Comprehensive Performance Regulation and Characterization of Polypropylene/Elastomer Composite Insulation Materials

Abstract

1. Introduction

2. Sample Preparation and Testing Methods

2.1. Material Preparation

2.2. Testing Methods

3. Results

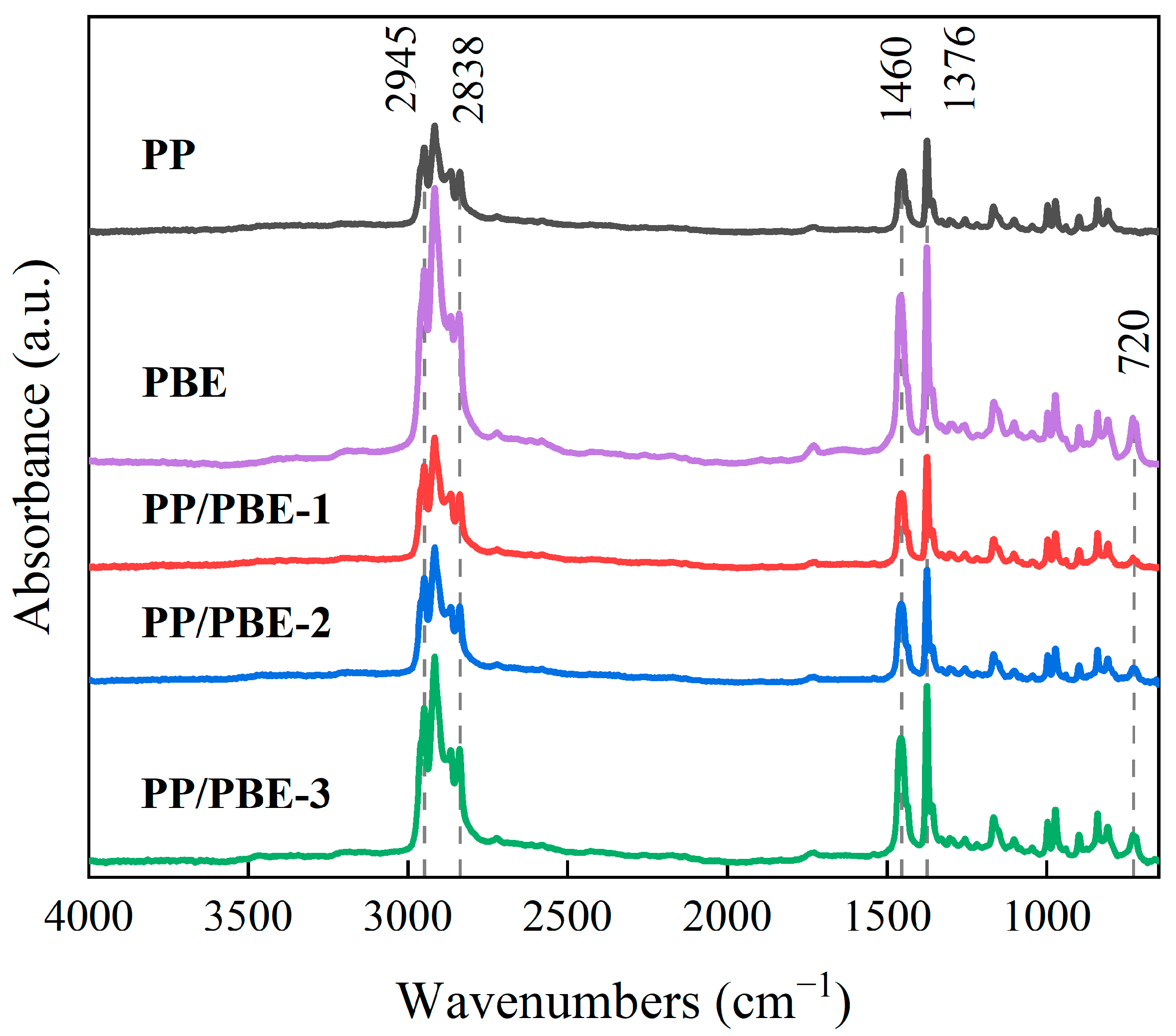

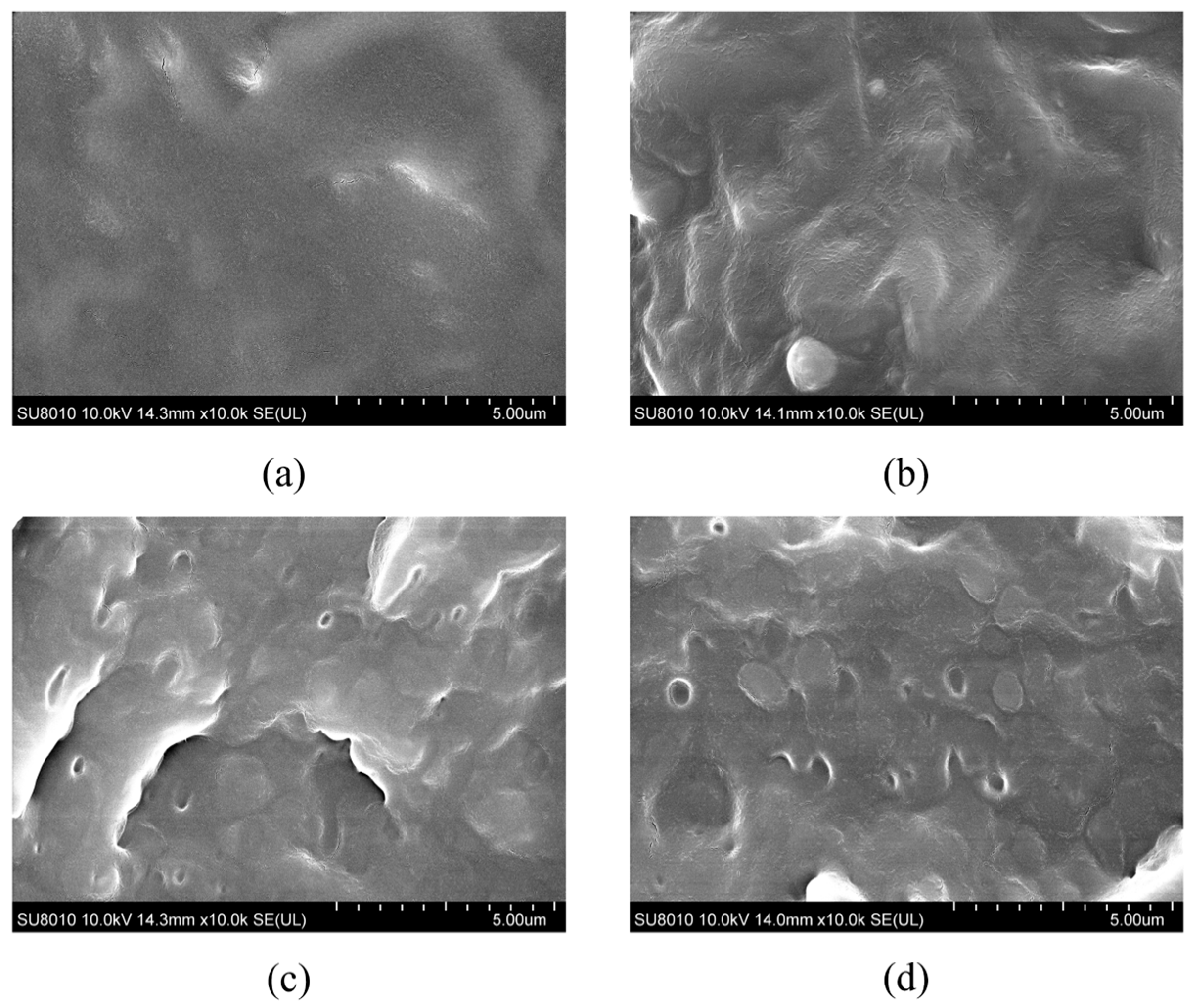

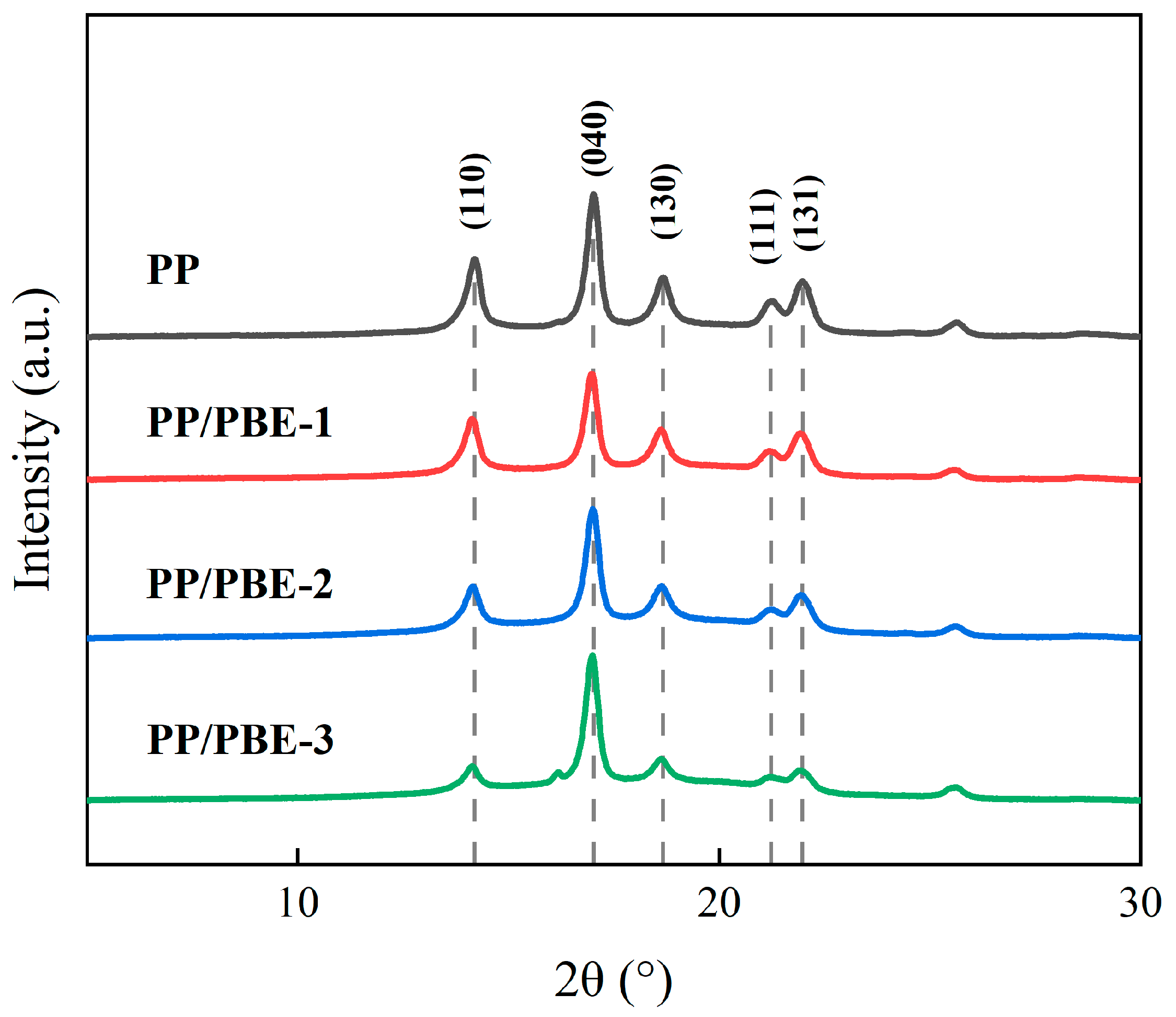

3.1. The Microstructure of PP/PBE Blends

3.2. Thermal Properties of PP/PBE Blends

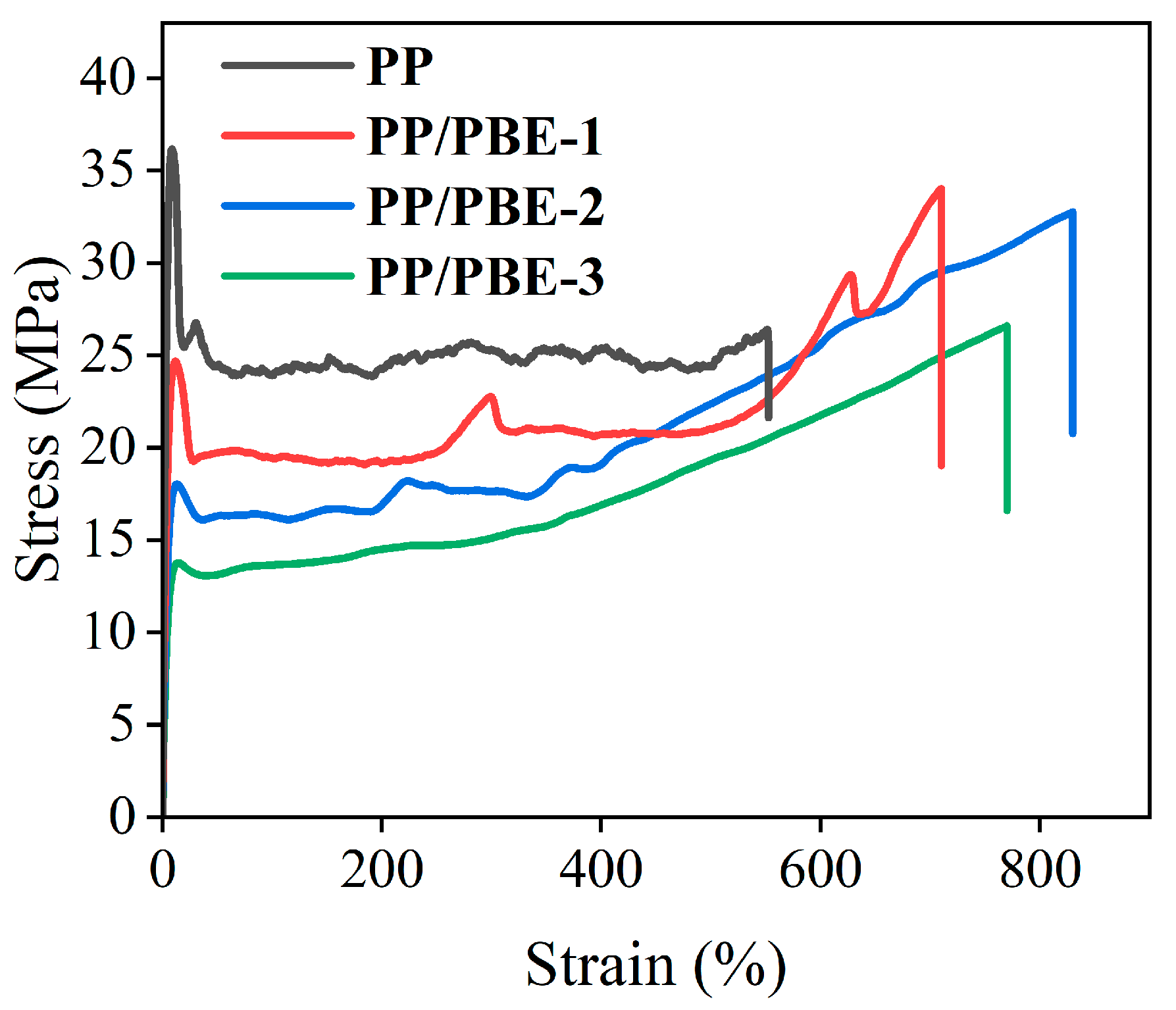

3.3. Mechanical Properties

3.4. DC Breakdown Strength

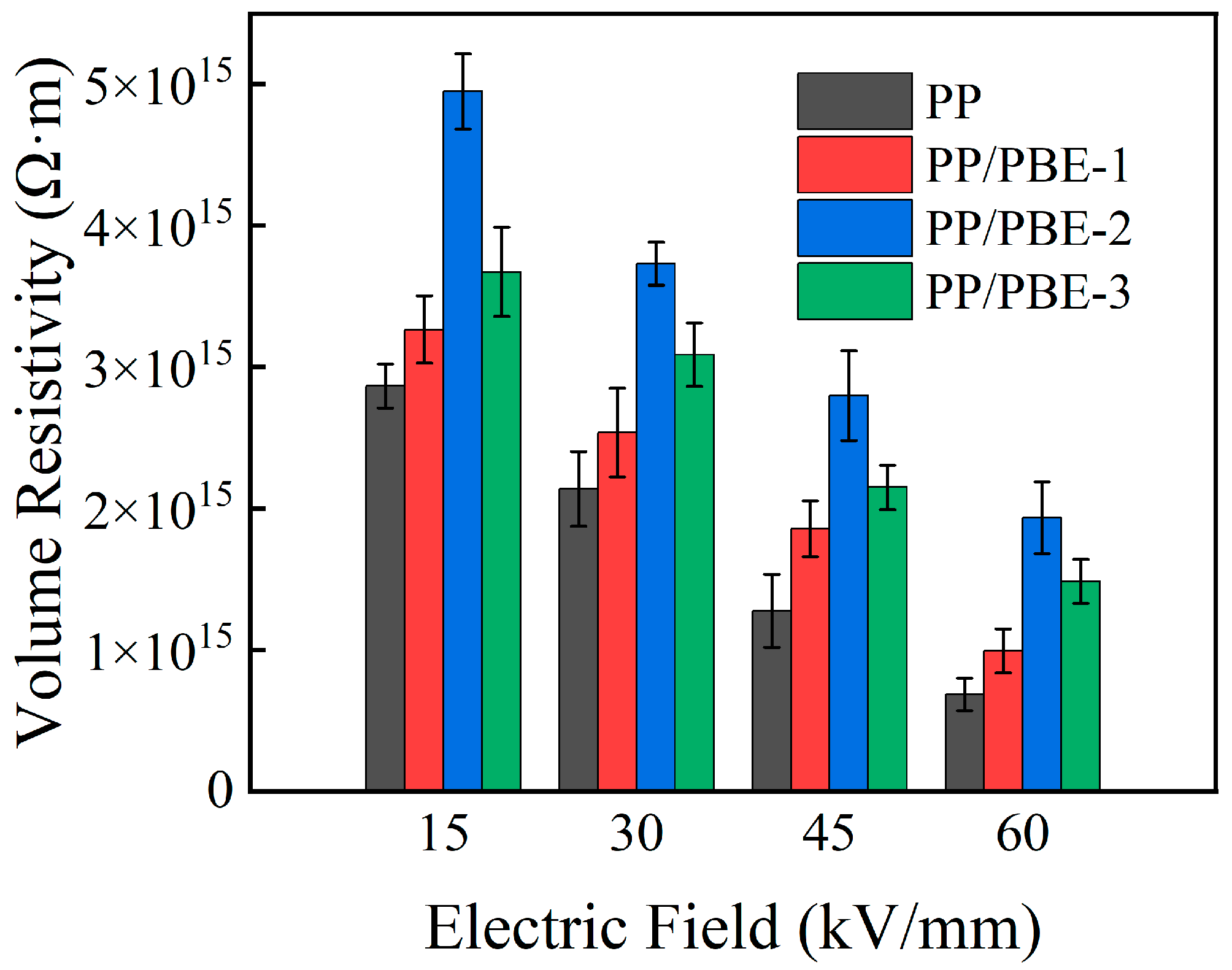

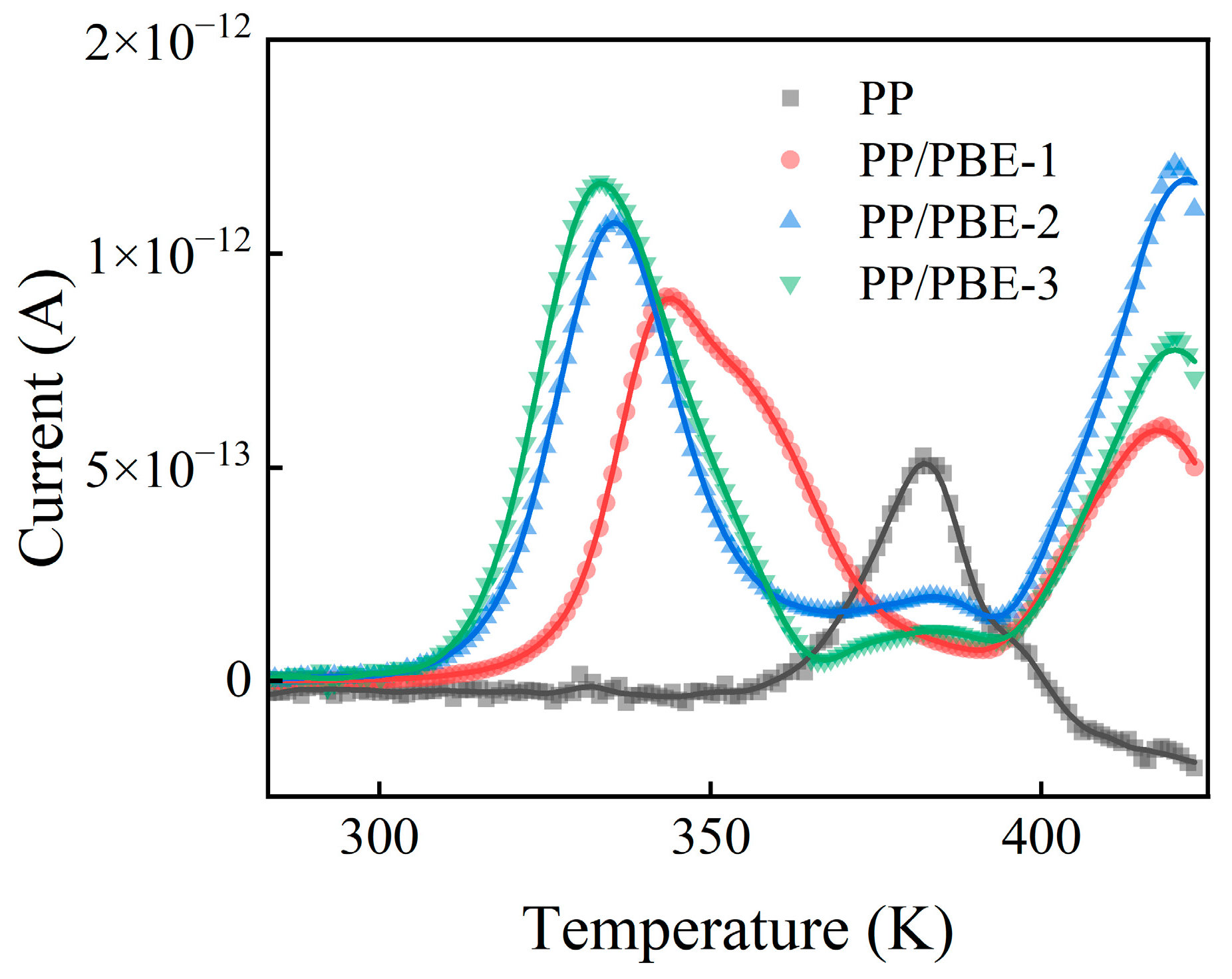

3.5. Conductivity

4. Discussion

5. Conclusions

- (1)

- The elastomer and the PP matrix inside the PP/PBE sample show a “sea–island structure”. The blending modification does not change the crystal form of PP, and the α-type remains dominant in PP/PBE samples. The crystallinity of the samples gradually decreases with the increase in ethylene content;

- (2)

- PBE and the PP matrix have better compatibility and significantly improve the mechanical properties of PP. Compared with PP, the tensile modulus of PP/PBE-2 decreases by 60.29%, and the elongation at break increases by 50.26% while still maintaining high tensile strength;

- (3)

- With the increase in PBE content, the breakdown strength and volume resistivity of PP/PBE samples increase and then decrease. The characteristic breakdown strength and volume resistivity of PP/PBE-2 are the highest, at 444.71 kV/mm and 4.95 × 1015 Ω·m, respectively, which represent increases of 6.43% and 72.47% compared with PP. The results show that an appropriate content of PBE can significantly enhance the insulation properties of PP/PBE samples;

- (4)

- A large number of boundaries between the crystalline and amorphous regions is generated in PP by blending elastomer, which can enter many deep traps. An appropriate content of PBE can balance the relationship between crystallinity and trap level and density, reduce carrier migration, hinder charge transport, and improve the electrical properties of the material.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Du, Y.; Zhang, H.; Han, W.; Du, X.; Shang, Y.; Yang, H.; Wang, X.; Chen, Q.; Li, Z. The network construction of a new byproduct-free XLPE-based insulation using a click chemistry-type reaction and a theoretical study of the reaction mechanism. Polymers 2024, 16, 3536. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.-Y.; Jin, Y.-Z.; Shi, Z.-X.; Wang, Z.-Y.; Wang, W. Study on the relationship between electron transfer and electrical properties of XLPE/modification SR under polarity reversal. Polymers 2024, 16, 2356. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Chen, G. Insulation materials for HVDC polymeric cables. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1307. [Google Scholar] [CrossRef]

- Pourrahimi, A.M.; Mauri, M.; D’Auria, S.; Pinalli, R.; Müller, C. Alternative concepts for extruded power cable insulation: From thermosets to thermoplastics. Adv. Mater. 2024, 36, 2313508. [Google Scholar] [CrossRef]

- Zhou, Y.; Dang, B.; Wang, H.; Liu, J.; Li, Q.; Hu, J.; He, J. Polypropylene-based ternary nanocomposites for recyclable high-voltage direct-current cable insulation. Compos. Sci. Technol. 2018, 165, 168–174. [Google Scholar] [CrossRef]

- Zhan, Y.; Yang, X.; Yang, J.; Hou, S.; Fu, M. Improved electrical properties of organic modified thermoplastic insulation material for direct current cable application. Polymers 2023, 16, 46. [Google Scholar] [CrossRef]

- Zhang, C.; Shi, W.; Wang, Q.; Diao, M.; Hiziroglu, H.R. Electrical property of polypropylene films subjected to different temperatures and DC electric fields. Polymers 2021, 13, 2956. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, J.; Jiang, P.; Tanaka, T. Material progress toward recyclable insulation of power cables part 2: Polypropylene-based thermoplastic materials. IEEE Electr. Insul. Mag. 2020, 36, 8–18. [Google Scholar] [CrossRef]

- Zhou, Y.; Peng, S.; Hu, J.; He, J. Polymeric insulation materials for HVDC cables: Development, challenges and future perspective. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1308–1318. [Google Scholar] [CrossRef]

- Li, Z.; Du, B. Polymeric insulation for high-voltage DC extruded cables: Challenges and development directions. IEEE Electr. Insul. Mag. 2018, 34, 30–43. [Google Scholar] [CrossRef]

- AlEidan, K.E.; Kenawy, E.-R.; Mandour, H.S.A.; Azaam, M.M.; AlOtaibi, B.S. Improving of impact copolymer PP (ICP) blends properties via compounding. Polym. Bull. 2024, 82, 861–884. [Google Scholar] [CrossRef]

- Hosier, I.L.; Vaughan, A.S.; Swingler, S.G. An investigation of the potential of polypropylene and its blends for use in recyclable high voltage cable insulation systems. J. Mater. Sci. 2011, 46, 4058–4070. [Google Scholar] [CrossRef]

- Zhou, Y.; He, J.; Hu, J.; Huang, X.; Jiang, P. Evaluation of polypropylene/polyolefin elastomer blends for potential recyclable HVDC cable insulation applications. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 673–681. [Google Scholar] [CrossRef]

- Ramírez-Vargas, E.; Navarro-Rodríguez, D.; Huerta-Martínez, B.M.; Medellín-rodríguez, F.J.; Lin, J.S. Morphological and mechanical properties of polypropylene [PP]/poly(ethylene vinyl acetate) [EVA] blends. I. homopolymer PP/EVA systems. Polym. Eng. Sci. 2000, 40, 2241–2250. [Google Scholar] [CrossRef]

- Zha, J.-W.; Wang, J.-F.; Wang, S.-J.; Qin, Q.; Dang, Z.-M. Effect of modified ZnO on electrical properties of PP/SEBS nanocomposites for HVDC cables. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 2358–2365. [Google Scholar] [CrossRef]

- Gao, Y.; Li, J.; Chen, G.; Han, T.; Du, B. Compatibility dependent space charge accumulation behavior of polypropylene/elastomer blend for HVDC cable insulation. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 947–955. [Google Scholar] [CrossRef]

- ISO 527-3:2018; Plastics—Determination of Tensile Properties. Part 3: Test Conditions for Films and Sheets. ISO: Geneva, Switzerland, 2018.

- Azmi, A.; Lau, K.Y.; Ahmad, N.A.; Abdul-Malek, Z.; Tan, C.W.; Ching, K.Y.; Vaughan, A.S. Structure-dielectric property relationship in polypropylene/multi-element oxide nanocomposites. IEEE Trans. Nanotechnol. 2021, 20, 377–385. [Google Scholar] [CrossRef]

- Fang, J.; Zhang, L.; Sutton, D.; Wang, X.; Lin, T. Needleless melt-electrospinning of polypropylene nanofibres. J. Nanomater. 2012, 2012, 382639. [Google Scholar] [CrossRef]

- Rahim, N.H.; Lau, K.Y.; Muhamad, N.A.; Mohamad, N.; Rahman, W.A.W.A.; Vaughan, A.S. Effects of filler calcination on structure and dielectric properties of polyethylene/silica nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 284–291. [Google Scholar] [CrossRef]

- Azrin, N.A.; Ahmad, N.A.; Lau, K.Y.; Kamarudin, S.N.H. Structure, mechanical, and dielectric properties of polypropylene blended with ethylene and propylene-based elastomers. J. Appl. Polym. Sci. 2024, 141, e56060. [Google Scholar] [CrossRef]

- Du, B.; Liu, H.; Li, Z. Effect of nucleating agent and cooling rate on dielectric Property of PP/POE cable insulation. IEEE Trans. Dielectr. Electr. Insul. 2024, 31, 929–936. [Google Scholar] [CrossRef]

- Chen, R.; Shangguan, Y.; Zhang, C.; Chen, F.; Harkin-Jones, E.; Zheng, Q. Influence of molten-state annealing on the phase structure and crystallization behaviour of high impact polypropylene copolymer. Polymer 2011, 52, 2956–2963. [Google Scholar] [CrossRef]

- Lezak, E.; Bartczak, Z.; Galeski, A. Plastic deformation of the γ phase in isotactic polypropylene in plane-strain compression. Macromolecules 2006, 39, 4811–4819. [Google Scholar] [CrossRef]

- Luo, G.; Liu, G.; Chen, Y.; Liang, W.; Liu, G.; Niu, Y.; Li, G. High performance glass fiber reinforced polypropylene realized by reactive extrusion technology. Compos. Sci. Technol. 2018, 165, 198–205. [Google Scholar] [CrossRef]

- Sangroniz, L.; Cavallo, D.; Santamaria, A.; Müller, A.J.; Alamo, R.G. Thermorheologically complex self-seeded melts of propylene–ethylene copolymers. Macromolecules 2017, 50, 642–651. [Google Scholar] [CrossRef]

- Huang, X.; Fan, Y.; Zhang, J.; Jiang, P. Polypropylene based thermoplastic polymers for potential recyclable HVDC cable insulation applications. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1446–1456. [Google Scholar] [CrossRef]

- Yang, K.; Ren, Y.; Wu, K.; Li, J.; Jing, Z.; Zhang, Z.; Dong, J.-Y. Enhancing electrical properties of impact polypropylene copolymer for eco-friendly power cable insulation by manipulating the multiphase structure through molten-state annealing. Compos. Sci. Technol. 2022, 223, 109422. [Google Scholar] [CrossRef]

- Zhou, Y.; Hu, J.; Dang, B.; He, J. Mechanism of highly improved electrical properties in polypropylene by chemical modification of grafting maleic anhydride. J. Phys. D Appl. Phys. 2016, 49, 415301. [Google Scholar] [CrossRef]

- Yang, K.; Liu, Y.; Yan, Z.; Tian, Y.; Liu, Y.; Jing, Z.; Li, J.; Li, S. Enhanced morphology-dependent tensile property and breakdown strength of impact polypropylene copolymer for cable insulation. Materials 2020, 13, 3935. [Google Scholar] [CrossRef]

- Tian, F.; Bu, W.; Shi, L.; Yang, C.; Wang, Y.; Lei, Q. Theory of modified thermally stimulated current and direct determination of trap level distribution. J. Electrostat. 2011, 69, 7–10. [Google Scholar] [CrossRef]

- Li, Z.; Zhong, Z.; Du, B. Dielectric relaxation and trap-modulated DC breakdown of polypropylene blend insulation. Polymer 2019, 185, 121935. [Google Scholar] [CrossRef]

- Peng, S.; Dang, B.; Zhou, Y.; Hu, J.; He, J. Functionalized TiO2 nanoparticles tune the aggregation structure and trapping property of polyethylene nanocomposites. J. Phys. Chem. C 2016, 120, 24754–24761. [Google Scholar] [CrossRef]

- Dang, B.; He, J.; Hu, J.; Zhou, Y. Large improvement in trap level and space charge distribution of polypropylene by enhancing the crystalline–amorphous interface effect in blends. Polym. Int. 2016, 65, 371–379. [Google Scholar] [CrossRef]

- Li, X.; Du, Q.; Kang, J.; Tu, D. Influence of microstructure on space charges of polypropylene. J. Polym. Sci. B Polym. Phys. 2002, 40, 365–374. [Google Scholar] [CrossRef]

| Samples | Crystal Planes | 2θ (°) | d (Å) | FWHM |

|---|---|---|---|---|

| PP | (110) | 14.20 | 6.23 | 0.405 |

| (040) | 17.02 | 5.21 | 0.348 | |

| (130) | 18.68 | 4.75 | 0.394 | |

| (111) | 21.24 | 4.18 | 0.220 | |

| (131) | 21.98 | 4.04 | 0.517 | |

| PP/PBE-1 | (110) | 14.16 | 6.25 | 0.408 |

| (040) | 17.00 | 5.21 | 0.349 | |

| (130) | 18.64 | 4.76 | 0.420 | |

| (111) | 21.24 | 4.18 | 0.295 | |

| (131) | 21.94 | 4.05 | 0.532 | |

| PP/PBE-2 | (110) | 14.14 | 6.26 | 0.423 |

| (040) | 17.00 | 5.21 | 0.353 | |

| (130) | 18.62 | 4.76 | 0.420 | |

| (111) | 21.20 | 4.19 | 0.445 | |

| (131) | 21.92 | 4.05 | 0.545 | |

| PP/PBE-3 | (110) | 14.12 | 6.27 | 0.434 |

| (040) | 17.98 | 5.22 | 0.363 | |

| (130) | 18.62 | 4.76 | 0.448 | |

| (111) | 21.20 | 4.19 | 0.456 | |

| (131) | 21.88 | 4.06 | 0.593 |

| Samples | Tm (°C) | Tc (°C) | Xc (%) |

|---|---|---|---|

| PP | 162.35 | 120.69 | 40.04 |

| PP/PBE-1 | 160.48 | 118.45 | 32.67 |

| PP/PBE-2 | 159.11 | 117.04 | 27.07 |

| PP/PBE-3 | 156.18 | 113.68 | 19.25 |

| Samples | α (kV/mm) | β |

|---|---|---|

| PP | 417.85 | 21.51 |

| PP/PBE-1 | 423.01 | 29.03 |

| PP/PBE-2 | 444.71 | 14.82 |

| PP/PBE-3 | 434.45 | 29.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, X.; Fan, X.; Wang, W. Comprehensive Performance Regulation and Characterization of Polypropylene/Elastomer Composite Insulation Materials. Polymers 2025, 17, 530. https://doi.org/10.3390/polym17040530

Dong X, Fan X, Wang W. Comprehensive Performance Regulation and Characterization of Polypropylene/Elastomer Composite Insulation Materials. Polymers. 2025; 17(4):530. https://doi.org/10.3390/polym17040530

Chicago/Turabian StyleDong, Xinhua, Xianhao Fan, and Wei Wang. 2025. "Comprehensive Performance Regulation and Characterization of Polypropylene/Elastomer Composite Insulation Materials" Polymers 17, no. 4: 530. https://doi.org/10.3390/polym17040530

APA StyleDong, X., Fan, X., & Wang, W. (2025). Comprehensive Performance Regulation and Characterization of Polypropylene/Elastomer Composite Insulation Materials. Polymers, 17(4), 530. https://doi.org/10.3390/polym17040530