Approach to the Performance of Polymers Designed Based on Poly(methyl methacrylate) (PMMA)/poly(urethane) (PU) with Recycled Cellulose Nanoparticles from Cold Drink Cups

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Cellulose Extraction from Cold Drink Cups

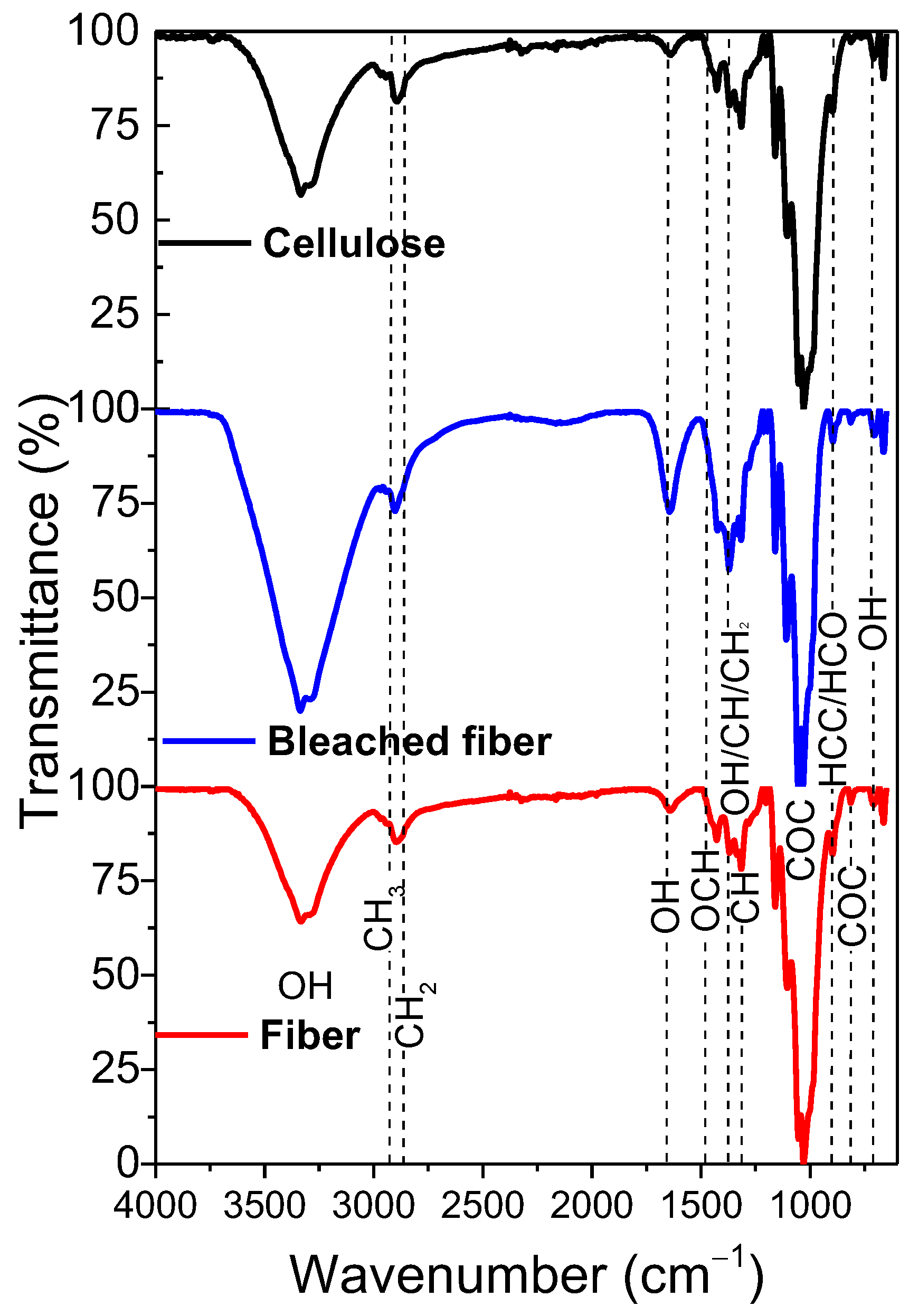

3.1.1. Structural Analysis Through FTIR Spectroscopy

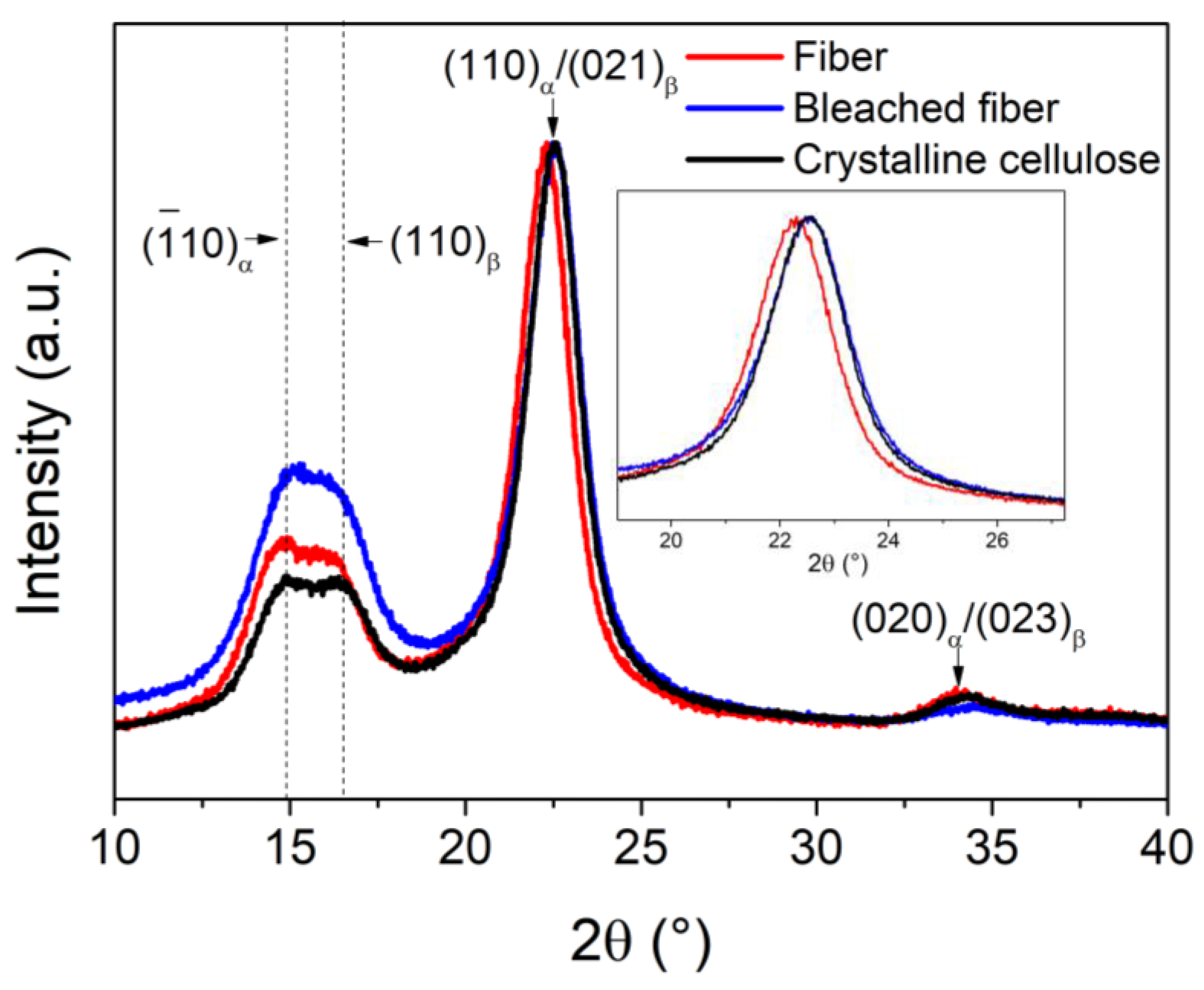

3.1.2. Polymorph Contribution of Cellulose Through XRD

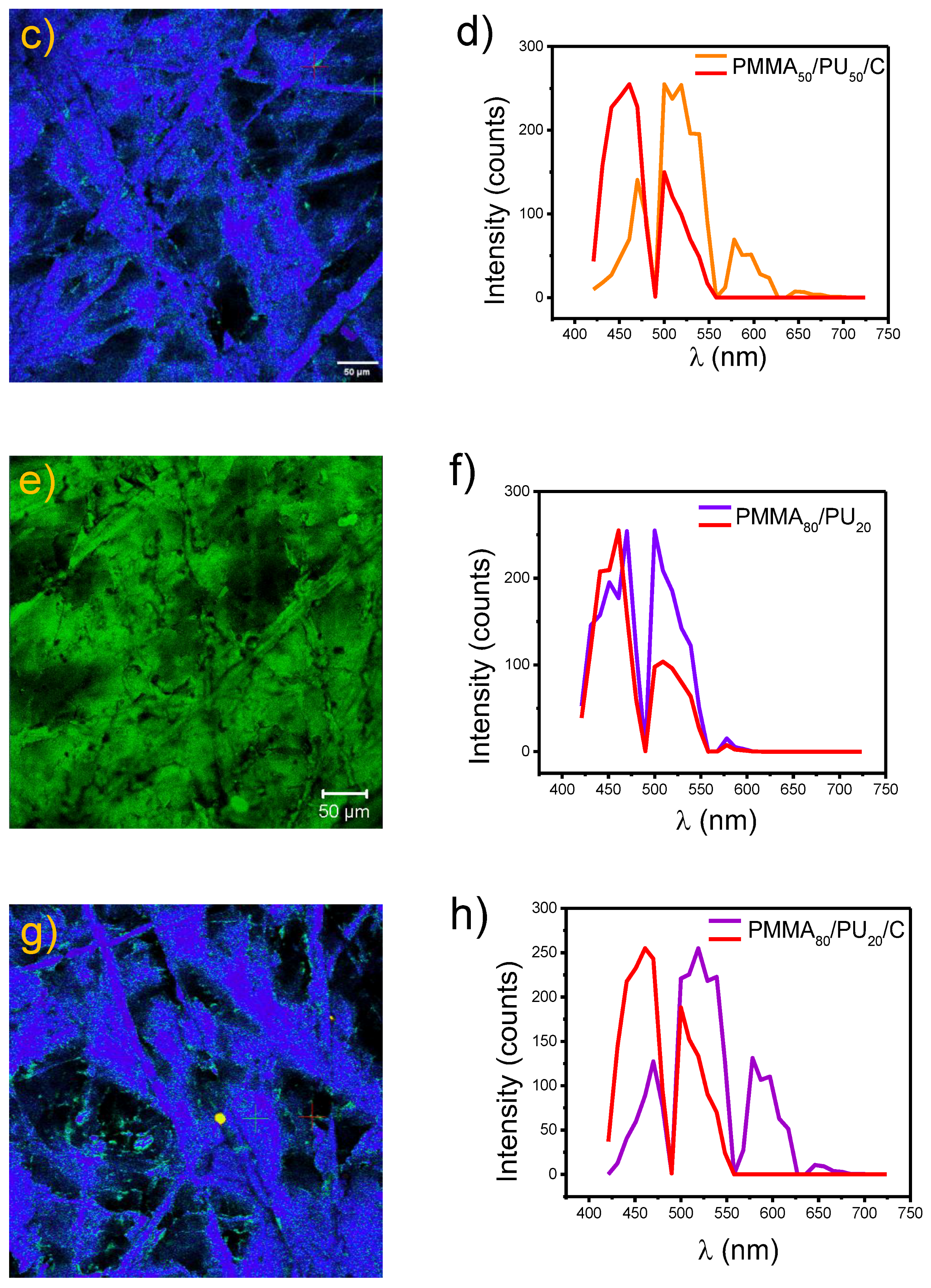

3.1.3. Morphological Analysis Through Optical and CLSM Microscopy

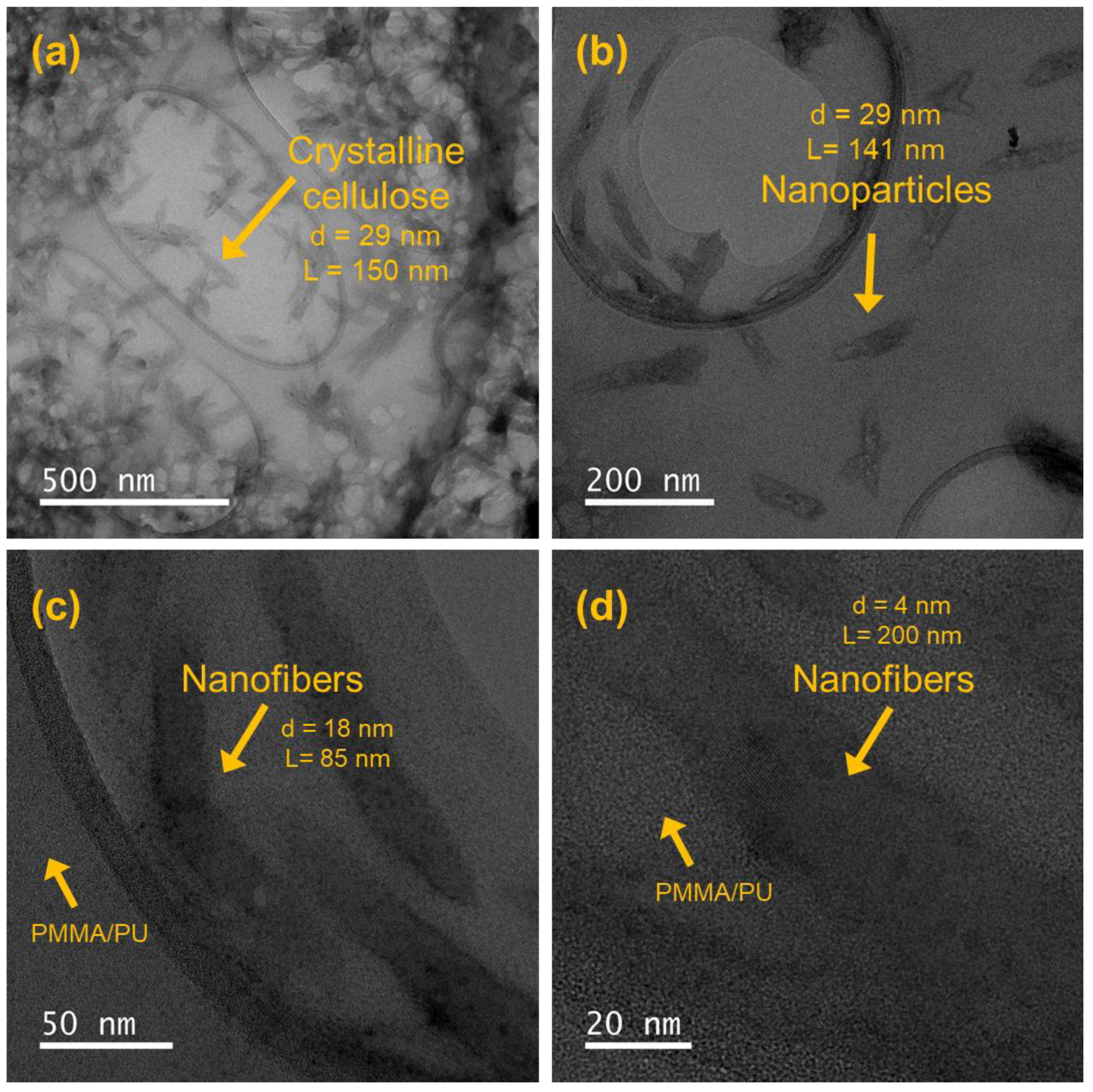

3.1.4. Dispersion Analysis of Crystalline Cellulose Through Morphological Analysis

3.2. Structural, Optical, and Mechanical Assessment of PMMA/PU/Cellulose IPNs

3.2.1. Structural Analysis of PMMA/PU/Cellulose IPNs

3.2.2. Evaluation of Optical Transparency Using UV–vis Spectroscopy

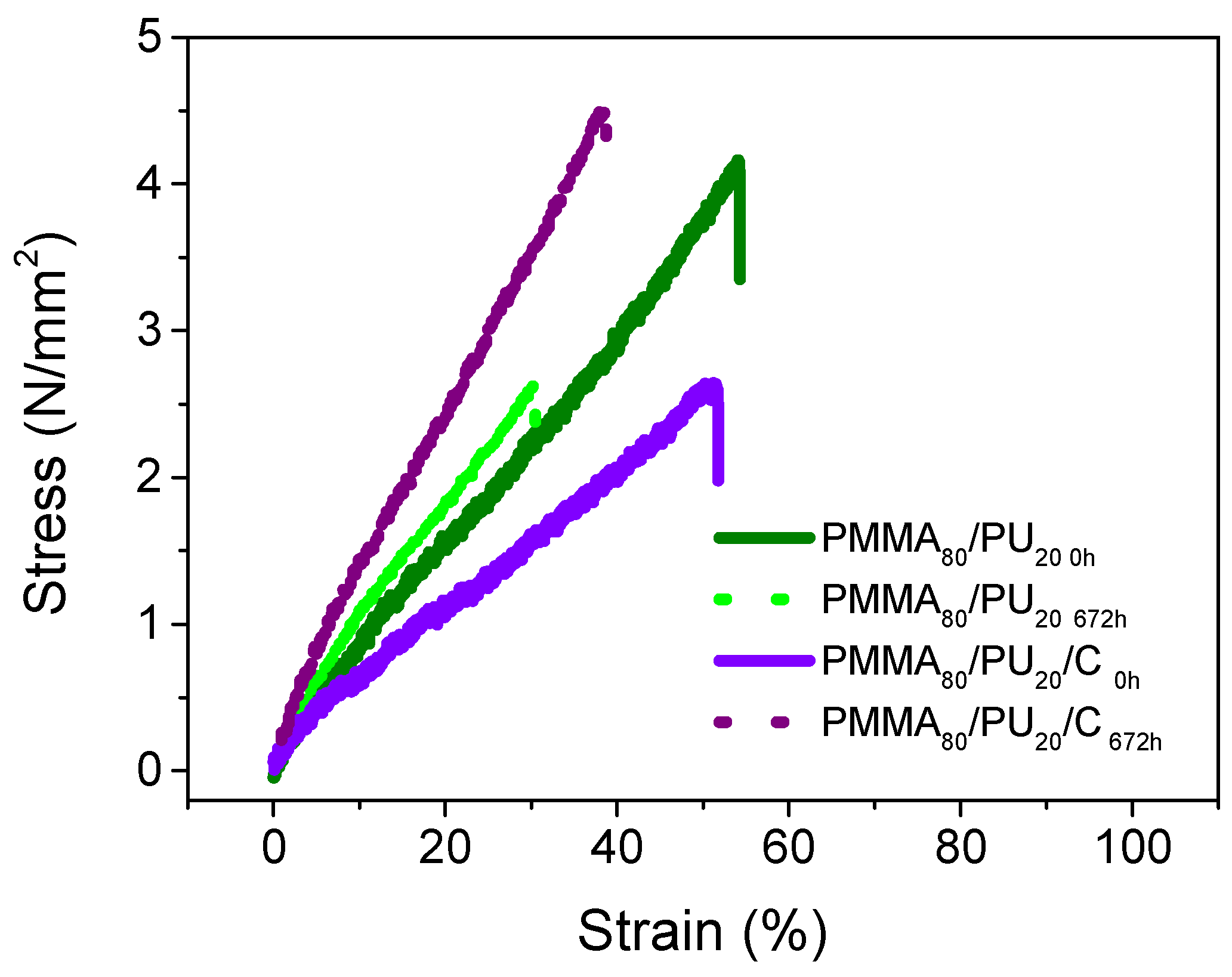

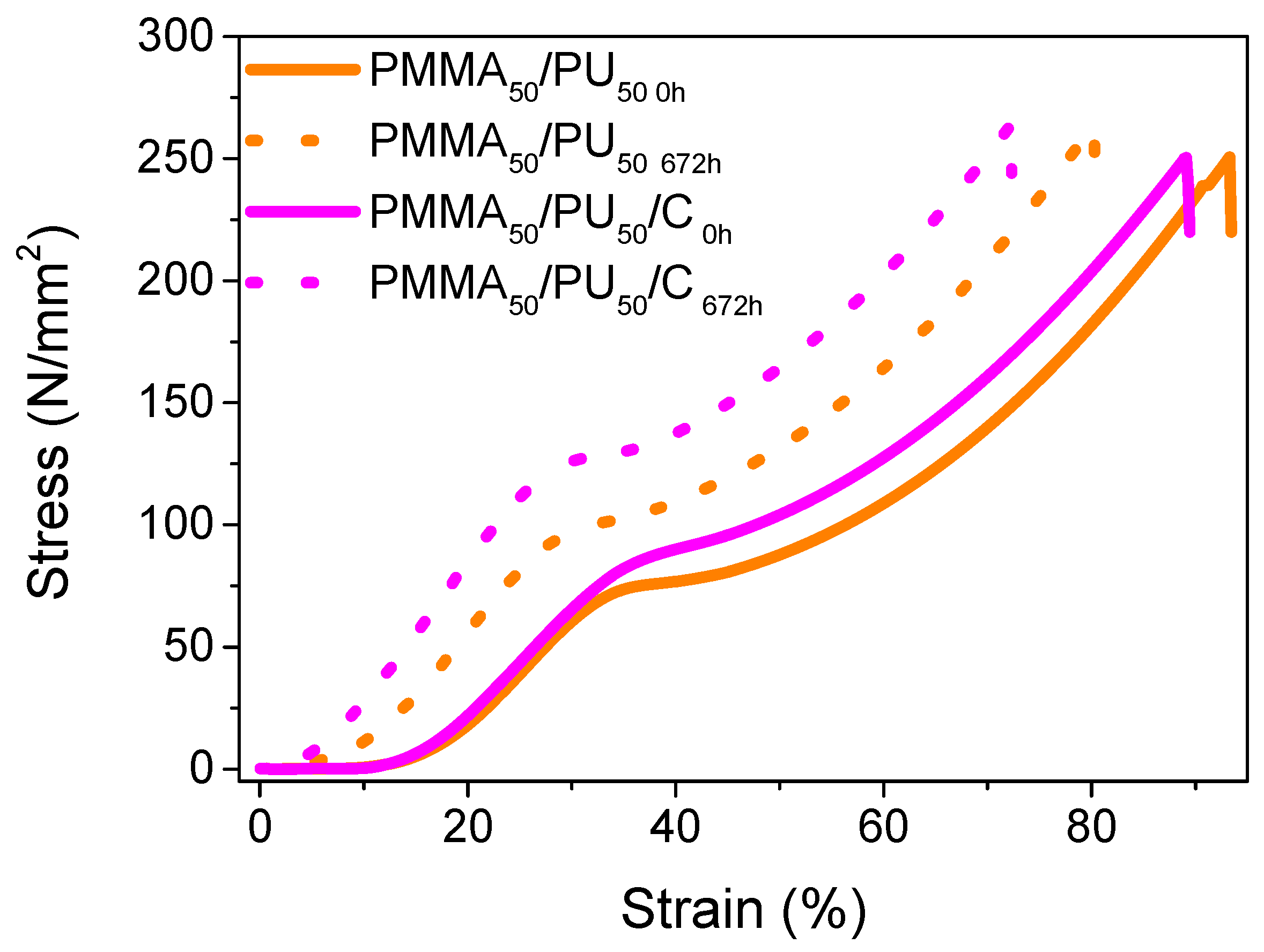

3.2.3. Tensile Behavior of PMMA/PU/Cellulose IPNs

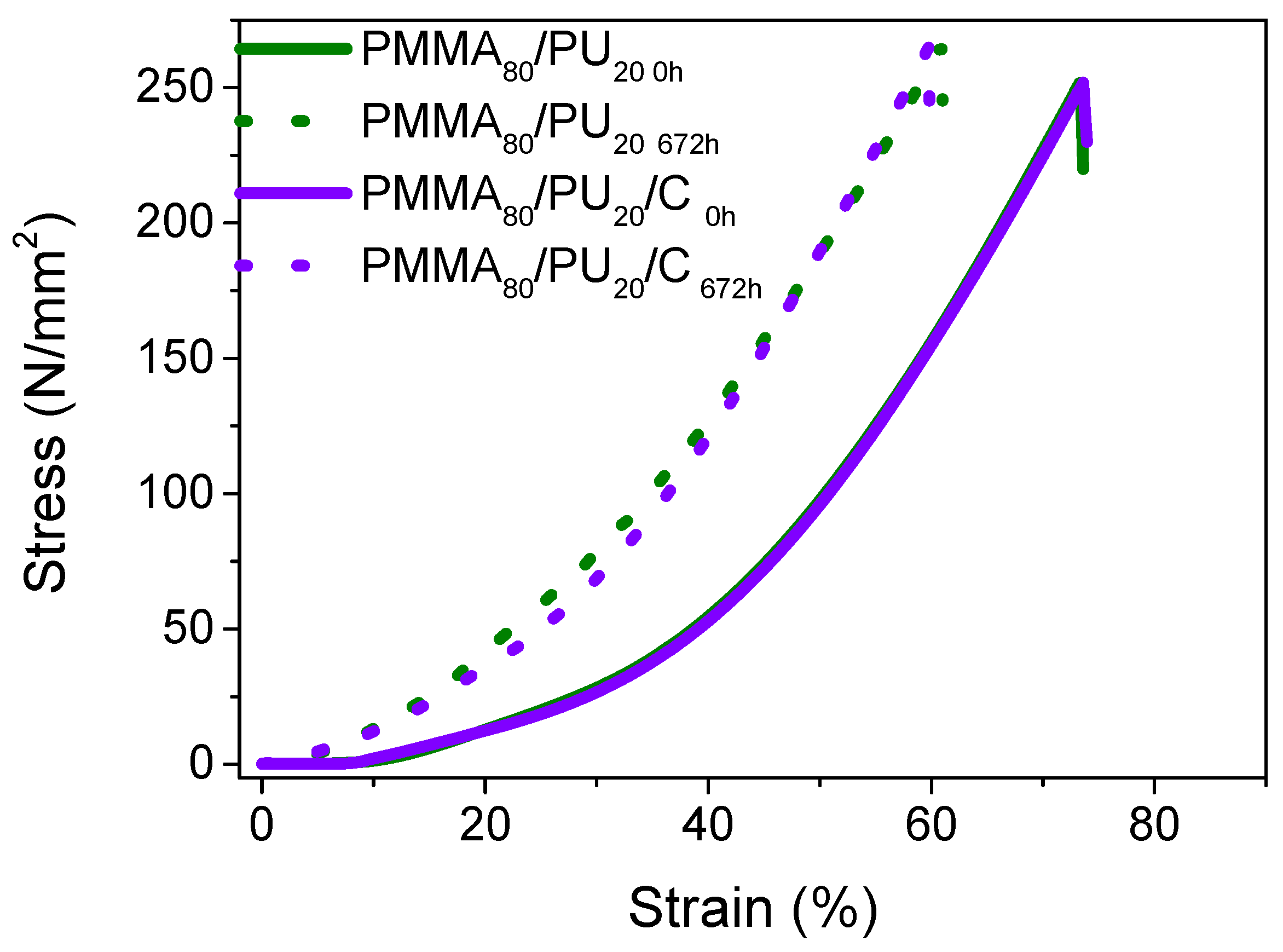

3.2.4. Compression Behavior of PMMA/PU/Cellulose Composites

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ferreira, M.M.; de Freitas Cunha Lins, V. Failure in automobile headlight lenses. Eng. Fail. Anal. 2019, 104, 844–855. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Pustode, M.D.; Singh, C.S.; Verma, R.; Kochi, T.; Barge, H.; Gouda, S.; Dutta, A. Root Cause Analysis and Mitigation of White Patch Formation in Automotive Headlamp. J. Fail. Anal. Prev. 2021, 21, 387–397. [Google Scholar] [CrossRef]

- Saleh, B.A.A.; Kraishan, A.; Elimat, Z.M.; Karaki, I.A.; Alzubi, R.I.; Juwhari, H.K. Effect of gamma radiation on the optical properties of PMMA composites with varying Al concentrations. Radiat. Phys. Chem. 2025, 226, 112342. [Google Scholar] [CrossRef]

- Nahida, J.; Marwa, R. Study of the optical constants of the PMMA/PC blends. AIP Conf. Proc. 2011, 1400, 585–595. [Google Scholar]

- Yan, C.; Zhang, J.; Han, J.; Wang, X.; Guan, Z.; Zhang, L.; Liu, C.; Shen, C. Improvement of environmental stress cracking resistance of polycarbonate by silicone coating. Polym. Test. 2017, 60, 6–11. [Google Scholar] [CrossRef]

- Wang, M.; Jiang, J.; Liang, S.; Sui, C.; Wu, S. Functional Semi-Interpenetrating Polymer Networks. Macromol. Rapid Commun. 2024, 45, 2400539. [Google Scholar] [CrossRef]

- Krishnan, S.M. Studies on corrosion resistant properties of sacrificial primed IPN coating systems in comparison with epoxy–PU systems. Prog. Org. Coat. 2006, 57, 383–391. [Google Scholar] [CrossRef]

- Majidi, R.; Keramatinia, M.; Ramezanzadeh, B.; Ramezanzadeh, M. Weathering resistance (UV-shielding) improvement of a polyurethane automotive clear-coating applying metal-organic framework (MOF) modified GO nano-flakes (GO-ZIF-7). Polym. Degrad. Stab. 2023, 207, 110211. [Google Scholar] [CrossRef]

- Yu, R.; Prabhakar, M.N.; Feng, J.; Yang, Y.; Hong, S.H.; Song, J.I. Enhancing the mechanical properties of flax fiber-reinforced epoxy composites through cellulose nanofiber incorporation. Ind. Crops Prod. 2025, 223, 120113. [Google Scholar] [CrossRef]

- Cai, J.; Chen, J.; Zhang, Q.; Lei, M.; He, J.; Xiao, A.; Ma, C.; Li, S.; Xiong, H. Well-aligned cellulose nanofiber-reinforced polyvinyl alcohol composite film: Mechanical and optical properties. Carbohydr. Polym. 2016, 140, 238–245. [Google Scholar] [CrossRef] [PubMed]

- Lam, D.-N.; Nguyen, N.T.T.; Thien, D.V.H.; Nguyen, C.-N.; Huang, C.-J.; Van-Pham, D.-T. Enhancing the mechanical strength and tuning the optical properties of reinforced PVA films: The effects of graphene oxide, cellulose nanocrystals, and PVA molecular weight. Carbohydr. Polym. Technol. Appl. 2024, 8, 100533. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, R.; Cao, J.; Chen, Y. Effects of UV weathering on surface properties of polypropylene composites reinforced with wood flour, lignin, and cellulose. Appl. Surf. Sci. 2014, 317, 385–392. [Google Scholar] [CrossRef]

- Kruer-Zerhusen, N.; Cantero-Tubilla, B.; Wilson, D.B. Characterization of cellulose crystallinity after enzymatic treatment using Fourier transform infrared spectroscopy (FTIR). Cellulose 2018, 25, 37–48. [Google Scholar] [CrossRef]

- Célino, A.; Gonçalves, O.; Jacquemin, F.; Fréour, S. Qualitative and quantitative assessment of water sorption in natural fibres using ATR-FTIR spectroscopy. Carbohydr. Polym. 2014, 101, 163–170. [Google Scholar] [CrossRef]

- Idamayanti, D.; Taufik, D.; Nadi, M.R.G.; Septiani, N.L.W.; Rochliadi, A.; Purwasasmita, B.S.; Yuliarto, B.; Nuruddin, A. The cellulose nanocrystal (CNC)-reinforced chitosan composite as a potential substrate for flexible hard carbon anode in sodium-ion battery. Cellulose 2023, 30, 7713–7728. [Google Scholar] [CrossRef]

- Sun, H.; Wang, W.; Liu, Y.; Wang, Q. A highly efficient, colorless phosphorus–nitrogen synergistic flame retardant for durable flame retardancy in wood pulp paper. Polym. Degrad. Stab. 2023, 215, 110468. [Google Scholar] [CrossRef]

- Guo, X.; Liu, L.; Wu, J.; Fan, J.; Wu, Y. Qualitatively and quantitatively characterizing water adsorption of a cellulose nanofiber film using micro-FTIR spectroscopy. RSC Adv. 2018, 8, 4214–4220. [Google Scholar] [CrossRef]

- Sharma, V.; Jagdeep, K.; Kumar, R. Proof of concept study for paper discrimination and age estimation through its degradation process by ATR-FTIR spectroscopy and chemometric models. Aust. J. Forensic Sci. 2021, 53, 703–726. [Google Scholar] [CrossRef]

- Salim, R.M.; Asik, J.; Sarjadi, M.S. Chemical functional groups of extractives, cellulose and lignin extracted from native Leucaena leucocephala bark. Wood Sci. Technol. 2021, 55, 295–313. [Google Scholar] [CrossRef]

- Liang, C.Y.; Marchessault, R.H. Infrared spectra of crystalline polysaccharides. II. Native celluloses in the region from 640 to 1700 cm−1. J. Polym. Sci. 1959, 39, 269–278. [Google Scholar] [CrossRef]

- Tong, Y.; Huang, S.; Meng, X.; Wang, Y. Aqueous-Cellulose-Solvent-Derived Changes in Cellulose Nanocrystal Structure and Reinforcing Effects. Polymers 2023, 15, 3030. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Hu, F.; Gan, M.; Xie, Y.; Feng, Q. A rapid, green method for the preparation of cellulosic self-reinforcing composites from wood and bamboo pulp. Ind. Crops Prod. 2021, 169, 113658. [Google Scholar] [CrossRef]

- Chan, H.; Chia, C.-h.; Zakaria, S.; Ahmad, I.; Dufresne, A. Production and Characterisation of Cellulose and Nano-Crystalline Cellulose from Kenaf Core Wood. BioResources 2012, 8, 785–794. [Google Scholar] [CrossRef]

- Sperling, L.H. Interpenetrating polymer networks and related materials. J. Polym. Sci. Macromol. Rev. 1977, 12, 141–180. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, Q.; Ji, X.; Peng, J.; Nawaz, H.; Xia, G.; Ji, X.; Zhang, J.; Zhang, J. Fabrication and Characterization of Transparent and Uniform Cellulose/Polyethylene Composite Films from Used Disposable Paper Cups by the “One-Pot Method”. Polymers 2022, 14, 1070. [Google Scholar] [CrossRef]

- Xu, Z.; Zhou, Q.; Wang, L.; Xia, G.; Ji, X.; Zhang, J.; Zhang, J.; Nawaz, H.; Wang, J.; Peng, J. Transparent Cellulose-Based Films Prepared from Used Disposable Paper Cups via an Ionic Liquid. Polymers 2021, 13, 4209. [Google Scholar] [CrossRef]

- Jia, P.; Ji, X.; Zheng, B.; Wang, C.; Hao, W.; Han, W.; Zhang, J.; Xia, G.; Ji, X.; Zhang, J. Eco-Friendly and Complete Recycling of Waste Bamboo-Based Disposable Paper Cups for Value-Added Transparent Cellulose-Based Films and Paper Plastic Composites. Polymers 2022, 14, 1589. [Google Scholar] [CrossRef]

- Kassab, Z.; Aziz, F.; Hannache, H.; Ben Youcef, H.; El Achaby, M. Improved mechanical properties of k-carrageenan-based nanocomposite films reinforced with cellulose nanocrystals. Int. J. Biol. Macromol. 2019, 123, 1248–1256. [Google Scholar] [CrossRef]

- Yurtsever, M. Are nonwoven fabrics used in foods made of cellulose or plastic? Cellulose/plastic separation by using Schweizer’s reagent and analysis based on a sample of tea bags. Process Saf. Environ. Prot. 2021, 151, 188–194. [Google Scholar] [CrossRef]

- Hobisch, M.A.; Bossu, J.; Mandlez, D.; Bardet, S.M.; Spirk, S.; Eckhart, R.; Bauer, W. Localization of cellulosic fines in paper via fluorescent labeling. Cellulose 2019, 26, 6933–6942. [Google Scholar] [CrossRef]

- Ding, Q.; Han, W.; Li, X.; Jiang, Y.; Zhao, C. New insights into the autofluorescence properties of cellulose/nanocellulose. Sci. Rep. 2020, 10, 21387. [Google Scholar] [CrossRef] [PubMed]

- Hiremath, A.; Murthy, A.A.; Thipperudrappa, S.; K N, B. Nanoparticles Filled Polymer Nanocomposites: A Technological Review. Cogent Eng. 2021, 8, 1991229. [Google Scholar] [CrossRef]

- Lozano Fernandez, M.E.; Miskolczi, N. Production of Cellulose Nano-Fibers and Its Application in Poly-Lactic-Acid: Property Improvement by New Types of Coupling Agents. Polymers 2022, 14, 1887. [Google Scholar] [CrossRef]

- Lohani, A.; Singh, G.; Bhattacharya, S.S.; Verma, A. Interpenetrating polymer networks as innovative drug delivery systems. J. Drug Deliv. 2014, 2014, 583612. [Google Scholar] [CrossRef]

- Myung, D.; Waters, D.; Wiseman, M.; Duhamel, P.E.; Noolandi, J.; Ta, C.N.; Frank, C.W. Progress in the development of interpenetrating polymer network hydrogels. Polym. Adv. Technol. 2008, 19, 647–657. [Google Scholar] [CrossRef]

- Dutta, S.; Gupta, R.S.; Pathan, S.; Bose, S. Interpenetrating polymer networks for desalination and water remediation: A comprehensive review of research trends and prospects. RSC Adv. 2023, 13, 6087–6107. [Google Scholar] [CrossRef]

- Zeng, C.; Hossieny, N.; Zhang, C.; Wang, B.; Walsh, S.M. Morphology and tensile properties of PMMA carbon nanotubes nanocomposites and nanocomposites foams. Compos. Sci. Technol. 2013, 82, 29–37. [Google Scholar] [CrossRef]

- Zhang, C.; Lyu, P.; Xia, L.; Wang, Y.; Li, C.; Xiang, X.; Dai, F.; Xu, W.; Liu, X.; Deng, B. Regulation of pore morphologies of PU films and thereof water vapor permeability by varying tetrahydrofuran concentration in binary solvent. Polym. Test. 2018, 69, 32–38. [Google Scholar] [CrossRef]

- Ramesh, S.; Leen, K.H.; Kumutha, K.; Arof, A.K. FTIR studies of PVC/PMMA blend based polymer electrolytes. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2007, 66, 1237–1242. [Google Scholar] [CrossRef]

- Rosu, D.; Rosu, L.; Cascaval, C.N. IR-change and yellowing of polyurethane as a result of UV irradiation. Polym. Degrad. Stab. 2009, 94, 591–596. [Google Scholar] [CrossRef]

- Mihaela, M.; Vlad, S.; Ciobanu, C.; Lebrun, L.; Popa, M. Polyurethane-hydroxypropyl cellulose membranes for sustained release of nystatin. Cellul. Chem. Technol. 2013, 47, 5–12. [Google Scholar]

- Cui, C.-W.; Yang, C.; Bao, J.; Huang, X.-J.; Zeng, X.-F.; Chen, J.-F. Monodispersed ZnO Nanoparticle-Poly(methyl methacrylate) Composites with Visible Transparency for Ultraviolet Shielding Applications. ACS Appl. Nano Mater. 2020, 3, 9026–9034. [Google Scholar] [CrossRef]

- Carbaugh, D.J.; Wright, J.T.; Parthiban, R.; Rahman, F. Photolithography with polymethyl methacrylate (PMMA). Semicond. Sci. Technol. 2016, 31, 025010. [Google Scholar] [CrossRef]

- Han, G.; Huan, S.; Han, J.; Zhang, Z.; Wu, Q. Effect of Acid Hydrolysis Conditions on the Properties of Cellulose Nanoparticle-Reinforced Polymethylmethacrylate Composites. Materials 2013, 7, 16. [Google Scholar] [CrossRef]

- Rogulska, M. Polycarbonate-based thermoplastic polyurethane elastomers modified by DMPA. Polym. Bull. 2019, 76, 4719–4733. [Google Scholar] [CrossRef]

- Rahman, S.S.; Mahmud, M.B.; Salehi, A.; Monfared, A.R.; Islam, M.A.; Filleter, T.; Lee, P.C.; Park, C.B. Mechanically strong and fully transparent PMMA composite with greatly improved toughness and impact strength incorporating PEBA nanofibrils. Chem. Eng. J. 2024, 480, 148311. [Google Scholar] [CrossRef]

- Jamaluddin, N.; Hsu, Y.-I.; Asoh, T.-A.; Uyama, H. Optically Transparent and Toughened Poly(methyl methacrylate) Composite Films with Acylated Cellulose Nanofibers. ACS Omega 2021, 6, 10752–10758. [Google Scholar] [CrossRef]

- Bangar, S.P.; Harussani, M.M.; Ilyas, R.A.; Ashogbon, A.O.; Singh, A.; Trif, M.; Jafari, S.M. Surface modifications of cellulose nanocrystals: Processes, properties, and applications. Food Hydrocoll. 2022, 130, 107689. [Google Scholar] [CrossRef]

- Sethi, J.; Illikainen, M.; Sain, M.; Oksman, K. Polylactic acid/polyurethane blend reinforced with cellulose nanocrystals with semi-interpenetrating polymer network (S-IPN) structure. Eur. Polym. J. 2017, 86, 188–199. [Google Scholar] [CrossRef]

- Mendoza, D.J.; Nasiri, N.; Duffin, R.N.; Raghuwanshi, V.S.; Mata, J.; Simon, G.P.; Hooper, J.F.; Garnier, G. Multifunctional graft-IPN hydrogels of cellulose nanofibers and poly(N-isopropyl acrylamide) via silver-promoted decarboxylative radical polymerization. Mater. Today Chem. 2024, 37, 102014. [Google Scholar] [CrossRef]

- Piñero, M.; Morales-Florez, V.; De la Rosa-Fox, N.; Esquivias, L. Propiedades mecánicas de aerogeles híbridos de sílice. Bol. Soc. Esp. Ceram. Y Vidr. 2005, 44, 291–293. [Google Scholar] [CrossRef]

- Ahmed, K.K.; Muheddin, D.Q.; Mohammed, P.A.; Ezat, G.S.; Murad, A.R.; Ahmed, B.Y.; Hussen, S.A.; Ahmed, T.Y.; Hamad, S.M.; Abdullah, O.G.; et al. A brief review on optical properties of polymer Composites: Insights into Light-Matter interaction from classical to quantum transport point of view. Results Phys. 2024, 56, 107239. [Google Scholar] [CrossRef]

- Natrayan, L.; Kaliappan, S.; Mothilal, T.; Balaji, N.; Maranan, R.; Ravi, D. Utilizing High-Performance Thermoplastics to Improve Durability and Efficiency in Automotive Instrument Panels; SAE International: Warrendale, PA, USA, 2025. [Google Scholar]

- Rühl, A.; Kolling, S.; Schneider, J. A transparent three-layered laminate composed of poly(methyl methacrylate) and thermoplastic polyurethane subjected to low-velocity impact. Int. J. Impact Eng. 2020, 136, 103419. [Google Scholar] [CrossRef]

- Yazici, M.; Güçlü, H.; Karen, İ.; Türkoğlu, İ.K.; Yagoub, S.; Malkoç, S. Numerical Analysis of Light Commercial Vehicle Headlamp for Pedestrian Safety. Int. J. Nat. Eng. Sci. 2015, 9, 034–038. [Google Scholar]

- Sefer, T.; Ayaz, R.; Ajder, A.; Nakir, I. Performance investigation of different headlights used in vehicles under foggy conditions. Sci. Rep. 2023, 13, 4698. [Google Scholar] [CrossRef]

| Sample | Transmittance (%) | |

|---|---|---|

| 320 nm | 650 nm | |

| PMMA50/PU50 0h | 99.8 | 100 |

| PMMA50/PU50 168h | 40.8 | 98.6 |

| PMMA50/PU50 336h | 37.4 | 95.1 |

| PMMA50/PU50/C0h | 32.2 | 90.0 |

| PMMA50/PU50/C336h | 30.1 | 92.3 |

| PMMA80/PU20 0h | 53.9 | 100 |

| PMMA80/PU20 168h | 50.9 | 100 |

| PMMA80/PU20 336h | 56.2 | 97.4 |

| PMMA80/PU20/C0h | 30.3 | 95.2 |

| PMMA80/PU20/C168h | 32.0 | 91.4 |

| PMMA80/PU20/C336h | 34.8 | 88.2 |

| Sample | Stress (MPa) | Strain (%) | Young’s Modulus (MPa) |

|---|---|---|---|

| PMMA50/PU50 0h | 14.18 ± 0.29 | 94.92 ± 0.03 | 82.83 ± 0.08 |

| PMMA50/PU50 336h | 13.54 ± 0.12 | 67.62 ± 0.12 | 152.50 ± 0.36 |

| PMMA50/PU50 672h | 25.01 ± 0.17 | 63.14 ± 0.23 | 198.50 ± 0.78 |

| PMMA50/PU50/C0h | 18.78 ± 0.12 | 40.73 ± 0.03 | 585.19 ± 0.21 |

| PMMA50/PU50/C504h | 26.48 ± 0.46 | 35.10 ± 0.04 | 750.71 ± 0.29 |

| PMMA50/PU50/C672h | 29.24 ± 1.12 | 33.59 ± 0.23 | 891.71 ± 0.56 |

| Sample | Stress (MPa) | Strain (%) | Young’s Modulus (MPa) |

|---|---|---|---|

| PMMA80/PU20 0h | 3.76 ± 0.37 | 54.20 ± 0.08 | 7.23± 0.36 |

| PMMA80/PU20 674h | 2.60 ± 0.72 | 30.44 ± 0.29 | 7.99 ± 0.85 |

| PMMA80/PU20)/C0h | 2.59 ± 0.04 | 51.17 ± 0.38 | 4.74 ± 0.45 |

| PMMA80/PU20/C674h | 3.14 ± 0.73 | 40.94 ± 0.23 | 10.92 ± 0.94 |

| Muestra | Stress (MPa) | Strain (%) | Young’s Modulus (MPa) |

|---|---|---|---|

| PMMA50/PU50 0h | 249.70 ± 0.97 | 93.10 ± 0.29 | 7.45 ± 0.03 |

| PMMA50/PU50 672h | 264.59 ± 0.31 | 80.35 ± 0.12 | 9.91 ± 0.09 |

| PMMA50/PU50/C0h | 249.87 ± 0.66 | 89.27 ± 0.16 | 13.21± 0.46 |

| PMMA50/PU50/C672h | 264.08 ± 0.27 | 72.65 ± 0.56 | 18.55 ± 0.45 |

| Sample | Stress (MPa) | Strain (%) | Young’s Modulus (MPa) |

|---|---|---|---|

| PMMA80/PU20 0h | 249.97 ± 1.31 | 73.51 ± 0.21 | 3.12 ± 2.84 |

| PMMA80/PU20 674h | 265.37 ± 0.37 | 60.94 ± 1.29 | 6.33 ± 0.06 |

| PMMA80/PU20)/C0h | 249.41 ± 1.23 | 74.00 ± 0.12 | 3.47 ± 1.27 |

| PMMA80/PU20/C674h | 265.05 ± 0.77 | 59.43 ± 0.50 | 7.60 ± 0.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reyes Piña, E.H.; Juárez Méndez, M.E.; Palma Ramírez, D.; López Benítez, A.; Neri Espinoza, K.A.; Cayetano Castro, N. Approach to the Performance of Polymers Designed Based on Poly(methyl methacrylate) (PMMA)/poly(urethane) (PU) with Recycled Cellulose Nanoparticles from Cold Drink Cups. Polymers 2025, 17, 1141. https://doi.org/10.3390/polym17091141

Reyes Piña EH, Juárez Méndez ME, Palma Ramírez D, López Benítez A, Neri Espinoza KA, Cayetano Castro N. Approach to the Performance of Polymers Designed Based on Poly(methyl methacrylate) (PMMA)/poly(urethane) (PU) with Recycled Cellulose Nanoparticles from Cold Drink Cups. Polymers. 2025; 17(9):1141. https://doi.org/10.3390/polym17091141

Chicago/Turabian StyleReyes Piña, Erick Habacuc, Mayra Elizabeth Juárez Méndez, Diana Palma Ramírez, Acela López Benítez, Karen Ailed Neri Espinoza, and Nicolás Cayetano Castro. 2025. "Approach to the Performance of Polymers Designed Based on Poly(methyl methacrylate) (PMMA)/poly(urethane) (PU) with Recycled Cellulose Nanoparticles from Cold Drink Cups" Polymers 17, no. 9: 1141. https://doi.org/10.3390/polym17091141

APA StyleReyes Piña, E. H., Juárez Méndez, M. E., Palma Ramírez, D., López Benítez, A., Neri Espinoza, K. A., & Cayetano Castro, N. (2025). Approach to the Performance of Polymers Designed Based on Poly(methyl methacrylate) (PMMA)/poly(urethane) (PU) with Recycled Cellulose Nanoparticles from Cold Drink Cups. Polymers, 17(9), 1141. https://doi.org/10.3390/polym17091141