Study on the Mechanical Properties of Carbon Fabric/Polyetherketoneketone Composites Under Different Environmental Conditions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

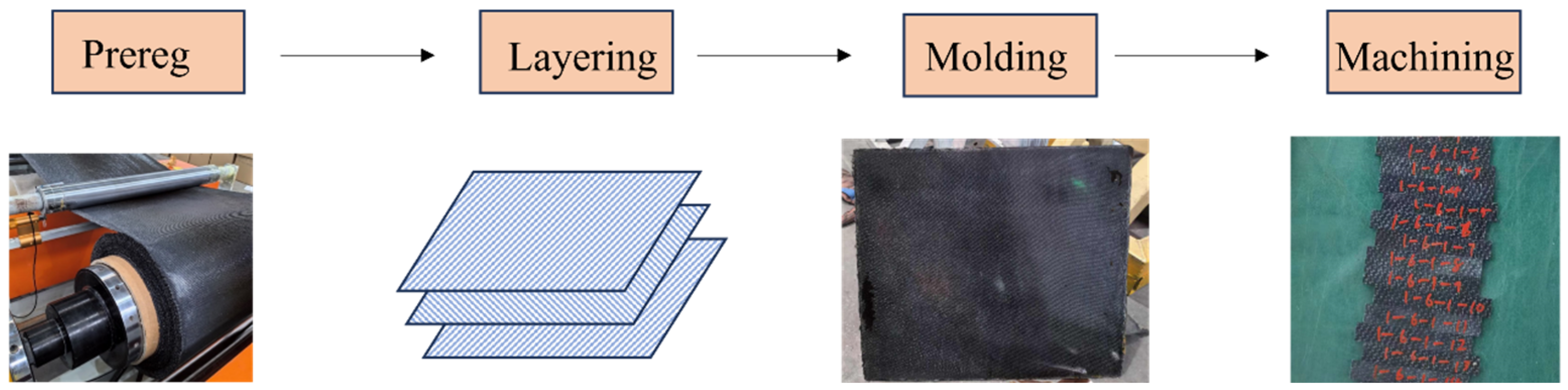

2.2. Preparation of Specimen

2.3. Hydrothermal Treatment

2.4. Mechanical Characterization

2.5. Morphological Analysis

3. Results

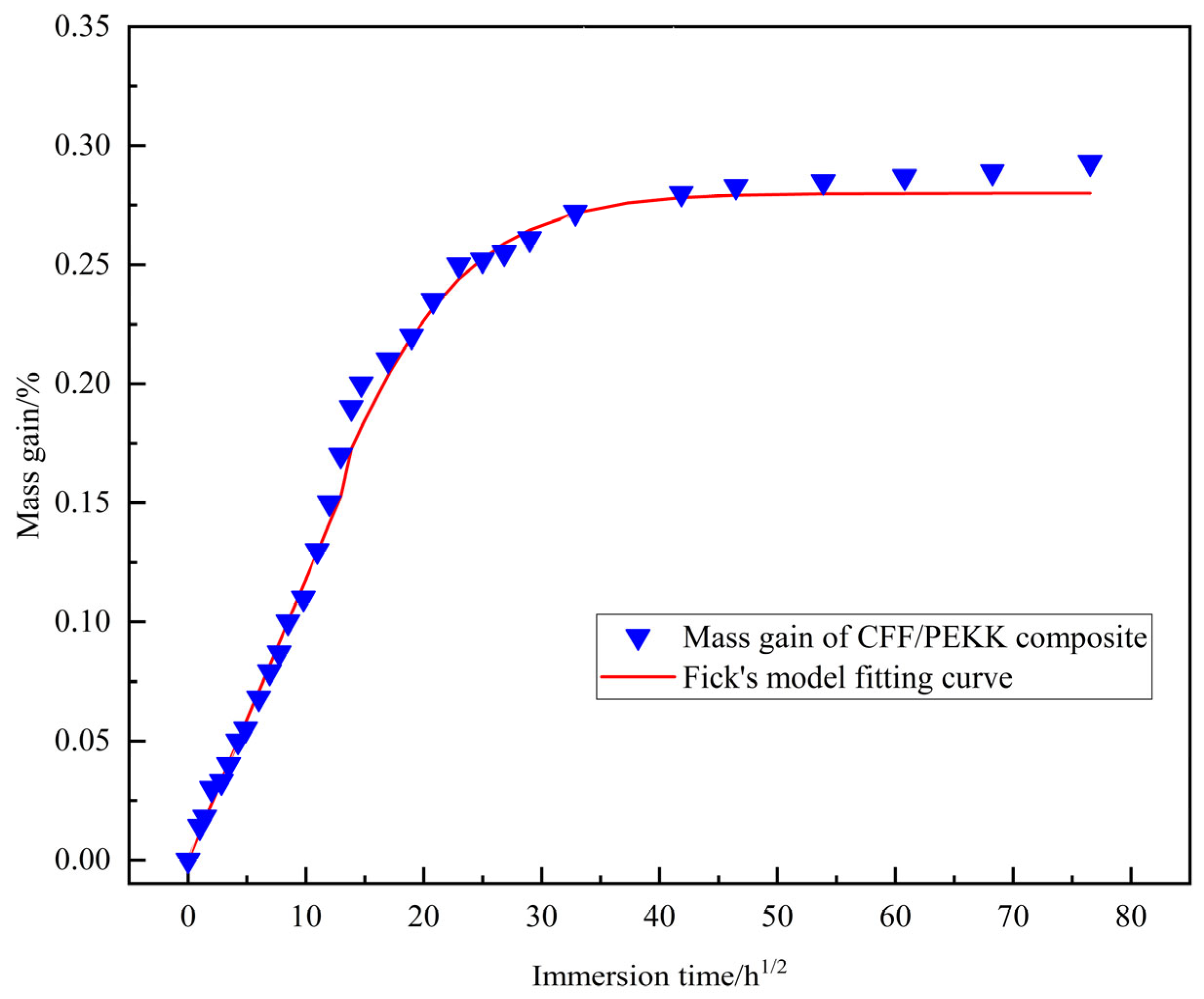

3.1. Moisture Kinetics

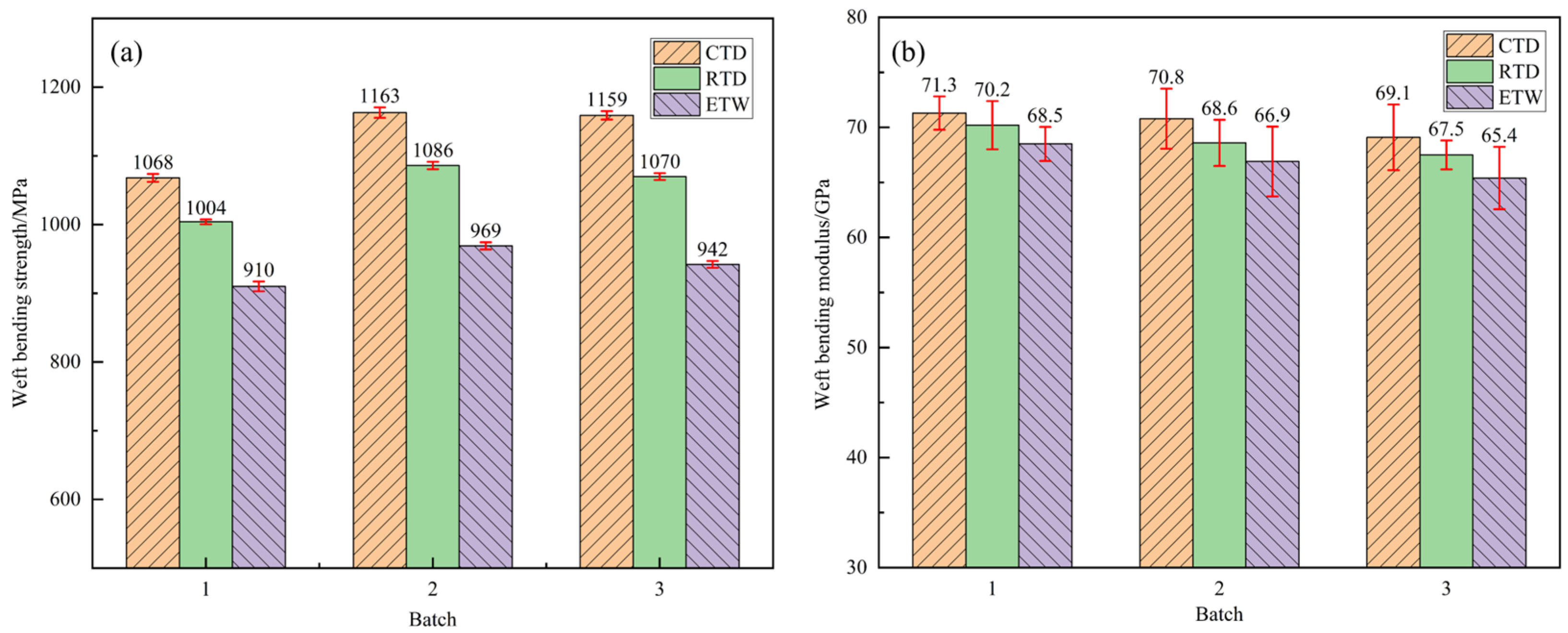

3.2. Bending Properties

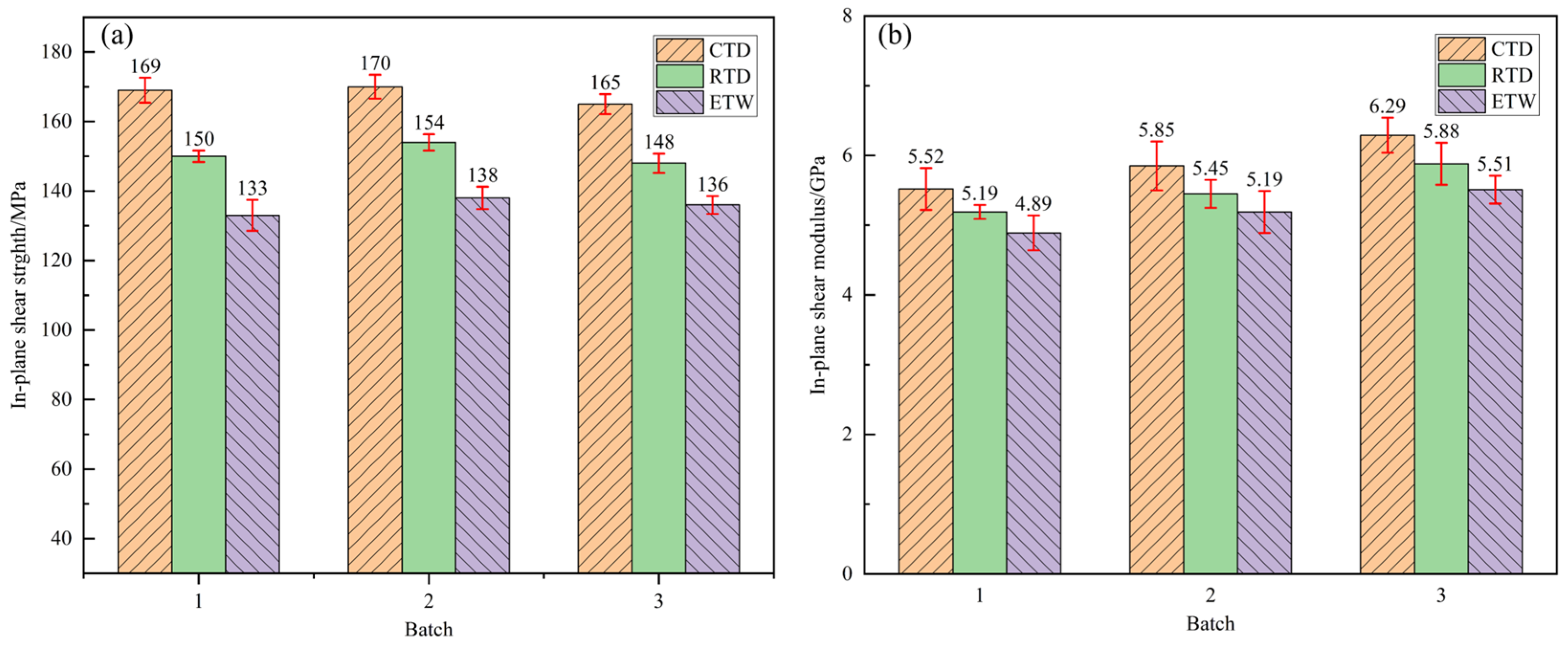

3.3. In-Plane Shear Properties

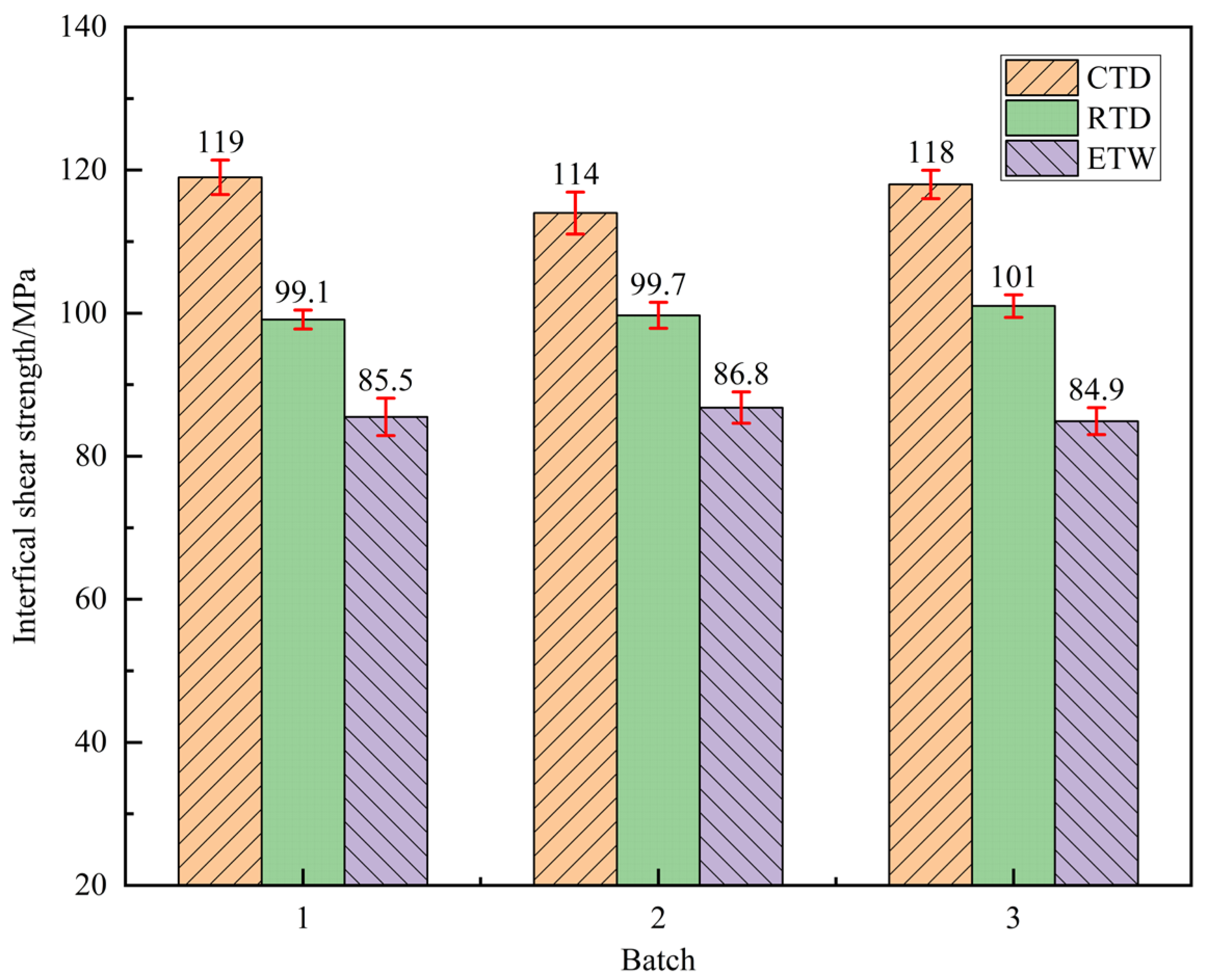

3.4. Interlaminar Shear Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Queiroz, d.H.F.M.; Pastor, V.; Mendonça, d.A.C.; Neto, J.S.S.; Cavalcanti, D.K.K.; Banea, M.D. Effect of hybridization and composite architecture symmetry in the bonded joint performance of jute/carbon fibre-reinforced composites. Int. J. Adhes. Adhes. 2024, 133, 103745. [Google Scholar] [CrossRef]

- Zhao, H.; Gao, Z.; Zhai, D.; Zhao, G. Enhanced mechanical property of continuous carbon fiber/polyamide thermoplastic composites by combinational treatments of carbon fiber fabric. Compos. Commun. 2023, 38, 101508. [Google Scholar] [CrossRef]

- Quan, S.; Zhang, Y.; Lin, P. Fatigue damage quantitative evaluation of carbon f iber composites at different stress ratios based on nonlinear ultrasonic. Results Phys. 2023, 51, 106695. [Google Scholar] [CrossRef]

- Liu, Y.; Lu, F.; Xu, N.; Wang, B.; Yang, L.; Huang, Y.; Hu, Z. Mechanically robust, hydrothermal aging resistant, imine-containing epoxy thermoset for recyclable carbon fiber reinforced composites. Mater. Des. 2022, 224, 111357. [Google Scholar] [CrossRef]

- Xu, X.; Peng, G.; Zhang, B.; Shi, F.; Gao, L.; Gao, J. Material performance, manufacturing methods, and engineering applications in aviation of carbon fiber reinforced polymers: A comprehensive review. Thin-Walled Struct. 2025, 209, 112899. [Google Scholar] [CrossRef]

- Tijs, B.H.A.H.; Turon, A.; Bisagni, C. Characterization and analysis of conduction welded thermoplastic composite joints considering the influence of manufacturing. Compos. Struct. 2024, 348, 118505. [Google Scholar] [CrossRef]

- Martín, I.; Fernández, K.; Cuenca, J.; Sánchez, C.; Anaya, S.; Élices, R. Design and manufacture of a reinforced fuselage structure through automatic laying-up and in-situ consolidation with co-consolidation of skin and stringers using thermoplastic composite materials. Heliyon 2023, 9, e12728. [Google Scholar] [CrossRef]

- Qiao, Y.; Fring, L.D.; Pallaka, M.R.; Simmons, K.L. A review of the fabrication methods and mechanical behavior of continuous thermoplastic polymer fiber-thermoplastic polymer matrix composites. Polym. Compos. 2023, 44, 694–733. [Google Scholar] [CrossRef]

- Yuan, C.; Ma, Z.; Pu, Y.; Liu, L.; Huang, Y. Soluble semi-aliphatic polyimide sizing in CF/PEI composites for improving mechanical performance and hydrothermal aging resistance. Compos. Commun. 2021, 28, 100982. [Google Scholar] [CrossRef]

- Dabees, S.; Wickramasingha, Y.A.; Akhavan, B.; Hayne, D.J.; Dharmasiri, B.; Henderson, L.C. Tribological behaviour of surface modified carbon-fibre-reinforced polyphenylene sulphide under dry condition. Tribol. Int. 2024, 194, 109528. [Google Scholar] [CrossRef]

- Stoeffler, K.; Andjelic, S.; Legros, N.; Roberge, J.; Schougaard, S.B. Polyphenylene sulfide (PPS) composites reinforced with recycled carbon fiber. Compos. Sci. Technol. 2013, 84, 65–71. [Google Scholar] [CrossRef]

- Matus-Aguirre, M.; Cosson, B.; Garnier, C.; Schmidt, F.; Akué-Asséko, A.C.; Chabert, F. Characterization and modeling of laser transmission welded polyetherketoneketone (PEKK) joints: Influence of process parameters and annealing on weld properties. J. Adv. Join. Process. 2024, 10, 100252. [Google Scholar] [CrossRef]

- Zhong, S.; Dong, Z.; Xiao, Y.; Li, Y.; Pei, L.; Wang, S.; Wang, G. The impact of crystalline PEEK sizing agent on the interfacial crystallization behavior and interfacial properties of carbon fiber reinforced PEEK composites. Compos. Part B 2025, 297, 112307. [Google Scholar] [CrossRef]

- Ge, J.; Luo, M.; Zhang, D.; Catalanotti, G.; Falzon, B.G.; McClelland, J.; Higgins, C.; Jin, Y.; Sun, D. Temperature field evolution and thermal-mechanical interaction induced damage in drilling of thermoplastic CF/PEKK—A comparative study with thermoset CF/epoxy. J. Manuf. Process. 2023, 88, 167–183. [Google Scholar] [CrossRef]

- Yildirima, C.; Ulusb, H.; Beylergile, B.; Al-Nadhari, A.; Topal, S.; Yildiz, M. Tailoring adherend surfaces for enhanced bonding in CF/PEKK composites: Comparative analysis of atmospheric plasma activation and conventional treatments. Compos. Part B 2024, 180, 108101. [Google Scholar] [CrossRef]

- Alamin, A.B.; Wu, Y.L.; Zhu, J.; Wang, K.B.; Zheng, H.Y. Investigation into forming yttria-stabilized zirconia/PEKK composite with superior mechanical and tribological properties. Mater. Today Commun. 2025, 42, 111272. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, Q.; Zhou, K.; Jing, B.; Zhu, K.; Shi, J.; Li, C. Effects of hygrothermal condition on water diffusion and flexural properties of carbon–glass hybrid fiber-reinforced epoxy polymer winding pipes. Polymers 2024, 16, 3433. [Google Scholar] [CrossRef]

- Li, S.; Chen, Z.; Wang, Y.; Huang, Y.; Yu, T. Quasi-static compression and hygrothermal stability of BMI/CE co-cured composite lattice cylindrical shell. Compos. Struct. 2021, 257, 113130. [Google Scholar] [CrossRef]

- Li, X.; Kumar, S.; Hwang, D.-W.; Shin, D.-H.; Kim, Y.-H. Pin-loaded tensile behavior and failure analysis of CF/PEKK composites under extreme temperature. Compos. Part A 2023, 175, 107823. [Google Scholar] [CrossRef]

- Yildirim, C.; Ulus, H.; Sas, H.S.; Topal, S.; Yildiz, M. Assessing the fracture and dynamic mechanical performance of CF/PEKK joints bonded with epoxy-based adhesive film for aerospace applications: Impact of thermal and cycling hygrothermal conditions. Compos. Part A 2025, 190, 108659. [Google Scholar] [CrossRef]

- Pedoto, G.; Grandidier, J.-C.; Gigliotti, M.; Vinet, A. Assessment and simulation of the thermomechanical tensile and creep behavior of C/PEKK composites for aircraft applications above the glass transition temperature. Compos. Struct. 2023, 318, 117069. [Google Scholar] [CrossRef]

- Yun, Z.X.; Zhu, S.W.; Chen, L.M.; Pan, X.; Deng, J.Q.; Fan, H.Y.; Li, W.G. Mode I delamination propagation of thermoplastic composite laminate at different temperatures: Experimental and numerical simulation. Compos. Struct. 2025, 363, 119096. [Google Scholar] [CrossRef]

- Dong, S.C.; Zhou, P.; Ning, Z.; Wu, X.; Li, C.G.; Xian, G.J. Durability of carbon- and glass-fiber reinforced thermoplastic polymer composites: A literature review. J. Build. Eng. 2024, 98, 111055. [Google Scholar] [CrossRef]

- Micelli, F.; Nanni, A. Durability of FRP rods for concrete structures. Constr. Build. Mater. 2004, 18, 491–503. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, B.; Shi, F.; Liu, K.; Peng, G.; Gao, L.; Gao, J.; Du, Y. Study on the Influence of hygrothermal aging on the mechanical properties of carbon fabric/polyetheretherketone Composites. Polymers 2025, 17, 724. [Google Scholar] [CrossRef]

- HB 7618; Data Presentation Guidelines on Mechanical Properties for Polymer Matrix Composite Materials. The Ministry of Industry and Information Technology of China: Beijing, China, 2013.

- ASTM D5229; Standard Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite Materials. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM D7264; Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM D2344; Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates. ASTM: West Conshohocken, PA, USA, 2022.

- ASTM D3518; Standard Test Method for in-Plane Shear Response of Polymer Matrix Composite Materials by Tensile Test of a ±45° Laminate. ASTM: West Conshohocken, PA, USA, 2021.

- Scida, D.; Assarar, M.; Poilâne, C.; Ayad, R. Influence of hygrothermal ageing on the damage mechanisms of flax-fibre reinforced epoxy composite. Compos. Part B Eng. 2013, 48, 51–58. [Google Scholar] [CrossRef]

- Amedewovo, L.; Levy, A.; Plessixa, B.d.P.d.; Orgéas, L.; Corre, S.L. Online characterization of moisture transport in a high-performance carbon fiber-reinforced thermoplastic composite at high temperatures: Identification of diffusion kinetics. Compos. Part B Eng. 2023, 256, 110629. [Google Scholar] [CrossRef]

- Kitamoto, K.; Minakuchi, S.; Yokozeki, T. Modeling nonlinear, hysteretic, and irreversible moisture-induced deformation of CFRP based on two-phase diffusion theory. Compos. Part A 2025, 192, 108765. [Google Scholar] [CrossRef]

- Wu, R.; Li, Y.; Yu, T. Comparative study on the hygrothermal durability of different fiber reinforced composites. Acta Mater. 2022, 39, 4406–4419. [Google Scholar] [CrossRef]

- He, F. Carbon Fibre and Graphite Fibre; Chemical Industry Press: Beijing, China, 2010; pp. 364–368. [Google Scholar]

- Mim, F.A. Effect of moisture absorption on the mechanical behavior of banana-bamboo-glass fiber reinforced hybrid composites in NaCl solution. Hybrid Adv. 2023, 10, 100451. [Google Scholar] [CrossRef]

- Szpoganicz, E.; Hübner, F.; Beier, U.; Geistbeck, M.; Ruckdäschel, H. The effect of prepreg ply thickness in carbon fiber reinforced composites on intralaminar toughness and shear strength in cryogenic environments for liquid hydrogen storage tanks. Compos. Part B Eng. 2025, 292, 112077. [Google Scholar] [CrossRef]

- Bandaru, A.K.; Pothnis, J.R.; Portela, A.; Gujjala, R.; Ma, H.; O’Higgins, R.M. Flexural and interlaminar shear response of novel methylmethacrylate composites reinforced with high-performance fibres. Polym. Test. 2024, 140, 108578. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Dashatan, S.H. 4.02 Influence of fiber/matrix interface properties on the performance of fiber reinforcedpolymer composites. Compr. Mech. Mater. 2024, 4, 22–30. [Google Scholar] [CrossRef]

- Vieille, B.; Albouy, W.; Taleb, L. Investigations on stamping of C/PEEK laminates: Influence on meso-structure and macroscopic mechanical properties under severe environmental conditions. Compos. Part B Eng. 2014, 63, 101–110. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, J.; Wei, J.; Liu, M.; Li, X.; Ding, A. Long-term mechanical properties of carbon fiber reinforced vinyl resin composites in hygrothermal environment. Acta Mater. 2023, 40, 1406–1416. [Google Scholar]

- Zhuang, X.J.; Ma, J.S.; Dan, Y.; Jiang, L.; Huang, Y. Hydrothermal aging of carbon fiber reinforced epoxy composites with different interface structures. Polym. Degrad. Stabil. 2023, 212, 110352. [Google Scholar] [CrossRef]

- Chiang, C.L.; Chou, H.Y.; Shen, M.Y. Effect of environmental aging on mechanical properties of graphene nanoplatelet/nanocarbon aerogel hybrid-reinforced epoxy/ carbon fiber composite laminates. Compos. Part A Appl. Sci. Manuf. 2020, 130, 105718. [Google Scholar] [CrossRef]

| Type | Lay-Up Design | Length/mm | Width/mm | Thickness/mm |

|---|---|---|---|---|

| Weft bending specimen | [0f]8 | 150 | 13 | 2.4 |

| Warp bending specimen | [90f]8 | 150 | 13 | 2.4 |

| Interfacial shear specimen | [0f]8 | 30 | 6 | 3 |

| In-plane shear test | [±45]2s | 250 | 25 | 2.4 |

| Moisture absorption specimen | [0f]8 | 50 | 50 | 2.4 |

| Material | n | k/h−n | Mm/wt% | D/(10−3 mm2/h−1) |

|---|---|---|---|---|

| CFF/PEKK composite | 0.48 | 0.063 | 0.27 | 2.01 |

| Sate | Fiber Direction | First Batch | Second Batch | Third Batch | Average |

|---|---|---|---|---|---|

| CTD | Warp | 109.13 | 107.11 | 106.90 | 107.71 |

| Weft | 106.37 | 107.09 | 108.31 | 107.26 | |

| ETW | Warp | 89.61 | 90.68 | 89.75 | 90.01 |

| Weft | 90.64 | 89.23 | 88.04 | 89.30 |

| Sate | Fiber Direction | First Batch | Second Batch | Third Batch | Average |

|---|---|---|---|---|---|

| CTD | Warp | 102.75 | 101.56 | 103.83 | 102.71 |

| Weft | 101.57 | 103.21 | 103.41 | 102.38 | |

| ETW | Warp | 97.68 | 96.89 | 98.40 | 97.66 |

| Weft | 97.58 | 97.52 | 96.89 | 97.33 |

| Property | State | First Batch | Second Batch | Third Batch | Average |

|---|---|---|---|---|---|

| Strength | RTD | 112.67 | 110.39 | 111.49 | 111.52 |

| ETW | 88.67 | 89.61 | 91.89 | 90.06 | |

| Modulus | RTD | 106.36 | 107.34 | 106.97 | 106.89 |

| ETW | 94.22 | 95.23 | 93.71 | 94.39 |

| State | First Batch | Second Batch | Third Batch | Average |

|---|---|---|---|---|

| RTD | 120.08 | 114.34 | 116.83 | 117.08 |

| ETW | 86.28 | 87.06 | 84.06 | 85.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Zhang, B.; Shi, F.; Liu, K.; Peng, G.; Gao, J. Study on the Mechanical Properties of Carbon Fabric/Polyetherketoneketone Composites Under Different Environmental Conditions. Polymers 2025, 17, 1142. https://doi.org/10.3390/polym17091142

Xu X, Zhang B, Shi F, Liu K, Peng G, Gao J. Study on the Mechanical Properties of Carbon Fabric/Polyetherketoneketone Composites Under Different Environmental Conditions. Polymers. 2025; 17(9):1142. https://doi.org/10.3390/polym17091142

Chicago/Turabian StyleXu, Xiangyu, Baoyan Zhang, Fenghui Shi, Kai Liu, Gongqiu Peng, and Junpeng Gao. 2025. "Study on the Mechanical Properties of Carbon Fabric/Polyetherketoneketone Composites Under Different Environmental Conditions" Polymers 17, no. 9: 1142. https://doi.org/10.3390/polym17091142

APA StyleXu, X., Zhang, B., Shi, F., Liu, K., Peng, G., & Gao, J. (2025). Study on the Mechanical Properties of Carbon Fabric/Polyetherketoneketone Composites Under Different Environmental Conditions. Polymers, 17(9), 1142. https://doi.org/10.3390/polym17091142