Bio-Based Stabilization of Natural Soil for Rammed Earth Construction: A Review on Mechanical and Water Durability Performance

Abstract

:1. Introduction

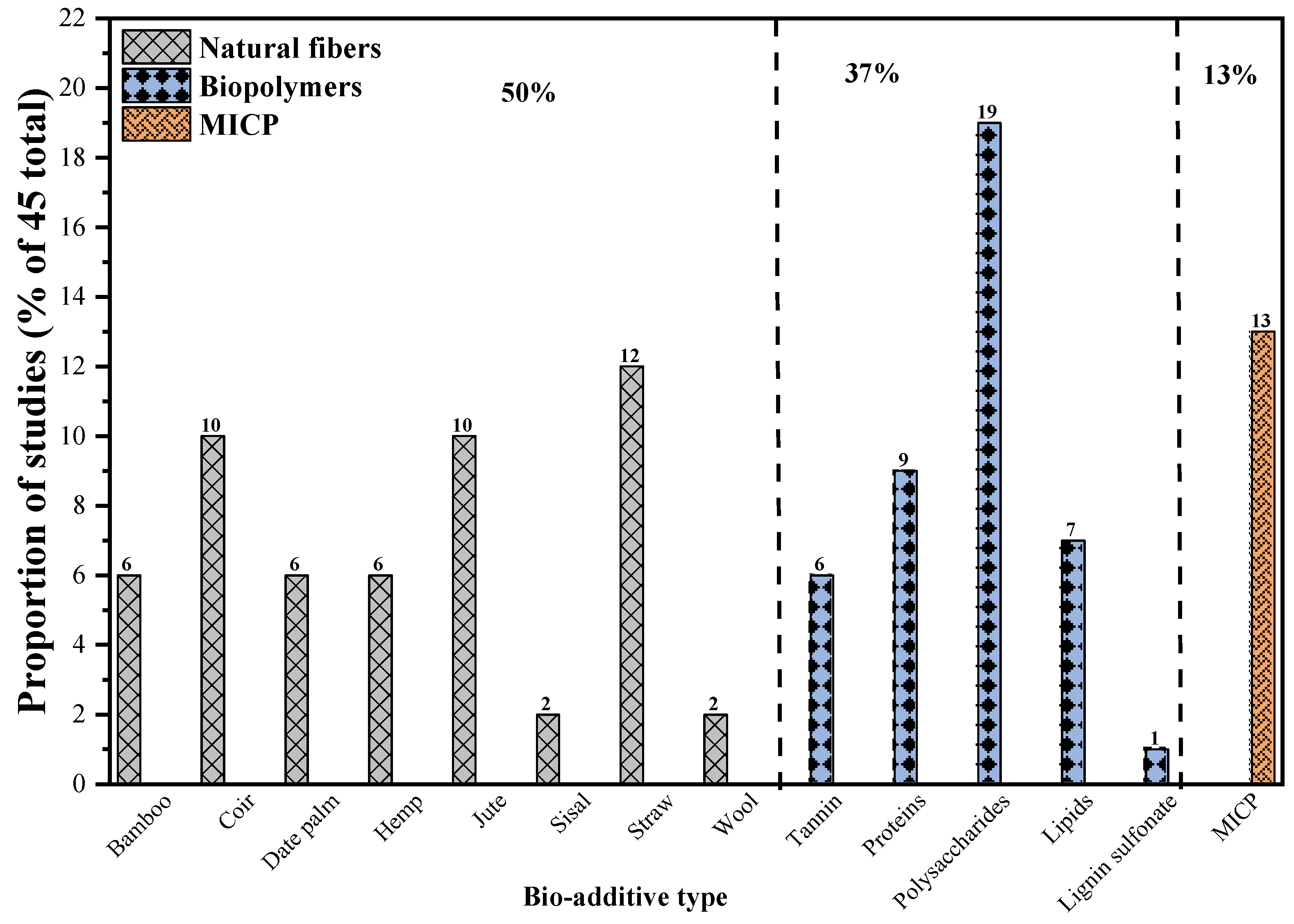

2. Literature Search Methodology

- Only studies about the RE construction method were considered. Research on bio-treatments for other earth construction techniques, such as cob, adobe, poured earth, and compressed earth blocks, was disregarded.

- The literature needed to focus on stabilizing plain RE using bio-based materials or techniques (e.g., NFs, biopolymers, MICP). Studies using bio-based materials as secondary additives in chemically stabilized rammed earth were briefly mentioned but not discussed or analyzed at significant length.

- Emphasis was placed on works investigating the mechanical and water durability performance of BRE mixes. Other performance evaluation themes such as hygrothermal behavior, acoustic performance, thermal comfort, energy performance, and cost evaluation are outside the scope of this review and were therefore not used as a basis for the literature search.

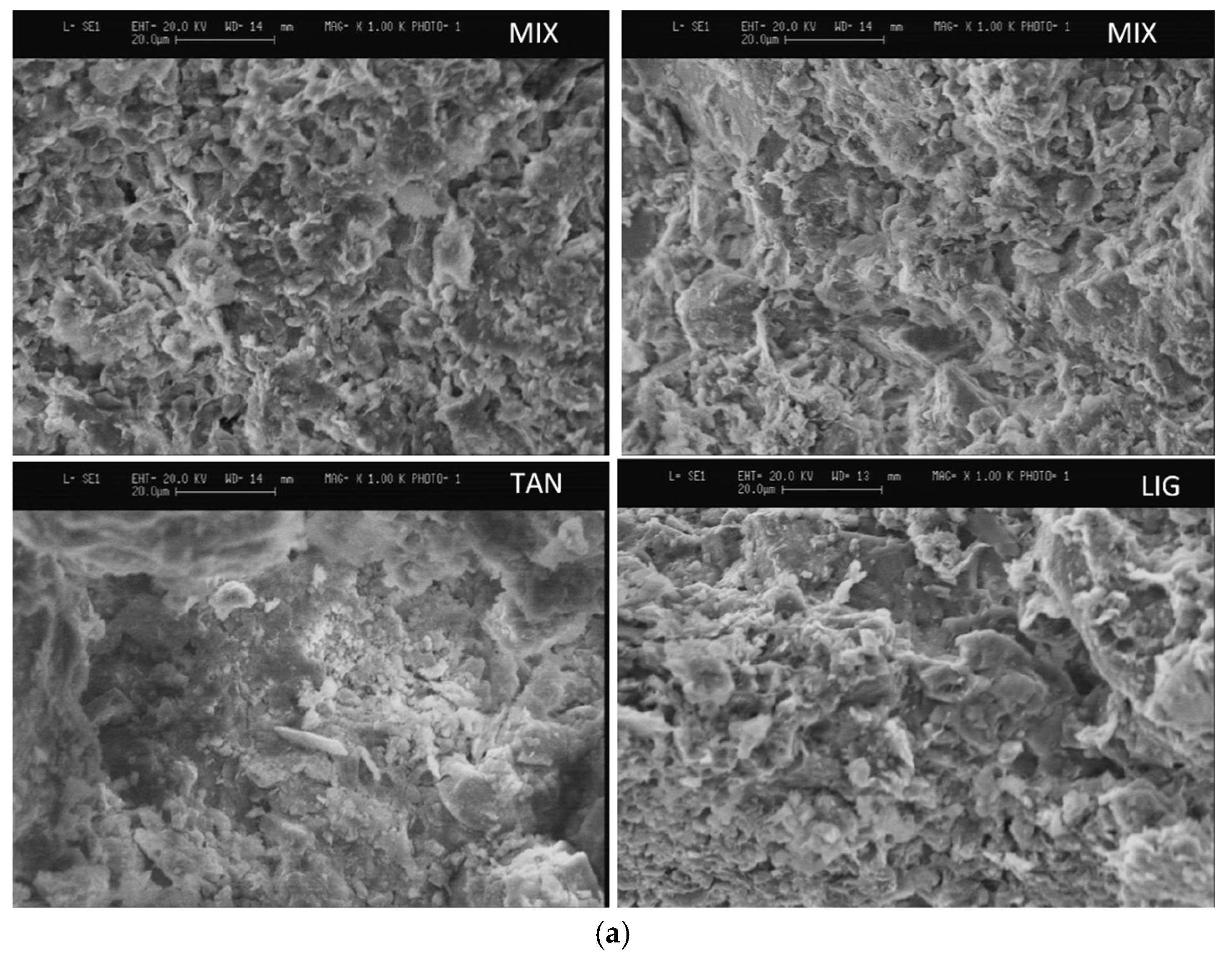

3. Brief Overview of the Bio-Additive Materials Used in RE Application

3.1. Natural Fibers

3.2. Biopolymers

3.2.1. Polysaccharides

3.2.2. Proteins

3.2.3. Lipids

3.2.4. Tannins

3.2.5. Lignin Sulfonate

3.3. Biocementation

3.3.1. Ureolytic Activity Rate

3.3.2. Nutrient Delivery Methods

3.3.3. Spatial Heterogeneity in Calcite Distribution

4. Mechanical Performance of BRE

4.1. Uniaxial Compression Strength

4.1.1. NF-Reinforced RE (NFRE)

4.1.2. Biopolymer-Stabilized RE (BPRE)

4.1.3. Microbially Indurated Rammed Earth (MIRE)

4.2. Tensile Strength

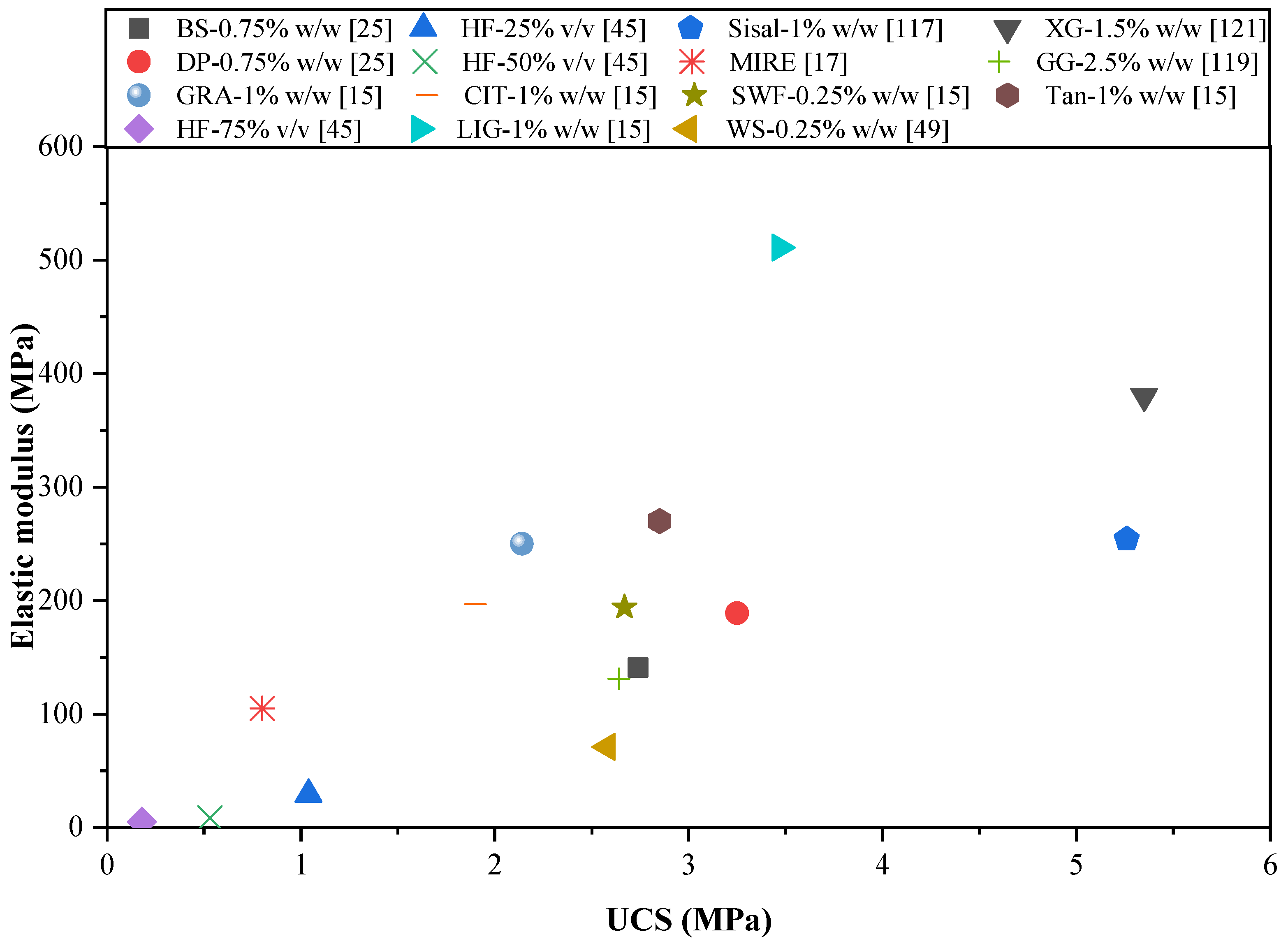

4.3. Elastic Modulus

4.4. Flexural and Shear Strength

5. Water Durability of BRE

5.1. Effect on Moisture Ingress Behaviour

5.2. Effect on Hydrophobicity

5.3. Effect on Strength Sensitivity in a Humid Environment

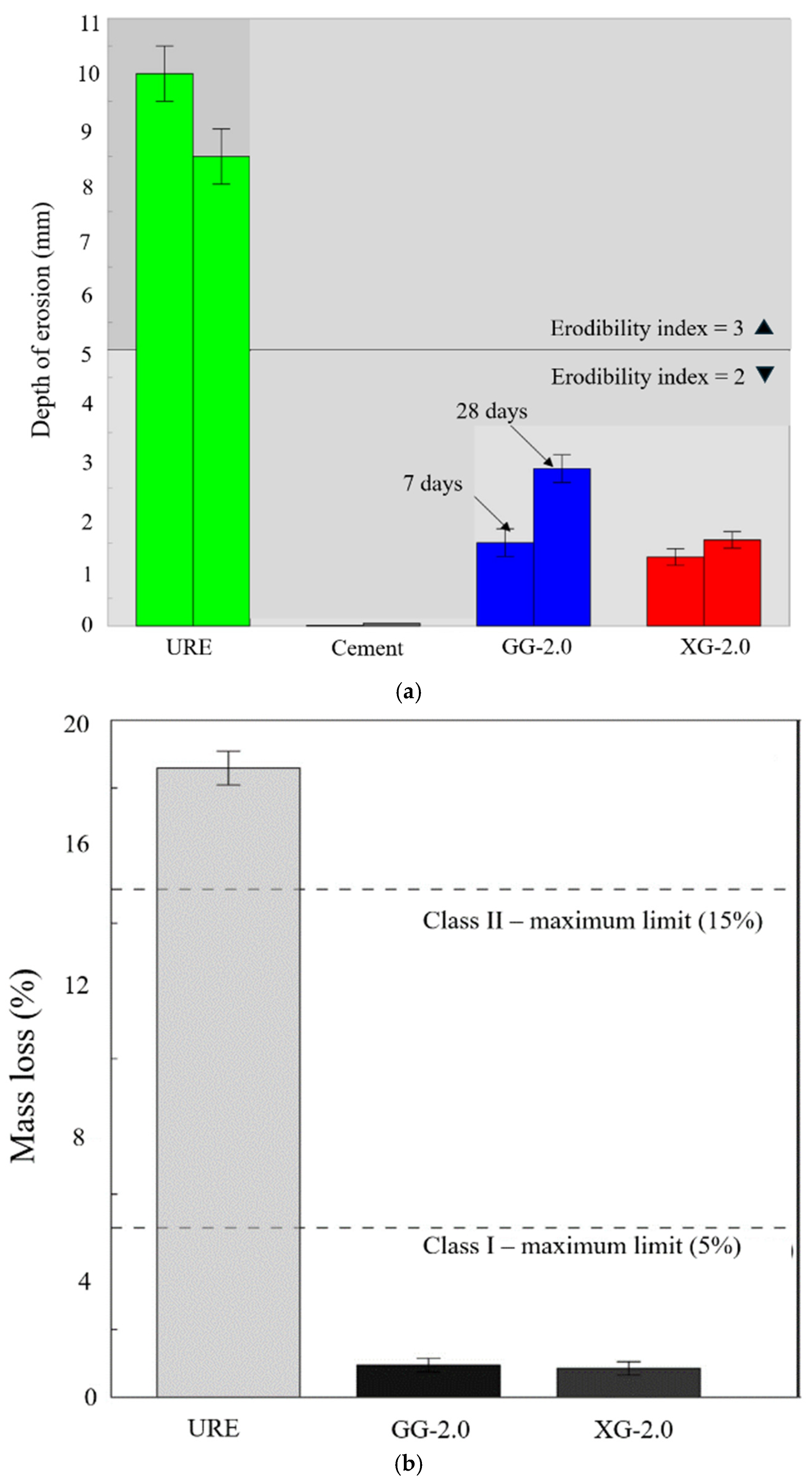

5.4. Effect on Water-Induced Erosion

6. Discussion on Current Challenges and Perspectives for Future Research

6.1. Hydrophilic and Biodegradable Nature of Bio-Based Materials

6.2. Soil Variability Issues

6.3. Limited Research on the Mechanical Performance of BRE

6.4. Issues Related to Water Durability Assessment Methods

7. Summary and Conclusions

- The compressive strength of RE is generally improved using biopolymers, with most studies showing an increase of around 13.3% to more than 100% compared to URE. Biopolymers enhance strength through surface coating, interparticle binding, or void filling.

- Natural fibers (NFs) and biocementation through MICP treatment have the potential to enhance the UCS of RE materials; however, the effectiveness is contingent upon several variables. For NFs, it is advisable to limit usage to no more than 1 wt% and a fiber length of 25 mm for stabilizing RE. Also, a fiber type that possesses high modulus, high tensile strength, and low water absorption typically benefits UCS enhancement. Regarding MICP, the UCS increase is reliant on the concentrations of both microorganisms and calcium present in the intergranular medium, as well as the nitrogen source.

- The reported tensile strengths of different BRE mixes appeared to be generally low, ranging from 0.1 to 0.5 MPa. However, their corresponding tensile-to-compressive (T/C) ratios fall between 0.07 and 0.11, which is considered acceptable for RE materials.

- The literature reveals a broader dispersion in the elastic modulus of BRE mixtures, with values spanning from 29.2 to 511 MPa. This variability arises from differing calculation methods employed by various authors, challenges in measuring strain, and variations in the bio-additive materials utilized. This study emphasizes the importance of establishing reliable standard procedures for strain measurement and the mathematical calculation of the elastic modulus of BRE mixtures.

- Some studies indicate that using biopolymers can improve RE’s water durability by limiting moisture ingress, reducing strength sensitivity in a humid environment, and improving erosion resistance. Furthermore, lipid-based biopolymers can increase hydrophobic properties by coating RE materials’ surfaces, thereby decreasing water penetration.

- The surface treatment of RE materials by MICP helps to reduce the erosion rate and limits water absorption to a certain extent. However, the durability of NFRE still needs to be thoroughly investigated.

- Holistically, the existing body of literature on BRE technology still needs improvement. By delving deeper into the possibilities of novel bio-based materials, improving the performance of current biopolymers and NFs through crosslinking and surface treatment, respectively, establishing suitable criteria for soil selection in BRE, broadening the assessment of BRE’s mechanical performance to encompass other pertinent parameters discussed in this study, and improving the reliability of BRE’s water durability assessment through a combination of laboratory and in situ long-term performance data, researchers can help shape this healthy, more sustainable and resilient building practice for generations to come.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- United Nations Environment Programme. Building Materials and the Climate: Constructing a New Future; United Nations Environment Programme: Nairobi, Kenya, 2023. [Google Scholar]

- Morel, J.-C.; Charef, R.; Hamard, E.; Fabbri, A.; Beckett, C.; Bui, Q.-B. Earth as construction material in the circular economy context: Practitioner perspectives on barriers to overcome. Philos. Trans. R. Soc. B Biol. Sci. 2021, 376, 20200182. [Google Scholar] [CrossRef] [PubMed]

- Khadka, B. Rammed earth, as a sustainable and structurally safe green building: A housing solution in the era of global warming and climate change. Asian J. Civ. Eng. 2020, 21, 119–136. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Earth construction: Lessons from the past for future eco-efficient construction. Constr. Build. Mater. 2012, 29, 512–519. [Google Scholar] [CrossRef]

- Minke, G. Building with Earth: Design and Technology of a Sustainable Architecture; De Gruyter: Berlin, Germany, 2006. [Google Scholar]

- Avila, F.; Puertas, E.; Gallego, R. Characterization of the mechanical and physical properties of unstabilized rammed earth: A review. Constr. Build. Mater. 2021, 270, 121435. [Google Scholar] [CrossRef]

- Beckett, C.; Jaquin, P.; Morel, J.-C. Weathering the storm: A framework to assess the resistance of earthen structures to water damage. Constr. Build. Mater. 2020, 242, 118098. [Google Scholar] [CrossRef]

- Maniatidis, V.; Walker, P. A Review of Rammed Earth Construction for DTi Partners in Innovation Project ‘Developing Rammed Earth for UK Housing’; University of Bath: Bath, UK, 2003. [Google Scholar]

- Gallipoli, D.; Bruno, A.W.; Bui, Q.-B.; Fabbri, A.; Faria, P.; Oliveira, D.V.; Ouellet-Plamondon, C.; Silva, R.A. Durability of Earth Materials: Weathering Agents, Testing Procedures and Stabilisation Methods. Testing and Characterisation of Earth-Based Building Materials and Elements: State-of-the-Art Report of the RILEM TC 274-TCE; Springer: Berlin/Heidelberg, Germany, 2021; pp. 211–241. [Google Scholar]

- Gupta, R. Characterizing material properties of cement-stabilized rammed earth to construct sustainable insulated walls. Case Stud. Constr. Mater. 2014, 1, 60–68. [Google Scholar] [CrossRef]

- Ciancio, D.; Beckett, C.; Carraro, J. Optimum lime content identification for lime-stabilised rammed earth. Constr. Build. Mater. 2014, 53, 59–65. [Google Scholar] [CrossRef]

- Siddiqua, S.; Barreto, P.N. Chemical stabilization of rammed earth using calcium carbide residue and fly ash. Constr. Build. Mater. 2018, 169, 364–371. [Google Scholar] [CrossRef]

- Meek, A.H.; Elchalakani, M.; Beckett, C.T.; Grant, T. Alternative stabilised rammed earth materials incorporating recycled waste and industrial by-products: Life cycle assessment. Constr. Build. Mater. 2021, 267, 120997. [Google Scholar] [CrossRef]

- Ávila, F.; Puertas, E.; Gallego, R. Characterization of the mechanical and physical properties of stabilized rammed earth: A review. Constr. Build. Mater. 2022, 325, 126693. [Google Scholar] [CrossRef]

- Losini, A.E.; Grillet, A.-C.; Woloszyn, M.; Lavrik, L.; Moletti, C.; Dotelli, G.; Caruso, M. Mechanical and microstructural characterization of rammed earth stabilized with five biopolymers. Materials 2022, 15, 3136. [Google Scholar] [CrossRef]

- Sen, B.; Chanda, D.; Saha, R. Mechanical strength characterization and seismic performance of rammed earthen walls built on eco-friendly lateritic soil and sustainable stabilizing materials. Sadhana 2024, 49, 37. [Google Scholar] [CrossRef]

- Porter, H.; Blake, J.; Dhami, N.K.; Mukherjee, A. Rammed earth blocks with improved multifunctional performance. Cem. Concr. Compos. 2018, 92, 36–46. [Google Scholar] [CrossRef]

- Calle, V.; Rojas, R.; Guillen, K.; Pantò, B.; Nakamatsu, J.; Silva, G.; Chácara, C. Use of Organic Residues for the Mechanical Enhancement of Sustainable Rammed Earth. In Proceedings of the International Conference on Earthen Construction, Edinburgh, UK, 8–10 July 2024; Springer: Cham, Switzerland, 2024; pp. 152–161. [Google Scholar]

- Kraus, C.; Hirmas, D.; Roberts, J. Microbially indurated rammed earth: A long awaited next phase of earthen architecture. ARCC Conf. Repos. 2013. [Google Scholar] [CrossRef]

- Masrour, I.; Baba, K.; Simou, S. Naturally Strengthening Rammed Earth: The Promising Potential of Biopolymers. Mediterr. Archit. Herit. RIPAM10 2024, 13, 233. [Google Scholar]

- Losini, A.; Grillet, A.; Bellotto, M.; Woloszyn, M.; Dotelli, G. Natural additives and biopolymers for raw earth construction stabilization–A review. Constr. Build. Mater. 2021, 304, 124507. [Google Scholar] [CrossRef]

- Nasr, Y.; El Zakhem, H.; Hamami, A.E.A.; El Bachawati, M.; Belarbi, R. Comprehensive Review of Innovative Materials for Sustainable Buildings’ Energy Performance. Energies 2023, 16, 7440. [Google Scholar] [CrossRef]

- Ghosh, E.; Fahim, S.; Shahariar, N.K.; Alam, T. Prospect of biopolymer application for sustainable and durable earthen structures in context of Bangladesh: A brief review. AIP Conf. Proc. 2023, 2713, 020026. [Google Scholar]

- Laborel-Préneron, A.; Aubert, J.; Magniont, C.; Tribout, C.; Bertron, A. Plant aggregates and fibers in earth construction materials: A review. Constr. Build. Mater. 2016, 111, 719–734. [Google Scholar] [CrossRef]

- El Bourki, A.; Koutous, A.; Hilali, E. A review on the use of date palm fibers to reinforce earth-based construction materials. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Thompson, D.; Augarde, C.; Osorio, J.P. A review of chemical stabilisation and fibre reinforcement techniques used to enhance the mechanical properties of rammed earth. Discov. Civ. Eng. 2025, 2, 27. [Google Scholar] [CrossRef]

- Bernardi, D.; DeJong, J.; Montoya, B.; Martinez, B. Bio-bricks: Biologically cemented sandstone bricks. Constr. Build. Mater. 2014, 55, 462–469. [Google Scholar] [CrossRef]

- Harkes, M.P.; van Paassen, L.A.; Booster, J.L.; Whiffin, V.S.; van Loosdrecht, M.C.M. Fixation and distribution of bacterial activity in sand to induce carbonate precipitation for ground reinforcement. Ecol. Eng. 2010, 36, 112–117. [Google Scholar] [CrossRef]

- Van Paassen, L.A.; Daza, C.M.; Staal, M.; Sorokin, D.Y.; Zon, W.v.d.; van Loosdrecht, M.C. Potential soil reinforcement by biological denitrification. Ecol. Eng. 2010, 36, 168–175. [Google Scholar] [CrossRef]

- Choi, S.-G.; Chang, I.; Lee, M.; Lee, J.-H.; Han, J.-T.; Kwon, T.-H. Review on geotechnical engineering properties of sands treated by microbially induced calcium carbonate precipitation (MICP) and biopolymers. Constr. Build. Mater. 2020, 246, 118415. [Google Scholar] [CrossRef]

- Ezzat, S.M. A critical review of microbially induced carbonate precipitation for soil stabilization: The global experiences and future prospective. Pedosphere 2023, 33, 717–730. [Google Scholar] [CrossRef]

- Steffens, F.; Steffens, H.; Oliveira, F.R. Applications Of Natural Fibers On Architecture. Procedia Eng. 2017, 200, 317–324. [Google Scholar] [CrossRef]

- Prakash, S.O.; Sahu, P.; Madhan, M.; Santhosh, A.J. A Review on Natural Fibre-Reinforced Biopolymer Composites: Properties and Applications. Int. J. Polym. Sci. 2022, 2022, 7820731. [Google Scholar] [CrossRef]

- Overhage, V.; Reiter, L.; Schrömbgens, N.; Gries, T. Bio-Based Fibre Materials as Reinforcement Materials in the Construction Industry. In International Conference on Bio-Based Building Materials; Springer: Cham, Switzerland, 2023; pp. 501–513. [Google Scholar]

- Jannat, N.; Hussien, A.; Abdullah, B.; Cotgrave, A. Application of agro and non-agro waste materials for unfired earth blocks construction: A review. Constr. Build. Mater. 2020, 254, 119346. [Google Scholar] [CrossRef]

- Danso, H.; Martinson, D.B.; Ali, M.; Williams, J.B. Physical, mechanical and durability properties of soil building blocks reinforced with natural fibres. Constr. Build. Mater. 2015, 101, 797–809. [Google Scholar] [CrossRef]

- Laibi, A.B.; Poullain, P.; Leklou, N.; Gomina, M.; Sohounhloué, D.K.C. Influence of the kenaf fiber length on the mechanical and thermal properties of Compressed Earth Blocks (CEB). KSCE J. Civ. Eng. 2018, 22, 785–793. [Google Scholar] [CrossRef]

- Mostafa, M.; Uddin, N. Experimental analysis of Compressed Earth Block (CEB) with banana fibers resisting flexural and compression forces. Case Stud. Constr. Mater. 2016, 5, 53–63. [Google Scholar] [CrossRef]

- Losini, A.E.; Lavrik, L.; Caruso, M.; Woloszyn, M.; Grillet, A.C.; Dotelli, G.; Stampino, P.G. Mechanical Properties of Rammed Earth Stabilized with Local Waste and Recycled Materials. Constr. Technol. Archit. 2022, 1, 113–123. [Google Scholar]

- Millogo, Y.; Morel, J.-C.; Aubert, J.-E.; Ghavami, K. Experimental analysis of Pressed Adobe Blocks rein-forced with Hibiscus cannabinus fibers. Constr. Build. Mater. 2014, 52, 71–78. [Google Scholar] [CrossRef]

- Ashour, T.; Wieland, H.; Georg, H.; Bockisch, F.-J.; Wu, W. The influence of natural reinforcement fibres on insulation values of earth plaster for straw bale buildings. Mater. Des. 2010, 31, 4676–4685. [Google Scholar] [CrossRef]

- Sen, B.; Saha, R. Experimental and numerical investigation of mechanical strength characteristics of natural fiber retrofitted rammed earth walls. Geotext. Geomembr. 2022, 50, 970–993. [Google Scholar] [CrossRef]

- Raavi, S.S.D.; Tripura, D.D. Predicting and evaluating the engineering properties of unstabilized and cement stabilized fibre reinforced rammed earth blocks. Constr. Build. Mater. 2020, 262, 120845. [Google Scholar] [CrossRef]

- Tripura, D.D.; Gupta, S.; Debbarma, B.; Deep, R.S.S. Flexural strength and failure trend of bamboo and coir reinforced cement stabilized rammed earth wallettes. Constr. Build. Mater. 2020, 242, 117986. [Google Scholar] [CrossRef]

- Hallal, M.M.; Sadek, S.; Najjar, S.S. Evaluation of Engineering Characteristics of Stabilized Rammed-Earth Material Sourced from Natural Fines-Rich Soil. J. Mater. Civ. Eng. 2018, 30, 04018273. [Google Scholar] [CrossRef]

- Mabrouk, Y.; Benazzouk, A.; Lahmar, A.; Azrour, M.; Mocerino, C.; Lahmar, A. Elaboration and characteriza-tion of lightweight rammed earth containing hemp particles. Mater. Today Proc. 2022, 58, 1389–1396. [Google Scholar] [CrossRef]

- Koutous, A.; Hilali, E. Reinforcing rammed earth with plant fibers: A case study. Case Stud. Constr. Mater. 2021, 14, e00514. [Google Scholar] [CrossRef]

- El Bourki, A.; Koutous, A.; Hilali, E. Date palm fiber-reinforcement impact on rammed earth mechanical behavior. Constr. Build. Mater. 2025, 461, 139918. [Google Scholar] [CrossRef]

- Sabbà, M.F.; Tesoro, M.; Falcicchio, C.; Foti, D. Rammed Earth with Straw Fibers and Earth Mortar: Mix Design and Mechanical Characteristics Determination. Fibers 2021, 9, 30. [Google Scholar] [CrossRef]

- Baibordy, A.; Yekrangnia, M.; Jahromi, S.G. A comprehensive study on the mechanical properties of natural fiber reinforced stabilized rammed earth using experimental and data-driven fuzzy logic-based analysis. Clean. Mater. 2025, 15, 100300. [Google Scholar] [CrossRef]

- Sun, Y.; Ma, X.; Hu, H. Marine polysaccharides as a versatile biomass for the construction of nano drug de-livery systems. Mar. Drugs 2021, 19, 345. [Google Scholar] [CrossRef] [PubMed]

- Vissac, A.; Bourgès, A.; Gandreau, D.; Anger, R.; Fontaine, L. Argiles & Biopolymères—Les Stabilisants Naturels pour la Construction en Terre; CRAterre: Villefontaine, France, 2017. [Google Scholar]

- Guihéneuf, S.; Rangeard, D.; Perrot, A.; Cusin, T.; Collet, F.; Prétot, S. Effect of bio-stabilizers on capillary absorption and water vapour transfer into raw earth. Mater. Struct. 2020, 53, 138. [Google Scholar] [CrossRef]

- Mikofsky, R.A.; Armistead, S.J.; Srubar, W.V., III. On the bonding characteristics of clays and biopolymers for sustainable Earthen construction. In International Conference on Bio-Based Building Materials; Springer: Cham, Switzerland, 2023; pp. 280–292. [Google Scholar]

- Bhat, I.M.; Wani, S.M.; Mir, S.A.; Masoodi, F. Advances in xanthan gum production, modifications and its applications. Biocatal. Agric. Biotechnol. 2022, 42, 102328. [Google Scholar] [CrossRef]

- Pydi, R.; Yadu, L.; Chouksey, S.K. Evaluation of Xanthan and Guar Gum for Stabilising Soil in Terms of Strength Parameters-A Review. Indian Geotech. J. 2023, 54, 1621–1643. [Google Scholar] [CrossRef]

- Moghal, A.A.B.; Vydehi, K.V. State-of-the-art review on efficacy of xanthan gum and guar gum inclusion on the engineering behavior of soils. Innov. Infrastruct. Solut. 2021, 6, 108. [Google Scholar] [CrossRef]

- Muguda, S.; Lucas, G.; Hughes, P.; Augarde, C.; Cuccurullo, A.; Bruno, A.W.; Perlot, C.; Gallipoli, D. Advances in the use of biological stabilisers and hyper-compaction for sustainable earthen construction ma-terials. Earthen Dwell. Struct. Curr. Status Their Adopt 2019, 191–201. [Google Scholar]

- Muguda, S.; Booth, S.; Hughes, P.; Augarde, C.; Perlot, C.; Bruno, A.; Gallipoli, D. Preliminary study on use of biopolymers in earthen construction. In Proceedings of the 7th International Conference on Unsaturated Soils, Hong Kong, China, 3–5 August 2018; 8, pp. 1–2. [Google Scholar]

- Muguda, S.; Hughes, P.N.; Augarde, C.E.; Perlot, C.; Walter Bruno, A.; Gallipoli, D. Cross-linking of biopol-ymers for stabilizing earthen construction materials. Build. Res. Inf. 2022, 50, 502–514. [Google Scholar] [CrossRef]

- Guihéneuf, S.; Rangeard, D.; Perrot, A. Addition of bio based reinforcement to improve workability, mechanical properties and water resistance of earth-based materials. Acad. J. Civ. Eng. 2019, 37, 184–192. [Google Scholar]

- Ilman, B.; Balkis, A.P. Sustainable biopolymer stabilized earthen: Utilization of chitosan biopolymer on mechanical, durability, and microstructural properties. J. Build. Eng. 2023, 76, 107220. [Google Scholar] [CrossRef]

- Moe, S.T.; Draget, K.I.; Skjak-Bræk, G.; Smidsrød, O. Food Polysaccharides and Their Applications; Stephen, A.M., Phillips, G.O., Eds.; Routledge Taylor & Francis Group: Boca Raton, FL, USA, 1995; p. 46. [Google Scholar]

- Menasria, F.; Perrot, A.; Rangeard, D. Using alginate biopolymer to enhance the mechanical properties of earth-based materials. Acad. J. Civ. Eng. 2017, 35, 143–147. [Google Scholar]

- Gîjiu, C.L.; Isopescu, R.; Dinculescu, D.; Memecică, M.; Apetroaei, M.-R.; Anton, M.; Schröder, V.; Rău, I. Crabs Marine Waste—A Valuable Source of Chitosan: Tuning Chitosan Properties by Chitin Extraction Optimization. Polymers 2022, 14, 4492. [Google Scholar] [CrossRef]

- Zemljič, L.F.; Strnad, S.; Šauperl, O.; Stana-Kleinschek, K. Characterization of Amino Groups for Cotton Fibers Coated with Chitosan. Text. Res. J. 2009, 79, 219–226. [Google Scholar] [CrossRef]

- Periolatto, M.; Ferrero, F.; Vineis, C. Antimicrobial chitosan finish of cotton and silk fabrics by UV-curing with 2-hydroxy-2-methylphenylpropane-1-one. Carbohydr. Polym. 2012, 88, 201–205. [Google Scholar] [CrossRef]

- Reddy, D.; Kowshik, K.; Kishor, M.J.; Chittaranajan, M.; Sravani, E. Investigation of chitosan bio-polymer effect on the geotechnical properties of an expansive soil. In Proceedings of the International Conference on Recent Trends in Engineering Materials, Management and Sciences (ICRTEMMS-2018), Hyderabad, India, 25–27 October 2018; pp. 25–27. [Google Scholar]

- Shariatmadari, N.; Reza, M.; Tasuji, A.; Ghadir, P.; Javadi, A.A. Experimental study on the effect of chitosan biopolymer on sandy soil stabilization. E3S Web Conf. EDP Sci. 2020, 195, 06007. [Google Scholar] [CrossRef]

- Kraus, C.; Hirmas, D.; Roberts, J. Compressive strength of blood stabilized earthen architecture. Earthen Archit. Past Present Future 2015, 217–220. [Google Scholar]

- Ma, J.; Abdelaal, A.; Zhang, H.; Zhou, A.; Fu, Y.; Xie, Y.M. Ultra-compressed earth block stabilized by bio-binder for sustainable building construction. Case Stud. Constr. Mater. 2024, 21, e03523. [Google Scholar] [CrossRef]

- Abdelaal, A.; Ma, J.; Gomaa, M.; Giustozzi, F.; Xie, Y.M. Stabilizing rammed earth using xanthan gum or animal glue as bio-binder. Front. Built Environ. 2025, 11, 1535947. [Google Scholar] [CrossRef]

- Dalgleish, D. Casein Micelles as Colloids: Surface Structures and Stabilities. J. Dairy Sci. 1998, 81, 3013–3018. [Google Scholar] [CrossRef]

- Eires, R.; Camões, A.; Jalali, S. Earth architecture: Ancient and new methods for durability improvement. In Structures and Architecture; CRC Press: London, UK, 2013. [Google Scholar]

- Thomas, L. Blood Plasma Components and Function. Available online: https://www.news-medical.net/health/Blood-Plasma-Components-and-Function.aspx (accessed on 16 May 2024).

- Piazza, G.J.; Nuñez, A.; Garcia, R.A. Identification of Highly Active Flocculant Proteins in Bovine Blood. Appl. Biochem. Biotechnol. 2011, 166, 1203–1214. [Google Scholar] [CrossRef]

- Sapkota, A. Lipids: Properties, Structure, Classification, Types, Functions. Available online: https://microbenotes.com/lipids/#:~:text=Properties%20of%20Lipids%201%20Lipids%20may%20be%20either,high%20proportions%20of%20saturated%20fatty%20acids.%20More%20items (accessed on 20 May 2024).

- Lin, H.; Liu, F.; Lourenço, S.; Schwantes, G.; Trumpf, S.; Holohan, D.; Beckett, C. Stabilization of an earthen material with Tung oil: Compaction, strength and hydrophobic enhancement. Constr. Build. Mater. 2021, 290, 123213. [Google Scholar] [CrossRef]

- Schaich, K.M. Lipid Oxidation: Theoretical Aspects. In Bailey’s Industrial Oil and Fat Products 1 (Part 7); John Wiley & Sons: Hoboken, NJ, USA, 2005; pp. 273–303. [Google Scholar]

- Arminger, B.; Jaxel, J.; Bacher, M.; Gindl-Altmutter, W.; Hansmann, C. On the drying behavior of natural oils used for solid wood finishing. Prog. Org. Coatings 2020, 148, 105831. [Google Scholar] [CrossRef]

- Hafshejani, K.S.; Moslemizadeh, A.; Shahbazi, K. A novel bio-based deflocculant for bentonite drilling mud. Appl. Clay Sci. 2016, 127, 23–34. [Google Scholar] [CrossRef]

- Digrak, M.; Alma, M.H.; Ilçim, A.; Sen, S. Antibacterial and Antifungal Effects of Various Commercial Plant Extracts. Pharm. Biol. 1999, 37, 216–220. [Google Scholar] [CrossRef]

- Lopes, P.J.G.; Calegari, L.; Silva, W.A.d.M.; Gatto, D.A.; Neto, P.N.d.M.; de Melo, R.R.; Bakke, I.A.; Delucis, R.d.A.; Missio, A.L. Tannin-based extracts of Mimosa tenuiflora bark: Features and prospecting as wood adhesives. Appl. Adhes. Sci. 2021, 9, 3. [Google Scholar] [CrossRef]

- Banakinao, S.; Tiem, S.; Lolo, K.; Koutsawa, Y.; Bedja, K.-S. Dataset of the use of tannin of néré (parkia-biglobosa) as a solution for the sustainability of the soil constructions in West Africa. Data Brief 2016, 8, 474–483. [Google Scholar] [CrossRef]

- Kaal, J.; Nierop, K.; Verstraten, J. Retention of tannic acid and condensed tannin by Fe-oxide-coated quartz sand. J. Colloid Interface Sci. 2005, 287, 72–79. [Google Scholar] [CrossRef]

- Aro, T.; Fatehi, P. Production and Application of Lignosulfonates and Sulfonated Lignin. ChemSusChem 2017, 10, 1861–1877. [Google Scholar] [CrossRef]

- Chen, Q.; Indraratna, B. Deformation behavior of lignosulfonate-treated sandy silt under cyclic. loading J. Geotech. Geoenviron. Eng. 2015, 141, 06014015. [Google Scholar] [CrossRef]

- Agrawal, A.; Kaushik, N.; Biswas, S. Derivatives and applications of lignin–an insight. Sci. Tech. J. 2014, 1, 30–36. [Google Scholar]

- Ragauskas, A.J.; Beckham, G.T.; Biddy, M.J.; Chandra, R.; Chen, F.; Davis, M.F.; Davison, B.H.; Dixon, R.A.; Gilna, P.; Keller, M.; et al. Lignin Valorization: Improving Lignin Processing in the Biorefinery. Science 2014, 344, 1246843. [Google Scholar] [CrossRef]

- Luo, H.; Abu-Omar, M.M. Chemicals From Lignin. In Encyclopedia of Sustainable Technologies; Abraham, M.A., Ed.; Elsevier: Oxford, UK, 2017; pp. 573–585. [Google Scholar]

- Shulga, G.; Rekner, F.; Varslavan, J. SW—Soil and water: Lignin-based interpolymer complexes as a novel adhesive for protection against erosion of sandy soil. J. Agric. Eng. Res. 2001, 78, 309–316. [Google Scholar] [CrossRef]

- Ta’Negonbadi, B.; Noorzad, R. Stabilization of clayey soil using lignosulfonate. Transp. Geotech. 2017, 12, 45–55. [Google Scholar] [CrossRef]

- Zhang, T.; Cai, G.; Liu, S. Assessment of mechanical properties in recycled lignin-stabilized silty soil as base fill material. J. Clean. Prod. 2018, 172, 1788–1799. [Google Scholar] [CrossRef]

- Vinod, J.S.; Indraratna, B.; Mahamud, M.A. Stabilisation of an erodible soil using a chemical admixture. Proc. Inst. Civ. Eng.-Ground Improv. 2010, 163, 43–51. [Google Scholar] [CrossRef]

- Indraratna, B.; Muttuvel, T.; Khabbaz, H.; Armstrong, R. Predicting the Erosion Rate of Chemically Treated Soil Using a Process Simulation Apparatus for Internal Crack Erosion. J. Geotech. Geoenviron. Eng. 2008, 134, 837–844. [Google Scholar] [CrossRef]

- Cai, G.; Zhang, T.; Liu, S.; Li, J.; Jie, D. Stabilization Mechanism and Effect Evaluation of Stabilized Silt with Lignin Based on Laboratory Data. Mar. Georesources Geotechnol. 2014, 34, 331–340. [Google Scholar] [CrossRef]

- Alazigha, D.P.; Indraratna, B.; Vinod, J.S.; Heitor, A. Mechanisms of stabilization of expansive soil with lignosulfonate admixture. Transp. Geotech. 2018, 14, 81–92. [Google Scholar] [CrossRef]

- Mujah, D.; Shahin, M.A.; Cheng, L. State-of-the-Art Review of Biocementation by Microbially Induced Calcite Precipitation (MICP) for Soil Stabilization. Geomicrobiol. J. 2016, 34, 524–537. [Google Scholar] [CrossRef]

- Akturk, B.; Gulen, H.; Cevher Keskin, B.; Yazar, T.; Akipek, F. Investigating the Possible Bio-Stabilization of Rammed Earth Through Microorganisms. NanoWorld J. 2023, 9, S24–S29. [Google Scholar]

- Barabesi, C.; Galizzi, A.; Mastromei, G.; Rossi, M.; Tamburini, E.; Perito, B. Bacillus subtilis Gene Cluster Involved in Calcium Carbonate Biomineralization. J. Bacteriol. 2007, 189, 228–235. [Google Scholar] [CrossRef]

- De Muynck, W.; De Belie, N.; Verstraete, W. Microbial carbonate precipitation in construction materials: A review. Ecol. Eng. 2010, 36, 118–136. [Google Scholar] [CrossRef]

- Zhu, T.; Dittrich, M. Carbonate Precipitation through Microbial Activities in Natural Environment, and Their Potential in Biotechnology: A Review. Front. Bioeng. Biotechnol. 2016, 4, 4. [Google Scholar] [CrossRef] [PubMed]

- Boling, J. Bioprecipitation of Calcite by Sporosarcina pasteurii: Developing Efficient Methodologies for Microbially Indurated Rammed Earth; University of Kansas: Kansas, KS, USA, 2015. [Google Scholar]

- Dhami, N.K.; Mukherjee, A. Can We Benefit from the Microbes Present in Rammed Earth? Cell 2015, 3, 7. [Google Scholar]

- Jiang, N.-J.; Wang, Y.-J.; Chu, J.; Kawasaki, S.; Tang, C.-S.; Cheng, L.; Du, Y.-J.; Shashank, B.S.; Singh, D.N.; Han, X.-L.; et al. Bio-mediated soil improvement: An introspection into processes, materials, characterization and applications. Soil Use Manag. 2022, 38, 68–93. [Google Scholar]

- Wu, Y.; Li, H.; Li, Y. Biomineralization induced by cells of Sporosarcina pasteurii: Mechanisms, applications and challenges. Microorganisms 2021, 9, 2396. [Google Scholar] [CrossRef]

- Kalantary, F.; Kahani, M. Optimization of the biological soil improvement procedure. Int. J. Environ. Sci. Technol. 2019, 16, 4231–4240. [Google Scholar]

- Dhami, N.K.; Mukherjee, A.; Reddy, M.S. Micrographical, minerological and nano-mechanical characterisation of microbial carbonates from urease and carbonic anhydrase producing bacteria. Ecol. Eng. 2016, 94, 443–454. [Google Scholar] [CrossRef]

- Jiang, N.-J.; Yoshioka, H.; Yamamoto, K.; Soga, K. Ureolytic activities of a urease-producing bacterium and purified urease enzyme in the anoxic condition: Implication for subseafloor sand production control by microbially induced carbonate precipitation (MICP). Ecol. Eng. 2016, 90, 96–104. [Google Scholar] [CrossRef]

- Fu, T.; Saracho, A.C.; Haigh, S.K. Microbially induced carbonate precipitation (MICP) for soil strengthening: A comprehensive review. Biogeotechnics 2023, 1, 100002. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, H.; Wang, Y.; Wang, J.; Cao, J.; Zhang, G. Improved methods, properties, applications and prospects of microbial induced carbonate precipitation (MICP) treated soil: A review. Biogeotechnics 2025, 3, 100123. [Google Scholar] [CrossRef]

- Reddy, D. Microbially induced stabilized rammed earth: Compressive strength-capillary water absorption Co-relationship. Heliyon 2025, 11, e42680. [Google Scholar] [CrossRef]

- CSIRO. Bulletin 5: Earth Wall Construction, 4th ed.; Commonwealth Scientific and Industrial Research Organisation-Division of Building Construction and Engineering National Building Technology Centre: Chatswood, NSW, Australia, 1987. [Google Scholar]

- New Mexico Earthen Building Materials Code; Construction Industries Division of the Regulation and Licensing Department: Santa Fe, NM, USA, 2021.

- SADC ZW HS 983, Rammed Earth Structures-Code of Practice THC 03; Southern African Development Community Cooperation in Standardization: Gaborone, Botswana, 2014.

- Solà, G.B.; Ros, F.M. Improved thermal capacity of rammed earth by the inclusion of natural fibres. In Rammed Earth Construction: Cutting-Edge Research on Traditional and Modern Rammed Earth; CRC Press: Leiden, The Netherlands, 2015. [Google Scholar]

- Giuffrida, G.; Costanzo, V.; Nocera, F.; Cuomo, M.; Caponetto, R. Natural and Recycled Stabilizers for Rammed Earth Material Optimization. In International Conference on Sustainability in Energy and Buildings; Springer: Cham, Switzerland, 2022; pp. 164–174. [Google Scholar]

- Xiao, Y.; Xiao, W.; Ma, G.; He, X.; Wu, H.; Shi, J. Mechanical performance of biotreated sandy road bases. J. Perform. Constr. Facil. 2022, 36, 04021111. [Google Scholar] [CrossRef]

- Toufigh, V.; Kianfar, E. The effects of stabilizers on the thermal and the mechanical properties of rammed earth at various humidities and their environmental impacts. Constr. Build. Mater. 2019, 200, 616–629. [Google Scholar] [CrossRef]

- Muguda, S.; Booth, S.J.; Hughes, P.N.; Augarde, C.E.; Perlot, C.; Bruno, A.W.; Gallipoli, D.; MugudaViswanath, S.; JohnBooth, S.; NeilHughes, P.; et al. Mechanical properties of biopolymer-stabilised soil-based construction materials. Geotech. Lett. 2017, 7, 309–314. [Google Scholar] [CrossRef]

- Patwa, D.; Dubey, A.A.; Ravi, K.; Sreedeep, S. Sreedeep, Biopolymer stabilization of highly plastic silty soil for rammed earth construction materials. In Indian Geotechnical Conference; Springer: Berlin/Heidelberg, Germany, 2022; pp. 379–389. [Google Scholar]

- Lin, H.; Lourenço, S.; Yao, T.; Zhou, Z.; Yeung, A.; Hallett, P.; Paton, G.; Shih, K.; Hau, B.; Cheuk, J. Imparting water repellency in completely decomposed granite with Tung oil. J. Clean. Prod. 2019, 230, 1316–1328. [Google Scholar] [CrossRef]

- Zhang, T.; Cai, G.; Liu, S. Application of lignin-based by-product stabilized silty soil in highway subgrade: A field investigation. J. Clean. Prod. 2017, 142, 4243–4257. [Google Scholar] [CrossRef]

- Yasuhara, H.; Neupane, D.; Hayashi, K.; Okamura, M. Experiments and predictions of physical properties of sand cemented by enzymatically-induced carbonate precipitation. Soils Found. 2012, 52, 539–549. [Google Scholar] [CrossRef]

- Chen, R.; Zhang, L.; Budhu, M. Biopolymer stabilization of mine tailings. J. Geotech. Geoenviron. Eng. 2013, 139, 1802–1807. [Google Scholar] [CrossRef]

- Rodríguez-Mariscal, J.; Solís, M.; Cifuentes, H. Methodological issues for the mechanical characterization of unfired earth bricks. Constr. Build. Mater. 2018, 175, 804–814. [Google Scholar] [CrossRef]

- Bati, S.B.; Fagone, M.; Loccarini, F.; Ranocchiai, G. Jute fabric to improve the mechanical properties of rammed earth constructions. Earthen Architecture. Past, present and future. In Proceedings of the International Conference on Vernacular Heritage, Sustainability and Earthen Architecture, Valencia, Spain, 11–13 September 2014; pp. 55–60. [Google Scholar]

- Bui, T.-T.; Bui, Q.-B.; Limam, A.; Maximilien, S. Failure of rammed earth walls: From observations to quantifications. Constr. Build. Mater. 2014, 51, 295–302. [Google Scholar] [CrossRef]

- NZS 4297; Engineering Design of Earth Buildings. Standards New Zealand: Wellington, New Zealand, 1998.

- Walker, P. The Australian Earth Building Handbook HB195; Standards Australia International Sydney: Sydney, Australia, 2002. [Google Scholar]

- Saha, R.; Debnath, R.; Dash, S.; Haldar, S. Engineering reconnaissance following the magnitude 5.7 Tripura earthquake on January 3, 2017. J. Perform. Constr. Facil. 2020, 34, 04020052. [Google Scholar] [CrossRef]

- Beckett, C.T.S.; Rimniceanu, A.; Lin, B.Y.X.; Reynolds, T.P. Reynolds, Bonding Behaviour of Bamboo Reinforcement in Rammed Earth. In International Conference on Earthen Construction; Springer: Cham, Switzerland, 2024; pp. 475–484. [Google Scholar]

- Fei, M.; Tang, X.; Yu, Y.; Li, K.; Fan, Z.; Xiang, Q. Synergistic Improvement Earthen Mortars with Tung Oil, Sticky Rice Pulp, and Aerial Lime: Application for the Conservation of Rammed Earth Structures Damaged by Exfoliation. Int. J. Arch. Heritage 2023, 18, 1519–1534. [Google Scholar] [CrossRef]

- Bui, Q.-B.; Morel, J.-C.; Hans, S.; Walker, P. Effect of moisture content on the mechanical characteristics of rammed earth. Constr. Build. Mater. 2014, 54, 163–169. [Google Scholar] [CrossRef]

- Morel, J.-C.; Bui, Q.-B.; Hamard, E. Weathering and durability of earthen material and structures. In Modern Earth Buildings; Elsevier: Oxford, UK, 2012; pp. 282–303. [Google Scholar]

- Muguda, S.; Lucas, G.; Hughes, P.; Augarde, C.; Perlot, C.; Bruno, A.; Gallipoli, D. Durability and hygroscopic behaviour of biopolymer stabilised earthen construction materials. Constr. Build. Mater. 2020, 259, 119725. [Google Scholar] [CrossRef]

- Killip, I.; Cheetham, D. The prevention of rain penetration through external walls and joints by means of pressure equalization. Build. Environ. 1984, 19, 81–91. [Google Scholar] [CrossRef]

- Müller, K.; Deurer, M. Review of the remediation strategies for soil water repellency. Agric. Ecosyst. Environ. 2011, 144, 208–221. [Google Scholar] [CrossRef]

- Schönemann, A.E.; Edwards, H.G.M. Raman and FTIR microspectroscopic study of the alteration of Chinese tung oil and related drying oils during ageing. Anal. Bioanal. Chem. 2011, 400, 1173–1180. [Google Scholar] [CrossRef] [PubMed]

- Heathcote, K. Durability of earthwall buildings. Constr. Build. Mater. 1995, 9, 185–189. [Google Scholar] [CrossRef]

- Gerard, P.; Mahdad, M.; McCormack, A.R.; François, B. A unified failure criterion for unstabilized rammed earth materials upon varying relative humidity conditions. Constr. Build. Mater. 2015, 95, 437–447. [Google Scholar] [CrossRef]

- Walker, P.; Keable, R.; Martin, J.; Maniatidis, V. Rammed Earth: Design and Construction Guidelines; BRE Bookshop: Watford, UK, 2005. [Google Scholar]

- Luo, Y.; Yang, M.; Ni, P.; Peng, X.; Yuan, X. Degradation of rammed earth under wind-driven rain: The case of Fujian Tulou, China. Constr. Build. Mater. 2020, 261, 119989. [Google Scholar] [CrossRef]

- NZS 4298; Materials and Workmanship for Earth Buildings. Standards New Zealand: Wellington, New Zealand, 1998.

- Deutsches Institut für Normung. Earth Blocks-Terms and Definitions, Requirements, Test Methods; Deutsches Institut für Normung: Berlin, Germany, 2013. [Google Scholar]

- Chandra, R.; Rustgi, R. Biodegradable polymers. Prog. Polym. Sci. 1998, 23, 1273–1335. [Google Scholar] [CrossRef]

- Sen, T.; Reddy, H.J. Application of sisal, bamboo, coir and jute natural composites in structural upgradation. Int. J. Innov. Manag. Technol. 2011, 2, 186. [Google Scholar]

- Ali, A.; Shaker, K.; Nawab, Y.; Jabbar, M.; Hussain, T.; Militky, J.; Baheti, V. Hydrophobic treatment of natural fibers and their composites—A review. J. Ind. Text. 2016, 47, 2153–2183. [Google Scholar] [CrossRef]

- Maitra, J.; Shukla, V.K. Cross-linking in hydrogels-a review. Am. J. Polym. Sci 2014, 4, 25–31. [Google Scholar]

- Burroughs, S. Soil property criteria for rammed earth stabilization. J. Mater. Civ. Eng. 2008, 20, 264–273. [Google Scholar] [CrossRef]

- Ciancio, D.; Jaquin, P.; Walker, P. Advances on the assessment of soil suitability for rammed earth. Constr. Build. Mater. 2013, 42, 40–47. [Google Scholar] [CrossRef]

- Ogunye, F.; Boussabaine, H. Diagnosis of assessment methods for weatherability of stabilised compressed soil blocks. Constr. Build. Mater. 2002, 16, 163–172. [Google Scholar] [CrossRef]

- Kharoti, I.; Walker, P.; Jayasinghe, C. Durability of Rammed Earth: A Comparative Study of Spray Erosion Testing and Natural Weathering. In Earthen Dwellings and Structures: Current Status in Their Adoption; Springer: Singapore, 2019; pp. 319–330. [Google Scholar]

- Bui, Q.; Morel, J.; Reddy, B.V.; Ghayad, W. Durability of rammed earth walls exposed for 20 years to natural weathering. Build. Environ. 2009, 44, 912–919. [Google Scholar] [CrossRef]

- Bui, Q.-B.; Morel, J.-C. First Exploratory Study on the Ageing of Rammed Earth Material. Materials 2014, 8, 1–15. [Google Scholar] [CrossRef]

| NF Material | Fiber Amount (wt% of Dry Soil) | Physical Properties | Mechanical Properties | Ref. | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Length (mm) | Thickness (mm) | Width (mm) | Diameter (mm) | Density (g/cm3) | Ultimate Elongation (%) | Water Absorption (%) | Tensile Strength | Elastic Modulus (GPa) | |||

| Coconut coir | N/A | - | 0.9 | - | - | 0.98 | 1.08 | - | 28 | 20.4 | [42] |

| 1, 3, 5 | 25, 50 | - | - | 0.4 | 1.27 | - | - | 80 | - | [43] | |

| 0.5 | 50 | - | - | - | - | - | - | 83.23 | - | [44] | |

| Hemp | 0.75, 1.25 | - | 0.13 | 0.65 | 0.41 | 1.4 | - | - | 276 | 21.7 | [45] |

| 25%v/v | - | - | - | - | 0.105 | - | 345 | - | - | [46] | |

| Jute | N/A | - | 0.85 | - | - | 1.23 | 1.46 | - | 35 | 24.5 | [42] |

| Bamboo | N/A | - | 0.85 | 10, 15 | - | 1.12 | 1.77, 1.89 | - | 49.5, 51.7 | 19.7 | [42] |

| Barely straw | 0.75 | 20–30 | - | - | 1–3 | 0.72 | - | 175 | 6–12 | 0.3–0.6 | [47] |

| Date palm | 0.75 | 30 | - | - | 1–2 | 0.94 | - | 89 | 233 | 5 | [47,48] |

| Rice straw | N/A | - | - | - | - | 0.98 | 2.26 | - | 14.76 | 20.8 | [16] |

| Wheat straw | 0.25 | 30 | - | - | - | - | - | 280–300 | 22–79 | 5–6 | [49,50] |

| Sheep wool | 0.25 | Up to 100 | - | - | - | - | - | - | - | - | [15] |

| Bacterial Strain | Nutrient Delivery Method | Urea Concentration (g/L) | Cementation Solution Composition | Application Rate Cementation Solution During RE Treatment | Ref. |

|---|---|---|---|---|---|

| Bacillus subtilis, S. pasteurii, and Bacillus subtilis subsp. Subtilis | Mixing method | 20 | 50 mL | - | [99] |

| S. pasteurii | Mixing method | 20 | 500 mM urea + 500 mM CaCl2 | 250 mL in 8 kg of dry soil | [103] |

| S. pasteurii | Mixing method | 20 | 500 mM urea + 500 mM CaCl2 | - | [19] |

| S. pasteurii | Gravimetric injection method | - | 500 mM urea + 500 mM CaCl2 | 17 mL sprayed on the RE surface for 24 h followed by 8 mL sprayed twice a day for 24 days | [17] |

| Bacillus megaterium, Bacillus sphaericus, and Bacillus sp. | Mixing method | - | 2% urea solution + 25 mM CaCl2 | 100 mL applied in RE mix | [112] |

| Bio-Based Additive | Optimum Additive Amount (wt%) | Compressive Mechanical Parameters | Tensile Mechanical Parameters | Tensile-to-Compressive (T/C) Strength Ratio 2 | Ref. | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| UCS (CoV) (MPa) | Peak Strain (CoV) (mm/mm) | Elastic Modulus (CoV) (MPa) | Compressive Strength Improvement (%) 1 | Tensile Strength (CoV) (MPa) | Tensile Strength Improvement (%) 1 | |||||

| Natural fiber | DP | 0.75 | 3.25 (4%) | 0.0172 (3%) | 189 (1%) | ↑ 62.5 | 0.46 | ↑ 12.5 | 0.14 | [47] |

| 1.0 | 2.29 (4.5%) | 0.0183 (10.8%) | 454 (9.7%) | ↑ 29.4 | 0.19 (3.1%) | ↑ 9 | 0.08 | [48] | ||

| BS | 0.75 | 2.74 (7%) | 0.0194 (7%) | 141 (2%) | ↑ 37 | 0.50 | ↑ 25 | 0.18 | [47] | |

| WS | 0.25 | 2.58 (3.1%) | 0.036 | 71 (6.32%) | - | 0.24 (11.7%) | - | 0.09 | [49] | |

| 0.5 | 0.76 | 0.0129 | 126 | ↑ 33.3 | 0.22 | ↑ 29.4 | 0.29 | [50] | ||

| SWF | 0.25 | 2.67 (6.7%) | - | 194 (19.6%) | ↑ 6.1 | - | - | - | [15] | |

| CIT | 1.0 | 1.90 (5.8%) | - | 197 (11.7%) | ↓ 24.5 | - | - | - | [15] | |

| GRA | 1.0 | 2.14 (26.6%) | - | 250 (22.8%) | ↓ 14.7 | - | - | - | [15] | |

| Coconut coir | 1.0 | 4.40 (6.4%) | - | - | ↑ 15.2 | 0.25 (12%) | ↑ 78.6 | 0.06 | [43] | |

| HF | 1.25 | - | - | - | - | 0.48 (29.1%) | ↑ >100 | - | [45] | |

| 25 vol% | 1.04 | 0.0497 | 29.2 | ↓ 43 | - | - | - | [46] | ||

| Jute fabric | - | 2.24 (9.8%) | - | 34.6 (55.1%) | ↑ 75 | - | - | - | [127] | |

| Sisal | 1.0 | 5.26 | 254 | ↑ 33.1 | [117] | |||||

| Biopolymer | GG | 2.5 | 2.64 (0.8%) | 0.0216 | 131 (2.8%) | ↑ >100 | 0.27 (21.1%) | ↑ 12.5 | 0.10 | [119] |

| 3.0 | 4.40 | 0.0225 | - | ↑ >100 | 0.125 | ↑ >100 | 0.03 | [116] | ||

| XG | 3.0 | 4.25 | 0.0195 | - | ↑ >100 | 0.288 | ↑ >100 | 0.07 | [120] | |

| 1.5 | 5.35 | 0.0175 | 380 | ↑ >100 | - | - | - | [121] | ||

| 1.0 | 5.58 | - | - | ↑ >100 | - | - | - | [71,72] | ||

| LIG | 1.0 | 3.47 (17%) | - | 511 (10.4%) | ↑ 38.3 | - | - | - | [15] | |

| TAN | 1.0 | 2.85 (8.8%) | - | 270 (21.9%) | ↑ 13.3 | - | - | - | [15] | |

| Animal glue | 1.0 | 6.86 | - | - | ↑ >100 | - | - | - | [71,72] | |

| TO | 10 | 2.64 | - | - | ↑ >100 | - | - | - | [78] | |

| BP | 73.8 mL/kg | 6.71 | - | - | ↑ 36 | - | - | - | [70] | |

| MICP | S. pasteurii bacteria | - | 0.6 (14-day strength) | - | - | ↑ >100 | - | - | - | [70] |

| Urea + S. pasteurii | 250 mL in 8 kg of dry soil | 3.3 | - | - | ↓ 31.4 | - | - | - | [103] | |

| 17 mL sprayed on the RE surface | 0.8 | 0.029 | 105 | ↑ 33.3 | - | - | - | [17] | ||

| Blood + S. pasteurii | 250 mL in 8 kg of dry soil | 6.21 | - | - | ↑ 45 | - | - | - | [103] | |

| Water Durability Assessment Topic | Bio-Based Treatment | Optimum Bio-Additive Amount (wt%) | Curing Time of BRE Samples (Days) | Durability Test Method (Test Parameter) | Main Finding (s) | Ref. |

|---|---|---|---|---|---|---|

| Moisture ingress behavior | Coconut coir fiber | 1.0 | 28 |

|

| [43] |

| MICP | - | 28 |

|

| [17] | |

| Chitosan | 2.5 | 28 |

|

| [62] | |

| GG, XG | 2.0 | 28 |

|

| [136] | |

| ALG, XG, CG, LO, casein, CT, OSE, VV | 0.5–2.0 | 7 |

|

| [53] | |

| Hydrophobicity | TO | 15.0 | 3, 7 and 28 |

|

| [78] |

| Strength sensitivity in a humid environment | GG | 2.5 | 28 |

|

| [119] |

| Water-induced erosion | MICP | - | 28 |

|

| [17] |

| XG | 1.5 | 7 |

|

| [121] | |

| GG, XG | 2.0 | 7 and 28 |

|

| [136] | |

| Chitosan | 2.5 | 28 |

|

| [62] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sesay, T.; Xie, Y.; Chen, Y.; Xue, J. Bio-Based Stabilization of Natural Soil for Rammed Earth Construction: A Review on Mechanical and Water Durability Performance. Polymers 2025, 17, 1170. https://doi.org/10.3390/polym17091170

Sesay T, Xie Y, Chen Y, Xue J. Bio-Based Stabilization of Natural Soil for Rammed Earth Construction: A Review on Mechanical and Water Durability Performance. Polymers. 2025; 17(9):1170. https://doi.org/10.3390/polym17091170

Chicago/Turabian StyleSesay, Taiwo, Yuekai Xie, Yue Chen, and Jianfeng Xue. 2025. "Bio-Based Stabilization of Natural Soil for Rammed Earth Construction: A Review on Mechanical and Water Durability Performance" Polymers 17, no. 9: 1170. https://doi.org/10.3390/polym17091170

APA StyleSesay, T., Xie, Y., Chen, Y., & Xue, J. (2025). Bio-Based Stabilization of Natural Soil for Rammed Earth Construction: A Review on Mechanical and Water Durability Performance. Polymers, 17(9), 1170. https://doi.org/10.3390/polym17091170