Humidity- and Temperature-Sensing Properties of 2D-Layered Tungsten Di-Selenide (2H-WSe2) Electroconductive Coatings for Cotton-Based Smart Textiles

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthetic Procedure for the Preparation of 2H-WSe2-Based Pastes

2.3. Application of 2H-WSe2-Based Pastes onto Cotton Samples

2.4. Characterizations

3. Results and Discussion

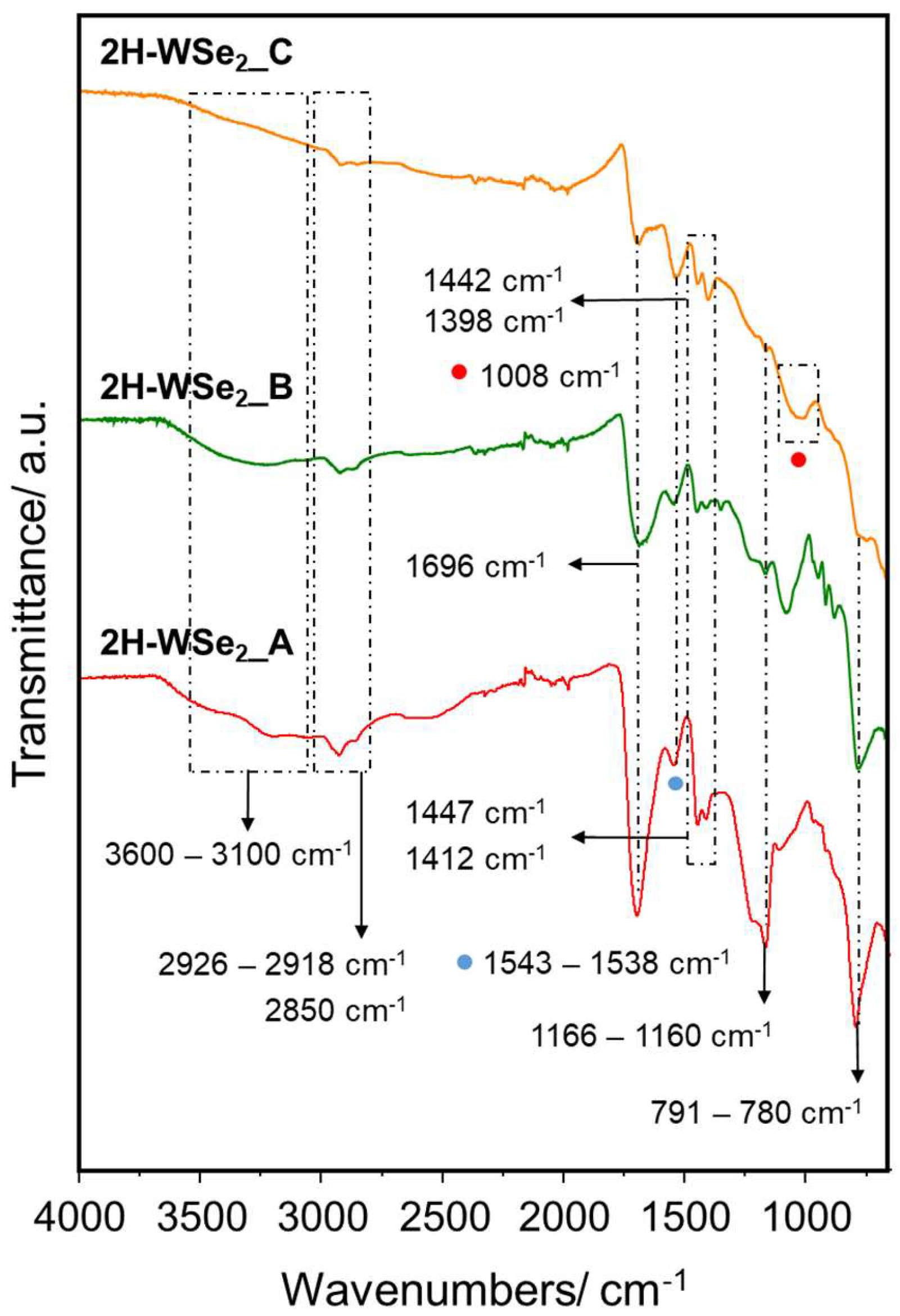

3.1. ATR-FTIR Spectroscopic Analysis of 2H-WSe2-Based Slurries

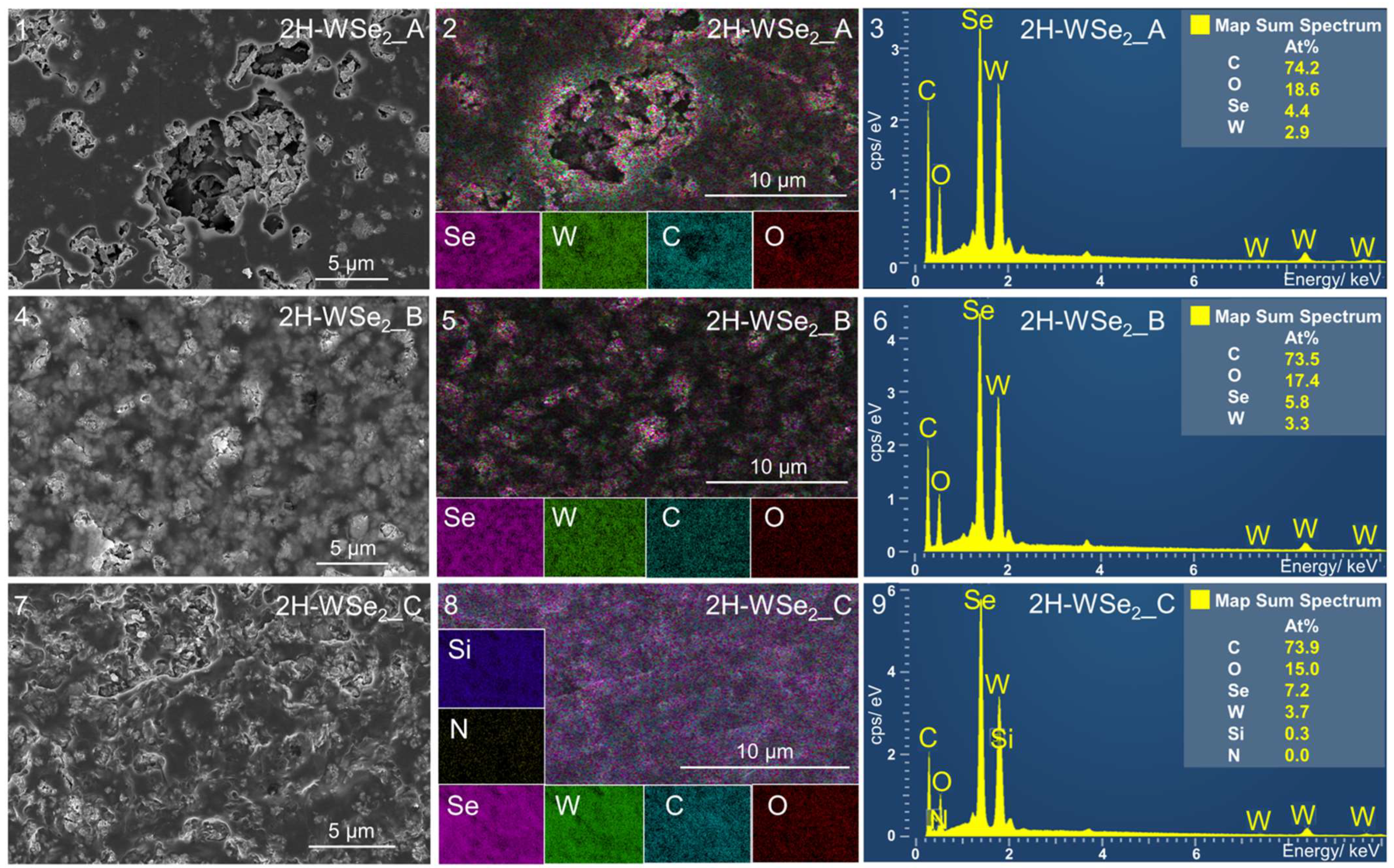

3.2. Understanding the Homogeneity of 2H-WSe2-Based Coatings

3.3. Chemical Characterization of 2H-WSe2-Coated Textiles

4. Humidity and Temperature Sensing of the 2D-WSe2-Coated Fabrics

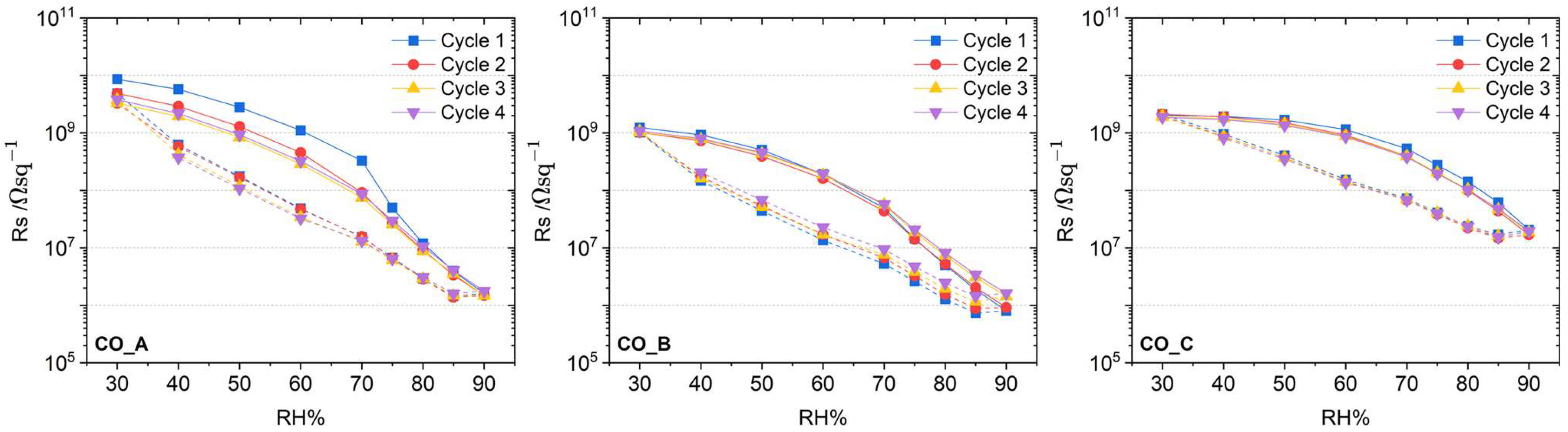

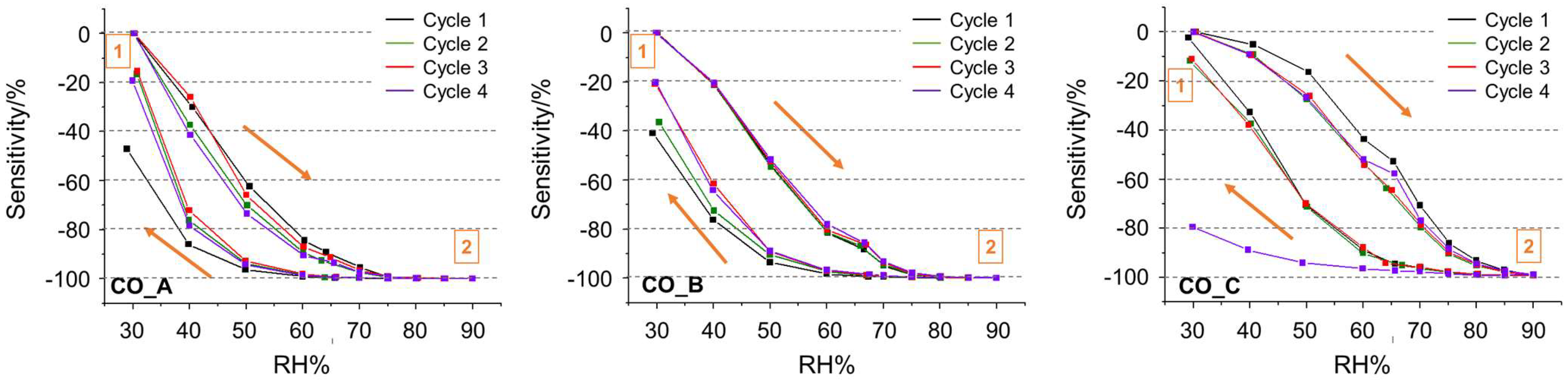

4.1. Humidity-Sensing Performance of 2D-Doped Cotton Fabrics

4.2. Temperature-Sensing Performance of 2D-Doped Cotton Fabrics

5. Stiffness Properties

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, M.; Duan, Z.; Yuan, Z.; Jiang, Y.; Tai, H. Observing Mixed Chemical Reactions at the Positive Electrode in the High-Performance Self-Powered Electrochemical Humidity Sensor. ACS Nano 2024, 18, 34158–34170. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Wei, J.; Wang, L. A Micro Capacitive Humidity Sensor Based on Al-Mo Electrodes and Polyimide Film. Polymers 2024, 16, 1916. [Google Scholar] [CrossRef] [PubMed]

- Rahad, R.; Sobhani, M.M.; Emon, M.J.H.; Afrid, S.M.T.-S.; Mahadi, M.K.; Mohsin, A.S.; Faruque, M.O.; Sagor, R.H. An Alternative Plasmonic Material-Based CMOS-Compatible Temperature Sensor. Opt. Commun. 2024, 569, 130749. [Google Scholar] [CrossRef]

- Li, F.; Xue, H.; Lin, X.; Zhao, H.; Zhang, T. Wearable Temperature Sensor with High Resolution for Skin Temperature Monitoring. ACS Appl. Mater. Interfaces 2022, 14, 43844–43852. [Google Scholar] [CrossRef]

- Eftekhari, A. Tungsten Dichalcogenides (WS2, WSe2, and WTe2): Materials Chemistry and Applications. J. Mater. Chem. A 2017, 5, 18299–18325. [Google Scholar] [CrossRef]

- Jung, D.H.; Kim, S.; Kim, T. Characteristics of Electrical Metal Contact to Monolayer WSe2. Thin Solid Film. 2021, 719, 138508. [Google Scholar] [CrossRef]

- Maiti, S.; Konar, R.; Sclar, H.; Grinblat, J.; Talianker, M.; Tkachev, M.; Wu, X.; Kondrakov, A.; Nessim, G.D.; Aurbach, D. Stabilizing High-Voltage Lithium-Ion Battery Cathodes Using Functional Coatings of 2D Tungsten Diselenide. ACS Energy Lett. 2022, 7, 1383–1391. [Google Scholar] [CrossRef]

- Yin, C.; Wang, X.; Chen, Y.; Li, D.; Lin, T.; Sun, S.; Shen, H.; Du, P.; Sun, J.; Meng, X.; et al. A Ferroelectric Relaxor Polymer-Enhanced p-Type WSe2 Transistor. Nanoscale 2018, 10, 1727–1734. [Google Scholar] [CrossRef]

- Trovato, V.; Teblum, E.; Kostikov, Y.; Pedrana, A.; Re, V.; Nessim, G.D.; Rosace, G. Sol-Gel Approach to Incorporate Millimeter-Long Carbon Nanotubes into Fabrics for the Development of Electrical-Conductive Textiles. Mater. Chem. Phys. 2020, 240, 122218. [Google Scholar] [CrossRef]

- Zeng, S.; Pan, Q.; Huang, Z.; Gu, C.; Wang, T.; Xu, J.; Yan, Z.; Zhao, F.; Li, P.; Tu, Y.; et al. Ultrafast Response of Self-Powered Humidity Sensor of Flexible Graphene Oxide Film. Mater. Des. 2023, 226, 111683. [Google Scholar] [CrossRef]

- An, D.; Zhang, X.; Bi, Z.; Shan, W.; Zhang, H.; Xia, S.; Qiu, M. Low-Dimensional Black Phosphorus in Sensor Applications: Advances and Challenges. Adv. Funct. Mater. 2021, 31, 2106484. [Google Scholar] [CrossRef]

- Late, D.J.; Huang, Y.-K.; Liu, B.; Acharya, J.; Shirodkar, S.N.; Luo, J.; Yan, A.; Charles, D.; Waghmare, U.V.; Dravid, V.P.; et al. Sensing Behavior of Atomically Thin-Layered MoS2 Transistors. ACS Nano 2013, 7, 4879–4891. [Google Scholar] [CrossRef] [PubMed]

- Jha, R.K.; Guha, P.K. Humidity Sensing Properties of Coexfoliated Heterogeneous WS2 /WSe2 Nanohybrids. IEEE Trans. Nanotechnol. 2018, 17, 582–589. [Google Scholar] [CrossRef]

- Feng, J.; Peng, L.; Wu, C.; Sun, X.; Hu, S.; Lin, C.; Dai, J.; Yang, J.; Xie, Y. Giant Moisture Responsiveness of VS2 Ultrathin Nanosheets for Novel Touchless Positioning Interface. Adv. Mater. 2012, 24, 1969–1974. [Google Scholar] [CrossRef]

- Jha, R.K.; Guha, P.K. Liquid Exfoliated Pristine WS2 Nanosheets for Ultrasensitive and Highly Stable Chemiresistive Humidity Sensors. Nanotechnology 2016, 27, 475503. [Google Scholar] [CrossRef]

- Awais, M.; Khan, M.U.; Hassan, A.; Bae, J.; Chattha, T.E. Printable Highly Stable and Superfast Humidity Sensor Based on Two Dimensional Molybdenum Diselenide. Sci. Rep. 2020, 10, 5509. [Google Scholar] [CrossRef]

- Liu, B.; Fathi, M.; Chen, L.; Abbas, A.; Ma, Y.; Zhou, C. Chemical Vapor Deposition Growth of Monolayer WSe2 with Tunable Device Characteristics and Growth Mechanism Study. ACS Nano 2015, 9, 6119–6127. [Google Scholar] [CrossRef]

- Moumen, A.; Konar, R.; Zappa, D.; Teblum, E.; Nessim, G.D.; Comini, E. Room-Temperature NO2 Sensing of CVD-Modified WS2–WSe2 Heterojunctions. ACS Appl. Nano Mater. 2023, 6, 7323–7329. [Google Scholar] [CrossRef]

- Pataniya, P.; Solanki, G.K.; Zankat, C.K.; Tannarana, M.; Patel, K.D.; Pathak, V.M. Giant Humidity Responsiveness of WSe2 Nanosheets for Novel Electronic Listening and Touchless Positioning Interface. J. Mater. Sci. Mater. Electron. 2019, 30, 3137–3143. [Google Scholar] [CrossRef]

- Awasthi, C.; Sehrawat, P.; Meena, R.C.; Asokan, K.; Islam, S.S. Temperature Sensing Performance of 2D-MoSe2 Based Thermistor. AIP Conf. Proc. 2020, 2276, 020028. [Google Scholar] [CrossRef]

- Taylor, S.R. Abundance of Chemical Elements in the Continental Crust: A New Table. Geochim Cosmochim Acta 1964, 28, 1273–1285. [Google Scholar] [CrossRef]

- Abid; Sehrawat, P.; Julien, C.M.; Islam, S.S. E-Textile Based Wearable Thermometer from WS2 -Quantum Dots. Nanotechnology 2021, 32, 335503. [Google Scholar] [CrossRef]

- Zu, Y.; Hu, J.; Yang, M.; Duan, Z.; Zhang, M.; Yuan, Z.; Jiang, Y.; Tai, H. Electrochemical Power Generation Humidity Sensor Based on WS2 Nanoflakes. Sens. Actuators B Chem. 2024, 405, 135325. [Google Scholar] [CrossRef]

- Tan, H.; Fan, Y.; Zhou, Y.; Chen, Q.; Xu, W.; Warner, J.H. Ultrathin 2D Photodetectors Utilizing Chemical Vapor Deposition Grown WS2 With Graphene Electrodes. ACS Nano 2016, 10, 7866–7873. [Google Scholar] [CrossRef]

- Khalil, H.M.W.; Khan, M.F.; Eom, J.; Noh, H. Highly Stable and Tunable Chemical Doping of Multilayer WS2 Field Effect Transistor: Reduction in Contact Resistance. ACS Appl. Mater. Interfaces 2015, 7, 23589–23596. [Google Scholar] [CrossRef]

- Zheng, Z.; Zhang, T.; Yao, J.; Zhang, Y.; Xu, J.; Yang, G. Flexible, Transparent and Ultra-Broadband Photodetector Based on Large-Area WSe2 Film for Wearable Devices. Nanotechnology 2016, 27, 225501. [Google Scholar] [CrossRef]

- Movva, H.C.P.; Rai, A.; Kang, S.; Kim, K.; Fallahazad, B.; Taniguchi, T.; Watanabe, K.; Tutuc, E.; Banerjee, S.K. High-Mobility Holes in Dual-Gated WSe2 Field-Effect Transistors. ACS Nano 2015, 9, 10402–10410. [Google Scholar] [CrossRef]

- Liu, B.; Ma, Y.; Zhang, A.; Chen, L.; Abbas, A.N.; Liu, Y.; Shen, C.; Wan, H.; Zhou, C. High-Performance WSe2 Field-Effect Transistors via Controlled Formation of In-Plane Heterojunctions. ACS Nano 2016, 10, 5153–5160. [Google Scholar] [CrossRef]

- Medina, H.; Li, J.-G.; Su, T.-Y.; Lan, Y.-W.; Lee, S.-H.; Chen, C.-W.; Chen, Y.-Z.; Manikandan, A.; Tsai, S.-H.; Navabi, A.; et al. Wafer-Scale Growth of WSe2 Monolayers Toward Phase-Engineered Hybrid WOx /WSe2 Films with Sub-Ppb NOx Gas Sensing by a Low-Temperature Plasma-Assisted Selenization Process. Chem. Mater. 2017, 29, 1587–1598. [Google Scholar] [CrossRef]

- Lee, W.S.; Choi, J. Two-Dimensional Tungsten Diselenides Integrated on Paper Substrate for Highly Flexible and Sensitive Gas Sensor. In Proceedings of the 2019 20th International Conference on Solid-State Sensors, Actuators and Microsystems & Eurosensors XXXIII (TRANSDUCERS & EUROSENSORS XXXIII), Berlin, Germany, 23–27 June 2019; pp. 681–684. [Google Scholar] [CrossRef]

- Ko, K.Y.; Lee, S.; Park, K.; Kim, Y.; Woo, W.J.; Kim, D.; Song, J.-G.; Park, J.; Kim, J.H.; Lee, Z.; et al. High-Performance Gas Sensor Using a Large-Area WS2x Se2–2x Alloy for Low-Power Operation Wearable Applications. ACS Appl. Mater. Interfaces 2018, 10, 34163–34171. [Google Scholar] [CrossRef]

- Jo, S.; Kang, D.; Shim, J.; Jeon, J.; Jeon, M.H.; Yoo, G.; Kim, J.; Lee, J.; Yeom, G.Y.; Lee, S.; et al. A High-Performance WSe2/h-BN Photodetector Using a Triphenylphosphine (PPh3)-Based N-Doping Technique. Adv. Mater. 2016, 28, 4824–4831. [Google Scholar] [CrossRef] [PubMed]

- Yao, J.; Zheng, Z.; Yang, G. Layered-Material WS 2/Topological Insulator Bi2Te3 Heterostructure Photodetector with Ultrahigh Responsivity in the Range from 370 to 1550 Nm. J. Mater. Chem. C 2016, 4, 7831–7840. [Google Scholar] [CrossRef]

- Trovato, V.; Mezzi, A.; Brucale, M.; Abdeh, H.; Drommi, D.; Rosace, G.; Plutino, M.R. Sol-Gel Assisted Immobilization of Alizarin Red S on Polyester Fabrics for Developing Stimuli-Responsive Wearable Sensors. Polymers 2022, 14, 2788. [Google Scholar] [CrossRef] [PubMed]

- Trovato, V.; Mezzi, A.; Brucale, M.; Rosace, G.; Rosaria Plutino, M. Alizarin-Functionalized Organic-Inorganic Silane Coatings for the Development of Wearable Textile Sensors. J. Colloid Interface Sci. 2022, 617, 463–477. [Google Scholar] [CrossRef]

- Trovato, V.; Vitale, A.; Bongiovanni, R.; Ferri, A.; Rosace, G.; Plutino, M.R. Development of a Nitrazine Yellow-Glycidyl Methacrylate Coating onto Cotton Fabric through Thermal-Induced Radical Polymerization Reactions: A Simple Approach towards Wearable pH Sensors Applications. Cellulose 2021, 28, 3847–3868. [Google Scholar] [CrossRef]

- Chen, W.Y.; Yen, C.-C.; Xue, S.; Wang, H.; Stanciu, L.A. Surface Functionalization of Layered Molybdenum Disulfide for the Selective Detection of Volatile Organic Compounds at Room Temperature. ACS Appl. Mater. Interfaces 2019, 11, 34135–34143. [Google Scholar] [CrossRef]

- Kim, S.; Han, J.; Kang, M.-A.; Song, W.; Myung, S.; Kim, S.-W.; Lee, S.S.; Lim, J.; An, K.-S. Flexible Chemical Sensors Based on Hybrid Layer Consisting of Molybdenum Disulphide Nanosheets and Carbon Nanotubes. Carbon 2018, 129, 607–612. [Google Scholar] [CrossRef]

- Xie, J.; Zhang, Y.; Dai, J.; Xie, Z.; Xue, J.; Dai, K.; Zhang, F.; Liu, D.; Cheng, J.; Kang, F.; et al. Multifunctional MoSe2@MXene Heterostructure-Decorated Cellulose Fabric for Wearable Thermal Therapy. Small 2023, 19, 2205853. [Google Scholar] [CrossRef]

- Abid; Sehrawat, P.; Julien, C.M.; Islam, S.S. WS2 Quantum Dots on e-Textile as a Wearable UV Photodetector: How Well Reduced Graphene Oxide Can Serve as a Carrier Transport Medium? ACS Appl. Mater. Interfaces 2020, 12, 39730–39744. [Google Scholar] [CrossRef]

- Chung, C.; Lee, M.; Choe, E. Characterization of Cotton Fabric Scouring by FT-IR ATR Spectroscopy. Carbohydr. Polym. 2004, 58, 417–420. [Google Scholar] [CrossRef]

- Fang, X.-Y.; Yu, X.-X.; Zheng, H.-M.; Jin, H.-B.; Wang, L.; Cao, M.-S. Temperature- and Thickness-Dependent Electrical Conductivity of Few-Layer Graphene and Graphene Nanosheets. Phys. Lett. A 2015, 379, 2245–2251. [Google Scholar] [CrossRef]

- Banaszczyk, J.; Schwarz, A.; De Mey, G.; Van Langenhove, L. The Van Der Pauw Method for Sheet Resistance Measurements of Polypyrrole-coated Para-aramide Woven Fabrics. J. Appl. Polym. Sci. 2010, 117, 2553–2558. [Google Scholar] [CrossRef]

- Shelke, N.T.; Late, D.J. Hydrothermal Growth of MoSe2 Nanoflowers for Photo- and Humidity Sensor Applications. Sens. Actuators A Phys. 2019, 295, 160–168. [Google Scholar] [CrossRef]

- DIN 53362:2024-11; Testing of Plastic Films and Textile Fabrics (Excluding Nonwovens), Coated or Not Coated Plastics—Determination of Stiffness in BendingMethod According to Cantilever. Deutsches Institut für Normung: Berlin, Germany, 2024.

- Konar, R.; Nessim, G.D. A Mini-Review Focusing on Ambient-Pressure Chemical Vapor Deposition (AP-CVD) Based Synthesis of Layered Transition Metal Selenides for Energy Storage Applications. Mater. Adv. 2022, 3, 4471–4488. [Google Scholar] [CrossRef]

- Konar, R.; Rosy; Perelshtein, I.; Teblum, E.; Telkhozhayeva, M.; Tkachev, M.; Richter, J.J.; Cattaruzza, E.; Pietropolli Charmet, A.; Stoppa, P.; et al. Scalable Synthesis of Few-Layered 2D Tungsten Diselenide (2H-WSe2) Nanosheets Directly Grown on Tungsten (W) Foil Using Ambient-Pressure Chemical Vapor Deposition for Reversible Li-Ion Storage. ACS Omega 2020, 5, 19409–19421. [Google Scholar] [CrossRef]

- Moumen, A.; Konar, R.; Zappa, D.; Teblum, E.; Perelshtein, I.; Lavi, R.; Ruthstein, S.; Nessim, G.D.; Comini, E. Robust Room-Temperature NO2 Sensors from Exfoliated 2D Few-Layered CVD-Grown Bulk Tungsten Di-Selenide (2H-WSe2). ACS Appl. Mater. Interfaces 2021, 13, 4316–4329. [Google Scholar] [CrossRef]

- Konar, R.; Tamari, R.; Teblum, E.; Nessim, G.D.; Meshi, L. In-Depth Characterization of Stacking Faults Forming during the Growth of Transition-Metal Di-Chalcogenides (TMDCs) by Ambient Pressure-CVD. Mater. Charact. 2022, 184, 111666. [Google Scholar] [CrossRef]

- Kannichankandy, D.; Pataniya, P.M.; Sumesh, C.K.; Solanki, G.K.; Pathak, V.M. WSe2-PANI Nanohybrid Structure as Efficient Electrocatalyst for Photo-Enhanced Hydrogen Evolution Reaction. J. Alloys Compd. 2021, 876, 160179. [Google Scholar] [CrossRef]

- Dong, J.; Ozaki, Y.; Nakashima, K. Infrared, Raman, and Near-Infrared Spectroscopic Evidence for the Coexistence of Various Hydrogen-Bond Forms in Poly(Acrylic Acid). Macromolecules 1997, 30, 1111–1117. [Google Scholar] [CrossRef]

- Melchiorre Di Crescenzo, M.; Zendri, E.; Sánchez-Pons, M.; Fuster-López, L.; Yusá-Marco, D.J. The Use of Waterborne Paints in Contemporary Murals: Comparing the Stability of Vinyl, Acrylic and Styrene-Acrylic Formulations to Outdoor Weathering Conditions. Polym. Degrad. Stab. 2014, 107, 285–293. [Google Scholar] [CrossRef]

- Doménech-Carbó, M.T.; Doménech-Carbó, A.; Gimeno-Adelantado, J.V.; Bosch-Reig, F. Identification of Synthetic Resins Used in Works of Art by Fourier Transform Infrared Spectroscopy. Appl. Spectrosc. 2001, 55, 1590–1602. [Google Scholar] [CrossRef]

- Yang, M.; Zhao, Y.S.; Qin, Y.; Nie, Y.J. Study on the Synthesis of Vinyl Ester and Its Using as Thickener for SMC. Adv. Mat. Res. 2011, 179–180, 1059–1062. [Google Scholar] [CrossRef]

- Rando, G.; Sfameni, S.; Hadhri, M.; Mezzi, A.; Brucale, M.; De Luca, G.; Piperopoulos, E.; Milone, C.; Drommi, D.; Rosace, G.; et al. Methyl Red-loaded halloysite nanotubes-based silica coatings for durable dyeing of polyester fabrics. Surf. Interfaces 2024, 53, 105006. [Google Scholar] [CrossRef]

- Ielo, I.; Giacobello, F.; Castellano, A.; Sfameni, S.; Rando, G.; Plutino, M.R. Development of Antibacterial and Antifouling Innovative and Eco-Sustainable Sol–Gel Based Materials: From Marine Areas Protection to Healthcare Applications. Gels 2021, 8, 26. [Google Scholar] [CrossRef]

- Giacobello, F.; Ielo, I.; Belhamdi, H.; Plutino, M.R. Geopolymers and Functionalization Strategies for the Development of Sustainable Materials in Construction Industry and Cultural Heritage Applications: A Review. Materials 2022, 15, 1725. [Google Scholar] [CrossRef]

- Rosace, G.; Trovato, V.; Colleoni, C.; Caldara, M.; Re, V.; Brucale, M.; Piperopoulos, E.; Mastronardo, E.; Milone, C.; De Luca, G.; et al. Structural and Morphological Characterizations of MWCNTs Hybrid Coating onto Cotton Fabric as Potential Humidity and Temperature Wearable Sensor. Sens. Actuators B Chem. 2017, 252, 428–439. [Google Scholar] [CrossRef]

- Trovato, V.; Teblum, E.; Kostikov, Y.; Pedrana, A.; Re, V.; Nessim, G.D.; Rosace, G. Electrically Conductive Cotton Fabric Coatings Developed by Silica Sol-Gel Precursors Doped with Surfactant-Aided Dispersion of Vertically Aligned Carbon Nanotubes Fillers in Organic Solvent-Free Aqueous Solution. J. Colloid Interface Sci. 2021, 586, 120–134. [Google Scholar] [CrossRef]

- Pekcan, O.; Evingür, G.A. Conductivity Percolation of Carbon Nanotubes in Polyacrylamide Gels. In Carbon Nanotubes—Polymer Nanocomposites; Yellampalli, S., Ed.; InTech: London, UK, 2011; pp. 197–214. [Google Scholar]

- Stanford, M.G.; Pudasaini, P.R.; Gallmeier, E.T.; Cross, N.; Liang, L.; Oyedele, A.; Duscher, G.; Mahjouri-Samani, M.; Wang, K.; Xiao, K.; et al. High Conduction Hopping Behavior Induced in Transition Metal Dichalcogenides by Percolating Defect Networks: Toward Atomically Thin Circuits. Adv. Funct. Mater. 2017, 27, 1702829. [Google Scholar] [CrossRef]

- Cao, J.; Chen, Q.; Wang, X.; Zhang, Q.; Yu, H.-D.; Huang, X.; Huang, W. Recent Development of Gas Sensing Platforms Based on 2D Atomic Crystals. Research 2021, 2021, 9863038. [Google Scholar] [CrossRef]

- Farahani, H.; Wagiran, R.; Hamidon, M. Humidity Sensors Principle, Mechanism, and Fabrication Technologies: A Comprehensive Review. Sensors 2014, 14, 7881–7939. [Google Scholar] [CrossRef]

- Chen, Z.; Lu, C. Humidity Sensors: A Review of Materials and Mechanisms. Sens. Lett. 2005, 3, 274–295. [Google Scholar] [CrossRef]

- Pawbake, A.S.; Date, A.; Jadkar, S.R.; Late, D.J. Temperature Dependent Raman Spectroscopy and Sensing Behavior of Few Layer SnSe2 Nanosheets. ChemistrySelect 2016, 1, 5380–5387. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, K.; Tong, J.; Xia, B. Layer-by-Layer Nanoassembly Fabrication and Humidity Sensing Behaviors of Multi-Walled Carbon Nanotubes/Polyelectrolyte Hybrid Film. J. Nanosci. Nanotechnol. 2016, 16, 6705–6710. [Google Scholar] [CrossRef]

- Li, Y.; Wu, T.; Yang, M. Humidity Sensors Based on the Composite of Multi-Walled Carbon Nanotubes and Crosslinked Polyelectrolyte with Good Sensitivity and Capability of Detecting Low Humidity. Sens. Actuators B Chem. 2014, 203, 63–70. [Google Scholar] [CrossRef]

- Fei, T.; Jiang, K.; Jiang, F.; Mu, R.; Zhang, T. Humidity Switching Properties of Sensors Based on Multiwalled Carbon Nanotubes/Polyvinyl Alcohol Composite Films. J. Appl. Polym. Sci. 2014, 131, 39726. [Google Scholar] [CrossRef]

- Kuzubasoglu, B.A.; Sayar, E.; Cochrane, C.; Koncar, V.; Bahadir, S.K. Wearable Temperature Sensor for Human Body Temperature Detection. J. Mater. Sci. Mater. Electron. 2021, 32, 4784–4797. [Google Scholar] [CrossRef]

- Neamen, D.A. Semiconductor Physics and Devices: Basic Principles; McGraw-Hill: New York, NY, USA, 2012. [Google Scholar]

- Kim, J.S.; Kim, J.; Zhao, J.; Kim, S.; Lee, J.H.; Jin, Y.; Choi, H.; Moon, B.H.; Bae, J.J.; Lee, Y.H.; et al. Electrical Transport Properties of Polymorphic MoS2. ACS Nano 2016, 10, 7500–7506. [Google Scholar] [CrossRef]

- Joung, D.; Khondaker, S.I. Efros-Shklovskii Variable-Range Hopping in Reduced Graphene Oxide Sheets of Varying Carbon Sp2 Fraction. Phys. Rev. B 2012, 86, 235423. [Google Scholar] [CrossRef]

- Mott, N.F.; Davis, E.A. Electronic Processes in Non-Crystalline Materials; Mott, N.F., Davis, E.A., Eds.; Oxford University Press: New York, NY, USA, 2012; ISBN 978-0-19-964533-6. [Google Scholar]

- Sun, L.; Campbell, M.G.; Dincă, M. Electrically Conductive Porous Metal-Organic Frameworks. Angew. Chem. Int. Ed. 2016, 55, 3566–3579. [Google Scholar] [CrossRef]

- Barati, F.; Grossnickle, M.; Su, S.; Lake, R.K.; Aji, V.; Gabor, N.M. Hot Carrier-Enhanced Interlayer Electron–Hole Pair Multiplication in 2D Semiconductor Heterostructure Photocells. Nat. Nanotechnol. 2017, 12, 1134–1139. [Google Scholar] [CrossRef]

- Davaji, B.; Cho, H.D.; Malakoutian, M.; Lee, J.-K.; Panin, G.; Kang, T.W.; Lee, C.H. A Patterned Single Layer Graphene Resistance Temperature Sensor. Sci. Rep. 2017, 7, 8811. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Perebeinos, V.; Freitag, M.; Avouris, P. Carrier Scattering, Mobilities, and Electrostatic Potential in Monolayer, Bilayer, and Trilayer Graphene. Phys. Rev. B 2009, 80, 235402. [Google Scholar] [CrossRef]

- Hwang, E.H.; Adam, S.; Sarma, S. Das Carrier Transport in Two-Dimensional Graphene Layers. Phys. Rev. Lett. 2007, 98, 186806. [Google Scholar] [CrossRef] [PubMed]

- Sehrawat, P.; Abid; Islam, S.S.; Mishra, P. Reduced Graphene Oxide Based Temperature Sensor: Extraordinary Performance Governed by Lattice Dynamics Assisted Carrier Transport. Sens. Actuators B Chem. 2018, 258, 424–435. [Google Scholar] [CrossRef]

- Veeralingam, S.; Badhulika, S. 2D—SnSe2 Nanoflakes on Paper with 1D—NiO Gate Insulator Based MISFET as Multifunctional NIR Photo Switch and Flexible Temperature Sensor. Mater. Sci. Semicond. Process 2020, 105, 104738. [Google Scholar] [CrossRef]

- Adepu, V.; Tathacharya, M.; Mattela, V.; Sahatiya, P. Development of WS2/MXene (Ti3C2Tx) nanohybrid based multi-functional textronic sensor for non-invasive personal healthcare monitoring. Flex. Print. Electron. 2023, 8, 015001. [Google Scholar] [CrossRef]

| Sample Code | 2H-WSe2 (mg) | Acrylic Thickener (mg) | EDAES (μL) | Acrylic Thickener: 2H-WSe2 | Sample Photo |

|---|---|---|---|---|---|

| 2H-WSe2_A | 77.6 | 165.7 | - | 2.1 |  |

| 2H-WSe2_B | 195 | 148.2 | - | 0.8 |  |

| 2H-WSe2_C | 197.5 | 136.3 | 33 | 0.7 |  |

| Type | Textile Substrate | Measurement Range and Sensing Parameters | Ref. | |||||

|---|---|---|---|---|---|---|---|---|

| %RH | °C | Sensitivity | TCR% | Hth% | Response/Recovery | |||

| WS2/Ti3C2Tx | cotton | 40–90% | - | 1.61787 | - | - | ~20.93s/~233.87s | [81] |

| MoSe2@ MXene/CFs | cotton | - | 20–160 °C | - | ~−1.3 × 10−3 | - | - | [39] |

| WS2-QD/RGO | cotton | - | 298–398 K | - | –0.58 | 5.22 | 92.65s/144.16s | [22] |

| WSe2 | cotton | 30–90% | 20–60 °C | ~−100% (at high %RH) | −2.41 (at 60°) | ~96 (at 60 °C) | * 10–30min (%RH cycles) * 1.8 h–2.5 h/1.5 h (temp. cycles) | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trovato, V.; Konar, R.; Teblum, E.; Lazzaroni, P.; Re, V.; Rosace, G.; Nessim, G.D. Humidity- and Temperature-Sensing Properties of 2D-Layered Tungsten Di-Selenide (2H-WSe2) Electroconductive Coatings for Cotton-Based Smart Textiles. Polymers 2025, 17, 752. https://doi.org/10.3390/polym17060752

Trovato V, Konar R, Teblum E, Lazzaroni P, Re V, Rosace G, Nessim GD. Humidity- and Temperature-Sensing Properties of 2D-Layered Tungsten Di-Selenide (2H-WSe2) Electroconductive Coatings for Cotton-Based Smart Textiles. Polymers. 2025; 17(6):752. https://doi.org/10.3390/polym17060752

Chicago/Turabian StyleTrovato, Valentina, Rajashree Konar, Eti Teblum, Paolo Lazzaroni, Valerio Re, Giuseppe Rosace, and Gilbert Daniel Nessim. 2025. "Humidity- and Temperature-Sensing Properties of 2D-Layered Tungsten Di-Selenide (2H-WSe2) Electroconductive Coatings for Cotton-Based Smart Textiles" Polymers 17, no. 6: 752. https://doi.org/10.3390/polym17060752

APA StyleTrovato, V., Konar, R., Teblum, E., Lazzaroni, P., Re, V., Rosace, G., & Nessim, G. D. (2025). Humidity- and Temperature-Sensing Properties of 2D-Layered Tungsten Di-Selenide (2H-WSe2) Electroconductive Coatings for Cotton-Based Smart Textiles. Polymers, 17(6), 752. https://doi.org/10.3390/polym17060752