Innovative and Eco-Friendly Natural Fiber Composites for Dental Impression Materials: A Study on Wheat Bran Reinforcement

Abstract

1. Introduction

1.1. Background

1.1.1. Dental Impression

1.1.2. Maximum Human Bite

1.1.3. Literature Review

1.2. Problem Statement

1.3. Objectives of the Study

- Develop a novel natural fiber composite material to reduce the cost of traditional dental impression materials.

- Perform a comparative analysis between the pure dental impression material and the newly developed natural fiber composite material, focusing on cost-effectiveness and mechanical properties such as compression and tensile strength.

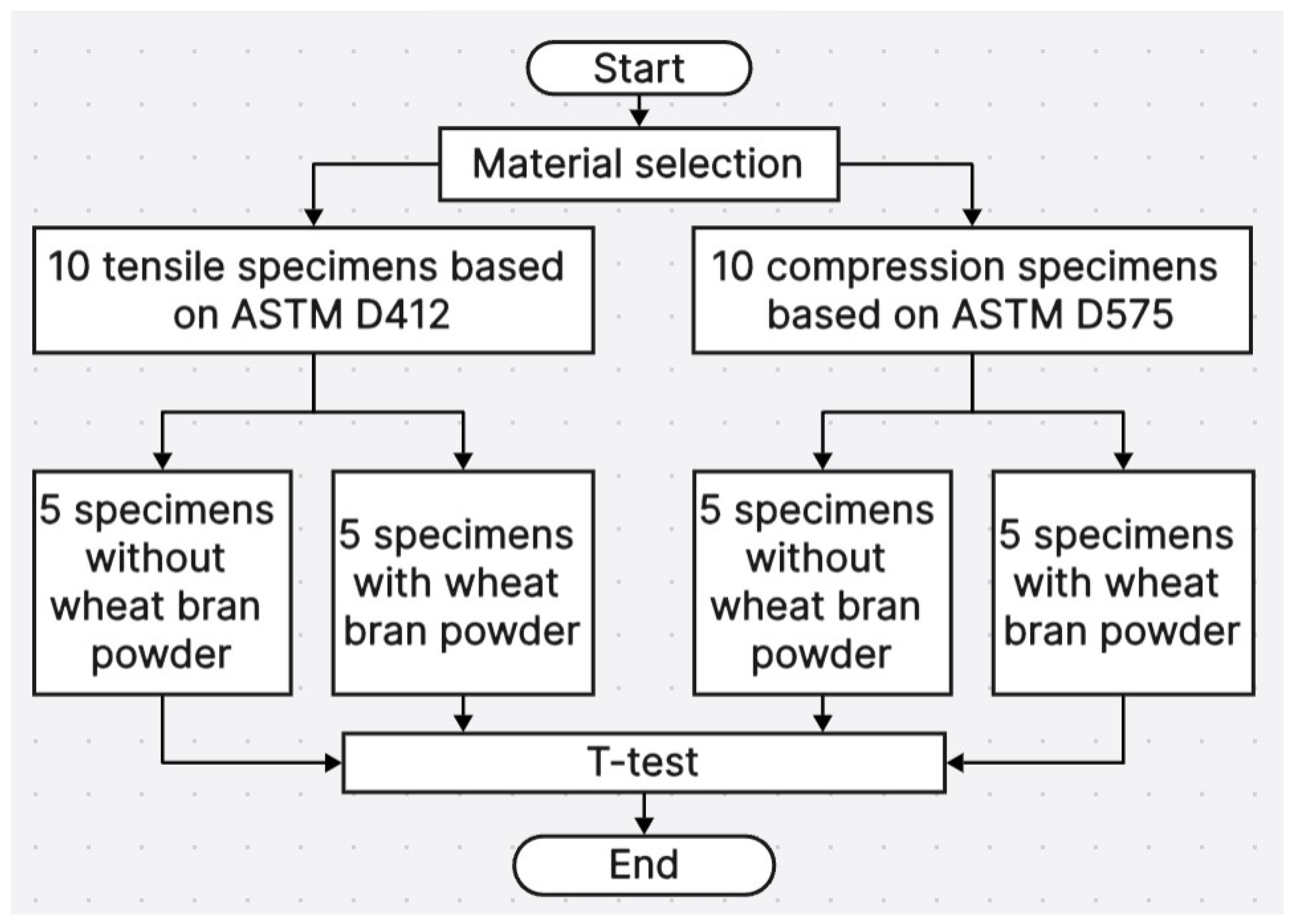

2. Materials and Methods

- Material Selection:

- 2.

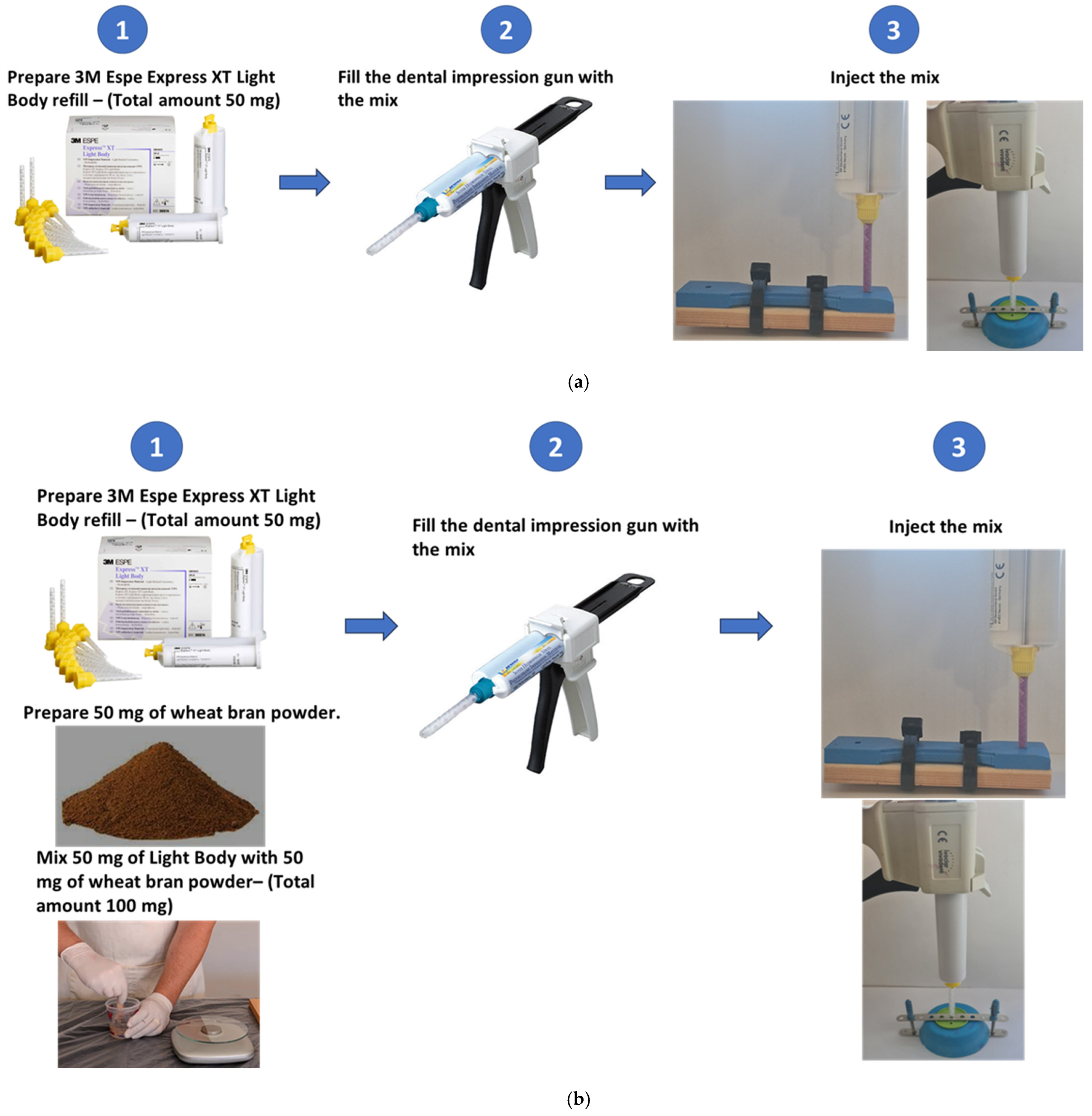

- Fabrication Procedures:

- 3.

- Specimen Partitioning:The 10 tensile specimens were divided into two subgroups:

- Group 1: Five specimens without wheat bran powder.

- Group 2: Five specimens with wheat bran powder.

Similarly, the 10 compression specimens were divided into two subgroups:- Group 1: Five specimens without wheat bran powder.

- Group 2: Five specimens with wheat bran powder.

- 4.

- Statistical Analysis:

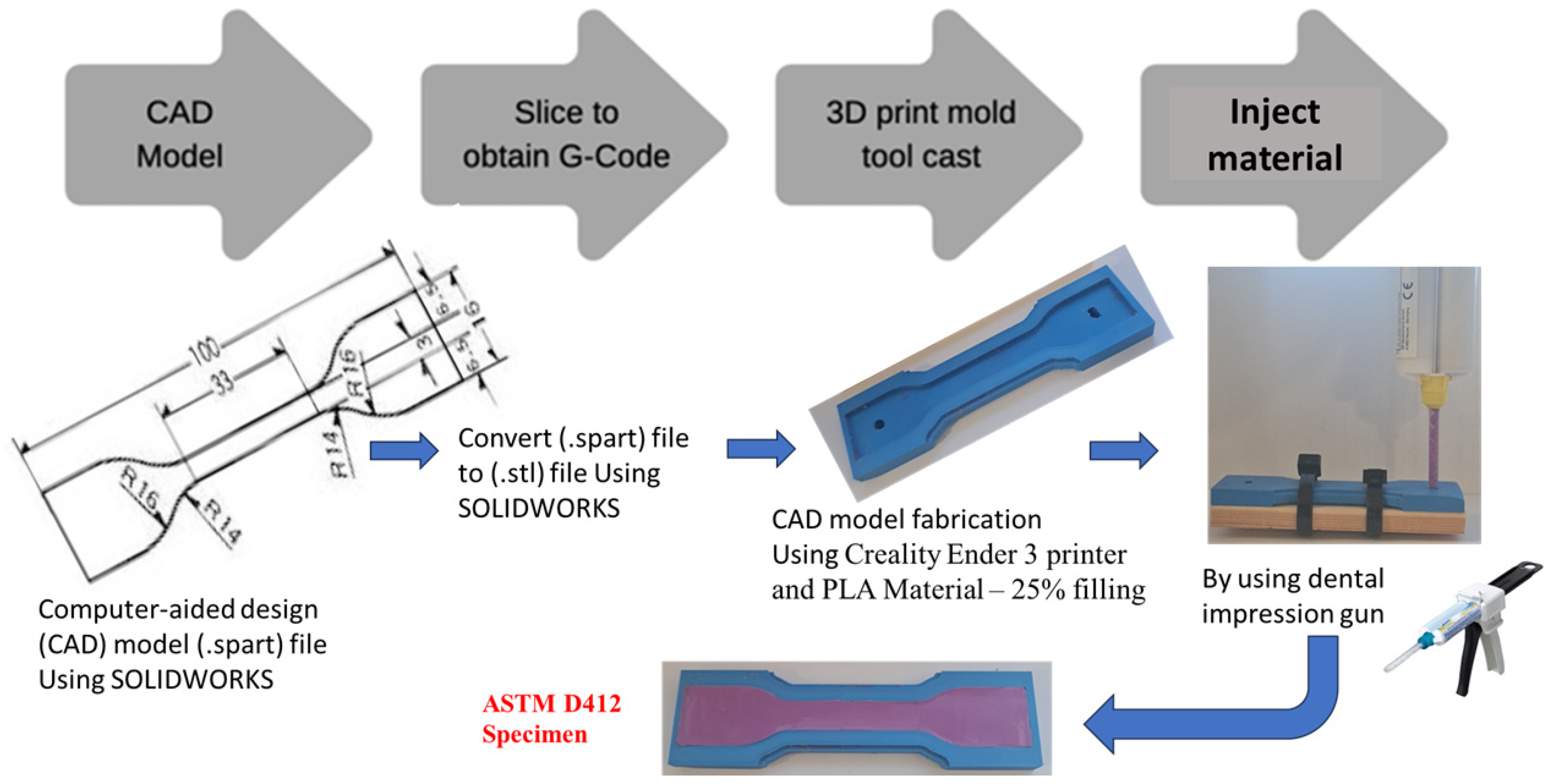

2.1. Fabrication Procedures

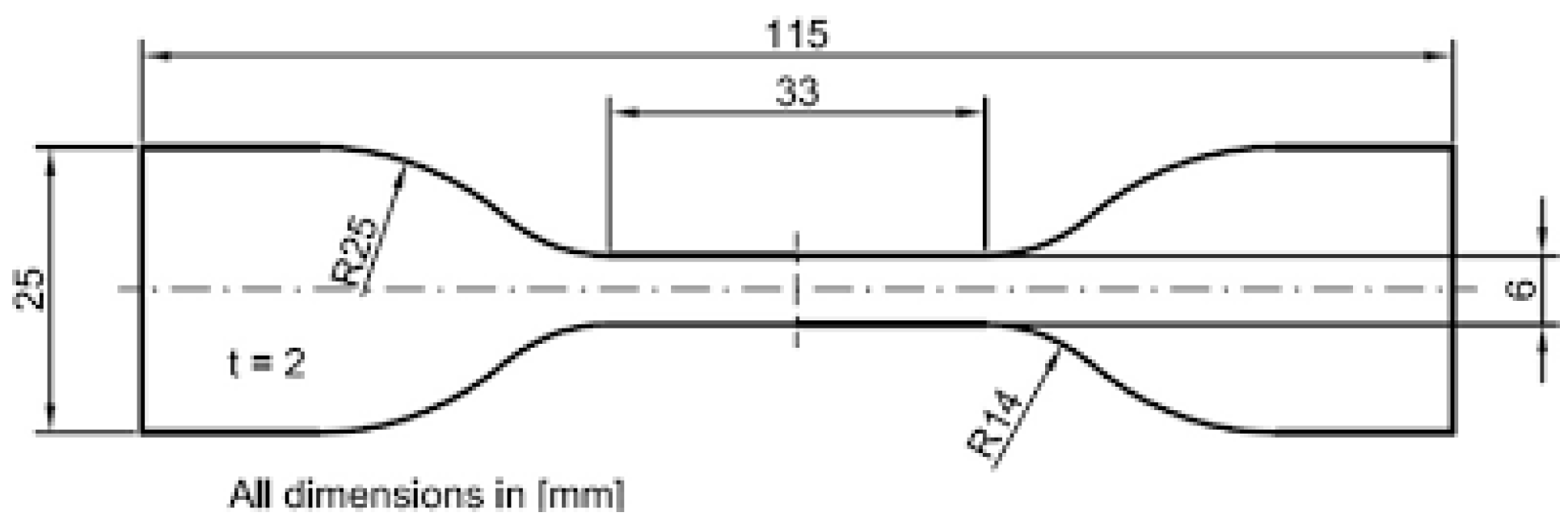

2.1.1. Fabrication of ASTM D412 Tensile Specimen Mold

2.1.2. Fabrication of ASTM D575 Compression Test Specimen Mold

2.2. Three-Dimensional Printer

Principle of Operation

2.3. t-Test

t-Test Equation

3. Results

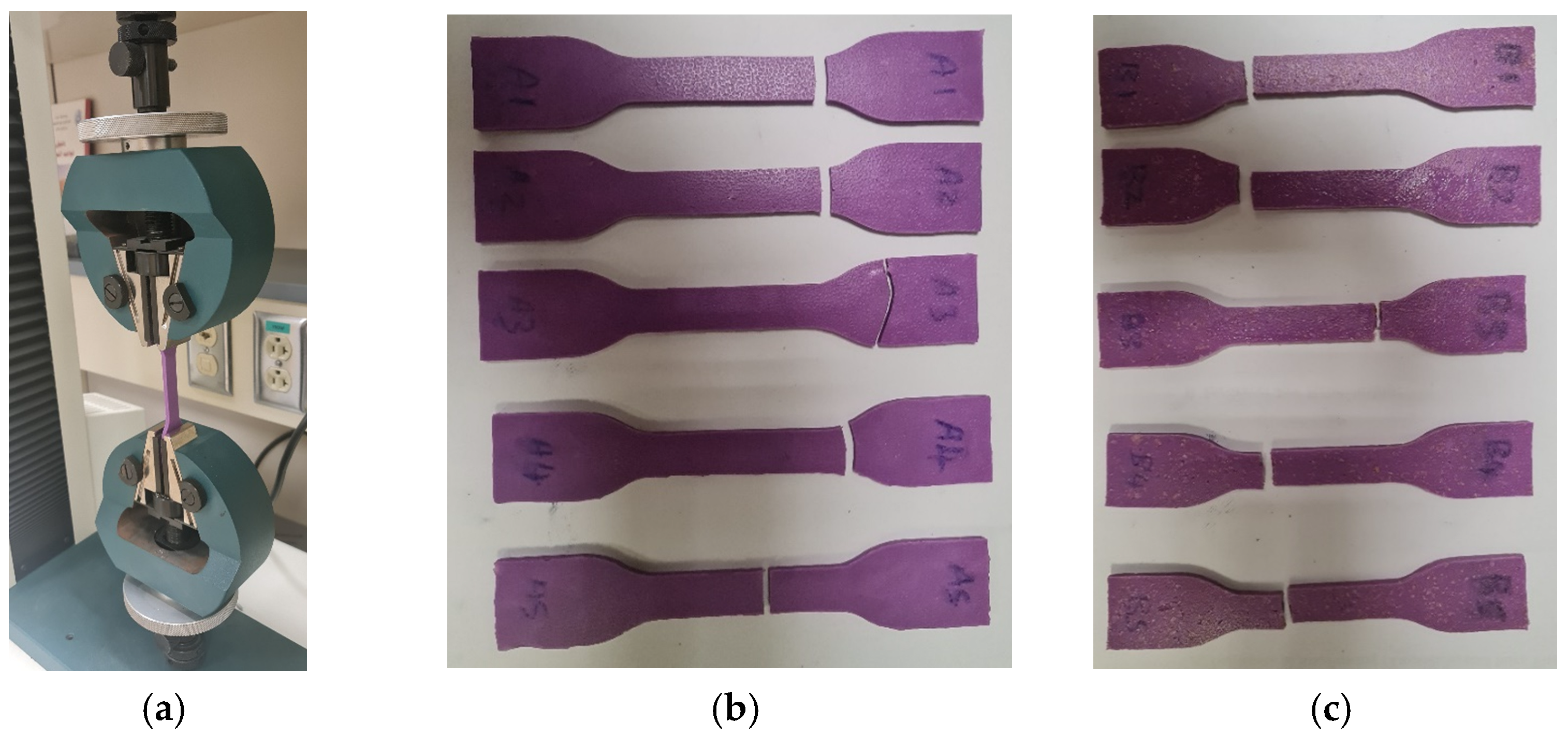

3.1. Universal Testing Machine

3.2. Compression Test Specimens

3.3. Tensile Test

3.3.1. Pure Elastomer Without Wheat Bran Powder

3.3.2. Elastomer Mixed with Wheat Bran Powder

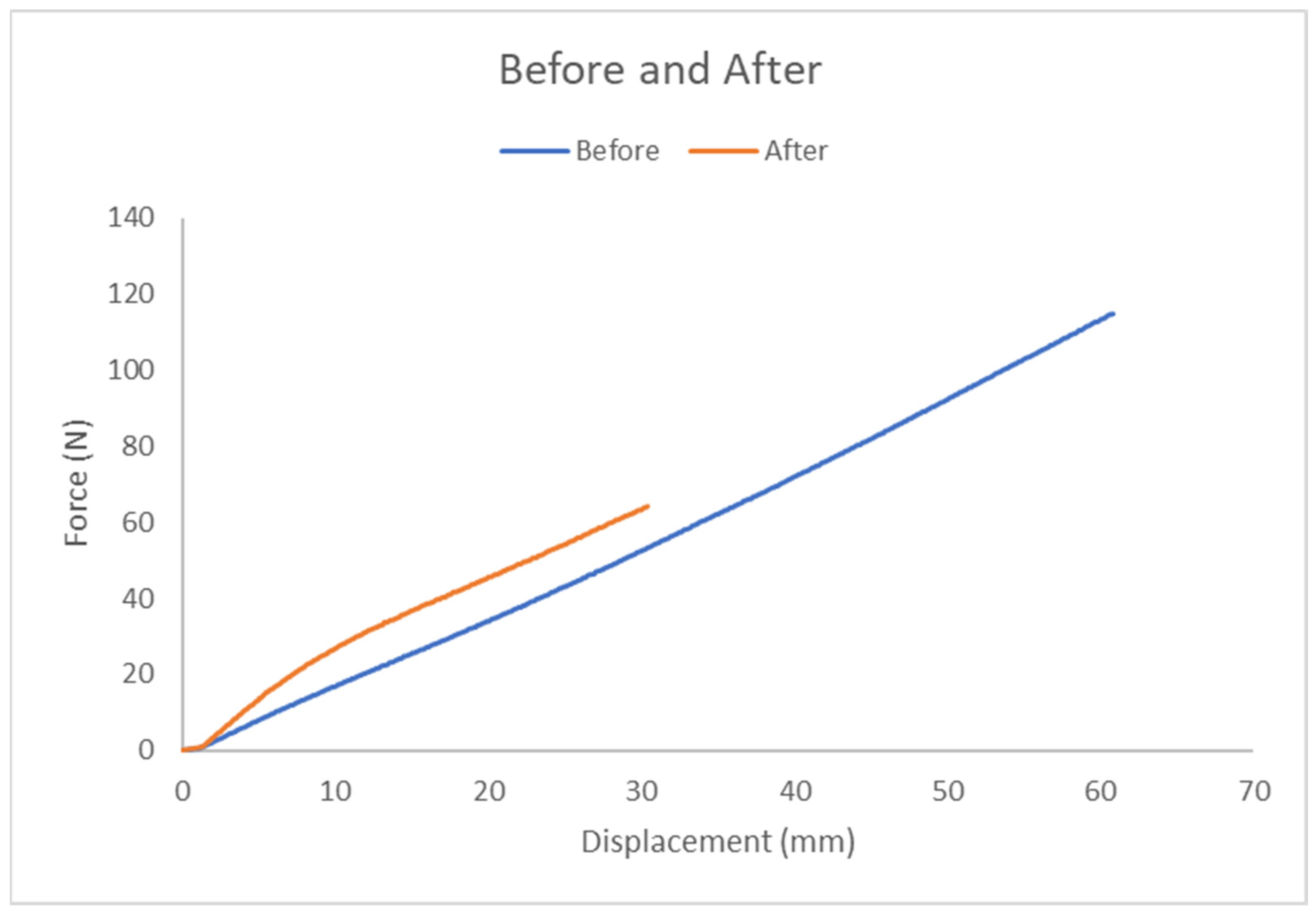

3.3.3. Comparison Before and After Adding Wheat Bran Powder

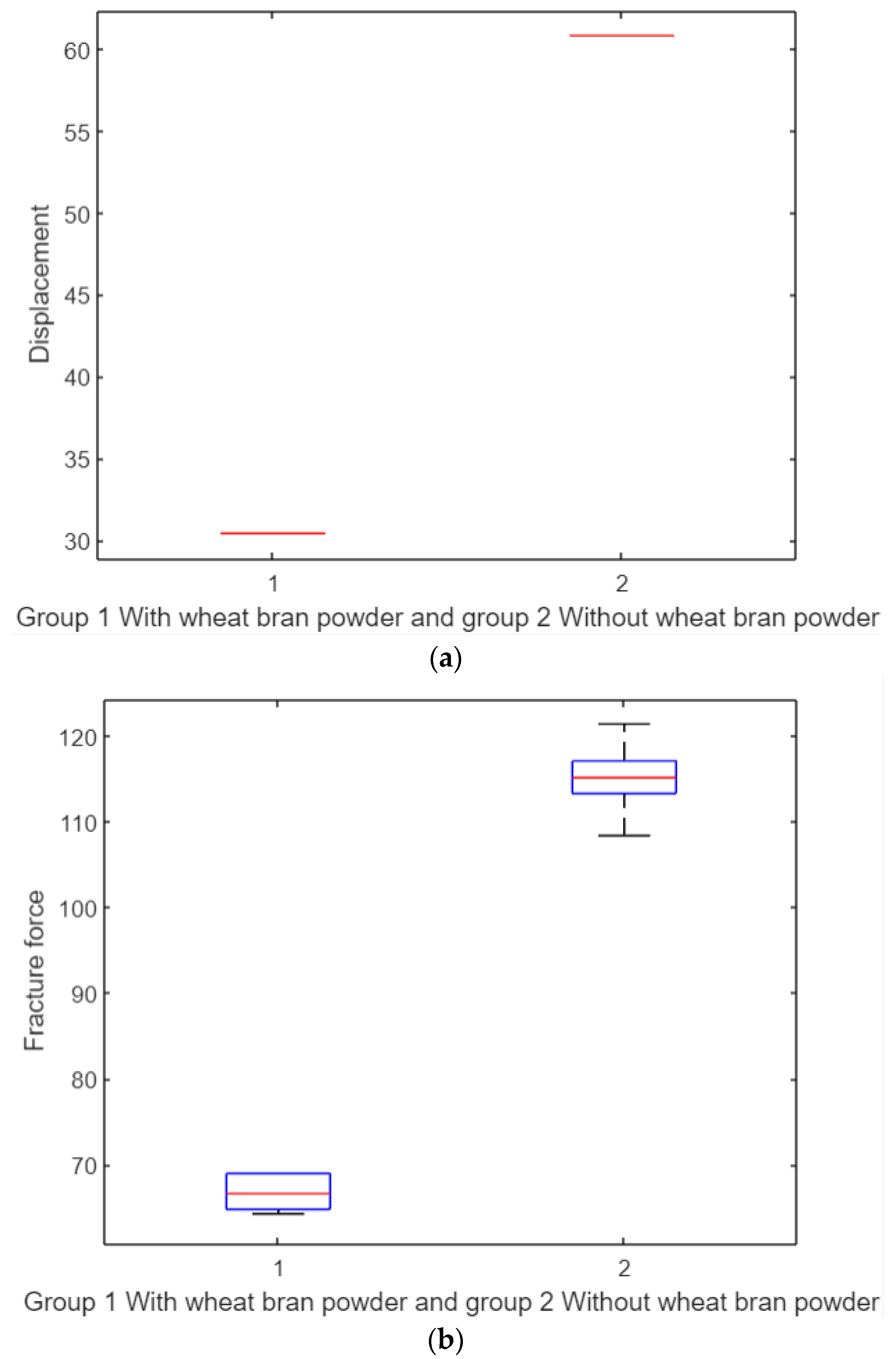

- With Wheat Bran Powder: ~66.8 ± 2.2 N; displacement ~30.4 ± 0 mm.

- Without Wheat Bran Powder: ~115 ± 4.6 N; displacement ~60.8 ± 0 mm.

3.3.4. t-Test for Tensile Test Specimens

- Group 1: With wheat bran powder.

- Group 2: Without wheat bran powder.

- Group 1: With wheat bran powder.

- Group 2: Without wheat bran powder.

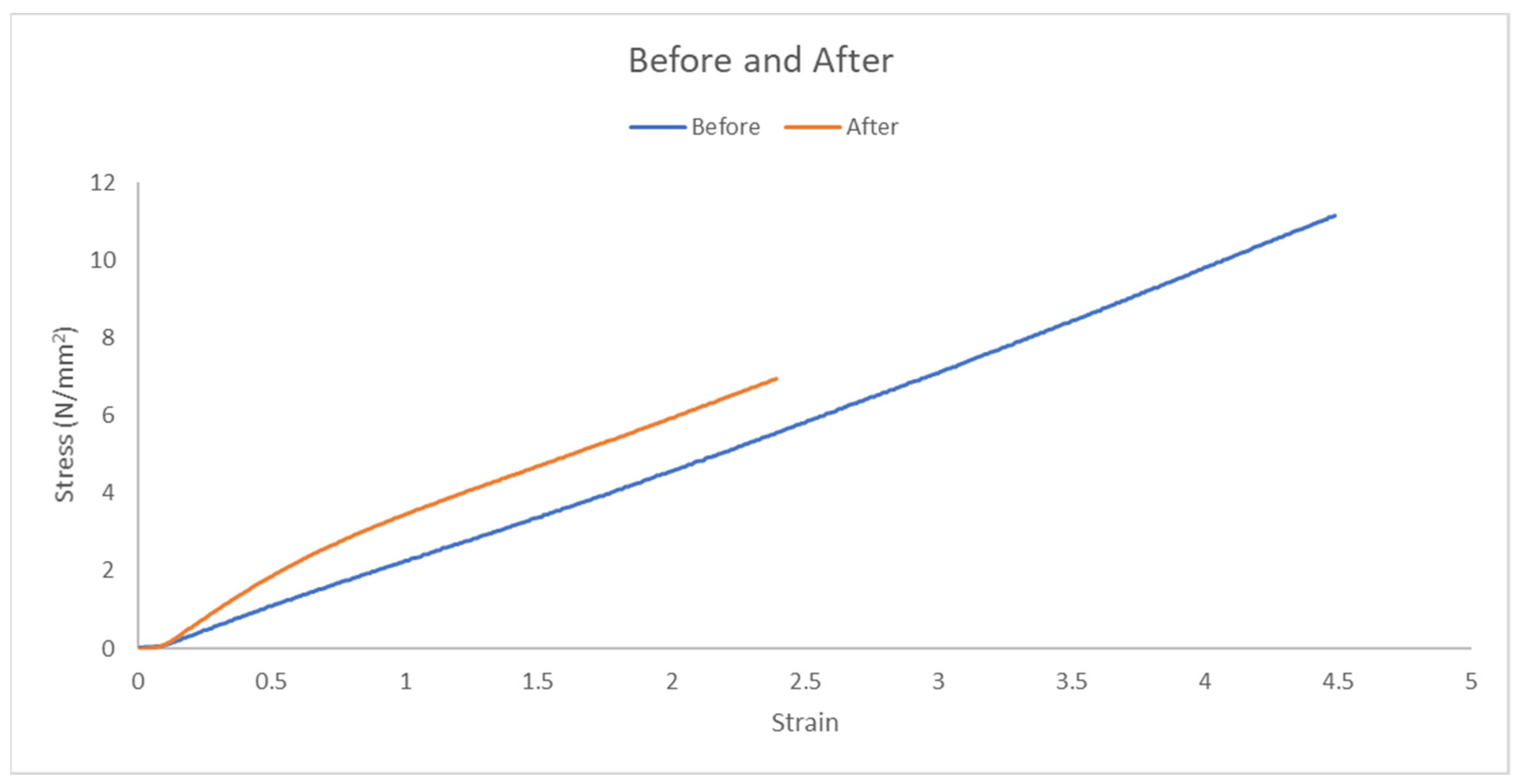

3.3.5. Average Stress–Strain Curves for Both Groups

- With Wheat Bran Powder: Fracture stress ~7 MPa, fracture strain ~2.5.

- Without Wheat Bran Powder: Fracture stress ~11 MPa, fracture strain ~4.5.

3.4. Compression Test

3.4.1. Pure Elastomer Without Wheat Bran Powder

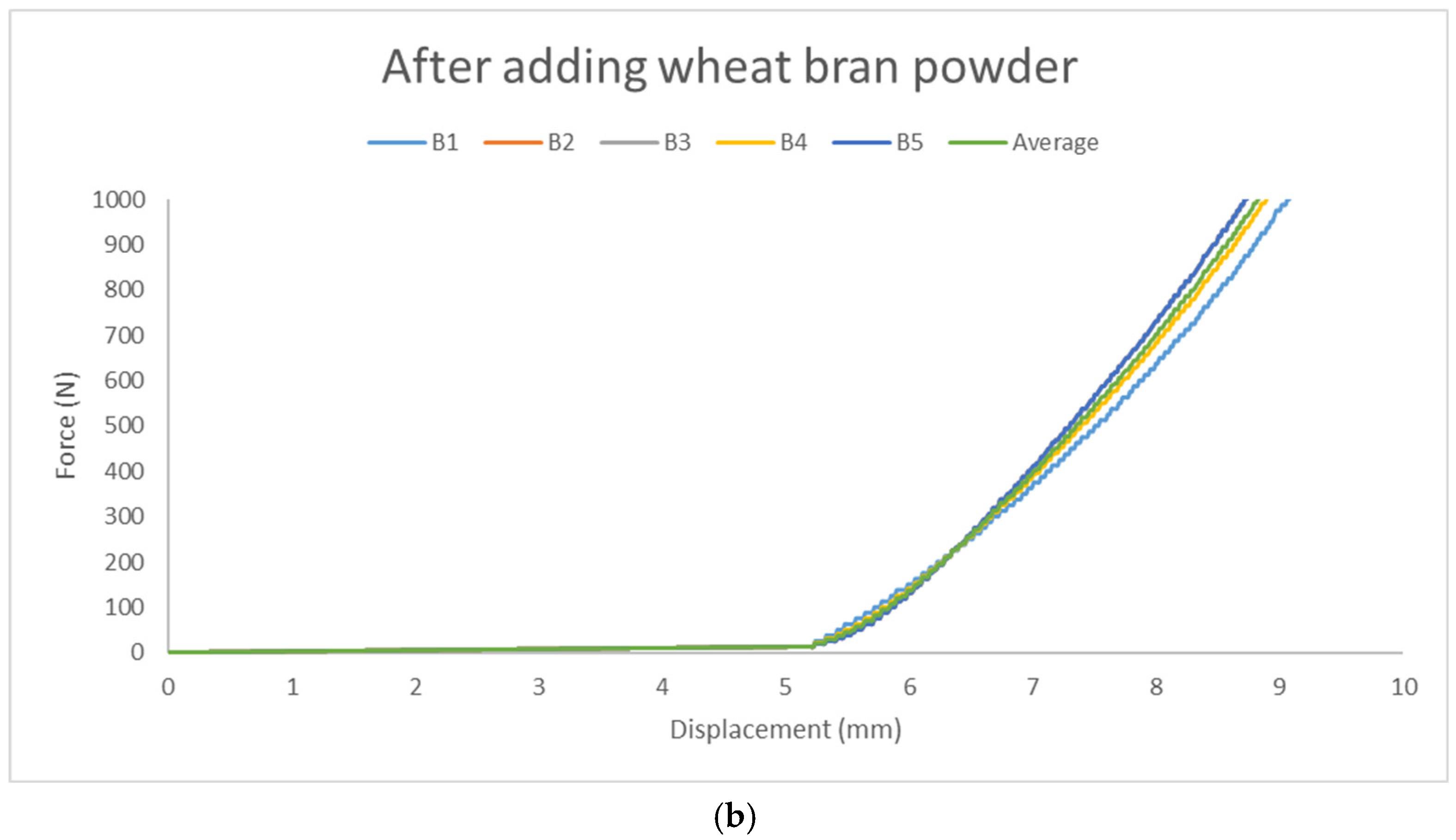

3.4.2. Elastomer Mixed with Wheat Bran Powder

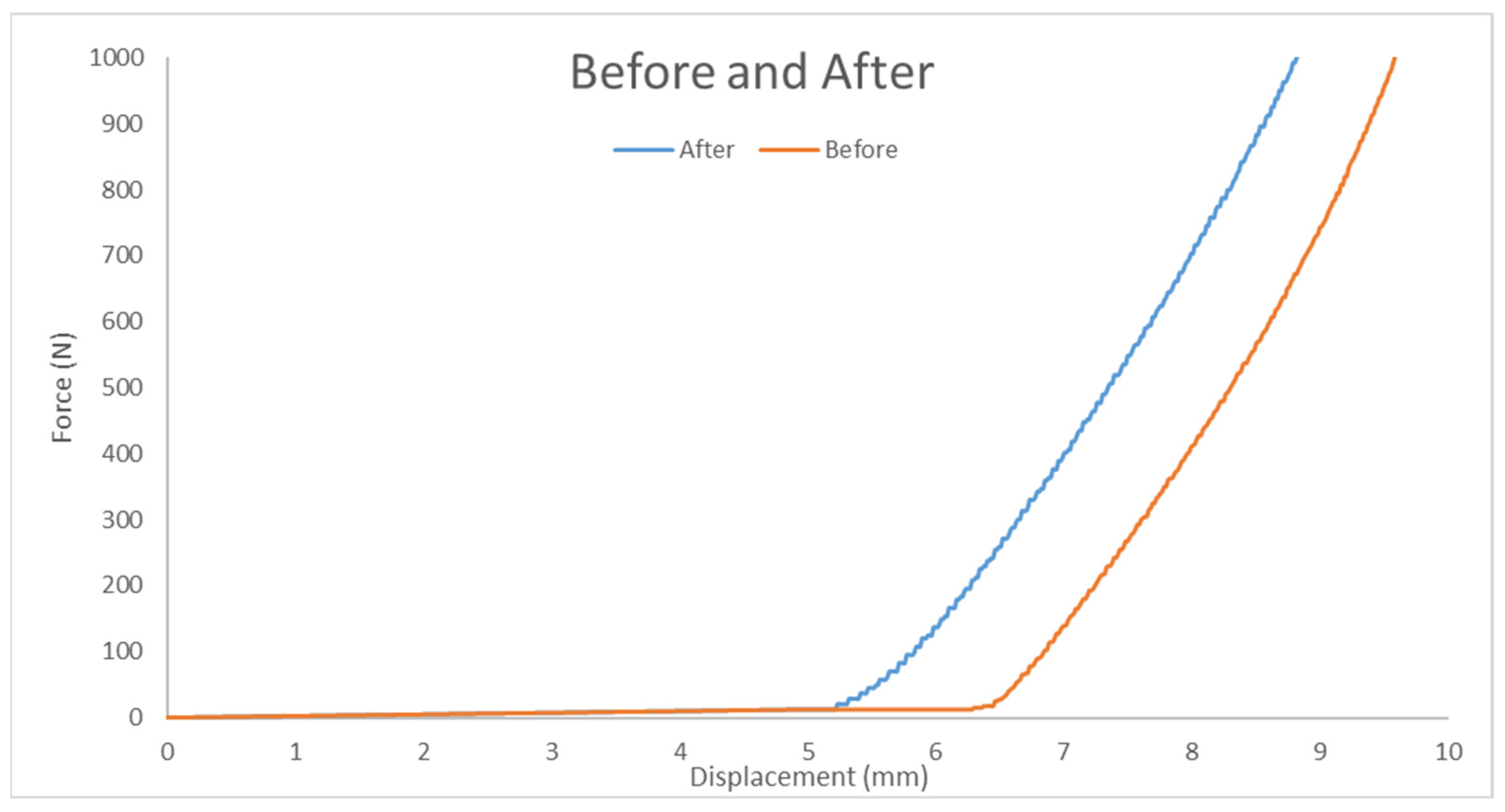

3.4.3. Comparison Before and After Adding Wheat Bran Powder

- Pure Elastomer Group: Supports greater displacement.

- Wheat Bran Powder Group: Sustains higher force in the displacement range of 5.5–9.5 mm.

- With Wheat Bran Powder: Fracture force ~1000 ± 0 N; displacement ~9.06 ± 0 mm.

- Without Wheat Bran Powder: Fracture force ~1000 ± 0 N; displacement ~9.6 ± 0.13 mm.

3.4.4. t-Test for Compression Test Specimens

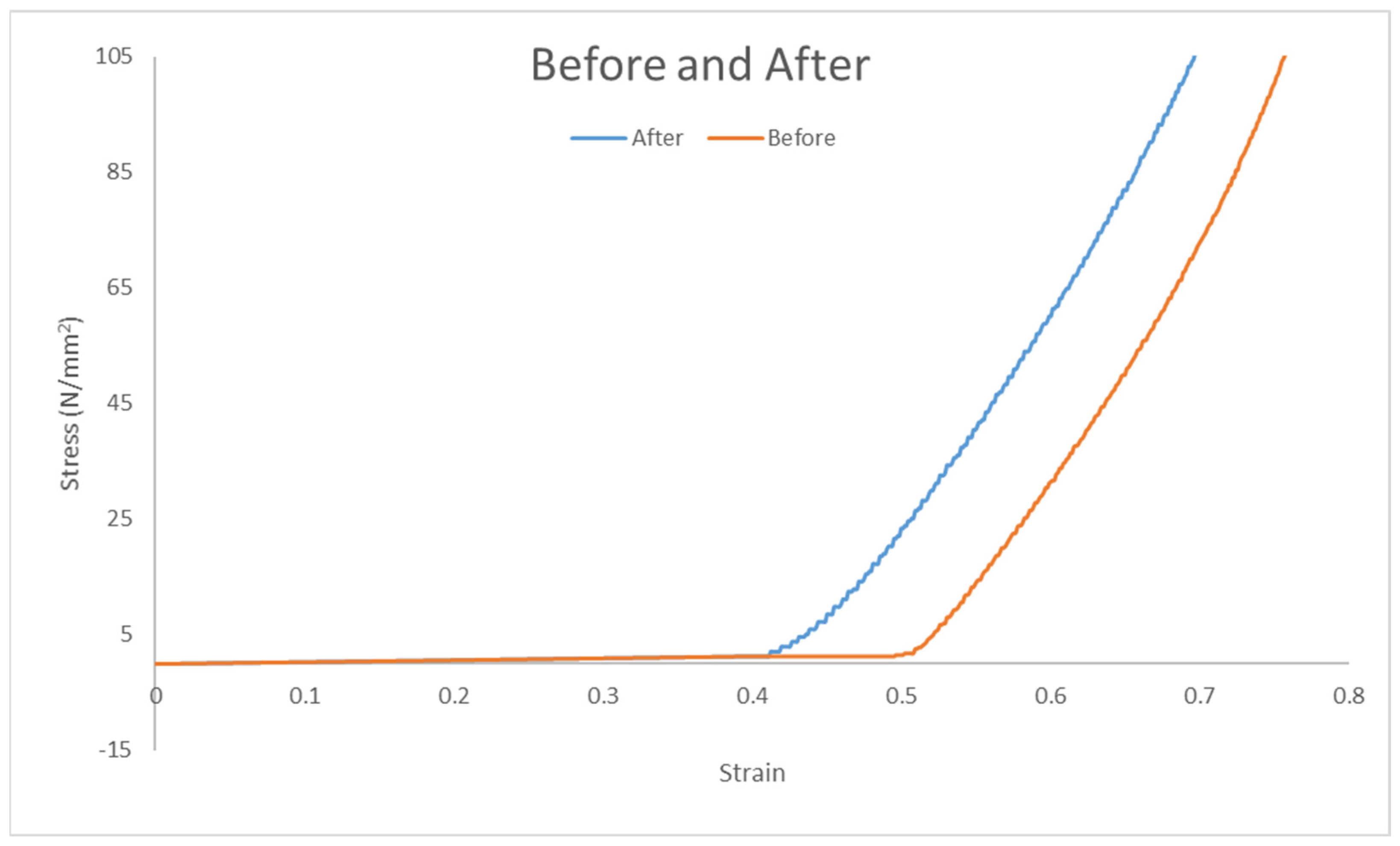

3.4.5. Average Stress–Strain Curves for Both Groups

- With Wheat Bran Powder: Fracture stress ~105 MPa, fracture strain ~0.7.

- Without Wheat Bran Powder: Fracture stress ~105 MPa, fracture strain ~0.78.

3.4.6. Maximum Human Bite Before and After Adding Wheat Bran Powder

3.5. Comparison Between Tensile Test and Compression Test

3.5.1. Tensile Test Results

With Wheat Bran Powder

- Average Strain: 2.5

- Average Stress: 7 MPa

Without Wheat Bran Powder

- Average Strain: 4.5

- Average Stress: 11 MPa

3.5.2. Compression Test Results

With Wheat Bran Powder

- Average Strain: 0.7

- Average Stress: 105 MPa

Without Wheat Bran Powder

- Average Strain: 0.78

- Average Stress: 105 MPa

3.5.3. Key Comparisons

Stress Performance

- In tensile tests, the pure elastomer (11 MPa) significantly outperforms the wheat bran powder composite (7 MPa).

- In compression tests, both materials achieve identical stress values (105 MPa), demonstrating that the addition of wheat bran powder does not compromise the stress-handling capacity under compression.

Strain Capacity

- In both tests, the pure elastomer exhibits higher strain values, indicating greater flexibility and elongation under load.

- The wheat bran powder composite shows reduced strain in both tensile (2.5 vs. 4.5) and compression (0.7 vs. 0.78) tests, highlighting its stiffness due to the filler.

3.5.4. Material Suitability

- Pure Elastomer: Performs better in tensile applications requiring high flexibility and strength, such as stretchable components and high-stress tensile environments.

- Wheat Bran Powder Composite: Performs well in compression-based applications where deformation control and cost-effectiveness are key priorities, such as load-bearing supports or compression-resistant structures.

- The comparison between the tensile and compression tests highlights the trade-offs introduced by incorporating wheat bran powder into the elastomer. While the wheat bran powder composite exhibits reduced tensile properties, it maintains comparable compression stress and provides better stiffness control. This makes the wheat bran powder composite a viable and cost-effective alternative for applications involving compression, whereas the pure elastomer remains preferable for tensile applications requiring higher flexibility and strength.

4. Discussion

4.1. Mechanical Behavior and Performance

4.2. Why Wheat Bran Improves Properties

4.3. Composition of Wheat Bran

- Cellulose provides high tensile strength and stiffness, enhancing the composite’s structural integrity.

- Hemicellulose facilitates bonding with the elastomer matrix due to its partially amorphous nature.

- Lignin contributes to increased stiffness and resistance to mechanical stress.

- Proteins and other minor components improve adhesion and interaction within the elastomer matrix, further reinforcing the material.

4.4. Suitability for Dental Applications

4.5. Broader Implications

5. Conclusions

6. Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gaikwad, A.; Joshi, A.A.; de Oliveira-Neto, O.B.; Padhye, A.M.; Nadgere, J.B.; Ram, S.M.; Yadav, S.R. An Overview of Systematic Reviews and Meta-Analyses Evaluating Different Impression Techniques for Implant-Supported Prostheses in Partially and Completely Edentulous Arches. Int. J. Oral Maxillofac. Implant. 2022, 37, 6. [Google Scholar] [CrossRef] [PubMed]

- Novac, A.C.; Tudor, A.; Pop, D.M.; Neagu, C.S.; Crăciunescu, E.L.; Romînu, M.; Negruțiu, M.L.; Duma, V.-F.; Sinescu, C. Conventional Dental Impressions vs. Impressions Reinforced with Rigid Mouthguards. Polymers 2024, 16, 994. [Google Scholar] [CrossRef] [PubMed]

- Rubel, B.S. Impression Materials: A Comparative Review of Impression Materials Most Commonly Used in Restorative Dentistry. Dent. Clin. N. Am. 2007, 51, 629–642. [Google Scholar] [CrossRef]

- Punj, A.; Bompolaki, D.; Garaicoa, J. Dental Impression Materials and Techniques. Dent. Clin. N. Am. 2017, 61, 779–796. [Google Scholar] [CrossRef] [PubMed]

- Takaki, P.; Vieira, M.; Bommarito, S. Maximum Bite Force Analysis in Different Age Groups. Int. Arch. Otorhinolaryngol. 2014, 18, 3. [Google Scholar] [CrossRef]

- Koc, D.; Dogan, A.; Bek, B. Bite Force and Influential Factors on Bite Force Measurements: A Literature Review. Eur. J. Dent. 2010, 4, 223–232. [Google Scholar] [CrossRef]

- Helkimo, E.; Carlsson, G.E.; Helkimo, M. Bite Force and State of Dentition. Acta Odontol. Scand. 1976, 35, 297–303. [Google Scholar] [CrossRef]

- Bakke, M. Bite Force and Occlusion. Semin. Orthod. 2006, 12, 120–126. [Google Scholar] [CrossRef]

- Kamegai, T.; Tatsuki, T.; Nagano, H.; Mitsuhashi, H.; Kumeta, J.; Tatsuki, Y.; Kamegai, T.; Inaba, D. A Determination of Bite Force in Northern Japanese Children. Eur. J. Orthod. 2005, 27, 53–57. [Google Scholar] [CrossRef] [PubMed]

- Usui, T.; Uematsu, S.; Kanegae, H.; Morimoto, T.; Kurihara, S. Change in Maximum Occlusal Force in Association with Maxillofacial Growth. Orthod. Craniofac. Res. 2007, 10, 226–234. [Google Scholar] [CrossRef] [PubMed]

- Tavares, T.D.; Antunes, J.C.; Ferreira, F.; Felgueiras, H.P. Biofunctionalization of Natural Fiber-Reinforced Biocomposites for Biomedical Applications. Biomolecules 2020, 10, 148. [Google Scholar] [CrossRef]

- Sivakanthan, S.; Rajendran, S.; Gamage, A.; Madhujith, T.; Mani, S. Antioxidant and Antimicrobial Applications of Biopolymers: A Review. Food Res. Int. 2020, 136, 109327. [Google Scholar] [CrossRef] [PubMed]

- Hart, A.; Summerscales, J. Effect of Time at Temperature for Natural Fibres. Procedia Eng. 2017, 200, 269–275. [Google Scholar] [CrossRef]

- Madueke, C.I.; Mbah, O.M.; Umunakwe, R. A Review on the Limitations of Natural Fibres and Natural Fibre Composites with Emphasis on Tensile Strength Using Coir as a Case Study. Polym. Bull. 2023, 80, 3489–3506. [Google Scholar] [CrossRef] [PubMed]

- Djafari Petroudy, S.R. Physical and Mechanical Properties of Natural Fibers. In Advanced High Strength Natural Fibre Composites in Construction; Elsevier: Amsterdam, The Netherlands, 2017; pp. 59–83. [Google Scholar] [CrossRef]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Adi, D.S.; Damayanti, R.; Subiyanto, B.; Fatriasari, W.; Fudholi, A. A Review on Natural Fibers for Development of Eco-Friendly Bio-Composite: Characteristics, and Utilizations. J. Mater. Res. Technol. 2021, 13, 2442–2458. [Google Scholar] [CrossRef]

- Rana, A.K.; Potluri, P.; Thakur, V.K. Cellulosic Grewia Optiva Fibres: Towards Chemistry, Surface Engineering and Sustainable Materials. J. Environ. Chem. Eng. 2021, 9, 106059. [Google Scholar] [CrossRef]

- Zamora-Mendoza, L.; Guamba, E.; Miño, K.; Romero, M.P.; Levoyer, A.; Alvarez-Barreto, J.F.; Machado, A.; Alexis, F. Antimicrobial Properties of Plant Fibers. Molecules 2022, 27, 7999. [Google Scholar] [CrossRef] [PubMed]

- Shesan, O.J.; Stephen, A.C.; Chioma, A.G.; Neerish, R.; Rotimi, S.E. Improving the Mechanical Properties of Natural Fiber Composites for Structural and Biomedical Applications. In Renewable and Sustainable Composites; Pereira, A.B., Fernandes, F.A.O., Eds.; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef]

- Zamora-Mendoza, L.; Gushque, F.; Yanez, S.; Jara, N.; Álvarez-Barreto, J.F.; Zamora-Ledezma, C.; Dahoumane, S.A.; Alexis, F. Plant Fibers as Composite Reinforcements for Biomedical Applications. Bioengineering 2023, 10, 804. [Google Scholar] [CrossRef] [PubMed]

- Chua, C.Y.X.; Liu, H.-C.; Di Trani, N.; Susnjar, A.; Ho, J.; Scorrano, G.; Rhudy, J.; Sizovs, A.; Lolli, G.; Hernandez, N.; et al. Carbon Fiber Reinforced Polymers for Implantable Medical Devices. Biomaterials 2021, 271, 120719. [Google Scholar] [CrossRef] [PubMed]

- Lau, A.K.; Cheung, K.H.Y. Natural Fiber-Reinforced Polymer-Based Composites. In Natural Fiber-Reinforced Biodegradable and Bioresorbable Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2017; pp. 1–18. Available online: https://linkinghub.elsevier.com/retrieve/pii/B9780081006566000017 (accessed on 31 January 2025).

- Roeder, R.K.; Converse, G.L.; Kane, R.J.; Yue, W. Hydroxyapatite-Reinforced Polymer Biocomposites for Synthetic Bone Substitutes. JOM 2008, 60, 38–45. [Google Scholar] [CrossRef]

- Roeder, R.K. Bioactive Polyaryletherketone Composites. In PEEK Biomaterials Handbook; Elsevier: Amsterdam, The Netherlands, 2019; pp. 203–227. Available online: https://linkinghub.elsevier.com/retrieve/pii/B9780128125243000120 (accessed on 31 January 2025).

- Yeo, J.C.C.; Muiruri, J.K.; Thitsartarn, W.; Li, Z.; He, C. Recent Advances in the Development of Biodegradable PHB-Based Toughening Materials: Approaches, Advantages, and Applications. Mater. Sci. Eng. C 2018, 92, 565–576. [Google Scholar] [CrossRef]

- Ho, M.P.; Wang, H.; Lee, J.H.; Ho, C.K.; Lau, K.T.; Leng, J.; Hui, D. Critical Factors on Manufacturing Processes of Natural Fibre Composites. Compos. B Eng. 2012, 43, 8–12. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Navaneethakrishnan, P.; Shankar, S. Tensile and Flexural Properties of Snake Grass Natural Fiber Reinforced Isophthallic Polyester Composites. Compos. Sci. Technol. 2012, 72, 1342–1348. [Google Scholar] [CrossRef]

- Yousif, B.F.; Shalwan, A.; Chin, C.W.; Ming, K.C. Flexural Properties of Treated and Untreated Kenaf/Epoxy Composites. Mater. Des. 2012, 40, 299–305. [Google Scholar] [CrossRef]

- Reddy, N.; Yang, Y. Biofibers from Agricultural Byproducts for Industrial Applications. Trends Biotechnol. 2005, 23, 22–28. [Google Scholar] [CrossRef] [PubMed]

- Re, D.; De Angelis, F.; Augusti, G.; Augusti, D.; Caputi, S.; D’Amario, M.; D’Arcangelo, C. Mechanical Properties of Elastomeric Impression Materials: An in Vitro Comparison. Int. J. Dent. 2015, 2015, 428286. [Google Scholar] [CrossRef] [PubMed]

- Hamalian, T.A.; Nasr, E.; Chidiac, J.J. Impression materials in fixed prosthodontics: Influence of choice on clinical procedure. J. Prosthodont. 2011, 20, 153–160. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Nguyen, B.; Powers, J.M. Mechanical properties of three hydrophilic addition silicone and polyether elastomeric impression materials. J. Prosthet. Dent. 2004, 92, 151–154. [Google Scholar] [CrossRef]

- Hondrum, S.O. Tear and energy properties of three impression materials. Int. J. Prosthodont. 1994, 7, 517–521. [Google Scholar]

- Chai, J.; Takahashi, Y.; Lautenschlager, E.P. Clinically relevant mechanical properties of elastomeric impression materials. Int. J. Prosthodont. 1998, 11, 219–223. [Google Scholar] [PubMed]

- Apinsathanon, P.; Bhattarai, B.P.; Suphangul, S.; Wongsirichat, N.; Aimjirakul, N. Penetration and Tensile Strength of Various Impression Materials of Vinylsiloxanether, Polyether, and Polyvinylsiloxane Impression Materials. Eur. J. Dent. 2022, 16, 93–99. [Google Scholar] [CrossRef]

- 3M Espe Express XT Light Body Refill. Available online: https://crocodental.eu/en/prod-182/3m-espe-express-xt-light-body-refill (accessed on 31 January 2025).

- ASTM D412-06; Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension. ASTM International: West Conshohocken, PA, USA, 2006.

- ISO 23529:2016; Rubber—General Procedures for Preparing and Conditioning Test Pieces for Physical Test Methods. ISO: Geneva, Switzerland, 2016.

- ASTM D575-91; Standard Test Methods for Rubber Properties in Compression. Reapproved 2012. ASTM International: West Conshohocken, PA, USA, 2014.

- Heinrichs, V.; Dieluweit, S.; Stellbrink, J.; Pyckhout-Hintzen, W.; Hersch, N.; Richter, D.; Merkel, R. Chemically defined, ultrasoft PDMS elastomers with selectable elasticity for mechanobiology. PLoS ONE 2018, 13, e0195180. [Google Scholar] [CrossRef] [PubMed]

- Luis, E.; Pan, H.M.; Bastola, A.K.; Bajpai, R.; Sing, S.L.; Song, J.; Yeong, W.Y. 3D Printed Silicone Meniscus Implants: Influence of the 3D Printing Process on Properties of Silicone Implants. Polymers 2020, 12, 2136. [Google Scholar] [CrossRef] [PubMed]

- Schneider, M.; Fritzsche, N.; Puciul-Malinowska, A.; Baliś, A.; Mostafa, A.; Bald, I.; Zapotoczny, S.; Taubert, A. Surface Etching of 3D Printed Poly(Lactic Acid) with NaOH: A Systematic Approach. Polymers 2020, 12, 1711. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Qin, Q.; Wang, J. A Review of Stereolithography: Processes and Systems. Processes 2020, 8, 1138. [Google Scholar] [CrossRef]

- Iftekar, S.F.; Aabid, A.; Amir, A.; Baig, M. Advancements and Limitations in 3D Printing Materials and Technologies: A Critical Review. Polymers 2023, 15, 2519. [Google Scholar] [CrossRef] [PubMed]

- Analysis of t-Test Misuses and SPSS Operations in Medical Research Papers. Burns & Trauma. 2019. Available online: https://burnstrauma.biomedcentral.com/articles/10.1186/s41038-019-0170-3 (accessed on 31 January 2025).

- Usman, M. On Consistency and Limitation of Independent t-Test, Kolmogorov-Smirnov Test, and Mann-Whitney U Test. IOSR J. Math. 2016, 12, 22–27. [Google Scholar] [CrossRef]

- Tinius Olsen. HW20 Wedge Grips. Available online: https://www.tiniusolsen.com/accessories/hw20-wedge-grips/ (accessed on 31 January 2025).

- Aboamer, M.A.; Alsuayri, A.S.; Alassaf, A.; Alqahtani, T.M.; Alresheedi, B.A.; Saijari, G.N.; Osman, E.A.; Mohamed, N.A.R. Hybrid Radiant Disinfection: Exploring UVC and UVB Sterilization Impact on the Mechanical Characteristics of PLA Materials. Polymers 2023, 15, 4658. [Google Scholar] [CrossRef]

- Aboamer, M.A.; Algethami, M.; Hakami, A.; Alassaf, A.; Alqahtani, T.M.; Alresheedi, B.A.; Mohamed, N.A.R. Radiant Reinforcement: Enhancing Composite Polymer Magnet Materials Mechanical Properties with UVC Medical Disinfection. Polymers 2023, 15, 4551. [Google Scholar] [CrossRef] [PubMed]

| Groups | Displacement (mm) | Force (N) | |

|---|---|---|---|

| With wheat bran powder | B1 | 30.4 | 66.65 |

| B2 | 30.4 | 69 | |

| B3 | 30.4 | 65 | |

| B4 | 30.4 | 69 | |

| B5 | 30.4 | 64.3 | |

| Average | 30.4 ± 0 | 66.8 ± 2.2 | |

| Without wheat bran powder | A1 | 60.825 | 108.34 |

| A2 | 60.825 | 121.35 | |

| A3 | 60.825 | 115.63 | |

| A4 | 60.825 | 114.9 | |

| A5 | 60.825 | 115.1 | |

| Average | 60.8 ± 0 | 115 ± 4.6 | |

| Groups | Average | |

|---|---|---|

| Strain | Stress (Mpa) | |

| With wheat bran powder | 2.5 | 7 |

| Without wheat bran powder | 4.5 | 11 |

| Groups | Displacement (mm) | Force (N) | |

|---|---|---|---|

| With wheat bran powder | B1 | 9.06 | 1000 |

| B2 | 9.06 | 1000 | |

| B3 | 9.06 | 1000 | |

| B4 | 9.06 | 1000 | |

| B5 | 9.06 | 1000 | |

| Average | 9.06 ± 0 | 1000 ± 0 | |

| Without wheat bran powder | A1 | 9.6 | 1000 |

| A2 | 9.7 | 1000 | |

| A3 | 9.71 | 1000 | |

| A4 | 9.59 | 1000 | |

| A5 | 9.38 | 1000 | |

| Average | 9.6 ± 0.13 | 1000 ± 0 | |

| Groups | Average | |

|---|---|---|

| Strain | Stress (Mpa) | |

| With wheat bran powder | 0.7 | 105 |

| Without wheat bran powder | 0.78 | 105 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aboamer, M.A.; Almutairi, A.R.; Alassaf, A.; Alqahtani, T.M.; Almutairi, T.F.; Saijari, G.N.; Mohamed, N.A.R. Innovative and Eco-Friendly Natural Fiber Composites for Dental Impression Materials: A Study on Wheat Bran Reinforcement. Polymers 2025, 17, 476. https://doi.org/10.3390/polym17040476

Aboamer MA, Almutairi AR, Alassaf A, Alqahtani TM, Almutairi TF, Saijari GN, Mohamed NAR. Innovative and Eco-Friendly Natural Fiber Composites for Dental Impression Materials: A Study on Wheat Bran Reinforcement. Polymers. 2025; 17(4):476. https://doi.org/10.3390/polym17040476

Chicago/Turabian StyleAboamer, Mohamed A., Abdulmajeed Rasheed Almutairi, Ahmad Alassaf, Tarek M. Alqahtani, Turki F. Almutairi, Ghazwan Najdat Saijari, and Nader A. Rahman Mohamed. 2025. "Innovative and Eco-Friendly Natural Fiber Composites for Dental Impression Materials: A Study on Wheat Bran Reinforcement" Polymers 17, no. 4: 476. https://doi.org/10.3390/polym17040476

APA StyleAboamer, M. A., Almutairi, A. R., Alassaf, A., Alqahtani, T. M., Almutairi, T. F., Saijari, G. N., & Mohamed, N. A. R. (2025). Innovative and Eco-Friendly Natural Fiber Composites for Dental Impression Materials: A Study on Wheat Bran Reinforcement. Polymers, 17(4), 476. https://doi.org/10.3390/polym17040476