Sustainable Asphalt Mixtures with Enhanced Water Resistance for Flood-Prone Regions Using Recycled LDPE and Carnauba–Soybean Oil Additive

Abstract

1. Introduction

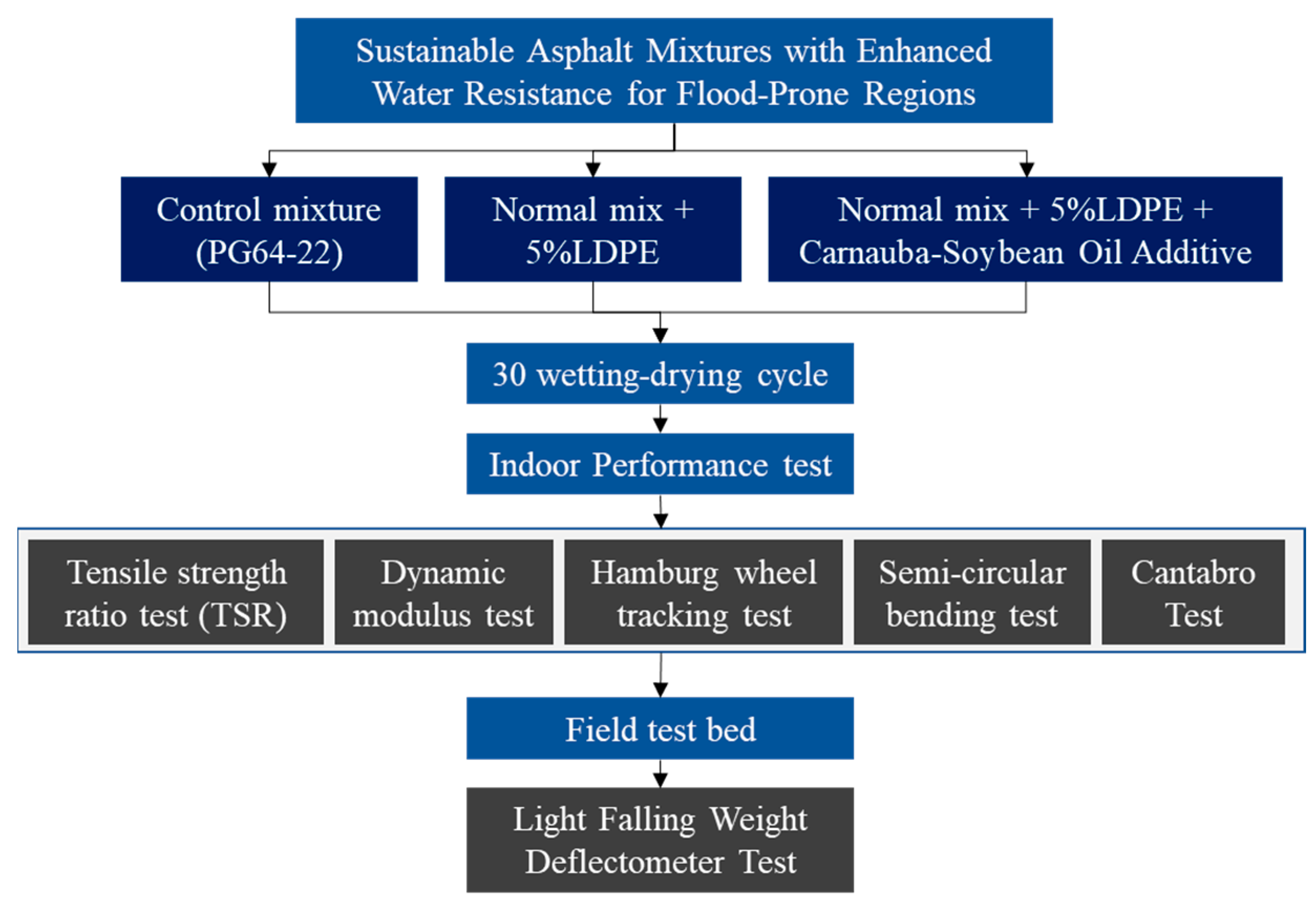

2. Materials and Methods

2.1. Materials

2.1.1. Asphalt Binder

2.1.2. Carnauba and Soybean Oil Additive

2.1.3. Aggregates

2.1.4. Mix Design

| Property | Control Binder | LDPE Modified Binder | LDPE Modified + Oil Modified Binder |

|---|---|---|---|

| Penetration (dmm) [34] | 70 | 55 | 45 |

| Softening Point (°C) [35] | 50 | 55 | 60 |

| Ductility (cm) [35] | 100 | 150 | 180 |

| Dynamic Shear Rheometer (DSR) [36] | 2000 Pa | 1800 Pa | 1600 Pa |

| Rotational Viscometer (RV) | 3000 cSt | 2500 cSt | 2200 cSt |

| RTFOT Mass Loss (%) [37] | 1.5 | 1.2 | 1.0 |

| RTFOT Residue Mass (%) | 99.0 | 98.8 | 99.2 |

| Pressure Aging Vessel (PAV) Mass Loss (%) [38] | 2.0 | 1.8 | 1.5 |

| PAV Residue Mass (%) | 97.5 | 97.9 | 98.5 |

2.1.5. Simulation of Wetting–Drying Cycle Conditions

2.2. Testing Methods

2.2.1. TSR Test Method

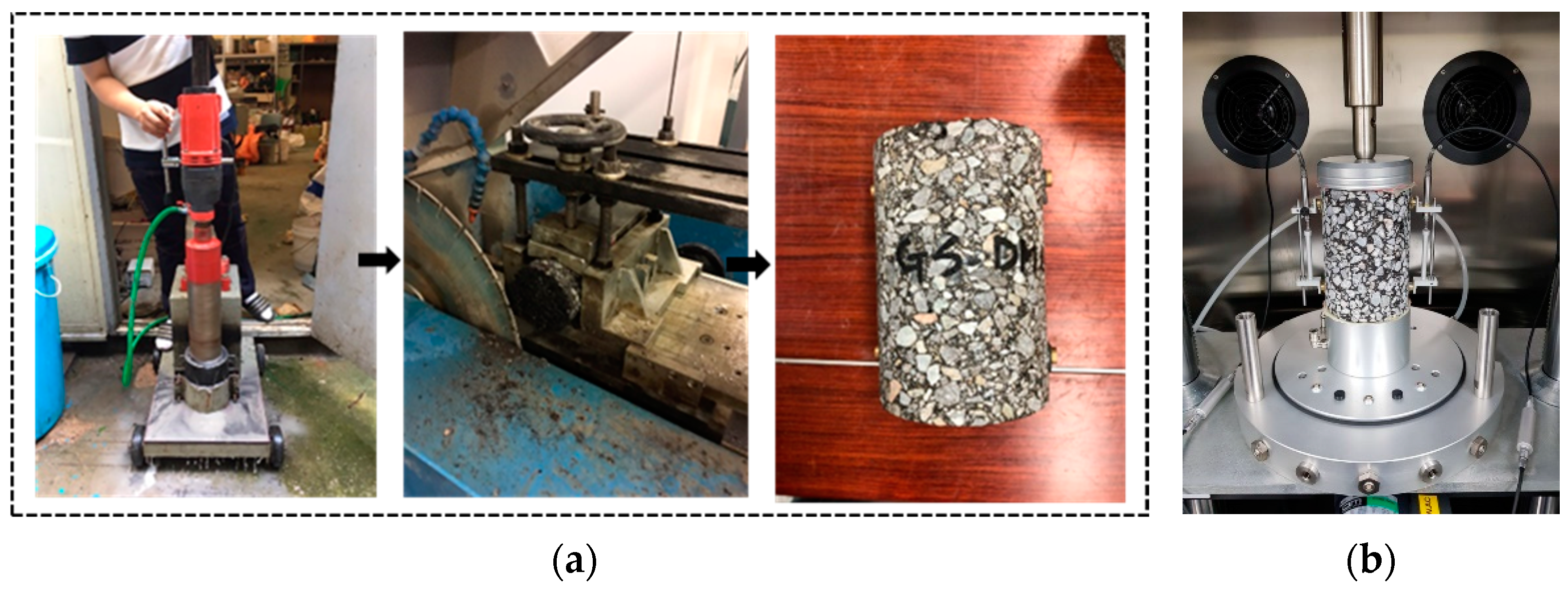

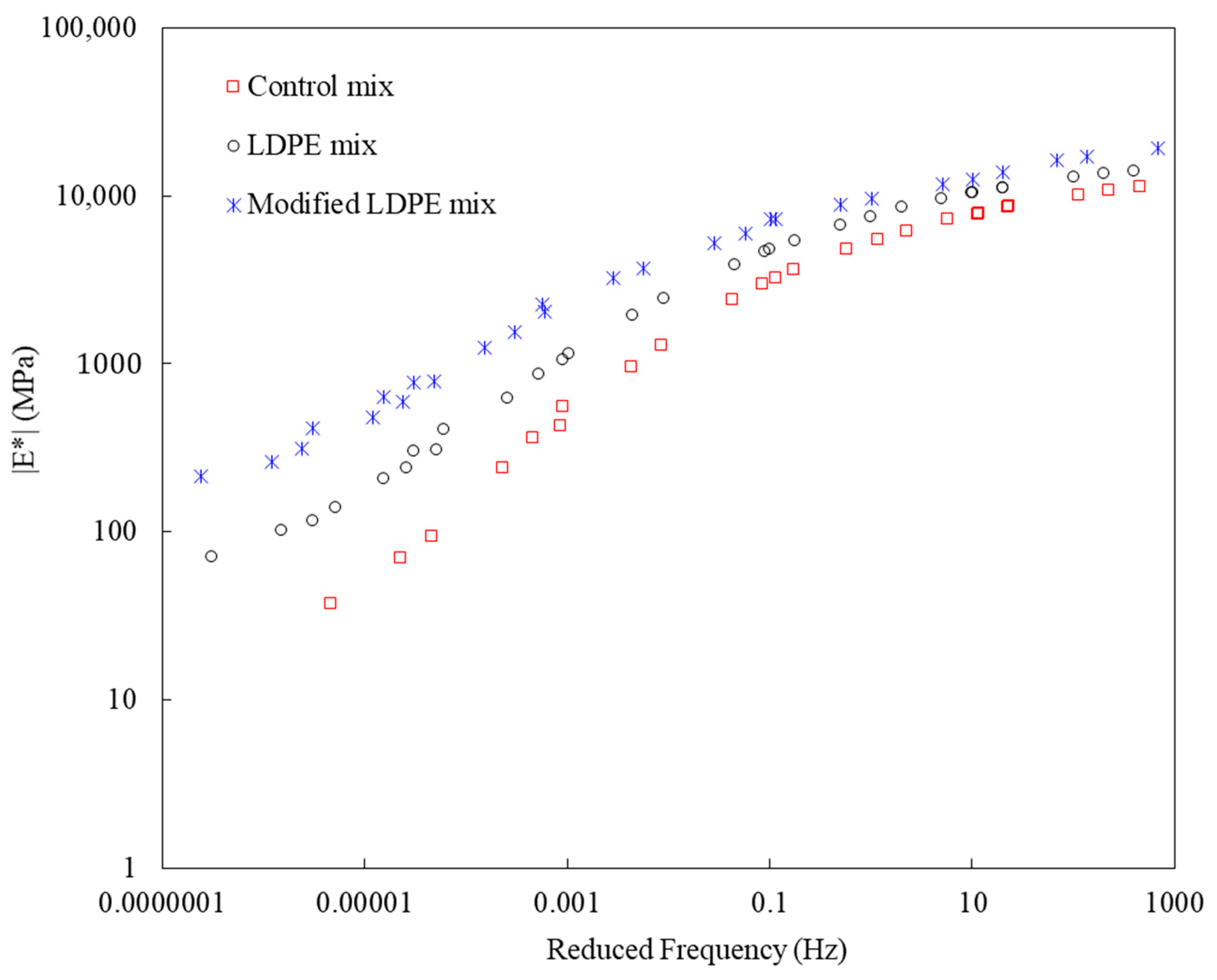

2.2.2. Dynamic Modulus Test

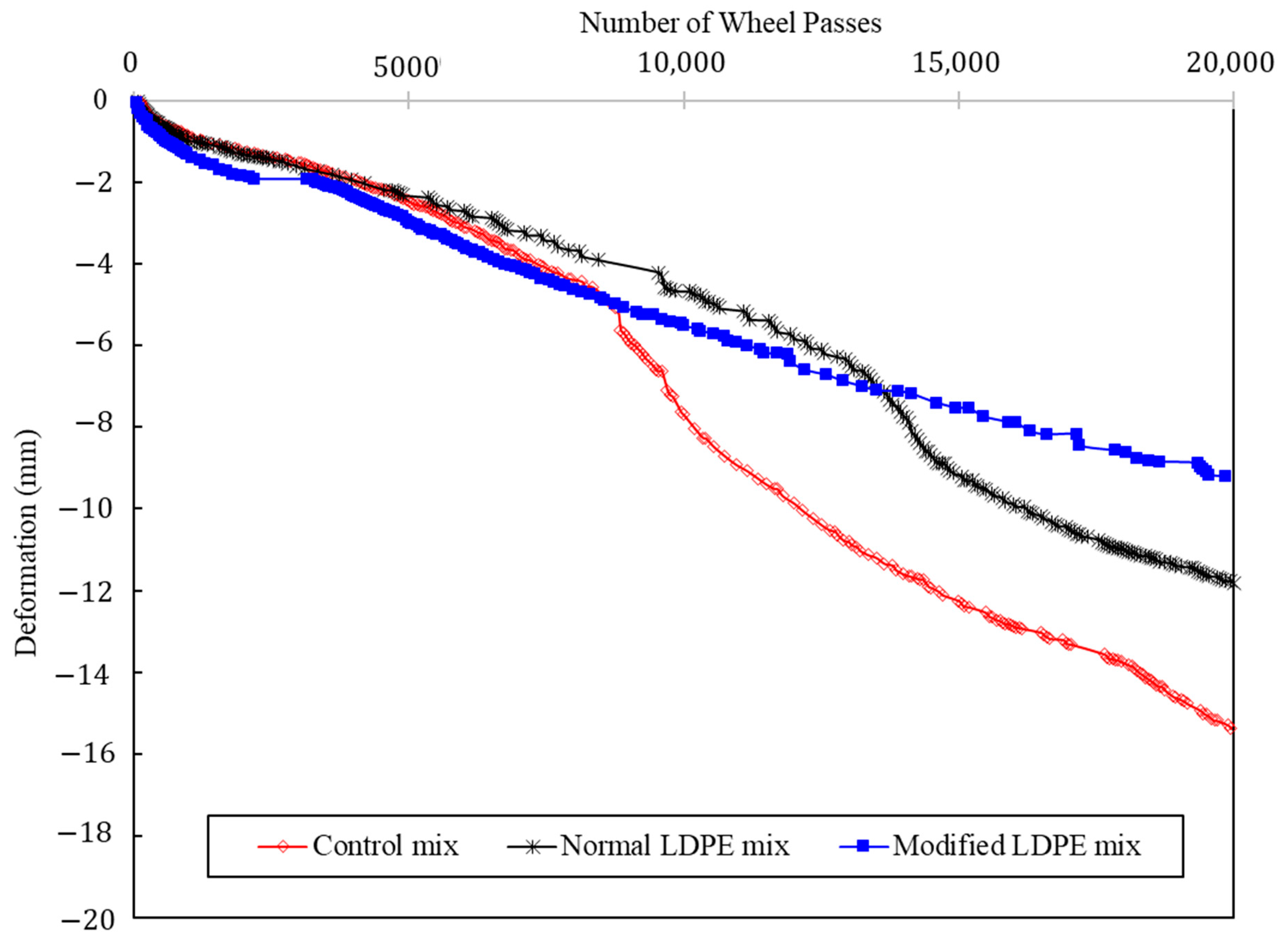

2.2.3. HWT Test

2.2.4. Semi-Circular Bending Test

2.2.5. Cantabro Test

2.2.6. Field Test

3. Results and Discussions

3.1. TSR Test Results

3.2. Dynamic Modulus Test Results

3.3. SCB Test Results

3.4. HWT Test Results

3.5. Cantabro Test Results

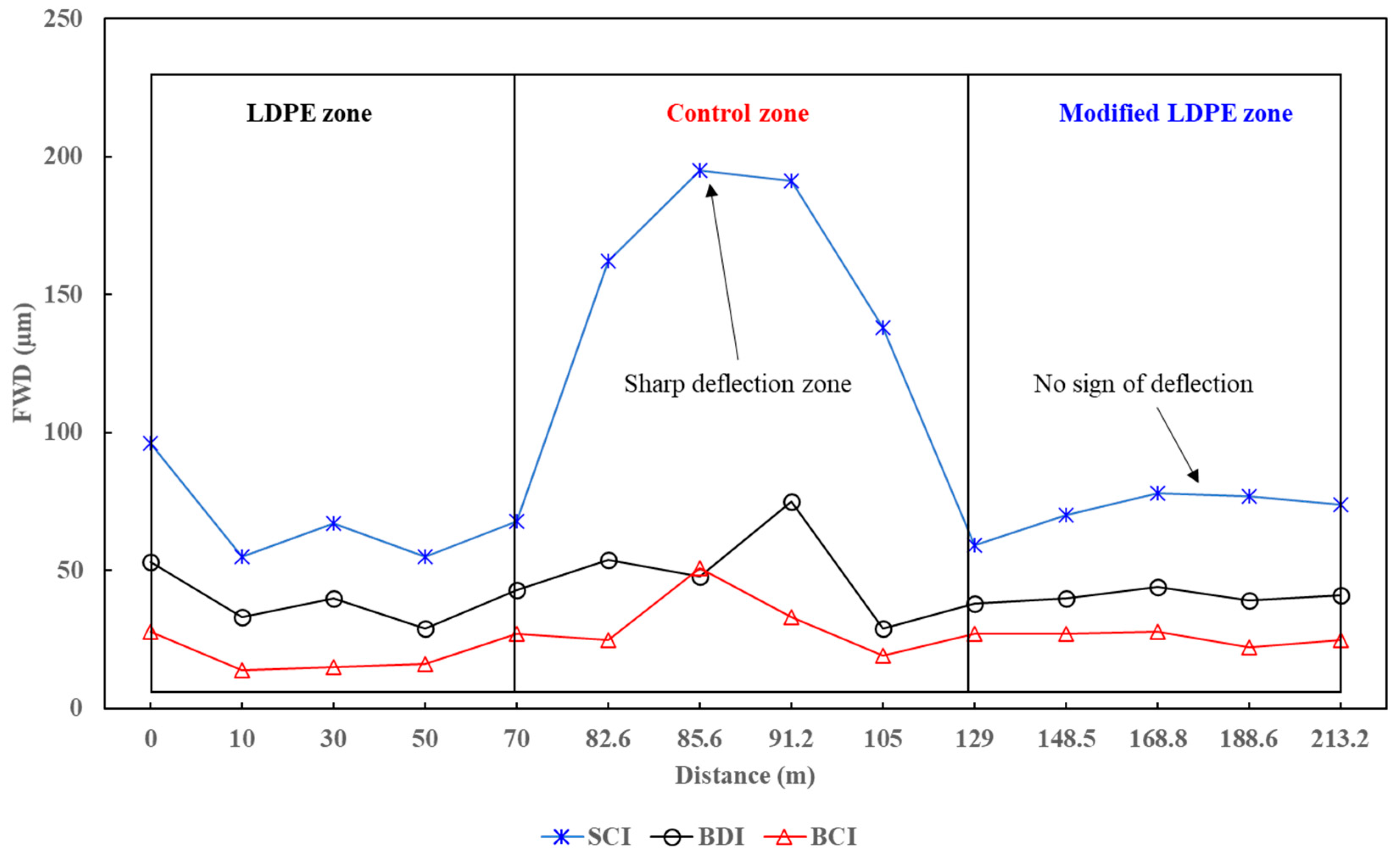

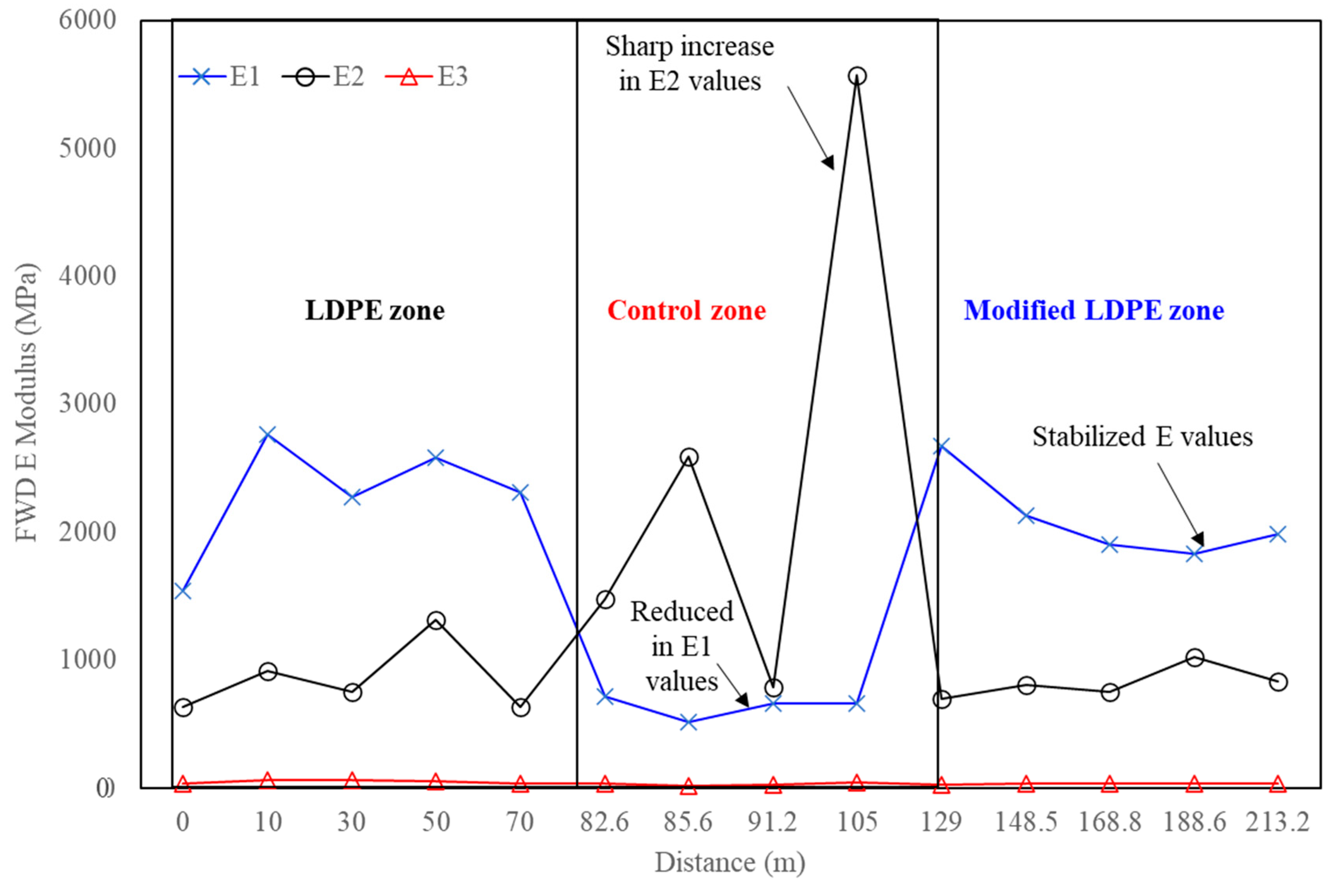

3.6. The Field Test Results

3.7. Feasibility for Large-Scale Application of Natural Oils Discussion

4. Conclusions

- In the blending process, the asphalt binder was heated to the specified mixing temperature, followed by the gradual introduction of recycled LDPE, Carnauba wax, Soybean Oil, and aggregates.

- In TSR tests, asphalt mixtures showed significant tensile strength improvements with innovative additives. The control mixture had a TSR of 82.9%, while LDPE (5%) yielded 83.4%. The most substantial improvement came from LDPE (5%) with 3% Oil, achieving an impressive TSR of 85.7%.

- The Dynamic Modulus test results reveal enhanced rutting resistance in asphalt mixtures with the incorporation of LDPE and a 3% oil additive. The Control mixture showed a Dynamic Modulus of 37 mPa at the lowest frequency, while LDPE (5%) + Control demonstrated a notable increase to 72 mPa. The LDPE (5%) with 3% Oil-modified mixture exhibited a remarkable improvement, reaching 214 mPa, highlighting the synergistic effects of LDPE and the oil additive. LDPE contributes to improved elastic and mechanical properties, while the oil additive acts as a rejuvenator.

- The SCB test reveals significant improvements in fracture characteristics and energy absorption by incorporating 5% LDPE and 3% oil into asphalt mixtures. The LDPE-modified mixture showed a stiffer break but a higher fracture point (6.2 mPa), while the LDPE (5%) with 3% Oil-modified mixture achieved a softer break, lower fracture point (5.4 mPa), and the highest fracture energy (518 J/m2).

- The HWT test assesses the resistance of asphalt mixtures to rutting and deformation under repetitive loading, simulating real-world traffic conditions. The LDPE (5%) + 3% Oil + Control mixture showed enhanced moisture resistance by exhibiting no sign of a stripping point throughout the test, indicating improved durability. In terms of rutting resistance, the LDPE (5%) + 3% Oil + Control mixture outperformed both counterparts at 20,000 cycles, with a deformation of 9.2 mm, representing a significant percentage reduction of approximately 39.7%.

- The Cantabro test results provide valuable insights into the aggregate shatter resistance of asphalt mixtures, emphasizing their cohesion and wear resistance. The LDPE (5%) + 3% Oil + Control mixture demonstrated the most significant enhancement with the lowest weight loss rate at 9.820%, showcasing the synergistic effects of LDPE and the introduced oil additive.

- The field test results offer crucial insights into the real-world performance of asphalt mixtures, specifically in terms of stress and deformation parameters. Analyzing the highest deflection in the surface layer, the LDPE (5%) + 3% Oil + Control mixture displayed superior stability with a 61% reduction in deflection compared to the Control mixture and a 19% improvement over the LDPE (5%) + Control mixture. Considering the lowest E1 (surface modulus), a key parameter indicating surface resistance to stress, the LDPE (5%) + 3% Oil + Control mixture demonstrated the highest E1 value at 1827 mPa, representing a notable 256% improvement over the Control mixture. Simultaneously, the LDPE (5%) + 3% Oil + Control mixture exhibited a low E2 stress of 1023 mPa, indicating a safe and well-distributed stress profile.

- While this study has advanced asphalt mixture performance with LDPE and an oil additive, it comes with limitations. Variations in climate and traffic conditions could affect outcomes, and long-term performance requires further observation. Future studies should explore diverse additives, consider varied environmental conditions, and assess economic feasibility. Additionally, examining the environmental impact and recyclability of modified mixtures would contribute to a comprehensive understanding of sustainability. This research serves as a foundation for ongoing exploration, aiming for advancements in creating durable, sustainable, and high-performance road pavement materials.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Lin, P.; Liu, X.; Ren, S.; Xu, J.; Li, Y.; Li, M. Effects of Bitumen Thickness on the Aging Behavior of High-Content Polymer-Modified Asphalt Mixture. Polymers 2023, 15, 2325. [Google Scholar] [CrossRef]

- Yao, L.; Leng, Z.; Ni, F.; Lu, G.; Jiang, J. Adaptive Maintenance Strategies to Mitigate Climate Change Impacts on Asphalt Pavements. Transp. Res. Part D Transp. Environ. 2024, 126, 104026. [Google Scholar] [CrossRef]

- Avilés-Rojas, N.; Suárez, F.; Chamorro, A.; González, A. Flood Impact on Structural Response of Asphalt Pavement: A Finite Element Modeling Approach. Structures 2023, 57, 105259. [Google Scholar] [CrossRef]

- Wang, P.; Qin, Y.; Wang, J.; Zeng, W.; Chang, R.; Zhang, Y.; Huang, W. Polyurethane Trackless Emulsified Asphalt Tack Coats with Self-Migration Properties for Tracking Resistance and Shear Resistance Enhancement. Mater. Lett. 2023, 332, 133553. [Google Scholar] [CrossRef]

- Suddeepong, A.; Intra, A.; Horpibulsuk, S.; Suksiripattanapong, C.; Arulrajah, A.; Shen, J.S. Durability against Wetting-Drying Cycles for Cement-Stabilized Reclaimed Asphalt Pavement Blended with Crushed Rock. Soils Found. 2018, 58, 333–343. [Google Scholar] [CrossRef]

- Hoy, M.; Rachan, R.; Horpibulsuk, S.; Arulrajah, A.; Mirzababaei, M. Effect of Wetting–Drying Cycles on Compressive Strength and Microstructure of Recycled Asphalt Pavement—Fly Ash Geopolymer. Constr. Build. Mater. 2017, 144, 624–634. [Google Scholar] [CrossRef]

- Rueda, E.J.; Caro, S.; Caicedo, B. Influence of Wetting-Drying Cycles on the Linear Viscoelastic Properties of Asphalt Mixtures. Constr. Build. Mater. 2023, 393, 132072. [Google Scholar] [CrossRef]

- Meng, Y.; Ouyang, J.; Ou, J. Investigation on the Wetting Behavior of Asphalt Emulsion on Aggregate for Asphalt Emulsion Mixture. Constr. Build. Mater. 2023, 400, 132844. [Google Scholar] [CrossRef]

- Capitão, S.; Picado-Santos, L.; Almeida, A.; Mendes, F. Assessment of Aged and Unaged Hot and Warm Asphalt Concrete Containing High Reclaimed Asphalt Pavement Rate Rejuvenated with Waste Cooking Oil. Constr. Build. Mater. 2023, 400, 132801. [Google Scholar] [CrossRef]

- Chen, X.; Ren, D.; Tian, G.; Xu, J.; Ali, R.; Ai, C. Investigation on Moisture Damage Resistance of Asphalt Pavement in Salt and Acid Erosion Environments Based on Multi-Scale Analysis. Constr. Build. Mater. 2023, 366, 130177. [Google Scholar] [CrossRef]

- Liu, J.; Wang, W.; Wang, Y.; Zhou, X.; Wang, S.; Liu, Q.; Yu, B. Towards the Sustainable Utilization of Steel Slag in Asphalt Pavements: A Case Study of Moisture Resistance and Life Cycle Assessment. Case Stud. Constr. Mater. 2023, 18, e01722. [Google Scholar] [CrossRef]

- Valdés-Vidal, G.; Calabi-Floody, A.; Mignolet-Garrido, C.; Díaz-Montecinos, C. Effect of a New Additive Based on Textile Fibres from End-of-Life Tyres (ELT) on the Mechanical Properties of Stone Mastic Asphalt. Polymers 2023, 15, 1705. [Google Scholar] [CrossRef]

- Lee, J.S.; Lee, S.Y.; Le, T.H.M. Developing Performance-Based Mix Design Framework Using Asphalt Mixture Performance Tester and Mechanistic Models. Polymers 2023, 15, 1692. [Google Scholar] [CrossRef]

- Agha, N.; Hussain, A.; Ali, A.S.; Qiu, Y. Performance Evaluation of Hot Mix Asphalt (HMA) Containing Polyethylene Terephthalate (PET) Using Wet and Dry Mixing Techniques. Polymers 2023, 15, 1211. [Google Scholar] [CrossRef] [PubMed]

- Dong, R.; Zhang, Z.; Zhou, T.; Deng, W.; You, H. Research on the Fatigue Properties of Rejuvenated Asphalt Prepared by Waste Cooking Oil Pre-Desulfurized Crumb Tire Rubber. Polymers 2023, 15, 740. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Guo, T.; Chen, Y.; Zhang, T.; Tang, D.; Hao, M.; Zhao, X.; Liu, J. Study on Road Performance of Polyurethane Cold-Recycled Mixture. Polymers 2023, 15, 1958. [Google Scholar] [CrossRef] [PubMed]

- Alnadish, A.M.; Singh, N.S.S.; Alawag, A.M. Applications of Synthetic, Natural, and Waste Fibers in Asphalt Mixtures: A Citation-Based Review. Polymers 2023, 15, 1004. [Google Scholar] [CrossRef] [PubMed]

- Nisar, J.; Shafi Mir, M. Study on Optimal Preparation and Rheological Characteristics of Waste Low Density Polyethylene (LDPE)/Styrene Butadiene Styrene (SBS) Composite Modified Asphalt Binder. Constr. Build. Mater. 2023, 407, 133459. [Google Scholar] [CrossRef]

- Hong, Z.; Yan, K.; Ge, D.; Wang, M.; Li, G.; Li, H. Effect of Styrene-Butadiene-Styrene (SBS) on Laboratory Properties of Low-Density Polyethylene (LDPE)/Ethylene-Vinyl Acetate (EVA) Compound Modified Asphalt. J. Clean. Prod. 2022, 338, 130677. [Google Scholar] [CrossRef]

- Genet, M.B.; Sendekie, Z.B.; Jembere, A.L. Investigation and Optimization of Waste LDPE Plastic as a Modifier of Asphalt Mix for Highway Asphalt: Case of Ethiopian Roads. Case Stud. Chem. Environ. Eng. 2021, 4, 100150. [Google Scholar] [CrossRef]

- Almutairi, H.; Baaj, H. Evaluating Self-Healing Behaviour of Asphalt Binders Modified with Phase-Change Materials, Polymers and Recycled Glass Powder. Polymers 2023, 15, 1934. [Google Scholar] [CrossRef]

- Yi, Y.; Chen, Y.; Shi, S.; Zhao, Y.; Wang, D.; Lei, T.; Duan, P.; Cao, W.; Wang, Q.; Li, H. Study on Properties and Micro-Mechanism of RHB-SBS Composite-Modified Asphalt. Polymers 2023, 15, 1718. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.-Y.; Kim, K.-W.; Yun, Y.; Minh Le, T.H. Evaluation of Eco-Friendly Asphalt Mixtures Incorporating Waste Plastic Aggregates and Additives: Magnesium, Fly Ash, and Steel Slag. Case Stud. Constr. Mater. 2024, 20, e02756. [Google Scholar] [CrossRef]

- Hwan, K.J.; Kim, K.; Haeng, J.S.; Le, T.H.M. Feasibility of Carnauba Wax Rejuvenators for Asphalt Concrete with Vacuum Tower Bottom Binder. Coatings 2023, 13, 1451. [Google Scholar] [CrossRef]

- He, L.; Tao, M.; Liu, Z.; Cao, Z.; Zhu, J.; Gao, J.; Bergh, W.V.D.; Chailleux, E.; Huang, Y.; Vasconcelos, K.; et al. Biomass Valorization toward Sustainable Asphalt Pavements: Progress and Prospects. Waste Manag. 2023, 165, 159–178. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Ge, J.; Qian, G.; Zhang, C.; Dai, W.; Li, P. Evaluation on the Rejuvenation and Diffusion Characteristics of Waste Cooking Oil on Aged SBS Asphalt Based on Molecular Dynamics Method. J. Clean. Prod. 2023, 406, 136998. [Google Scholar] [CrossRef]

- Dinh, B.H.; Park, D.W.; Le, T.H.M. Effect of Rejuvenators on the Crack Healing Performance of Recycled Asphalt Pavement by Induction Heating. Constr. Build. Mater. 2018, 164, 246–254. [Google Scholar] [CrossRef]

- Xu, N.; Wang, H.; Wang, H.; Kazemi, M.; Fini, E. Research Progress on Resource Utilization of Waste Cooking Oil in Asphalt Materials: A State-of-the-Art Review. J. Clean. Prod. 2023, 385, 135427. [Google Scholar] [CrossRef]

- Hou, Y.; Chen, Y.; Zou, H.; Ji, X.; Shao, D.; Zhang, Z.; Chen, Y. Investigation of Surface Micro-Mechanical Properties of Various Asphalt Binders Using AFM. Materials 2022, 15, 4358. [Google Scholar] [CrossRef]

- Aliyu Yaro, N.S.; Sutanto, M.H.; Habib, N.Z.; Napiah, M.; Usman, A.; Jagaba, A.H.; Al-Sabaeei, A.M. Application and Circular Economy Prospects of Palm Oil Waste for Eco-Friendly Asphalt Pavement Industry: A Review. J. Road Eng. 2022, 2, 309–331. [Google Scholar] [CrossRef]

- Gaudenzi, E.; Canestrari, F.; Lu, X.; Cardone, F. Performance Assessment of Asphalt Mixture Produced with a Bio-Based Binder. Materials 2021, 14, 918. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.Y.; Ho Minh Le, T.; Kim, Y.M. Full-Scale and Laboratory Investigations on the Performance of Asphalt Mixture Containing Recycled Aggregate with Low Viscosity Binder. Constr. Build. Mater. 2023, 367, 130283. [Google Scholar] [CrossRef]

- Lee, S.Y.; Le, T.H.M. Evaluating Pavement Performance in Bus Rapid Transit Systems: Lessons from Seoul, South Korea. Case Stud. Constr. Mater. 2023, 18, e02065. [Google Scholar] [CrossRef]

- ASTM D5; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D36-16; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D7175-15; Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer. ASTM International: West Conshohocken, PA, USA, 2020; pp. 1–11.

- Aashto T350-14; AASHTO T350 Standard Method of Test for Multiple Stress Creep Recovery (MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials: Washington, D.C., USA, 2014; pp. 3–6.

- Anderson, D.A.; Bahia, H.U.; Dongre, R. Rheological Properties of Mineral Filler-Asphalt Mastics and Its Importance to Pavement Performance. ASTM Spec. Tech. Publ. 1992, 131–153. [Google Scholar] [CrossRef]

- ASTM D6931; Standard Test Method for Indirect Tensile (IDT) Strength of Bituminous Mixtures. ASTM International: West Conshohocken, PA, USA, 2017; pp. 1–5.

- AASHTO T342-11; Standard Method of Test for Determining Dynamic Modulus of Hot-Mix Asphalt Concrete Mixtures. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2019.

- AASHTO T324; Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Hot Mixtures. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2017; Volume 3, pp. 1–8.

- ASTM D8044-16; Standard Test Method for Evaluation of Asphalt Mixture Cracking Resistance Using the Semi-Circular Bend Test (SCB) at Intermediate Temperatures. ASTM International: West Conshohocken, PA, USA, 2016; pp. 1–7.

- ASTM D7064-08; Standard Practice for Open-Graded Friction Course (OGFC) Mix Design. ASTM International: West Conshohocken, PA, USA, 2013; Volume 8, pp. 1–7.

- ASTM E2835-07; Standard Test Method for Measuring Deflections with a Light Weight Deflectometer (LWD). ASTM International: West Conshohocken, PA, USA, 2015; Volume 7, pp. 5–7.

- Kennedy, J. A Full-Scale Laboratory Investigation into Railway Track Substructure Performance and Ballast Reinforcement. Ph.D. Thesis, Heriot-Watt University, Edinburgh, UK, 2011; 274p. [Google Scholar]

| Property | Value |

|---|---|

| Polymer Type | LDPE |

| Source of LDPE | Recycled post-consumer plastic waste |

| Molecular Weight | 90,000 g/mol |

| Melting Point | 110 °C |

| Glass Transition Temperature | −80 °C |

| Density | 0.92 g/cm3 |

| Melt Flow Index | 2.5 g/10 min |

| Chemical Structure | Linear hydrocarbon polymer |

| Particle Size Distribution | 100–500 microns |

| Compatibility with Asphalt | Excellent |

| Environmental Impact | Sustainable, recycled material |

| Specimen Weight (g) | Weight after the Test (g) | Loss Rate (within 20% Based on Drainage) | |

|---|---|---|---|

| Controlled mix | 1217.268 | 1037.646 | 15.051 |

| LDPE (5%) + Control Mixture | 1214.82 | 1066.716 | 12.434 |

| LDPE (5%) + 3% Oil + Control Mixture | 1216.248 | 1099.152 | 9.820 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.-M.; Kim, K.; Le, T.H.M. Sustainable Asphalt Mixtures with Enhanced Water Resistance for Flood-Prone Regions Using Recycled LDPE and Carnauba–Soybean Oil Additive. Polymers 2024, 16, 600. https://doi.org/10.3390/polym16050600

Kim Y-M, Kim K, Le THM. Sustainable Asphalt Mixtures with Enhanced Water Resistance for Flood-Prone Regions Using Recycled LDPE and Carnauba–Soybean Oil Additive. Polymers. 2024; 16(5):600. https://doi.org/10.3390/polym16050600

Chicago/Turabian StyleKim, Yeong-Min, Kyungnam Kim, and Tri Ho Minh Le. 2024. "Sustainable Asphalt Mixtures with Enhanced Water Resistance for Flood-Prone Regions Using Recycled LDPE and Carnauba–Soybean Oil Additive" Polymers 16, no. 5: 600. https://doi.org/10.3390/polym16050600

APA StyleKim, Y.-M., Kim, K., & Le, T. H. M. (2024). Sustainable Asphalt Mixtures with Enhanced Water Resistance for Flood-Prone Regions Using Recycled LDPE and Carnauba–Soybean Oil Additive. Polymers, 16(5), 600. https://doi.org/10.3390/polym16050600