Abstract

Onion production is reliant on synthetic chemical inputs such as fertilizer and pesticides to ensure its profitability. In the Great Lakes region (USA), onion thrips (Thrips tabaci) and a complex of bacterial pathogens that cause bulb rot disease threaten the sustainability of onion production. The potential exists for reducing T. tabaci infestations and bulb rot disease incidence in onions by decreasing the amounts of fertilizer applied at planting and the insecticide applied to foliage during the season. In a three-year study that included 20 New York commercial onion fields, the impact of synthetic fertilizer (no fertilizer, half rate, and full rate) and insecticide use (action threshold-based application program and weekly application program) on T. tabaci populations and bulb rot disease incidence was examined. Results indicated that the amount of fertilizer applied to an onion at planting had no impact on T. tabaci population levels, bulb rot disease incidence, or onion bulb size and yield. In contrast, insecticide use had the greatest impact on reducing T. tabaci densities. Both the action threshold-based program and weekly spray program reduced T. tabaci infestation levels below the economic injury level, but the action threshold program averaged 2.3 fewer applications per season. The insecticide program had no effect on bulb rot incidence, bulb size, or yield. We conclude that synthetic fertilizer and insecticide inputs can be reduced substantially without compromising onion bulb yields, and this should lead to greater profits and a reduction of chemicals in the environment.

1. Introduction

Dry bulb onion (Allium cepa L.) is a high-value, fresh-market vegetable crop that generates approximately 1 billion USD annually [1]. In the Great Lakes region (USA), onions are commonly produced in muck soils, which contain up to 80% organic matter and are highly fertile [2,3]. Onion production in this region involves intensive cultivation and heavy reliance on synthetic inputs such as fertilizer and pesticides [4]. Given the high cost of these inputs and the crop value, effective and economical management of onion pests and diseases is essential.

Onion thrips (Thrips tabaci Lindeman) is one of the most economically damaging pests of onions worldwide [5,6]. The rasping–sucking feeding by adults and larvae reduces photosynthetic potential through removal of mesophyll, which can contribute to as much as 60% lower bulb yield [7,8,9]. In addition, T. tabaci contributes to the spread of numerous economically significant plant pathogens through the movement of fungal spores, transmission of viruses, and creation of wounds for bacteria to enter through [9,10,11].

Insecticide usage is the primary tactic for managing T. tabaci in onions. In the Great Lakes region, T. tabaci adults move into onion fields mid-season (June and early July) and feed for 6–8 weeks until plants approach maturity, requiring multiple insecticide applications per season [12]. Consequently, insecticide resistance management is important. Historically, T. tabaci has developed resistance to certain insecticides when applied repeatedly within and across seasons [13,14,15]. Action thresholds for newer insecticides have been developed [12,16], and application sequences have been recommended to mitigate resistance development [17,18,19]. Following these recommendations, onion growers in New York (USA) have reduced the number of insecticide applications by 13–50%, compared with a weekly insecticide spray schedule [12]. Although adoption of action threshold programs has increased throughout the Great Lakes region, some growers continue to follow weekly insecticide programs [19]. Thus, there is a need to improve the robustness of T. tabaci management in onion fields by identifying new thrips management tactics that are compatible with insecticide use and by encouraging further adoption of action threshold-based insecticide programs.

Bacterial diseases also are major constraints for dry bulb onion production [20]. Bacteria that infest bulbs can cause them to either discolor internally or rot, and this renders bulbs unmarketable. In the Great Lakes region, multiple species of pathogenic bacteria are responsible for causing bulb rot diseases such as sour skin (Burkholderia spp.), internal bulb decay (Enterobacter spp., Pseudomonas spp., Lactococcus spp., Rahnella spp., Klebsiella spp., Kosakonia cowanii, and Serratia marcescens), and center rot (Pantoea spp.) [9,21,22,23,24,25,26]. Unlike other onion pathogens, highly effective management options are lacking for bacterial bulb rot diseases.

Reducing the rate of synthetic fertilizer at planting is a cultural tactic that may help reduce both T. tabaci infestations and bacterial bulb rot disease incidence in onions. Reduced amounts of nitrogen applied to onions grown in mineral soils decreased T. tabaci infestations by 30–70% [27,28]. In contrast, reduced amounts of either nitrogen alone or phosphorous alone have not reduced T. tabaci populations in onions grown in New York muck soils [9,24]. Reducing nitrogen levels has reduced the incidence of bacterial bulb rot in mineral soils [25,29,30]. In contrast, reduced amounts of either nitrogen alone or phosphorous alone have not consistently reduced bacterial bulb rot disease incidence in onions grown in New York muck soils [24]. While T. tabaci infestations and bulb rot disease levels have not been reduced by specifically decreasing either nitrogen alone or phosphorous alone in New York, an overall reduction in all three nutrients (i.e., nitrogen, phosphorous, and potassium together) may elicit a reduction in T. tabaci infestation levels and bulb rot disease incidence. Ideally, such a reduction in pest and disease incidence would occur in the absence of bulb yield reduction.

Our goal was to provide commercial growers with the information needed to optimize their use of synthetic chemicals for producing onions. Unlike previous studies, we aimed to evaluate a concomitant reduction in synthetic fertilizer (nitrogen–phosphorus–potassium [N–P–K], rather than a single nutrient like N or P) and insecticide use on T. tabaci infestations and bacterial bulb rot disease incidence in commercially produced onions grown in muck soil. Our hypotheses were as follows: (1) T. tabaci population levels and bacterial bulb rot disease incidence would decline with a reduction in the quantity of fertilizer applied at planting; (2) T. tabaci population levels and bulb rot disease incidence in onions managed with insecticides following an action threshold-based program would be equivalent to those following a weekly spray program, but that fewer applications would be made following the action threshold program; and (3) bulb size and yield for onions that received standard amounts of fertilizer would be similar to those receiving substantially lower amounts. Unlike previous studies, our three-year study in New York was conducted in two production regions on five farms, totalling 20 fields and seven cultivars. Additionally, onion growers applied all fertilizer treatments and most of the insecticide applications.

2. Materials and Methods

2.1. Field Locations

This experiment was conducted in commercial onion (Allium cepa L.) fields in Orleans County, NY from 2019 to 2021 (n = 4, 5, and 5 fields, respectively) and Wayne County, NY in 2020 and 2021 (n = 3 fields in both years) (Table S1). Soils in Orleans County fields were classified as either ‘Carlisle’ muck or ‘Palms’ muck, whereas Wayne County fields were all ‘Carlisle’ muck [31]. All dry bulb onions were commonly grown yellow cultivars and were planted in April or May (Table S1). Onion seeds were treated with either FarMore FI500 with Regard SC (spinosad [0.2 mg ai seed−1], thiamethoxam [0.2 mg ai seed−1], mefenoxam [0.15 g ai kg−1], fludioxonil [0.025 g ai kg−1], and azoxystrobin [0.025 g ai kg−1]) plus Pro-Gro (carboxin [7.5 g ai kg−1] and thiram [12.5 g ai kg−1]) or FarMore FI500 with Trigard OMC (cyromazine [0.225 mg ai seed−1], thiamethoxam [0.2 mg ai seed−1], mefenoxam [0.15 g ai kg−1], fludioxonil [0.025 g ai kg−1], and azoxystrobin [0.025 g ai kg−1]) plus EverGol Prime (penflufen [2.5 g ai kg−1]) to control maggot pests (Delia spp.) and seedling diseases. Thrips tabaci populations are not affected by either thiamethoxam or cyromazine seed treatments (BAN, pers. obs). All fields in Wayne County and one field in Orleans County each year were planted with potatoes (Solanum tuberosum L.) the previous season. All other Orleans County fields were planted with onions continuously for many seasons.

2.2. Experimental Design

Three fertilizer treatments were evaluated, including the onion grower’s full rate (standard) of granular nitrogen–phosphorus–potassium (N–P–K) fertilizer, half the standard rate, and no fertilizer (Table S2). Two insecticide treatments were evaluated, including a weekly application program and an action threshold-based application program. The experimental design was a split-plot with fertilizer treatment as the main plot factor and insecticide treatment as the sub-plot factor. Each commercial onion field was considered as a replicate (or block) with n = 4, 8, and 8 fields in 2019, 2020, and 2021, respectively.

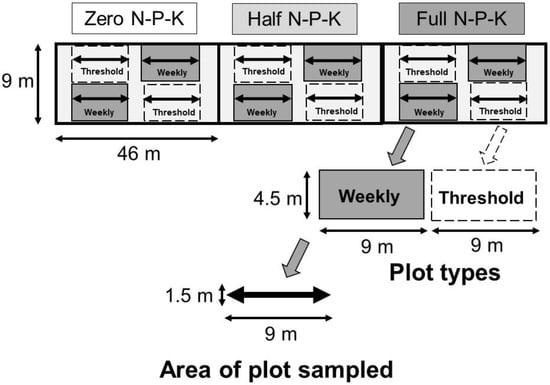

Within each commercial field, a 9.1 m wide by 138 m long area was separated equally into three sections, and each section was randomly selected to receive one of the three fertilizer treatments (Figure 1; Table S2). Within each fertilizer treatment, four 4.5 m wide by 9 m long plots were designated as either the weekly insecticide program or the action threshold-based program (Figure 1). Thus, in each field, there were a total of 12 plots. Six plots received an insecticide application every week for the entire duration of the onion growing season regardless of thrips densities, while six plots received insecticide applications based only on an action threshold. All plots were positioned well within the center area of each fertilizer treatment to reduce the risk of sampling in areas where nutrients might have moved between treatments or from soil surrounding the trial. All data were taken along a transect in the center of each plot (1.5 m wide × 9 m long) (Figure 1).

Figure 1.

An illustration (not to scale) of one replicate (or block) within a single commercial onion field in New York (USA), including dimensions for the fertilizer main plots (levels: zero fertilizer and half rate and full rate of fertilizer; 9 m wide × 46 m long) and insecticide program sub-plots (levels: action threshold and weekly applications; 4.5 m wide × 9 m long). The dark gray box and the white box outlined with dashed lines denote the two types of insecticide sub-plots. The dark gray area was sprayed by both the onion grower using a ground rig and by us using a backpack sprayer, whereas the white areas outlined by dashed lines were only sprayed by the onion grower. The black double-arrow lines signify each 1.5 m wide × 9 m long transect in a plot (experimental unit) where all thrips were counted and bulbs were harvested, graded, weighed, and inspected for bacterial bulb rot.

2.3. Fertilizer Applications

All fertilizer was formulated as a granular pre-mix and purchased from either Carolina Eastern-Crocker, LLC, Stafford, NY (two growers in Orleans Co.), or Nutrien Ag Solutions in Fancher, NY, and Sodus, NY (one grower in Orleans Co. and two in Wayne Co.). Fertilizer mixtures for onions typically contain ammonium sulfate and urea to provide nitrogen, monoammonium phosphate to provide phosphorus, K-Mag (commercial potassium and magnesium blend) and potassium chloride to provide potassium, and copper and manganese oxy-sulfate to provide additional micronutrients (Table S3). Fertilizer mixes were custom blended for each grower by the fertilizer company based on soil test results acquired by the grower (Table S2). Before applying fertilizer, growers used a mouldboard plough to turn the soil over and then a disk cultivator to flatten the field before preparing the seed bed. All fertilizer was applied at planting, and most growers applied it using a drop spreader in a swath that was at least 9.1 m wide and then lightly tilled it into the soil before planting onion seeds.

2.4. Insecticide Programs and Applications

The action threshold-based insecticide program followed a threshold of 1 thrips per leaf [16]. The entire field that contained the experiment was scouted on a weekly basis by Cornell Cooperative Extension (CCE) staff to assess T. tabaci population densities. Approximately 50 plants were inspected for thrips following an x-type sampling pattern that covered the entire field. If the mean thrips density for the entire field met or exceeded the action threshold, the grower would apply an insecticide to the entire field, including our study area (Figure 1). Growers co-applied insecticides with adjuvants to improve efficacy [32]. Spray volume ranged from 281 to 374 L ha−1, and pressure ranged from 276 to 345 kPa. If the action threshold was not exceeded that week, the grower would not make an insecticide application to that field. In such instances, we applied insecticides to plots designated as receiving the weekly insecticide program. These applications were made using a CO2-pressurized backpack sprayer with four twin flat-fan nozzles (TJ-60-8003VS; TeeJet Technologies, Harrisburg, PA, USA) calibrated to deliver 337 L ha−1 at 276 kPa. Insecticides also were co-applied with methylated seed oils in combination with specialized organosilicone-based nonionic surfactants (Dyne-Amic; Helena, Collierville, TN, USA) at a rate of 0.25% v:v to increase efficacy [32]. Therefore, applications of insecticide to plots designated to receive insecticide applications following the action threshold-based program were made only by the grower, whereas applications to those designated to receive insecticides based on a weekly application program were made by both the grower and by us. Both insecticide programs began in late June to early July, when each grower made the first insecticide application targeting T. tabaci, and then finished in August, when the crop reached maturity (Table S4). Insecticide products selected during the season generally followed a logical sequence designed to maximize management of thrips over the course of the season and to delay the development of insecticide resistance by generally avoiding application of any active ingredient more than twice consecutively [33].

2.5. Soil Nutrient Assessments

Soil nutrient content in the three fertilizer treatments was assessed in early May shortly after planting and prior to crop uptake and again in late June or early July to capture levels after most vegetative growth had been completed; an exception occurred in 2019 when sampling was done only in July. Within each fertilizer treatment, two of the four plots were randomly chosen such that eight 30 cm soil cores were collected and homogenized from each plot (n = 2 for each fertilizer treatment per field). Within 24 h of collection, soil samples were delivered to Dairy One (Lansing, NY, USA) for a modified Morgan analysis for phosphorus and potassium and a PSNT analysis for nitrate.

Within each field and sampling period, soil nutrient samples from each fertilizer treatment were averaged before analysis. In each field, the average amount of nitrogen, phosphorus, and potassium detected from the full and half rate fertilizer treatments were divided by the amounts of each nutrient in the zero fertilizer treatment and multiplied by 100 to determine the percent difference between half and zero and between full and zero rate fertilizer treatments. In 2019, none of the nutrients in the full rate and half rate differed from those in the zero fertilizer treatment, but some were numerically greater (Table S5; Figure S1A). In contrast, at both sampling dates in 2020 and 2021, average levels of nitrogen (N) and potassium (K) in treatments that received a half and full rate of fertilizer were significantly greater than those that received no fertilizer (Table S5; Figure S1B–E). On sampling dates in 2020 and 2021, the average levels of phosphorus (P) never differed significantly between soil that received fertilizer and soil that did not (Table S5; Figure S1B–E). Precipitation in May 2019 was two to three times greater than precipitation in either May 2020 or May 2021 (Table S6), which could have influenced the availability of nutrients in the soil at the time of sampling. Overall, soil nutrient analysis results verified that fertilizer was applied to designated areas of the field required to receive fertilizer, but the results lacked the ability to distinguish between those receiving half and full rates. Perhaps the characteristics of the muck soil combined with environmental factors also played a role in the difficulty in distinguishing between the two rates.

2.6. Thrips Density Assessments

Because Thrips tabaci is the only pestiferous thrips species that causes damage to onions in New York, all sampling and subsequent management decisions focused on this species. Within each plot each week, thrips adults and larvae were counted from 25 plants (experimental unit). Thus, thrips were counted from a total of 50 plants (two experimental units) in each fertilizer × insecticide program treatment for a total of 300 plants per field (50 plants × 3 fertilizer × 2 insecticide program treatments). Additionally, the number of leaves from five plants per plot was recorded weekly until the week after the last insecticide application of the season. Voucher thrips specimens are kept in the Department of Entomology, Cornell AgriTech, Geneva, NY, USA.

2.7. Bulb Size, Yield, and Bulb Rot Assessments

After onions reached maturity, 100 plants were pulled from each plot and transported to Cornell AgriTech where they were placed in a ventilated building and permitted to air dry until the onion foliage had completely dried (3–4 weeks after pulling). Dried foliage was removed, and the bulbs were graded by diameter, assigned a size class of ‘boiler’ (2.5–4.8 cm), ‘standard’ (4.9–7.6 cm), or ‘jumbo’ (≥7.7 cm), and then weighed. Bulbs that were either ‘standard’ or ‘jumbo’ were considered marketable, and ‘boiler’ bulbs were considered unmarketable in our study [34]. Within each marketable size class (standard and jumbo), a subset of bulbs was examined for bacterial rot symptoms. If a size class had at least 20 bulbs, all 20 were evaluated. If a marketable size class had fewer than 20 bulbs, all bulbs from that size class were evaluated. Bulbs from the unmarketable size class (boiler) were not examined for rot. To evaluate bacterial rot presence or absence, bulbs were cut longitudinally and inspected for symptoms of discoloration and decay [20]. Marketable yields were extrapolated to a mean metric ton per hectare basis after multiplying the mean bulb weight in each size class by the average number of onion plants in each plot. Adjusted marketable yields were calculated for each plot by subtracting the percent of bulbs with bacterial rot from the estimated marketable yield.

2.8. Statistical Analyses

All data were analyzed using linear mixed models in R Version 3.5.1 (R Core Team 2018; ‘nlme’) [35]. Data from each year were analyzed separately because environmental conditions and thrips populations differed considerably each year. All dependent variables were analyzed with fertilizer treatment, insecticide program, and their interaction as fixed effects, while the field (or block) was considered random in the model.

In each field on each sample date, the mean number of thrips per leaf was calculated by averaging the densities between the two sampling units within each plot. Next, the season’s average number of thrips per leaf was calculated by dividing the sum of the mean number of thrips per leaf on each date by the total number of sampling dates. Data were the square root or cube root transformed as needed to fit the assumptions of a normal distribution, but untransformed means are illustrated.

Adjusted marketable bulb yields and the percent of bulbs with bacterial rot symptoms also were averaged between both plots within each fertilizer treatment in each field. Soil nutrient differences, thrips densities, onion yield, and percentage of bulbs with bacterial rot were analyzed using linear mixed models (function lme) in the nlme package [35]. For thrips densities, onion yield, and percentage of bulbs with bacterial rot, linear mixed models were fitted with the fertilizer rate, insecticide program, and their interaction as fixed effects and plots nested within the field as random effects. Post hoc, pairwise tests of means between each treatment were compared using Tukey’s honest significant difference test at p < 0.05. The varComp function in the ape package was used to partition the variance explained by field in each model.

3. Results

3.1. Thrips Densities

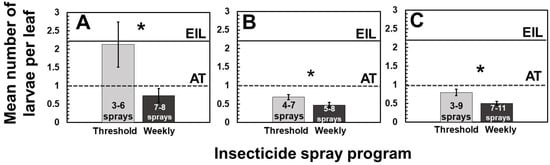

In all three years, seasonal average densities of T. tabaci larvae were affected significantly by the insecticide program but not by the fertilizer rate or by an interaction between the fertilizer rate and insecticide program (Table 1). Although the thrips densities in onions treated with insecticides following an action threshold program were significantly greater than those following a weekly insecticide program each year (mean for action threshold program across all three years = 1.2 larvae per leaf; mean for weekly program across all three years = 0.6 larva per leaf), the average thrips densities over the season in the threshold treatment remained below the economic injury level of 2.2 larvae per leaf (Figure 2) [7].

Table 1.

Summary ANOVA table for main treatment effects and their effects on Thrips tabaci larval densities, marketable onion bulb yield, and bacterial bulb rot incidence in onion fields in New York (USA) from 2019 through 2021.

Figure 2.

Mean (±SEM) number of T. tabaci larvae per leaf over the duration of our sampling in onions treated with insecticides following either an action threshold program or weekly application program in 2019 (A), 2020 (B), and 2021 (C) in New York (USA). Because thrips densities were not significantly affected by fertilizer rate or an interaction between fertilizer rate and insecticide program, data were pooled across all three fertilizer treatments. Asterisks indicate significant differences between spray programs (Tukey’s HSD, p < 0.05). The range in number of sprays applied in each program in each year are denoted within each bar. The economic injury level (EIL) of 2.2 thrips larvae per leaf is denoted by a solid line, and the action threshold (AT) of 1 thrips larva per leaf is denoted by a dotted line.

3.2. Insecticide Application Frequency

Onions treated following the action threshold-based insecticide program received an average (± SEM) of 4.5 ± 0.6, 5.8 ± 0.4, and 6.4 ± 0.8 applications in 2019, 2020, and 2021, respectively, while those that received weekly insecticide applications averaged 7.5 ± 0.3, 7.4 ± 0.4, and 9.1 ± 0.7 applications in 2019, 2020, and 2021, respectively (Figure 2; Table S4).

In our three-year study, significantly fewer insecticide applications were made following the action-threshold based program (5.8 ± 0.4) than were made following the weekly program (8.1 ± 0.4) (F = 22.2; df = 1,36; p < 0.0001). The greatest reduction occurred in one field in 2019 where five fewer sprays were made (three versus eight) following the action threshold program.

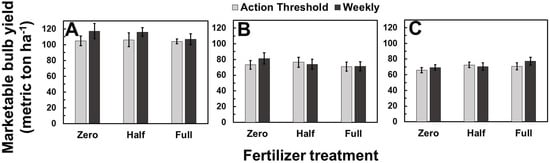

3.3. Marketable Bulb Yield

Marketable bulb yield in 2019 tended to be numerically greater than yield in either 2020 or 2021. Onion bulb yields were not significantly affected by the fertilizer rate, insecticide program, or their interaction in any of the three years (Table 1; Figure 3).

Figure 3.

Mean (±SEM) marketable onion bulb yield for each fertilizer rate and insecticide program combination in 2019 (A), 2020 (B), and 2021 (C). There were no significant differences among treatments within each year (Tukey’s HSD, p > 0.05).

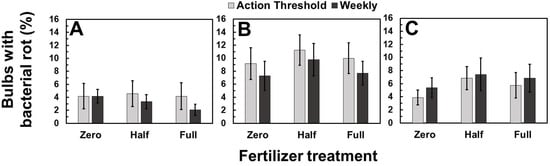

3.4. Bacterial Bulb Rot

Bacterial bulb rot tended to be numerically greater in 2020, followed by 2021, and then 2019. The average incidence of bulb rot was not significantly affected by the fertilizer rate, insecticide program, or their interaction in any of the three years (Table 1; Figure 4).

Figure 4.

Mean (±SEM) percent bulbs with symptoms of bacterial bulb rot in each fertilizer rate and insecticide program combination in 2019 (A), 2020 (B), and 2021 (C). There were no significant differences among treatments within each year (Tukey’s HSD, p > 0.05).

4. Discussion

4.1. Thrips Densities

Reducing synthetic fertilizer (N–P–K) levels at planting did not reduce T. tabaci densities in onion fields in our study. The results were similar to those reported by Leach et al. [9,24], who evaluated the impact of reducing individual nutrient levels (N and P) on T. tabaci populations on onions grown in muck soils in New York. For example, T. tabaci densities in onions that received 67 kg ha−1 nitrogen fertilizer did not differ from those that received 140 kg ha−1 [9]. A second study evaluated five rates of nitrogen fertilizer, ranging from 0 kg ha−1 to 151 kg ha−1, and the T. tabaci densities were similar between the lowest and highest rates [24]. Thrips tabaci densities also were similar among four rates of phosphorus fertilizer ranging from 0 kg ha−1 to 168 kg ha−1 [24]. Thus, our results reducing all nutrients (N-P-K) simultaneously were consistent with those shown by Leach et al. [9,24], who only reduced individual nutrients (N or P) applied to muck soil.

Educational efforts have helped increase awareness and adoption of action thresholds for making insecticide applications to manage T. tabaci infestations in onions [19], but more research is needed to convince those who still opt for the conservative, weekly insecticide program. In our multi-year study across multiple farms, T. tabaci densities in onions treated following an action threshold-based program were twice as high as those in onions treated weekly; however, season mean thrips densities in both insecticide programs remained below the economic injury level of 2.2 thrips per leaf [7]. Additionally, an average of 2.3 fewer insecticide applications, or 28%, were made following the action threshold program compared with the weekly spray program. Nault and Huseth [12] also reported a similar level of T. tabaci control in onions when there was a 40% reduction in insecticide applications per season when following an action threshold of one thrips per leaf compared with a weekly spray program. Leach et al. [9] showed that an action threshold-based insecticide program and a weekly spray program both reduced T. tabaci larval densities by 60–81% relative to those in the untreated control, but 2.8 fewer applications were needed following the action threshold program. These findings indicate that an action threshold of one thrips per leaf continues to work effectively to manage T. tabaci infestations while enabling growers to apply insecticides less frequently [9,12,19]. Our results also suggest the potential for considerable savings in insecticide costs by making fewer applications following action thresholds.

4.2. Bulb Rot Incidence

Neither reduced rates of synthetic fertilizer (N–P–K) nor an action threshold-based insecticide program impacted the incidence of bulb rot in our study. Previous work in both mineral and muck soils has demonstrated decreased bulb rot incidence as nitrogen decreased [29,30,36]. However, that relationship has not been observed consistently among years when either nitrogen alone or phosphorus alone has been reduced in muck soils in New York [24]. Thrips tabaci can play a role in the transmission of Pantoea spp., which is one group of bacteria contributing to bulb rot symptoms [10]. However, Pantoea spp. are much less common than other species of bacteria found in New York onion fields, and previous studies have not identified a clear relationship between T. tabaci densities and bulb rot incidence [24]. Overall, there does not appear to be any negatives to reducing synthetic fertilizer levels when it comes to bacterial rot incidence, even if benefits are inconsistent.

4.3. Bulb Yield

Our ability to detect the differences in soil nutrient levels was inconsistent between years and among nutrients. The rich organic matter content of muck soil helps retain nutrients and lessen the amount of fertilizer needed to support crop growth [3,37]. Previous work in New York’s muck fields has failed to detect differences in onion yield when low rates of either nitrogen alone or phosphorus alone were applied in comparison to higher rates [9,24]. However, our results are the first to demonstrate that onion bulb yield in fields receiving standard levels of synthetic fertilizer (N–P–K) can be equivalent to those receiving no fertilizer at all. These results were impressive given their consistency across seven cultivars, 20 fields, five farms, two production regions, and three years. The implications of these results are that onion growers can substantially reduce existing levels of fertilizer and not compromise bulb quality and yield.

5. Conclusions

The amount of synthetic fertilizer applied to onions at planting had no impact on T. tabaci population levels, bulb rot incidence, or bulb size and yield during this three-year study. Reducing fertilizer quantities does not appear to be a viable management tool for either T. tabaci or bulb rot, but we discovered that fertilizer quantities can be reduced substantially without a reduction in marketable bulb yield. Insecticide use had the greatest impact on reducing T. tabaci densities. Both the action threshold-based program and weekly spray program reduced T. tabaci infestation levels below the economic injury level, but the action threshold program averaged 2.3 fewer applications than the weekly program. The insecticide program had no effect on bulb rot incidence, bulb size, or yield. Although our study was much more comprehensive (i.e., multiple production regions, farms, fields, and cultivars) than previous studies examining similar impacts of reducing synthetic chemicals on T. tabaci populations, bulb rot, and bulb yield in New York onion fields, our results were similar. The implications of these findings indicate that growers who produce onions on muck soils can reduce synthetic chemical inputs without compromising bulb yields, and this should lead to greater profits and a reduction of chemicals in the environment.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/agronomy12061292/s1. Table S1: Locations, cultivars, planting, and harvest dates for all onion fields sampled in New York (USA) in 2019, 2020, and 2021; Table S2: Amount of synthetic N–P–K fertilizer (kg ha−1) applied in each onion field each year, as well as the rates recommended by the 2019 Cornell Integrated Crop and Pest Management Guidelines for Commercial Vegetable Production for growing dry bulb onions on muck soils in New York (USA); Table S3: Example composition of typical fertilizer mix that onion growers order custom-blended based on soil test results; Table S4: Insecticides and rates applied in all onion fields in this study, including those made following an action threshold-based spray program and the additional sprays made in the weekly spray program in New York (USA) in 2019, 2020, and 2021; Table S5: Summary ANOVA table of soil nutrient levels in the portions of all onion fields that received half and full rate applications of N–P–K fertilizer compared with zero fertilizer applied in New York (USA) in 2019, 2020, and 2021; Table S6: Mean temperature and mean total precipitation in the two general regions where our study was conducted in New York (USA) in 2019, 2020, and 2021; Figure S1: Nutrient levels from muck soil sampled in onion fields in July 2019 (A), May 2020 (B), July 2020 (C), May 2021 (D), and June 2021 (E) in New York (USA). Results are illustrated as the percent difference in nutrients from sample transects where no fertilizer was applied to those receiving either a half or full rate of N–P–K fertilizer applied. Error bars represent standard error, and NS indicates no significant differences within each nutrient between either half or full rates applied and zero fertilizer applied (Tukey’s HSD, p < 0.05). No differences were detected between half and full rates of fertilizer for any nutrient in this study (2019–2021).

Author Contributions

Conceptualization of the study, K.H.R. and B.A.N.; performing the field research, K.H.R. and B.A.N.; data analyses, K.H.R.; writing—original draft preparation, K.H.R.; writing—review and editing, K.H.R. and B.A.N.; funding acquisition, B.A.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Institute of Food and Agriculture, U.S. Department of Agriculture’s Specialty Crop Research Initiative (# 2018-51181-28435) titled, “Development and delivery of integrated management packages for the most serious pest and diseases threatening U.S. allium industries”.

Data Availability Statement

Data are provided only in Supplementary Materials.

Acknowledgments

We thank Big O Onion Farms, Triple G Farms, G. Mortellaro and Sons, Johnson Potato Farms, and Abe Datthyn Farms for allowing us to conduct research trials in their onion fields, for conducting all necessary field setup and maintenance, and for applying fertilizer and insecticide treatments during the trials. We also thank Dugan Doeblin, Erin Equinozzi, Matthew Garlick, Riley Harding, Nathan Hesler, Lindsy Iglesias, Megan Kelley, Lidia Komondy, Pin-Chu Lai, Erica Moretti, Ramandeep Sandhi, Leonardo Salgado, and Lily Sellers for assisting with data collection. We are very appreciative of Christy Hoepting and John Gibbons (Cornell Cooperative Extension), who scouted onion fields for thrips and provided results to cooperating growers so they could make insecticide-control decisions based on action thresholds. Finally, we thank Erika Mudrak (Department of Statistics, Cornell University) for consultation on statistical analysis.

Conflicts of Interest

The authors declare no conflict of interest.

References

- USDA National Agricultural Statistics Service (NASS). Statistics by Subject: National Statistics for Onion. Available online: https://www.nass.usda.gov/Statistics_by_Subject/result.php?F68BE147-6498-37BC-A9A5-9D7EFB926592§or=CROPS&group=VEGETABLES&comm=ONIONS (accessed on 2 April 2022).

- Wilson, B.D.; Townsend, G.R. Some nitrogen relationships in muck soils. Cornell Univ. Agric. Exp. Stn. Bull. 1931, 137, 3–5. [Google Scholar]

- Haynes, R. Mineral Nitrogen in the Plant-Soil System, 1st ed.; Elsevier Science: Burlington, MA, USA, 2012; pp. 166–241. [Google Scholar] [CrossRef]

- Alyokhin, A.; Nault, B.; Brown, B. Soil conservation practices for insect pest management in highly disturbed agroecosystems—A review. Entomol. Exper. Appl. 2019, 168, 7–27. [Google Scholar] [CrossRef]

- Diaz-Montano, J.; Fuchs, M.; Nault, B.A.; Shelton, A.M. Evaluation of onion cultivars for resistance to onion thrips (Thysanoptera: Thripidae) and Iris yellow spot virus. J. Econ. Entomol. 2010, 103, 925–937. [Google Scholar] [CrossRef] [PubMed]

- Gill, H.K.; Garg, H.; Gill, A.K.; Gillett-Kaufman, J.L.; Nault, B.A. Onion thrips (Thysanoptera: Thripidae) biology, ecology, and management in onion production systems. J. Integr. Pest Manag. 2015, 6, 1–9. [Google Scholar] [CrossRef]

- Fournier, F.; Boivin, G.; Stewart, R. Effect of Thrips tabaci Thysanoptera: Thripidae on yellow onion yields and economic thresholds for its management. J. Econ. Entomol. 1995, 88, 1401–1407. [Google Scholar] [CrossRef]

- Rueda, A.; Badenes-Perez, F.R.; Shelton, A.M. Developing economic thresholds for onion thrips in Honduras. Crop Prot. 2007, 26, 1099–1107. [Google Scholar] [CrossRef]

- Leach, A.; Reiners, S.; Fuchs, M.; Nault, B.A. Evaluating integrated pest management tactics for onion thrips and pathogens they transmit to onion. Agric. Ecosyst. Environ. 2017, 250, 89–101. [Google Scholar] [CrossRef]

- Dutta, B.; Barman, A.K.; Srinivasan, R.; Avci, U.; Ullman, D.E.; Langston, D.B.; Gitaitis, R.D. Transmission of Pantoea ananatis and P. agglomerans, causal agents of center rot of onion (Allium cepa), by onion thrips (Thrips tabaci) through feces. Phytopathology 2014, 104, 812–819. [Google Scholar] [CrossRef]

- Leach, A.B.; Hay, F.; Harding, R.S.; Damann, K.C.; Nault, B.A. Relationship between onion thrips (Thrips tabaci) and Stemphylium versicarium in the development of Stemphylium leaf blight in onion. Ann. Appl. Biol. 2020, 176, 55–64. [Google Scholar] [CrossRef]

- Nault, B.A.; Huseth, A.S. Evaluating an action-threshold based insecticide program on onion cultivars varying in resistance to onion thrips Thysanoptera: Thripidae. J. Econ. Entomol. 2016, 1094, 1772–1778. [Google Scholar] [CrossRef]

- Shelton, A.M.; Nault, B.A.; Plate, J.; Zhao, J.Z. Regional and temporal variation in susceptibility to lambda-cyhalothrin in onion thrips, Thrips tabaci Thysanoptera: Thripidae, in onion fields in New York. J. Econ. Entomol. 2003, 96, 1843–1848. [Google Scholar] [CrossRef] [PubMed]

- Shelton, A.M.; Zhao, J.Z.; Nault, B.A.; Plate, J.; Musser, F.R.; Larentzaki, E. Patterns of insecticide resistance in onion thrips (Thysanoptera: Thripidae) in onion fields in New York. J. Econ. Entomol. 2006, 99, 1798–1804. [Google Scholar] [CrossRef] [PubMed]

- Allen, J.K.M.; Scott-Dupree, C.D.; Tolman, J.H.; Harris, C.R. Resistance of Thrips tabaci to pyrethroid and organophosphate insecticides in Ontario, Canada. Pest Manag. Sci. 2005, 61, 809–815. [Google Scholar] [CrossRef]

- Nault, B.A.; Shelton, A.M. Impact of insecticide efficacy on developing action thresholds for pest management: A case study of onion thrips (Thysanoptera: Thripidae) on onion. J. Econ. Entomol. 2010, 103, 1315–1326. [Google Scholar] [CrossRef] [PubMed]

- Nault, B.A.; Shelton, A.M. Battling onion thrips using insecticides. Cornell Cooperative Extension, Cornell Vegetable Program. VegEdge 2010, 6, 15–17. [Google Scholar]

- Werling, B.; Szendrei, Z. Recipe for a Cost-Effective Onion Thrips Control Program. Michigan State University Extension. Available online: http://vegetable.ent.msu.edu/wp-content/uploads/2015_Onion-thrips-control-factsheet-3-1.pdf (accessed on 2 April 2022).

- Leach, A.B.; Hoepting, C.A.; Nault, B.A. Grower adoption of insecticide resistance management practices increase with extension-based program. Pest Manag. Sci. 2019, 75, 515–526. [Google Scholar] [CrossRef]

- Schwartz, H.F.; Mohan, S.K. Compendium of Onion and Garlic Diseases and Pests, 2nd ed.; American Phytopathological Society: St. Paul, MN, USA, 2008; pp. 55–69. [Google Scholar]

- Beer, S.; Zaid, A.; Bonasera, J. Studies of bacterial problems of onion in New York. In Proceedings of the 2010 Empire Sate Fruit and Vegetable Expo, Syracuse, NY, USA, 27 January 2010. [Google Scholar]

- Zaid, A.M.; Bonasera, J.M.; Beer, S.V. First report of Enterobacter bulb decay of onions caused by Enterobacter cloacae in New York. Plant Dis. 2011. [Google Scholar] [CrossRef] [PubMed]

- Bonasera, J.M.; Asselin, J.E.; Beer, S.V. Lactic acid bacteria cause a leaf blight and bulb decay of onion (Allium cepa). Plant Dis. 2017, 101, 29–33. [Google Scholar] [CrossRef]

- Leach, A.; Reiners, S.; Nault, B. Challenges in integrated pest management: A case study of onion thrips and bacterial bulb rot in onion. Crop Prot. 2020, 133, 105123. [Google Scholar] [CrossRef]

- Pfeufer, E.E.; Gugino, B.K. Environmental and management factors associated with bacterial diseases of onion in Pennsylvania. Plant Dis. 2018, 102, 2205–2211. [Google Scholar] [CrossRef]

- Asselin, J.E.; Eikemo, H.; Perminow, J.; Nordskog, B.; Brurberg, M.B.; Beer, S.V. Rahnella spp. are commonly isolated from onion (Allium cepa) bulbs and are weakly pathogenic. J. Appl. Microbiol. 2019, 127, 812–824. [Google Scholar] [CrossRef] [PubMed]

- Buckland, K.; Reeve, J.R.; Alston, D.; Nischwitz, C.; Drost, D. Effects of nitrogen fertility and crop rotation on onion growth and yield, thrips densities, Iris yellow spot virus and soil properties. Agric. Ecosys. Environ. 2013, 177, 63–74. [Google Scholar] [CrossRef]

- Malik, M.F.; Nawaz, M.; Ellington, J.; Sanderson, R.; El-Heneidy, A.H. Effect of different nitrogen regimes on onion thrips, Thrips tabaci Lindeman, on onions, Allium cepa L. Southwest. Entomol. 2009, 34, 219–225. [Google Scholar] [CrossRef]

- Wright, P.J. Effects of nitrogen fertilizer, plant maturity at lifting, and water during field-curing on the incidence of bacterial soft rot of onions in store. N. Z. J. Crop Hortic. Sci. 1993, 21, 377–381. [Google Scholar] [CrossRef]

- Diaz-Perez, J.C.; Purvis, A.C.; Paulk, J.T. Bolting, yield, and bulb decay of sweet onion as affected by nitrogen fertilization. J. Am. Soc. Hortic. Sci. 2003, 128, 144–149. [Google Scholar] [CrossRef]

- Natural Resources Conservation Service (NRCS) Soil Survey Staff, Natural Resources Conservation Service, United States Department of Agriculture. Web Soil Survey. Available online: https://websoilsurvey.sc.egov.usda.gov/ (accessed on 2 April 2022).

- Nault, B.A.; Hsu, C.; Hoepting, C. Consequences of co-applying insecticides and fungicides for managing Thrips tabaci (Thysanoptera: Thripidae) on onion. Pest Manag. Sci. 2013, 69, 841–849. [Google Scholar] [CrossRef]

- Hoepting, C.; Nault, B. Cornell guidelines for onion thrips management in onion. Cornell Cooperative Extension, Cornell Vegetable Program. VegEdge 2019, 15, 8–9. [Google Scholar]

- USDA United States Standards for Grades of Onions (Other Than Bermuda Granex-Grano and Creole Type). Available online: https://www.ams.usda.gov/grades-standards/onions-other-bermuda-granex-grano-and-creole-type-grades-and-standards (accessed on 2 April 2022).

- Pinheiro, J.; Bates, D.; DebRoy, S.; Sarkar, D.; Heisterkamp, S.; Van Willigen, B.; Ranke, J. nlme: Linear and Nonlinear Mixed Effects Models. R Package. Version 3.1-111. Available online: https://cran.r-project.org/web/packages/nlme/index.html (accessed on 18 February 2022).

- Batal, K.M.; Bondari, K.; Granberry, D.M.; Mullinix, B.G. Effects of source, rate, and frequency of N application on yield, marketable grades and rot incidence of sweet onion (Allium cepa L. cv. Granex-33). J. Hortic. Sci. 1994, 69, 1043–1051. [Google Scholar] [CrossRef]

- Gonzalez, M.Q.; Pellerin, A.; Parent, L.E. Onion response to added N in histosols of contrasting C and N contents. Am. J. Plant Sci. 2016, 7, 469–478. [Google Scholar] [CrossRef][Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).