Design and Optimization of Rice Grain Screening System Based on DEM–CFD Coupled Rice Seed Testing Platform

Abstract

:1. Introduction

2. Materials and Methods

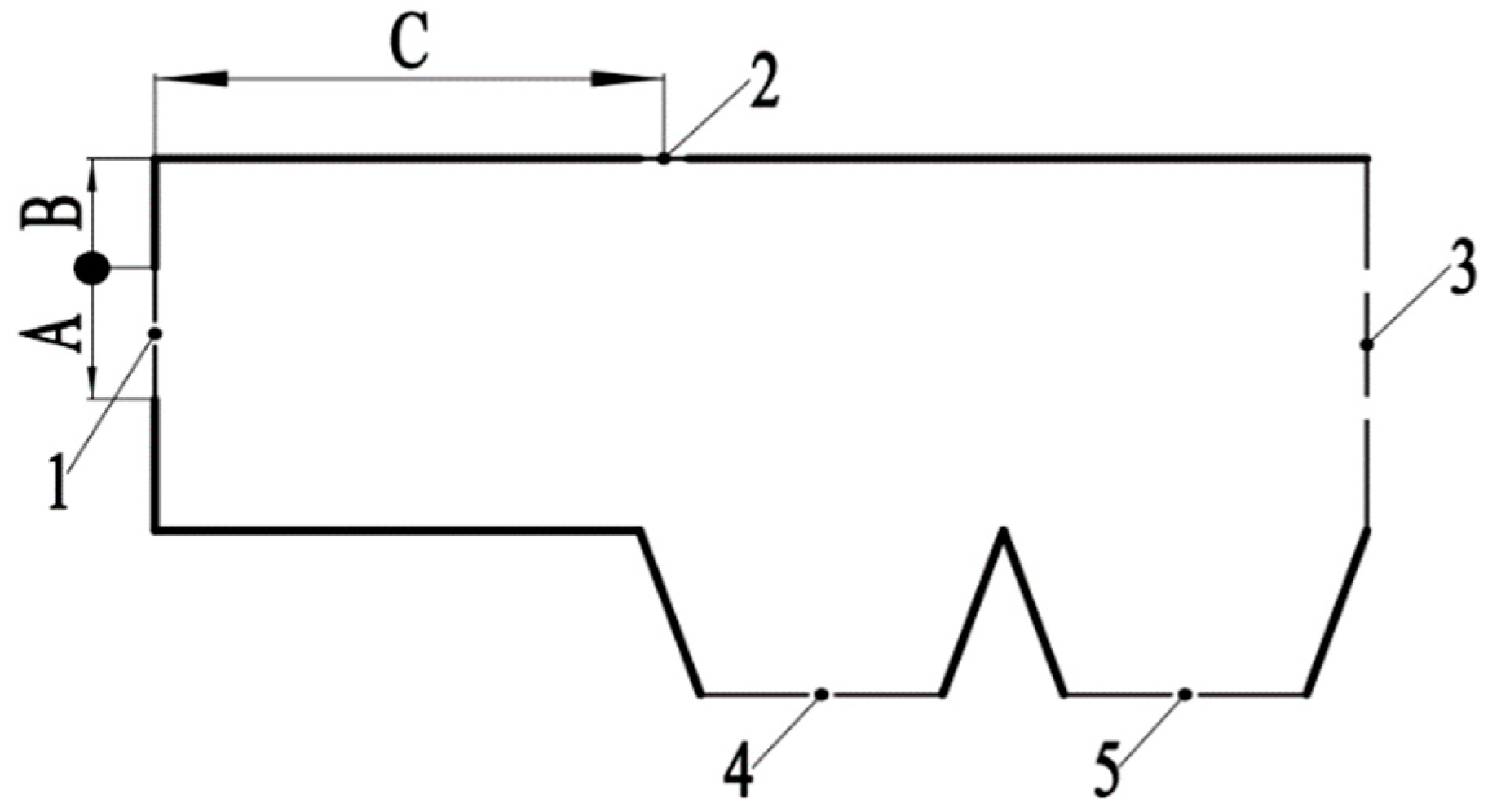

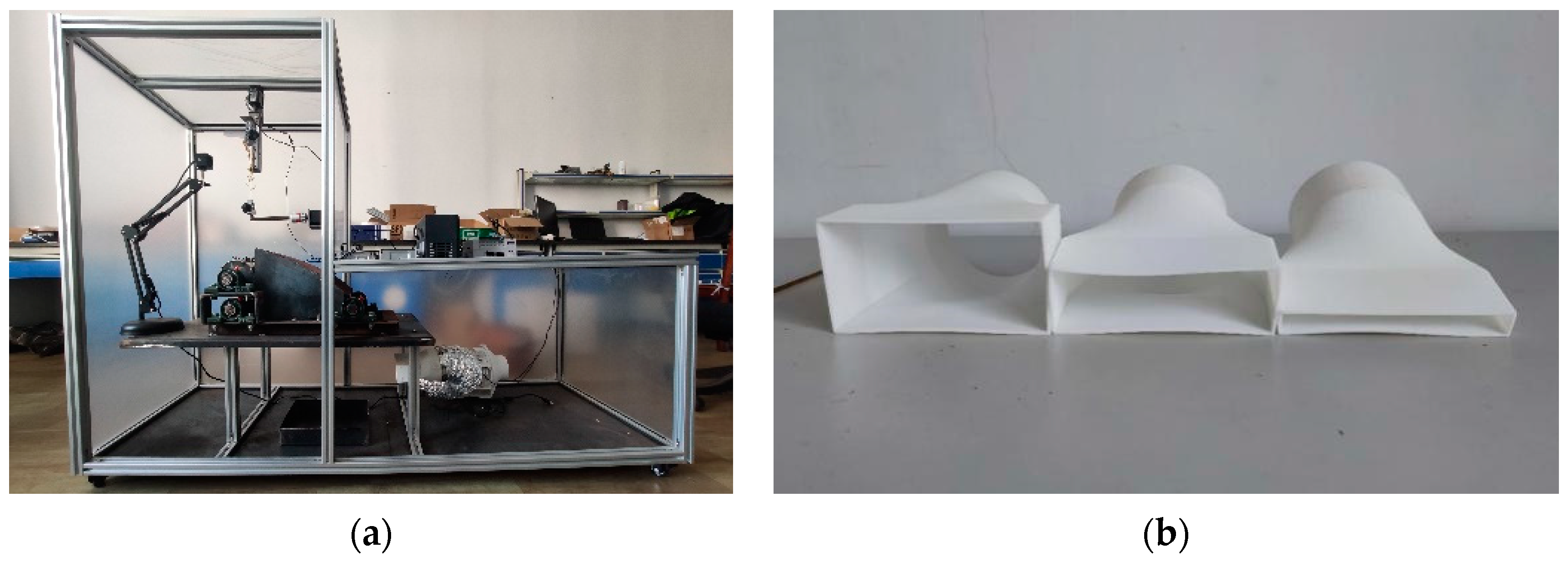

2.1. Structure and Working Principle of Seed Test Platform Screening System

2.2. Discrete Element Simulation Analysis

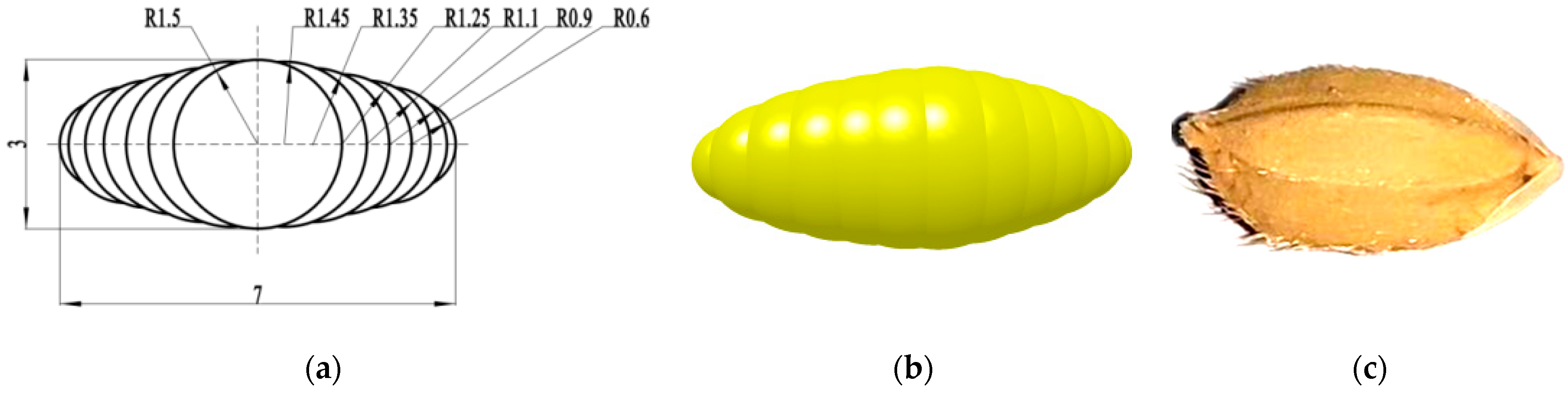

2.2.1. Establishment of CFD–DEM Coupling Model

2.2.2. Particle Contact Impact Model

2.2.3. Calculation Model

2.3. Setting of Simulation Parameters

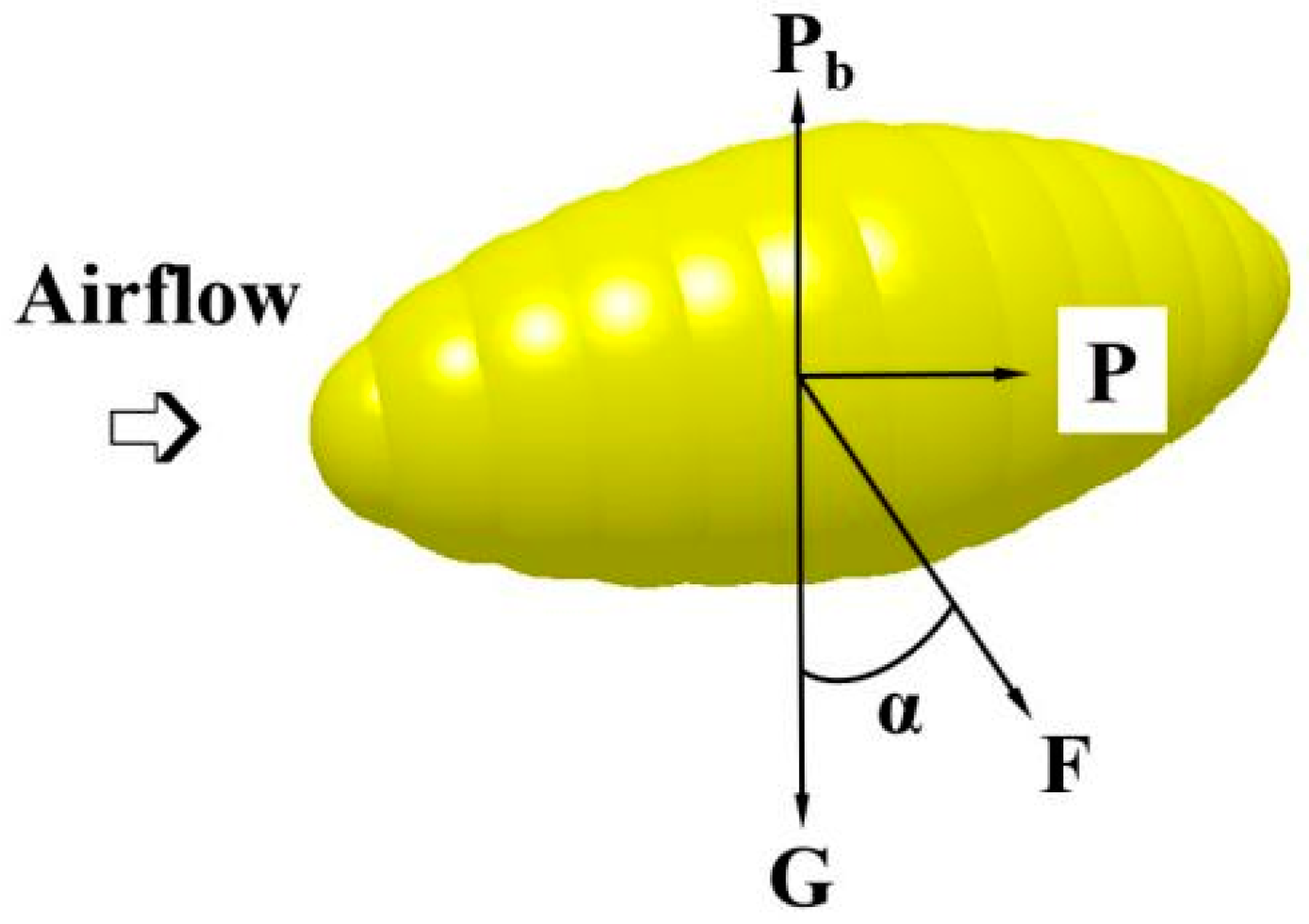

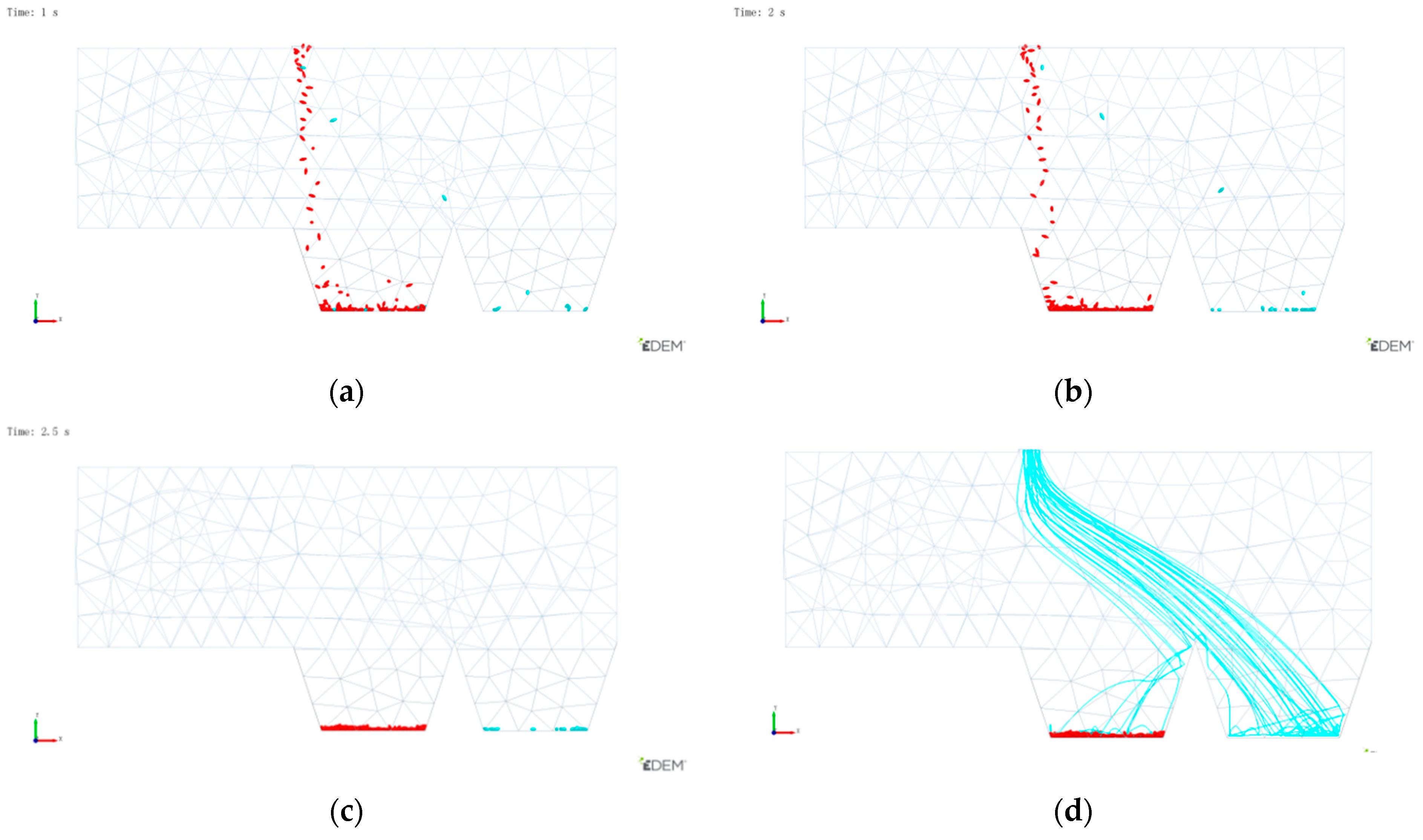

2.4. Particle Motion Analysis

2.5. Seed Test Platform

3. Results and Analysis

3.1. Orthogonal Test

3.1.1. Test Design and Method

3.1.2. Test Design and Method

3.2. Regression Model and Variance Analysis

3.2.1. Regression Equation

3.2.2. Regression Model Analysis of Variance

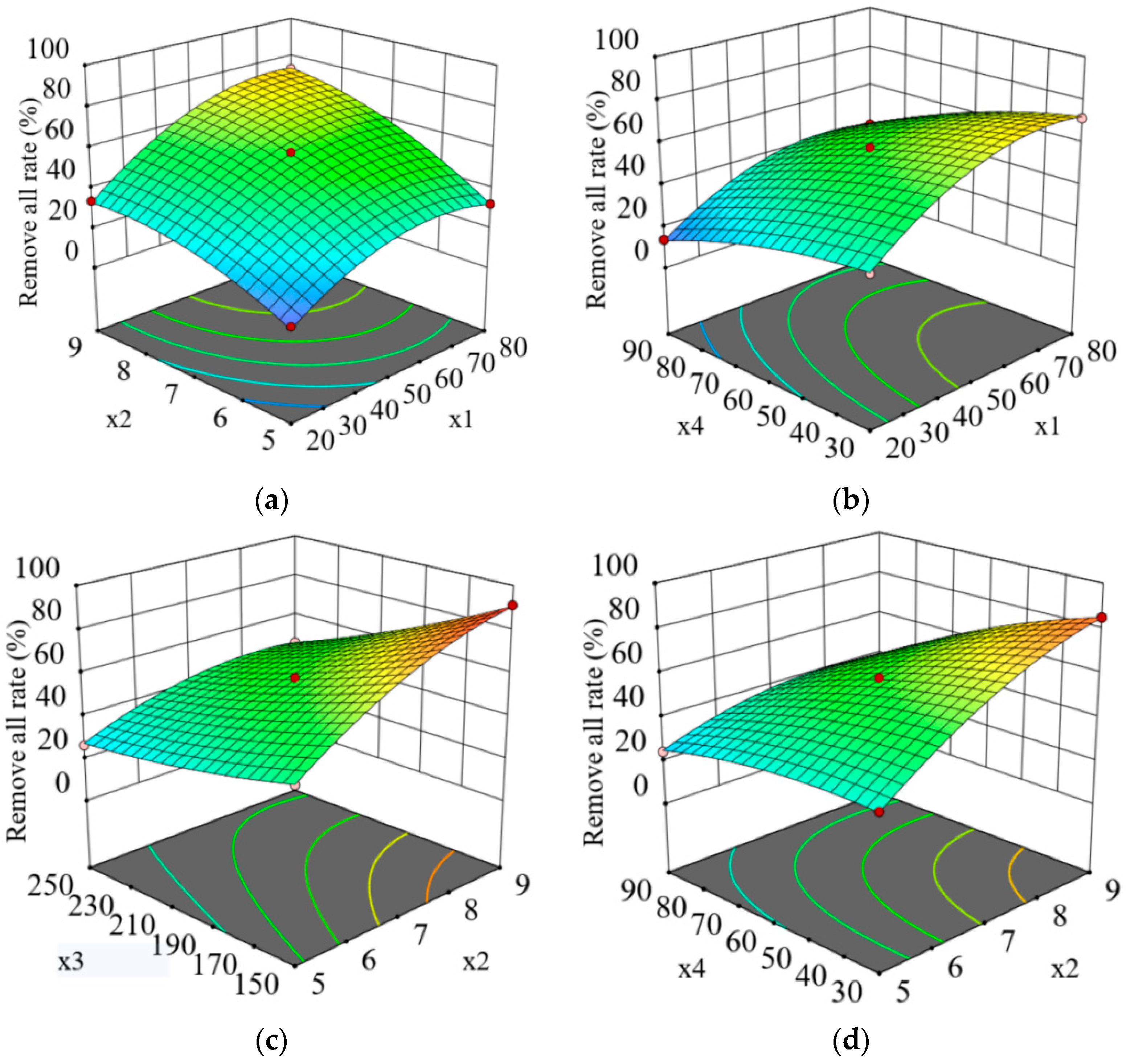

3.3. Response Surface Analysis

3.4. Rice Grain Screening Experiment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, H. The Design and Implementation of Rice Seed Counting System Based on Image Processing. Master’s Thesis, University of Electronic Science and Technology of China, Chengdu, China, 2019. (In Chinese with English abstract). [Google Scholar]

- Zhang, J. Performance Test of 5TR-20 Type Rice Thresher for Single Plant and Single Ear. Agric. Sci. Technol. Equip. 2020, 1, 19–20, (In Chinese with English abstract). [Google Scholar]

- Tang, H.; Xu, C.; Wang, Z.; Wang, Q.; Wang, J. Optimized Design, Monitoring System Development and Experiment for a Long-Belt Finger-Clip Precision Corn Seed Metering Device. Front. Plant Sci. 2022, 13, 814747. [Google Scholar] [CrossRef] [PubMed]

- Fu, J.; Chen, Z.; Han, L.; Ren, L. Review of grain threshing theory and technology. Int. J. Agric. Biol. Eng. 2018, 11, 12–20. [Google Scholar] [CrossRef]

- Du, X.; Ni, K.; Chen, J.; Wu, C.; Zhao, Y. Numerical simulation and experiment of gas-solid two-phase flow in a cross-flow grain cleaning device. In American Society of Agricultural and Biological Engineers; American Society of Agricultural and Biological Engineers: Kansas City, MI, USA, 2013; p. 1. [Google Scholar]

- Binelo, M.O.; de Lima, R.F.; Khatchatourian, O.A.; Stransky, J. Modelling of the drag force of agricultural seeds applied to the discrete element method. Biosyst. Eng. 2019, 178, 168–175. [Google Scholar] [CrossRef]

- Lin, J. Study on Design and Experiment of winnowing Machine by specific gravity for Apricot stone Shell and Kernel. Master’s Thesis, Xinjiang Agricultural University, Urumchi, China, 2013. (In Chinese with English abstract). [Google Scholar]

- Krishnan, P.; Berlage, A. Separation of shells from walnut meats using magnetic methods. Trans. ASAE 1984, 27, 1990–1992. [Google Scholar] [CrossRef]

- Li, H.; Li, Y.; Gao, F.; Zhao, Z.; Xu, L. CFD–DEM simulation of material motion in air-and-screen cleaning device. Comput. Electron. Agric. 2012, 88, 111–119. [Google Scholar] [CrossRef]

- Zhang, T.; Li, Y.; Xu, L.; Liu, Y.; Ji, K.; Jiang, S. Experimental Study on Fluidization Behaviors of Wet Rice Threshed Materials with Hot Airflow. Agriculture 2022, 12, 601. [Google Scholar] [CrossRef]

- Chen, S. Simulation and Key Parameter Optimization of Wheat Harvester Cleaning based on CFD-DEM. Master’s Thesis, University of Jinan, Jinan, China, 2021. (In Chinese with English abstract). [Google Scholar]

- Wang, C.-N.; Yang, F.-C.; Nguyen, V.T.T.; Vo, N.T.M. CFD Analysis and Optimum Design for a Centrifugal Pump Using an Effectively Artificial Intelligent Algorithm. Micromachines 2022, 13, 1208. [Google Scholar] [CrossRef]

- Ren, J.; Wu, T.; Mo, W.; Li, K.; Hu, P.; Xu, F.; Liu, Q. Discrete Element Simulation Modeling Method and Parameters Calibration of Sugarcane Leaves. Agronomy 2022, 12, 1796. [Google Scholar] [CrossRef]

- Xu, J.; Hou, J.; Wu, W.; Han, C.; Wang, X.; Tang, T.; Sun, S. Key Structure Design and Experiment of Air-Suction Vegetable Seed-Metering Device. Agronomy 2022, 12, 675. [Google Scholar] [CrossRef]

- Zhang, N.; Fu, J.; Chen, Z.; Chen, X.; Ren, L. Optimization of the Process Parameters of an Air-Screen Cleaning System for Frozen Corn Based on the Response Surface Method. Agriculture 2021, 11, 794. [Google Scholar] [CrossRef]

- Liu, P.; Jin, C.; Liu, Z.; Zhang, G.; Cai, Z.; Kang, Y.; Yin, X. Optimization of field cleaning parameters of soybean combine harvester. Trans. Chin. Soc. Agric. Eng. 2020, 36, 35–45, (In Chinese with English abstract). [Google Scholar]

- Zhu, P. Simulation Research on Grain Air-and-Screen Cleaning Process and Optimization of Key Parameters. Master’s Thesis, Zhejiang University, Hangzhou, China, 2019. (In Chinese with English abstract). [Google Scholar]

- Geng, L.; Yang, F.; Wang, S.; Han, R.; Hu, J. Experimental Study on Aerodynamic Characteristics of Chinese Cabbage Seed Extraction Components. J. Agric. Mech. Res. 2020, 42, 161–165. [Google Scholar] [CrossRef]

- Ma, Z.; Li, Y.; Xu, L. Testing and analysis on rape excursion components characteristics in floating, friction and wettability. Trans. Chin. Soc. Agric. Eng. 2011, 27, 13–17, (In Chinese with English abstract). [Google Scholar]

- Tang, H.; Xu, C.; Qi, X.; Wang, Z.; Wang, J.; Zhou, W.; Wang, Q.; Wang, J. Study on Periodic Pulsation Characteristics of Corn Grain in a Grain Cylinder during the Unloading Stage. Foods 2021, 10, 2314. [Google Scholar] [CrossRef]

- Zhang, C.; Fan, X.; Li, M.; Li, G.; Zhao, C.; Sun, W. Simulation Analysis and Experiment of Soil Disturbance by Chisel Plow Base on EDEM. Trans. Chin. Soc. Agric. Mach. 2022, 53, 52–59, (In Chinese with English abstract). [Google Scholar]

- Ding, H. Study of grain vertical air separation based on DEM-CFD coupling. Master’s Thesis, University of Science and Technology Liaoning, Anshan, China, 2020. (In Chinese with English abstract). [Google Scholar]

- Wang, M.; Liu, Q.; Ou, Y.; Zou, X. Numerical Simulation and Verification of Seed-Filling Performance of Single-Bud Billet Sugarcane Seed-Metering Device Based on EDEM. Agriculture 2022, 12, 983. [Google Scholar] [CrossRef]

- He, S.; Zang, Y.; Huang, Z.; Tao, W.; Xing, H.; Qin, W.; Jiang, Y.; Wang, Z. Design of and Experiment on a Cleaning Mechanism of the Pneumatic Single Seed Metering Device for Coated Hybrid Rice. Agriculture 2022, 12, 1239. [Google Scholar] [CrossRef]

- Tang, H.; Xu, C.; Xu, W.; Xu, Y.; Xiang, Y.; Wang, J. Method of straw ditch buried returning, development of supporting machine and analysis of influencing factors. Front. Plant Sci. 2022, 13, 967838. [Google Scholar] [CrossRef]

- Gao, X.; Shi, W.; Shi, Y.; Chang, H.; Zhao, T. DEM-CFD Simulation and Experiments on the Flow Characteristics of Particles in Vortex Pumps. Water 2020, 12, 2444. [Google Scholar] [CrossRef]

- Han, D.; Zhang, D.; Jing, H.; Yang, L.; Cui, T.; Ding, Y.; Wang, Z.; Wang, Y.; Zhang, T. DEM-CFD coupling simulation and optimization of an inside-filling air-blowing maize precision seed-metering device. Comput. Electron. Agric. 2018, 150, 426–438. [Google Scholar] [CrossRef]

- Napolitano, E.S.; di Renzo, A.; di Maio, F.P. Coarse-grain DEM-CFD modelling of dense particle flow in Gas–Solid cyclone. Sep. Purif. Technol. 2022, 287, 120591. [Google Scholar] [CrossRef]

- Sharma, A.; Thakur, A.; Saha, S.K.; Sharma, A.; Sharma, D.; Chaudhuri, P. Thermal-hydraulic characteristics of purge gas in a rectangular packed pebble bed of a fusion reactor using DEM-CFD and porous medium analyses. Fusion Eng. Des. 2020, 160, 111848. [Google Scholar] [CrossRef]

- Zhao, L.; Chen, L.; Yuan, F.; Wang, L. Simulation Study of Rice Cleaning Based on DEM-CFD Coupling Method. Processes 2022, 10, 218. [Google Scholar] [CrossRef]

- Ma, X.; Zhao, L.; Guo, B.; Dang, H. Simulation and experiment of rice cleaning in air-separation device based on DEM-CFD coupling method. Int. J. Agric. Biol. Eng. 2020, 13, 226–233. [Google Scholar] [CrossRef]

- Wang, L.; Liao, Y.; Wan, X.; Wang, B.; Hu, Q.; Liao, Q. Design and Test on Mixing Component of Air-assisted Centralized Metering Device for Rapeseed and Wheat. Trans. Chin. Soc. Agric. Mach. 2022, 53, 68–79+97, (In Chinese with English abstract). [Google Scholar]

- Wang, Y.; Li, H.; Hu, H.; He, J.; Wang, Q.; Lu, C.; Liu, P.; He, D.; Lin, X. DEM—CFD coupling simulation and optimization of a self-suction wheat shooting device. Powder Technol. 2021, 393, 494–509. [Google Scholar] [CrossRef]

- Nguyen, V.; Tran, T.; Nguyen, T.; Huynh, H.; To, V.; Doan, D.; Nguyen, T.; Van Thanh, D. An investigation of designing and manufacturing the hard-shell peanut peeling machine with a small scale-size. Int. J. Sci. Technol. Res 2019, 8, 9. [Google Scholar]

- Bekkering, C.S.; Huang, J.; Tian, L. Image-Based, Organ-Level Plant Phenotyping for Wheat Improvement. Agronomy 2020, 10, 1287. [Google Scholar] [CrossRef]

- Tien, N.V.T.; Van, A.D.; Ngoc, T.T.; Cong, H.N.; Dai, H.V.; Dang, K.N.; Ngoc, L.N.; Quang, L.N.; Thien, L.T.; Tan, N.B.; et al. An investigation on design innovation, fabrication and experiment of a soy bean peeling machine-scale. Int. J. Eng. Technol. 2018, 7, 2704–2709. [Google Scholar]

- Lu, Y.R.; Nikrityuk, P.A. Steam methane reforming driven by the Joule heating. Chem. Eng. Sci. 2022, 251, 117446. [Google Scholar] [CrossRef]

- Tian, L.; Jin, E.; Wang, J.; Wang, X.; Bing, W.; Jin, H.; Zhao, J.; Ren, L. Exploring the antifouling effect of elastic deformation by DEM-CFD coupling simulation. Rsc Adv. 2019, 9, 40855–40862. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Takabatake, K.; Sakai, M. Flexible discretization technique for DEM-CFD simulations including thin walls. Adv. Powder Technol. 2020, 31, 1825–1837. [Google Scholar] [CrossRef]

- Wang, C.; Hausberger, A.; Nothdurft, P.; Lackner, J.M.; Schwarz, T. The Potential of Tribological Application of DLC/MoS2 Coated Sealing Materials. Coatings 2018, 8, 267. [Google Scholar] [CrossRef] [Green Version]

- Tan, Z.; Liang, C.; Chen, X.; Li, J. Comparisons of TFM and DEM-CFD simulation analyses on the influence mechanism of electrostatics on single bubble in gas-solid fluidized bed. Powder Technol. 2019, 351, 238–258. [Google Scholar] [CrossRef]

- Zhao, Y.; Jin, Y.; Pan, C.; Wu, C.; Yuan, X.; Zhou, G.; Han, W. Characterization of Bond Fracture in Discrete Groove Wear of Cageless Ball Bearings. Materials 2022, 15, 6711. [Google Scholar] [CrossRef]

- Mindlin, R.D. Compliance of Elastic Bodies in Contact. J. Appl. Mech 1949, 16, 259–268. [Google Scholar]

- Rossander, M.; Dyachuk, E.; Apelfröjd, S.; Trolin, K.; Goude, A.; Bernhoff, H.; Eriksson, S. Evaluation of a Blade Force Measurement System for a Vertical Axis Wind Turbine Using Load Cells. Energies 2015, 8, 5973–5996. [Google Scholar] [CrossRef]

- Yuan, H.; Liu, Y.; Song, M.; Zhu, Y.; Cao, W.; Jiang, X.; Ni, J. Design of the Mechanical Structure of a Field-Based Crop Phenotyping Platform and Tests of the Platform. Agronomy 2022, 12, 2162. [Google Scholar] [CrossRef]

- Boac, J.M.; Casada, M.E.; Maghirang, R.G.; Harner, J.P. MATERIAL AND INTERACTION PROPERTIES OF SELECTED GRAINS AND OILSEEDS FOR MODELING DISCRETE PARTICLES. Trans. ASABE 2010, 53, 1201–1216. [Google Scholar] [CrossRef] [Green Version]

- Cleary, P.W. Particulate mixing in a plough share mixer using DEM with realistic shaped particles. Powder Technol. 2013, 248, 103–120. [Google Scholar] [CrossRef]

- Correa, P.C.; da Silva, F.S.; Jaren, C.; Afonso, P.C.; Arana, I. Physical and mechanical properties in rice processing. J. Food Eng. 2007, 79, 137–142. [Google Scholar] [CrossRef]

- Jia, H.L.; Deng, J.Y.; Deng, Y.L.; Chen, T.Y.; Wang, G.; Sun, Z.J.; Guo, H. Contact parameter analysis and calibration in discrete element simulation of rice straw. Int. J. Agric. Biol. Eng. 2021, 14, 72–81. [Google Scholar] [CrossRef]

- GB/T 5982-2017; Thresher-Testing Method. General Administration of Quality Supervision, Inspection and Quarantine of the People ‘s Republic of China: Beijing, China, 2017.

- Liu, B.F.; Li, J.; He, J. Study on hyperspectral remote sensing monitoring and diagnosis model of total phosphorus content in maize leaves. J. Agric. Mach. 2015, 46, 252–258+280. [Google Scholar]

- Ren, J.; Wu, T.; Liu, Q.; Zou, X.; Li, K. Design and Test of the Structure of Extractor Negative Pressure Zone of Sugarcane Chopper Harvester. Agronomy 2022, 12, 2336. [Google Scholar] [CrossRef]

| Poisson’s Ratio | Shear Modulus/Pa | Density/kg·m−3 | |

|---|---|---|---|

| Filled grain | 0.30 | 2 × 106 | 1380 |

| Unfilled grain | 0.40 | 1 × 106 | 100 |

| Steel | 0.29 | 7.992 × 1010 | 7800 |

| Coefficient of Restitution | Coefficient of Static Friction | Coefficient of Rolling Friction | |

|---|---|---|---|

| filled grain–filled grain | 0.2 | 1.0 | 0.01 |

| filled grain–unfilled grain | 0.2 | 0.8 | 0.01 |

| filled grain–steel | 0.5 | 0.7 | 0.01 |

| unfilled grain–unfilled grain | 0.2 | 0.7 | 0.01 |

| unfilled grain–steel | 0.2 | 0.8 | 0.01 |

| Coding | Factors | |||

|---|---|---|---|---|

| Section Width (mm) | Air Speed of Inlet (m·s−1) | Horizontal Distance (mm) | Vertical Distance (mm) | |

| −1 | 20 | 5 | 150 | 30 |

| 0 | 50 | 7 | 200 | 60 |

| 1 | 80 | 9 | 250 | 90 |

| Serial Number | Section Width (mm) x1 | Air Speed of Inlet (m·s−1) x2 | Horizontal Distance (mm) x3 | Vertical Distance (mm) x4 | Removal Rate (%) Y |

|---|---|---|---|---|---|

| 1 | 50 | 5 | 200 | 90 | 24.3 |

| 2 | 50 | 9 | 250 | 60 | 45.9 |

| 3 | 50 | 7 | 200 | 60 | 56.7 |

| 4 | 80 | 7 | 200 | 30 | 71.8 |

| 5 | 50 | 5 | 200 | 30 | 35.6 |

| 6 | 50 | 9 | 150 | 60 | 91.2 |

| 7 | 20 | 5 | 200 | 60 | 12.3 |

| 8 | 20 | 7 | 200 | 90 | 13.8 |

| 9 | 50 | 5 | 150 | 60 | 45.4 |

| 10 | 80 | 7 | 250 | 60 | 51.6 |

| 11 | 80 | 9 | 200 | 60 | 73.2 |

| 12 | 50 | 7 | 250 | 30 | 56.9 |

| 13 | 50 | 7 | 150 | 30 | 83.4 |

| 14 | 20 | 7 | 200 | 30 | 36.4 |

| 15 | 50 | 7 | 250 | 90 | 25.2 |

| 16 | 20 | 7 | 250 | 60 | 9.9 |

| 17 | 50 | 7 | 150 | 90 | 58.6 |

| 18 | 80 | 5 | 200 | 60 | 32.4 |

| 19 | 80 | 7 | 150 | 60 | 74.6 |

| 20 | 50 | 7 | 200 | 60 | 57.2 |

| 21 | 20 | 9 | 200 | 60 | 33.9 |

| 22 | 50 | 9 | 200 | 30 | 85.1 |

| 23 | 20 | 7 | 150 | 60 | 50.9 |

| 24 | 80 | 7 | 200 | 90 | 39.7 |

| 25 | 50 | 5 | 250 | 60 | 26.5 |

| 26 | 50 | 7 | 200 | 60 | 58.1 |

| 27 | 50 | 9 | 200 | 90 | 37.6 |

| Project | Removal Rate (%) | ||

|---|---|---|---|

| Squares | F | P | |

| Model | 13,221.36 | 768.70 | <0.0001 |

| A | 2886.10 | 2349.21 | <0.0001 |

| B | 3021.01 | 2459.02 | <0.0001 |

| C | 2948.47 | 2399.97 | <0.0001 |

| D | 2408.33 | 1960.32 | <0.0001 |

| AB | 81.00 | 75.02 | <0.0001 |

| AC | 92.16 | 65.93 | <0.0001 |

| AD | 22.56 | 18.37 | 0.0011 |

| BC | 174.24 | 141.83 | <0.0001 |

| BD | 327.61 | 266.67 | <0.0001 |

| CD | 11.90 | 9.69 | 0.0090 |

| A2 | 848.40 | 690.58 | <0.0001 |

| B2 | 280.33 | 228.18 | <0.0001 |

| C2 | 29.14 | 23.72 | 0.0004 |

| D2 | 90.75 | 73.87 | <0.0001 |

| Residual | 14.74 | ||

| Lack of Fit | 13.74 | 2.73 | 0.2979 |

| Pure Error | 1.01 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, H.; Zhang, B.; Jiang, T.; Zhang, Y.; Qu, J.; Chen, C.; Xiao, Y.; Ding, Y.; Xi, X. Design and Optimization of Rice Grain Screening System Based on DEM–CFD Coupled Rice Seed Testing Platform. Agronomy 2022, 12, 3069. https://doi.org/10.3390/agronomy12123069

Dong H, Zhang B, Jiang T, Zhang Y, Qu J, Chen C, Xiao Y, Ding Y, Xi X. Design and Optimization of Rice Grain Screening System Based on DEM–CFD Coupled Rice Seed Testing Platform. Agronomy. 2022; 12(12):3069. https://doi.org/10.3390/agronomy12123069

Chicago/Turabian StyleDong, Hao, Baofeng Zhang, Tao Jiang, Yifu Zhang, Jiwei Qu, Chao Chen, Yawen Xiao, Yuhao Ding, and Xiaobo Xi. 2022. "Design and Optimization of Rice Grain Screening System Based on DEM–CFD Coupled Rice Seed Testing Platform" Agronomy 12, no. 12: 3069. https://doi.org/10.3390/agronomy12123069

APA StyleDong, H., Zhang, B., Jiang, T., Zhang, Y., Qu, J., Chen, C., Xiao, Y., Ding, Y., & Xi, X. (2022). Design and Optimization of Rice Grain Screening System Based on DEM–CFD Coupled Rice Seed Testing Platform. Agronomy, 12(12), 3069. https://doi.org/10.3390/agronomy12123069