Lignin from Plant-Based Agro-Industrial Biowastes: From Extraction to Sustainable Applications

Abstract

:1. Introduction

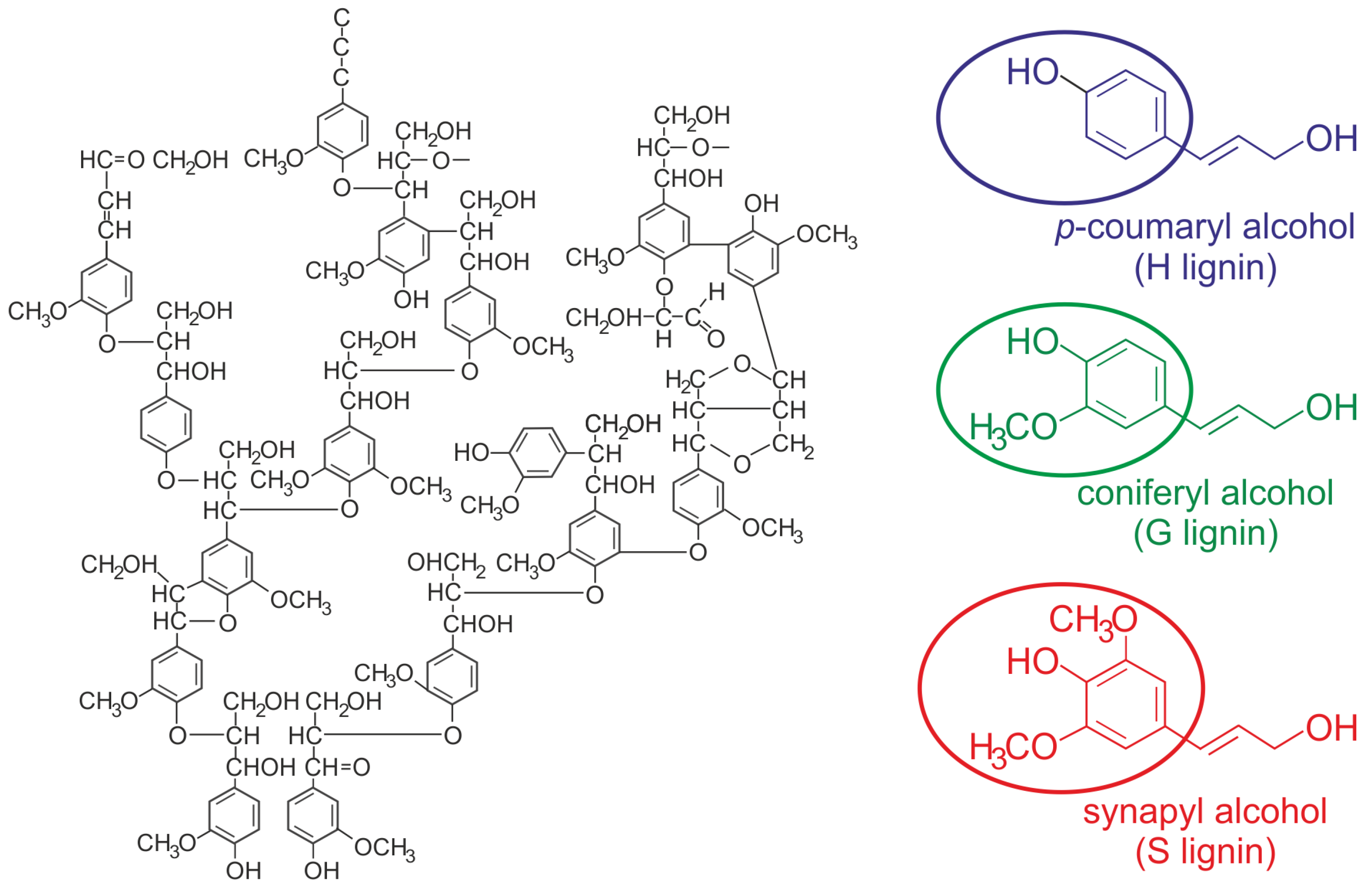

2. Lignin in Lignocellulosic Agro-Industrial Wastes

- 1.

- Ether bond (C-O-C) which can be originated either between two carbon atoms of different benzene rings or between the propane chain of a phenylpropane (elementary unit often referred to as monolignol) and a carbon of a different benzene ring. One type of bond related to the last situation is the -O-4 alkyl–aryl ether, considered the most common interaction in lignin (≃40–60% of connections [4,8]), but weaker than other bonds in lignin. A not-too-high dissociation energy for -O-4 alkyl–aryl ether (289 kJ/mol) [23] allows the biopolymer to break at that position during depolymerization processes. However, -aryl ether bonds are hydrolyzed around 100 times faster (due to a smaller bond dissociation energy, 215 KJ/mol) than -aryl ether bonds.

- 2.

- Carbon–carbon (C-C) bonds between aliphatic chains of different benzenes or between a benzene and another aliphatic chain. This type of link is more difficult to break which accentuates the recalcitrant nature of lignocellulose biomass, with 5–5′ and - bonds representing a high frequency of occurrence, 10–20% and 10–12% of connections, respectively [4].

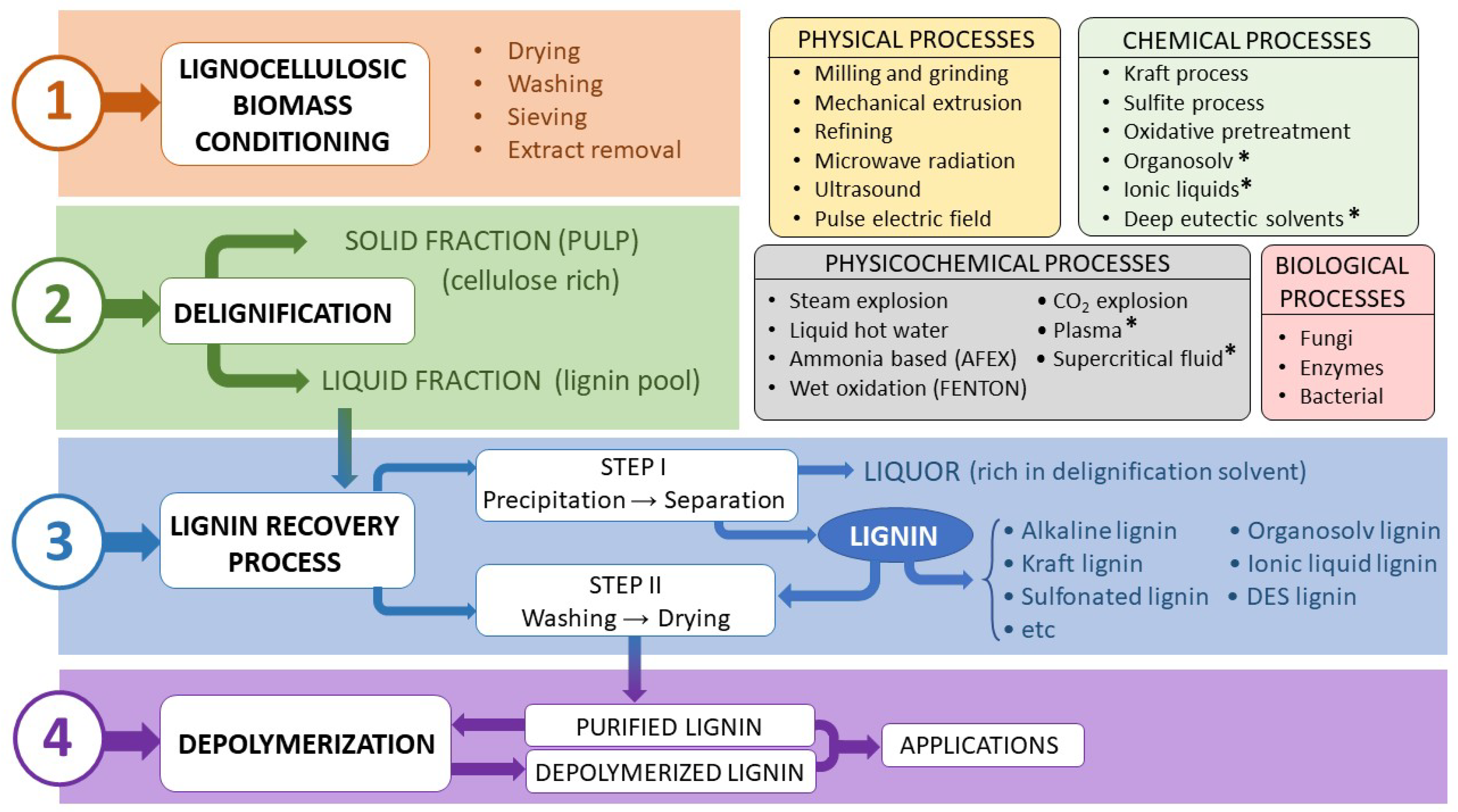

3. Global Process for Lignin Extraction

3.1. Methods for Lignin Extraction

3.1.1. Physical Treatments

3.1.2. Chemical Treatments

- Kraft process: Known as sulfate pulping, this is a chemical treatment used in 85% of cellulose pulp production processes from lignocellulosic materials [170,172,173], with an annual lignin extraction volume in the range of 50–70 million tonnes [174,175]. This process aims to extract lignin by using an aqueous solution (white liquid) of sodium hydroxide (NaOH) and sodium sulfide (S), in the presence of sodium sulfate, although this is not the active form that reacts, and temperatures between 140 and 180 °C [176,177]. The sodium sulfate is used to obtain S. The initial pH of the process is close to 13, although this depends on the initial concentration of the alkaline solution. At this pH, more than half of the S is in the form of sulfide ions, which are hydrolyzed during the treatment to generate and ions to a pH of 10–12 at the end of the kraft process. Both ions ( and ) will attack the biomass, causing the recovery of lignin in the resulting black liquid [178,179], by lowering the pH with or sulfuric acid, among other techniques, until its precipitation. The lignins extracted will have a molecular weight between 1000 and 15,000 g , and will be soluble in both alkalis and organic solvents [177]. Other authors [180] state that the lignin content in the black liquor from the kraft pulp manufacturing process is in the range of 30–45% wt.Another more sustainable alternative, using oxygen in some stages of the kraft process, has been proposed in order to reduce the demand for other chemical agents such as sodium sulfide, bleaching agents or chlorine-derived compounds, and also recover some chemicals from effluents generated in the process, as this stream would be free of corrosive chloride ions [177].Some authors establish the composition of the white liquid by means of the concept “sulfidity” [25]. This technical term is an important parameter in the pulp and paper industry and affects the efficiency of the cooking process and the quality of the final product. It is calculated as the ratio between the amount of sodium sulfide and the amount of active alkali (NaOH + S) in percentage, Equation (2), and it is usually expressed on a O basis. A value of 20% for this parameter is recommended in the case of hardwoods (Eucalyptus), although this optimum value is strongly dependent on the type of biomass, alkali charge, treatment temperature and final product characteristics [178].Although the kraft process has very important advantages in generating a highly purified cellulose pulp (depending on the operating variables), offering easy reagent recovery, it also has drawbacks to overcome such as low yields in the biomass conversion into cellulose, high production costs and corrosiveness in digesters [178]. Apart from that, the lignin generated has 1–3% sulfur due to the incorporation of aliphatic thiol groups in its structure [181], causing a characteristic odor in this type of lignin [176] and environmental pollution; some studies indicate that 70–75% of the hydroxyl groups may be sulfonated [181]. Furthermore, kraft lignin attainment involves severe conditions producing fragmented but also repolymerizated (condensated) lignins, with higher amounts of recalcitrant carbon–carbon bonds and hydroxyl groups, and less ether linkages, making it difficult to break them up, and even less selective [170]. Finally, the precipitated cellulosic pulp could exhibit surface adherences of condensed lignin, decreasing the purity of the pulp obtained. Therefore, approximately 95% of all kraft lignin is currently burned as a low value fuel [170]. In other cases, the extracted kraft lignin can have annexed hemicellulose-related residues, leading to lignins with amphiphilic behavior like surfactants [177].

- Sulfite process: Together with hydrolysis processes, this accounts for 5% of commercial technical lignin [172], representing 1 million tonnes per year [175]. LAIWs can react with a mixture of alkaline earth metal sulfites at 120–180 °C and high pressure for 3–7 h [174]. Sulfite can be formed by reaction between and calcium carbonate or magnesium oxide at a pH of 1 to 5 [177]. This treatment allows the extraction of lignins of an amphiphilic nature, containing both hydrophilic groups such as sulfonates, (highly polar), or hydroxyl groups, with hydrogen bonding capability, but also hydrophobic groups, encompassing aromatic rings and alkyl groups that have relatively non-polar character. The balance between hydrophilic and hydrophobic groups in sulfite lignin determines its overall solubility and compatibility with other materials. It is considered that the high presence of sulfonate groups makes sulfite lignin more hydrophilic than other types of lignin, such as kraft lignin, which has fewer ionic groups. Therefore, sulfite lignins can form polyelectrolytes because they contain ionizable functional groups (sulfonic, carboxyl and phenolic hydroxyls) when dissolved in water, giving rise to a molecule with multiple negative electrical charges. The electrostatic repulsion between the negative charges of the sulfonate groups causes the lignin chain to expand, occupying a larger volume in the solution. This also enhances the solubility of lignin in water through ion–dipole interactions. Subsequent hydrolysis of the formed sulfonates allows lignin to be solubilized in water. These lignosulfonates will have a high molecular weight (1000–50,000 g ), sulfur content of 2.1–9.4%, mainly in the benzylic position, and high ash percentage (4.0–8.0%) [181,182]. On the other hand, polyelectrolytes could interact with cations to give rise to chemical complexes that modify the solution properties.

- Klason treatment: This is a chemical process that involves a first stage of treatment with concentrated sulfuric acid (72%) for 1 h at 30 °C, and a second hydrolysis stage of the residual solid with dilute sulfuric acid (4%) for 1 h at 121 °C [183]. The main drawback of the process is that the extracted lignin is highly altered, so it is only used as a quantitative method at an experimental level.

- Acid treatments: These processes, historically established and appealing due to their cost-effective and high efficiency, have limited utility for biomass delignification. This limitation arises because these pretreatments are optimized for hemicellulose recovery rather than maximizing solubilized lignin extraction. Several industrial companies carry out acid treatments of waste biomass to generate second generation biofuels, although this technology is not yet consolidated, which justifies that research is still ongoing [184]. Many studies use traditional mineral diluted acids such as hydrochloric, nitric, phosphoric and especially sulfuric acid (which is the most employed acid) considering acid concentrations in the range 0.2–8% (w/w), liquid:solid ratios from 5:1 to 20:1 (v/w), temperature range from 80 °C to 210 °C, and reaction times from 5 to 300 min [184,185] in order to preferentially solubilize hemicellulose, amorphous cellulose or soluble lignin, but leading to cellulignin solids in which lignin is still present to a considerable extent. Therefore, hydrolytic treatments with diluted inorganic acids could be of interest only in the case of LAIWs with a low lignin content; using diluted inorganic acids, only delignification percentages of 5–10% can be achieved [184]. Studies using more concentrated acids in the hydrolytic process tend to use lower temperatures (<60 °C), higher solid:liquid ratios from 1:2.5 to 1:10 (w/v) and acid concentration of more than 10% (w/v) [12,185,186]. Some authors mention in their studies acid concentrations as high as 65–86% (w/v) sulfuric acid, 41% (w/v) hydrochloric acid or 85% (w/w) phosphoric acid [187], and times in the range 2 to 10 h under atmospheric pressure [12]. Problems of equipment corrosivity, partial cellulose solubilization (especially amorphous fraction), mandatory need to recover the acid and production of undesirable compounds (e.g., inhibitors), in residual liquid streams, contribute to the environment pollution and cost increase. For these reasons, other environmentally friendly alternatives, employing weak organic acids such as formic, maleic, acetic, oxalic, citric, propionic or lactic acids, have been proposed. Some of these acids (formic, acetic, propionic or lactic) are considered “organosolv” because of their low toxicity, low cost and high recoverability. Specifically, Singh et al. [188] employed wheat straw and bagasse by applying a sequential treatment with concentrated sulfuric acid and then dilute acid, achieving lignin recovery percentages of 21.5% for one of the bagasse types. Table 2 presents the experimental conditions and delignification percentages of the most recent studies.

| LAIWs | Experimental Conditions | Delignification, % | Ref. |

|---|---|---|---|

| Sugarcane straw | Acetic acid 7.51 g LAIW-6.7 mL acid + 20 mg | 91.0 | [189] |

| Coffee husk | NaCl four times, 60 min, 80 °C | 80.0 | |

| Corn cob | p-Toluenesulfonic acid 70%, 70 °C, 30 min | 82.4 | [52] |

| Corn stover | Acetic acid 2%, 12 ± 2 h, 15 psi, 121 °C, 90 min 1 g LAIW-15 mL acid | 75.7 | [190] |

| Empty palm fruit bunch | 2% w/v, 150 °C, 30 min | 65.7 | [191] |

| Rice husk | 2% (v/v), 120 °C, 60 min 1 g LAIW-10 g acid | 18.8 | [192] |

| Rice straw | 0.75%

(v/v) +

Boric acid 1% (w/v) + glycerol 0.5% (v/v) 1 g LAIW-5 mL acid, 150 °C, 20 min | 44.0 | [193] |

| Acetic acid 99%, 80 °C, 24 h 1 g LAIW-10 mL acid | 4.7 | [29] | |

| p-Toluene sulfonic acid 60% (w/w), 80 °C, 45 min | 52.4 | [194] | |

| Sugarcane bagasse | Formic acid 80.0%, 130 °C, 90 min 1 g LAIW-10 mL acid | 90.6 | [195] |

| 1.5% (v/v), 121 °C, 20 min 1 g LAIW-10 mL acid | 33.1 | [196] | |

| Soybean hull | Citric acid 4.22%, 120 °C, 105 min 1 g LAIW-15 mL acid | 30.4 | [149] |

| Wheat straw | p-Toluenesulfonic acid 15%, 25%, 35% (w/w) 90 °C, 120 min | 24, 48, 66 | [197] |

| Maleic acid 60% (w/w) 110 °C, 60 min | 66.5 | [198] | |

| Sulfuric acid 1.5% (w/w) 121 °C, 15 lb/inch2, 75 min | 74.0 | [199] |

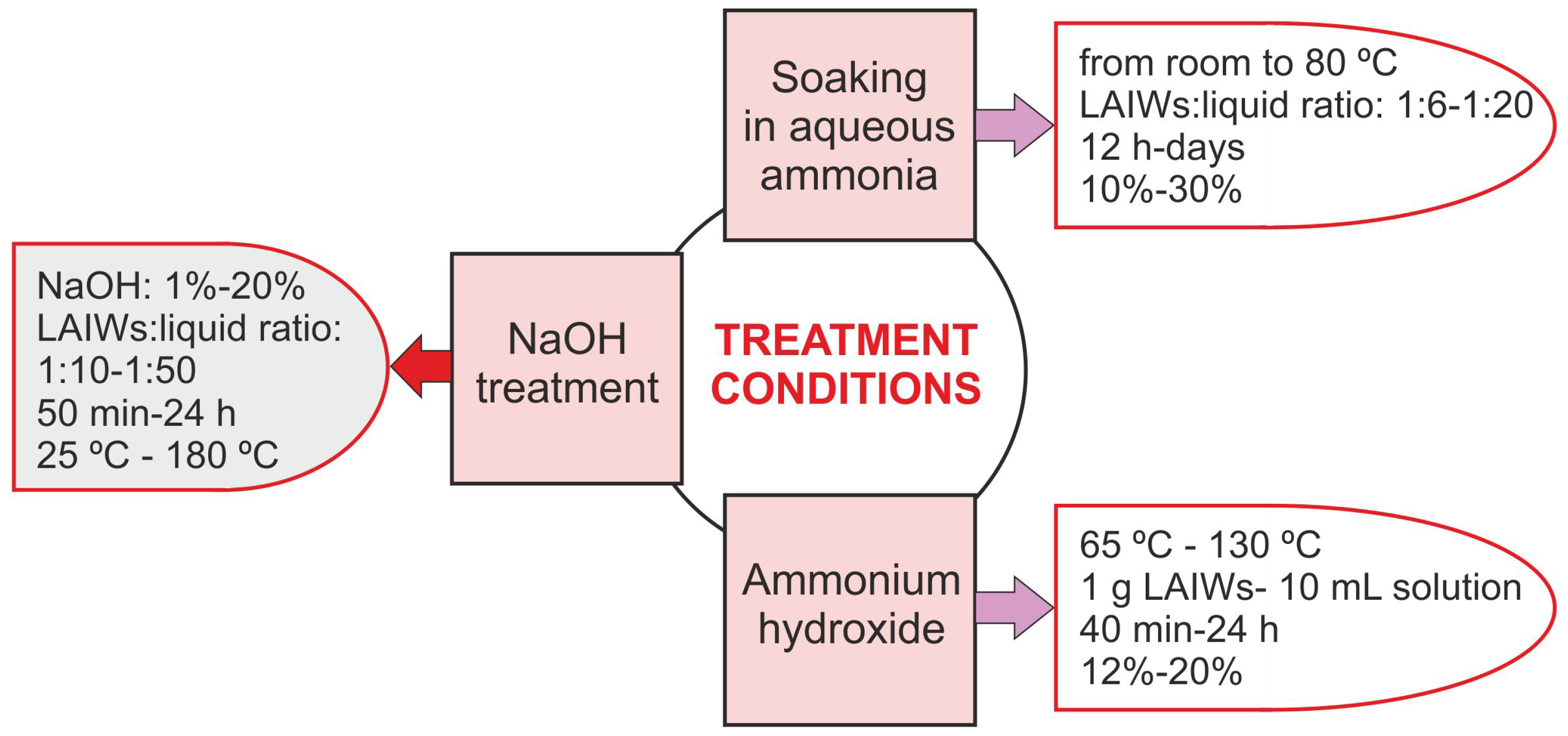

- Alkaline (AK) treatments: One of the best known hydrolytic processes is the so-called “soda pulping”, the preferred pulping process for agro-waste fractionation [174]. This chemical method uses NaOH solutions (10–16%) at high pressures and temperatures (140–170 °C) to produce the alkaline hydrolysis of LAIWs and extract the lignin (soda lignin) although anthraquinone is sometimes added in order to stabilize the hydrocelluloses [174,177]. It is traditionally applied to non-wood matrices like straw or bagasse [11] and allows obtaining 15% of the lignin marketed [172], with an annual extraction of 6000 tonnes [175]. In this case, the extracted lignin (soda lignin) is lighter in color, more soluble in water and has lower sulfur content compared with kraft lignin. Furthermore, it has a low molecular weight (generally 1000–3000 g ) and methane emissions are produced [201]. The application of soda extraction processes leads to efficient depolymerization of the material, extracting alkaline lignin (AL) with very high purity [202] and zero sulfur content [181]. Furthermore, soda lignins contain more hydroxyl groups and relatively more carbon–carbon bonds compared to native lignin [177]. The values of the combined severity factor for soda pulping are usually in the range of 0.3–4.5 for this type of process [170], so that an increase in the degree of delignification from 25.3% to 95.4% has been evidenced when the severity varies from 1 to 5, respectively. However, from combined severity factor values above 3, lignin starts to be degraded, undergoing changes in its structure as condensation reactions take place [170]. In this sense, poplar wood hydrolysis solid was subjected to alkaline lignin extraction (NaOH, 1 M at 75 °C, 3 h) recovering 48% lignin [203]. Ammonium hydroxide, anhydrous ammonia, sodium carbonate and sodium sulfite have also proven to exhibit LAIWs delignification, Table 3. Figure 3 resumes the conditions of the main alkaline treatments.

| LAIWs | Experimental Conditions | Delignification, % | Ref. |

|---|---|---|---|

| African oil palm fiber Coffee pulp waste Sugarcane bagasse | Ca(OH)2 0.1% (w/w)

40 °C, 1 g LAIW-28 mL solution | 31.3 35.0 32.8 | [204] |

| Banana stem | KOH 1–5% (w/w), 90 °C, 25 min 1 g LAIW-10 mL solution | 43.0 | [205] |

| Sugarcane bagasse Coconut husk Rice straw Corn stover | NaOH 3% 1:12 (w/v)

121 °C, 15 psi | 31.3 38.5 19.4 15.8 | [202] |

| Chestnut shell | NaOH or KOH: 1–5% (w/w) | 15.5–51.1 | [206] |

| Corncob | 0.5–4%

(w/v)

30–70 °C, 1–8 h 1 g LAIW-10 to 30 g solution | 46.8 | [205] |

| Corn stalk | NaOH 1.5%

(w/v), 121 °C, 30 min 1 g LAIW-10 g solution | 42.2 | [207] |

| Corn stover | OH 12%

(w/w)

130 °C, 40 min 1 g LAIW-10 mL AK solution | 75.1 | [208] |

| 29.5% room temperature, 60 days | 73.5 | [209] | |

| 15.0%

60 °C, 12 h | 62.0 | [209] | |

| 15.0%

90 °C, 1 g LAIW-12.5 mL solution | 68.9 | [210] | |

| 15.0% (w/w)

60 °C, 12 h 1 g LAIW-10 mL AK solution | 70.0 | [211] | |

| Groundnut shell | NaOH 1.75 N

80 °C, 6 h, 400 rpm 0.8 g LAIW-100 mL AK solution | 41.8 | [212] |

| Miscanthus giganteus | NaOH 0.16–1.0 mol/L

100–180 °C, 60–360 min, 360 rpm | 25.3–95.4 | [170] |

| Olive pomace | NaOH 8% (w/v), 50 °C, 24 h 1 g LAIW-59 mL AK solution | 68.0 | [213] |

| Pistachio shell | NaOH 1.75 N

80 °C, 6 h, 400 rpm 0.8 g LAIW-100 mL AK solution | 38.0 | [212] |

| Rice hull | 20%, 100 °C, 1 g LAIW-10 mL | 62.0 | [214] |

| Rice straw | 8% 140 °C, 1 g LAIW-6 g solution | 41.8 | [208] |

| : 5% 121 °C, 60 min, 15 psi 1 g LAIW-10 mL solution | 78.4 | [215] | |

| 2–10% (w/v)

80 °C, 180 min, 15 psi 1 g LAIW-10 mL solution | 28.3–60.5 | [216] | |

| Sugarcane bagasse | NaOH 5, 10, 15% KOH: 5, 10, 15% 98 °C, 90 min 1 g LAIW-10 mL AK solution | 5.0–17.4 9.7–18.3 | [217] |

| Urea/KOH (1:1 ratio) 3–12% −20 °C, 1–12 h 1 g LAIW-(20–50) g AK solution | 41.5 | [218] | |

| 1.5% (w/w) NaOH 1.5% (w/w) 121 °C, 20 min 1 g LAIW-10 mL solution | 35.3 38.3 | [196] | |

| NaOH 6% (w/w), 90 °C, 60 min 1 g LAIW-15 mL solution | 81.0 | [219] | |

| OH 20% (v/v) 70 °C, 24 h | 41.5 | [220] | |

| Sugarcane straw | NaOH 1% (w/v) 10% (w/v) OH 10% (w/v) 120 °C, 60 min, 1 g LAIW-10 g AK solution | 28.5 25.1 46.3 | [221] |

| Sweet sorghum residue | NaOH 2%

121 °C, 50 min, 15 psi 1 g LAIW-10 mL AK solution | 41.8 | [222] |

| Wheat straw | NaOH 0.1 M room temperature, 120 min 1 g LAIW-10 mL solution | 21.1 | [223] |

| OH 15% (w/w) 65 °C, 15 h 1 g LAIW-10 mL solution | 50.0 | [224] | |

| 15% (w/w) room temperature, 7 days 1 g LAIW-20 mL solution | 9.0 | [225] |

- Hydrotropic extraction: A novel development for the fractionation of LAIWs is the use of hydrotropic compounds in aqueous solution, that contain hydrophilic and hydrophobic groups (with very short chains), such as (sodium or potassium) alkyl benzene sulfonates, xylene sulfonates, toluene sulfonates, salicylates and urea. These compounds have the ability to increase the solubility of lignins, that are normally insoluble in water, during the initial treatment phase. Subsequently, the lignin may be precipitated by diluting the hydrotrope solution with water [226] so, in many experimental studies, quite acceptable delignification percentages of LAIWs have been obtained, Table 4.

| LAIWs | Hydrotropic Solvent | Experimental Conditions | Delignification, % | Ref. |

|---|---|---|---|---|

| Rice straw | Sodium cumene sulfonate 20% | 1 g LAIW-20 g acid, 121 °C, 1 h, 50% | 50.0 | [227] |

| Sodium xylene sulfonate 20% | 34.0 | |||

| Sugarcane bagasse | Sodium xylene sulfonate 40% | 170 °C, 1 h | 6.8 | [228] |

| Sodium xylene sulfonate 30% | 1 g LAIW-2 g hydrotrope 115 °C | 85.0 | [229] |

- Organosolv treatment: Process to extract technical lignin from LAIWs, using several organic solvents (30–100% w/w), solid–liquid ratios in the range 1:2 and 1:15, although 1:10 balance is the most common, temperatures in the range 100–250 °C (temperatures > 180 °C are required for higher delignification) and residence times from 30 to 60 min [177,230,231]. This treatment is implemented on a pilot scale for raw biomass with an annual organosolv lignin extraction of 1000 tonnes [175]. One such method is the “Alcell” process, which uses ethanol: water mixtures (1:1) at 180–210 °C and 2–3.5 MPa to solubilize lignin from lignocellulosic biomasses [232]; the “Alcell” process has evolved into the “Lignol” process whose main difference is the addition of an inorganic acid (e.g., sulfuric acid) to maintain the pH in the range 2–3.7 [233].Other organosolv pretreatment with the addition of catalysts is becoming the focus of much research for LAIWs [230]. Although ethanol is the most common solvent involved due to its advantageous properties (low cost and toxicity, high quality of the recovered lignin and high recyclability [231,234]), other organic solvents are involved, such as methanol, 1-butanol, isobutanol, 2-methyltetrahydrofuran (MeTHF), tetrahydrofuran (THF), glycerol, ethylene glycol, cyrene, triethylene glycol (TEG), polyethylene glycol (PEG), acetone, formic acid, acetic acid, dimethyl isosorbide, ethyl lactate and -valerolactone, being used for LAIWs depolymerization and subsequent lignin recovery. Although there is research based on dioxane treatments, its use in industrial processes has been severely restricted due to the risks it poses to human health and the environment. Organosolv treatment achieves, in many cases, high lignin removal rates (>70%) with low loss of cellulose (<2%) [235], but research needs to address their main disadvantages: high material cost, solvent volatility and solvent recovery cost [236]. Table 5 shows organosolv experimental conditions and grades of delignification for different LAIWs.Table 5. Experimental conditions for organosolv delignification using LAIWs.

LAIWs Organosolv Solvent Experimental Conditions Delignification, % Ref. Bamboo culms

Formic acid:acetic acid:water

30:50:20 v/v/v1 g LAIW-20 mL OS

60 °C, 1 h + 107 °C, 3 h31.5

[237]

Corn stalks

Formic acid:acetic acid:water

60:30:10 v/v/v1 g LAIW-5 g OS

90 °C, 180 min18.6

[238]

Corn Methanol 0–2.5% w/v 1 g LAIW-2 mL OS 55.0 [239] stover (alkali catalyzed) 80 °C, 60 min 70.7 [240] Corn straw Cyrene 50% w/w 120 °C, 60 min 78.0 [231] Cotton stalks

Formic acid 100%

2% w/w1 g LAIW-10 g OS

80 °C, 60 min81.0

[207]

Rice straw

Glycerol 90% w/w (salt catalyzed) 1 g LAIW-20 mL OS 150 °C, 20 min 71.9

[241]

Sugarcane

bagasseEthylene glycol 90% v/v

(acid catalyzed)1 g LAIW-10 mL OS

150 °C, 60 min67.1

[242]

Ethylene glycol 90% v/v

(acid catalyzed)1 g LAIW-20 mL OS

120 °C, 60 min, 1% HCl61.2

[243]

Ethanol 60% v/v

(acid catalyzed)1 g LAIW-10 mL OS

170 °C, 15 min, 25 g86.0

[244]

Ethanol 60% v/v

(alkali catalyzed)1 g LAIW-10 mL OS

180 °C, 30 min, 8% NaOH82.6

[245]

TEG 5% w/v

(alkali catalyzed)1 g LAIW-20 mL OS

90 °C, 120 min, 1% NaOH80.0

[246]

Wheat straw

Water–ethanol 3:7 to 1:9 v/v

1 g LAIW-25 mL OS

90 °C, 120 min50.0

[247]

Glycerol 70%

1 g LAIW-10 g OS

220 °C, 3 h65.0

[248]

Recently, the role of certain organic compounds to prevent lignin repolymerization processes has been discovered. Thus, compounds such as 2-naphthol and dimethyl phloroglucinol have been used to stimulate delignification processes, protecting lignin from condensation reactions [249].These compounds can yield lignin practically free of sulfur (0–0.3% [181]), molecular weight of 500 to 5000 g and also having high purity and reactivity, preserving almost completely the chemical structure of the natural lignin [177] without condensation. Furthermore, organosolv lignin has a high hydrophobic character, so it is practically insoluble in water favoring lignin precipitation processes for its recovery. Research is currently prioritizing the application of this method due to the low environmental impact of the process and the high purity of the lignin recovered, although further study is needed to improve the economic aspects of the process, for example, towards the recovery of the solvents used. In this sense, only solvents with low boiling points are easy to recycle by evaporation, but they are volatile and highly flammable with requirements of expensive high-pressure equipment. On the other hand, solvents with high boiling points present recovery problems; impurities can appear frequently [231]. - Ionosolv treatment (IL): Chemical treatment that intends to use ionic liquids, salts with low melting point (usually <100 °C) [4], to recover lignin (and hemicellulose) from LAIWs, leaving the cellulose unaltered. Other advantageous properties of ionic solvents, apart from being in a liquid state at a low temperature, encompass their non-volatility and non-flammability, high conductivity and thermal stability [250], but some drawbacks are also presented concerning the high cost for the production of these solvents [251]. Although some ionic solvents used in the past were labeled as toxic and corrosive (contain anions such as , , , [ and [), there is now a shift towards more environmentally friendly liquids. According to some studies, the constituent cations of the salts belong to different groups (quaternary ammonium or phosphine salts, imidazole and pyridine), while the most advisable anions are [ (acetate), [ (glycinate), [ (citrate), [ (hydrogen phosphate), [ (dihydrogen phosphate), [ (tosylate), [ (mesylate), [CH(OH) (lactate), etc. [251]. When treatments are carried out at high temperatures, phosphonium-based ionic solvents are preferred to imidazolium- and ammonium-based ionic solvents, as the stability of phosphonium salts is higher.

- Deep eutectic solvent (DES) treatment: This is considered an environmentally friendly chemical alternative for lignin extraction as solvents are required have low toxicity, high recyclability and biodegradability; other properties are non-flammability, being 20% cheaper than ionic solvents, high chemical and thermal stability, low vapor pressure, low volatility and biocompatibility [252,253,254]. This process generally consists of a binary system based on two organic components (solids under normal conditions): one of them is a hydrogen bond donor (HBD) and the other a hydrogen bond acceptor (HBA). Both compounds result in a mixture with a melting point much lower than the one for each compound separately [255], due to charge delocalization via hydrogen bonds between molecules of both organic compounds [256]. The main groups of HBA are quaternary ammonium, phosphonium or sulfonium halide salts [257], choline chloride (ChCl) being the most common natural deep eutectic solvent because of the low toxicity of cholinium, although mixtures consisting of choline chloride:glycerol and betaine: amino acid are also frequently reported. Concerning HBDs, the most relevant chemicals are amide, carboxylic acid [257] and polyols [258], but other solvents may also be used. In summary, Table 6 shows various HBAs or HBDs reported in recent studies with DESs. The most commonly used DESs for biomass processing are usually based on the following types of mixtures: quaternary ammonium salt with hydrated metal halide, due to their resistance to air and moisture, and lower melting point compared to non-hydrated forms, as well as quaternary ammonium salts and carboxylic acids for their low cost and easy preparation. Additionally, inorganic transition metals and some HBDs such as urea can also be used. Recently, incipient research is underway considering only non-ionic molecules with ambiguous HBD/HBA roles in DESs [259], as is the case of the combination of N-methylacetamide and a long-chain carboxylic acid (lauric acid) [223]. Microwave radiation-assisted DES treatments have sometimes been used, so that solvents with high electrical conductivity and high dielectric constant favored collisions with lignocellulosic biomass, promoting delignification processes [259].Table 6. Main hydrogen bond acceptors and donors in deep eutectic solvent technology.

Hydrogen bond acceptors (HBAs) Choline chloride (ChCl), N,N-diethyl-2-hydroxy-N-(2-hydroxyethyl)ethan-1-aminium chloride, Ammonium chloride, Tetra-hydroxymethyl phosphonium chloride (TPC), Tetramethyl-ammonium chloride (TMAC), Tetraethyl ammonium chloride (TAC), Tetrabutylammonium chloride, Tetrabutylammonium hydroxide (TAH), Methyltriphenylphosphonium bromide, Triethyl benzyl ammonium chloride (TEBAC), N-benzyl-2-hydroxy-N,N-dimethylethanamine, Tetraethylammonium chloride, Benzyltriethylammonium chloride (BTEAC), 2-acetate-N,N,N-trimethylethanaminium chloride, Glyoxylic acid (GA), Betaine (Be), Hydrated metal halide: AlCl3·6H2O; FeCl3·6H2O; CrCl3·6H2O, FeCl2·4H2O [253,256,258,259,260,261,262,263] Hydrogen bond donors (HBDs) Urea, Formamide, Thiourea ethanolamine (EA), Diethanolamine (DEA), Methyldiethanolamine, 3-aminopropanol (AP), Isopropanolamine (IPA), Triethanolamine (TEA), N-methyldiethanolamine (NMDEA), 1,3-diamino-2-propanol (DAP), 2-amino-1,3-propanediol (ADP), 4-hydroxy benzyl alcohol, Ethylene glycol (EG), Propylene glycol 1.4-butenediol, Acetamide (AC), Benzamide, Glycerol, Imidazole, Boric acid (BA), Monocarboxylic acids: glycolic, lactic (LA), levulinic, acetic (AA), formic (FA), propionic, butyric, octanoic, decanoic, Di or tricarboxylic acids: malonic, oxalic (OA), succinic, malic (MA), maleic, glutaric and citric (CA) acids, Glucose, Fructose, Sucrose, Xylitol, Salicylic acid, Gallic acid, p-coumaric acid, Vanillin, p-hydroxybenzoic acid, p-hydroxybenzaldehyde, p-hydroxybenzyl alcohol, Catechol, Resorcinol, Glycerol (Gly) Both HBDs and HBAs Menthol (Men)

2,6-dimethoxyphenol (Dmp)[99] DESs have a high viscosity, due to the existence of hydrogen bonding, electrostatic interactions and van der Waal forces between HBAs and HBDs. Some studies have linked a higher viscosity for those DESs with a higher number of hydroxyl groups, in the chemical composition of HBDs, due to the formation of a higher number of hydrogen bonds [259]. Nevertheless, viscosity can be lowered by both increasing the temperature or dilution with water to break the existing bonds, originating HBD–water interactions, although dilutions above 30% are not advisable [257]. Density is also an important factor for DES mobility and activity: the more hydroxyl groups and the shorter chain length of the HBDs, the higher density of the DESs [264]. In addition, the chemical nature of the HBDs could also condition the effectiveness of the lignin fractionation process. Effectiveness in DESs can be improved if some remarks are considered such as shortening alkyl chains in carboxylic acids, using monocarboxylic acid-based HBDs instead of di- or tri-carboxylic acids, increasing the presence of hydroxyl groups in a-hydroxyl acid-based DES, increasing the amount of amine/amide groups in HBDs and enhancing HBD:HBA molar ratio in DES [259]. In general, the molar ratio between HBDs and HBAs will affect the physicochemical properties (density, viscosity, polarity, melting point, etc.) of the generated mixture [265].Recent research has shown the suitability of incorporating co-solvents into the initial eutectic mixtures to increase the efficiency of biomass fractionation. In this sense, the incorporation of substances such as O or small amounts of water to DES systems would favor the fractionation and cleavage of lignin bonds, as a large amount of acid protons could be generated. Apart from that, the addition of water would decrease the viscosity and increase the diffusivity and interactions of DESs in the biomass [259]. Other advances in the field of fractionation with DESs are based on the use of simultaneous technologies, in particular the use of DESs combined with physical treatments such as microwave radiation and ultrasound techniques, promoting both the breaking of chemical bonds and the appearance of cavities or micropores, that favor the action of eutectic solvents.Lignins from DES treatment are characterized by a large number of phenolic hydroxyl groups and small molecular size [266]. Although the effectiveness of the use of DESs has been demonstrated, one of the main concerns related to eutectic solvents is that it results in more condensated lignin extraction. Although condensated lignins imply positive aspects for both the manufacture of composite materials and activated carbon production (increased surface area, more functional groups and less rigid structure), they also have serious drawbacks when soluble lignin is required, also hindering enzymatic hydrolysis as undesirable lignin could be deposited on the cellulose surface, hindering the cellulose activity [253]. Several studies have shown that deep eutectic solvents used for lignocellulosic material delignification have resulted in lignins with a large number of hydroxyl groups and high antioxidant activity, therefore promoting their reactivity and use [254]. To minimize the undesired effect of lignin condensation, recent research points to the use of ternary mixtures, e.g., by adding polyol-based solvents, such as ethylene glycol, to certain binary mixtures (choline chloride–oxalic acid). These polyols would react with benzylic intermediates in a -position with respect to the -O-4 ether bonds, inhibiting lignin condensation [267]. The precise mechanisms involving DES biomass delignification are still under investigation but the high capacity for DESs to form hydrogen bonds, interacting with lignin functional groups (hydroxyl, phenolic, methoxyl, etc.) against groups present in cellulose and hemicellulose could explain LAIW depolymerization, interacting and leading selectively to the preferential dissolution of lignin [268]. Table 7 summarizes some of the most recent research with DESs for different LAIWs. Although dependent on the type of DES used and the extraction conditions, the lignins extracted will, in general, have greater thermal stability, due to a lower presence of labile functional groups in their structure, with higher molecular weight and more conserved structure, as they are extracted with milder solvents, compared to lignins extracted by traditional basic or acidic methods.On the other hand, since around 2020, much research work has focused specifically on the use of lignin extraction methods adapted to preserve the structural characteristics of the lignin in the original material, so that it undergoes as few modifications as possible during the polymer extraction process. In this way, the field of application of the lignins obtained could be extended by applying specific depolymerization processes according to the applications to be given to the lignins obtained.

| LAIWs | DES | Experimental Conditions | Delignification, % | Ref. |

|---|---|---|---|---|

| Boehmeria nivea stalks | Be:GA 1:6 molar ratio | 1 g LAIW-10 g DES 130 °C, 2 h | 81.9 | [263] |

| Brewer’s spent grains | ChCl-LA/ChCl-Gly

1:10; 1:2 molar ratio | 1 g LAIW-20 g DES 60–80 °C, 24 h | 34.5–39.3 | [262] |

| Camellia oleifera shell | ChCl-EA/ChCl-AP/ChCl-IPA 1:6 molar ratio | 1 g LAIW-20 mL DES 90 °C, 1–12 h | 59.9 | [261] |

| Corncob | ChCl-Gly/ChCl-urea/ChCl- Imidazole 1:2; 1:2; 3:7 molar ratio | 1 g LAIW-16 g DES 115 °C, 15 h | 88.0 | [269] |

| Be-Lysine/Be-Arginine/ Be-Histidine 1:1 molar ratio | 1 g LAIW-10 to 25 g DES 60 °C, 5 h | 24.4–57.0 | [270] | |

| Corn stover | ChCl-LA/TMAC-LA 1:2 molar ratio | 1 g LAIW-10 g DES 130 °C, 2 h | 62.6 | [271] |

| Corn straw | ChCl-LA/Be-LA 1:2 molar ratio | 1 g LAIW-20 mL DES 120 °C, 6 h | 32.3–89.7 | [272] |

| Industrial xylose residues | Guanidinium hydrochloride-LA 2:1 to 1:2 molar ratio | 1 g LAIW-20 mL DES 120 °C, 2 h | 57.5–73.5 | [273] |

| Oil palm empty fruit brunch | ChCl-different

carboxylic acids | 1 g LAIW-10 g DES 120 °C, 8 h | >60.0 | [274] |

| ChCl-LA 1:2 molar ratio | 1 g LAIW-10 mL DES 100–120 °C, 10-30 min | 9.1–57.1 | [275] | |

| Reed straw | BTEAC-FA 1:2 to 1:6 molar ratio | 1 g LAIW-10 g DES 130 °C, 3 h | 78.1 | [276] |

| Be:LA:H2O 1:5:5 molar ratio | 1 g LAIW-20 g DES 80 °C, 24 h | 52.0 | [277] | |

| Rice straw | MA-proline/ChCl-OA/ChCl-urea 1:3; 2:1; 1:2 molar ratio | 1 g LAIW-10 g DES 120 °C, 4–12 h | 35.0–75.0 | [278] |

| ChCl-glycerol 1:3 to 1:9 molar ratio | 1 g LAIW-19 g DES 80–150 °C, 3–24 h | 53.3–74.2 | [279] | |

| Sugarcane bagasse | ChCl-LA/ChCl-CA/ChCl-AA

1:4 to 4:1 molar ratio | 1 g LAIW-15 mL DES 130 °C, 90 min | 2.7–54.5 | [280] |

| ChCl-OA/ChCl-trifluoracetic acid 1:2 to 1:1.5 molar ratio | 1 g LAIW-19 g DES | 51.0–56.0 | [281] | |

| ChCl-LA/Be:LA 10–5% w/w | 1 g LAIW-9 g DES 140 °C, 2 h | 16.6–39.4 | [282] | |

| Wheat straw | ChCl-CA-EG; ChCl-MA-EG;

ChCl-FA-EG; ChCl-AA-EG; ChCl-BA-EG; ChCl-LA-EG | 1 g LAIW-20 g DES 80–140 °C, 3–24 h | 35.7–92.4 | [253] |

| TEBAC-Gly-Al chloride 1:2:0.05 molar ratio | 10 g LAIW-3% DES 100 °C, 16 h | 1.2–7.8 | [283] | |

| Gly-K2CO3 1:5 molar ratio | 1 g LAIW-10 g DES 100–140 °C, 1 h | 70.5–83.0 | [284] |

- Oxidative treatments: These promote delignification processes using chemical oxidants, Table 8, such as alkaline hydrogen peroxide (), wet oxidation, organic peracid pretreatments, Fenton oxidation and ozone technology [234]. As this process takes place under conditions of medium severity, the formation of inhibitory compounds is more unlikely than other promising technologies with options to be implemented on an industrial scale (such as steam explosion).Hydrogen peroxide is considered by many authors to be an effective treatment that promotes sustainability [285]. This oxidative compound, in strongly alkaline media, generates hydroxyl (·OH) and superoxide radicals (), with a strong oxidizing character, encouraging lignin depolymerization. While medium-severity conditions in oxidative treatments with allow attacking mainly the hydrocarbon chains of lignin, more severe treatments would oxidize aromatic rings. It has been noted that, at pH higher than 10, the effectiveness of the hydrogen peroxide is high but no delignification was achieved below this value [286].These hydroxyl radicals are also produced by the Fenton process based on the oxidation, in a more efficient way, of LAIWs using and hydrogen peroxide under acidic conditions, to avoid the loss of reagent by the formation of complexes of this cation or the formation of Fe(OH)3, in the case of basic conditions [287]. Treatment by wet oxidation implies using oxygen (or air) and water at 120–238 °C and 3–35 air bars with lower production of inhibitors but higher production of collateral products, compared to other techniques (e.g., steam explosion) [234].

| LAIWs | Oxidative Treatment | Experimental Conditions | Delignification, % | Ref. |

|---|---|---|---|---|

| Brewer spent grains | Hydrogen peroxide

(alkaline conditions) | 1–8% , 20 °C, 0–12 h, pH = 11.5 1 g LAIW-12.5–50 g oxidant | 17–36 | [288] |

| Chinese hickory shell | Hydrogen

peroxide (alkaline conditions) | 0–3 mL (30%), 20 °C, 300 rpm, 3 h 1 g LAIW-15 mL oxidant | 50.0 | [289] |

| Oil palm empty fruit bunch | Fenton | 200 mM , 24 h, room temperature 1 g LAIW-50 mL oxidant | 71.2 | [287] |

| Rice husk | Hydrogen peroxide (alkaline conditions) | 1% , 5.3% NaOH, 20 °C 0–12 h, 150 rpm | 59.6 | [290] |

| Sisal waste | Ultraviolet-catalyzed hydrogen peroxide (alkaline conditions) | 0.05–0.4 g /g LAIW, pH = 10 1 g LAIW-20 mL oxidant | 76.2 | [291] |

| Toonna sinensis branches | Hydrogen

peroxide + acetic acid (100 mM as catalyzer) | 12% , 37.6% acetic acid, 170 °C, 90 min | 77.0 | [292] |

| Wheat straw | Hydrogen peroxide (alkaline conditions) | 4% , 110 °C, 2 h, pH = 11.5, 400 rpm 1 g LAIW-40 mL oxidant | 70.7 | [293] |

3.1.3. Physicochemical Treatments

- Liquid hot water (also known as autohydrolysis [294]) is a hydrothermal method focused on the solubilization mainly of hemicellulose (with the generation of oligosaccharides and monosaccharides), although the solubilization of smaller amounts of lignin can also be achieved; in particular, delignification percentages of 20–30% can be reached [295]. Pressurized water is used to carry out the hydrolysis of LAIWs involving an auto-catalyzed process by both hydronium ions, generated by the ionization of water, and the action of acetic acid formed from the acetyl groups, released from the hemicelluloses. Additionally, the way in which lignin depolymerization takes place is strongly dependent on the experimental conditions (mainly temperature, reaction time and solid:liquid ratio). Although more severe conditions would imply higher degrees of delignification of residual biomasses, bioproducts that are difficult to control would also be extracted, so typical conditions (140–240 °C and liquid:solid ratios of 10, [12,294,296]) are geared towards biofuel more than lignin extraction. Frequently, the terms “subcritical water” and “liquid hot water” are often used interchangeably to describe water that is at temperatures above its normal boiling point but below its critical point. From a more general point of view, this treatment consists of using water at temperatures between 100 °C and 374 °C and pressures high enough to keep it in a liquid state (under 1–20 MPa for 10–50 min) [296]. Some researchers have shown that the use of subcritical water as a one-stage method is not effective the for delignification of LAIWs [297] and they are frequently used for both bioactive compounds and sugars production. Nevertheless, delignification data (13.73%) have been obtained using mango seed shell (180 °C, 15 min, 2.5 MPa) [298]. More recent studies employ subcritical water in combination with other techniques such as deep eutectic or ionic solvents [299], obtaining significant delignification, especially by the contribution of other solvents apart from water [300], Table 9.

- Steam explosion method: This is a hydrothermal treatment considered as an environmentally friendly technique for four relevant reasons: the main agent used is water vapor, an abundant and renewable resource, high energy efficiency, low use of chemical reagents (diluted acid or alkali) and recovery of almost intact lignin. The disintegration of the biomass occurs by abrupt decompression after reaching high temperatures and pressures, usually in the ranges (160–270 °C) and (10–50 bars), respectively [39,301]. Residence times (2–40 min) and biomass properties (moisture content or particle size) are also determining factors in the depolymerization process of LAIWs [301,302,303]. Considering the reduction in fermentation inhibitors, the combination of a low temperature and longer residence time may be a better choice. In contrast, the option of a short residence time at high catalyst concentrations is less ideal [163].Finally, the concentration of the main catalysts (, and ) used to increase efficiency is strongly dependent on the type of catalyst, nature of biomass and purpose of the treatments. Most of the research studies, using this hydrothermal treatment, have focused on experimental conditions to enrich the solid resulting from steam explosion treatment in cellulose, for subsequent enzymatic hydrolysis and biofuel obtainment, as well as treatments for xylo-oligosaccharides or anaerobic gas production. In this sense, considering sugarcane bagasse depolymerization by acid catalyzed steam explosion [304] uses phosphoric acid concentrations between 0.05 and 0.4% (w/v) to disintegrate the structure of sugarcane bagasse. However, when using , concentrations in the range of 0.9-3% are used to treat the same material.In the latest LAIW delignification studies, the steam explosion technique has been used in combination with other main chemical, physicochemical or biological processes [303], as shown in Table 9, concerning combined biomass treatments, to increase the efficiency of the global lignin removal process.Table 9. Parameters and delignification percentages for different LAIWs using hydrothermal processes.Table 9. Parameters and delignification percentages for different LAIWs using hydrothermal processes.

LAIWs Hydrothermal Method Experimental Conditions Delignification, % Ref. Barley straw

Deionized water

(subcritical)60% v/v, 180 °C, 50 bar

5 mL/min61.0

[305]

Canola straw

Deionized water

(subcritical)60% v/v, 180 °C, 50 bar, 5 mL/min

51.0

[305]

Chestnut shell

Liquid hot water

100 °C, 24 h

1 g LAIW-10 mL water18.8

[306]

Rice straw Subcritical water 170–200 °C, 4.67 mL/min 85.0 [307] Sugarcane

bagasseSteam explosion

(NaOH)0.1 M calatyst 180 °C, 5 min, 20 bar 65.0

[308]

Liquid hot water

180 °C, 20 min, 160 psi

1 g LAIW-9 mL water12.8

[309]

Sugarcane straw

Steam explosion

Deionized water soaked 2 h at 20 °C

210 °C, 15 min, 20 bar6.0

[310]

Sugarcane trash

Steam explosion

(NaOH)

Double impregnation:

1 g LAIW-10 mL water

1 g-20 mL NaOH

17%, 190 °C, 17 min70.5

[311]

Wheat bran

Steam explosion

0.05 (v/w)

218 °C, 8 min25.1

[228]

Wheat straw

Liquid hot water

180 °C, 40 min

1 g LAIW-10 mL water21.6

[312]

Liquid hot water 160–200 °C, 30–90 min 10–35 [313] Subcritical water 121 °C, 45 min, 15 lb/inch2 57.0 [199] - Supercritical or subcritical fluids: Supercritical fluids (carbon dioxide, ammonia, water, acetone, ethanol, methanol, and hydrocarbons such as propane and butane) are obtained when they are subjected to pressures and temperatures above their critical point, so that there is no transition phase and the liquid and solid phases become indistinguishable. Therefore, these fluids are chemical compounds that have properties of both liquids and gases [314] and advantageous characteristics such as low viscosity, low dielectric constant and high diffusivity [4], improving the solubility of hydrophobic compounds in water and encouraging lignin fractionation [315]. In the case of , one of the most commonly used fluids due to its low cost, non-toxicity and a relatively low critical point, temperatures above 31.7 °C and pressures of 7.38 MPa are required [186]; however, water requires conditions above 374 °C and 221 bar [314]. In some cellulose and biofuel research, the delignification conditions must be carefully chosen, so that the yields in carbohydrate fraction are high as well as the quality of the recovered collateral lignin [316].Recently, the use of supercritical fluids, especially , in combination with other delignification treatments, has been advocated, as it is possible to preserve the structure of the lignin to a greater extent. Some experimental conditions for one-step treatments are shown in Table 10, exceptionally collecting delignification results from research prior to the time interval for which the review has been conducted.Table 10. Parameters and delignification percentages for different LAIWs using critical fluids.

LAIWs Fluid Experimental Conditions Delignification, % Ref. Barley straw

Ethanol

60% v/v, 220 °C,

50 bar, 40 min

5 mL/min60.0

[52]

Ethanol

20% v/v, 180 °C,

50 bar

5 mL/min54.0

[305]

Canola straw

Ethanol

20% v/v, 180 °C,

50 bar

5 mL/min45.0

[305]

Corn stover

(supercritical)

ethanol-water

2:1 v/v

200 °C, 13 MPa,

80 min

1 g LAIW:40 mL90.0

[317]

Hemp fibers

(supercritical)

ethanol-water

2:1 molar ratio

180 °C, 6 MPa,

60 min

1 g LAIW:6 mL89.6

[99]

Rice husk

(supercritical)

ethanol-water,

80 °C, 270 bar,

10 min34–91

[192]

Sugarcane bagasse

(supercritical)190 °C, 16 MPa,

60 min88.4

[318]

(supercritical)60 °C,

200 kgf/cm28.1

[319]

- Ammonia Fiber Expansion (AFEX): This treatment of LAIWs, with liquid ammonia at pressures of 0.7–2.7 MPa, temperatures of 60–100 °C and residence times in the range 5–60 min, involves rapid ammonia expansion and release of pressure at the end of the treatment, causing swelling of the biomass, changes in the structure of the lignin, some solubilization of the hemicellulose and partial delignification [12,209,320,321]. When concentrated ammonia is brought into contact with water, ammonium and hydroxide ions appear in solution, through an exothermic reaction that increases the temperature of the reaction medium. The simplicity of ammonia recovery makes this treatment very useful. However, some research reports a lack of effectiveness of the delignification process for some LAIWs such as corn stover [322] or agave bagasse [323]. No additional information on recent delignification data of LAIWs has been found by applying this process apart from those listed in Table 11.A modification of the AFEX process is the ammonia recycle percolation ( in continuous recirculation and recycling in a percolation reactor) [324]. Experimental conditions for this process usually comprise 140–210 °C, residence time 14–90 min, 5–15% (w/w) of ammonia solution and velocity of 1 cm [324,325] for woods. Soaking aqueous ammonia is also considered a modification of the AFEX process by using batch reactors, but under milder temperature conditions (25–60 °C) and longer reaction times (10–60 days).

| LAIWs | AFEX Conditions | Delignification, % | Ref. |

|---|---|---|---|

| Corn stover | 58.7% w/w 30 °C, 10 min 0.5 H2O2 loading (30%) | 24.0 | [326] |

| Pine chips | 70% moisture 130 °C, 15 min 1 g LAIW: 1 g | 4.0 | [327] |

| Wheat straw | 10 g-7 mL deionized water 130 °C, 15 min 1 g LAIW: 1 g | 3.8 | [328] |

- Hydrodynamic cavitation: This treatment allows, using non-rotational systems (orifices, Venturis, vortex diodes, swirling jet), or advanced rotational reactors to provoke liquid contraction, the growth and collapse of vapor bubbles in the solvent in which the residual biomass is found, by a pressure drop below the saturation pressure of the liquid. In this process, pressures of ∼500 bar, temperatures of ∼5000 °C and oxidation processes (by hydroxyl radical formation) are presented [329], causing mechanical and chemical effects on the biomass, and producing its disintegration.A hydrodynamic system has been used [330] to assist different alkaline pretreatment processes for sugarcane bagasse, achieving 48.31% delignification using KOH (0.5 mol/L) at 60 °C, 20 min, dropping the pressure from 3 bar to 0.3 bar in the flowing fluid through the orifice plate. The same experimental conditions but using NaOH (0.3 mol/L) produced a delignification of 43.63%. On the other hand, information collected from Iskalieva et al. [331] summarizes experimental conditions for LAIWs treated by this technique, generally in conjunction with other chemical processes, showing percentages of lignin release, solubilization or removal in the range 2.2–78.5%.

- Non-thermal plasma (cold plasma) technique: Although there are also high temperature processes, low-temperature plasma (in the range 25–100 °C) [81] are regarded as being more environmentally friendly, especially more than those using chemical agents, although its novelty justifies the need for further studies to be optimized [332]. Cold plasma processes are generally used in combination with other chemical treatments. In addition, the biomass can undergo mechanical as well as chemical depolymerization, if there is the possibility of free radical formation which can oxidize LAIWs. This technique is characterized by the presence of electrically charged particles, a mixture of electrons, ions, radicals and neutral particles (in varying proportions depending on full or partial ionization) by the action of an electrical discharge with sufficient voltage on a gas (air, oxygen, helium, air–argon, ozone, etc). The interactions produced between the electrons (attaining temperatures of 105–5000 °C) and the gas molecules also generate active free radicals that attack the biomass and lead to its degradation [333]. The main advantage is that, although electrons reach extremely high temperatures, the gas surrounding them is at a relatively low temperature, so that no dissociation of the reaction products is observed and no cooling is necessary. In addition, this technique avoids problems of environmental damage, waste generation and inhibitors production, in contrast to many of the commonly used chemical treatments. Its proven efficiency in lignin extraction, low cost and its non-toxic character make it a promising strategy in lignocellulosic biomass fractionation processes.

3.1.4. Combined or Assisted Methods

3.1.5. Thermochemical Treatments

3.1.6. Biological Treatments

3.2. Lignin Recovery and Depolymerization

| STEP I: Precipitation → Separation | STEP II: Washing → Drying | LAIWs | Ref. | ||

|---|---|---|---|---|---|

| Precip./Extraction | Separation | Washing | Drying | ||

| POOL FROM ALKALINE PROCESS | |||||

| 20% w/w final pH = 2 | Centrifugation 4000 rpm 15 min | Hot water | 60 °C, 5 days | Bagasse Coconut husk Rice straw Corn stover | [202] |

| 24% w/w final pH = 4 + enzymatic hydrolysis | Centrifugation 3000 rpm 60 min | 5× with buffer to pH = 4 | 60 °C | Miscanthus giganteus | [170] |

final pH = 2 | Centrifugation 12,000 rpm 15 °C, 20 min | until pH = 7 | Sugarcane bagasse | [217] | |

| , latic and formic acid 4 M pH = 4 | Centrifugation | until pH = 3 | Sugarcane bagasse | [219] | |

| HCl 12% 70 °C, pH = 2–3 | Centrifugation 9000 rpm | until pH = 7 | 60 °C | Green sandalwood | [365] |

| 30% | Vacuum

filtration | Spray drying | Sugarcane bagasse | [373] | |

| POOL FROM KRAFT PULPING | |||||

| LignoBoost using pH = 9.5 | Centrifugation | HCl pH = 2.5 + acetic acid pH = 3.5 | Freeze-dried | Pine Acacia Eucalyptus | [25] |

| HCl 1 M pH = 2 Ethanol pH = 7, 8 h | Vacuum filtering | Dried 45 °C, 24 h | A. mangium | [374] | |

| POOL FROM DEEP EUTECTIC SOLVENT TREATMENT | |||||

| Acetone:water 1:1

Evaporation 60 °C + freezing −80 °C | Rotavapor 60 °C, 30 min | Freeze-dried | Reed | [277] | |

| Deionized water precipitation | Centrifugation rpm, 5 min | Ethanol:water 1:9 v/v | Freeze-dried | Wheat straw | [253] |

| Cooling + Deionized water precipitation | Centrifugation and decanting | Lyophilization | Camellia oleifera shell | [261] | |

| Ethanol:water 1:1 v/v | Distilled water to pH = 7 | Freeze-dried | Rice straw | [375] | |

| Ethanol:water 1:2 v/v | Centrifugation | Distilled water 2 times | Oven dried 40 °C | Oil palm fruit bunch | [274] |

| Ethanol 3 times | Rotavapor 40 °C deionized water filtration | Deionized water 2 times | Oven dried 40 °C | Reed straw | [276] |

| Ethanol:water 9:1 v/v | Rotavapor | Ultrapure water 3 times | 45 °C, 24 h | Brewer’s spent grains | [262] |

| NaOH 0.1 M room temperature | Centrifugation + decantation | Distilled water 3 times | Lyophilization | Corncob | [270] |

| Ethanol:water 1:9 v/v | Centrifugation | Ethanol:water 1:9 v/v | Corn straw | [272] | |

| Distilled water | Centrifugation | Freeze-dried 48 h | Ind. xylose residues | [273] | |

| Water | Centrifugation | Cold water | 49 °C, 48 h | Oil cane bagasse | [282] |

| Deionized water | Vacuum filtered | Deionized water, pH = 7 | 70 °C | Oil palm fruit bunch | [275] |

| POOL FROM COMBINED TREATMENT | |||||

| Acetone 96% | Rotavapor 35 °C | 40 °C | Defatted grape seed | [376] | |

| 20% | Centrifugation 3500 rpm | Water to pH = 2 | 50 °C, 24 h | Coconut husk | [335] |

| HCl pH = 2 | Centrifugation

8500 rpm | Distilled water, 60 °C | 60 °C | Rice straw | [343] |

| Ethanol or acetone used in previous organosolv

treatment | Filtration | Vacuum 80 °C 4 h | Apricot kernel shells | [334] | |

| POOL FROM ORGANOSOLV TREATMENT | |||||

| Ethanol | Centrifugation

1200 rpm | Freeze-dried | Corn stover | [337] | |

| Pure water | Centrifugation | Deionized water | Freeze-dried 50 °C, 48 h | Corn stover | [377] |

| Distilled water | Filtration | 60 °C, 24 h | Sugarcane bagasse | [244] | |

| Water | Centrifugation | Freeze drying | Bamboo culms | [237] | |

| Acidic deionized water pH = 3–4 | Centrifugation 4000 rpm | 45 °C | Wheat straw | [247] | |

| Ethyl acetate | Filtration +

rotavapor | Vacuum dried 60 °C | Corn stalks | [238] | |

| 95% pH = 1.5–2.0 | Centrifugation 3220× g | Acidified water pH = 2 | Persimmon tree pruning waste | [378] | |

| POOL FROM TREATMENT | |||||

| HCl 6 M | Centrifugation | Freeze-dried | Chinese hickory shell | [289] | |

| POOL FROM ACID/ENZYMATIC TREATMENT | |||||

| Deionized water pH = 2 | Centrifugation

4000 rpm | Lyophilization | Corn stover | [379] | |

| 2.5 M 70 °C, 1 h | Filtration | Water wash | 80 °C | Poplar wood hydrolysis solid | [203] |

| POOL FROM SUPERCRITICAL/SUBCRITICAL TREATMENT | |||||

| HCl pH = 2 | Vacuum filtration | Deionized water | Freeze-dried | Hemp fibers | [99] |

4. Characterization of Recovered Lignin

4.1. Lignin Characterization Methods

4.1.1. Differential Scanning Calorimetry (DSC)

4.1.2. Thermogravimetric Analysis (TGA)

4.1.3. X-Ray Diffraction (XRD)

4.1.4. Size-Exclusion Chromatography (SEC)

4.1.5. UV-Vis Spectroscopy

4.1.6. Fourier Transform Infrared (FTIR) Spectroscopy

- OH and CH Stretching Region (3460–2800 ): O-H stretching of phenolic and aliphatic structures (3410–3460 ) takes place, while C-H stretching is found in aromatic methoxyls, methyl and methylene groups (2938, 2842 ). A further example is additional aliphatic methylene bands in hemp, jute and flax lignins (2917, 2847 ), that can be originated from fatty acids in lignins.

- Carbonyl/Carboxyl Region (1750–1600 ): Weak bands that may be attributed to unconjugated carbonyl/carboxyl stretching (1705–1720 ) are found, with shoulder peaks attributed to conjugated carbonyl/carboxyl stretching (1680 ). Intensity variations and broadening at 1705–1600 in oxidized, solvent-extracted lignins, sulfur-free lignin depending on the treatment may be originated due to potential protein or water-related bands around 1650 .

- Fingerprint Region (1400–400 ): Complex region difficult to analyze due to band complexity with contributions of various vibration modes. This region provides information about monolignol units and linkages, including guaiacyl unit bands (1269 , G ring and CO stretch; 1140 , CH in-plane deformation; 854 and 817 , CH out-of-plane vibrations in position 2, 5 and 6 of guaiacyl units). In this region can also be found information on syringyl unit bands (1326, 843 ), that are typical of hardwood and all non-wood lignins e.g., wheat straw, acacia and eucalyptus. Lastly, phenolic OH and aliphatic C-H bands (1370–1375, 1215–1220 ), and potential polysaccharide-related bands (1000–1300 ) can also be detected.

4.1.7. Raman Spectroscopy

- Aliphatic and Aromatic C-H Stretching: Bands in the 2700–3200 region indicate C-H stretching vibrations in aliphatic and aromatic groups. The intensity of the 2940 band, associated with methoxyl groups, may be higher in hardwood due to its higher syringyl content.

- Aromatic Ring Vibrations and Carbonyl/Carboxyl Stretching: The 1350–1850 region shows bands related to aromatic ring vibrations, C=C and C=O stretching. Differences in band intensities can be found between softwood and hardwood due to variations in aromatic ring-conjugated structures [425].

- Fingerprint Region: The 250–1450 region reveals differences between softwood and hardwood, with certain bands being more intense in one type or the other. These differences can be attributed to variations in specific functional groups and linkages.

4.1.8. Nuclear Magnetic Resonance (NMR) Spectroscopy

4.1.9. X-Ray Photoelectron Spectroscopy (XPS)

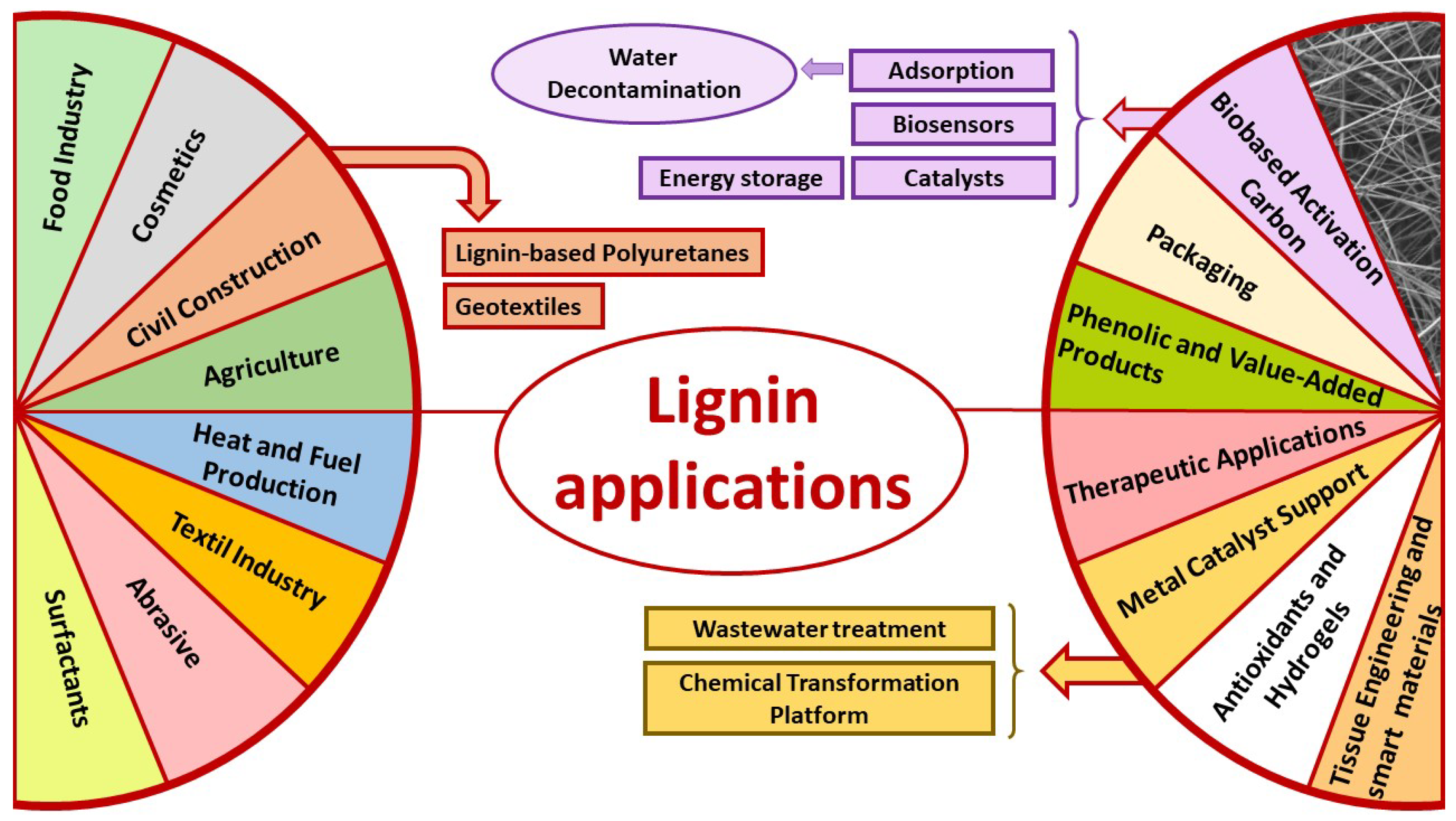

5. Industrial Applications of Lignin

- Heat and fuel production: Bio-oil obtained by pyrolysis, gasification or hydrothermal liquefaction can be used for heat production by direct burning. However, bio-oil contains significant amounts of water, acids and heavy oligomers, so it has a low energy content that makes it unviable as a vehicle fuel, unless it is subjected to hydrodeoxygenation processes [397]. Additionally, steam reforming of pyrolysis bio-oil from biomass is intensively being investigated to produce hydrogen. Apart from that, lignin pyrolysis processes give rise to significant amounts of phenols and phenolic compounds, depending on the experimental conditions employed. These phenolic compounds can form part of phenolic resins that are highly valued as binders for composite wood products, such as plywood and oriented strand boards. Another possible way of utilizing lignin would be through combustion processes, for example of waste black liquor from kraft pulp production [440], generating and O as the main products, which can be used to produce heat or electricity. Additionally, lignin can be also converted into suitable diesel, gasoline and aviation fuel [441]. Another study demonstrates that lignin from wheat straw can be converted, by catalytic depolymerization, into aromatic C6–C8 fractions and can subsequently give rise to aromatic C8–C15 fractions, by low-temperature alkylation using ionic liquids, with suitable characteristics for jet fuels [442]. Other studies focus on the harnessing of lignin from LAIWs (e.g., wheat straw) by different gasification technologies (fixed bed updraft, bubbling fluidized bed and indirect gasification) for the production of syngas that can be fermented to obtain bioalcohols [443].The techno-economic assessment of the application of lignin to heat and fuel production (e.g., by gasification or hydrothermal liquefaction) shows significant incentives such as those derived from life cycle analysis or those associated with the price of fossil fuels [444].

- Civil construction: Lignin is added to cements and mortars, to make lignin-based cement composites. In this way, the amount of water required is reduced, increasing the particle-to-particle adhesion, plasticity and workability. Lignin may adhere to the particles and act as dispersant, providing steric hindrance and electrostatic repulsions, that prevent the formation of aggregates when lignin is adsorbed or adhered on the cement particles through the formation of a film [445,446]. Accordingly, lignin-based polyurethanes can be produced by replacing polyols from urethane with lignin, originating composites with modified properties with applicability as foam, for thermal insulation, to improve the energy efficiency of buildings apart from gap filler and adhesive for materials such as wood, metal, concrete and ceramics [447]. It also has been shown that lignin molecules can adhere to the surface of the metal, forming a protective layer with an anti-corrosion effect [445]. These protective properties in coatings and adhesive properties have also been demonstrated in lignin-based epoxy resins [132]. Additionally, lignin-based phenol resins are utilized in the production of various building materials such as particleboards, laminates, coatings, plywood and adhesives.There are also studies that demonstrate the benefits of lignin in the field of pavement engineering, as lignin-modified asphalt has advantages over conventional asphalt in terms of improved properties of the resulting material [448]. In this sense, the addition of lignin can not only reduce the proportion of asphalt in the asphalt pavement, but also improve its properties. Moreover, from an economic point of view, the use of lignin in the asphalt binder industry can save costs, given the market price of lignin (about USD 297 per ton) compared to that of asphalt (USD 484 per ton), positioning lignin pavement as a promising material in upcoming applications [448]. In addition, lignin can also act as a protective coating of natural fiber geotextiles against degradation processes in materials [449]. The incorporation of lignin in geotextiles used in pavements can increase their durability and wear resistance, preventing blockages. Geotextiles containing lignin can also protect underground pipelines from damage caused by soil movement.

- Bio-based activated carbon attainment: Composite carbon nanofiber from lignin can be obtained considering four sequential stages: fiber spinning, fiber stabilization, fiber carbonization and surface treatment [450]. In particular, this promising porous material could be employed for energy storage or adsorption. Energy applications are based on capacitors and battery production while adsorption methods can also be conducted, through electrostatic interactions of compounds with the polarized surface of the bioadsorbent, offering advantages such as low-cost, high surface area, high thermal and electrical stability, suitable thermal properties and corrosion resistance [436]. The current reliance on polyacrylonitrile for the production of carbon nanofibers limits and makes their industrial applications more expensive, with a market price in the range of USD 5–44/kg. The incorporation of lignin would reduce these costs, expanding the current demand for carbon fibers (140,000 tonnes in 2020) [451].Concerning energy storage, lignin-based phenolic resin carbon microspheres have been used to produce capacitors [452]. Related to sustainable energy storage, the generation of hydrogels from lignin, used for the preparation of electrolytes, is seen as a promising alternative for organosolv lignin [453]. The combination of these hydrogels with lignin-derived electrodes results in supercapacitors with improved electrochemical properties. Likewise, activated carbons prepared from waste lignin, once thermochemically activated (microwave-assisted KOH treatment) were integrated together with polyvinyl alcohol to form electrodes in supercapacitors, using LiCl as the gel electrolyte [454]. These authors also obtained, through a carbonization process followed by microwave-assisted chemical activation of lignin, a superconductor with a low production cost.These energy applications of activated carbons from LAIWs are not restricted to the production of supercapacitors; empty fruit bunch and rice husk KOH activated carbons have been used to produce biomaterials for hydrogen storage [168] and residual lignin can also be integrated in nanocomposites to form battery anodes and cathodes for hydrogen storage. The large number of oxygen atoms in lignin favors the adsorption of electrolyte ions, and the occurrence of redox reactions, increasing the energy storage capacity in batteries and supercapacitors [437]. Other recent research into the use of lignin includes the use of consistent nanoporous carbon, generated by low-temperature carbonization (350 °C, 30 min) and physical activation with (1000 °C) of organosolv lignin from materials such as hemphurds, eucalyptus chips, flax straw and rice husk for hydrogen storage by adsorption [455].On the other hand, hydrocarbons from the hydrothermal carbonization of coconut shell powder, in the presence of zinc chloride, leads to a mesoporous material rich in functional groups suitable for contaminant removal [456]. In the same line, activated carbon, obtained by chemical activation of charred materials, has higher porosity and surface area than that obtained by physical processes. The chemical treatment of lignins to obtain activated carbon involves the use of high temperatures (500–900 °C), inert atmosphere of Ar or , in the presence of agents such as , NaOH, , or preferably KOH as it generates a large number of pores with a high specific surface area [436].In this line, porous carbon materials have been applied to water treatment, using for example alkali lignin to retain Congo red effectively by adsorption [457]. An important application of lignin is in the adsorption of chromophore groups present in dyes, through different types of interactions: through the hydrogen bonding of OH groups of lignin and polar functional groups of chromophore dyes (carbonyls or amines). Hydrophobic interactions (London dispersion forces) between aromatic rings of the lignin and hydrophobic portions of chromophore groups could also take place. In addition, ionic interactions of charged lignin groups (sulfonates and carboxyl groups) with charged chromophore groups could also occur.Kraft lignin is rich in hydroxyl and aliphatic groups, both polar, so it has a high affinity for polar aromatic groups and some metals. It has been successfully used for the removal of dyes by the formation of kraft lignin hydrogels [458]. With respect to sulfite lignin, it contains a high amount of sulfonate groups, which makes it highly soluble in water, limiting its capacity to retain heavy metals (lead, cadmium and chromium) from wastewater [459], although electrostatic interactions with sulfonate groups and the use of modified lignins could be promising alternatives to improve their adsorptive capacity. Concerning organosolv lignin, it has a more conserved and less condensed structure than other lignins and, in general, tends to be more hydrophobic than kraft or sulfite lignin due to its preserved structure rich in aromatic rings and alkyl groups, which are hydrophobic. Nevertheless, its adsorption capacity depends on the nature of the solvent used in the extraction and the reaction conditions. In general, organosolv lignin has a limited solubility in water, so it has a great potential for the removal of pollutants from water [459]. Finally, it is possible to modify the properties of lignin by oxidation, reduction or functionalization processes to improve its adsorption capacity for certain pollutants. The production of lignin composites is currently a promising alternative for the adsorption of metals in polluted water, for example, by introducing into the structure of certain LAIWs, such as wheat husks [460]. The structure of lignin, with the presence of a multitude of functional groups, favors interaction with particles dissolved in water, promoting their purification by flocculation processes [446].

- Antioxidants and hydrogels: Significant research efforts have been made in recent years to develop hydrogels with appropriate structures for drug delivery. The variability and complexity of lignin makes it difficult to interact with the three-dimensional matrices of these materials and to create porous scaffolds [461]. The high aromaticity of lignin and, in particular, the presence of phenolic compounds, determine the antioxidant power of lignin. This antioxidant capacity of lignin can be chemically enhanced, resulting in modified lignins. In this context, alkali lignin extracted from cornstalk was chemically modified by the Mannich reaction (using ethylenediamine aqueous solution and, sequentially, formaldehyde), achieving significant increases in their antioxidant activity. This antioxidant capacity could be employed in biomedicine, food packaging, cosmetics and medical devices through the production of lignin-based films as carriers or in biocompatible scaffolds [462]. On the other hand, hydrogels from lignin can be used to encapsulate medicines. The hydrophilic character of lignin allows it to retain water, which causes the three-dimensional network of the lignin to facilitate drug-controlled release at the site of injury [463].

- Packaging: Lignin-derived biomaterials can be substitutes for plastic, offering more sustainable applications. Thermoplastic and thermosetting lignin polyester has gained great attention [464] to produce flexible and tough lignin-based films for packaging. Regarding this application, oxypropylated kraft lignin (5%) with polylactic acid biocomposites have shown suitable characteristics for being used in food packaging [465]. In addition to antimicrobial and flame retardant properties, the use of lignin to generate UV-blocking materials has also been investigated, attributing this property to the phenolic and carbonyl groups in the lignin [368,466], absorbing light in the UV range (200–400 nm). Apart from that, lignin can also be useful to prepare lignin-based bio-finish in order to provide hydrophobic materials [467]. Transparency of the wrapper is a highly appreciated quality, so the amount of added lignin (which could give a brown coloring) should be optimized. Boarino and Klok [466] collected in their research information on biodegradable polymers based on different types of lignins (soda, kraft, organosolv and lignosulfonates) with different matrices (polylactic acid, polyvinyl alcohol and poly(3-hydroxybutyrate)/polyhydroxyalkanoates), showing how soda lignin biocomposites have antioxidant capabilities and UV barrier activity, only demonstrated for punctual kraft and organosolv lignins. Additionally, from lignin, different phenolic compounds can be obtained to be used in packaging applications. There are microorganisms (Actynomyces, Aspergillus, Clostridium and Lactobacillus species) capable of generating feruloyl esterase enzymes, necessary for the generation of phenolic compounds from lignocellulosic biomass. The addition of feruloyl esterase to the biomass (usually pretreated) allows the hydrolysis of the ester bonds, releasing ferulic acids and other phenolic compounds [196], acting as protective coatings on cardboard boxes, paper bags and other types of packaging. Ferulic acid has been used in blends with polymers such as low-density polyethylene and ethylene vinyl acetate to make effective packaging films [468]. Likewise, a recent study [469] was able to effectively incorporate lignin nanoparticles into starch polymeric matrices, obtaining biofilm composites that were used for soybean oil packaging, observing a delay in its oxidative deterioration.For food packaging applications, lignin can not only improve the mechanical properties of polymeric biofilms, but also antioxidant and anti-UV barriers. The main challenge is to achieve their compatibility with the surrounding matrix, through proper lignin functionalization. Another challenge is to improve the digestibility of biofilms in composting processes [466].

- Agriculture: The application of lignin-based materials for agricultural mulching increases the water and nutrient retention capacity of the soil, as well as its organic matter supply through the gradual decomposition of lignin [470]. Lignin can be transformed into agrochemicals such as slow-release nitrogen fertilizer, pesticides, soil amendments and plant growth regulators [471]. The use of lignin-coated urea reduces the rate at which urea dissolves in the soil, reducing soil losses and controlling nitrogen levels, implying a higher utility of mixed lignin compared to the use of urea alone, as it provides higher crop yields [471]. On the other hand, when lignin is added to pesticides, in some cases, lignin can act as a dispersant, reducing the attractive forces between pesticide particles and thus reducing viscosity. As pesticides can penetrate more quickly, increasing the effectiveness and decreasing the consumption of the product. Thus, the use of lignin in the development of innovative materials and formulations, compared to traditional agrochemicals, is one of the main challenges in agriculture, demonstrating a growing use, high efficacy and cost-effectiveness [472].

- Surfactants: Lignin has great potential as a low-cost surfactant because of its hydrophobic aromatic configuration and multifunctionality. In this sense, lignosulfonates have been used as a surfactant in industry, but their purity and limited efficiency have hindered their application. This justifies the need to advance in the knowledge regarding the performance and property correlation of lignin-based surfactants in order to be widely incorporated in the market [473]. Kraft lignin is an excellent starting material to obtain surfactants with similar behavior to synthetic ones, as it possesses a wide variety of functional groups such as hydroxyl, carbonyl and methoxy which give it an amphipathic character (there are hydrophilic and hydrophobic parts). In this context, lignin from kraft pulping was diluted in ammonia and then soaked in a dilute solution of polyvinyl alcohol for surfactant generation [374]. These surfactants could be used as foamers, dispersants and emulsifiers. Likewise, small concentrations of cationic kraft lignin surfactants successfully stabilized oil–water emulsions [474]. On the other hand, lignosulfonates have been used as anionic surfactants in concrete admixtures, although they have little efficacy in decreasing the surface tension of water or the interfacial tension of water–oil mixtures [473].

- Biotransformed phenolic and other compounds: Monomers from lignin phenols obtained after the depolymerization of lignocellulosic biomass involves vanillin (producing vanillin alcohol by reduction), vanillic acid (reduced to vanillin), syringic acid that can be reduced to syringaldehyde, guaiacols, (iso) eugenol, ferulic acid, p-coumaric acid and alkylphenols [475], used in food, beverages, cosmetics and pharmaceuticals (due to their anti-inflammatory, antioxidant and anti-tumor properties). The separation of vanillin after the depolymerization (alkaline oxidation) of lignin (Indulin AT) has been efficiently carried out by chromatography, using water and ethanol as eluents [476]. Additionally, pyrolysis, gasification, liquefaction, hydrogenolysis and biological routes are alternatives for the depolymerization of lignin to produce benzene, toluene and xylene. However, the production of these compounds accounts for only 5% of lignin-based chemicals, with the drawback of their low price compared to other chemical compounds such as vanillin [6]. Other researchers have succeeded in obtaining compounds such as sodium levulinate, sodium 4-hydroxyvalerate, sodium acetate and sodium formate from the dearomatization of lignin in aqueous media, using as an electrolyte, by an electrocatalytic process [394].Related to phenolic compound production, the most significant cost contributions are solvent consumption and maintenance due to the costs of the dissolution and transformation of lignin to polyphenols. Challenges mostly concern their selling price, as they are heavily dependent on the quality of the lignin-derived resin, which is not currently competitive with those derived from petroleum. The profit could also be increased by reducing costs regarding dissolution, which is a process that is still in its early stage and could have a crucial impact on the product’s final quality [477].

- Cosmetics: The main applications of lignin in this field are based on its high antioxidant and ultraviolet radiation absorption capacity. There are studies that support the suitability of the use of sugarcane bagasse alkaline lignin in topical applications [373], as ingredient of sunscreens and blemish balm or antiaging cream, temporary skin sensitization, mutagenicity and cytotoxicity tests. The benefits of lignin from hazelnut and walnut or coconut husk, as an ultraviolet radiation protector, have also been corroborated [478,479].The global lignin cosmetics market is projected to grow at a compound annual growth rate (CAGR) of 10.7%, reaching approximately USD 13.5 billion by 2032 [480].

- Textile industry: Lignin is drawn as a textile fiber by the melt spinning method and electrospinning method [481]. The property of lignin to generate char when burnt has been the starting point for the use of this polymer in flame retardants and intumescent polylactic acid textile components [4]. In addition, lignin–silica-based materials recovered from rice husk have also been used as a flame retardant, overcoming one of the most important drawbacks of cotton textiles, namely its high flammability [255]. Some studies reveal that lignin-based epoxy resins can generate highly thermally and mechanically stable materials [132] for creating water, stain and abrasion resistant finishes on a wide range of fabrics. A textile application was established by Abdel-Shakur et al. [482], using corn straw lignin to make single-use medical textiles with demonstrated antimicrobial activity. Lignin can also be used as a dispersant in the textile industry and is expected to grow at an annual rate of 6% between 2020–2026 [483].

- Food industry: Lignin-derived nanogels, lignin-based films and lignin nanoparticles can also be used in the food field for the delivery of pre-encapsulated vitamins and food dyes [484]. This encapsulation technique using nanoparticles from alkali lignin has also been used to preserve essential oils, increasing their thermal stability as well as their antibacterial properties against S. aureus and E. coli [485]. Furthermore, lignin–whey protein has been used for the microencapsulation of Lactobacillus probiotic bacteria, under similar conditions to those of the digestive system [486]. According to this, alginate microcapsules are frequently used as encapsulation materials although, in order to improve their properties, either alginate microspheres cross-linked with calcium ions or a combination of alginate with other compounds (chitosan, calcium carbonate, gelatin or whey protein) are usually used for better protection of bacterial cells [486].