Synchronous Sound Recognition and Energy Harvesting by Flexible Piezoelectric PLLA/VB2 Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of PLLA/VB2 Composites

2.3. Characterization of PLLA/VB2 Composites

3. Results and Discussion

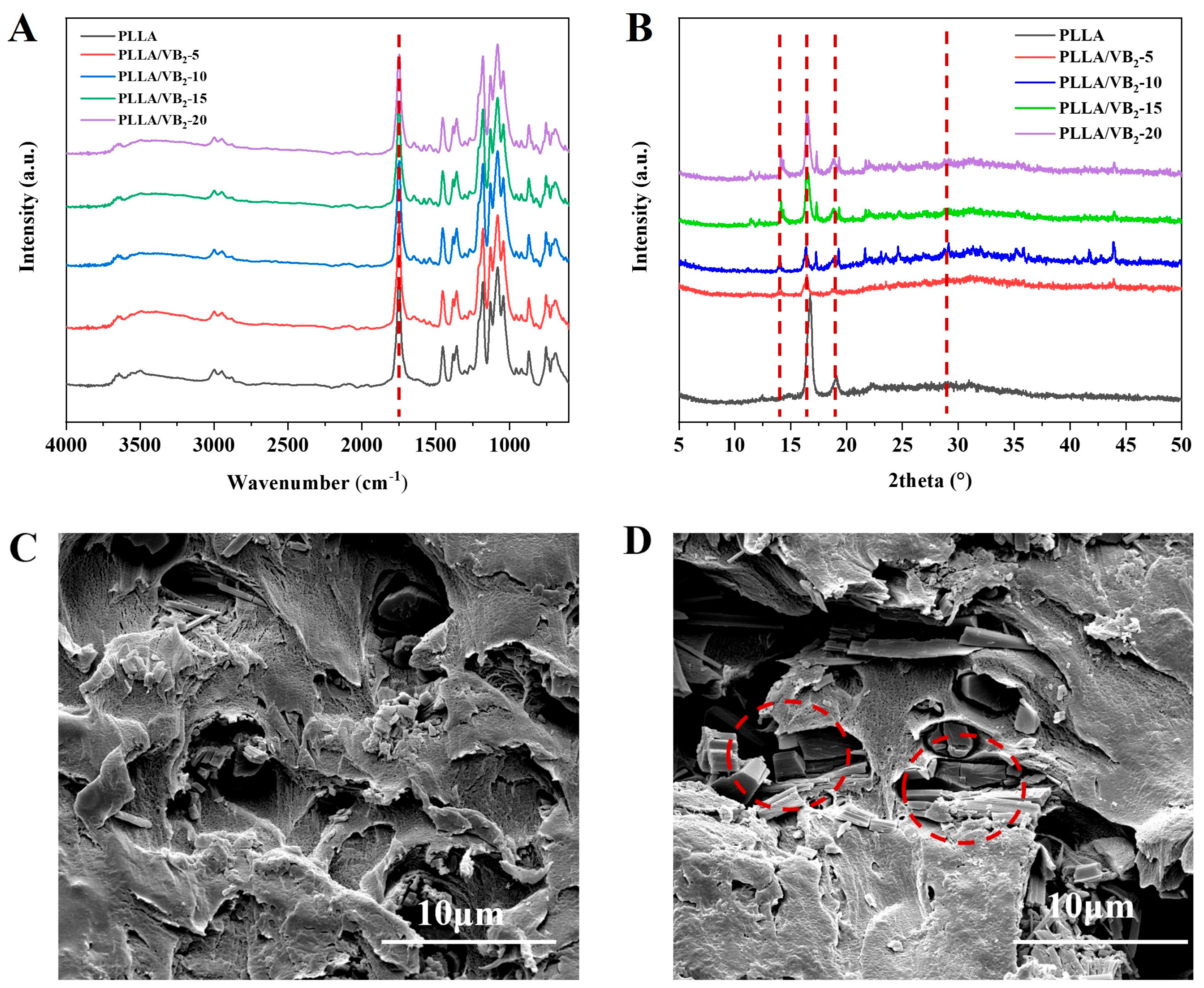

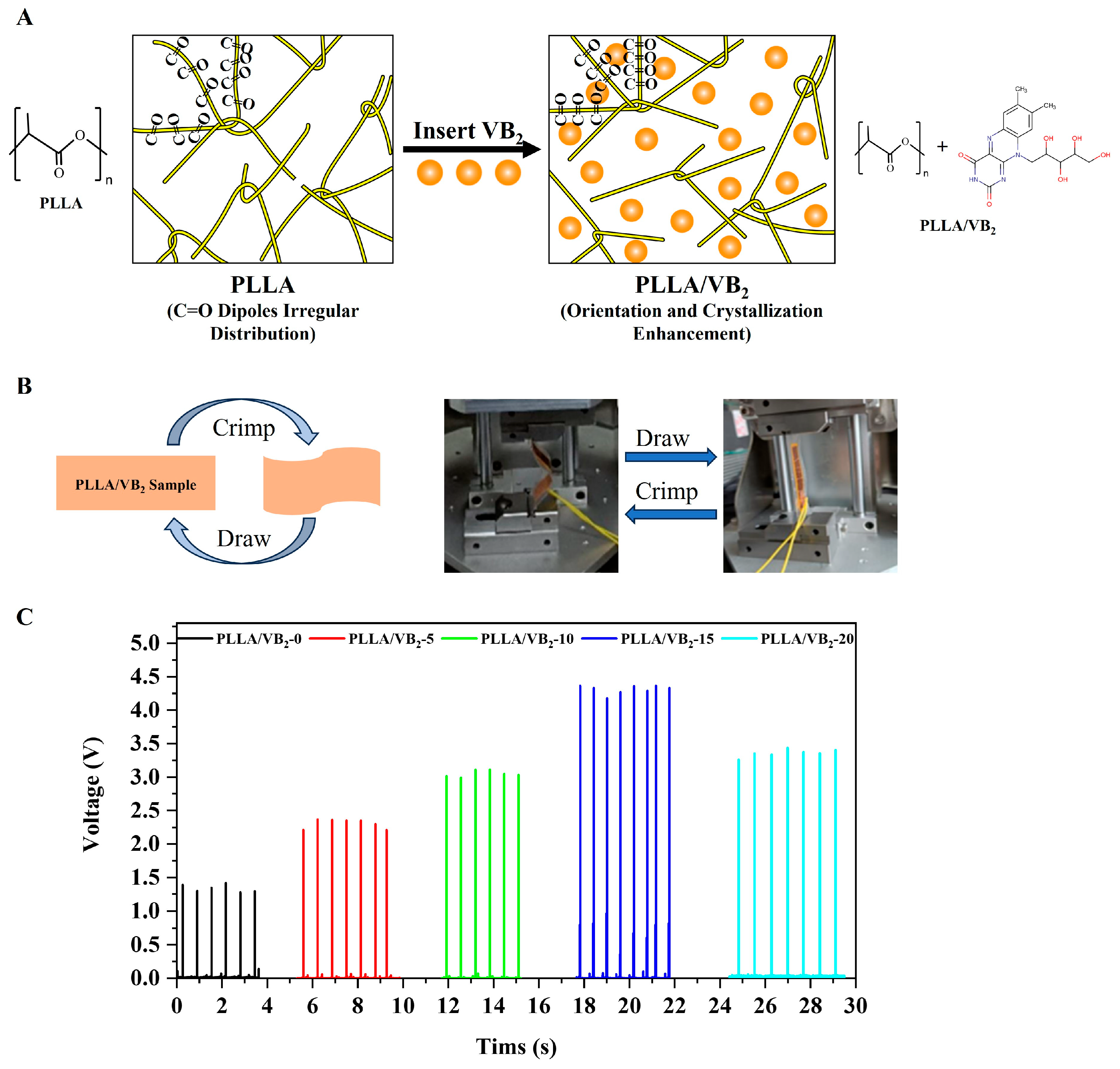

3.1. Characterization of PLLA/VB2 Composites

3.2. Piezoelectric Performance of PLLA/VB2 Composites

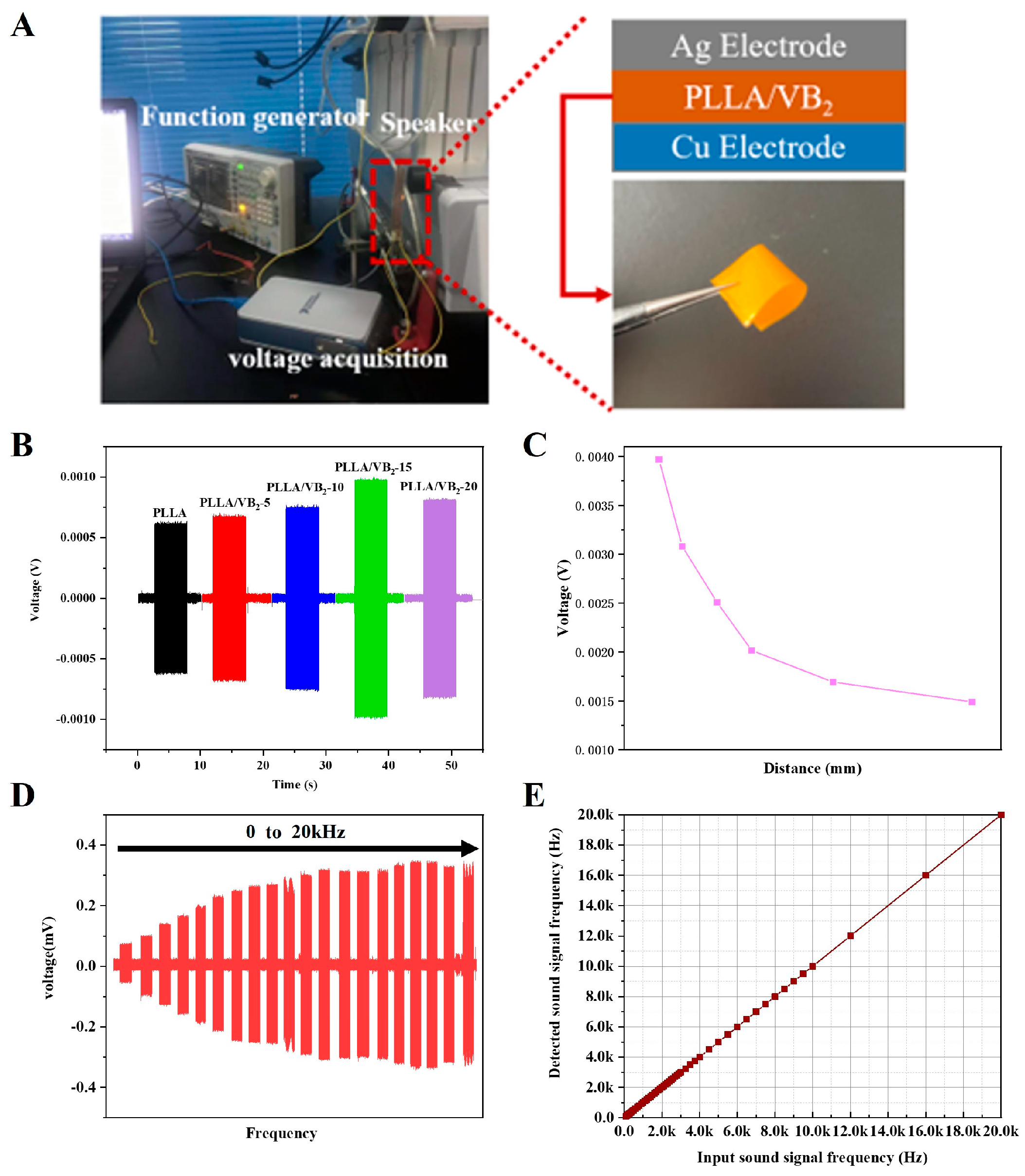

3.3. Piezoelectric Acoustical Performance of PLLA/VB2 Composites

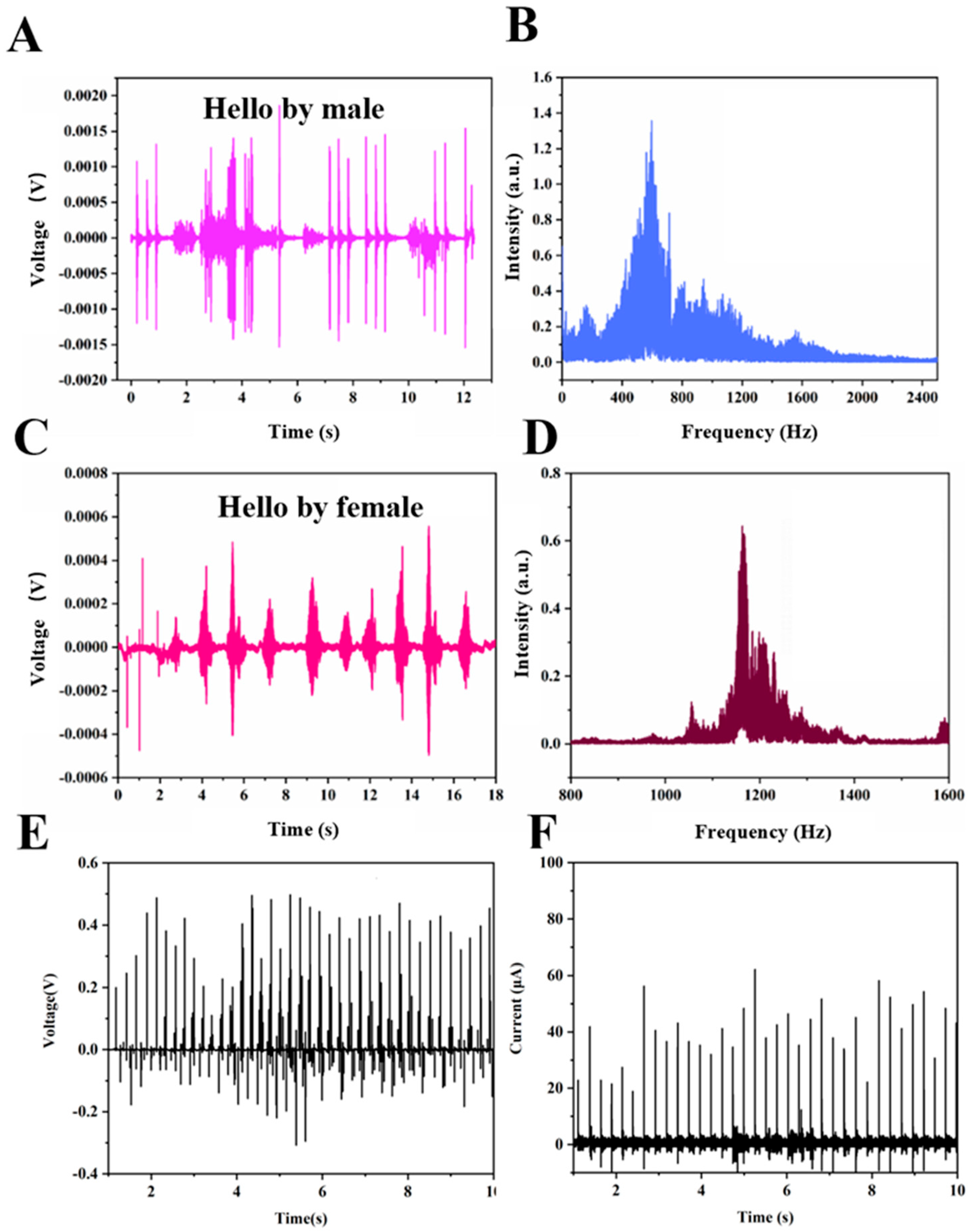

3.4. Sound Recognition and Energy Harvesting Performance of PLLA/VB2 Composites

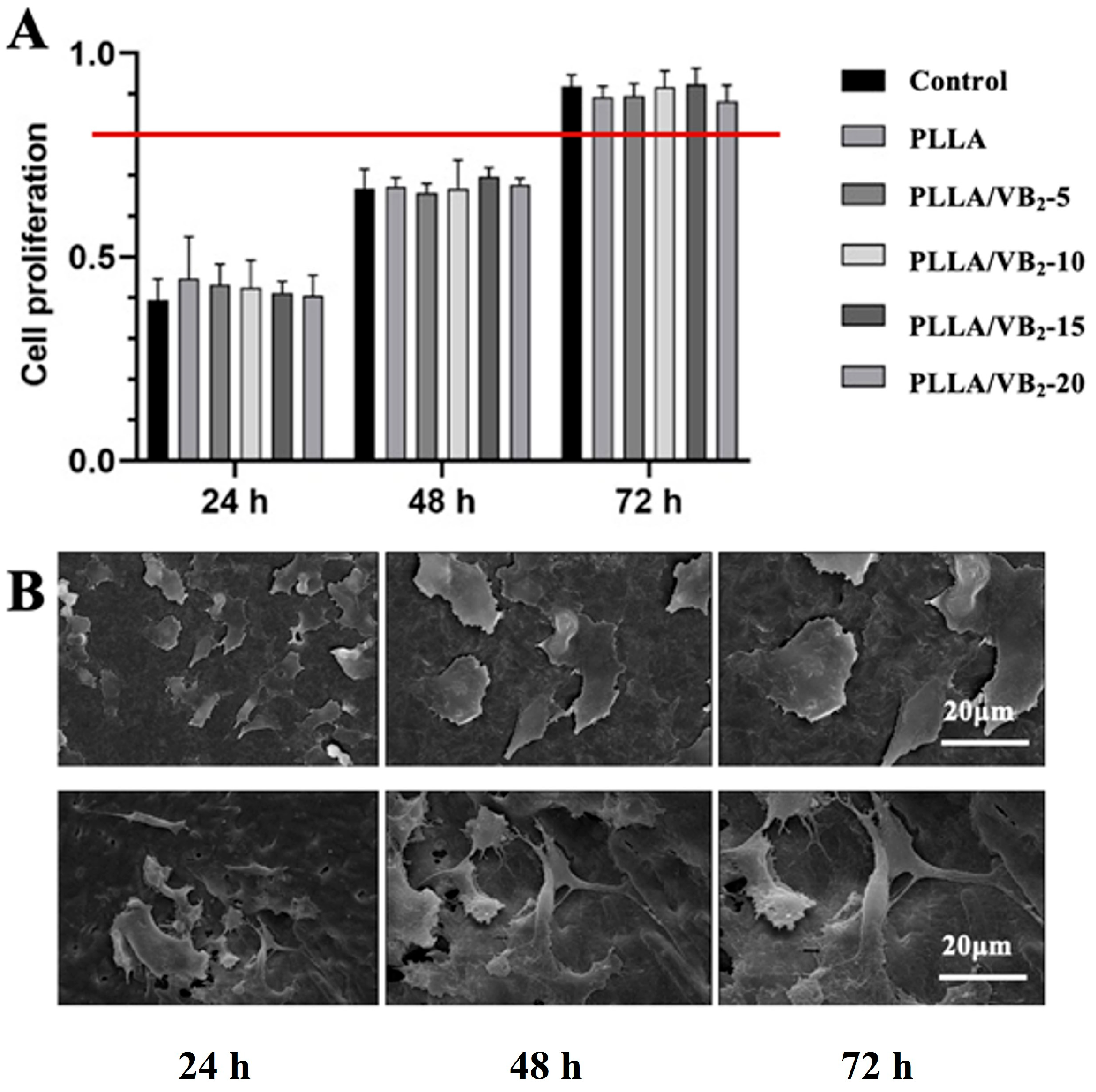

3.5. Cytotoxicity and Biocompatibility of PLLA/VB2 Composites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Roundy, S.; Wright, P.K.; Rabaey, J. A study of low level vibrations as a power source for wireless sensor nodes. Comput. Commun. 2003, 26, 1131–1144. [Google Scholar] [CrossRef]

- Guerreiro, A.J.; Pereira, C.L.; Fernandes, J.C.S.; Fernandes, F.M. Energy harvesting for wearable devices: A review. Sensors 2019, 19, 1985. [Google Scholar] [CrossRef]

- Wang, W.; Yang, X.; Zhu, Y.; Wu, Z.; Liu, Y.; Wang, Z.L. Nanogenerator: A hybrid energy harvesting cell with multiple sources. Nanotechnology 2007, 18, 424002. [Google Scholar]

- Sodano, H.A.; Inman, D.J. Experimental comparison of piezoelectric energy harvesting circuits for powering wireless sensors. Smart Mater. Struct. 2007, 16, 2408–2417. [Google Scholar]

- Topalov, E.; Stoychev, I.G. Piezoelectric energy harvesting: A review. Izv. Vis. Ucheb. Zaved. Elektromekh. 2014, 57, 38–44. [Google Scholar]

- Aktakka, A.; Senentxu Lanceros-Méndez, M.P. Energy harvesting solutions for wearable technologies. Materials 2019, 12, 528. [Google Scholar]

- Mirvakili, S.M.; Hajjaj, M.; Tutumluer, S.; Wang, L.; Beeby, S.P. Development of wearable multi-modal energy harvesting systems for IoT applications. Appl. Energy 2019, 238, 684–696. [Google Scholar]

- Park, J.Y.; Son, S.H.; Kim, J.P. A review of energy harvesting for portable electronics. Asian J. Chem. 2015, 27, 1763–1770. [Google Scholar]

- Xiao, L.; Chan, H.L.W.; Wang, X. Piezoelectric energy harvesting under different temperature and loadings. Smart Mater. Struct. 2008, 17, 065037. [Google Scholar]

- Zhang, L.; Xu, Z.; Li, Y.; Chen, H.Y. Piezoelectric nanogenerators for self-powered sensing, self-powered communication and self-powered healthcare. Nano Energy 2020, 70, 104532. [Google Scholar]

- Kim, H.; Ghaffari, R.; Kim, Y.S.; Lee, H.J.; Kim, H.R.; Kim, S.M.; Choi, Y.D.; Chung, C.S.; Kim, J.K. Stretchable, transparent graphene interconnects for arrays of microscale inorganic light emitting diodes on rubber substrates. Nano Lett. 2011, 11, 3880–3886. [Google Scholar] [CrossRef] [PubMed]

- O’Keefe, S.R.; Ehlert, J.C.; Cross, L.E.; Weigand, P.M. Use of bimorph elements for efficient piezoelectric energy conversion. J. Appl. Phys. 1973, 44, 3104–3110. [Google Scholar]

- Roundy, S.; Wright, P.K. Energy scavenging for wireless sensor networks: With special focus on vibrations. Proc. IEEE 2005, 93, 1285–1296. [Google Scholar]

- Sun, W.; Kou, F.; Wang, J.J.; Wang, X.; Yang, Q.; Zhou, F.; Li, J.; Xu, S.; Zhang, J. Toward a self-powered wireless temperature sensor system based on a piezoelectric energy harvester using a cantilever beam. IEEE Sens. J. 2016, 16, 5968–5977. [Google Scholar]

- Wang, X.; Lv, F.; Xiang, Y.; Zhang, Y.; Hao, Z.; Yan, C.; Su, J. A self-powered and low-cost acoustic sensor based on a piezoelectric energy harvester for wireless structural health monitoring. Front. Built Environ. 2019, 5, 121. [Google Scholar]

- Yang, B.; Hahn, J.M.; Yang, Y.; Kim, E.; Kim, B.W.; Sung, H.J.; Lee, S. An energy harvesting device using a bistable composite laminated beam for vibration-based wireless sensor nodes. J. Intell. Mater. Syst. Struct. 2013, 24, 1197–1206. [Google Scholar]

- Zhang, X.; Ni, Y.; Sun, Y.; Shi, J. A vibration energy harvesting device with magnetoelectric laminate composites. Appl. Phys. Lett. 2013, 103, 103501. [Google Scholar]

- Zhang, W.; Alamry, M.Y.; ElAtab, H.A.; Irazoqui, J.P. Vibration-based energy harvesting from a wearable bracelet using a piezoelectric double-clamped beam. Smart Mater. Struct. 2016, 25, 095015. [Google Scholar]

- Lee, N.; Shin, J.; Hong, J.; Zou, X.; Yu, W.; Lee, D.Y. Fabric-based piezoelectric energy harvesting device based on polyvinylidene fluoride-co-trifluoroethylene: A feasibility study. Sensors 2018, 18, 357. [Google Scholar]

- Liu, Z.; Cheng, G.; Xu, L.; Kang, Z. A piezoelectric nanogenerator based on PVDF-TrFE thick films for harvesting vibration energy. J. Micromech. Microeng. 2010, 20, 115021. [Google Scholar]

- Hu, Z.; Qi, Y.; Li, Z.; Zhang, M.; Lu, F.; Guo, X. Enhancing the β-phase crystallinity of PVDF for integration of PVDF and PS on a single chip. Sens. Actuators A Phys. 2013, 203, 69–77. [Google Scholar]

- Li, Z.; Kim, C.Y.; Vashaee, D. Enhancement of piezoelectric properties of PVDF-TrFE through Cr doping. J. Micromech. Microeng. 2015, 25, 095008. [Google Scholar]

- Sodano, H.A.; Park, G.; Inman, D.J. Comparison of polyvinylidene fluoride and lead zirconate titanate in an energy harvesting vibration-based device. Smart Mater. Struct. 2005, 14, 1459–1465. [Google Scholar]

- Kim, S.; Hong, S.; Lee, S.; Lee, M. Highly piezoelectric poly(vinylidenefluoride-co-trifluoroethylene) random copolymer with unusual crystal phases. Macromolecules 2011, 44, 773–778. [Google Scholar]

- Shrout, T.R.; Jitianu, S.; Goeringer, R.L.; Cann, D.P.; Subramanian, M.A.; Sharma, N.K.; Shaw, T.M. Piezoelectric property enhancement of poly(vinylidene fluoride) with inclusion of BaTiO3 ceramics. J. Electroceram. 1999, 3, 329–337. [Google Scholar]

- Xu, C.; Song, Y.; Han, M.; Zhang, H. Portable and wearable self-powered systems based on emerging energy harvesting technology. Microsyst. Nanoeng. 2021, 7, 25. [Google Scholar] [CrossRef] [PubMed]

- Yuan, D.; Chen, H.; Zhang, X. Enhancing piezoelectric response of poly(vinylidene fluoride) by incorporating reduced graphene oxide. Carbon 2014, 78, 467–473. [Google Scholar]

- Wang, J.; Cai, S.; Yao, M.; Li, Y.; Tang, J.; Li, P. Enhanced piezoelectric performance of PVDF/ZnO nanorod composite films by the bridging effect of carbon nanotubes. J. Mater. Sci. 2014, 49, 7775–7781. [Google Scholar]

- Yang, J.; Fan, X.; Xiang, Y.; Wang, Y.; Gong, L.; Yu, K.; Gao, B.; Su, J. Preparation and piezoelectricity of poly(vinylidene fluoride-co-trifluoroethylene) nanocomposites with BaTiO3 nanocrystals decorated graphene oxide. Appl. Phys. Lett. 2016, 108, 063901. [Google Scholar]

- Sumanta, K.K.; Sandip, M.; Anand, K.A.; Amit, K.D.; Anirban, M.; Sarbaranjan, P.; Aswini, B.; Ranadip, B.; Lopamudra, H.; Avnish, K.M.; et al. Designing high energy conversion efficient bio-inspired vitamin assisted single-structured based self-powered piezoelectric/wind/acoustic multi-energy harvester with remarkable power density. Nano Energy 2019, 59, 169–183. [Google Scholar]

- Akiko, O.; Toshiki, H.; Takashi, W.; Yoshio, O.; Toshihiro, K. Electrospun microfiber meshes of silicon-doped vaterite/poly(lactic acid) hybrid for guided bone regeneration. Acta Biomater. 2010, 6, 1248–1257. [Google Scholar]

- Duan, B.; Wu, K.; Chen, X.; Ni, J.; Ma, X.; Meng, W.; Lam, K.H.; Yu, P. Bioinspired PVDF Piezoelectric Generator for Harvesting Multi-Frequency Sound Energy. Adv. Electron. Mater. 2023, 9, 2300348. [Google Scholar] [CrossRef]

- Zin, S.H.M.; Velayutham, T.S.; Furukawa, T.; Kodama, H.; Gan, W.C.; Chio-Srichan, S.; Kriechbaum, M.; Nakajima, T. Quantitative study on the face shear piezoelectricity and its relaxation in uniaxially-drawn and annealed poly-l-lactic acid. Polymer 2022, 254, 125095. [Google Scholar]

- Ramadan, K.S.; Sameoto, D.; Evoy, S. A review of piezoelectric polymers as functional materials for electromechanical transducers. Smart Mater. Struct. 2014, 23, 033001. [Google Scholar] [CrossRef]

- Panda, P.K.; Sahoo, B. PZT to Lead Free Piezo Ceramics: A Review. Ferroelectrics 2015, 474, 128–143. [Google Scholar] [CrossRef]

- Fu, Y.Q.; Luo, J.K.; Nguyen, N.T.; Walton, A.J.; Flewitt, A.J.; Zu, X.T.; Li, Y.; McHale, G.; Matthews, A.; Iborra, E.; et al. Advances in piezoelectric thin films for acoustic biosensors, acoustofluidics and lab-on-chip applications. Prog. Mater. Sci. 2017, 89, 31–91. [Google Scholar] [CrossRef]

- Marauska, S.; Hrkac, V.; Dankwort, T.; Jahns, R.; Quenzer, H.J.; Knöchel, R.; Kienle, L.; Wagner, B. Sputtered thin film piezoelectric aluminum nitride as a functional MEMS material. Microsyst. Technol. 2012, 18, 787–795. [Google Scholar] [CrossRef]

- Crisler, D.F.; Cupal, J.J.; Moore, A.R. Dielectric, piezoelectric, and electromechanical coupling constants of zinc oxide crystals. Proc. IEEE 1968, 56, 225–226. [Google Scholar] [CrossRef]

- Cai, L.; Qin, X.; Xu, Z.; Song, Y.; Jiang, H.; Wu, Y.; Ruan, H.; Chen, J. Comparison of Cytotoxicity Evaluation of Anticancer Drugs between Real-Time Cell Analysis and CCK-8 Method. ACS Publ. 2019, 4, 12036–12042. [Google Scholar] [CrossRef]

- Liao, J.; Zheng, H.; Fei, Z.; Lu, B.; Zheng, H.; Li, D.; Xiong, X.; Yi, Y. Tumor-targeting and pH-responsive nanoparticles from hyaluronic acid for the enhanced delivery of doxorubicin. Int. J. Biol. Macromol. 2018, 113, 737–747. [Google Scholar] [CrossRef]

| Performance Index | Units | PZT [35] | AlN [37] | ZnO [38] | PLLA/VB2 |

|---|---|---|---|---|---|

| Density | (kg/m3) | 7800 | 3230 | 5610 | 1250 |

| Young’s modulus Y | (GPa) | 60 | 308 | 201 | 2.7 |

| Dielectric constant εr | εr33 | 2400 | 10.5 | 11 | 2.6 |

| Piezoelectric constant | (pC/N) | d33 = 500 | d33 = 5.5 | d33 = 12.4 | d14 = 10 |

| Sound velocity | m/s | 6500 | 10000 | 5500 | 2300 |

| Whether polarization is required | Yes or No | Yes | Yes | Yes | No |

| Whether it is toxic or not | Yes or No | Yes | Yes | Yes | No |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Liu, Q.; Xue, W.; Xiang, Y.; Hu, X. Synchronous Sound Recognition and Energy Harvesting by Flexible Piezoelectric PLLA/VB2 Composites. Polymers 2024, 16, 1071. https://doi.org/10.3390/polym16081071

Zhang Q, Liu Q, Xue W, Xiang Y, Hu X. Synchronous Sound Recognition and Energy Harvesting by Flexible Piezoelectric PLLA/VB2 Composites. Polymers. 2024; 16(8):1071. https://doi.org/10.3390/polym16081071

Chicago/Turabian StyleZhang, Qian, Qiang Liu, Weidong Xue, Yong Xiang, and Xiaoran Hu. 2024. "Synchronous Sound Recognition and Energy Harvesting by Flexible Piezoelectric PLLA/VB2 Composites" Polymers 16, no. 8: 1071. https://doi.org/10.3390/polym16081071

APA StyleZhang, Q., Liu, Q., Xue, W., Xiang, Y., & Hu, X. (2024). Synchronous Sound Recognition and Energy Harvesting by Flexible Piezoelectric PLLA/VB2 Composites. Polymers, 16(8), 1071. https://doi.org/10.3390/polym16081071