Edible Coatings for Ready-to-Eat Products: Critical Review of Recent Studies, Sustainable Packaging Perspectives, Challenges and Emerging Trends

Abstract

:1. Introduction

2. Edible Coatings

3. Recent Studies with Edible Coatings for RTE Products

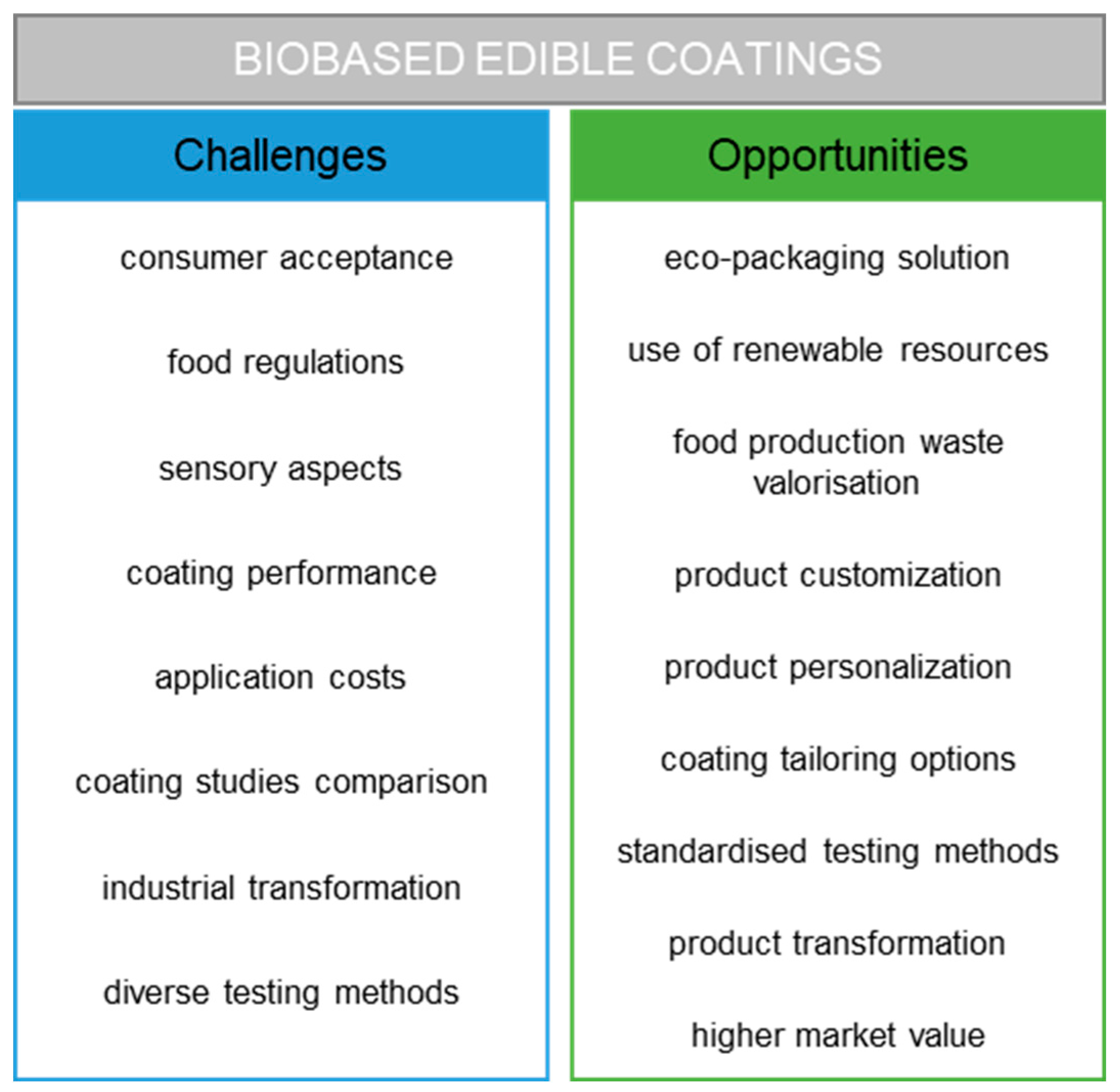

4. Challenges and Emerging Trends

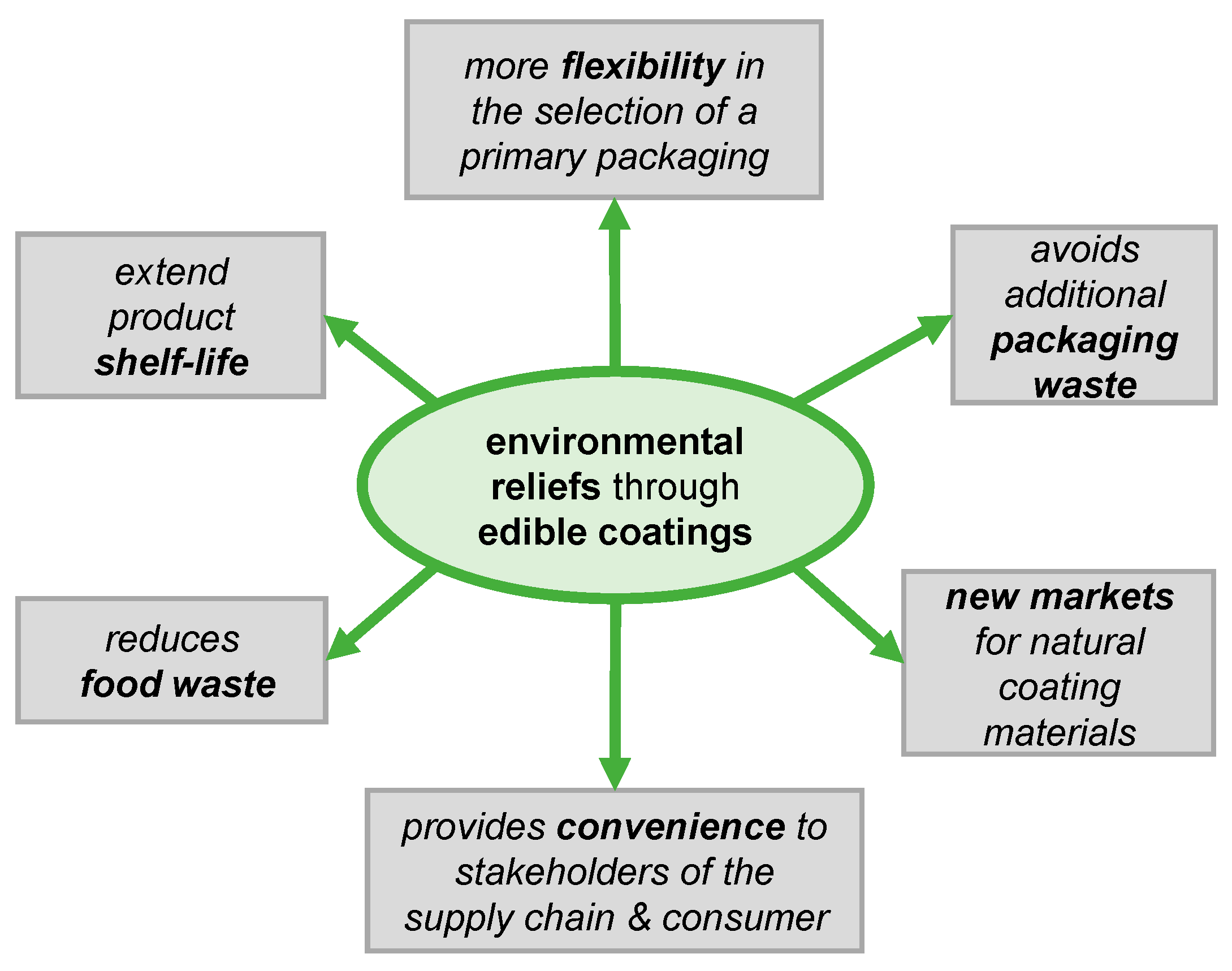

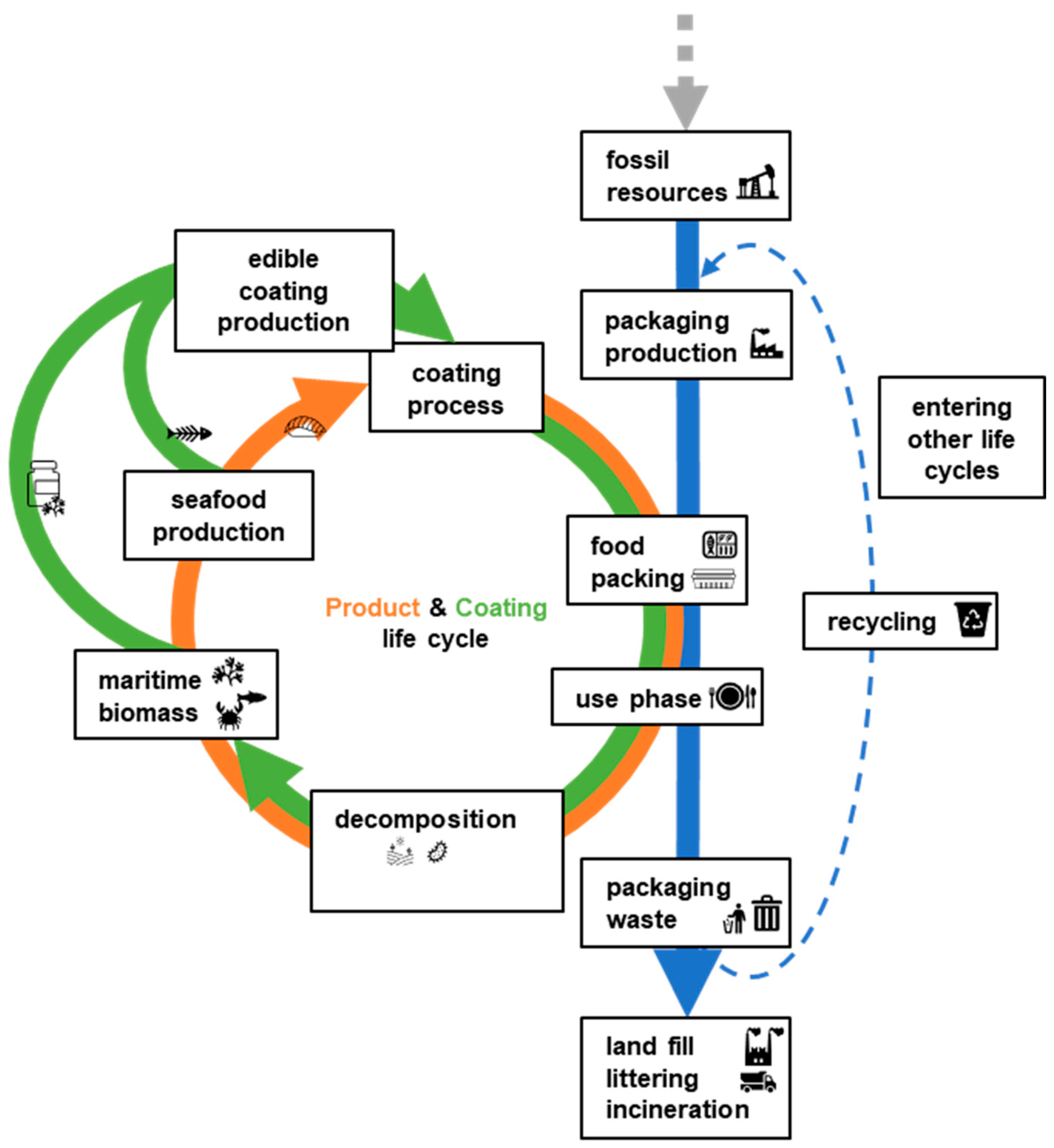

4.1. Can an Edible Coating Provide an Eco-Packaging Solution?

4.2. Developing Strategies for Edible Coatings

4.3. Edible Coatings: An Integrated Part of Food Products

4.4. Strategies to Improve Coating Performance: Active and Intelligent Coatings

4.5. Coating Application Methods

4.6. Coating Performance Measurement Methods

5. Conclusions and Future Trends

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Han, J.-W.; Ruiz-Garcia, L.; Qian, J.-P.; Yang, X.-T. Food Packaging: A Comprehensive Review and Future Trends. Compr. Rev. Food Sci. Food Saf. 2018, 17, 860–877. [Google Scholar] [CrossRef] [PubMed]

- Janes, M.E.; Dai, Y. Edible films for meat, poultry and seafood. In Advances in Meat, Poultry and Seafood Packaging; Kerry, J.P., Ed.; Woodhead Publishing Series in Food Science, Technology and Nutrition Series: V. 220; Elsevier Science & Technology: Amsterdam, The Netherlands, 2012; pp. 504–521. [Google Scholar] [CrossRef]

- Bourlieu, C.; Guillard, V.; Vallès-Pamiès, B.; Gontard, N. Edible Moisture Barriers for Food Product Stabilization. In Food Materials Science: Principles and Practice; Aguilera, J.M., Lillford, P.J., Eds.; Springer: New York, NY, USA, 2008; pp. 547–575. [Google Scholar] [CrossRef]

- Cerqueira, M.A.; Sousa-Gallagher, M.J.; Macedo, I.; Rodriguez-Aguilera, R.; Souza, B.W.S.; Teixeira, J.A.; Vicente, A.A. Use of galactomannan edible coating application and storage temperature for prolonging shelf-life of “Regional” cheese. J. Food Eng. 2010, 97, 87–94. [Google Scholar] [CrossRef]

- Nešić, A.; Cabrera-Barjas, G.; Dimitrijević-Branković, S.; Davidović, S.; Radovanović, N.; Delattre, C. Prospect of Polysaccharide-Based Materials as Advanced Food Packaging. Molecules 2019, 25, 135. [Google Scholar] [CrossRef]

- Yousuf, B.; Sun, Y.; Wu, S. Lipid and Lipid-containing Composite Edible Coatings and Films. Food Rev. Int. 2021, 38, 574–597. [Google Scholar] [CrossRef]

- Bremenkamp, I.; Sousa-Gallagher, M.J. Design and Development of an Edible Coating for a Ready-to-Eat Fish Product. Polymers 2024, 16, 346. [Google Scholar] [CrossRef]

- Sørbø, S.; Lerfall, J. Effect of edible coating and modified atmosphere packaging on the microbiological and physicochemical stability of retail maki sushi. J. Food Sci. 2022, 87, 1211–1229. [Google Scholar] [CrossRef] [PubMed]

- Martínez, O.; Salmerón, J.; Epelde, L.; Vicente, M.; de Vega, C. Quality enhancement of smoked sea bass (Dicentrarchus labrax) fillets by adding resveratrol and coating with chitosan and alginate edible films. Food Control 2018, 85, 168–176. [Google Scholar] [CrossRef]

- Hager, J.V.; Rawles, S.D.; Xiong, Y.L.; Newman, M.C.; Thompson, K.R.; Webster, C.D. Listeria monocytogenes is inhibited on fillets of cold-smoked sunshine bass, Morone chrysops × Morone saxatilis with an edible corn zein-based coating incorporated with lemongrass essential oil or nisin. J. World Aquac. Soc. 2019, 50, 575–592. [Google Scholar] [CrossRef]

- Carrión-Granda, X.; Fernández-Pan, I.; Jaime, I.; Rovira, J.; Maté, J.I. Improvement of the microbiological quality of ready-to-eat peeled shrimps (Penaeus vannamei) by the use of chitosan coatings. Int. J. Food Microbiol. 2016, 232, 144–149. [Google Scholar] [CrossRef]

- Sanjuás-Rey, M.; Pourashouri, P.; Barros-Velázquez, J.; Aubourg, S.P. Effect of oregano and thyme essential oils on the microbiological and chemical quality of refrigerated (4 °C) ready-to-eat squid rings. Int. J. Food Sci. Technol. 2012, 47, 1439–1447. [Google Scholar] [CrossRef]

- Jiang, Z.; Neetoo, H.; Chen, H. Control of Listeria monocytogenes on cold-smoked salmon using chitosan-based antimicrobial coatings and films. J. Food Sci. 2011, 76, M22–M26. [Google Scholar] [CrossRef]

- López-Caballero, M.E.; Gómez-Guillén, M.C.; Pérez-Mateos, M.; Montero, P. A chitosan–gelatin blend as a coating for fish patties. Food Hydrocoll. 2005, 19, 303–311. [Google Scholar] [CrossRef]

- Diao, X.; Huan, Y.; Chitrakar, B. Extending the Shelf Life of Ready-to-Eat Spiced Chicken Meat: Garlic Aqueous Extracts-Carboxymethyl Chitosan Ultrasonicated Coating Solution. Food Bioprocess Technol. 2020, 13, 786–796. [Google Scholar] [CrossRef]

- Antoniadou, D.; Govaris, A.; Ambrosiadis, I.; Sergelidis, D. Effect of chitosan coating on the shelf life of ready-to-eat bovine meatballs and the control of Listeria monocytogenes growth on their surface during refrigeration storage. J. Hell. Vet. Med. Soc. 2019, 70, 1495. [Google Scholar] [CrossRef]

- Guo, M.; Jin, T.Z.; Wang, L.; Scullen, O.J.; Sommers, C.H. Antimicrobial films and coatings for inactivation of Listeria innocua on ready-to-eat deli turkey meat. Food Control 2014, 40, 64–70. [Google Scholar] [CrossRef]

- Jiang, Z.; Neetoo, H.; Chen, H. Efficacy of freezing, frozen storage and edible antimicrobial coatings used in combination for control of Listeria monocytogenes on roasted turkey stored at chiller temperatures. Food Microbiol. 2011, 28, 1394–1401. [Google Scholar] [CrossRef] [PubMed]

- Juck, G.; Neetoo, H.; Chen, H. Application of an active alginate coating to control the growth of Listeria monocytogenes on poached and deli turkey products. Int. J. Food Microbiol. 2010, 142, 302–308. [Google Scholar] [CrossRef]

- Beverlya, R.L.; Janes, M.E.; Prinyawiwatkula, W.; No, H.K. Edible chitosan films on ready-to-eat roast beef for the control of Listeria monocytogenes. Food Microbiol. 2008, 25, 534–537. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Rhim, J.W.; Weller, C.L.; Hamouz, F.; Cuppett, S.; Schnepf, M. Moisture Loss and Lipid Oxidation for Precooked Beef Patties Stored in Edible Coatings and Films. J. Food Sci. 2000, 65, 300–304. [Google Scholar] [CrossRef]

- Marcos, B.; Gou, P.; Arnau, J.; Guàrdia, M.D.; Comaposada, J. Co-extruded alginate as an alternative to collagen casings in the production of dry-fermented sausages: Impact of coating composition. Meat Sci. 2020, 169, 108184. [Google Scholar] [CrossRef]

- Singh, P.; Wani, A.; Langowski, H.-C. (Eds.) Food Packaging Materials; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar] [CrossRef]

- FAO. Moving Forward on Food Loss and Waste Reduction. In The State of Food and Agriculture; Food and Agriculture Organization of the United Nations: Rome, Italy, 2019; Volume 2019. [Google Scholar]

- Farris, S.; Piergiovanni, L. Emerging coating technologies for food and beverage packaging materials. In Emerging Food Packaging Technologies: Principles and Practice; Yam, K.L., Lee, D.S., Eds.; Woodhead Publishing Series in Food Science, Technology and Nutrition: No. 230; Woodhead Publishing: Cambridge, UK, 2012; pp. 274–302. [Google Scholar] [CrossRef]

- Morris, M.A.; Padmanabhan, S.C.; Cruz-Romero, M.C.; Cummins, E.; Kerry, J.P. Development of active, nanoparticle, antimicrobial technologies for muscle-based packaging applications. Meat Sci. 2017, 132, 163–178. [Google Scholar] [CrossRef]

- Emblem, H.J. Packaging and environmental sustainability. In Packaging Technology: Fundamentals, Materials and Processes; Emblem, A., Emblem, H., Eds.; Woodhead Publishing in Materials; Woodhead Publishing: Cambridge, UK, 2012; pp. 65–86. [Google Scholar] [CrossRef]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. Lond. Ser. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [PubMed]

- Kaiser, K.; Schmid, M.; Schlummer, M. Recycling of Polymer-Based Multilayer Packaging: A Review. Recycling 2018, 3, 1. [Google Scholar] [CrossRef]

- Morris, B.A. The Science and Technology of Flexible Packaging: Multilayer Films from Resin and Process to End Use; Plastics Design Library (PDL) Handbook Series; Elsevier Ltd.: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Dainelli, D. Recycling of food packaging materials: An overview. In Environmentally Compatible Food Packaging; Chiellini, E., Ed.; Woodhead Publishing in Food Science, Technology and Nutrition; CRC: Boca Raton, FL, USA, 2008; pp. 294–325. [Google Scholar] [CrossRef]

- Puttalingamma, V. Edible Coatings of Carnauba Wax—A Novel Method For Preservation and Extending Longevity of Fruits and Vegetables—A Review. Internet J. Food Saf. 2014, 16, 1004–1008. [Google Scholar]

- European Commission. COM(2014) 389 Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: Towards a Circular Economy: A Zero Waste Programme for Europe; European Commission: Brussels, Belgium, 2014; pp. 1–14. [Google Scholar]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Olsen, R.L.; Toppe, J.; Karunasagar, I. Challenges and realistic opportunities in the use of by-products from processing of fish and shellfish. Trends Food Sci. Technol. 2014, 36, 144–151. [Google Scholar] [CrossRef]

- Kandra, P.; Challa, M.M.; Jyothi, H.K.P. Efficient use of shrimp waste: Present and future trends. Appl. Microbiol. Biotechnol. 2012, 93, 17–29. [Google Scholar] [CrossRef] [PubMed]

- Mouritsen, O.G. Seaweeds: Edible, Available & Sustainable; University of Chicago Press: Chicago, IL, USA, 2013. [Google Scholar]

- Fabra, M.J.; Martínez-Sanz, M.; Gómez-Mascaraque, L.G.; Coll-Marqués, J.M.; Martínez, J.C.; López-Rubio, A. Development and characterization of hybrid corn starch-microalgae films: Effect of ultrasound pre-treatment on structural, barrier and mechanical performance. Algal Res. 2017, 28, 80–87. [Google Scholar] [CrossRef]

- Zhang, C.; Show, P.-L.; Ho, S.-H. Progress and perspective on algal plastics—A critical review. Bioresour. Technol. 2019, 289, 121700. [Google Scholar] [CrossRef]

- Merz, C.R.; Main, K.L. Microalgae Bioproduction—Feeds, Food, Nutraceuticals, and Polymers. In Fuels, Chemicals and Materials from the Oceans and Aquatic Sources; Kerton, F.M., Yan, N., Eds.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2017; pp. 83–112. [Google Scholar] [CrossRef]

- Mathiot, C.; Ponge, P.; Gallard, B.; Sassi, J.-F.; Delrue, F.; Le Moigne, N. Microalgae starch-based bioplastics: Screening of ten strains and plasticization of unfractionated microalgae by extrusion. Carbohydr. Polym. 2019, 208, 142–151. [Google Scholar] [CrossRef] [PubMed]

- Zia, K.M.; Tabasum, S.; Nasif, M.; Sultan, N.; Aslam, N.; Noreen, A.; Zuber, M. A review on synthesis, properties and applications of natural polymer based carrageenan blends and composites. Int. J. Biol. Macromol. 2017, 96, 282–301. [Google Scholar] [CrossRef] [PubMed]

- Andriani, V.; Handdayani, N.A. Recent technology of edible coating production: A review. Mater. Today Proc. 2023, 87, 200–206. [Google Scholar] [CrossRef]

- Hosseini, S.F.; Gómez-Guillén, M.C. A state-of-the-art review on the elaboration of fish gelatin as bioactive packaging: Special emphasis on nanotechnology-based approaches. Trends Food Sci. Technol. 2018, 79, 125–135. [Google Scholar] [CrossRef]

- Nunes, C.; Silva, M.; Farinha, D.; Sales, H.; Pontes, R.; Nunes, J. Edible Coatings and Future Trends in Active Food Packaging–Fruits’ and Traditional Sausages’ Shelf Life Increasing. Foods 2023, 12, 3308. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Weller, C.L.; Hamouz, F.; Cuppett, S.; Schnepf, M. Moisture Loss and Lipid Oxidation for Precooked Ground-Beef Patties Packaged in Edible Starch-Alginate-Based Composite Films. J. Food Sci. 2001, 66, 486–493. [Google Scholar] [CrossRef]

- Ben Azaza, Y.; Hamdi, M.; Charmette, C.; Jridi, M.; Li, S.; Nasri, M.; Nasri, R. Development and characterization of active packaging films based on chitosan and sardinella protein isolate: Effects on the quality and the shelf life of shrimps. Food Packag. Shelf Life 2022, 31, 100796. [Google Scholar] [CrossRef]

- European Commission. Commission Regulation (EC) No 450/2009 of 29 May 2009 on Active and Intelligent Materials and Articles Intended to Come into Contact with Food; European Commission: Brussels, Belgium, 2009. [Google Scholar]

- Mirzapour-Kouhdasht, A.; Moosavi-Nasab, M. Shelf-life extension of whole shrimp using an active coating containing fish skin gelatin hydrolysates produced by a natural protease. Food Sci. Nutr. 2020, 8, 214–223. [Google Scholar] [CrossRef]

- Antonino, C.; Difonzo, G.; Faccia, M.; Caponio, F. Effect of edible coatings and films enriched with plant extracts and essential oils on the preservation of animal-derived foods. J. Food Sci. 2023, 89, 748–772. [Google Scholar] [CrossRef]

- Souza, V.G.L.; Pires, J.R.A.; Rodrigues, C.; Coelhoso, I.M.; Fernando, A.L. Chitosan Composites in Packaging Industry-Current Trends and Future Challenges. Polymers 2020, 12, 417. [Google Scholar] [CrossRef]

- Mahmud, N.; Islam, J.; Tahergorabi, R. Marine Biopolymers: Applications in Food Packaging. Processes 2021, 9, 2245. [Google Scholar] [CrossRef]

- Pérez-Gago, M.B.; Rhim, J.W. Chapter 13—Edible Coatings and Film Materials: Lipid Bilayers and Lipid Emulsions. In Innovations in Food Packaging: A Volume in Food Science and Technology; Han, J.H., Ed.; Academic Press: Cambridge, MA, USA, 2014; pp. 325–350. [Google Scholar]

- Poverenov, E.; Danino, S.; Horev, B.; Granit, R.; Vinokur, Y.; Rodov, V. Layer-by-Layer Electrostatic Deposition of Edible Coating on Fresh Cut Melon Model: Anticipated and Unexpected Effects of Alginate–Chitosan Combination. Food Bioprocess Technol. 2014, 7, 1424–1432. [Google Scholar] [CrossRef]

- Bourlieu, C.; Guillard, V.; Vallès-Pamiès, B.; Guilbert, S.; Gontard, N. Edible moisture barriers: How to assess of their potential and limits in food products shelf-life extension? Crit. Rev. Food Sci. Nutr. 2009, 49, 474–499. [Google Scholar] [CrossRef] [PubMed]

- Morillon, V.; Debeaufort, F.; Blond, G.; Capelle, M.; Voilley, A. Factors affecting the moisture permeability of lipid-based edible films: A review. Crit. Rev. Food Sci. Nutr. 2002, 42, 67–89. [Google Scholar] [CrossRef] [PubMed]

- Bremenkamp, I.; Sousa-Gallagher, M.J. Life cycle assessment methods for investigating novel food packaging systems. Environ. Sci. Adv. 2024, 3, 1337–1350. [Google Scholar] [CrossRef]

- Senturk Parreidt, T.; Müller, K.; Schmid, M. Alginate-Based Edible Films and Coatings for Food Packaging Applications. Foods 2018, 7, 170. [Google Scholar] [CrossRef]

- Cisneros-Zevallos, L.; Krochta, J.M. Dependence of Coating Thickness on Viscosity of Coating Solution Applied to Fruits and Vegetables by Dipping Method. J. Food Sci. 2003, 68, 503–510. [Google Scholar] [CrossRef]

- Amanatidou, A.; Slump, R.A.; Gorris, L.G.M.; Smid, E.J. High Oxygen and High Carbon Dioxide Modified Atmospheres for Shelf-Life Extension of Minimally Processed Carrots. J. Food Sci. 2000, 65, 61–66. [Google Scholar] [CrossRef]

- Zhao, X.; Zhou, Y.; Zhao, L.; Chen, L.; He, Y.; Yang, H. Vacuum impregnation of fish gelatin combined with grape seed extract inhibits protein oxidation and degradation of chilled tilapia fillets. Food Chem. 2019, 294, 316–325. [Google Scholar] [CrossRef] [PubMed]

- Comaposada, J.; Marcos, B.; Bou, R.; Gou, P. Influence of surfactants and proteins on the properties of wet edible calcium alginate meat coatings. Food Res. Int. 2018, 108, 539–550. [Google Scholar] [CrossRef]

- Nowzari, F.; Shábanpour, B.; Ojagh, S.M. Comparison of chitosan-gelatin composite and bilayer coating and film effect on the quality of refrigerated rainbow trout. Food Chem. 2013, 141, 1667–1672. [Google Scholar] [CrossRef] [PubMed]

- Avena-Bustillos, R.D.J.; Krochta, J.M.; Saltveit, M.E. Water Vapor Resistance of Red Delicious Apples and Celery Sticks Coated with Edible Caseinate-Acetylated Monoglyceride Films. J. Food Sci. 1997, 62, 351–354. [Google Scholar] [CrossRef]

- Ben-Yehoshua, S.; Burg, S.P.; Young, R. Resistance of citrus fruit to mass transport of water vapor and other gases. Plant Physiol. 1985, 79, 1048–1053. [Google Scholar] [CrossRef] [PubMed]

- Bravin, B.; Peressini, D.; Sensidoni, A. Development and application of polysaccharide–lipid edible coating to extend shelf-life of dry bakery products. J. Food Eng. 2006, 76, 280–290. [Google Scholar] [CrossRef]

- Chiumarelli, M.; Hubinger, M.D. Stability, solubility, mechanical and barrier properties of cassava starch—Carnauba wax edible coatings to preserve fresh-cut apples. Food Hydrocoll. 2012, 28, 59–67. [Google Scholar] [CrossRef]

- Vargas, M.; Pastor, C.; Chiralt, A.; McClements, D.J.; González-Martínez, C. Recent advances in edible coatings for fresh and minimally processed fruits. Crit. Rev. Food Sci. Nutr. 2008, 48, 496–511. [Google Scholar] [CrossRef] [PubMed]

- Socaciu, M.-I.; Semeniuc, C.; Vodnar, D. Edible Films and Coatings for Fresh Fish Packaging: Focus on Quality Changes and Shelf-life Extension. Coatings 2018, 8, 366. [Google Scholar] [CrossRef]

| Product | Edible Coating Material and Coating Method | Additional Packaging | Storage Conditions | Source |

|---|---|---|---|---|

| Ready-to-eat seafood | Chitosan in acetic acid and glycerol, or alginate with no glycerol using dipping method | - | 4 and 14 °C | [7] |

| Retail maki sushi | Chitosan coating applied using spraying method | Packed under MAP conditions | 4 and 8 °C | [8] |

| Smoked sea bass fillets | Chitosan, alginate with glycerol, applied using dipping method | Packed under vacuum | 4 °C | [9] |

| Cold-smoked bass fillet | Corn zein-based coating with lemongrass essential oil or nisin applied using spraying method | PVC bags with headspace or in vacuum | 4 °C | [10] |

| Cooked and peeled shrimps | Chitosan, glycerol, Tween 80 coating incorporated with 0.5% of oregano and thyme EO applied with dipping method | Packed under MAP conditions (40% CO2/60% N2) in polystyrene trays with a PET/PVdC/PE film | 4 °C | [11] |

| RTE squid rings | Oregano and thyme essential oils with dipping method | Packed under MAP conditions (70% N2, 25% CO2, 5% O2) in film bag | 4 °C | [12] |

| Cold smoked salmon | Chitosan coating with and without antimicrobials with spreading method | Vacuum packed | 4 °C | [13] |

| Fish patties (RtC) | Chitosan—fish gelatine coating applied using dipping method | - | 2 °C | [14] |

| Cooked chicken meat | Carboxymethyl chitosan with garlic aqueous extract applied using dipping method | Open packaging pouch | 4 °C | [15] |

| Fried bovine meatballs | Chitosan (HMW) with dipping method | EPS trays in plastic food bag | 5 °C | [16] |

| Deli turkey meat | Chitosan with antimicrobials (lauric arginate ester or nisin or in combination) with spreading method | Vacuum pouches | 10 °C | [17] |

| Roasted sliced turkey | Pectin, alginate, chitosan, starch with different antimicrobials with spreading method | High barrier pouches, vacuum | 4 °C | [18] |

| Deli turkey and in pouched cooked sliced turkey | Polysaccharide carry materials (alginate, kappa-carrageenan, pectin, xanthan gum, starch) with different antimicrobials with spreading method | Vacuum packed | 22 °C, 4 °C | [19] |

| Roast beef | Chitosan coating (different molecular weights and solvents) with dipping method | Bagged | 4 °C | [20] |

| Precooked beef patties | Wheat gluten, soy protein, carrageenan, and chitosan coatings with dipping method | - | 4 °C | [21] |

| Dry sausages | Alginate, polyglycerol esters of fatty acids, pea protein, and collagen with extrusion method | - | 13 °C | [22] |

| Product Category | Product Name | Maritime Source | Market Implementation |

|---|---|---|---|

| Polysaccharide | Alginate | Seaweed (brown algae) | Established |

| Polysaccharide | Agar | Seaweed (red algae) | Established |

| Polysaccharide | Carrageenan | Seaweed (red algae) | Established |

| Polysaccharide | Chitin | Crustacean exoskeleton (waste product), algae | Established |

| Polysaccharide | Chitosan | Crustacean exoskeleton (waste product), algae | Established |

| Polysaccharide | Cellulose | Microalgae | Development stage |

| Polysaccharide | Starch | Microalgae | Development stage |

| Protein | Collagen | Fish waste (skin/bone) | Established |

| Protein | Gelatine | Fish waste (skin/bone) | Established |

| Protein | Glycoprotein (antifreeze protein) | Fish (blood) | Established |

| Lipid | Fish oil | Fish waste | Established |

| Minerals | Calcium chloride | Crustacean exoskeleton (waste product) | Industrial side product |

| Studied Material | Property Category | Property Details | Methodology |

|---|---|---|---|

| coating formulation | viscoelastic properties | handling application industrial feasibility | pH elastic modulus viscosity modulus solubility phase angle electrical charge |

| casted films | barrier properties | molecule transfer | water permeability gas permeability |

| coated product | barrier properties | molecule transfer | water resistance gas exchange range |

| coated product | coating formation properties | adhesiveness thickness penetration/absorption integrity durability | contact angle imaging analysis scanning electron microscope wettability cohesiveness |

| coated product | sensory properties | appearance texture odour taste | colour/opacity hardness, elasticity chewiness/gumminess |

| coated product | physical-chemical properties | fat oxidation water migration | water loss, water activity nitrogen degradation peroxide value malondialdehyde value total volatile basic nitrogen trimethylamine-nitrogen pH adenosine triphosphate breakdown |

| coated product | anti-microbial properties | safety and quality degradation | bacterial growth yeast growth mould growth |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bremenkamp, I.; Sousa Gallagher, M.J. Edible Coatings for Ready-to-Eat Products: Critical Review of Recent Studies, Sustainable Packaging Perspectives, Challenges and Emerging Trends. Polymers 2025, 17, 376. https://doi.org/10.3390/polym17030376

Bremenkamp I, Sousa Gallagher MJ. Edible Coatings for Ready-to-Eat Products: Critical Review of Recent Studies, Sustainable Packaging Perspectives, Challenges and Emerging Trends. Polymers. 2025; 17(3):376. https://doi.org/10.3390/polym17030376

Chicago/Turabian StyleBremenkamp, Ina, and Maria José Sousa Gallagher. 2025. "Edible Coatings for Ready-to-Eat Products: Critical Review of Recent Studies, Sustainable Packaging Perspectives, Challenges and Emerging Trends" Polymers 17, no. 3: 376. https://doi.org/10.3390/polym17030376

APA StyleBremenkamp, I., & Sousa Gallagher, M. J. (2025). Edible Coatings for Ready-to-Eat Products: Critical Review of Recent Studies, Sustainable Packaging Perspectives, Challenges and Emerging Trends. Polymers, 17(3), 376. https://doi.org/10.3390/polym17030376