Investigation of the Mechanical, Fatigue, and Creep Properties of PA6/GO Nanocomposites Manufactured by a Combination of Melt and Solvent Mixing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

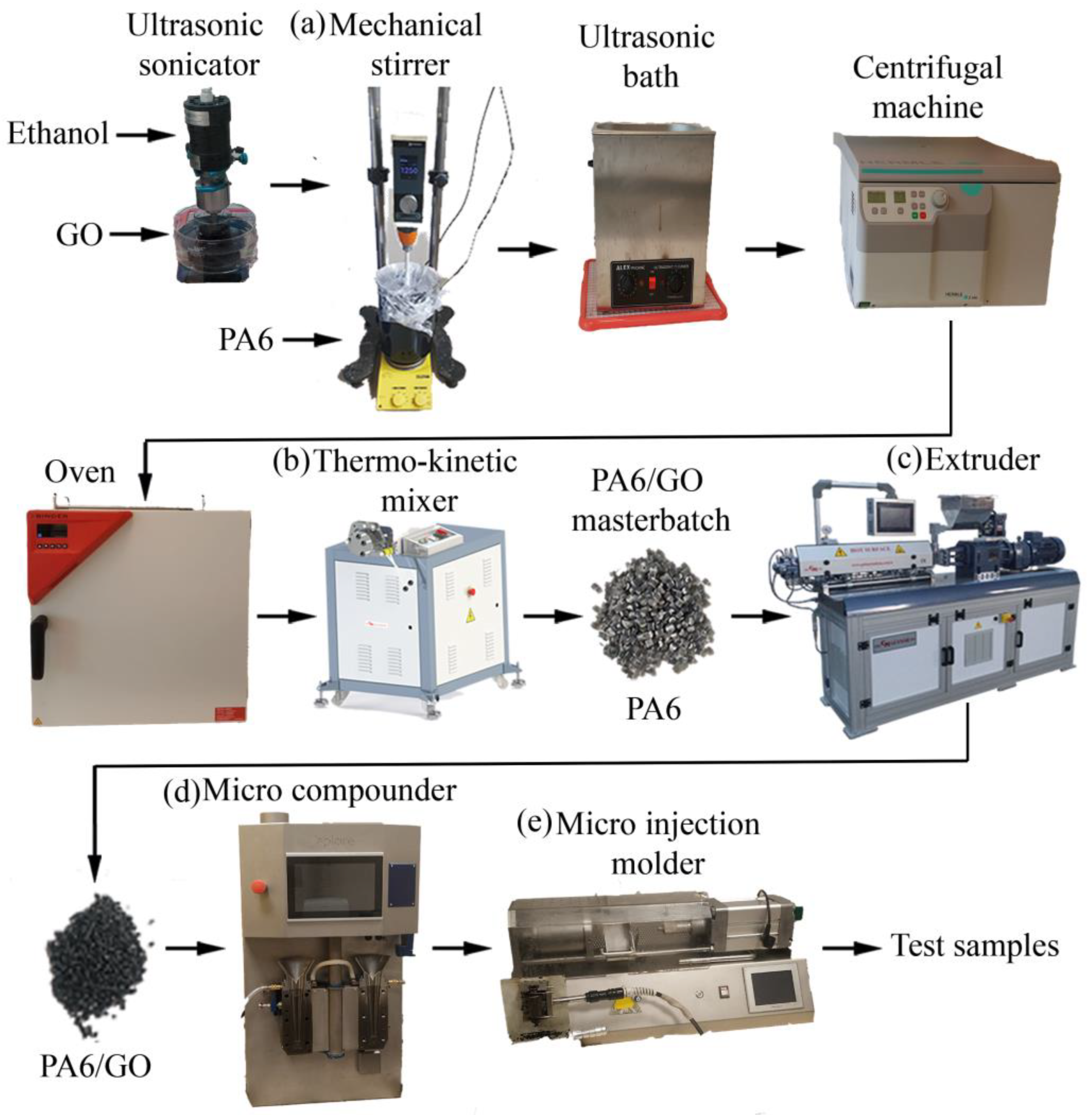

2.2. Manufacturing of Polymer Nanocomposites

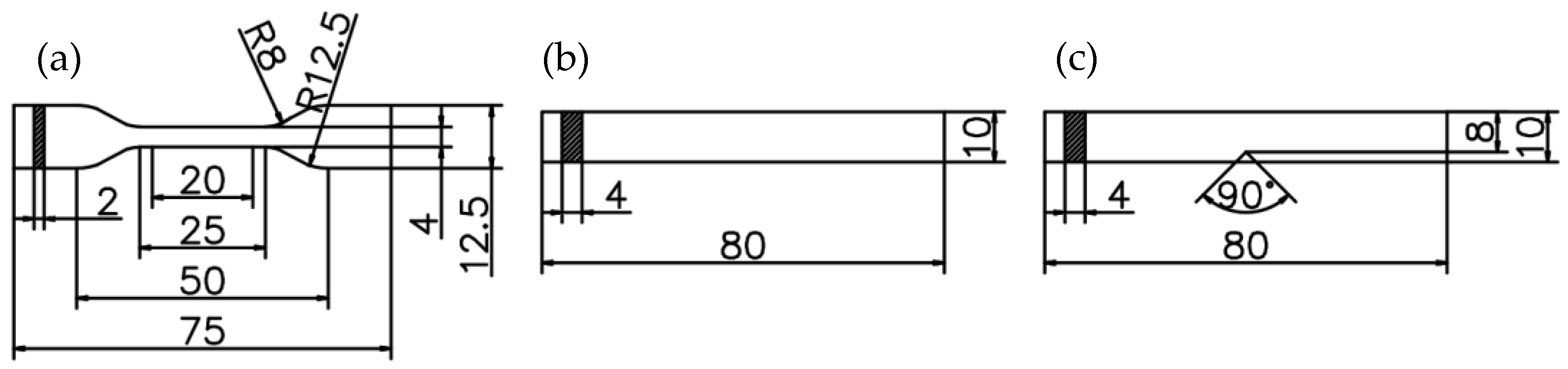

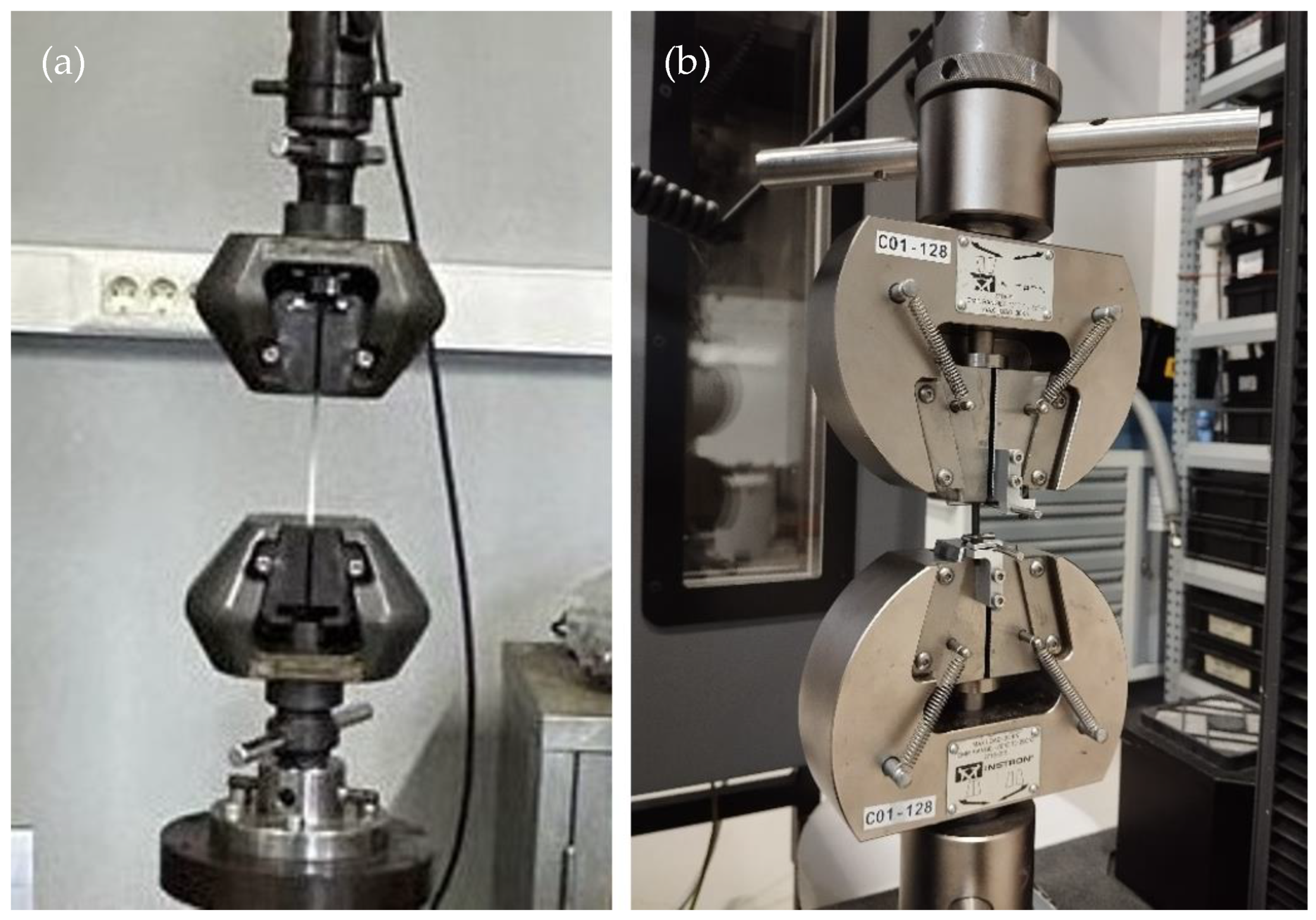

2.3. Mechanical Tests

2.4. Fatigue

2.5. DMA

2.6. Creep

3. Results and Discussion

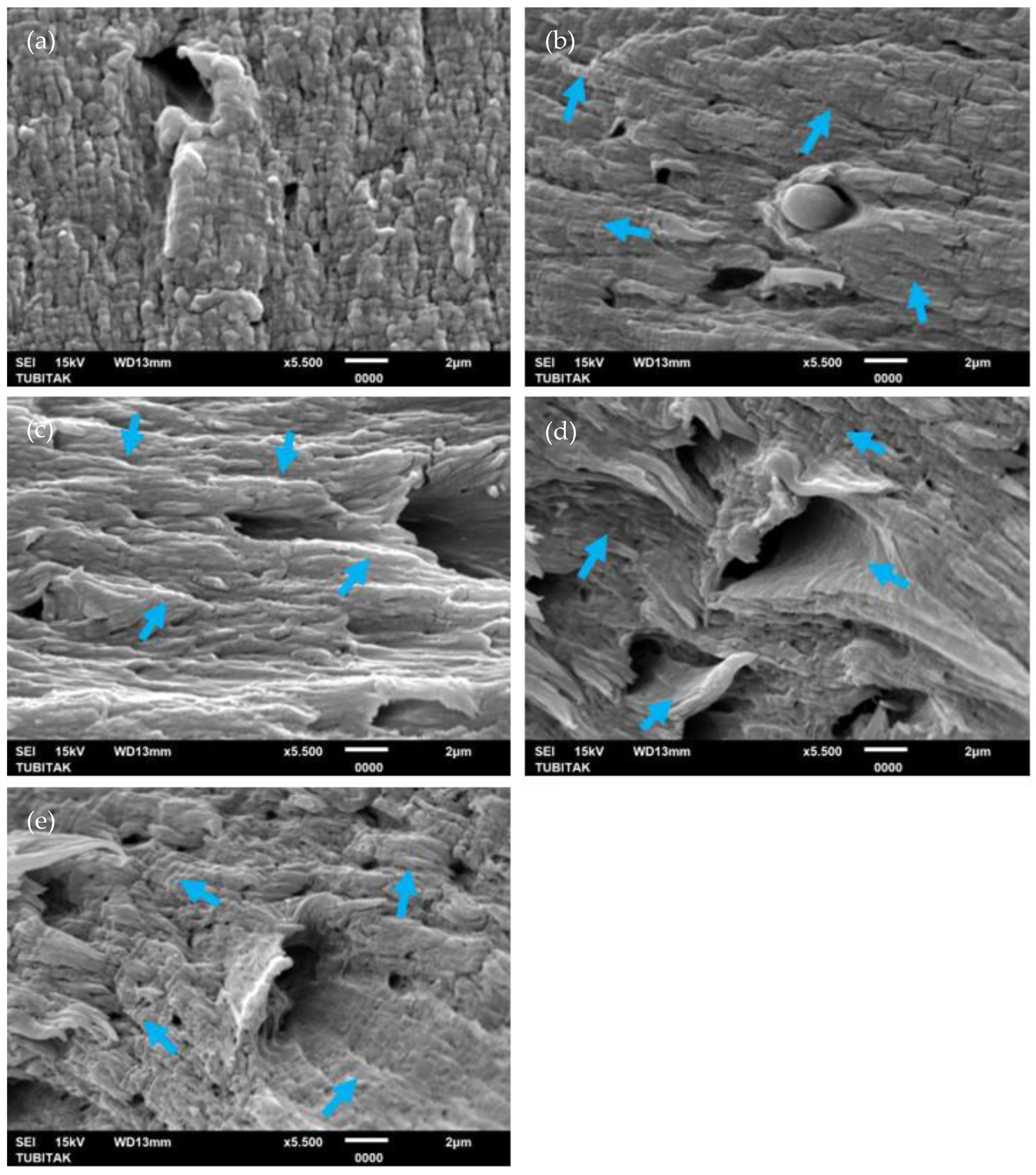

3.1. Mechanical Tests

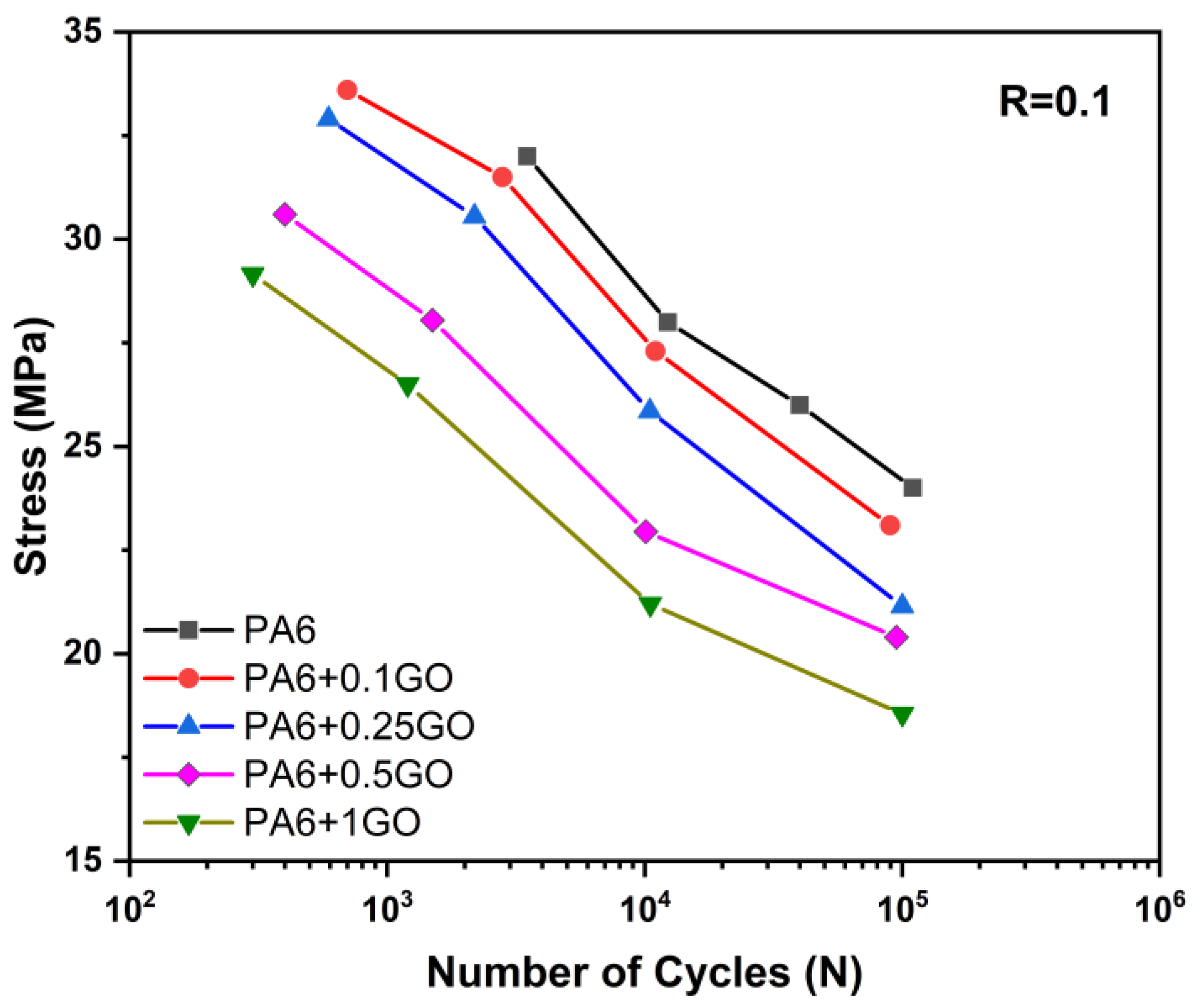

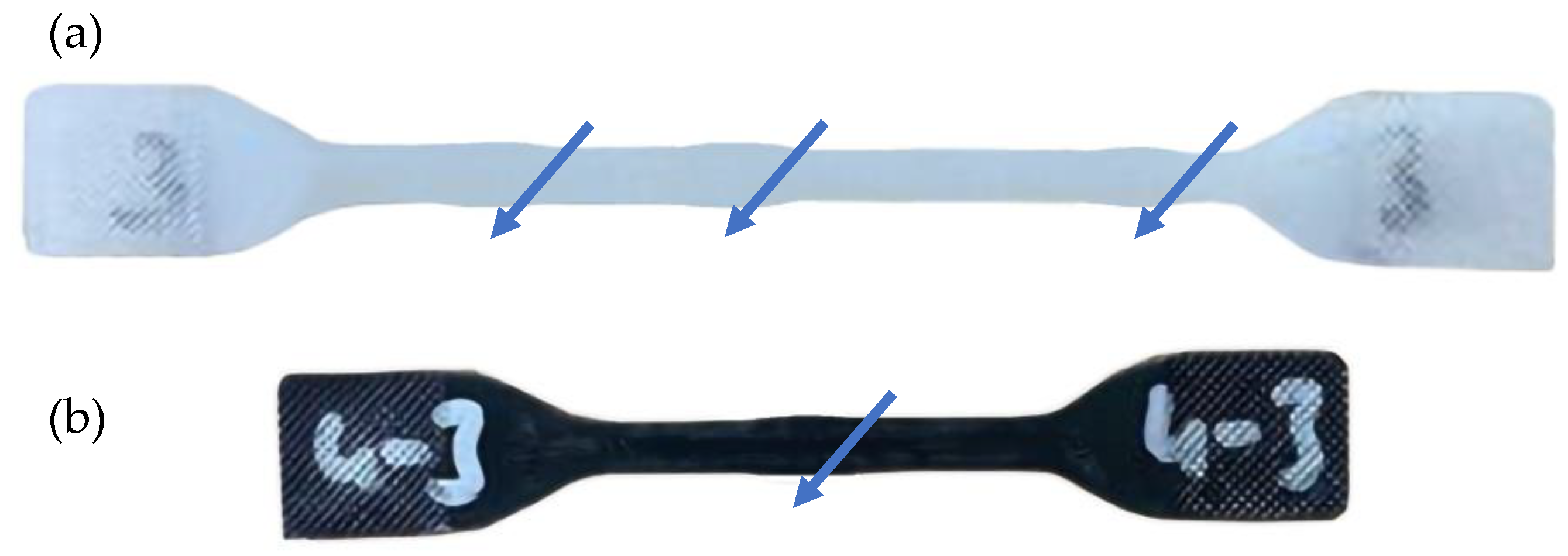

3.2. Fatigue

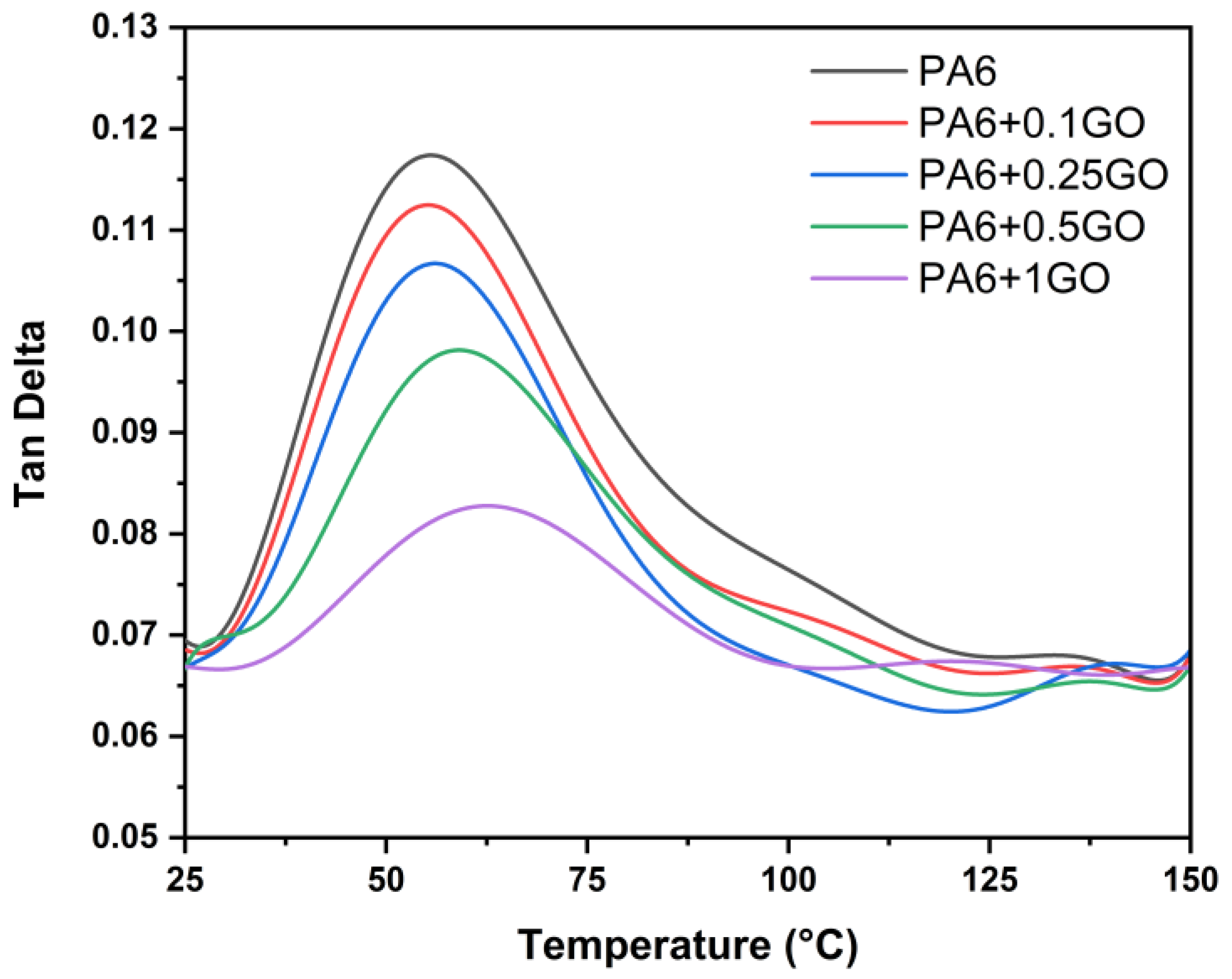

3.3. DMA

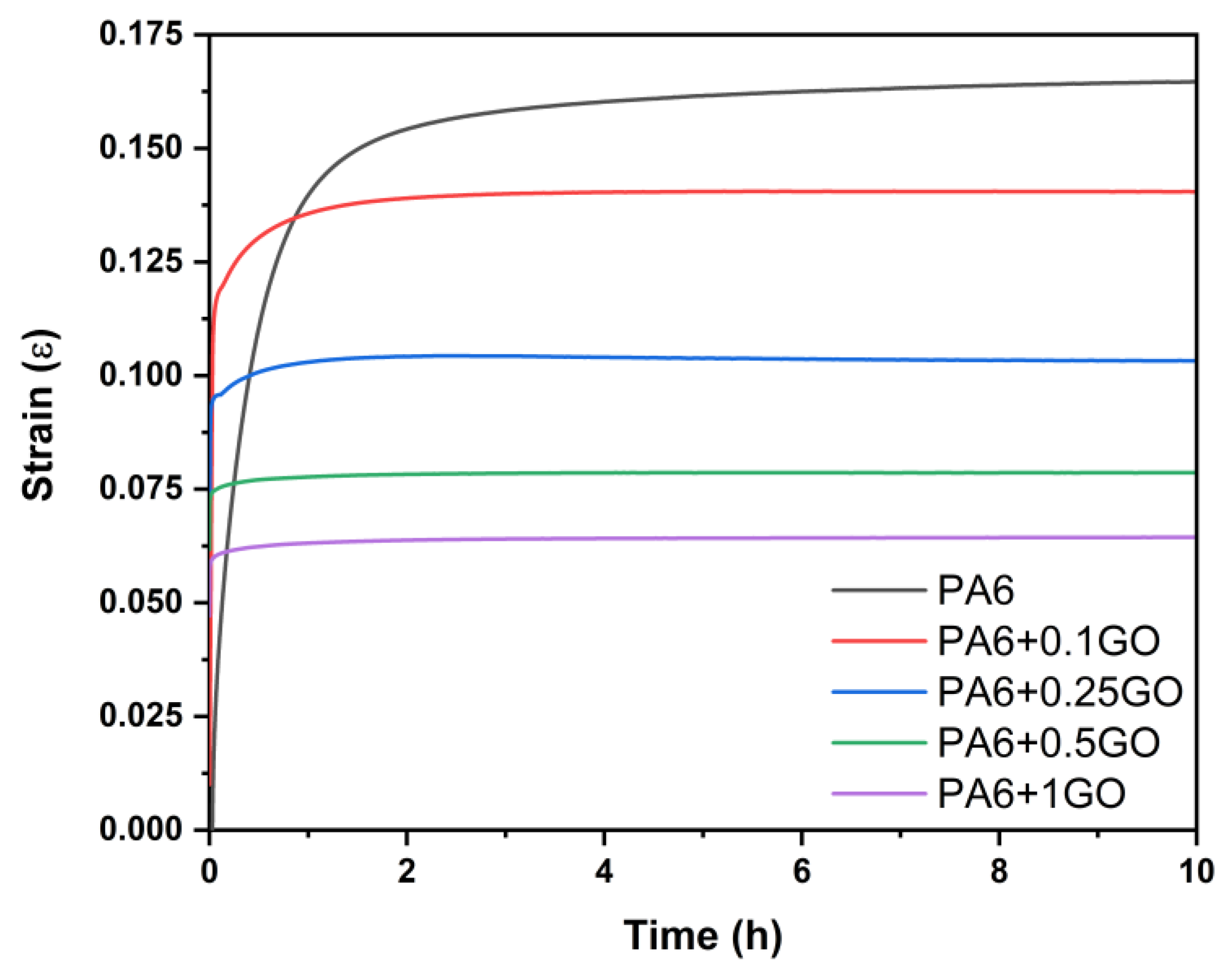

3.4. Creep

4. Conclusions

- It was observed that increasing GO content improved the tensile and bending strengths of the PA6/GO nanocomposites. Tensile tests performed at different temperatures revealed that PA6’s tensile strength decreased with rising temperature, but the reduction in tensile strength in PA6/GO nanocomposites was less pronounced due to the reinforcing effect of GO. Charpy impact tests indicated that GO restricted strain, facilitating crack propagation and weakening the impact strength of the nanocomposites.

- Rigid GO reduced the cyclic strain amplitude of the PA6 matrix in PA6/GO nanocomposites and increased the modulus of elasticity, thereby reducing hysteresis heating caused by viscous effects. In contrast to PA6, which exhibited necking behavior at multiple points due to local neck formation and thermal softening, the PA6/GO nanocomposites did not show such behavior because of rigid GO.

- DMA results demonstrated that the storage modulus of PA6/GO nanocomposites increased with the addition of GO. Tan Delta values of nanocomposites decreased, and the Tg also rose, confirming the efficient dispersion and contribution of GO to the matrix.

- Creep tests revealed that PA6/GO nanocomposites had lower creep rates than PA6, indicating enhanced dimensional stability under stress.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AFM | Atomic Force Microscope |

| CNTs | Carbon Nanotubes |

| DMA | Dynamic Mechanical Analysis |

| DSC | Differential Scanning Calorimetry |

| EVA | Ethylene-Vinyl Acetate |

| G | Graphene |

| GO | Graphene Oxide |

| HDPE | High-Density Polyethylene |

| Nano-SiO2 | Nano-Silica |

| PA6 | Polyamide 6 |

| rGO | Reduced Graphene Oxide |

| SEM | Scanning Electron Microscope |

| SiC | Silicon Carbide |

| SiO2 | Silicon Dioxide |

| Tg | Glass Transition Temperature |

| TGA | Thermogravimetric Analysis |

References

- Unal, H.; Mimaroglu, A. Friction and Wear Performance of Polyamide 6 and Graphite and Wax Polyamide 6 Composites Under Dry Sliding Conditions. Wear 2012, 289, 132–137. [Google Scholar] [CrossRef]

- Mittal, G.; Dhand, V.; Rhee, K.Y.; Park, S.J.; Lee, W.R. A Review on Carbon Nanotubes and Graphene as Fillers in Reinforced Polymer Nanocomposite. J. Ind. Eng. Chem. 2015, 21, 11–25. [Google Scholar] [CrossRef]

- Leon, A.C.; Chen, Q.; Palaganas, N.B.; Palaganas, J.O.; Manapat, J.; Advincula, R.C. High Performance Polymer Nanocomposites for Additive Manufacturing Applications. React. Funct. Polym. 2016, 103, 141–155. [Google Scholar] [CrossRef]

- Tjong, S.C. Structural and Mechanical Properties of Polymer Nanocomposites. Mater. Sci. Eng. R Rep. 2006, 53, 73–197. [Google Scholar] [CrossRef]

- Rao, B.D.; Pradhan, A.; Sethi, K.K. Study of Wear Performance and Mechanical Properties of HDPE on Addition of CNT Fillers. Mater. Today Proc. 2022, 62, 7501–7508. [Google Scholar] [CrossRef]

- Urs, M.V.D.; Suresha, B.; Hemanth, G.; Kulkarni, G.; Charan, M.R.S. Influence of Graphene Nanoplatelets on Tribological Properties of Short Carbon Fibre Reinforced PA-66/TCE Composites. Mater. Today Proc. 2021, 43, 1640–1646. [Google Scholar]

- Chen, J.; Zhu, J.; Li, Q.; Wu, H.; Guo, S.; Qiu, J. Constructing 3D Interconnected CNTs Network in PA6 Composites with Well-Dispersed UHMWPE for Excellent Tribological and Heat Dissipation Properties. Compos. Part B Eng. 2022, 246, 110252. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Z. Impact Behaviour of Polypropylene Filled with Multi-Walled Carbon Nanotubes. Eur. Polym. J. 2007, 43, 3197–3207. [Google Scholar] [CrossRef]

- Esmizadeh, E.; Vahidifar, A.; Shojaie, S.; Naderi, G.; Kalaei, M.R.; Mekonnen, T.H. Tailoring the Properties of PA6 into High-Performance Thermoplastic Elastomer: Simultaneous Reinforcement and Impact Property Modification. Mater. Today Commun. 2021, 26, 102027. [Google Scholar] [CrossRef]

- Sabatini, V.; Taroni, T.; Rampazzo, R.; Bompieri, M.; Maggioni, D.; Meroni, D.; Ortenzi, M.A.; Ardizzone, S. PA6 and Halloysite Nanotubes Composites with Improved Hydrothermal Ageing Resistance: Role of Filler Physicochemical Properties, Functionalization and Dispersion Technique. Polymers 2020, 12, 211. [Google Scholar] [CrossRef]

- Saeed, K.; Park, S.Y. Preparation of Multiwalled Carbon Nanotube/Nylon-6 Nanocomposites by In Situ Polymerization. J. Appl. Polym. Sci. 2007, 106, 3729–3735. [Google Scholar] [CrossRef]

- Zhang, G.; Wetzel, B.; Wang, Q. Tribological Behavior of PEEK-Based Materials Under Mixed and Boundary Lubrication Conditions. Tribol. Int. 2015, 88, 153–161. [Google Scholar] [CrossRef]

- Senturk, A.E. Thermo-Mechanical Properties of Different Structures of BC2N. Mol. Simul. 2021, 47, 1493–1501. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Katsnelson, M.I.; Grigorieva, I.V.; Dubonos, S.V.; Firsov, A.A. Two-Dimensional Gas of Massless Dirac Fermions in Graphene. Nature 2005, 438, 197–200. [Google Scholar] [CrossRef] [PubMed]

- Ghaleb, Z.A.; Mariatti, M.; Ariff, Z.M. Properties of Graphene Nanopowder and Multi-Walled Carbon Nanotubefilled Epoxy Thin-Film Nanocomposites for Electronic Applications: The Effect of Sonication Time and Filler Loading. Compos. Part A Appl. Sci. Manuf. 2014, 58, 77–83. [Google Scholar] [CrossRef]

- Li, W.; Dichiara, A.; Bai, J. Carbon Nanotube–Graphene Nanoplatelet Hybrids as High-Performance Multifunctional Reinforcements in Epoxy Composites. Compos. Sci. Technol. 2013, 74, 221–227. [Google Scholar] [CrossRef]

- Ghislandi, M.; Tkalya, E.; Schillinger, S.; Koning, C.E.; Gijsbertusde, W. High Performance Graphene and MWCNTs Based PS-PPO Composites Obtained via Organic Solvent Dispersion. Compos. Sci. Technol. 2013, 80, 16–22. [Google Scholar] [CrossRef]

- Ferrás, L.L.; Fernandes, C.; Semyonov, D.; Nóbrega, J.M.; Covas, J.A. Dispersion of Graphite Nanoplates in Polypro-pylene by Melt Mixing: The Effects of Hydrodynamic Stresses and Residence Time. Polymers 2021, 13, 102. [Google Scholar] [CrossRef]

- Han, M.; Yun, J.; Kim, H.; Lee, Y. Effect of Surface Modification of Graphene Oxide on Photochemical Stability of Poly(vinyl alcohol)/Graphene Oxide Composites. J. Ind. Eng. Chem. 2012, 18, 752–756. [Google Scholar] [CrossRef]

- Cho, J.W.; Paul, D.R. Nylon 6 Nanocomposites by Melt Compounding. Polymers 2001, 42, 1083–1094. [Google Scholar] [CrossRef]

- Johnson, D.W.; Dobson, B.P.; Coleman, K.S. A Manufacturing Perspective on Graphene Dispersions. Curr. Opin. Colloid Interface Sci. 2015, 20, 367–382. [Google Scholar] [CrossRef]

- Huang, S.; Pan, B.; Xie, M.; Gao, J.; Zhao, G.; Niu, Y.; Wang, H. Synergistic Effects of Graphene Oxide and Paraffin Wax on the Tribological Properties of Monomer Casting Nylon-6 Composites. Tribol. Int. 2021, 154, 106726. [Google Scholar] [CrossRef]

- Zhao, Y.; Meng, Y.; Zhu, F.; Su, J.; Han, J. Mechanical Reinforcement in Nylon 6 Nanocomposite Fiber Incorporated with Dopamine Reduced Graphene Oxide. Materials 2022, 15, 5095. [Google Scholar] [CrossRef] [PubMed]

- Senturk, O.; Palabiyik, M. Exploring the Tribological Properties of PA6/GO Nanocomposites Produced by In Situ Polymerization. J. Mater. Sci. 2023, 58, 10318–10339. [Google Scholar] [CrossRef]

- Chae, B.K.; Janggeon, L.; Jaehyun, C.; Munju, G. Thermal Conductivity Enhancement of Reduced Graphene Oxide via Chemical Defect Healing for Efficient Heat Dissipation. Carbon 2018, 139, 386–392. [Google Scholar]

- Zhang, X.; Wan, D.; Peng, K.; Zhang, W. Enhancement of Thermal Conductivity and Mechanical Properties of Cu-Reduced Graphene Oxide Composites by Interface Modification. J. Mater. Eng. Perform. 2019, 28, 5165–5171. [Google Scholar] [CrossRef]

- Lee, P.C.; Kim, S.Y.; Ko, Y.K.; Ha, J.U.; Jeoung, S.K.; Shin, D.; Kim, J.H.; Kim, M.G. Tribological Properties of Polyamide 46/Graphene Nanocomposites. Polymers 2022, 14, 1139. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, H.; Zhou, S.; Huang, J.; Zhao, G.; Liu, Y. Improving Tribological Performance of Porous Oil-Impregnated GO/PA6 Composites with Double Lubrication Structure. Diam. Relat. Mater. 2022, 126, 109062. [Google Scholar] [CrossRef]

- Kim, M.; Lee, J.; Cho, M.; Kim, J. Improvement of Thermal and Abrasion Resistance Performance of Polyphenylene Sulfide Composite Through 3-Mercaptopropyl Trimethoxysilane Treatment of Carbon Fiber and Graphene Oxide Fillers. Polym. Test. 2022, 108, 107517. [Google Scholar] [CrossRef]

- Maio, A.; Fucarino, R.; Khatibi, R.; Rosselli, S.; Bruno, M.; Scaffaro, R. A Novel Approach to Prevent Graphene Oxide Re-Aggregation During the Melt Compounding with Polymers. Compos. Sci. Technol. 2015, 119, 131–137. [Google Scholar] [CrossRef]

- Khan, U.; May, P.; O’Neill, A.; Coleman, J. Development of Stiff, Strong, Yet Tough Composites by the Addition of Solvent Exfoliated Graphene to Polyurethane. Carbon 2010, 48, 4035–4041. [Google Scholar] [CrossRef]

- Głuchowski, M.; Kowalewski, T.; Jędrzejewska, S.; Kowalewska, M.; Sierżant, M.; Mazur, M.; Rydosz, A. Mechanical and Antimicrobial Properties of the Graphene-Polyamide 6 Composite. Materials 2025, 17, 3465. [Google Scholar] [CrossRef] [PubMed]

- Senturk, O.; Palabiyik, M. Investigating Mechanical, Viscoelastic, and Tribological Properties of PA6/HDPE + GO Polymer Blend Nanocomposites. J. Mater. Eng. Perform. 2024, 27, 1429–1439. [Google Scholar] [CrossRef]

- Xu, Q.; Li, X.; Chena, F.; Zhanga, Z. Improving the Mechanical Properties of Polyamide 6-Nanosilica Nanocomposites by Combining Masterbatch Technique with In Situ Polymerization. J. Braz. Chem. Soc. 2014, 25, 1218–1225. [Google Scholar]

- Scaffaro, R.; Maio, A. Influence of Oxidation Level of Graphene Oxide on the Mechanical Performance and Pho-to-Oxidation Resistance of a Polyamide 6. Polymers 2019, 11, 857. [Google Scholar] [CrossRef]

- Ambhorkar, A.; Dargahi, A.; Christopher, N.; Cross, D.; Naguib, H.E. Synergistic enhancement of creep resistance and thermal stability in epoxy nanocomposites reinforced with graphene nanoplatelets and halloysite nanotubes for optoe-lectronic applications. Polym. Compos. 2025, 46, 1234–1245. [Google Scholar]

- ISO 527-2:2012; Plastics—Determination of tensile properties—Part 2: Test conditions for moulding and extrusion plastics. ISO Copyright Office: Geneva, Switzerland, 2012.

- ISO 178:2019; Plastics—Determination of flexural properties. ISO Copyright Office: Geneva, Switzerland, 2019.

- ISO 179-1:2023; Plastics—Determination of Charpy impact properties. ISO Copyright Office: Geneva, Switzerland, 2023.

- Chen, J.; Chen, X.; Meng, F.; Li, D.; Tian, X.; Wang, Z.; Zhou, Z. Super-high thermal conductivity of polyam-ide-6/graphene-graphene oxide composites through in situ polymerization. High Perform. Polym. 2017, 29, 395–402. [Google Scholar] [CrossRef]

- Jing, Q.; Liu, W.; Pan, Y.; Silberschmidt, V.V.; Li, L.; Dong, Z. Chemical functionalization of graphene oxide for improving mechanical and thermal properties of polyurethane composites. Mater. Des. 2015, 85, 808–814. [Google Scholar] [CrossRef]

- Abdollahi, R.; Taghizadeh, M.; Savani, S. Thermal and Mechanical Properties of Graphene Oxide Nanocomposite Hydrogel Based on Poly (acrylic acid) Grafted onto Amylose. Polym. Degrad. Stab. 2018, 147, 151–158. [Google Scholar] [CrossRef]

- Graziano, A.; Jaffer, S.; Sain, M. Graphene Oxide Modification for Enhancing High-Density Polyethylene Properties: A Comparison Between Solvent Reaction and Melt Mixing. J. Polym. Eng. 2019, 39, 85–93. [Google Scholar] [CrossRef]

- Heydari, S.; Shahgholi, M.; Karimipour, A.; Salehi, M.; Galehdari, S. The Effects of Graphene Oxide Nanoparticles on the Mechanical and Thermal Properties of Polyurethane/Polycaprolactone Nanocomposites; a Molecular Dynamics Approach. Results Eng. 2024, 24, 102933. [Google Scholar] [CrossRef]

- Gudarzi, M.M.; Sharif, F. Enhancement of dispersion and bonding of graphene-polymer through wet transfer of func-tionalized graphene oxide. J. Appl. Polym. Sci. 2012, 125, 2986–2992. [Google Scholar]

- Sun, L.; Cao, M.; Xiao, F.; Xu, J.; Chen, Y. POSS Functionalized Graphene Oxide Nanosheets with Multiple Reaction Sites Improve the Friction and Wear Properties of Polyamide 6. Tribol. Int. 2021, 154, 106747. [Google Scholar] [CrossRef]

- Albdiry, M.T.; Yousif, B.F. Toughening of brittle polyester with functionalized halloysite nanocomposites. Compos. Part B 2019, 160, 94–109. [Google Scholar] [CrossRef]

- Cicero, S.; Parra, J.L.; Arroyo, B.; Procopio, I. Graphene Oxide Does Not Seem to Improve the Fracture Properties of Injection Molded PA6. Procedia Struct. Integr. 2020, 28, 67–73. [Google Scholar] [CrossRef]

- Xu, Z.; Gao, C. In Situ Polymerization Approach to Graphene-Reinforced Nylon-6 Composites. Macromolecules 2010, 43, 6716–6723. [Google Scholar] [CrossRef]

- Chen, Y.; Li, D.; Yang, W.; Xiao, C. Enhancement of Mechanical, Thermal and Tribological Properties of AAPS-Modified Graphene Oxide/Polyamide 6 Nanocomposites. Compos. Part B Eng. 2018, 138, 55–65. [Google Scholar] [CrossRef]

- Dadashi, P.; Babaei, A.; Khoshnood, M. Investigating the Role of PA6/GO Interactions on the Morphological, Rheological, and Mechanical Properties of PA6/ABS/GO Nanocomposites. Polym.-Plast. Technol. Mater. 2023, 62, 756–770. [Google Scholar] [CrossRef]

- Umesh, G.L.; Prasad, N.J.K.; Rudresh, B.M.; Devegowda, M. Influence of Nano Graphene on Mechanical Behavior of PA66/PA6 Blend Based Hybrid Nano Composites: Effect of Micro Fillers. Mater. Today Proc. 2020, 20, 228–235. [Google Scholar] [CrossRef]

- Ramkumar, A.; Gnanamoorthy, R. Axial Fatigue Behavior of Polyamide-6 and Polyamide-6 Nanocomposites at Room Temperature. Compos. Sci. Technol. 2008, 68, 3401–3405. [Google Scholar] [CrossRef]

- Ahmadifar, M.; Benfriha, K.K.; Shirinbayan, M. Thermal, Tensile and Fatigue Behaviors of the PA6, Short Carbon Fiber-Reinforced PA6, and Continuous Glass Fiber-Reinforced PA6 Materials in Fused Filament Fabrication (FFF). Polymers 2023, 15, 507. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Zhang, M.; Wang, L.; Chen, J.; Liu, C. Size effect of graphene nanoplatelets on the morphology and mechanical behavior of glass fiber/epoxy composites. J. Mater. Sci. 2016, 51, 1–12. [Google Scholar]

- Lin, S.; Anwer, M.A.S.; Zhou, Y.; Sinha, A.; Carson, L.; Naguib, H.E. Evaluation of the Thermal, Mechanical and Dynamic Mechanical Characteristics of Modified Graphite Nanoplatelets and Graphene Oxide High-Density Polyethylene Composites. Compos. Part B Eng. 2018, 132, 61–68. [Google Scholar] [CrossRef]

- Pan, X.; Debije, M.G.; Schenning, A.P.H.J.; Bastiaansen, C.W.M. Enhanced Thermal Conductivity in Oriented Polyvinyl Alcohol/Graphene Oxide Composites. Appl. Mater. Interfaces 2021, 13, 28864–28869. [Google Scholar] [CrossRef]

- Etaati, A.; Pather, S.; Fang, Z.; Wang, H. The Study of Fibre/Matrix Bond Strength in Short Hemp Polypropylene Composites from Dynamic Mechanical Analysis. Compos. Part B Eng. 2014, 62, 19–28. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, Z.; Friedrich, K.; Schlarb, A.K. Creep resistant polymer nanocomposites reinforced with multiwalled carbon nanotubes. Macromol. Rapid Commun. 2007, 28, 955–961. [Google Scholar] [CrossRef]

- Joshi, W.; Wang, Z.; Kane, R.S.; Koratkar, N. Creep mitigation in composites using carbon nanotube additives. Nanotechnology 2007, 18, 185703. [Google Scholar]

- Tehrani, M.; Safdari, M.; Al-Haik, M.S. Nanocharacterization of creep behavior of multiwall carbon nanotubes/epoxy nanocomposite. Int. J. Plast. 2011, 27, 887–901. [Google Scholar] [CrossRef]

- Bakbak, O.; Çolak, Ö. Effect of graphene on the creep and stress relaxation behaviors of epoxy-nanocomposite in viscoplastic deformation regime. Sigma J. Eng. Nat. Sci. 2024, 42, 49–56. [Google Scholar]

- Wang, X.; Gong, L.-X.; Tang, L.-C.; Peng, K.; Pei, Y.-B.; Zhao, L.; Wu, L.-B.; Jiang, J.-X. Temperature dependence of creep and recovery behaviors of polymer composites filled with chemically reduced graphene oxide. J. Appl. Polym. Sci. 2018, 135, 46334. [Google Scholar] [CrossRef]

| PA6 | GO | ||

|---|---|---|---|

| Density | 1.14 g/cm3 | Bulk density | 0.2–0.3 g/cm3 |

| Viscosity number | 145 mL/g | C:O atomic ratio | 1.5 |

| Melt volume rate | 165 cm3/10 min | Layer numbers | 3–10 |

| Melting point | 221 °C | Specific surface area | 120–140 m2/g |

| VICAT softening | 200 °C | ||

| Tensile modulus | 1000 MPa | ||

| Yield strength | 40 MPa | ||

| Flexural modulus | 900 MPa | ||

| Flexural strength | 35 MPa | ||

| Charpy notched | 4.5 kJ/m2 | ||

| Hardness Rockwell | 120 Scale R | ||

| Formulation | GO (wt.%) |

|---|---|

| PA6 | 0 |

| PA6 + 0.1GO | 0.1 |

| PA6 + 0.25GO | 0.25 |

| PA6 + 0.5GO | 0.5 |

| PA6 + 1GO | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palabiyik, M.; Aydin, S.; Senturk, O. Investigation of the Mechanical, Fatigue, and Creep Properties of PA6/GO Nanocomposites Manufactured by a Combination of Melt and Solvent Mixing. Polymers 2025, 17, 1186. https://doi.org/10.3390/polym17091186

Palabiyik M, Aydin S, Senturk O. Investigation of the Mechanical, Fatigue, and Creep Properties of PA6/GO Nanocomposites Manufactured by a Combination of Melt and Solvent Mixing. Polymers. 2025; 17(9):1186. https://doi.org/10.3390/polym17091186

Chicago/Turabian StylePalabiyik, Mehmet, Serhat Aydin, and Oguzkan Senturk. 2025. "Investigation of the Mechanical, Fatigue, and Creep Properties of PA6/GO Nanocomposites Manufactured by a Combination of Melt and Solvent Mixing" Polymers 17, no. 9: 1186. https://doi.org/10.3390/polym17091186

APA StylePalabiyik, M., Aydin, S., & Senturk, O. (2025). Investigation of the Mechanical, Fatigue, and Creep Properties of PA6/GO Nanocomposites Manufactured by a Combination of Melt and Solvent Mixing. Polymers, 17(9), 1186. https://doi.org/10.3390/polym17091186