Design and Verification of the Variable Capacity Roller-Wheel Precision Rice Direct Seed-Metering Device

Abstract

:1. Introduction

2. Materials and Methods

2.1. Configuration and Working Principle

2.1.1. Configuration of Seed-Metering Device

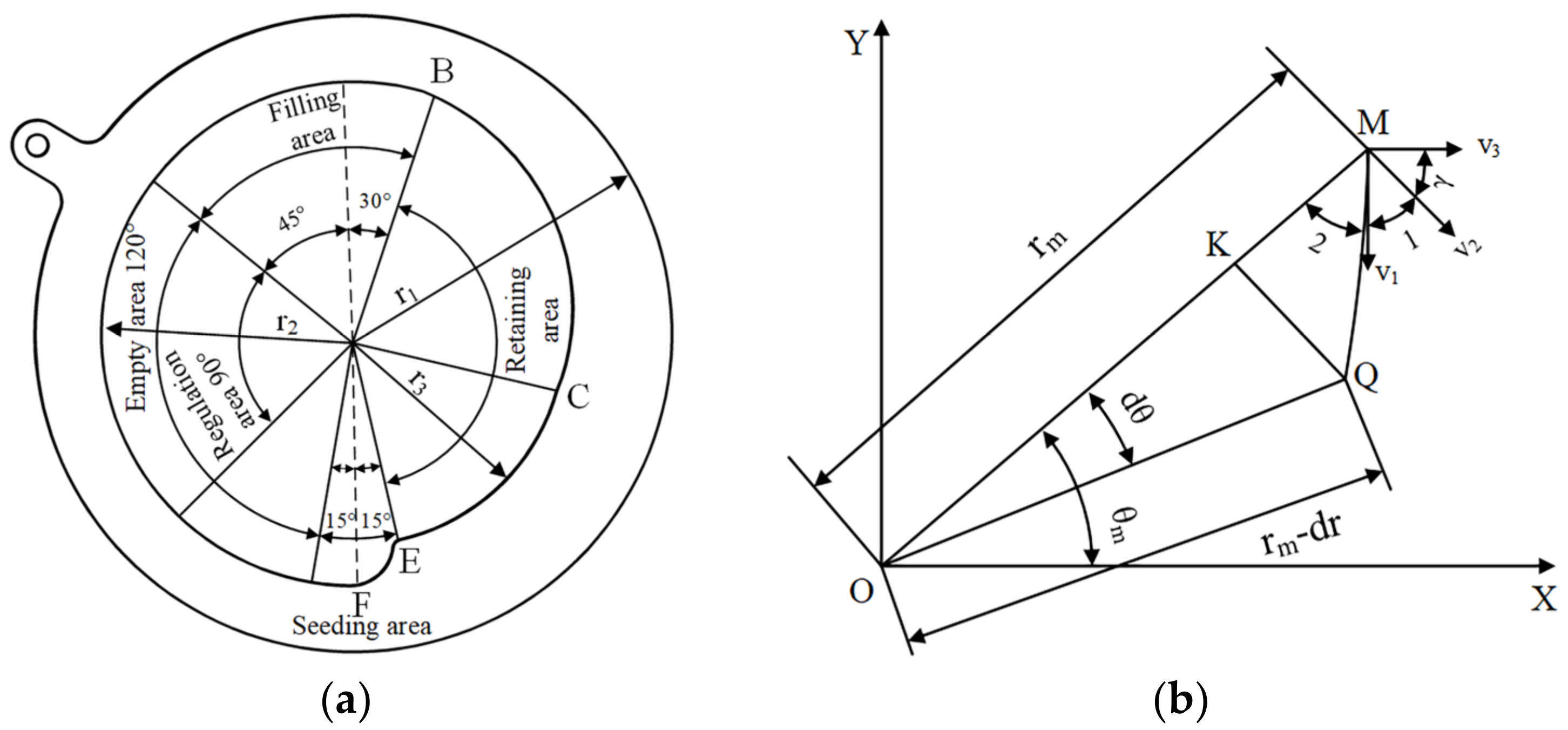

2.1.2. Working Principle of the Seed-Metering Device

2.2. Design of Crucial Components

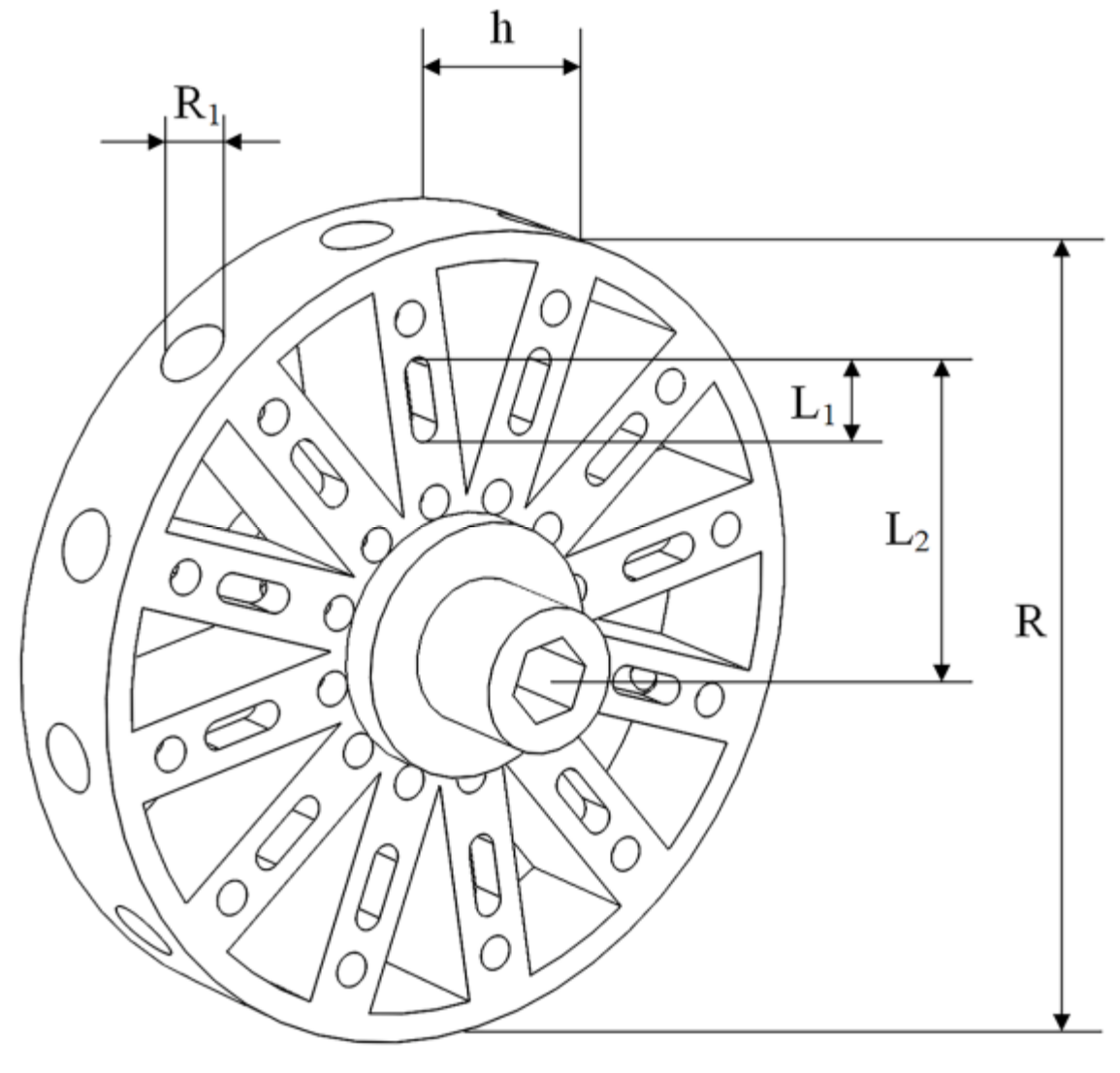

2.2.1. Structural Design of the Seeding Wheel

- Design of the Diameter and Thickness of the Seeding Wheel

- Design of the Hole Number

- Design of Diameter of Hole and Adjustment Depth

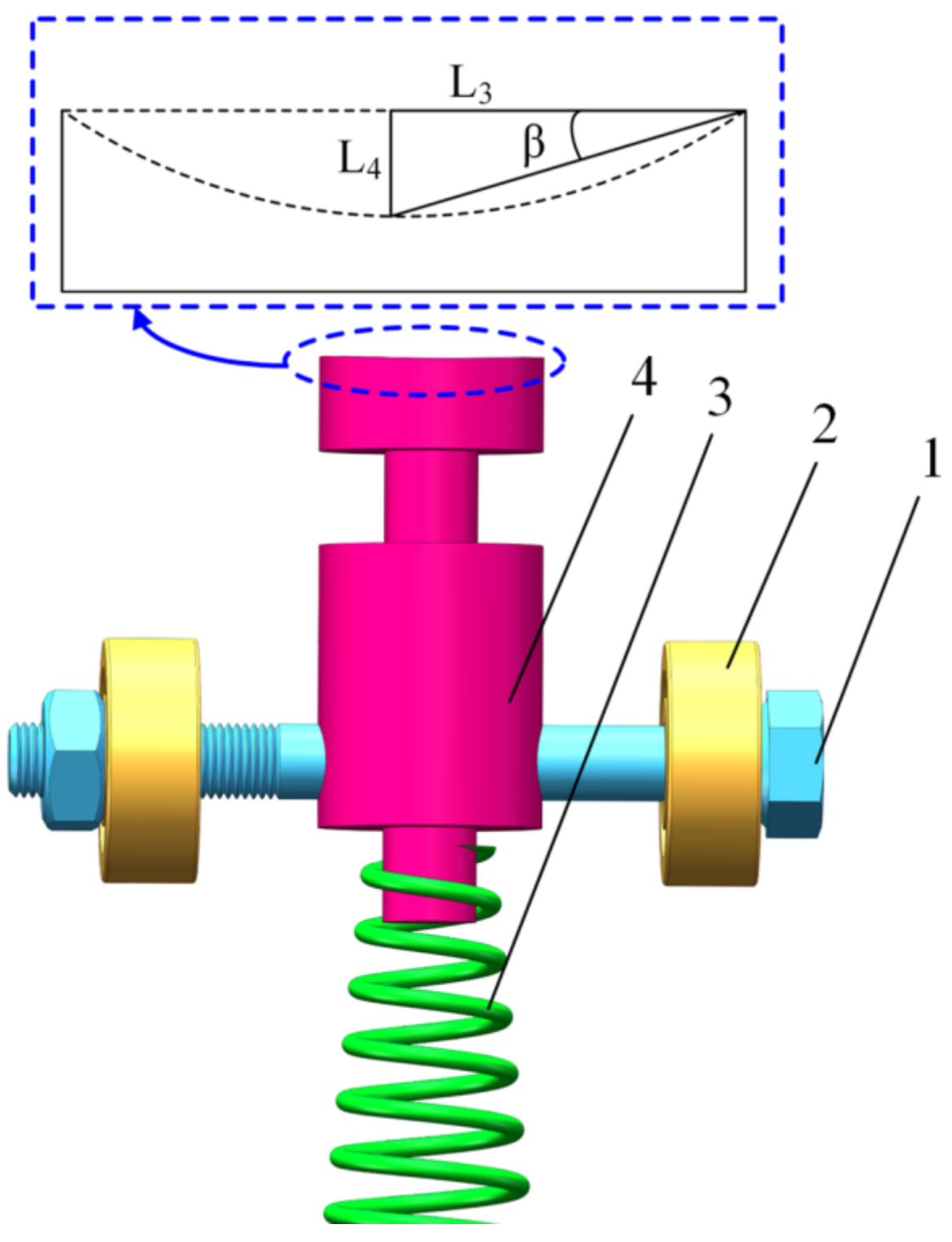

2.2.2. Design of Forced Seeding Mechanism

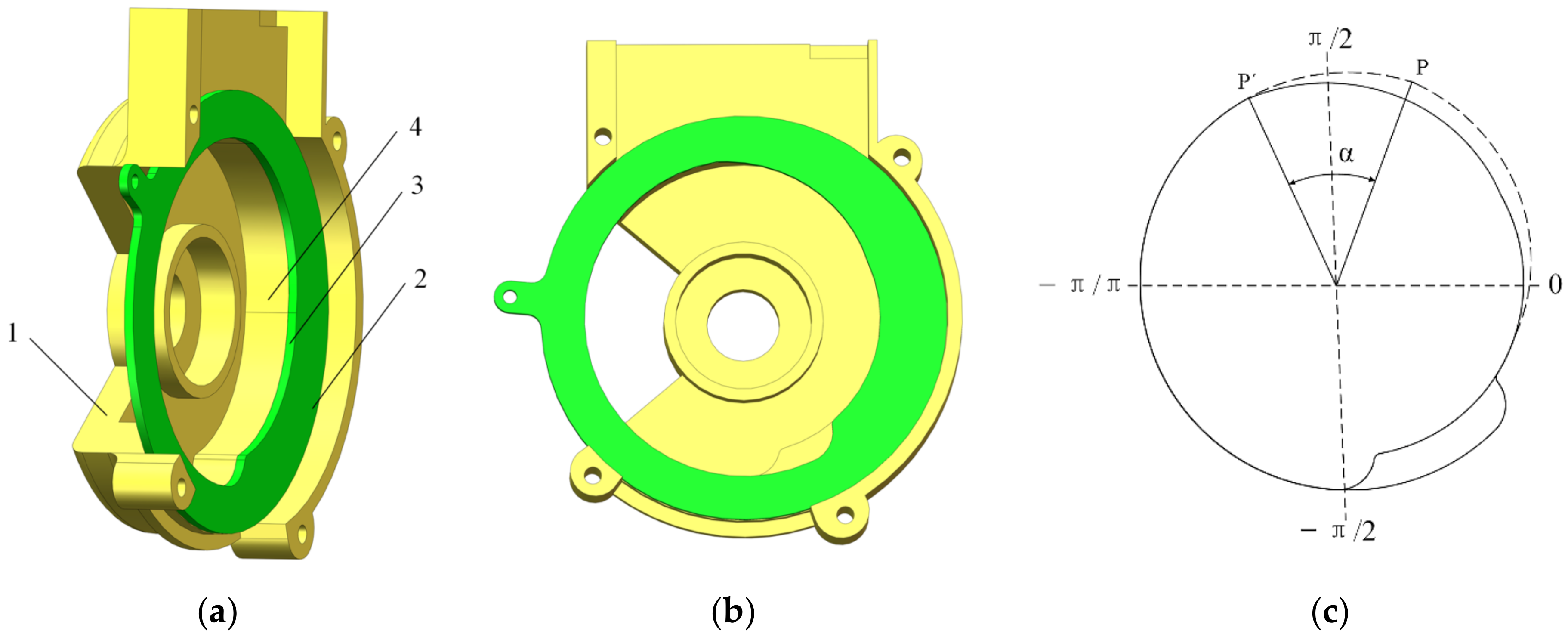

2.2.3. Design of the Seeding Rate Adjusting Mechanism

2.3. Experimental Materials

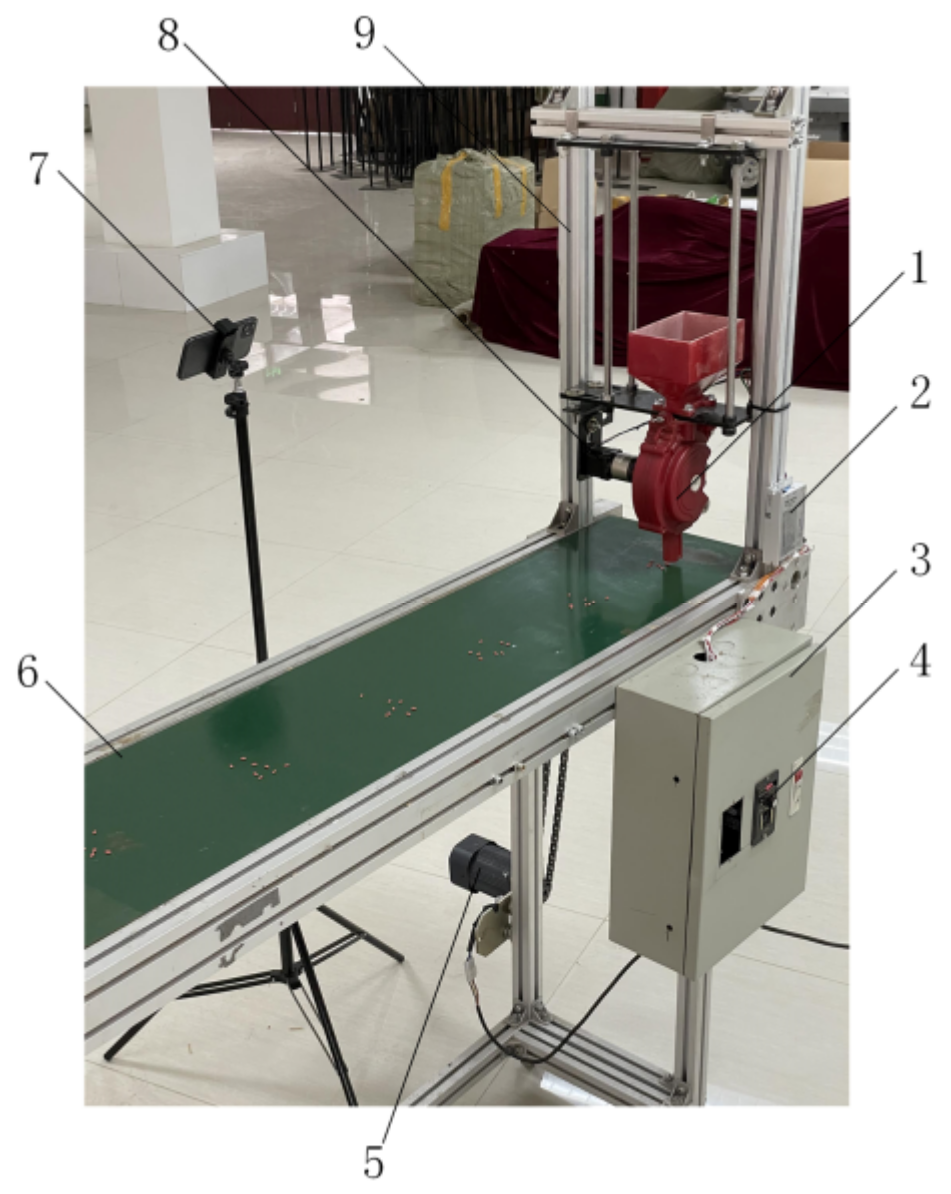

2.4. Experimental Equipment

2.5. Experimental Design

2.6. Evaluation Indicators

3. Results and Analysis

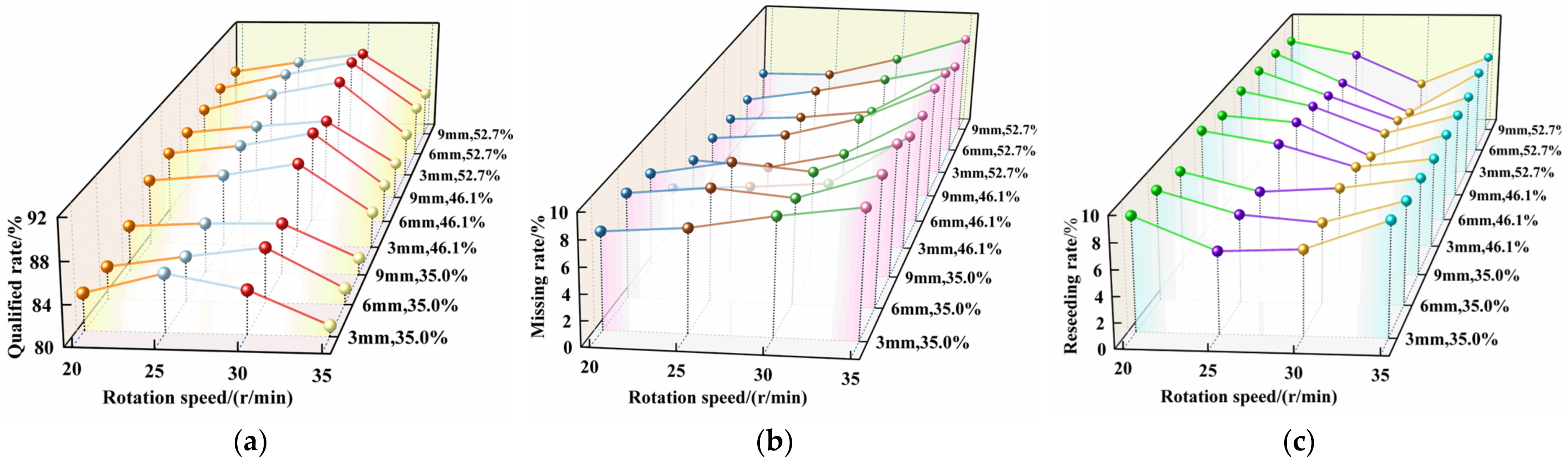

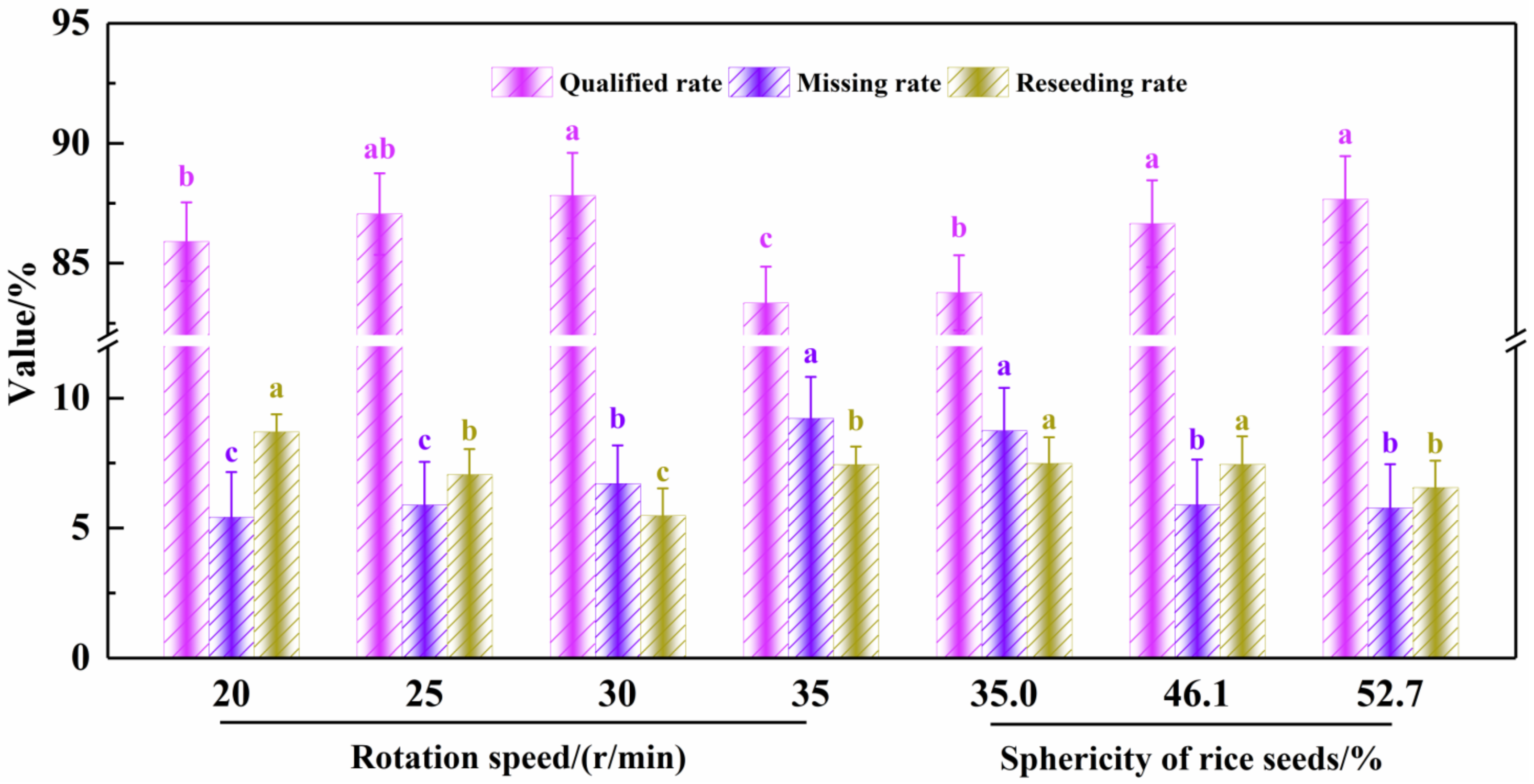

3.1. Seeding Accuracy Experiment

3.2. Seeding Performance Experiment

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liquan, T.; Yongsen, X.; Zhao, D.; Zhan, S. Design and Performance Test of Direct Seed Metering Device for Rice Hill. INMATEH Agric. Eng. 2021, 64, 257–268. [Google Scholar] [CrossRef]

- Hu, Z.; Huang, X.; Wang, X.; Xia, H.; Liu, X.; Sun, Y.; Sun, S.; Hu, Y.; Cao, Y. Overexpression of OsPHT1;4 Increases Phosphorus Utilization Efficiency and Improves the Agronomic Traits of Rice cv. Wuyunjing 7. Agronomy 2022, 12, 1332. [Google Scholar] [CrossRef]

- Zhang, K.; Khan, Z.; Liu, J.; Luo, T.; Zhu, K.; Hu, L.; Bi, J.; Luo, L. Germination and Growth Performance of Water-Saving and Drought-Resistant Rice Enhanced by Seed Treatment with Wood Vinegar and Biochar under Dry Direct-Seeded System. Agronomy 2022, 12, 1223. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, Y.; Wang, B.; Zhang, M.; Ma, Y.; Ke, X.; Luo, X. Design and experiment of rice precision metering device with sowing amountstepless adjusting. Trans. CSAE 2018, 34, 9–16. [Google Scholar]

- Zhang, H.; Yu, C.; Chen, K.; Kong, X.; Liu, H.; Chen, J.; Gu, J.; Liu, L.; Wang, Z.; Yang, J. Effect of direct-seeding methods on physiological characteristics and grain yield of rice and its cost analysis. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2017, 33, 58–64. [Google Scholar]

- Luo, X.; Wang, Z.; Zeng, S.; Zang, Y.; Yang, W.; Zhang, M. Recent advances in mechanized direct seeding technology for rice. J. South China Agric. Univ. 2019, 40, 1–13. [Google Scholar]

- Tang, H.; Jiang, Y.; Xu, C.; Zhou, W.; Wang, Q.; Wang, Y. Experimental study on the correlation between hill direct seeding rate and field seedling rate of typical rice varieties in cold areas. Int. J. Agric. Biol. Eng. 2021, 14, 63–71. [Google Scholar] [CrossRef]

- Xi, X.; Gao, W.; Gu, C.; Shi, Y.; Han, L.; Zhang, Y.; Zhang, B.; Zhang, R. Optimisation of no-tube seeding and its application in rice planting. Biosyst. Eng. 2021, 210, 115–128. [Google Scholar] [CrossRef]

- Wu, Z.; Li, M.; Lei, X.; Wu, Z.; Jiang, C.; Zhou, L.; Ma, R.; Chen, Y. Simulation and parameter optimisation of a centrifugal rice seeding spreader for a UAV. Biosyst. Eng. 2020, 192, 275–293. [Google Scholar] [CrossRef]

- Cao, C.; Qin, K.; Wang, A.; Sun, Y.; Zhou, M.; Li, W. Design and Experiment on Rice Hill Seeder with Air-blowing Special Hole and Scoop-wheel. Trans. CSAM 2015, 46, 66–72. [Google Scholar]

- Yang, Z.; Cheng, Q.; Liao, Q.; Fu, H.; Zhang, J.; Zhu, Y.; Lv, T.; Sun, Y.; Ma, J.; Li, N. Can reduced-input direct seeding improve resource use efficiencies and profitability of hybrid rice in China? Sci. Total Environ. 2022, 833, 155186. [Google Scholar] [CrossRef] [PubMed]

- Asenso, E.; Zhang, L.; Tang, L.; Issaka, F.; Tian, K.; Li, J.; Hu, L. Moldboard Plowing with Direct Seeding Improves Soil Properties and Sustainable Productivity in Ratoon Rice Farmland in Southern China. Sustainability 2019, 11, 6499. [Google Scholar] [CrossRef] [Green Version]

- Wu, L.; Liu, F.; Song, Y.; Xin, M.; Kong, A.; Liu, C.; Pan, S.; Cui, H.; Ren, W.; Zhang, B. Experimental study on dry-land rice direct seeding in northeast of China. Int. Agric. Eng. J. 2018, 27, 90–98. [Google Scholar]

- Xing, H.; Wang, Z.; Luo, X.; Cao, X.; Liu, C.; Zang, Y. General structure design and field experiment of pneumatic rice direct-seeder. Int. J. Agric. Biol. Eng. 2017, 10, 31–42. [Google Scholar]

- Dai, Y.; Luo, X.; Zhang, M.; Lan, F.; Zhou, Y.; Wang, Z. Design and experiments of the key components for centralized pneumatic rice dry direct seeding machine. Trans. CSAE 2020, 36, 1–8. [Google Scholar]

- Wang, J.; Qi, X.; Xu, C.; Wang, Z.; Jiang, Y.; Tang, H. Design Evaluation and Performance Analysis of the Inside-Filling Air-Assisted High-Speed Precision Maize Seed-Metering Device. Sustainability 2021, 13, 5483. [Google Scholar] [CrossRef]

- Xing, H. Optimization Design and Experiment of Precision Pneumatic Hill-Drop Drilling of Rice. Master’s Thesis, South China Agricultural University, Guangzhou, China, 2016. [Google Scholar]

- Zhang, G.; Zang, Y.; Luo, X.; Wang, Z.; Zhang, Q.; Zhang, S. Design and indoor simulated experiment of pneumatic rice seed metering device. Int. J. Agric. Biol. Eng. 2015, 8, 10–18. [Google Scholar]

- Li, B.; Ahmad, R.; Qi, X.; Li, H.; Nyambura, S.M.; Wang, J.; Chen, X.; Li, S. Design Evaluation and Performance Analysis of a Double-Row Pneumatic Precision Metering Device for Brassica chinensis. Sustainability 2021, 13, 1374. [Google Scholar] [CrossRef]

- Xing, H.; Wang, Z.; Luo, X.; Zang, Y.; Yang, W.; Zhang, M.; Ma, Y. Design of an active seed throwing and cleaning unit for pneumatic rice seed metering device. Int. J. Agric. Biol. Eng. 2018, 11, 62–69. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, W.; Tian, L.; Li, S.; Zhang, Z. Virtual simulation analysis and verification of seed-filling mechanism for dipper hill-drop precision direct rice seeder. Int. J. Agric. Biol. Eng. 2017, 10, 77–85. [Google Scholar]

- Wei, F.; Zhiyuan, Z.; Ying, Z.; Xiwen, L.; Shan, Z.; Zaiman, W. Development and experiment of rice hill-drop drilling machine for dry land based on proportional speed regulation. Int. J. Agric. Biol. Eng. 2017, 10, 77–86. [Google Scholar] [CrossRef] [Green Version]

- Xing, H.; Zang, Y.; Wang, Z.; Luo, X.; Pei, J.; He, S.; Xu, P.; Liu, S. Design and parameter optimization of rice pneumatic seeding metering device with adjustable seeding rate. Trans. CSAE 2019, 35, 20–28. [Google Scholar]

- Maleki, M.R.; Jafari, J.F.; Raufat, M.H.; Mouazen, A.M.; Baerdemaeker, J.D. Evaluation of Seed Distribution Uniformity of a Multi-flight Auger as a Grain Drill Metering Device. Biosyst. Eng. 2006, 94, 535–543. [Google Scholar] [CrossRef]

- Maleki, M.R.; Mouazen, A.M.; De Ketelaere, B.; De Baerdemaeker, J. A New Index for Seed Distribution Uniformity Evaluation of Grain Drills. Biosyst. Eng. 2006, 94, 471–475. [Google Scholar] [CrossRef]

- Gaikwad, B.B.; Sirohi, N.P.S. Design of a low-cost pneumatic seeder for nursery plug trays. Biosyst. Eng. 2008, 99, 322–329. [Google Scholar] [CrossRef]

- Luo, X.; Liu, T.; Jiang, E.; Li, Q. Design and experiment of hill sowing wheel of precision rice direct-seeder. Trans. CSAE 2007, 23, 108–112. [Google Scholar]

- Luo, X.; Wang, Z.; Jiang, E.; Li, J.; Li, Q.; Chen, W. Design of Disassemble Rubber Guard Device for Cell Wheel Feed. Trans. CSAM 2008, 39, 60–63. [Google Scholar]

- Zhang, M.; Wang, Z.; Luo, X.; Jiang, E.; Dai, Y.; Xing, H. Effect of double seed-filling chamber structure of combined type-hole metering device on filling properties. Trans. CSAE 2018, 34, 8–15. [Google Scholar]

- Zhu, D.; Li, L.; Wen, S.; Zhang, S.; Jiang, R.; Wu, L. Numerical simulation and experiment on seeding performance of slide hole-wheel precision seed-metering device for rice. Trans. CSAE 2018, 34, 17–26. [Google Scholar]

- Tian, L.; Wang, J.; Tang, H.; Li, S.; Zhou, W.; Shen, H. Design and Performance Experiment of Helix Grooved Rice Seeding Device. Trans. CSAM 2016, 47, 46–52. [Google Scholar]

- Tang, C.; Luo, H.; Wu, M.; Li, M. Design and test on seed metering device with variable capacity model-hole roller. Trans. CSAE 2010, 26, 114–119. [Google Scholar]

- Liu, J. Design and Experiment on Scoop Hole-Wheel Precision Seed-Metering Device for Rice. Master’s Thesis, Anhui Agricultural University, Hefei, China, 2021. [Google Scholar]

- Wen, S. Design and Experimental Study of Rice Precision Hill Direct Seed Metering Device. Master’s Thesis, Anhui Agricultural University, Hefei, China, 2018. [Google Scholar]

- Ahmad, R.; Hussain, S.; Farooq, M.; Atique Ur, R.; Jabbar, A. Improving the Performance of Direct Seeded System of Rice Intensification by Seed Priming. Int. J. Agric. Biol. 2013, 15, 791–794. [Google Scholar]

- Wang, B.; Luo, X.; Wang, Z.; Zheng, L.; Zhang, M.; Dai, Y.; Xing, H. Design and field evaluation of hill-drop pneumatic central cylinder direct-seeding machine for hybrid rice. Int. J. Agric. Biol. Eng. 2018, 11, 33–40. [Google Scholar] [CrossRef]

- Wang, B.; Na, Y.; Liu, J.; Wang, Z. Design and Evaluation of Vacuum Central Drum Seed Metering Device. Appl. Sci. 2022, 12, 2159. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, Z.; Luo, X.; Zang, Y.; Yang, W.; Xing, H.; Wang, B.; Dai, Y. Review of precision rice hill-drop drilling technology and machine for paddy. Int. J. Agric. Biol. Eng. 2018, 11, 1–11. [Google Scholar] [CrossRef]

- Zhang, M. Optimal Design and Experimental Research of pPrecision Rice Hill-Drop Drilling Machine. Ph.D. Thesis, South China Agricultural University, Guangzhou, China, 2017. [Google Scholar]

- Tian, L.; Tang, H.; Wang, J.; Li, S.; Zhou, W.; Yan, D. Design and Experiment of Rebound Dipper Hill-drop Precision Direct Seed-metering Device for Rice. Trans. CSAM 2017, 48, 65–72. [Google Scholar]

- Guo, Q.; Zhang, X.; Xu, Y.; Li, P.; Chen, C.; Wu, S. Design and experiment of cutting blade for cane straw. Trans. CSAE 2014, 30, 47–53. [Google Scholar]

- Zhang, X.; Wang, Z.; Li, Y.; Liang, D. Design and experiment of sliding-cutting and anti-twining returning device for banana straw. Trans. CSAE 2018, 34, 26–34. [Google Scholar]

| Species | Long Axis (mm) | Short Axis (mm) | Thickness (mm) | Sphericity (%) | Moisture Content (%) |

|---|---|---|---|---|---|

| Huang Hua Zhan | 9.79 ± 0.32 | 2.16 ± 0.12 | 1.91 ± 0.10 | 35.0 | 23.4 |

| Xiang Zao Xian 45 | 7.92 ± 0.20 | 2.83 ± 0.14 | 2.17 ± 0.08 | 46.1 | 25.3 |

| Long Dao 6 | 7.18 ± 0.30 | 3.39 ± 0.11 | 2.22 ± 0.06 | 52.7 | 24.3 |

| Level | Factor | ||

|---|---|---|---|

| Speed of the Seed-Metering Device X1 (r min−1) | Rice Seed Sphericity X2 (%) | Adjustment Depth X3 (mm) | |

| 1 | 20 | 35.0 | 3 |

| 2 | 25 | 46.1 | 6 |

| 3 | 30 | 52.7 | 9 |

| 4 | 35 | ||

| Indicators | Factors | X31 | X32 | X33 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| X21 | X22 | X23 | X21 | X22 | X23 | X21 | X22 | X23 | ||

| y1 (%) | X11 | 83.61 ± 1.44 | 86.53 ± 1.32 | 87.04 ± 1.28 | 83.23 ± 1.54 | 86.91 ± 1.43 | 87.29 ± 1.32 | 84.49 ± 1.87 | 86.79 ± 1.59 | 87.17 ± 1.44 |

| X12 | 85.64 ± 1.54 | 87.17 ± 1.41 | 88.82 ± 1.36 | 84.37 ± 1.65 | 87.8 ± 1.63 | 88.94 ± 1.57 | 84.88 ± 1.96 | 87.55 ± 1.73 | 88.31 ± 1.63 | |

| X13 | 84.24 ± 1.67 | 88.44 ± 1.56 | 90.22 ± 1.44 | 85.39 ± 1.74 | 89.2 ± 1.75 | 90.34 ± 1.61 | 85.01 ± 2.15 | 88.18 ± 1.84 | 89.33 ± 1.76 | |

| X14 | 81.07 ± 1.71 | 83.61 ± 1.64 | 84.5 ± 1.60 | 81.58 ± 1.91 | 83.87 ± 1.81 | 85.26 ± 1.69 | 81.70 ± 2.22 | 83.73 ± 1.96 | 84.75 ± 1.82 | |

| y2 (%) | X11 | 7.50 ± 0.71 | 4.19 ± 0.76 | 4.07 ± 0.82 | 8.13 ± 0.72 | 4.45 ± 0.81 | 3.94 ± 0.87 | 7.50 ± 0.88 | 4.32 ± 0.92 | 4.57 ± 0.95 |

| X12 | 8.01 ± 0.62 | 4.57 ± 0.72 | 4.45 ± 0.79 | 8.77 ± 0.69 | 4.07 ± 0.79 | 4.96 ± 0.83 | 8.64 ± 0.87 | 4.83 ± 0.81 | 4.70 ± 0.91 | |

| X13 | 9.15 ± 0.59 | 5.08 ± 0.68 | 5.21 ± 0.77 | 8.26 ± 0.67 | 5.46 ± 0.76 | 6.23 ± 0.79 | 8.13 ± 0.78 | 6.48 ± 0.80 | 6.35 ± 0.88 | |

| X14 | 10.04 ± 0.44 | 9.15 ± 0.65 | 8.77 ± 0.72 | 10.29 ± 0.56 | 8.89 ± 0.72 | 7.62 ± 0.76 | 10.55 ± 0.69 | 9.28 ± 0.78 | 8.39 ± 0.85 | |

| y3 (%) | X11 | 8.89 ± 0.73 | 9.28 ± 0.44 | 8.89 ± 0.46 | 8.64 ± 0.82 | 8.64 ± 0.62 | 8.77 ± 0.45 | 8.01 ± 0.99 | 8.89 ± 0.67 | 8.26 ± 0.49 |

| X12 | 6.35 ± 0.92 | 8.26 ± 0.69 | 6.73 ± 0.57 | 6.86 ± 0.96 | 8.13 ± 0.84 | 6.10 ± 0.74 | 6.48 ± 1.09 | 7.62 ± 0.92 | 6.99 ± 0.72 | |

| X13 | 6.61 ± 1.08 | 6.48 ± 0.88 | 4.57 ± 0.67 | 6.35 ± 1.07 | 5.34 ± 0.99 | 3.43 ± 0.82 | 6.86 ± 1.37 | 5.34 ± 1.04 | 4.32 ± 0.88 | |

| X14 | 8.89 ± 1.27 | 7.24 ± 0.99 | 6.38 ± 0.88 | 8.13 ± 1.35 | 7.24 ± 1.09 | 7.12 ± 0.93 | 7.75 ± 1.53 | 6.99 ± 1.18 | 6.86 ± 0.97 | |

| y4 (seed/hill) | X11 | 2.98 ± 0.12 | 3.16 ± 0.13 | 3.20 ± 0.15 | 5.92 ± 0.10 | 6.12 ± 0.14 | 6.16 ± 0.15 | 8.99 ± 0.09 | 9.11 ± 0.13 | 9.26 ± 0.14 |

| X12 | 2.95 ± 0.14 | 3.11 ± 0.16 | 3.14 ± 0.13 | 5.85 ± 0.12 | 6.08 ± 0.14 | 6.13 ± 0.13 | 8.82 ± 0.13 | 9.09 ± 0.15 | 9.18 ± 0.10 | |

| X13 | 2.91 ± 0.15 | 3.08 ± 0.13 | 3.09 ± 0.13 | 5.83 ± 0.14 | 6.04 ± 0.12 | 6.09 ± 0.14 | 8.73 ± 0.13 | 9.06 ± 0.12 | 9.12 ± 0.14 | |

| X14 | 2.85 ± 0.13 | 3.03 ± 0.12 | 3.06 ± 0.17 | 5.78 ± 0.11 | 6.02 ± 0.13 | 6.04 ± 0.16 | 8.72 ± 0.10 | 9.03 ± 0.13 | 9.07 ± 0.16 | |

| y5 (%) | X11 | 36.38 ± 1.20 | 31.20 ± 1.24 | 29.81 ± 1.29 | 22.36 ± 1.21 | 20.59 ± 1.28 | 19.85 ± 1.33 | 16.40 ± 1.34 | 15.41 ± 1.38 | 15.15 ± 1.40 |

| X12 | 37.92 ± 1.12 | 32.62 ± 1.21 | 32.42 ± 1.27 | 23.03 ± 1.18 | 21.07 ± 1.27 | 20.59 ± 1.30 | 18.95 ± 1.33 | 15.83 ± 1.28 | 16.45 ± 1.37 | |

| X13 | 38.9 ± 1.10 | 36.36 ± 1.17 | 34.35 ± 1.25 | 23.73 ± 1.16 | 21.78 ± 1.24 | 20.75 ± 1.27 | 19.05 ± 1.26 | 17.21 ± 1.28 | 17.12 ± 1.34 | |

| X14 | 39.61 ± 0.97 | 39.29 ± 1.15 | 35.62 ± 1.21 | 24.16 ± 1.07 | 22.75 ± 1.21 | 22.73 ± 1.24 | 21.07 ± 1.18 | 18.34 ± 1.26 | 17.81 ± 1.32 | |

| Indicators | Factors | SS | Df | MS | F | p | Significance | R2 |

|---|---|---|---|---|---|---|---|---|

| y1 (%) | X1 | 103.39 | 3.00 | 34.46 | 124.17 | 0.00 | ** | 0.963 |

| X2 | 98.06 | 2.00 | 49.03 | 176.66 | 0.00 | ** | ||

| X3 | 0.47 | 2.00 | 0.24 | 0.85 | 0.44 | |||

| y2 (%) | X1 | 77.70 | 3.00 | 25.90 | 65.08 | 0.00 | ** | 0.929 |

| X2 | 67.98 | 2.00 | 33.99 | 85.40 | 0.00 | ** | ||

| X3 | 0.57 | 2.00 | 0.29 | 0.72 | 0.50 | |||

| y2 (%) | X1 | 47.51 | 3.00 | 15.84 | 32.68 | 0.00 | ** | 0.803 |

| X2 | 6.56 | 2.00 | 3.28 | 6.77 | 0.00 | ** | ||

| X3 | 1.06 | 2.00 | 0.53 | 1.10 | 0.35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Zhao, C.; Yan, B.; Ling, L.; Meng, Z. Design and Verification of the Variable Capacity Roller-Wheel Precision Rice Direct Seed-Metering Device. Agronomy 2022, 12, 1798. https://doi.org/10.3390/agronomy12081798

Li H, Zhao C, Yan B, Ling L, Meng Z. Design and Verification of the Variable Capacity Roller-Wheel Precision Rice Direct Seed-Metering Device. Agronomy. 2022; 12(8):1798. https://doi.org/10.3390/agronomy12081798

Chicago/Turabian StyleLi, Hanqing, Chunjiang Zhao, Bingxin Yan, Lin Ling, and Zhijun Meng. 2022. "Design and Verification of the Variable Capacity Roller-Wheel Precision Rice Direct Seed-Metering Device" Agronomy 12, no. 8: 1798. https://doi.org/10.3390/agronomy12081798