An Intrinsically Transparent Polyamide Film with Superior Toughness and Great Optical Performance

Abstract

1. Introduction

2. Experimental

2.1. Materials

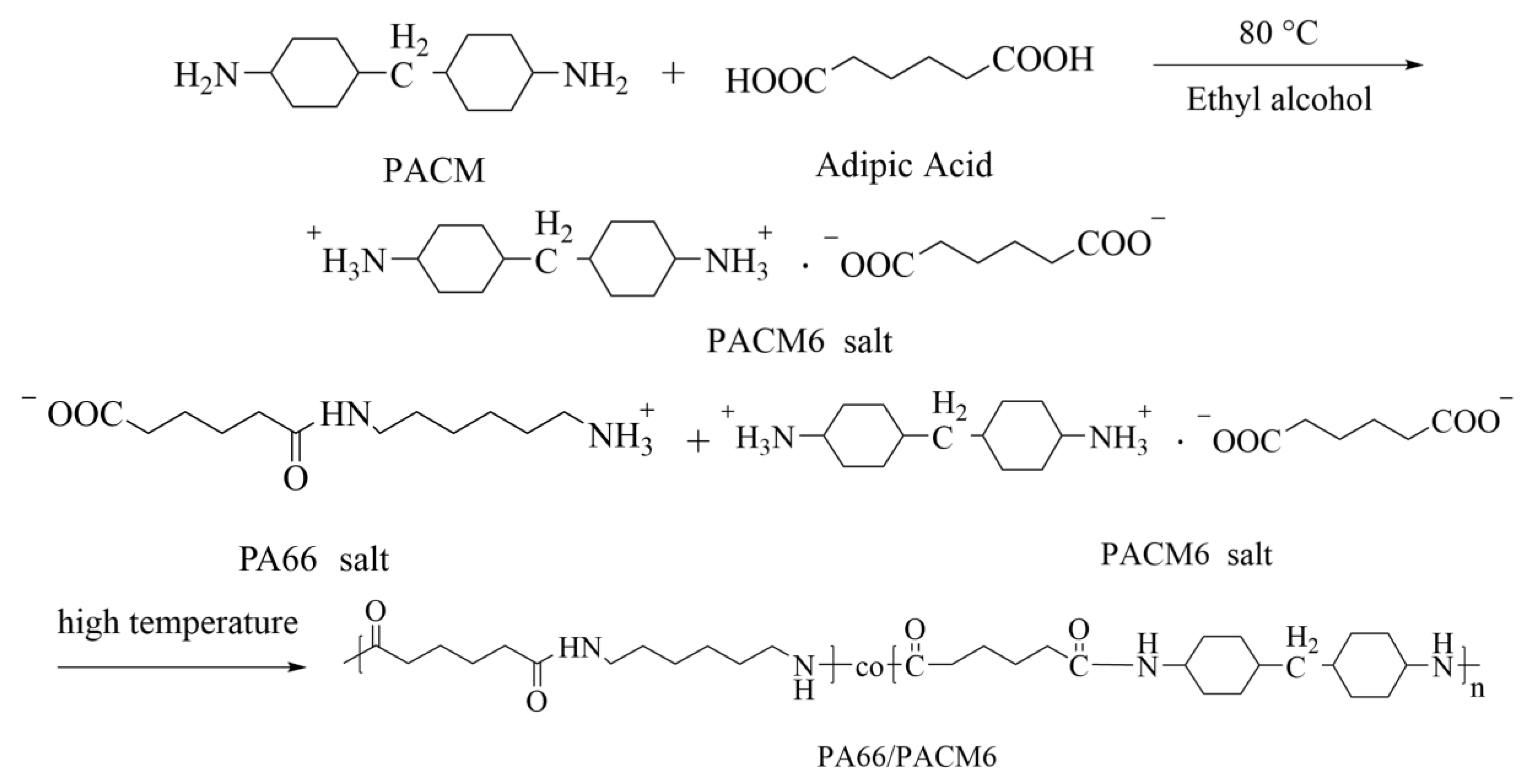

2.2. Preparation of Copolymers

2.3. Preparation of Casting Films and Biaxially Oriented Films

2.4. Measurements

3. Results and Discussion

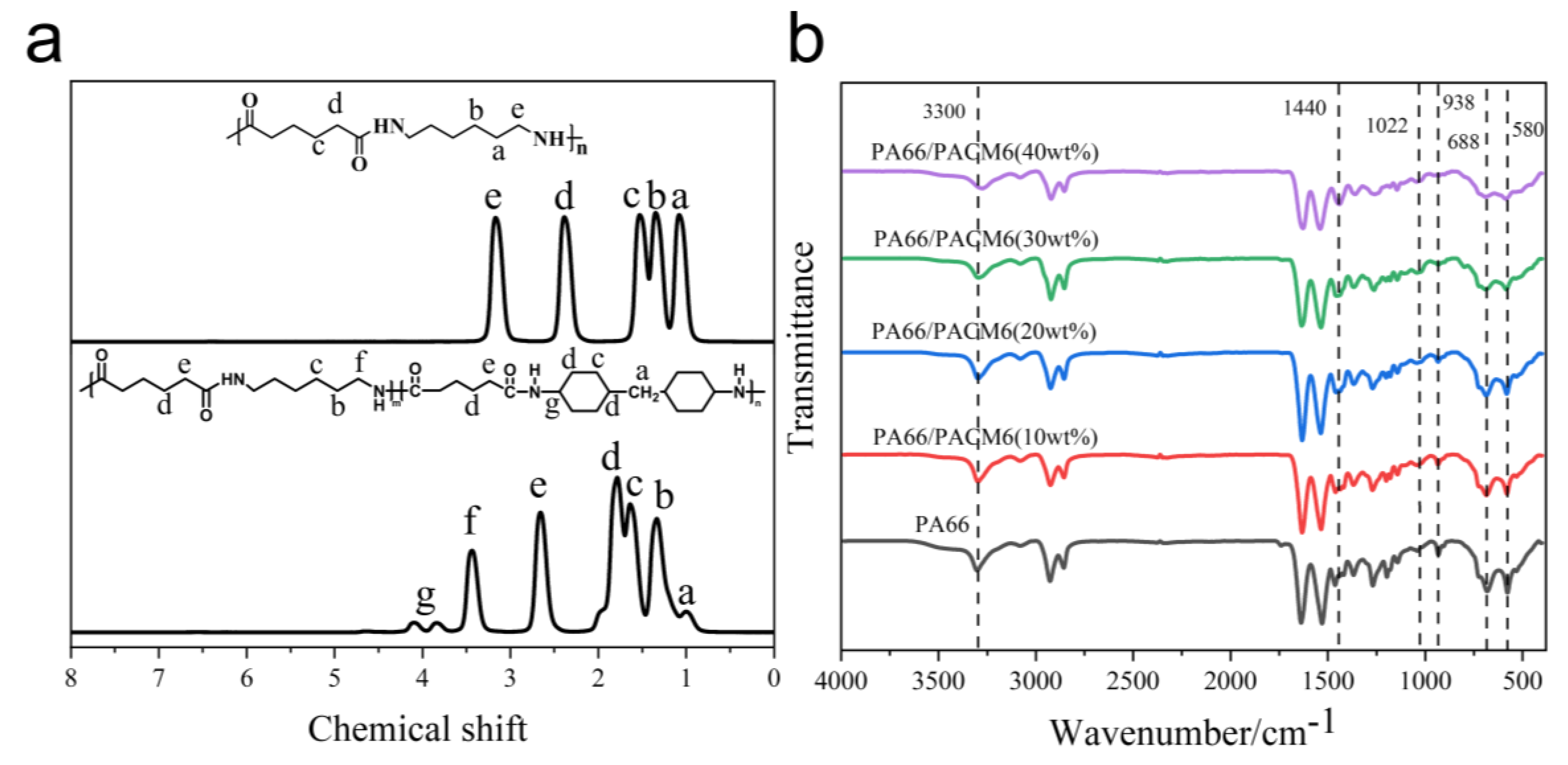

3.1. Structural Characterization Analysis

3.2. Crystallization Behavior Analysis

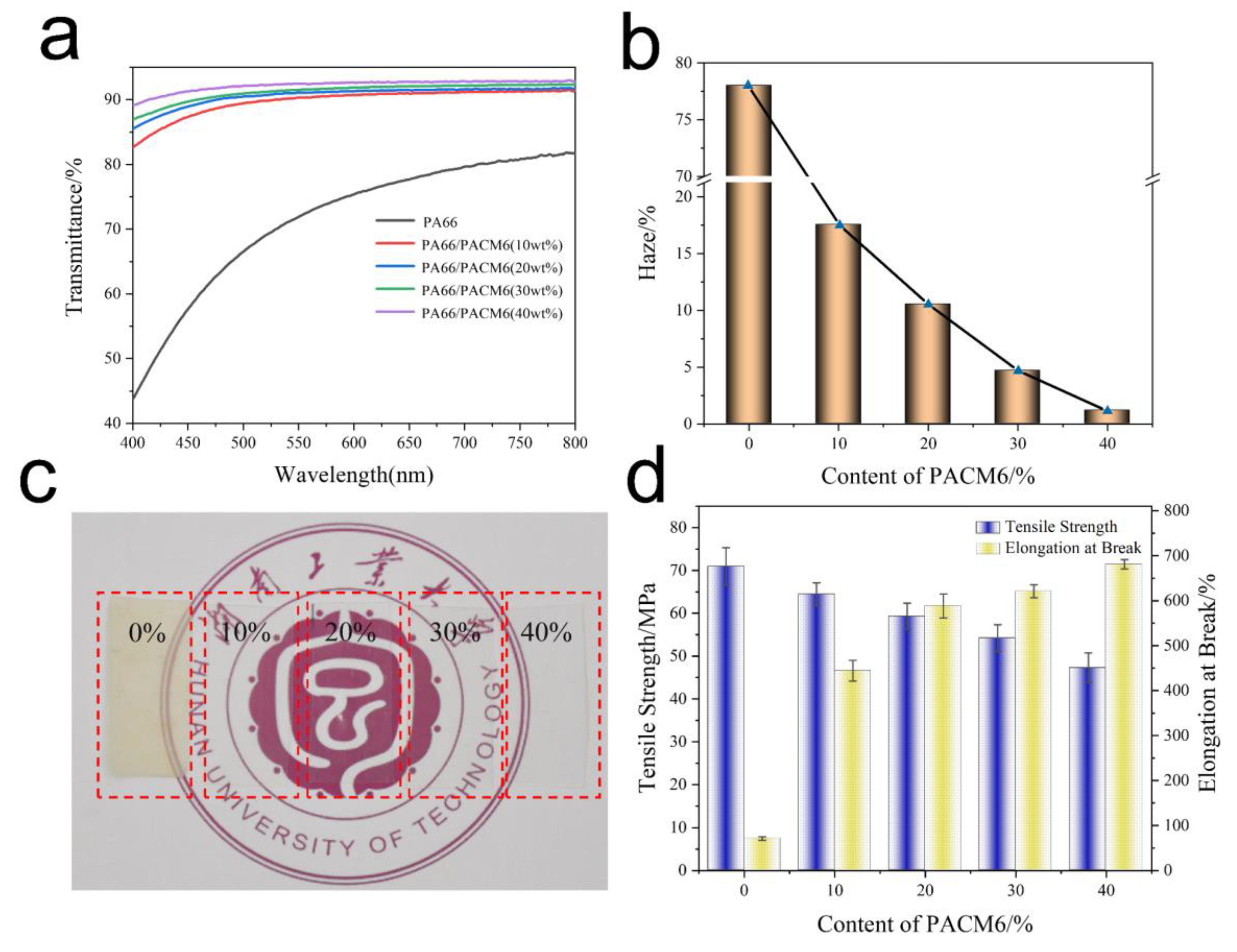

3.3. Optical Performance Analysis

3.4. Mechanical Properties Analysis

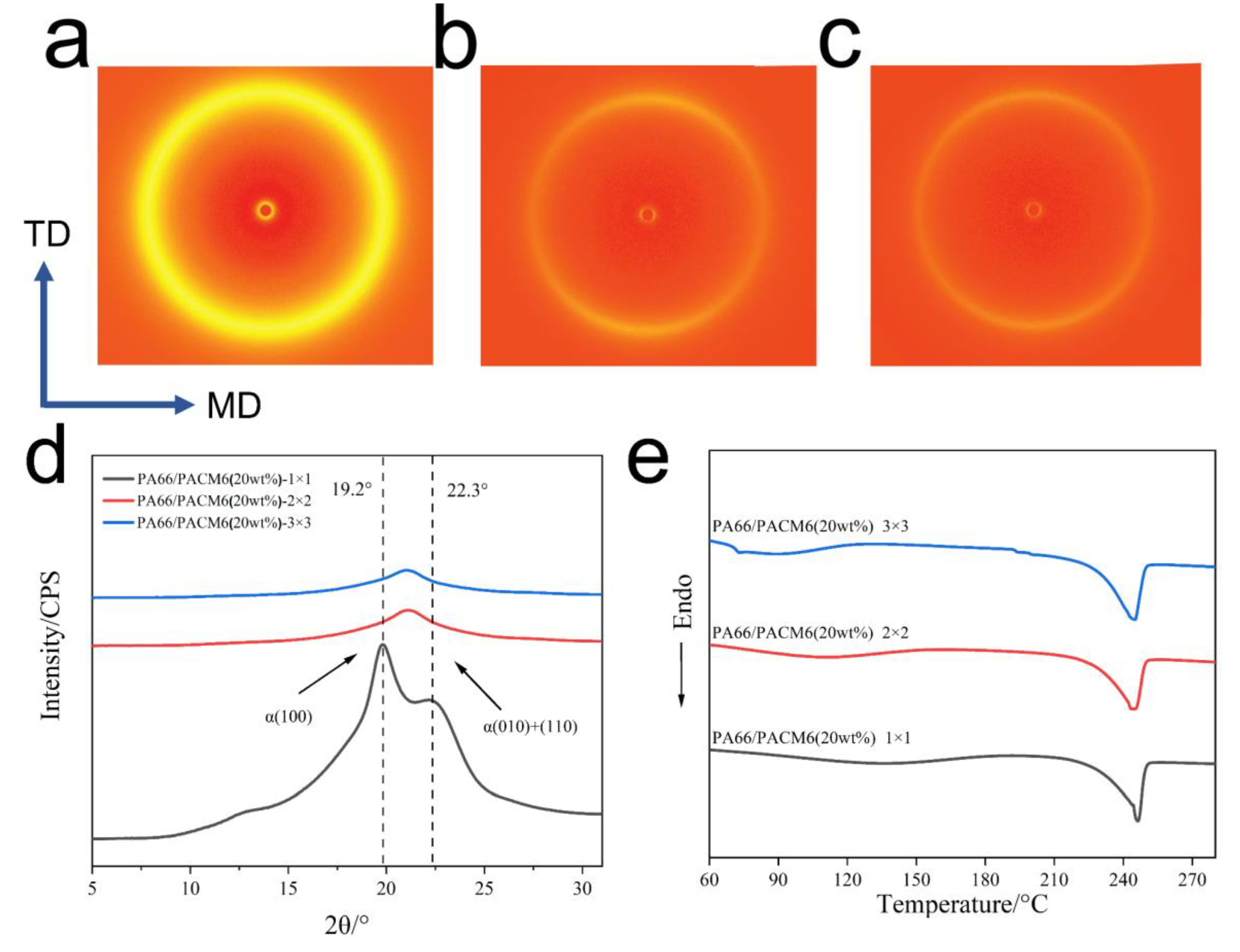

3.5. Crystallization Behavior of BO-PA66/PACM6 Films

3.6. The Optical Performance Analysis of BO-PA66/PACM6 Films

3.7. Mechanical Properties of the BO-PA66/PACM6 Films

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kohan, M.I. History and development of nylon-66. Abstr. Pap. Am. Chem. Soc. 1986, 191, 38-HIST. [Google Scholar]

- Jia, F.; Mao, J.L.; Yang, X.Y.; Ma, Y.; Yao, C. Thermal, physical and mechanical properties of hydrogenated dimer acid-based Nylon 636/Nylon 66 copolymers. Chin. Chem. Lett. 2013, 24, 654–658. [Google Scholar] [CrossRef]

- Li, Y.L.; Hao, X.M.; Guo, Y.F.; Chen, X.; Yang, Y.; Wang, J.M. Study on the Acid Resistant properties of Bio-based Nylon 56 Fiber Compared with the Fiber of Nylon 6 and Nylon 66. Adv. Mater. Res. 2014, 1048, 57–61. [Google Scholar] [CrossRef]

- Kagan, V.A.; Bray, R.G.; Kuhn, W.P. Laser transmission welding of semi-crystalline thermoplastics—Part I: Optical characterization of nylon based plastics. J. Reinf. Plast. Compos. 2002, 21, 1101–1122. [Google Scholar] [CrossRef]

- O’Brien, D.J.; Chin, W.K.; Long, L.R.; Wetzel, E.D. Polymer matrix, polymer ribbon-reinforced transparent composite materials. Compos. Part A-Appl. Sci. Manuf. 2014, 56, 161–171. [Google Scholar] [CrossRef]

- Gavande, V.; Nagappan, S.; Seo, B.; Cho, Y.S.; Lee, W.K. Transparent nylon 6 nanofibers-reinforced epoxy matrix composites with superior mechanical and thermal properties. Polym. Test. 2023, 122, 108002. [Google Scholar] [CrossRef]

- Jiang, S.; Greiner, A.; Agarwal, S. Short nylon-6 nanofiber reinforced transparent and high modulus thermoplastic polymeric composites. Compos. Sci. Technol. 2013, 87, 164–169. [Google Scholar] [CrossRef]

- Jiang, S.H.; Hou, H.Q.; Greiner, A.; Agarwal, S. Tough and Transparent Nylon-6 Electrospun Nanofiber Reinforced Melamine-Formaldehyde Composites. ACS Appl. Mater. Interfaces 2012, 4, 2597–2603. [Google Scholar] [CrossRef]

- Li, B.Y.; Wei, S.; Xuan, H.Y.; Xue, Y.; Yuan, H.H. Tailoring fineness and content of nylon-6 nanofibers for reinforcing optically transparent poly(methyl methacrylate) composites. Polym. Compos. 2021, 42, 3243–3252. [Google Scholar] [CrossRef]

- Shen, T.; Zhang, B.; Wang, Y.Y.; Yang, P.P.; Li, M.; Hu, R.J.; Guo, K.; Chen, K.Q.; Zhu, N.; Wang, L.; et al. Production of 100% bio-based semi-aromatic nylon by aerobic oxidation of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid with bio aliphatic diamine. Chem. Eng. J. 2022, 437, 135361. [Google Scholar] [CrossRef]

- Sim, K.; Gao, Y.; Chen, Z.; Song, J.Z.; Yu, C.J. Nylon Fabric Enabled Tough and Flaw Insensitive Stretchable Electronics. Adv. Mater. Technol. 2019, 4, 1800466. [Google Scholar] [CrossRef]

- Feng, J.X.; Zhang, G.J.; MacInnis, K.; Olah, A.; Baer, E. Formation of microporous membranes by biaxial orientation of compatibilized PP/Nylon 6 blends. Polymer 2017, 123, 301–310. [Google Scholar] [CrossRef]

- Chen, J.; Wu, W.; You, Y.; Fan, W.; Chen, Y.J. Morphology and Properties of the PA66/PC/Silicone Rubber Composites. J. Appl. Polym. Sci. 2010, 117, 2964–2971. [Google Scholar] [CrossRef]

- Fu, Q.; Zhang, Q.; Liu, Y.F.; Sheng, Z.B.; Du, R.N.; Zhou, N. Crystal structure and properties of PC/Nylon 6 alloy. Chem. J. Chin. Univ.-Chin. 2000, 21, 659–661. [Google Scholar]

- Xie, D.L.; Chen, D.; Jiang, B.; Yang, C.Z. Synthesis of novel compatibilizers and their application in PP/nylon-66 blends. I. Synthesis and characterization. Polymer 2000, 41, 3599–3607. [Google Scholar] [CrossRef]

- Li, B.Y.; Yuan, H.H.; Zhang, Y.Z. Transparent PMMA-based nanocomposite using electrospun graphene-incorporated PA-6 nanofibers as the reinforcement. Compos. Sci. Technol. 2013, 89, 134–141. [Google Scholar] [CrossRef]

- Rahmadiawan, D.; Shi, S.-C.; Abral, H.; Ilham, M.K.; Sugiarti, E.; Muslimin, A.N.; Ilyas, R.A.; Lapisa, R.; Putra, N.S.D. Comparative Analysis of the Influence of Different Preparation Methods on the Properties of TEMPO-Oxidized Bacterial Cellulose Powder Films. J. Nat. Fibers 2024, 21, 2301386. [Google Scholar] [CrossRef]

- Gavande, V.; Im, D.; Lee, W.K. Development of highly transparent UV-curable nylon 6 nanofiber-reinforced polyurethane acrylate nanocomposite coatings for pre-coated metals. J. Appl. Polym. Sci. 2021, 138, 50614. [Google Scholar] [CrossRef]

- Shinde, S.; Bait, S.P.; Adivarekar, R.; Nethi, N.S. Benzophenone based disperse dyes for UV protective clothing: Synthesis, comparative study of UPF, light fastness and dyeing properties and computational study. J. Text. Inst. 2021, 112, 71–84. [Google Scholar] [CrossRef]

- Huang, C.N.; Wu, C.M.; Lo, H.W.; Lai, C.C.; Teng, W.F.; Liu, L.C.; Chen, C.M. Synthesis and Physical Properties of Non-Crystalline Nylon 6 Containing Dimer Acid. Polymers 2019, 11, 386. [Google Scholar] [CrossRef]

- Liu, F.F.; Hurley, J.M.; Khare, N.P.; McAuley, K.B. Mathematical Modeling of Nylon 6/6,6 Copolymerization: Beneficial Influence of Comonomers on Degree of Polymerization in Batch Reactor. Macromol. React. Eng. 2017, 11, 1700002. [Google Scholar] [CrossRef]

- Guo, J.B.; Li, H.J.; Xue, B.F.; Zhu, D.H.; Zhang, X.M.; Zhao, H.T.; Qiao, X.G.; Cui, Z.; Fu, P.; Zhao, Q.X.; et al. A synthesized semi-aromatic copolyamaide through synergy of three different kinds of monomers: Toward high transparency, excellent heat resistance and melt flowing property. J. Appl. Polym. Sci. 2021, 138, 49678. [Google Scholar] [CrossRef]

- Liu, B.X.; Hu, G.S.; Zhang, J.T.; Fang, C.H. Synthesis, characterization and thermal decomposition kinetics of a bio-based transparent nylon 10I/10T. Des. Monomers Polym. 2018, 21, 182–192. [Google Scholar] [CrossRef]

- Du, L.X.; Yu, H.N.; Zhang, B.H.; Tang, R.L.; Zhang, Y.; Qi, C.S.; Wolcott, M.P.; Yu, Z.M.; Wang, J.W. Transparent oxygen barrier nanocellulose composite films with a sandwich structure. Carbohydr. Polym. 2021, 268, 118206. [Google Scholar] [CrossRef] [PubMed]

- Gao, H.W.; Cao, W.K.; He, J.M.; Bai, Y.P. Highly transparent biaxially oriented poly(ester amide) film with improved gas barrier properties and good mechanical strength. Eur. Polym. J. 2021, 156, 110620. [Google Scholar] [CrossRef]

- Lin, X.T.; Wu, Y.C.; Cui, L.N.; Chen, X.; Fan, S.H.; Liu, Y.J.; Liu, X.C.; Zheng, W. Crystal structure, morphology, and mechanical properties of biaxially oriented polyamide-6 films toughened with poly(ether block amide). Polym. Adv. Technol. 2022, 33, 137–145. [Google Scholar] [CrossRef]

- Jiang, W.J.; Liang, Y.K.; Zhang, Y.; Xie, Z.H.; Zhou, J.; Kang, J.; Cao, Y.; Xiang, M. Preparation of graphene oxide-silica nanohybrid/poly(lactic acid) biaxially oriented films with enhanced mechanical properties. Polymer 2022, 261, 125410. [Google Scholar] [CrossRef]

- Kanai, T.; Okuyama, Y.; Takashige, M. Dynamics and structure development for biaxial stretching polyamide 6 films. Adv. Polym. Technol. 2018, 37, 2894–2904. [Google Scholar] [CrossRef]

- Li, Z.P.; Chen, X.Y.; Zhang, C.; Baer, E.; Langhe, D.; Ponting, M.; Brubaker, M.; Hosking, T.; Li, R.P.; Fukuto, M.; et al. High Dielectric Constant Polycarbonate/Nylon Multilayer Films Capacitors with Self-Healing Capability. ACS Appl. Polym. Mater. 2019, 1, 867–875. [Google Scholar] [CrossRef]

- Yi, Z.W.; Liu, Y.J.; Liu, X.C.; Fan, S.H.; Yang, J.; Mao, L.; Lin, X.T.; Peng, S.M.; Zheng, W. Biaxially stretched polyamide 6/ethylene vinyl alcohol copolymer films with improved oxygen barrier and mechanical properties. Polym. Bull. 2023, 80, 3085–3101. [Google Scholar] [CrossRef]

- Dow, T.-B. Sustainable packaging solutions and ENGAGETM PV POE Win 2018 R&D 100 Awards. China Chem. Rep. 2019, 30, 6. [Google Scholar]

- Marchildon, K. Polyamides—Still Strong After Seventy Years. Macromol. React. Eng. 2011, 5, 22–54. [Google Scholar] [CrossRef]

- Dasari, A.; Yu, Z.Z.; Yang, M.S.; Zhang, Q.X.; Xie, X.L.; Mai, Y.W. Micro- and nano-scale deformation behavior of nylon 66-based binary and ternary nanocomposites. Compos. Sci. Technol. 2006, 66, 3097–3114. [Google Scholar] [CrossRef]

- Thomas, S.; Visakh, P. Handbook of Engineering and Specialty Thermoplastics, Volume 4: Nylons; John Wiley & Sons: Hoboken, NJ, USA, 2011; Volume 4. [Google Scholar]

- Skrovanek, D.J.; Howe, S.E.; Painter, P.C.; Coleman, M.M. Hydrogen bonding in polymers: Infrared temperature studies of an amorphous polyamide. Macromolecules 1985, 18, 1676–1683. [Google Scholar] [CrossRef]

- Vasanthan, N.; Salem, D. FTIR spectroscopic characterization of structural changes in polyamide-6 fibers during annealing and drawing. J. Polym. Sci. Part B Polym. Phys. 2001, 39, 536–547. [Google Scholar] [CrossRef]

- Vasanthan, N.; Murthy, N.S.; Bray, R.G. Investigation of Brill transition in nylon 6 and nylon 6, 6 by infrared spectroscopy. Macromolecules 1998, 31, 8433–8435. [Google Scholar] [CrossRef]

- Charles, J.; Ramkumaar, G.R.; Azhagiri, S.; Gunasekaran, S. FTIR and Thermal Studies on Nylon-66 and 30% Glass Fibre Reinforced Nylon-66. E-J. Chem. 2009, 6, 23–33. [Google Scholar] [CrossRef]

- Dong, J.; Fan, Z. Nonisothermal Crystallization Behaviour of a Novel Cycloaliphatic Microcrystalline Poly(4,4’-Aminocyclohexyl Methylene Dodecanedicarboxylamide). Polym. Polym. Compos. 2014, 22, 401–408. [Google Scholar] [CrossRef]

- Rwei, S.P.; Tseng, Y.C.; Chiu, K.C.; Chang, S.M.; Chen, Y.M. The crystallization kinetics of Nylon 6/6T and Nylon 66/6T copolymers. Thermochim. Acta 2013, 555, 37–45. [Google Scholar] [CrossRef]

- Itoh, T.; Yamagata, T.; Hasegawa, Y.; Hashimoto, M.; Konishi, T. Energetically stable conformations of nylon 66 and nylon 6 molecules in crystals. Jpn. J. Appl. Phys. Part 1-Regul. Pap. Short Notes Rev. Pap. 1996, 35, 4474–4475. [Google Scholar] [CrossRef]

- Chi, E.Y.; Tang, Y.J.; Wang, Z.B. In Situ SAXS and WAXD Investigations of Polyamide 66/Reduced Graphene Oxide Nanocomposites During Uniaxial Deformation. ACS Omega 2021, 6, 11762–11771. [Google Scholar] [CrossRef]

- Lin, X.T.; Liu, Y.J.; Jin, R.J.; Peng, Y. Structure evolution and properties enhancement of polyamide-6/polyamide-1010 films under uniaxial and biaxial stretching. J. Appl. Polym. Sci. 2023, 140, e54253. [Google Scholar] [CrossRef]

- Pepin, J.; Gaucher, V.; Lefebvre, J.M.; Stroeks, A. Biaxial stretching behavior as a probe of H-bond organization in semi-crystalline polyamides. Polymer 2016, 101, 217–224. [Google Scholar] [CrossRef]

- Shanak, H.; Ehses, K.H.; Götz, W.; Leibenguth, P.; Pelster, R. X-ray diffraction investigations of α-polyamide 6 films: Orientation and structural changes upon uni- and biaxial drawing. J. Mater. Sci. 2009, 44, 655–663. [Google Scholar] [CrossRef]

- Huan, Y.; Liu, Y.Y.; Yang, Y.F. Simultaneous stretching and static electric field poling of poly(vinylidene fluoride-hexafluoropropylene) copolymer films. Polym. Eng. Sci. 2007, 47, 1630–1633. [Google Scholar] [CrossRef]

- Lin, Y.; Bilotti, E.; Bastiaansen, C.W.M.; Peijs, T. Transparent semi-crystalline polymeric materials and their nanocomposites: A review. Polym. Eng. Sci. 2020, 60, 2351–2376. [Google Scholar] [CrossRef]

- Abad, M.; Ares, A.; Barral, L.; Cano, J.; Diez, F.; Lopez, J.; Ramirez, C. Characterization of biaxially oriented polypropylene films by atomic force microscopy and microthermal analysis. J. Appl. Polym. Sci. 2002, 85, 1553–1561. [Google Scholar] [CrossRef]

- Nie, H.-Y.; Walzak, M.; McIntyre, N. Draw-ratio-dependent morphology of biaxially oriented polypropylene films as determined by atomic force microscopy. Polymer 2000, 41, 2213–2218. [Google Scholar] [CrossRef]

- Mushtaq, N.; Wang, Q.; Chen, G.; Bashir, B.; Lao, H.; Zhang, Y.; Sidra, L.R.; Fang, X. Synthesis of polyamide-imides with different monomer sequence and effect on transparency and thermal properties. Polymer 2020, 190, 122218. [Google Scholar] [CrossRef]

- Havel, M.; Behler, K.; Korneva, G.; Gogotsi, Y. Transparent Thin Films of Multiwalled Carbon Nanotubes Self-Assembled on Polyamide 11 Nanofibers. Adv. Funct. Mater. 2008, 18, 2322–2327. [Google Scholar] [CrossRef]

- Jiang, S.; Duan, G.; Hou, H.; Greiner, A.; Agarwal, S. Novel Layer-by-Layer Procedure for Making Nylon-6 Nanofiber Reinforced High Strength, Tough, and Transparent Thermoplastic Polyurethane Composites. ACS Appl. Mater. Interfaces 2012, 4, 4366–4372. [Google Scholar] [CrossRef] [PubMed]

- Lao, H.; Mushtaq, N.; Chen, G.; Jiang, H.; Jiao, Y.; Zhang, A.; Fang, X. Transparent polyamide-imide films with high Tg and low coefficient of thermal expansion: Design and synthesis. Polymer 2020, 206, 122889. [Google Scholar] [CrossRef]

- Liaw, D.J.; Chen, W.H.; Hu, C.K.; Lee, K.R.; Lai, J.Y. High optical transparency, low dielectric constant and light color of novel organosoluble polyamides with bulky alicyclic pendent group. Polymer 2007, 48, 6571–6580. [Google Scholar] [CrossRef]

- Lao, H.; Mushtaq, N.; Chen, G.; Wang, B.; Ba, Y.; Fang, X. Synthesis and properties of transparent random and multi-block polyamide-imide films with high modulus and low CTE. Eur. Polym. J. 2021, 153, 110512. [Google Scholar] [CrossRef]

- Yang, B.; Leng, J.; He, B.; Liu, H.; Zhang, Y.; Duan, Z. Influence of fiber length and compatibilizer on mechanical properties of long glass fiber reinforced polyamide 6,6. J. Reinf. Plast. Compos. 2012, 31, 1103–1112. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Yi, Y.; Wang, C.; Lu, W.; Liao, M.; Jing, X.; Wang, W. An Intrinsically Transparent Polyamide Film with Superior Toughness and Great Optical Performance. Polymers 2024, 16, 599. https://doi.org/10.3390/polym16050599

Li J, Yi Y, Wang C, Lu W, Liao M, Jing X, Wang W. An Intrinsically Transparent Polyamide Film with Superior Toughness and Great Optical Performance. Polymers. 2024; 16(5):599. https://doi.org/10.3390/polym16050599

Chicago/Turabian StyleLi, Jianlin, Yong Yi, Chunhua Wang, Weijian Lu, Mingxi Liao, Xin Jing, and Wenzhi Wang. 2024. "An Intrinsically Transparent Polyamide Film with Superior Toughness and Great Optical Performance" Polymers 16, no. 5: 599. https://doi.org/10.3390/polym16050599

APA StyleLi, J., Yi, Y., Wang, C., Lu, W., Liao, M., Jing, X., & Wang, W. (2024). An Intrinsically Transparent Polyamide Film with Superior Toughness and Great Optical Performance. Polymers, 16(5), 599. https://doi.org/10.3390/polym16050599