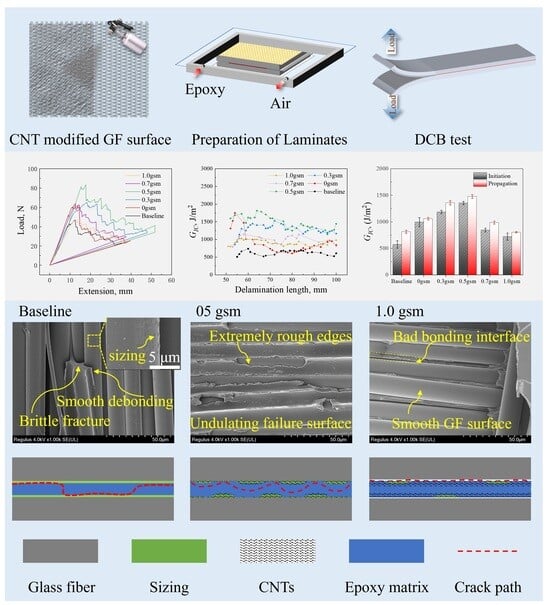

Maximizing Interlaminar Fracture Toughness in Bidirectional GFRP through Controlled CNT Heterogeneous Toughening

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Surface Modification

2.3. Laminate Preparation

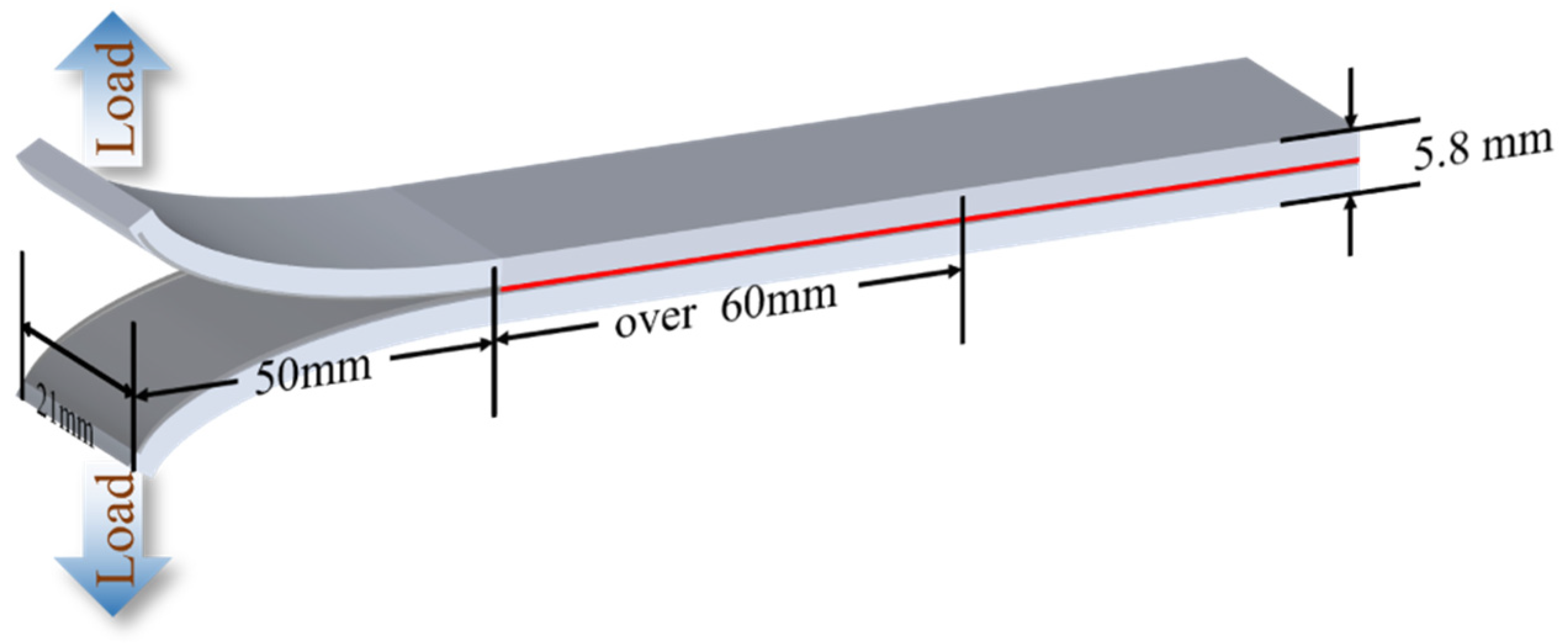

2.4. Fracture Tests

2.5. Other Characterizations

3. Result and Discussion

3.1. Characterization of Short CNT

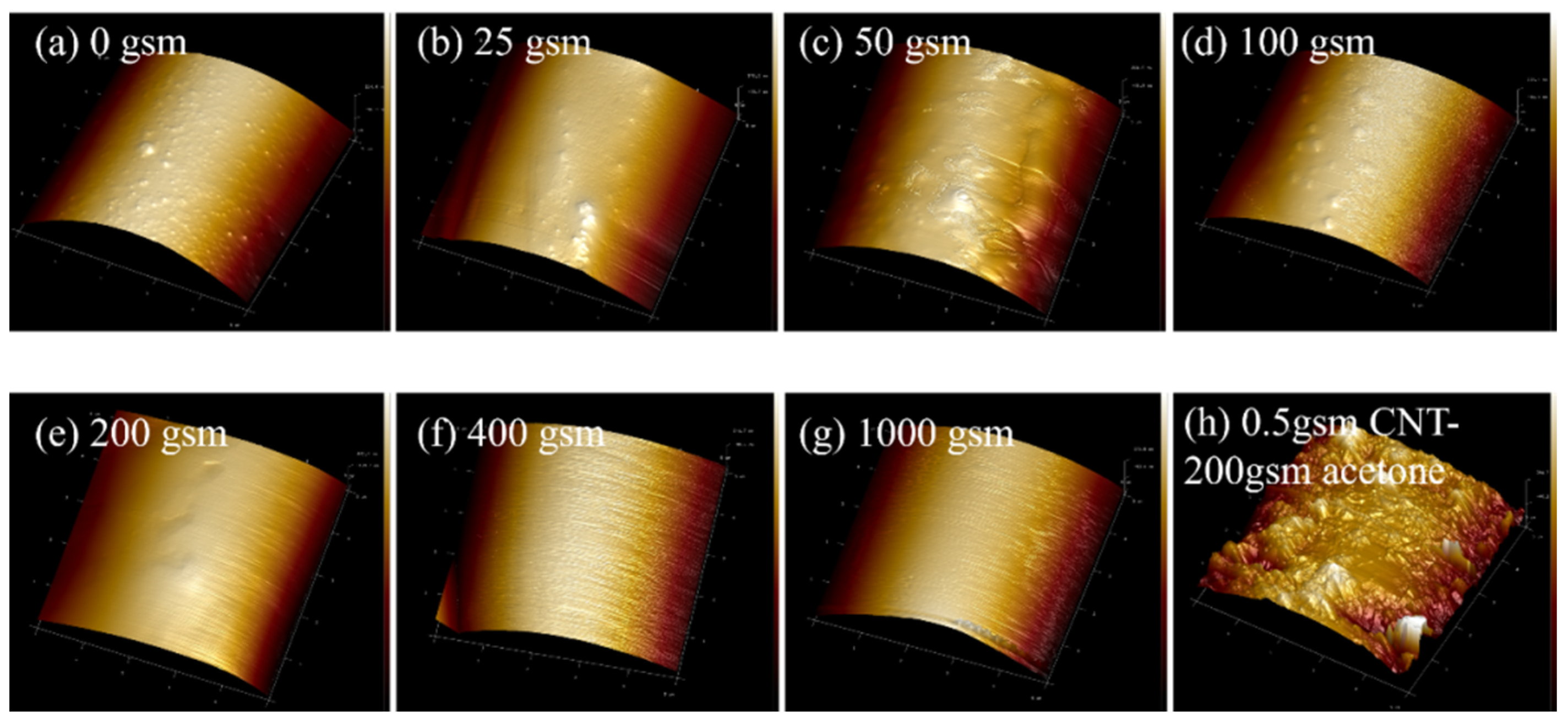

3.2. Surface Morphology of CNT-Coated Glass Fiber Fabrics

3.3. Mode I Interlaminar Fracture Toughness

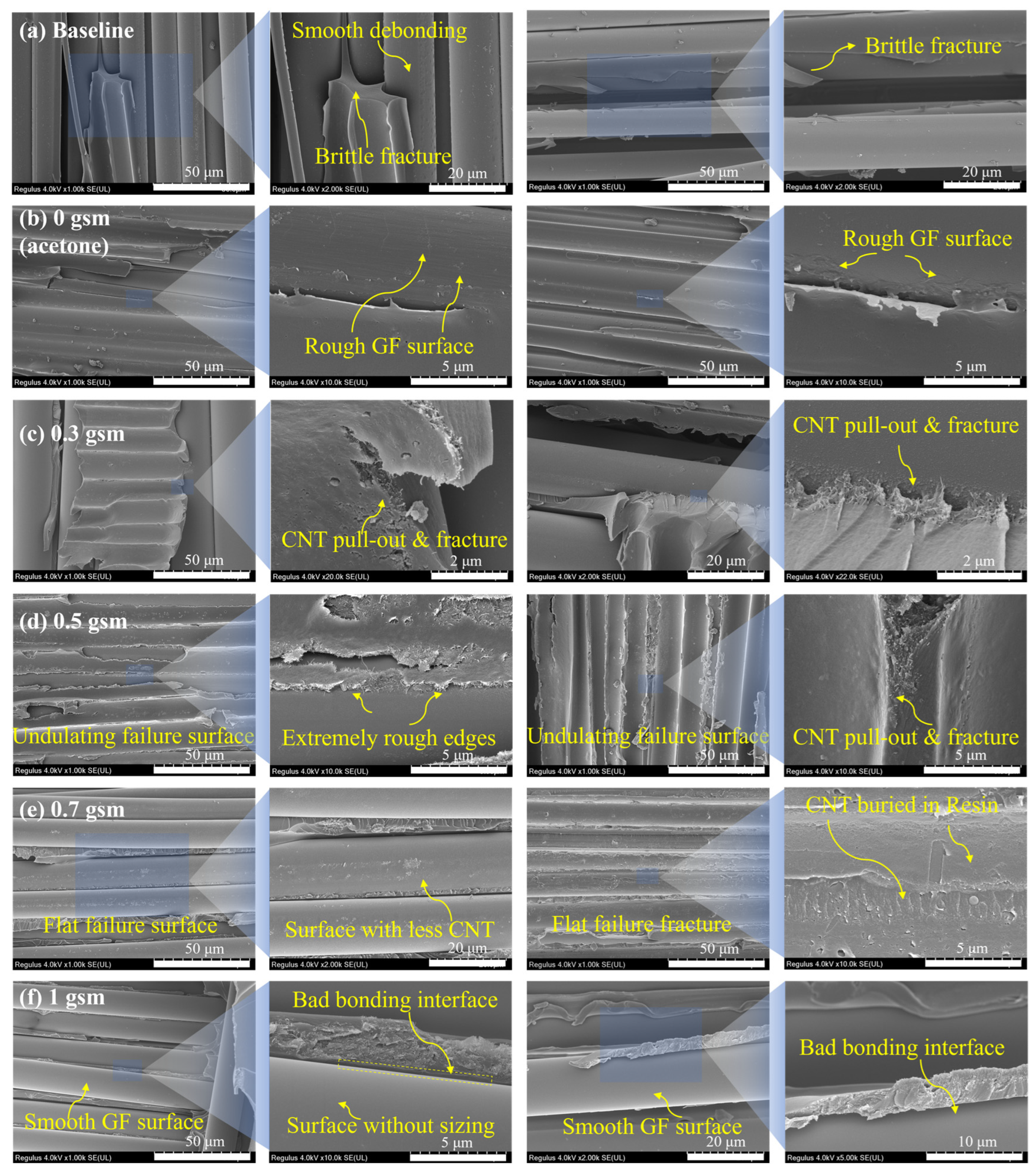

3.4. Fractography and Toughening Mechanisms

3.5. Comparison with the State of the Art

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shrivastava, R.; Singh, K.K. Interlaminar Fracture Toughness Characterization of Laminated Composites: A Review. Polym. Rev. 2020, 60, 542–593. [Google Scholar] [CrossRef]

- Quan, D.; Flynn, S.; Artuso, M.; Murphy, N.; Rouge, C.; Ivanković, A. Interlaminar Fracture Toughness of CFRPs Interleaved with Stainless Steel Fibres. Compos. Struct. 2019, 210, 49–56. [Google Scholar] [CrossRef]

- Boon, Y.D.; Joshi, S.C. A Review of Methods for Improving Interlaminar Interfaces and Fracture Toughness of Laminated Composites. Mater. Today Commun. 2020, 22, 100830. [Google Scholar] [CrossRef]

- Arai, M.; Noro, Y.; Sugimoto, K.; Endo, M. Mode I and Mode II Interlaminar Fracture Toughness of CFRP Laminates Toughened by Carbon Nanofiber Interlayer. Compos. Sci. Technol. 2008, 68, 516–525. [Google Scholar] [CrossRef]

- Chandra, R.; Singh, S.P.; Gupta, K. Damping Studies in Fiber-Reinforced Composites—A Review. Compos. Struct. 1999, 46, 41–51. [Google Scholar] [CrossRef]

- Tang, Y.; Ye, L.; Zhang, Z.; Friedrich, K. Interlaminar Fracture Toughness and CAI Strength of Fibre-Reinforced Composites with Nanoparticles—A Review. Compos. Sci. Technol. 2013, 86, 26–37. [Google Scholar] [CrossRef]

- Hojo, M.; Matsuda, S.; Tanaka, M.; Ochiai, S.; Murakami, A. Mode I Delamination Fatigue Properties of Interlayer-Toughened CF/Epoxy Laminates. Compos. Sci. Technol. 2006, 66, 665–675. [Google Scholar] [CrossRef]

- Chen, Q.; Wu, F.; Jiang, Z.; Zhang, H.; Yuan, J.; Xiang, Y.; Liu, Y. Improved Interlaminar Fracture Toughness of Carbon Fiber/Epoxy Composites by a Combination of Extrinsic and Intrinsic Multiscale Toughening Mechanisms. Compos. Part B Eng. 2023, 252, 110503. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Z.; Fu, J.; Liang, Z.; Hui, D.; Ramakrishnan, K.R. Effect of CNT Film Interleaves on the Flexural Properties and Strength after Impact of CFRP Composites. Nanotechnol. Rev. 2023, 12, 20230177. [Google Scholar] [CrossRef]

- Boroujeni, A.Y.; Al-Haik, M.S. Interlaminar Fracture Toughness of Hybrid Carbon Fiber-Carbon Nanotubes-Reinforced Polymer Composites. Polym. Compos. 2019, 40, E1470–E1478. [Google Scholar] [CrossRef]

- Sabri, F.N.A.M.; Zakaria, M.R.; Akil, H.M.; Abidin, M.S.Z.; Rahman, A.A.A.; Omar, M.F. Interlaminar Fracture Toughness Properties of Hybrid Glass Fiber-Reinforced Composite Interlayered with Carbon Nanotube Using Electrospray Deposition. Nanotechnol. Rev. 2021, 10, 1766–1775. [Google Scholar] [CrossRef]

- He, Y.; Zhang, J.; Yao, L.; Tang, J.; Che, B.; Ju, S.; Jiang, D. A Multi-Layer Resin Film Infusion Process to Control CNTs Distribution and Alignment for Improving CFRP Interlaminar Fracture Toughness. Compos. Struct. 2021, 260, 113510. [Google Scholar] [CrossRef]

- Davis, D.C.; Whelan, B.D. An Experimental Study of Interlaminar Shear Fracture Toughness of a Nanotube Reinforced Composite. Compos. Part B Eng. 2011, 42, 105–116. [Google Scholar] [CrossRef]

- Zhu, Y.; Bakis, C.E.; Adair, J.H. Effects of Carbon Nanofiller Functionalization and Distribution on Interlaminar Fracture Toughness of Multi-Scale Reinforced Polymer Composites. Carbon 2012, 50, 1316–1331. [Google Scholar] [CrossRef]

- Ou, Y.; Fu, A.; Wu, L.; Yi, X.; Mao, D. Enhanced Interlaminar Fracture Toughness of Unidirectional CFRP Laminates with Tailored Microstructural Heterogeneity of Toughening Layer. Compos. Part A Appl. Sci. Manuf. 2024, 176, 107872. [Google Scholar] [CrossRef]

- Wicks, S.S.; Wang, W.; Williams, M.R.; Wardle, B.L. Multi-Scale Interlaminar Fracture Mechanisms in Woven Composite Laminates Reinforced with Aligned Carbon Nanotubes. Compos. Sci. Technol. 2014, 100, 128–135. [Google Scholar] [CrossRef]

- Ou, Y.; Wu, L.; Yi, X.; Mao, D. Understanding Mode I Interlaminar Toughening of Unidirectional CFRP Laminates Interleaved with Aligned Ultrathin CNT Fiber Veils: Thickness and Orientation Effects. Compos. Part B Eng. 2023, 254, 110578. [Google Scholar] [CrossRef]

- Eskizeybek, V.; Yar, A.; Avcı, A. CNT-PAN Hybrid Nanofibrous Mat Interleaved Carbon/Epoxy Laminates with Improved Mode I Interlaminar Fracture Toughness. Compos. Sci. Technol. 2018, 157, 30–39. [Google Scholar] [CrossRef]

- Zheng, N.; Huang, Y.; Liu, H.-Y.; Gao, J.; Mai, Y.-W. Improvement of Interlaminar Fracture Toughness in Carbon Fiber/Epoxy Composites with Carbon Nanotubes/Polysulfone Interleaves. Compos. Sci. Technol. 2017, 140, 8–15. [Google Scholar] [CrossRef]

- Ou, Y.; González, C.; Vilatela, J.J. Understanding Interlaminar Toughening of Unidirectional CFRP Laminates with Carbon Nanotube Veils. Compos. Part B Eng. 2020, 201, 108372. [Google Scholar] [CrossRef]

- Dai, S.; Zhou, Y.; Li, W.; Bai, W.; Zhao, H.; Bai, H.; Hu, X. Interlaminar toughening of carbon fiber/epoxy composites with graphene oxide-carbon nanotube composite film. Acta Mater. Compos. Sin. 2023, 40, 3862–3873. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y.; Cao, J.; Meng, X.; Aamir, R.M.; Lu, W.; Suo, T. Effects of Loading Rates on Mode I Interlaminar Fracture Toughness of Carbon/Epoxy Composite Toughened by Carbon Nanotube Films. Compos. Part B Eng. 2020, 200, 108270. [Google Scholar] [CrossRef]

- Shin, Y.-C.; Kim, S.-M. Enhancement of the Interlaminar Fracture Toughness of a Carbon-Fiber-Reinforced Polymer Using Interleaved Carbon Nanotube Buckypaper. Appl. Sci. 2021, 11, 6821. [Google Scholar] [CrossRef]

- Li, N.; Wang, G.D.; Melly, S.K.; Peng, T.; Li, Y.C.; Di Zhao, Q.; de Ji, S. Interlaminar Properties of GFRP Laminates Toughened by CNTs Buckypaper Interlayer. Compos. Struct. 2019, 208, 13–22. [Google Scholar] [CrossRef]

- Liu, G.; Hu, X.; Zhang, P.; Yu, R.; Bao, J.; Chen, M.; Li, Q.; Yi, X. Carbon Nanotube Film Interlayer Toughened Carbon Fiber Reinforced Epoxy Resin Hybrid Composites. Acta Polym. Sin. 2013, 10, 1334–1340. [Google Scholar] [CrossRef]

- Ni, X.; Furtado, C.; Fritz, N.K.; Kopp, R.; Camanho, P.P.; Wardle, B.L. Interlaminar to Intralaminar Mode I and II Crack Bifurcation Due to Aligned Carbon Nanotube Reinforcement of Aerospace-Grade Advanced Composites. Compos. Sci. Technol. 2020, 190, 108014. [Google Scholar] [CrossRef]

- Lee, S.-H.; Kim, H.; Hang, S.; Cheong, S.-K. Interlaminar Fracture Toughness of Composite Laminates with CNT-Enhanced Nonwoven Carbon Tissue Interleave. Compos. Sci. Technol. 2012, 73, 1–8. [Google Scholar] [CrossRef]

- Ma, H.; Aravand, M.A.; Falzon, B.G. Influence on Fracture Toughness Arising from Controlled Morphology of Multiphase Toughened Epoxy Resins in the Presence of Fibre Reinforcement. Compos. Sci. Technol. 2022, 217, 109095. [Google Scholar] [CrossRef]

- Aravand, M.; Lomov, S.V.; Gorbatikh, L. Morphology and Fracture Behavior of POM Modified Epoxy Matrices and Their Carbon Fiber Composites. Compos. Sci. Technol. 2015, 110, 8–16. [Google Scholar] [CrossRef]

- Turmel, D.J.-P.; Partridge, I.K. Heterogeneous Phase Separation around Fibres in Epoxy/PEI Blends and Its Effect on Composite Delamination Resistance. Compos. Sci. Technol. 1997, 57, 1001–1007. [Google Scholar] [CrossRef]

- Zhang, Y.; Stringer, J.; Grainger, R.; Smith, P.J.; Hodzic, A. Fabrication of Patterned Thermoplastic Microphases between Composite Plies by Inkjet Printing. J. Compos. Mater. 2015, 49, 1907–1913. [Google Scholar] [CrossRef]

- Zainol Abidin, M.S.; Herceg, T.; Greenhalgh, E.S.; Shaffer, M.; Bismarck, A. Enhanced Fracture Toughness of Hierarchical Carbon Nanotube Reinforced Carbon Fibre Epoxy Composites with Engineered Matrix Microstructure. Compos. Sci. Technol. 2019, 170, 85–92. [Google Scholar] [CrossRef]

- Qian, X.; Kravchenko, O.G.; Pedrazzoli, D.; Manas-Zloczower, I. Effect of Polycarbonate Film Surface Morphology and Oxygen Plasma Treatment on Mode I and II Fracture Toughness of Interleaved Composite Laminates. Compos. Part A Appl. Sci. Manuf. 2018, 105, 138–149. [Google Scholar] [CrossRef]

- Han, C.L.; Wang, G.-D.; Li, N.; Wang, M.; Liu, X.L.; Ma, J.H. Study on Interlaminar Performance of CNTs/Epoxy Film Enhanced GFRP under Low-Temperature Cycle. Compos. Struct. 2021, 272, 114191. [Google Scholar] [CrossRef]

- Wang, G.; Yao, S.; Zhang, J.; Han, C.; Zhang, H. Interlaminar Performance of 3D CNTs/Carbon Black Film Enhanced GFRP under Low-Temperature Cycling. J. Alloys Compd. 2023, 947, 169595. [Google Scholar] [CrossRef]

- Wu, N.; Yang, J.; Zheng, S.; Wang, J.; Chen, L. Improvement of Interlaminar Fracture Toughness in Glass Fiber Reinforced Plastic Laminates with Inorganic Nanofiber Sheet Interleaf. Fibers Polym. 2019, 20, 2175–2183. [Google Scholar] [CrossRef]

- Bhanushali, H.; Bradford, P.D. Woven Glass Fiber Composites with Aligned Carbon Nanotube Sheet Interlayers. J. Nanomater. 2016, 2016, e9705257. [Google Scholar] [CrossRef]

| Interleaf Material | Addition Amount | GIC,ini Improvement (%) | GIC,prop Improvement (%) | Refs. |

|---|---|---|---|---|

| Polycarbonate film | 127 μm | - | 53 | [33] |

| Plasma-treated polycarbonate film | 127 μm | - | 53 | [33] |

| CNT/epoxy film | 10 μm | 113 | 43 | [34] |

| Toner/epoxy film | 40 μm | 92 | 23 | [34] |

| CNT buckypaper | 40 μm | 39 | 67 | [24] |

| CNT film | 30.5 μm | −22 | −73 | [35] |

| CNT/carbon black film | 33 μm | 119 | 30 | [35] |

| CNT/GO films | 32 μm | 11 | 2 | [35] |

| TiO2 nanofiber sheets | 11 μm | - | 74.35 | [36] |

| 2-layer aligned CNT sheet | 0.354 gsm | - | 46.77 | [37] |

| 4 layer aligned CNT sheet | 0.708 gsm | - | −45.16 | [37] |

| CNT spray coating (0.3 gsm) | 0.3 gsm | 107.0 | 67.6 | This work |

| CNT spray coating (0.5 gsm) | 0.5 gsm | 136.0 | 82.0 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, H.; Zhang, Y.; Ou, Y.; Wu, L.; Li, J.; Yao, X.; Yang, X.; Mao, D. Maximizing Interlaminar Fracture Toughness in Bidirectional GFRP through Controlled CNT Heterogeneous Toughening. Polymers 2024, 16, 1011. https://doi.org/10.3390/polym16071011

Zhao H, Zhang Y, Ou Y, Wu L, Li J, Yao X, Yang X, Mao D. Maximizing Interlaminar Fracture Toughness in Bidirectional GFRP through Controlled CNT Heterogeneous Toughening. Polymers. 2024; 16(7):1011. https://doi.org/10.3390/polym16071011

Chicago/Turabian StyleZhao, Hongchen, Yunxiao Zhang, Yunfu Ou, Longqiang Wu, Juan Li, Xudan Yao, Xiongwu Yang, and Dongsheng Mao. 2024. "Maximizing Interlaminar Fracture Toughness in Bidirectional GFRP through Controlled CNT Heterogeneous Toughening" Polymers 16, no. 7: 1011. https://doi.org/10.3390/polym16071011

APA StyleZhao, H., Zhang, Y., Ou, Y., Wu, L., Li, J., Yao, X., Yang, X., & Mao, D. (2024). Maximizing Interlaminar Fracture Toughness in Bidirectional GFRP through Controlled CNT Heterogeneous Toughening. Polymers, 16(7), 1011. https://doi.org/10.3390/polym16071011