrossRef]

- Lu, K.; Miao, M.; Ye, F.; Cui, S.W.; Li, X.; Jiang, B. Impact of dual-enzyme treatment on the octenylsuccinic anhydride esterification of soluble starch nanoparticle. Carbohydr. Polym. 2016, 147, 392–400. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Wang, L.; Yue, X.; Xiong, G.; Wu, W.; Qiao, Y.; Liao, L. Physicochemical properties of lipase-catalyzed laurylation of corn starch. Starch Stärke 2014, 66, 450–456. [Google Scholar] [CrossRef]

- Zarski, A.; Ptak, S.; Siemion, P.; Kapusniak, J. Esterification of potato starch by a biocatalysed reaction in an ionic liquid. Carbohydr. Polym. 2016, 137, 657–663. [Google Scholar] [CrossRef] [PubMed]

- Zarski, A.; Bajer, K.; Zarska, S.; Kapusniak, J. From high oleic vegetable oils to hydrophobic starch derivatives: I. Development and structural studies. Carbohydr. Polym. 2019, 214, 124–130. [Google Scholar] [CrossRef]

- Zarski, A.; Bajer, K.; Raszkowska-Kaczor, A.; Rogacz, D.; Zarska, S.; Kapusniak, J. From high oleic vegetable oils to hydrophobic starch derivatives: II. Physicochemical, processing and environmental properties. Carbohydr. Polym. 2020, 243, 116499. [Google Scholar] [CrossRef]

- Lu, K.; Zhu, J.; Bao, X.; Liu, H.; Yu, L.; Chen, L. Effect of starch microstructure on microwave-assisted esterification. Int. J. Biol. Macromol. 2020, 164, 2550–2557. [Google Scholar] [CrossRef]

- Yang, Q.; Qi, L.; Luo, Z.; Kong, X.; Xiao, Z.; Wang, P.; Peng, X. Effect of microwave irradiation on internal molecular structure and physical properties of waxy maize starch. Food Hydrocoll. 2017, 69, 473–482. [Google Scholar] [CrossRef]

- Oyeyinka, S.A.; Akintayo, O.A.; Adebo, O.A.; Kayitesi, E.; Njobeh, P.B. A review on the physicochemical properties of starches modified by microwave alone and in combination with other methods. Int. J. Biol. Macromol. 2021, 176, 87–95. [Google Scholar] [CrossRef] [PubMed]

- Zhao, K.; Li, B.; Xu, M.; Jing, L.; Gou, M.; Yu, Z.; Zheng, J.; Li, W. Microwave pretreated esterification improved the substitution degree, structural and physicochemical properties of potato starch esters. LWT Food Sci. Technol. 2018, 90, 116–123. [Google Scholar] [CrossRef]

- Lin, D.; Zhou, W.; He, Q.; Xing, B.; Wu, Z.; Chen, H.; Wu, D.; Zhang, Q.; Qin, W. Study on preparation and physicochemical properties of hydroxypropylated starch with different degree of substitution under microwave assistance. Int. J. Biol. Macromol. 2019, 125, 290–299. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Ming, J.; Li, W.; Zhao, G. Synthesis, characterisation and in vitro digestibility of carboxymethyl potato starch rapidly prepared with microwave-assistance. Food Chem. 2012, 133, 1196–1205. [Google Scholar] [CrossRef]

- Hu, A.; Chen, X.; Wang, J.; Wang, H.; Zheng, J.; Wang, L. Effects on the structure and properties of native corn starch modified by enzymatic debranching (ED), microwave assisted esterification with citric acid (MCAE) and by the dual ED/MCAE treatment. Int. J. Biol. Macromol. 2021, 171, 123–129. [Google Scholar] [CrossRef]

- Horchani, H.; Chaabouni, M.; Gargouri, Y.; Sayari, A. Solvent-free lipase-catalyzed synthesis of long-chain starch esters using microwave heating: Optimization by response surface methodology. Carbohydr. Polym. 2010, 79, 466–474. [Google Scholar] [CrossRef]

- Adak, S.; Banerjee, R. A green approach for starch modification: Esterification by lipase and novel imidazolium surfactant. Carbohydr. Polym. 2016, 150, 359–368. [Google Scholar] [CrossRef]

- Lukasiewicz, M.; Kowalski, S. Low power microwave-assisted enzymatic esterification of starch. Starch Stärke 2012, 64, 188–197. [Google Scholar] [CrossRef]

- Li, X.; He, Y.; Huang, C.; Zhu, J.; Lin, A.H.M.; Chen, L.; Li, L. Inhibition of plasticizer migration from packaging to foods during microwave heating by controlling the esterified starch film structure. Food Control 2016, 66, 130–136. [Google Scholar] [CrossRef]

- Hoover, R.; Hughes, T.; Chung, H.; Liu, Q. Composition, molecular structure, properties, and modification of pulse starches: A review. Food Res. Int. 2010, 43, 399–413. [Google Scholar] [CrossRef]

- Chong, W.T.; Uthumporn, U.; Karim, A.A.; Cheng, L.H. The influence of ultrasound on the degree of oxidation of hypochlorite-oxidized corn starch. LWT Food Sci. Technol. 2013, 50, 439–443. [Google Scholar] [CrossRef]

- Apopei Loghin, D.F.; Biliuta, G.; Coseri, S.; Dragan, E.S. Preparation and characterization of oxidized starch/poly(N,N-dimethylaminoethyl methacrylate) semi-IPN cryogels and in vitro controlled release evaluation of indomethacin. Int. J. Biol. Macromol. 2017, 96, 589–599. [Google Scholar] [CrossRef] [PubMed]

- Biliuta, G.; Sacarescu, L.; Socoliuc, V.; Iacob, M.; Gheorghe, L.; Negru, D.; Coseri, S. Carboxylated Polysaccharides Decorated with Ultrasmall Magnetic Nanoparticles with Antibacterial and MRI Properties. Macromol. Chem. Phys. 2017, 218, 1700062. [Google Scholar] [CrossRef]

- Baron, R.I.; Bercea, M.; Avadanei, M.; Lisa, G.; Biliuta, G.; Coseri, S. Green route to produce self-healable hydrogels based on tricarboxy cellulose and poly (vinyl alcohol). Int. J. Biol. Macromol. 2019, 123, 744–751. [Google Scholar] [CrossRef]

- Culica, M.E.; Avadanei, M.; Baron, R.I.; Chibac-Scutaru, A.L.; Asandulesa, M.; Biliuta, G.; Lisa, G.; Coseri, S. The source of conductivity and proton dynamics study in TEMPO-oxidized cellulose doped with various heterocyclic molecules. Cellulose 2020, 27, 8585–8604. [Google Scholar] [CrossRef]

- Baron, R.I.; Coseri, S. Preparation of water-soluble cellulose derivatives using TEMPO radical-mediated oxidation at extended reaction time. React. Funct. Polym. 2020, 157, 104768. [Google Scholar] [CrossRef]

- Duceac, I.A.; Vereștiuc, L.; Coroaba, A.; Arotăriței, D.; Coseri, S. All-polysaccharide hydrogels for drug delivery applications: Tunable chitosan beads surfaces via physical or chemical interactions, using oxidized pullulans. Int. J. Biol. Macromol. 2021, 181, 1047–1062. [Google Scholar] [CrossRef] [PubMed]

- Bercea, M.; Biliuta, G.; Avadanei, M.; Baron, R.I.; Butnaru, M.; Coseri, S. Self-healing hydrogels of oxidized pullulan and poly(vinyl alcohol). Carbohydr. Polym. 2019, 206, 210–219. [Google Scholar] [CrossRef]

- Baron, R.I.; Culica, M.E.; Biliuta, G.; Bercea, M.; Gherman, S.; Zavastin, D.; Ochiuz, L.; Avadanei, M.; Coseri, S. Physical Hydrogels of Oxidized Polysaccharides and Poly(Vinyl Alcohol) for Wound Dressing Applications. Materials 2019, 12, 1569. [Google Scholar] [CrossRef]

- Hao, J.; Wu, F.; Tang, R.; Sunb, Y.; Liu, D.; Zhang, Z. Preparation of 1,4-linked α-D-glucuronans from starch with 4-acetamide-TEMPO/NaClO2/NaClO system. Int. J. Biol. Macromol. 2020, 151, 740–746. [Google Scholar] [CrossRef]

- Yang, G.; Xia, Y.; Lin, Z.; Zhang, K.; Fatehi, P.; Chen, J. Physicochemical impact of cellulose nanocrystal on oxidation of starch and starch based composite films. Int. J. Biol. Macromol. 2021, 184, 42–49. [Google Scholar] [CrossRef] [PubMed]

- Zuo, Y.; Liu, W.; Xiao, J.; Zhao, X.; Zhu, Y.; Wu, Y. Preparation and characterization of dialdehyde starch by one-step acid hydrolysis and oxidation. Int. J. Biol. Macromol. 2017, 103, 1257–1264. [Google Scholar] [CrossRef] [PubMed]

- Dou, Y.; Huang, X.; Zhang, B.; He, M.; Yin, G.; Cui, Y. Preparation and characterization of a dialdehyde starch crosslinked feather keratin film for food packaging application. RSC Adv. 2015, 5, 27168–27174. [Google Scholar] [CrossRef]

- Wu, W.; Li, Y.; Yang, L.; Ma, Y.; Pan, D.; Li, Y. A Facile One-Pot Preparation of Dialdehyde Starch Reduced Graphene Oxide/Polyaniline Composite for Supercapacitors. Electrochim. Acta 2014, 139, 117–126. [Google Scholar] [CrossRef]

- Lewicka, K.; Siemion, P.; Kurcok, P. Chemical Modifications of Starch: Microwave Effect. Int. J. Polym. Sci. 2015, 2015, 867697. [Google Scholar] [CrossRef]

- Lukasiewicz, M.; Bednarz, S.; Ptaszek, A. Environmental friendly polysaccharide modification—Microwave-assisted oxidation of starch. Starch Stärke 2011, 63, 268–273. [Google Scholar] [CrossRef]

- León, O.; Soto, D.; López, D.; Muñoz-Bonilla, A.; Fernández-García, M. Fat-Replacer Properties of Oxidized Cassava Starch Using Hydrogen Peroxide/Sodium Bicarbonate Redox System in Mayonnaise Formulation and Its Stability. Starch Stärke 2019, 71, 1900112. [Google Scholar] [CrossRef]

- Li, J.; Zhou, M.; Cheng, F.; Lin, Y.; Shi, L.; Zhu, P.-X. Preparation of oxidized corn starch with high degree of oxidation by fenton-like oxidation assisted with ball milling. Mater. Today Commun. 2020, 22, 100793. [Google Scholar] [CrossRef]

- Barbosa, J.V.; Martins, J.; Carvalho, L.; Bastos, M.M.S.M.; Magalhães, F.D. Effect of peroxide oxidation on the expansion of potato starch foam. Ind Crops Prod. 2019, 137, 428435. [Google Scholar] [CrossRef]

- Maache-Rezzoug, Z.; Zarguili, I.; Loisel, C.; Queveau, D.; Buléon, A. Structural modifications and thermal transitions of standard maize starch after DIC hydrothermal treatment. Carbohydr. Polym. 2008, 74, 802–814. [Google Scholar] [CrossRef]

- Bahrani, S.A.; Loisel, C.; Rezzoug, S.A.; Doublier, J.L.; Maache-Rezzoug, Z. Role of vacuum steps added before and after steaming treatment of maize starch. Impact on pasting, morphological and rheological properties. Carbohydr. Polym. 2012, 89, 810–820. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, S.; Deng, L.; Wu, C.; Zhong, G. Effect of Vacuum Treatment on the Characteristics of Oxidized Starches Prepared Using a Green Method. Starch Stärke 2018, 70, 1700216. [Google Scholar] [CrossRef]

- Wei, B.; Qi, H.; Wang, Z.; Bi, Y.; Zou, J.; Xu, B.; Ren, X.; Ma, H. The ex-situ and in-situ ultrasonic assisted oxidation of corn starch: A comparative study. Ultrason. Sonochem. 2020, 61, 104854. [Google Scholar] [CrossRef]

- Fan, Z. Impact of ultrasound on structure, physicochemical properties, modifications, and applications of starch. Trends Food Sci. Technol. 2015, 43, 1–17. [Google Scholar]

- Tian, Y.L.; Ying, M.; Shi, F.Y.; Shi, J.; Xue, S. The effect of ball milling treatment on structure and porosity of maize starch granule. Innov. Food Sci. Emerg. Technol. 2011, 12, 586–593. [Google Scholar]

- Zhang, J.; Cao, S.; Liu, P.; Shan, Z. Electrochemical Oxidation of Starch Investigated by Single-Current-Transition Method. Starch Stärke 2022, 74, 2100154. [Google Scholar] [CrossRef]

- Sevket, T.; Melayib, B. Enhancement of anaerobic digestion of waste activated sludge by chemical pretreatment. Fuel 2019, 254, 115671. [Google Scholar]

- Hornung, P.S.; Avila, S.; Lazzarotto, M.; da Silveira Lazzarotto, S.R.; de Andrade de Siqueira, G.L.; Schnitzler, E.; Ribani, R.H. Enhancement of the functional properties of Dioscoreaceas native starches: Mixture as a green modification process. Thermochim. Acta 2017, 649, 31–40. [Google Scholar] [CrossRef]

- Dang, X.; Chen, H.; Wang, Y.; Shan, Z. Freeze-drying of oxidized corn starch: Electrochemical synthesis and characterization. Cellulose 2018, 25, 2235–2247. [Google Scholar] [CrossRef]

- Kurdziel, M.; Łabanowska, M.; Pietrzyk, S.; Sobolewska-Zielińska, J.; Michalec, M. Changes in the physicochemical properties of barley and oat starches upon the use of environmentally friendly oxidation methods. Carbohydr. Polym. 2019, 210, 339–349. [Google Scholar] [CrossRef] [PubMed]

- Çatal, H.; Ibanoglu, S. Effect of aqueous ozonation on the pasting, flow and gelatinization properties of wheat starch. Food Sci. Technol. 2014, 59, 577–582. [Google Scholar] [CrossRef]

- Castanha, N.; Matta, M.D., Jr.; Augusto, P.E.D. Potato starch modification using the ozone technology. Food Hydrocoll. 2017, 66, 343–356. [Google Scholar] [CrossRef]

| Starch Type | Barley | Maize | Potato | Rice | Wheat | Tapioca |

|---|---|---|---|---|---|---|

| Source | Cereal | Cereal | Tuber | Cereal | Cereal | Root |

| Grain shape | Lenticular, round | Polyhedral, round | Round, oval | Polygonal, angular | Lenticular, round | Oval |

| Grain diameter [µm] | 2–40 | 2–30 | 5–100 | 1–35 | 1–40 | 4–45 |

| Polymorphism type | A | A | B | A | A | A/C |

| Amylose [%] | ~22 | 23–32 | 18–29 | ~22 | 23–29 | 17–30 |

| Amylopectin [%] | 78 | 75 | 78 | 78 | 77 | 80 |

| Lipid [%] | 0.6–0.9 | 0.8 | 0.01 | 0.3 | 0.9 | 0.02 |

| Protein [%] | 0.1 | 0.35 | 0.1 | 0.3 | 0.4 | 0.1 |

| Phosphorus [%] | 0.05 | 0.09 | 0.20 | 0.09 | 0.3 | 0.009 |

| Type of Starch | Type of Dual Modification | Changes in Starch Properties | Reference |

|---|---|---|---|

| Corn | Infrared HMT | Decrease thermal stability, pasting properties, and viscosity | [46] |

| Wheat | Infrared HMT | Decrease thermal stability, pasting properties, and viscosity | [47] |

| Corn | Extrusion and HMT | Increase resistant starch content; decrease solubility and swelling power | [48] |

| Barley | Annealing and hydroxypropylation | Increase rheological properties, solubility, and freeze–thaw stability | [49] |

| Corn | Lactic, citric, and acetic acids and HMT | Increase resistant starch content, thermal stability, and rheological properties; decreased crystallinity | [50] |

| Corn | Lactic acid and HMT | Decrease viscosity; increase resistant content and thermal stability | [51] |

| Potato | Inclusion complexes with sodium stearate and HMT | Decrease swelling power and retrogradation; increase thermal stability and resistant fraction content | [52] |

| Starch Nanostructure | Type of Starch | Method of Preparation | Min. Size [nm] | Reference |

|---|---|---|---|---|

| Nanocrystal | High-amylose maize | Acid-catalyzed hydrolysis | 118 | [58] |

| Waxy | Acid-catalyzed hydrolysis | 70 | [59] | |

| Nanofiber | High-amylose maize | Electrospinning | 300 | [60] |

| High-amylose maize | Electrospinning | 30 | [61] | |

| Corn | Coaxial electrospinning | 110 | [62] | |

| Nanogel | Potato | Graft copolymerization | 120 | [63] |

| α-starch | Crosslinking | 30 | [64] | |

| Nanomicelle | Starch octanoate | Esterification | 410 | [65] |

| Waxy maize | Emulsification | 60 | [66] | |

| Corn | Graft copolymerization | 20 | [67] |

| Starch Source | Modification Conditions/Reagent | Type of RS | Reference |

|---|---|---|---|

| Unpeeled raw banana powder, peeled raw banana powder, and banana starch from Kluai Namwa Luang | Fruits were sliced, dried, and milled; starch was extracted from peeled raw banana powder | RS2 | [90] |

| Lotus stem | Native starch digested with protease, lipase, α-amylase, and amyloglucosidase and subjected to ultrasonic treatment | RS2 + modification | [91] |

| Pea starch | Native; acid hydrolysis and pullulanase debranching | RS2 and RS3 | [92] |

| Wrinkled and round pea starches | Heat–moisture treatment | RS3 | [93] |

| Sago | Autoclaving, debranching by pullulanase, autoclaving, and cooling | RS3 | [94] |

| Potato peels | Debranching by pullulanase, autoclaving, and cooling | RS3 | [95] |

| Maize flour | Autoclaving in citrate buffer, protease, and amylase (+pullulanase in [96]) application, second autoclaving, and cooling | RS3 | [96,97] |

| Pea and normal maize starches | Acid thinning, debranching, and recrystallization | RS3 | [98] |

| Highly branched potato starch, waxy potato starch, amylomaltase-modified potato starch, and waxy rice starch | Debranching and recrystallization | RS3 | [99,100] |

| Cyperus esculentus (tiger nut) starch | Debranching and nanoprecipitation | RS3 | [101] |

| Sago starch | Autoclaving, debranching by pullulanase, autoclaving, and cooling (RS) and RS treated with 0.5 M hydrochloric acid | RS3 | [102] |

| Cowpea starch | Autoclaving–cooling cycles (1, 3, and 5) | RS3 | [103] |

| Waxy and normal maize starch | Gelatinized starches were subjected to temperature cycling between 4 and 30 °C (1 day at each temperature) or isothermal storage (4 °C) for 2 or 8 days | RS3 | [104] |

| Highland barley, oat, and buckwheat starches | Enzymatic hydrolysis (α-amylase and pullulanase), autoclaving, and cooling | RS3 | [105] |

| Waxy maize starch | Gelatinization, debranching by pullulanase, cooling, and self-assembly of nanoparticles | RS3 | [106] |

| Potato starch | Gelatinization, debranching by pullulanase, autoclaving, and cooling | RS3 | [107] |

| Different types of bean starches and maize starch | Autoclaving–cooling and α-amylase action or autoclaving and pullulanase | RS3 | [108] |

| Sorghum starch and waxy rice starch | Heating/cooling with or without debranching gelatinized starch | RS3 | [109] |

| High-amylose maize starches | Extrusion cooking with different moisture content | RS3 | [110] |

| Culinary banana starch | Autoclaving or debranching with pullulanase | RS3 | [111] |

| Waxy maize starch | Ultrasound-assisted annealing treatment of fractionated debranched starch | RS3 | [112] |

| Fractionated lotus seed starch | Autoclaving–cooling and α-amylase and glucoamylase action | RS3 | [113] |

| Cassava starch | Debranching by pullulanase and cooling | RS3 | [114] |

| Maize flour and maize starch | Autoclaving–cooling treatments | RS3 | [115] |

| Maize starch | Amylase and isoamylase hydrolysis and autoclaving–cooling | RS3 | [116] |

| Lotus seed starch | Autoclaving–cooling or microwave heated/water bath heated, cooling, and purified by amylase and glucoamylase | RS3 | [117,118] |

| Oat flour | Dual autoclaving–retrogradation treatment | RS3 | [119] |

| Maize starch | 1,4-maltotriohydrolase action, debranching using pullulanase, and autoclaving–cooling | RS3 | [120] |

| Faba bean starch | Debranching using pullulanase and retrogradation treatment | RS3 | [121] |

| Sweet potato, cassava, and high-amylose maize starches | Autoclaving in acetate buffer, debranching by amylase and pullulanase, autoclaving, and cooling | RS3 | [122] |

| Maize and sorghum starches | Extrusion and different storage time | RS3 | [123] |

| Pea starch | Ultrasonic treatment and cooling | RS3 | [124] |

| Green banana flour | Autoclaving and debranching by pullulanase | RS3 | [125] |

| Waxy proso millet grains | Debranching and retrogradation | RS3 | [126] |

| Potato, wheat, corn, and tapioca starch | Retrogradation of starch and acetylation by acetic anhydride | RS3/RS4 | [127,128] |

| Potato starch | Retrograded and acetylated starch produced via starch extrusion or starch hydrolysis with pullulanase | RS3/RS4 | [129] |

| Potato starch | Retrograded and crosslinked by adipic acid | RS3/RS4 | [130] |

| Potato starch | Retrograded, acetylated by acetic acid anhydride, and crosslinked by adipic acid | RS3/RS4 | [131,132] |

| Cassava, potato, sweet potato, lentil, and banana | Octenyl succinic anhydride (OSA) | RS4 | [133,134] |

| Canna | Acetic anhydride | RS4 | [135] |

| Sorghum starch | Extrusion of phosphorylated starch | RS4 | [136] |

| Pea starch | Crosslinking starch with sodium trimetaphosphate and sodium tripolyphosphate | RS4 | [137] |

| Three Korean rice varieties | Crosslinking starch with sodium trimetaphosphate and sodium tripolyphosphate | RS4 | [138] |

| Cassava and sweet potato roots, unripe banana, potato tubers, and lentil seeds | 20, 40, and 60% of citric acid | RS4 | [139] |

| Maize starch | Crosslinking starch with sodium trimetaphosphate and sodium tripolyphosphate under sonication and conventional conditions at various levels of pH | RS4 | [140] |

| Potato starch | Extrusion combined with phosphorylation or succinylation | RS4 | [141] |

| Waxy rice starch | Nanoparticles prepared by acid hydrolysis, crosslinking with sodium trimetaphosphate and freeze drying, freeze drying after sonication, and ethanol dehydration after sonication | RS4 | [142] |

| High-amylose maize starch | Acetic anhydride, propionic anhydride, and butyric anhydride | RS4 | [143,144] |

| Sweet potato starch | Microwave-assisted L-malic acid modification | RS4 | [145] |