Recent Progress on Conversion of Lignocellulosic Biomass by MOF-Immobilized Enzyme

Abstract

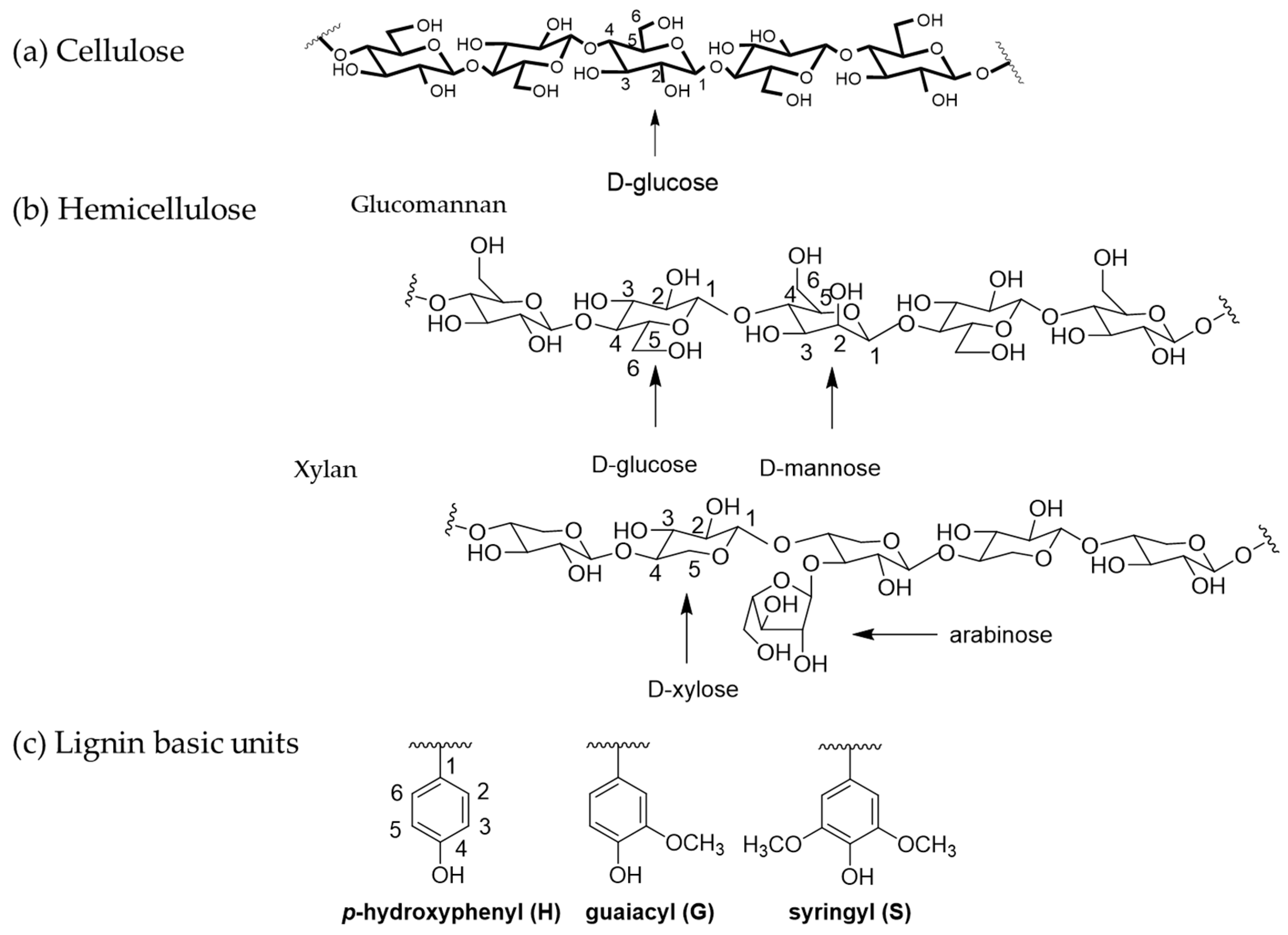

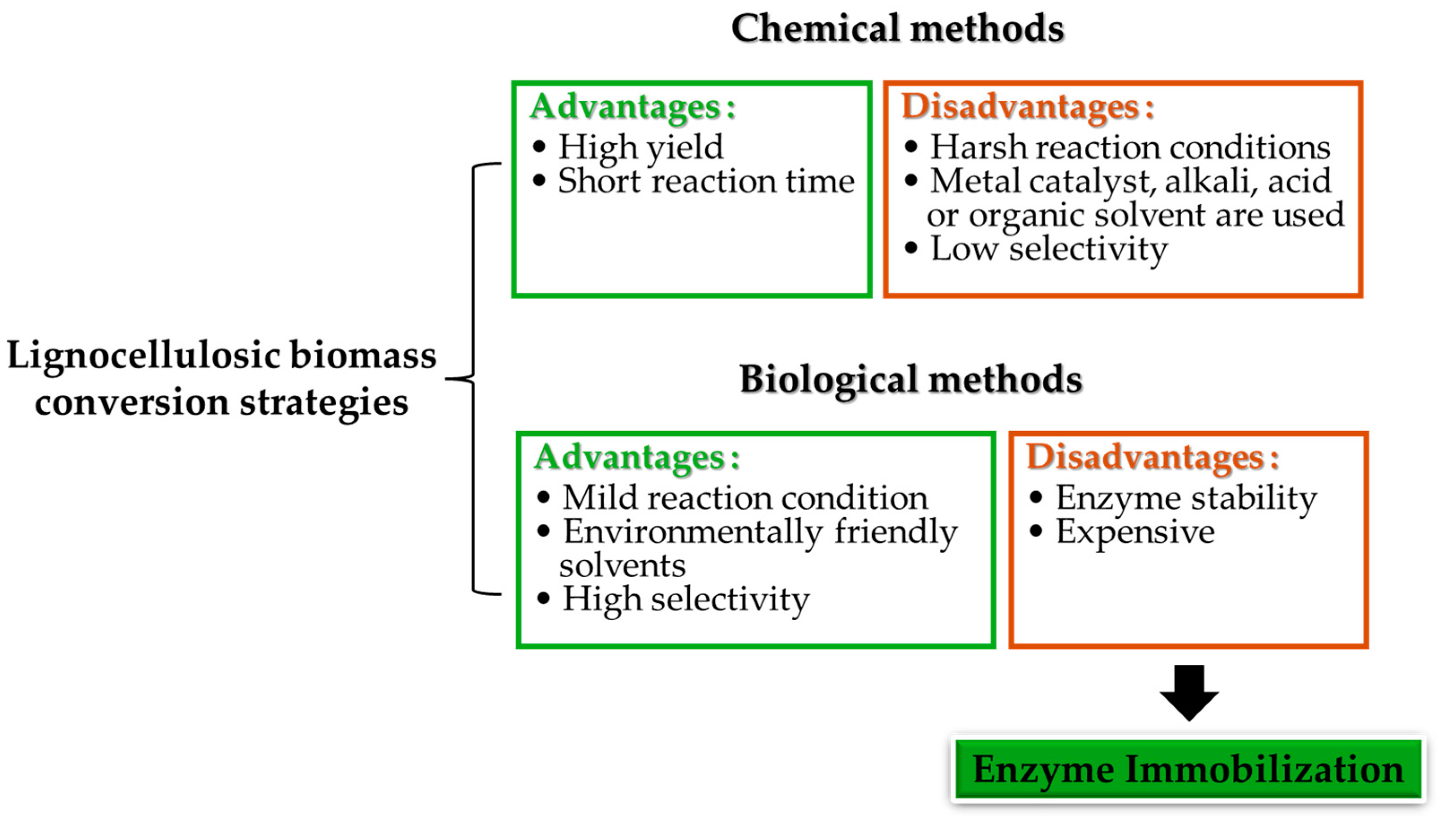

1. Introduction

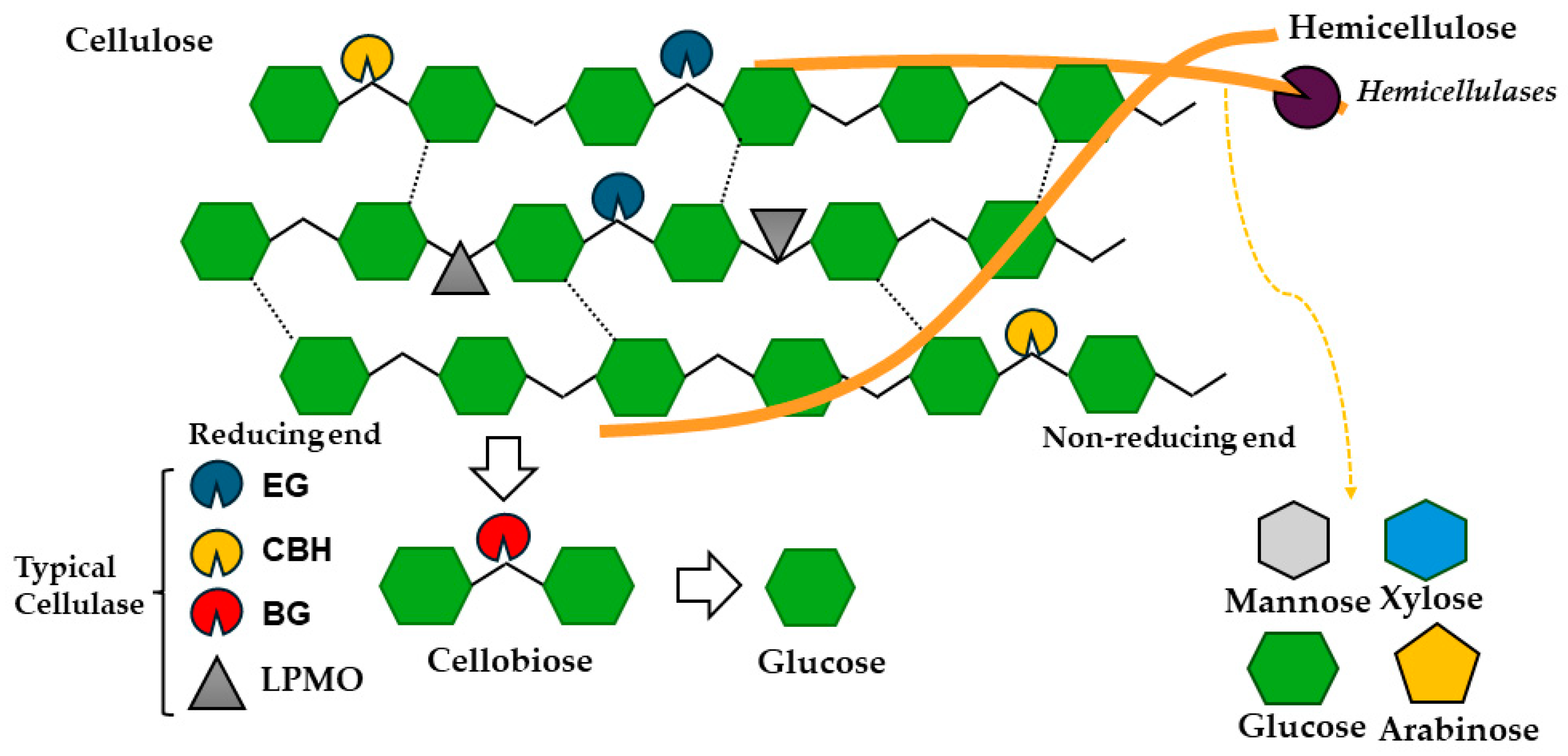

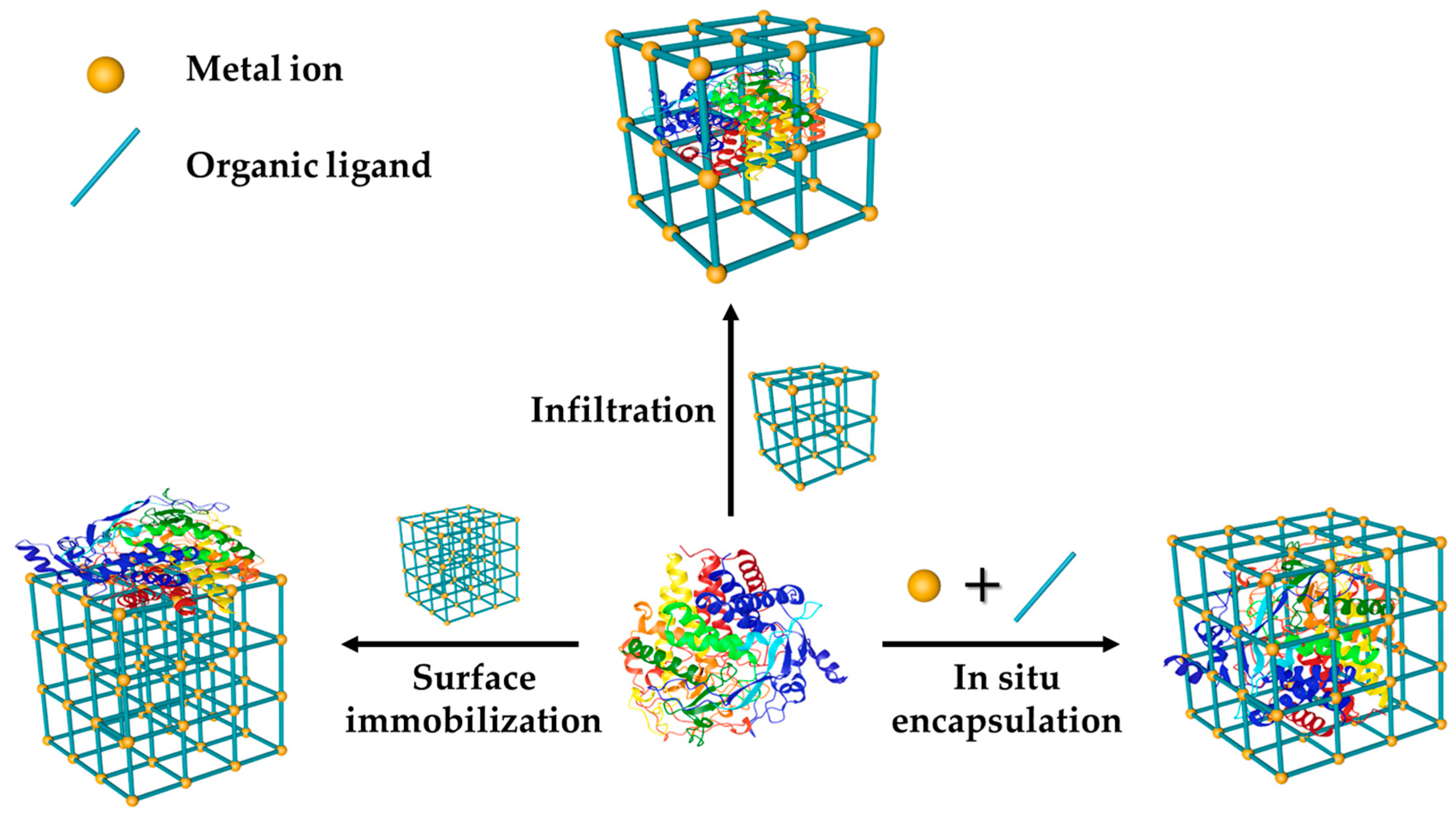

2. Conversion of Cellulose by MOF-Immobilized Enzyme

3. Conversion of Hemicellulose by MOF-Immobilized Enzyme

4. Conversion of Lignin by MOF-Immobilized Enzyme

5. Summary and Prospective

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Isikgor, F.H.; Becer, C.R. Lignocellulosic biomass: A sustainable platform for the production of bio-based chemicals and polymers. Polym. Chem. 2015, 6, 4497–4559. [Google Scholar] [CrossRef]

- Miroshnikova, A.V.; Baryshnikov, S.V.; Malyar, Y.N.; Li, X.; Alekseeva, M.V.; Kuznetsov, B.N.; Taran, O.P. Depolymerization of pine wood organosolv lignin in ethanol medium over NiCu/SiO2 and NiCuMo/SiO2 catalysts: Impact of temperature and catalyst composition. Polymers 2023, 15, 4722. [Google Scholar] [CrossRef] [PubMed]

- Bazhenova, M.A.; Kulikov, L.A.; Makeeva, D.A.; Maximov, A.L.; Karakhanov, E.A. Hydrodeoxygenation of lignin-based compounds over ruthenium catalysts based on sulfonated porous aromatic frameworks. Polymers 2023, 15, 4618. [Google Scholar] [CrossRef] [PubMed]

- Qu, C.; Ito, K.; Katsuyama, I.; Mitani, T.; Kashimura, K.; Watanabe, T. Directly microwave-accelerated cleavage of C-C and C-O bonds of lignin by copper oxide and H2O2. ChemSusChem 2020, 13, 4510–4518. [Google Scholar] [CrossRef] [PubMed]

- Stöcker, M. Perspectives for thermochemical conversions of lignocellulosic biomass. Small 2023, 6, e2302495. [Google Scholar] [CrossRef]

- Wang, S.; Dai, G.; Yang, H.; Luo, Z. Lignocellulosic biomass pyrolysis mechanism: A state-of-the art review. Prog. Energy Combust. Sci. 2017, 62, 33–86. [Google Scholar] [CrossRef]

- Fang, R.; Dhakshinamoorthy, A.; Li, Y.; Garcia, H. Metal organic frameworks for biomass conversion. Chem. Soc. Rev. 2020, 49, 3638–3687. [Google Scholar] [CrossRef] [PubMed]

- de Souza, T.S.P.; Kawaguti, H.Y. Cellulases, hemicellulases, and pectinases: Applications in the food and beverage industry. Food Bioproc. Technol. 2021, 14, 1446–1477. [Google Scholar] [CrossRef]

- Østby, H.; Hansen, L.D.; Horn, S.J.; Eijsink, V.G.H.; Várnai, A. Enzymatic processing of lignocellulosic biomass: Principles, recent advances and perspectives. J. Ind. Microbiol. Biotechnol. 2020, 47, 623–657. [Google Scholar] [CrossRef]

- Banerjee, G.; Scott-Craig, J.S.; Walton, J.D. Improving enzymes for biomass conversion: A basic research perspective. Bioenergy Res. 2010, 3, 82–92. [Google Scholar] [CrossRef]

- Maghraby, Y.R.; El-Shabasy, R.M.; Ibrahim, A.H.; Azzazy, H.M.E. Enzyme immobilization technologies and industrial applications. ACS Omega 2023, 8, 5184–5196. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Xun, G.; Feng, Y. The state-of-the-art strategies of protein engineering for enzyme stabilization. Biotechnol. Adv. 2019, 37, 530–537. [Google Scholar] [CrossRef] [PubMed]

- Giri, P.; Pagar, A.D.; Patil, M.D.; Yun, H. Chemical modification of enzymes to improve biocatalytic performance. Biotechnol. Adv. 2021, 53, 107863. [Google Scholar] [CrossRef] [PubMed]

- Jørgensen, H.; Pinelo, M. Enzyme recycling in lignocellulosic biorefineries. Biofuels Bioprod. Biorefin. 2017, 11, 150–167. [Google Scholar] [CrossRef]

- Periyasamy, K.; Santhalembi, L.; Mortha, G.; Aurousseau, M.; Boyer, A.; Subramanian, S. Bioconversion of lignocellulosic biomass to fermentable sugars by immobilized magnetic cellulolytic enzyme cocktails. Langmuir 2018, 34, 6546–6555. [Google Scholar] [CrossRef] [PubMed]

- Sirisha, V.L.; Jain, A.; Jain, A. Enzyme immobilization: An overview on methods, support material, and applications of immobilized enzymes. Adv. Food Nutr. Res. 2016, 79, 179–211. [Google Scholar] [CrossRef]

- Li, L.; He, J.; Wang, Y.; Lv, X.; Gu, X.; Dai, P.; Liu, D.; Zhao, X. Metal-organic frameworks: A promising platform for constructing non-noble electrocatalyst for oxygen-reduction reaction. J. Mater. Chem. A 2019, 7, 1964–1988. [Google Scholar] [CrossRef]

- Hu, C.; Bai, Y.; Hou, M.; Wang, Y.; Wang, L.; Cao, X.; Chan, C.-W.; Sun, H.; Li, W.; Ge, J.; et al. Defect-induced activity enhancement of enzyme-encapsulated metal-organic frameworks revealed in microfluidic gradient mixing synthesis. Sci. Adv. 2020, 6, eaax5785. [Google Scholar] [CrossRef]

- Salehipour, M.; Rezaei, S.; Asadi Khalili, H.F.; Motaharian, A.; Mogharabi-Manzari, M. Nanoarchitectonics of enzyme/metal–organic framework composites for wastewater treatment. J. Inorg. Organomet. Polym. Mater. 2022, 32, 3321–3338. [Google Scholar] [CrossRef]

- Shortall, K.; Otero, F.; Bendl, S.; Soulimane, T.; Magner, E. Enzyme immobilization on metal organic frameworks: The effect of buffer on the stability of the support. Langmuir 2022, 38, 13382–13391. [Google Scholar] [CrossRef]

- Tao, J.; Qu, C. Advances in the application of metal-organic framework materials in the wastewater decolorization treatment. Energy Environ. Prot. 2023, 37, 78–85. [Google Scholar] [CrossRef]

- Liang, W.; Flint, K.; Yao, Y.; Wu, J.; Wang, L.; Doonan, C.; Huang, J. Enhanced bioactivity of enzyme/MOF biocomposite via host framework engineering. J. Am. Chem. Soc. 2023, 145, 20365–20374. [Google Scholar] [CrossRef] [PubMed]

- Ye, N.; Kou, X.; Shen, J.; Huang, S.; Chen, G.; Ouyang, G. Metal-organic frameworks: A new platform for enzyme immobilization. ChemBioChem 2020, 21, 2585–2590. [Google Scholar] [CrossRef] [PubMed]

- Koistinen, A.; Phiri, J.; Kesari, K.K.; Vuorinen, T.; Maloney, T. Effect of pulp prehydrolysis conditions on dissolution and regenerated cellulose pore structure. Cellulose 2023, 30, 2827–2840. [Google Scholar] [CrossRef]

- Trache, D.; Hussin, M.H.; Chuin, C.T.H.; Sabar, S.; Fazita, M.R.N.; Taiwo, O.F.A.; Hassan, T.M.; Haafiz, M.K.M. Microcrystalline cellulose: Isolation, characterization and bio-composites application—A review. Int. J. Biol. Macromol. 2016, 93, 789–804. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Feng, X.; Li, X.; Zhao, J. The adsorption properties of endoglucanase to lignin and their impact on hydrolysis. Bioresour. Technol. 2018, 267, 110–116. [Google Scholar] [CrossRef]

- Zheng, F.; Tu, T.; Wang, X.; Wang, Y.; Ma, R.; Su, X.; Xie, X.; Yao, B.; Luo, H. Enhancing the catalytic activity of a novel GH5 cellulase GtCel5 from Gloeophyllum trabeum CBS 900.73 by site-directed mutagenesis on loop 6. Biotechnol. Biofuels 2018, 11, 76. [Google Scholar] [CrossRef]

- Liang, S.; Wu, X.; Xiong, J.; Zong, M.; Lou, W. Metal-organic frameworks as novel matrices for efficient enzyme immobilization: An update review. Coord. Chem. Rev. 2020, 406, 213149. [Google Scholar] [CrossRef]

- Qi, B.; Luo, J.; Wan, Y. Immobilization of cellulase on a core-shell structured metal-organic framework composites: Better inhibitors tolerance and easier recycling. Bioresour. Technol. 2018, 268, 577–582. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, S.; Tao, J.; Wang, X. In situ encapsulation of cellulase in a novel mesoporous metal-organic framework. Catal. Lett. 2022, 152, 699–706. [Google Scholar] [CrossRef]

- Narisetty, V.; Tarafdar, A.; Bachan, N.; Madhavan, A.; Tiwari, S.; Chaturvedi, P.; Varjani, S.; Sirohi, R.; Kumar, V.; Awasthi, M.K.; et al. An overview of cellulase immobilization strategies for biofuel production. Bioenergy Res. 2023, 16, 4–15. [Google Scholar] [CrossRef]

- Doonan, C.; Riccò, R.; Liang, K.; Bradshaw, D.; Falcaro, P. Metal-organic frameworks at the biointerface: Synthetic strategies and applications. Acc. Chem. Res. 2017, 50, 1423–1432. [Google Scholar] [CrossRef] [PubMed]

- Zheng, T.; Yang, L.; Ding, M.; Huang, C.; Yao, J. Metal-organic framework promoting high-solids enzymatic hydrolysis of untreated corncob residues. Bioresour. Technol. 2022, 270, 126163. [Google Scholar] [CrossRef]

- Cai, G.; Jiang, H.L. A modulator-induced defect-formation strategy to hierarchically porous metal-organic frameworks with high stability. Angew. Chem. Int. Ed. 2017, 56, 563–567. [Google Scholar] [CrossRef]

- Ahmed, I.N.; Yang, X.-L.; Dubale, A.A.; Li, R.-F.; Ma, Y.-M.; Wang, L.-M.; Hou, G.-H.; Guan, R.-F.; Xie, M.-H. Hydrolysis of cellulose using cellulase physically immobilized on highly stable zirconium based metal-organic frameworks. Bioresour. Technol. 2018, 270, 377–382. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Zhi, W.; Wan, J.; Han, J.; Li, C.; Wang, Y. Recyclable β-glucosidase by one-pot encapsulation with Cu-MOFs for enhanced hydrolysis of cellulose to glucose. ACS Sustain. Chem. Eng. 2019, 7, 3339–3348. [Google Scholar] [CrossRef]

- Zhou, M.; Ju, X.; Zhou, Z.; Yan, L.; Chen, J.; Yao, X.; Xu, X.; Li, L.-Z. Development of an immobilized cellulase system Based on metal-organic frameworks for improving ionic liquid tolerance and in situ saccharification of bagasse. ACS Sustain. Chem. Eng. 2019, 7, 19185–19193. [Google Scholar] [CrossRef]

- Jiao, R.; Pang, Y.; Yang, D.; Li, Z.; Lou, H. Boosting hydrolysis of cellulose at high temperature by β-glucosidase induced metal-organic framework in-situ co-precipitation encapsulation. ChemSusChem 2022, 15, e202201354. [Google Scholar] [CrossRef]

- Jiao, R.; Wang, Y.; Pang, Y.; Yang, D.; Li, Z.; Lou, H.; Qiu, X. Construction of macroporous β-glucosidase by a metal competitive coordination and oxidation strategy for efficient cellulose conversion at 120 °C. ACS Appl. Mater. Interfaces 2023, 15, 8157–8168. [Google Scholar] [CrossRef]

- Zhou, Z.; Ju, X.; Chen, J.; Wang, R.; Zhong, Y.; Li, L. Charge-oriented strategies of tunable substrate affinity based on cellulase and biomass for improving in situ saccharification: A review. Bioresour. Technol. 2021, 319, 124159. [Google Scholar] [CrossRef]

- Peng, P.; She, D. Isolation, structural characterization, and potential applications of hemicelluloses from bamboo: A review. Carbohydr. Polym. 2014, 112, 701–720. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, S.; Xu, Z.; Shi, J. Degradation of hemicellulose by microbial enzymes and its application in brewing industry. Food Fermn. Ind. 2020, 46, 255–262. [Google Scholar] [CrossRef]

- Bhardwaj, N.; Kumar, B.; Verma, P. A detailed overview of xylanases: An emerging biomolecule for current and future prospective. Bioresour. Bioprocess. 2019, 6, 40. [Google Scholar] [CrossRef]

- Rao, J.; Lv, Z.; Chen, G.; Peng, F. Hemicellulose: Structure, chemical modification, and application. Prog. Polym. Sci. 2023, 140, 101675. [Google Scholar] [CrossRef]

- Milessi, T.S.; Corradini, F.A.S.; Marçal, J.V.M.; Baldez, T.O.; Kopp, W.; Giordano, R.C.; Giordano, R.L.C. Xylooligosaccharides production chain in sugarcane biorefineries: From the selection of pretreatment conditions to the evaluation of nutritional properties. Ind. Crops Prod. 2021, 172, 114056. [Google Scholar] [CrossRef]

- Kaushal, J.; Arya, S.K.; Khatri, M.; Singh, G.; Azelee, N.I.W.; Rajagopal, R.; Chang, S.W.; Ravindran, B.; Awasthi, M.K. Efficacious bioconversion of waste walnut shells to xylotetrose and xylopentose by free xylanase (Xy) and MOF immobilized xylanase (Xy-Cu-BTC). Bioresour. Technol. 2022, 357, 127374. [Google Scholar] [CrossRef]

- Gui, Y.; Wu, Y.; Shu, T.; Hou, Z.; Hu, Y.; Li, W.; Yu, L. Multi-point immobilization of GH 11 endo-β-1,4-xylanase on magnetic MOF composites for higher yield of xylo-oligosaccharides. Int. J. Biol. Macromol. 2024, 260, 129277. [Google Scholar] [CrossRef]

- Bakar, B.; Dik, G.; Ulu, A.; Ateş, B. Immobilization of xylanase into zeolitic imidazolate framework-67 (ZIF-67) and manganese-doped ZIF-67 (Mn/ZIF-67): A comparison study. Top. Catal. 2024. [Google Scholar] [CrossRef]

- Kaushal, J.; Khatri, M.; Singh, G.; Arya, S.K. Xylanase enzyme from novel strain and its immobilization onto metal organic framework MOF for fruit juice clarification. Biotechnol. Bioprocess Eng. 2024, 29, 197–210. [Google Scholar] [CrossRef]

- Li, N.; Xia, H.; Jiang, Y.; Xiong, J.; Lou, W. Co-immobilization of β-xylosidase and endoxylanase on zirconium based metal-organic frameworks for improving xylosidase activity at high temperature and in acetone. Bioresour. Technol. 2023, 383, 129240. [Google Scholar] [CrossRef]

- Parthasarathi, R.; Romero, R.A.; Redondo, A.; Gnanakaran, S. Theoretical study of the remarkably diverse linkages in lignin. J. Phys. Chem. Rev. 2011, 2, 2660–2666. [Google Scholar] [CrossRef]

- Hu, Y.; Yan, L.; Zhao, X.; Wang, C.; Li, S.; Zhang, X.; Ma, L.; Zhang, Q. Mild selective oxidative cleavage of lignin C-C bonds over a copper catalyst in water. Green Chem. 2021, 23, 7030–7040. [Google Scholar] [CrossRef]

- Sánchez, C. Lignocellulosic residues: Biodegradation and bioconversion by fungi. Biotechnol. Adv. 2009, 27, 185–194. [Google Scholar] [CrossRef]

- Park, G.W.; Gong, G.; Joo, J.C.; Song, J.; Lee, J.; Lee, J.-P.; Kim, H.T.; Ryu, M.H.; Sirohi, R.; Zhuang, X.; et al. Recent progress and challenges in biological degradation and biotechnological valorization of lignin as an emerging source of bioenergy: A state-of-the-art review. Renew. Sustain. Energy Rev. 2022, 157, 112025. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, S.; Chen, G. Mechanisms of lignin-degrading enzymes. Protein Pept. Lett. 2020, 27, 574–581. [Google Scholar] [CrossRef]

- Leynaud Kieffer Curran, L.M.C.; Pham, L.T.M.; Sale, K.L.; Simmons, B.A. Review of advances in the development of laccases for the valorization of lignin to enable the production of lignocellulosic biofuels and bioproducts. Biotechnol. Adv. 2022, 54, 107809. [Google Scholar] [CrossRef]

- Cai, D.; Tien, M. Lignin-degrading peroxidases of Phanerochaete chrysosporium. J. Biotechnol. 1993, 30, 79–90. [Google Scholar] [CrossRef]

- Agarwal, A.; Rana, M.; Park, J. Advancement in technologies for the depolymerization of lignin. Fuel Process. Technol. 2018, 181, 115–132. [Google Scholar] [CrossRef]

- Zhang, S.; Dong, Z.; Shi, J.; Yang, C.; Fang, Y.; Chen, G.; Chen, H.; Tian, C. Enzymatic hydrolysis of corn stover lignin by laccase, lignin peroxidase, and manganese peroxidase. Bioresour. Technol. 2022, 361, 127699. [Google Scholar] [CrossRef]

- Agustin, M.B.; de Carvalho, D.M.; Lahtinen, M.H.; Hilden, K.; Lundell, T.; Mikkonen, K.S. Laccase as a tool in building advanced lignin-based materials. ChemSusChem 2021, 14, 4615–4635. [Google Scholar] [CrossRef]

- Ren, S.; Wang, F.; Gao, H.; Han, X.; Zhang, T.; Yuan, Y.; Zhou, Z. Recent progress and future prospects of laccase immobilization on MOF supports for industrial applications. Appl. Biochem. Biotechnol. 2024, 196, 1669–1684. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, W.; Gan, Y.; Yang, J.; Zhang, S. Laccase immobilization with metal-organic frameworks: Current status, remaining challenges and future perspectives. Crit. Rev. Environ. Sci. Technol. 2022, 52, 1282–1324. [Google Scholar] [CrossRef]

- Pang, S.; Wu, Y.; Zhang, X.; Li, B.; Ouyang, J.; Ding, M. Immobilization of laccase via adsorption onto bimodal mesoporous Zr-MOF. Process Biochem. 2016, 51, 229–239. [Google Scholar] [CrossRef]

- Zhong, Z.; Pang, S.; Wu, Y.; Jiang, S.; Ouyang, J. Synthesis and characterization of mesoporous Cu–MOF for laccase immobilization. J. Chem. Technol. Biotechnol. 2017, 92, 1841–1847. [Google Scholar] [CrossRef]

- Samui, A.; Sahu, S.K. One-pot synthesis of microporous nanoscale metal organic frameworks conjugated with laccase as a promising biocatalyst. New J. Chem. 2018, 42, 4192–4200. [Google Scholar] [CrossRef]

- Jia, Y.; Chen, Y.; Luo, J.; Hu, Y. Immobilization of laccase onto meso-MIL-53 (Al) via physical adsorption for the catalytic conversion of triclosan. Ecotoxicol. Environ. Saf. 2019, 184, 109670. [Google Scholar] [CrossRef]

- Wu, E.; Li, Y.; Huang, Q.; Yang, Z.; Wei, A.; Hu, Q. Laccase immobilization on amino-functionalized magnetic metal organic framework for phenolic compound removal. Chemosphere 2019, 233, 327–335. [Google Scholar] [CrossRef]

- Wang, J.; Yu, S.; Feng, F.; Lu, L. Simultaneous purification and immobilization of laccase on magnetic zeolitic imidazolate frameworks: Recyclable biocatalysts with enhanced stability for dye decolorization. Biochem. Eng. J. 2019, 150, 107285. [Google Scholar] [CrossRef]

- Wang, D.; Lou, J.; Yuan, J.; Xu, J.; Zhu, R.; Wang, Q.; Fan, X. Laccase immobilization on core-shell magnetic metal-organic framework microspheres for alkylphenol ethoxylate compound removal. J. Environ. Chem. Eng. 2021, 9, 105000. [Google Scholar] [CrossRef]

- Birhanlı, E.; Noma, S.A.A.; Boran, F.; Ulu, A.; Yeşilada, Ö.; Ateş, B. Design of laccase-metal-organic framework hybrid constructs for biocatalytic removal of textile dyes. Chemosphere 2022, 292, 133382. [Google Scholar] [CrossRef]

- Yuan, L.; Chai, J.; Wang, S.; Li, T.; Yan, X.; Wang, J.; Yin, H. Biomimetic laccase-Cu2O@MOF for synergetic degradation and colorimetric detection of phenolic compounds in wastewater. Environ. Technol. 2023, 30, 103085. [Google Scholar] [CrossRef]

- Kuah, E.; Toh, S.; Yee, J.; Ma, Q.; Gao, Z. Enzyme mimics: Advances and applications. Chemistry 2016, 22, 8404–8430. [Google Scholar] [CrossRef]

- Zhang, Y.; Muhammad, F.; Wei, H. Inorganic enzyme mimics. ChemBioChem 2021, 22, 1496–1498. [Google Scholar] [CrossRef]

- Liang, H.; Lin, F.; Zhang, Z.; Liu, B.; Jiang, S.; Yuan, Q.; Liu, J. Multicopper laccase mimicking nanozymes with nucleotides as ligands. ACS Appl. Mater. Interfaces 2017, 9, 1352–1360. [Google Scholar] [CrossRef]

- Shams, S.; Ahmad, W.; Memon, A.H.; Wei, Y.; Yuan, Q.; Liang, H. Facile synthesis of laccase mimic Cu/H3BTC MOF for efficient dye degradation and detection of phenolic pollutants. RSC Adv. 2019, 9, 40845–40854. [Google Scholar] [CrossRef]

- Wang, J.; Huang, R.; Qi, W.; Su, R.; He, Z. Preparation of amorphous MOF based biomimetic nanozyme with high laccase- and catecholase-like activity for the degradation and detection of phenolic compounds. Chem. Eng. J. 2022, 434, 134677. [Google Scholar] [CrossRef]

- Liang, S.; Wu, X.-L.; Xiong, J.; Yuan, X.; Liu, S.-L.; Zong, M.-H.; Lou, W.-Y. Multivalent Ce-MOFs as biomimetic laccase nanozyme for environmental remediation. Chem. Eng. J. 2022, 450, 138220. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, J.; Guo, Y.; Wang, X.; Xiao, L.-P.; Zhou, J. Biodegradation of lignin into low-molecular-weight oligomers by multicopper laccase-mimicking nanoymes of the Cu/GMP complex at room temperature. ACS Sustain. Chem. Eng. 2022, 10, 5489–5499. [Google Scholar] [CrossRef]

- Usmani, A.; Sharma, M.; Gupta, P.; Karpichev, Y.; Gathergood, N.; Bhat, R.; Gupta, V.K. Ionic liquid based pretreatment of lignocellulosic biomass for enhanced bioconversion. Bioresour. Technol. 2020, 304, 123003. [Google Scholar] [CrossRef]

- Fan, Y.; Ji, H.; Ji, X.; Tian, Z.; Chen, J. Lignocellulosic biomass pretreatment with a lignin stabilization strategy and valorization toward multipurpose fractionation. Int. J. Biol. Macromol. 2024, 259, 129186. [Google Scholar] [CrossRef]

- Li, R.; Huang, D.; Lei, L.; Chen, S.; Chen, Y.; Wang, G.; Du, L.; Zhou, W.; Tao, J.; Chen, H. Lignin and metal-organic frameworks: Mutual partners on the road to sustainability. J. Mater. Chem. A 2023, 11, 2595–2617. [Google Scholar] [CrossRef]

- Wang, K.Y.; Zhang, J.; Hsu, Y.C.; Lin, H.; Han, Z.; Pang, J.; Yang, Z.; Liang, R.R.; Shi, W.; Zhou, H.C. Bioinspired framework catalysts: From enzyme immobilization to biomimetic catalysis. Chem. Rev. 2023, 12, 5347–5420. [Google Scholar] [CrossRef] [PubMed]

| MOF | Immobilization Method | Maximum Loading (mg/g) | Optimal Reaction Conditions | Recycling Times | Residual Activity (%) | Reference |

|---|---|---|---|---|---|---|

| Fe3O4@UIO-66-NH2 | Surface immobilization | 126.2 | pH 5.0, 50 °C | 5 | 70 | [29] |

| UiO-66-NH2 | Surface immobilization | 350 | pH 5.0, 55 °C | 10 | 72 | [35] |

| Cu-MOF | In situ encapsulation | 162.95 | pH 5.0, 60 °C | 10 | 90 | [36] 1 |

| ZIF-8 | Surface immobilization | 176.16 | pH 5.0, 60 °C | 5 | 56 2 | [37] |

| Zn-mIm | In situ encapsulation | 350 | pH 4.8, 50 °C | 4 | 77 | [30] |

| MOF(PABA) | In situ encapsulation | 176.9 | pH 4.8, 110 °C | 5 | 86 3 | [38] 1 |

| MOF-Fe | In situ encapsulation | 224.8 | pH 4.8, 120 °C | 5 | 30 3 | [39] 1 |

| Enzyme | MOF | Immobilization Method | Recycling Times | Residual Activity (%) | Product Conversion Efficiency (%) | Reference |

|---|---|---|---|---|---|---|

| Xylanase | Cu-BTC | Surface immobilization | - | - | 87.4 (XOS) | [46] |

| GH 11 endo-β-1,4-xylanase | Fe3O4@PDA@MOF | Surface immobilization | 10 | 60 | 23 (XOS) | [47] |

| Xylanase | ZIF-67 | In situ encapsulation | 8 | 70 | 94.73 (Reducing sugar) | [48] |

| Mn/ZIF-67 | 8 | 70 | 84.13 (Reducing sugar) | |||

| Xylanase | MOFCu-BTC | Surface immobilization | 21 | 61 | 57.97 (Reducing sugar) | [49] |

| β-Xylosidase/endoxylanase | UiO-66-NH2 | Surface immobilization | 5 | 70 | 30 (Reducing sugar) | [50] |

| MOF | Immobilization Method | Maximum Loading (mg/g) | Optimal Reaction Conditions | Recycling Times | Residual Activity (%) | Substrate Conversion Efficiency (%) | Reference |

|---|---|---|---|---|---|---|---|

| Zr-MOF, MMU | Surface immobilization | 221.83 | pH 4.0 40 °C | 10 | 50 | - | [63] |

| Cu-MOF | Surface immobilization | 502 | pH 4.0 50 °C | 7 | 50 | - | [64] |

| NH2-MIL-53(Al) | In situ encapsulation | 625 | pH 3.0 30 °C | 10 | 63 | - | [65] |

| meso-MIL-53(Al) | Surface immobilization | 218 | pH 5.0 45 °C | 8 | 60 | 99.24 (Triclosan) | [66] |

| Fe3O4-NH2@MIL-101(Cr) | Surface immobilization | 69 | pH 4.0 65 °C | 3 | 40 | 85 (2,4-Dichlorophenol) | [67] |

| Fe3O4@ZIF-8 | Surface immobilization | - | pH 7.0 80 °C | 7 | - | 100 (Indigo carmine) | [68] |

| Fe3O4-NH2@MIL-100(Fe) | Surface immobilization | 61.60 ± 2.92 | pH 5.0 50 °C | 4 | - | 100 (OPEO) 1 98.16 (NPEO) | [69] |

| Co-MOF | Surface immobilization | - | pH 4.5 50 °C | 12 | 56.5 | 88 (RB171) 77 (RB198) | [70] |

| Cu-MOF | - | pH 5.0 50 °C | 12 | 55.8 | 89 (RB171) 39 (RB198) | ||

| Cu2O@MOF | Surface immobilization | 148 | pH 4.0 55 °C | - | - | 82.5 (2,4-Dichlorophenol) | [71] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, J.; Song, S.; Qu, C. Recent Progress on Conversion of Lignocellulosic Biomass by MOF-Immobilized Enzyme. Polymers 2024, 16, 1010. https://doi.org/10.3390/polym16071010

Tao J, Song S, Qu C. Recent Progress on Conversion of Lignocellulosic Biomass by MOF-Immobilized Enzyme. Polymers. 2024; 16(7):1010. https://doi.org/10.3390/polym16071010

Chicago/Turabian StyleTao, Juan, Shengjie Song, and Chen Qu. 2024. "Recent Progress on Conversion of Lignocellulosic Biomass by MOF-Immobilized Enzyme" Polymers 16, no. 7: 1010. https://doi.org/10.3390/polym16071010

APA StyleTao, J., Song, S., & Qu, C. (2024). Recent Progress on Conversion of Lignocellulosic Biomass by MOF-Immobilized Enzyme. Polymers, 16(7), 1010. https://doi.org/10.3390/polym16071010