Performance Evaluation of a Water-Circulating Tomato Root-Zone Substrate-Cooling System Using a Chiller and Its Effect on Tomato Vegetative Growth in Chinese Solar Greenhouse

Abstract

:1. Introduction

2. Materials and Methods

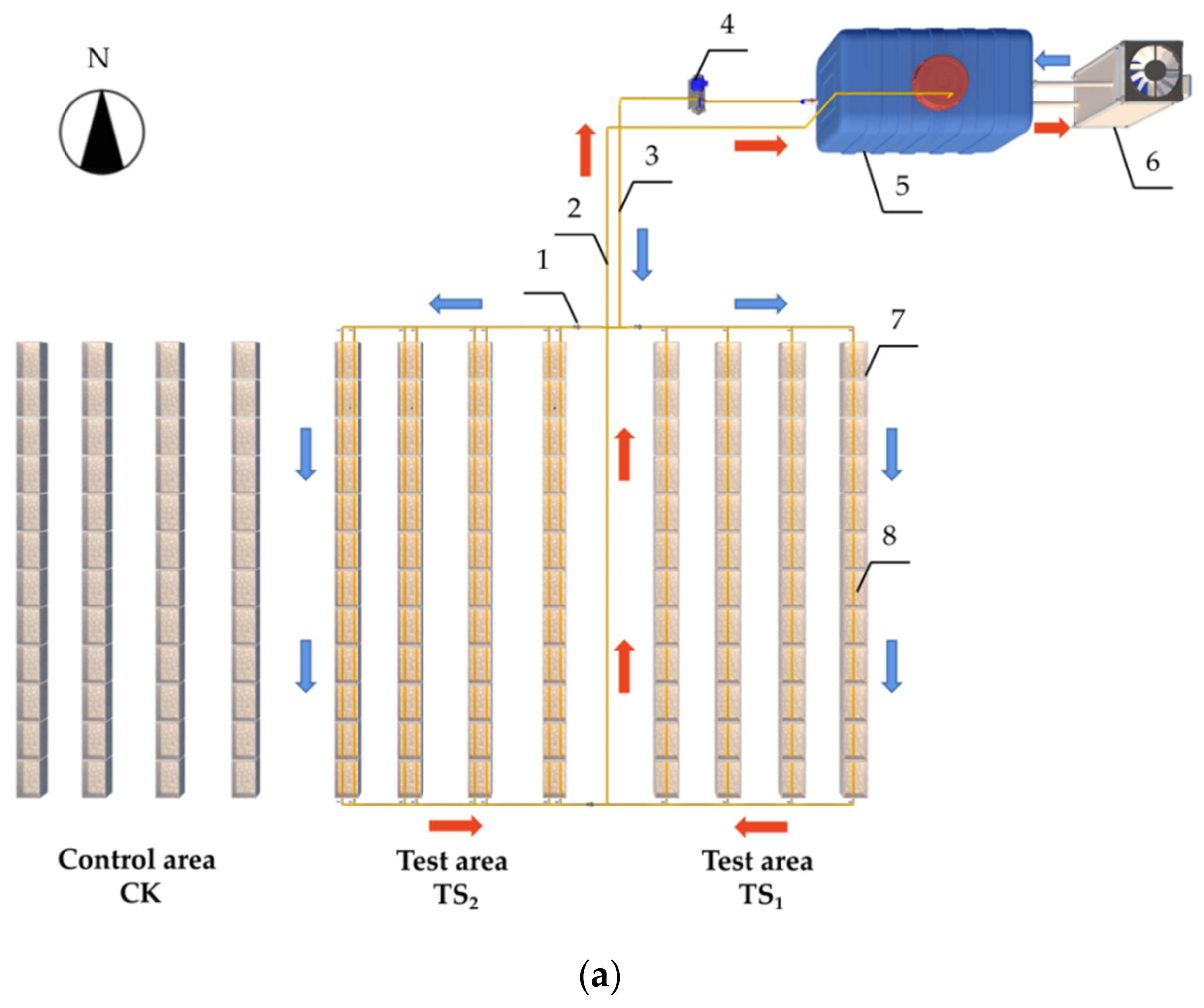

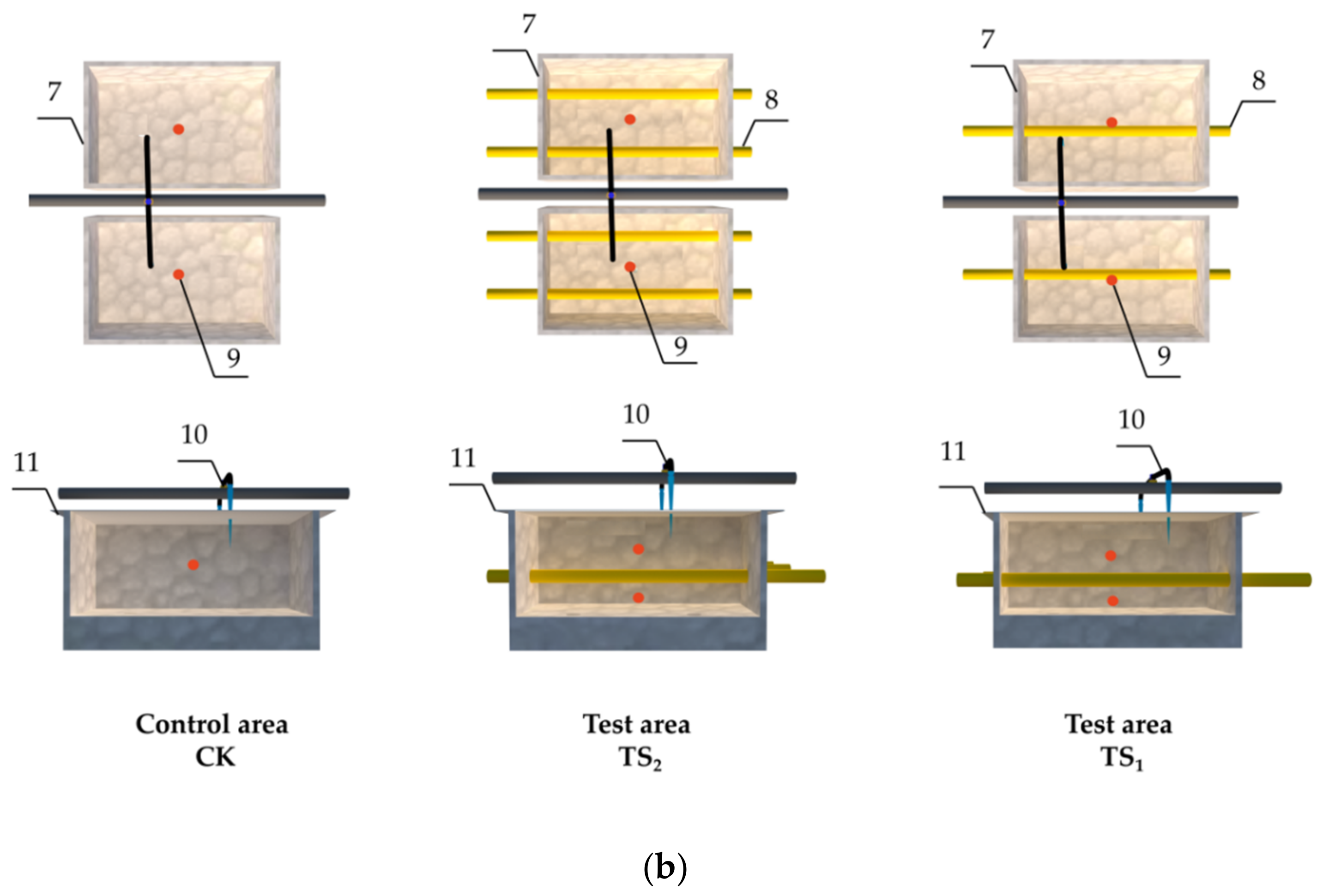

2.1. Introduction of WCTRZSCS

2.1.1. WCTRZSCS Composition

2.1.2. WCTRZSCS Working Principle

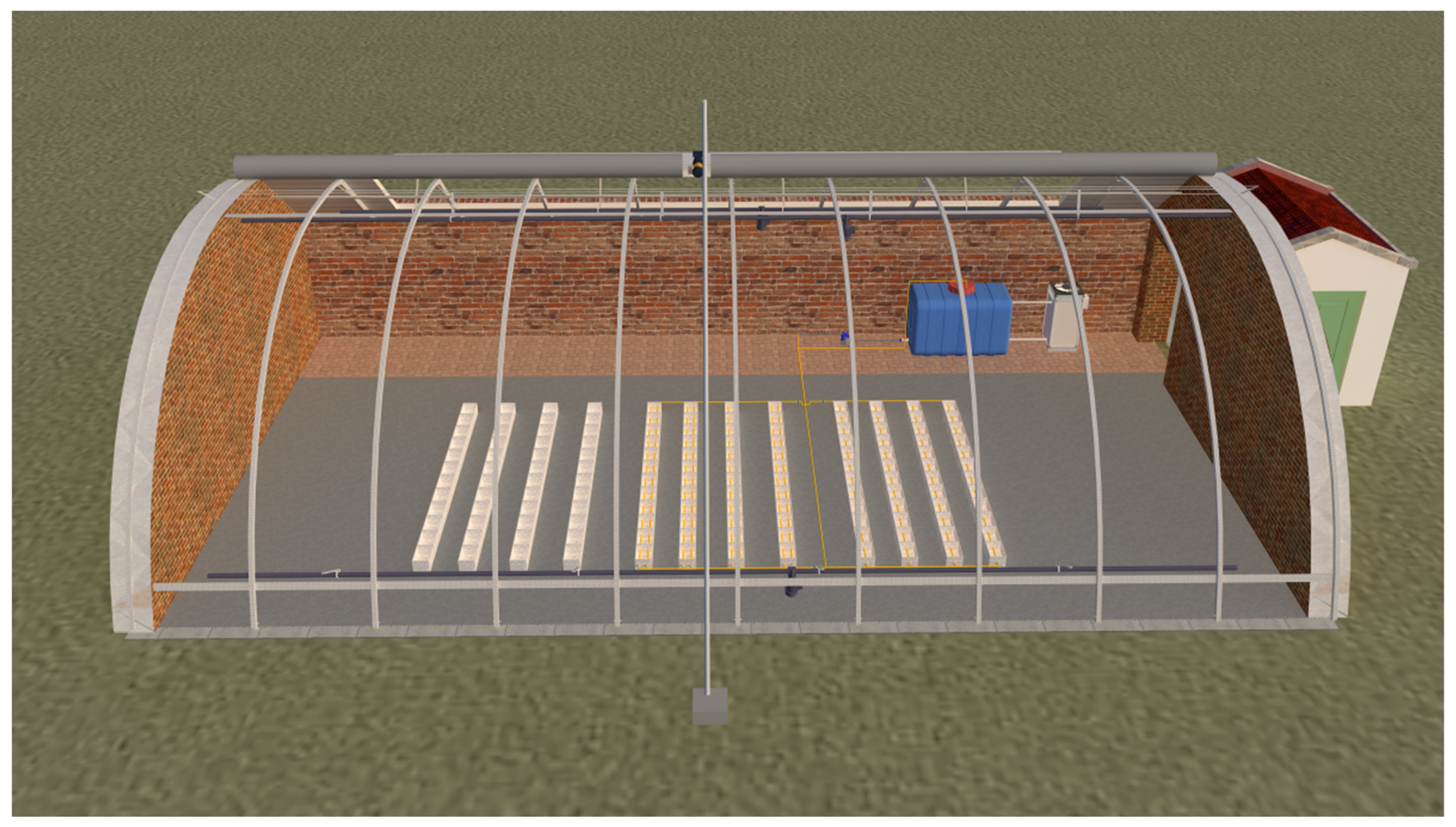

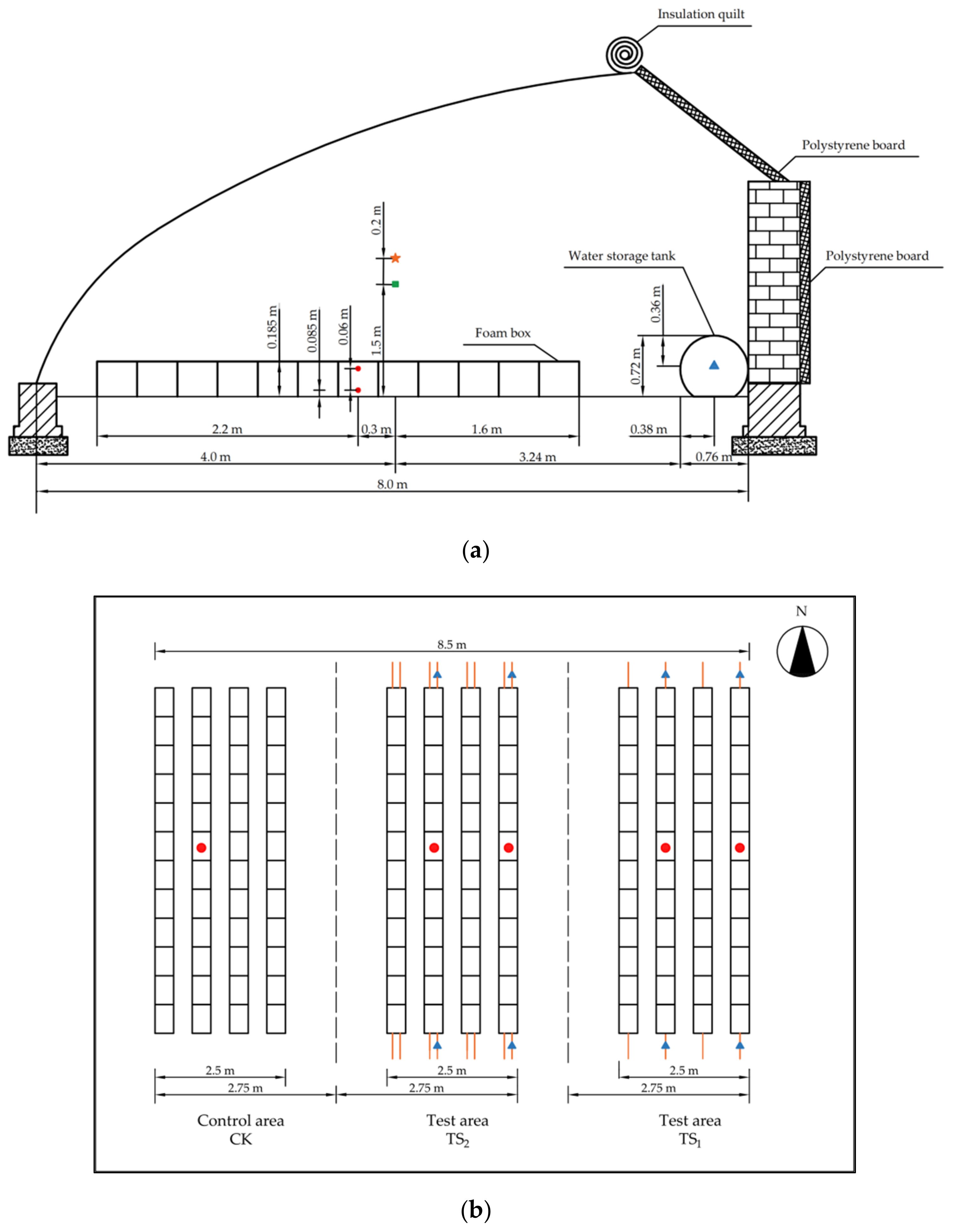

2.2. Introduction of Experimental Greenhouse

2.3. Experimental Method

2.4. Relevant Sensor Placement

2.4.1. Solar Radiation and Air Temperature, and Humidity Sensor Placement

2.4.2. Substrate Temperature Sensor Placement

2.4.3. Water Temperature Sensor Placement

2.5. Information on Sensors and Instruments

2.6. Calculation of Daily Substrate’s Effective Accumulated Temperature in the Root Zone of Tomato

2.7. Growth Rate of Tomato

2.8. Light-Utilization Efficiency of Tomato

2.9. Energy Consumption Calculation of WCTRZSCS

3. Results and Analysis

3.1. Effects of WCTRZSCS on Substrate Temperature

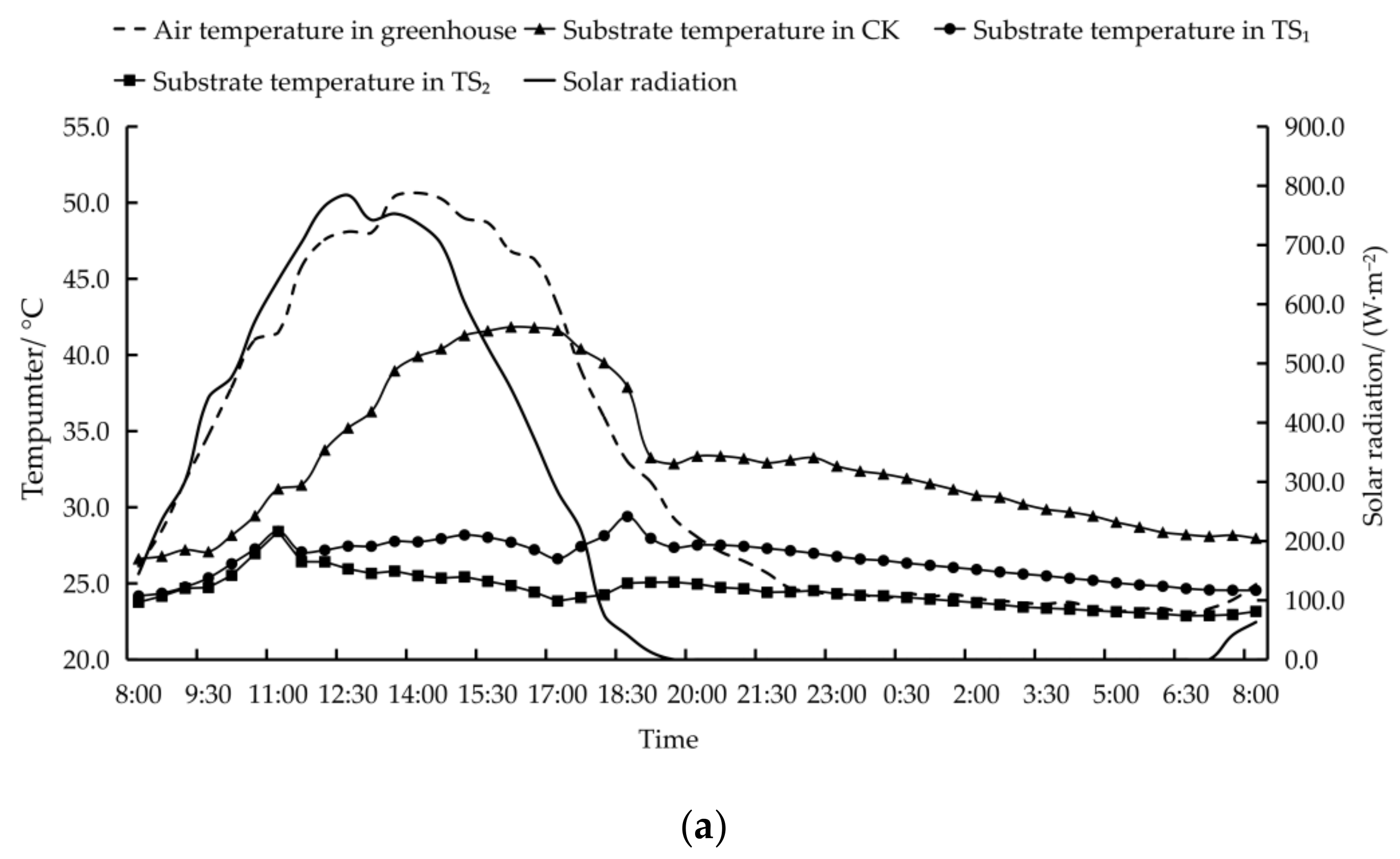

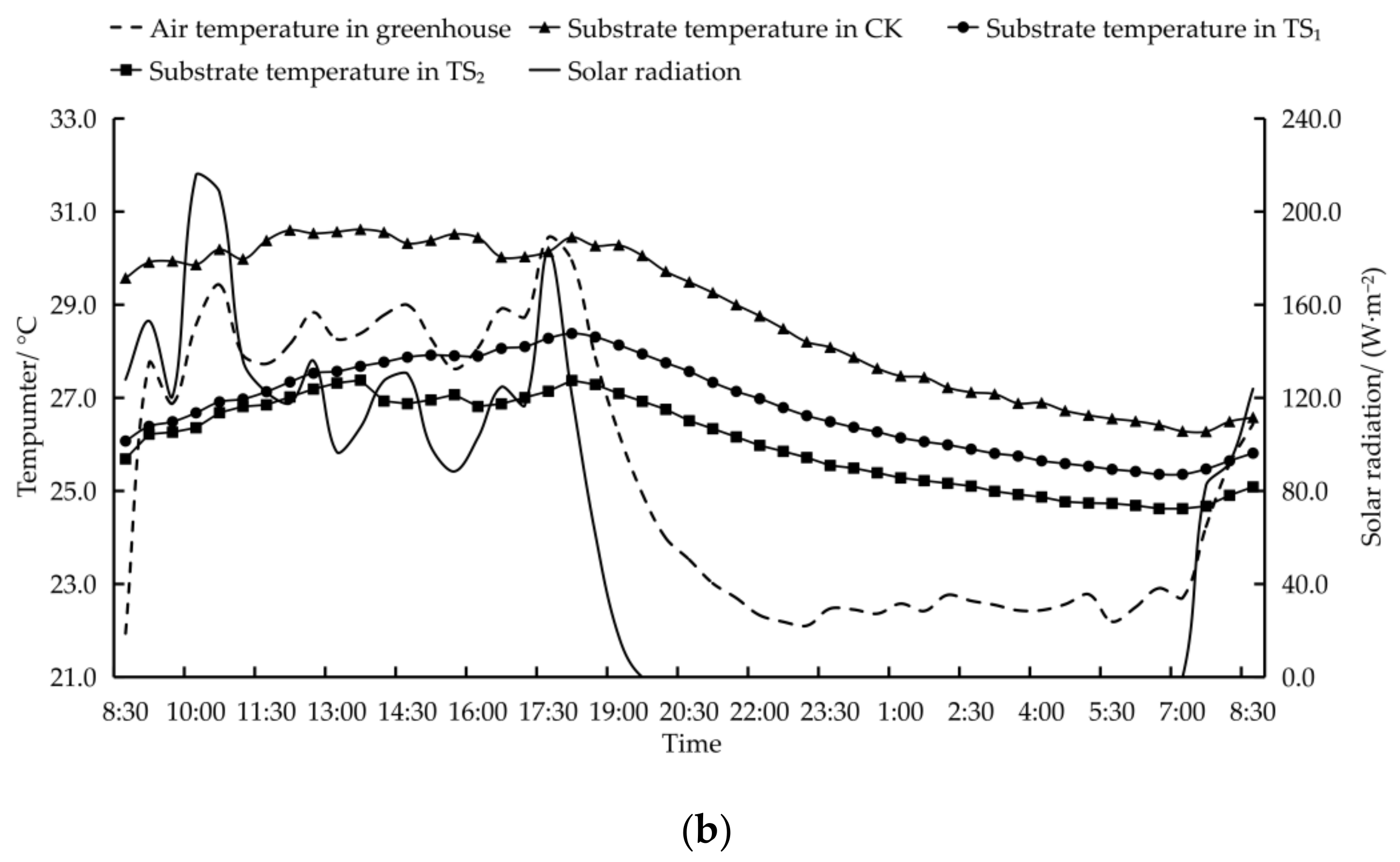

3.1.1. The Variation of Substrate Temperature under Typical Sunny Day

3.1.2. The Variation of Substrate Temperature under Typical Cloudy Day

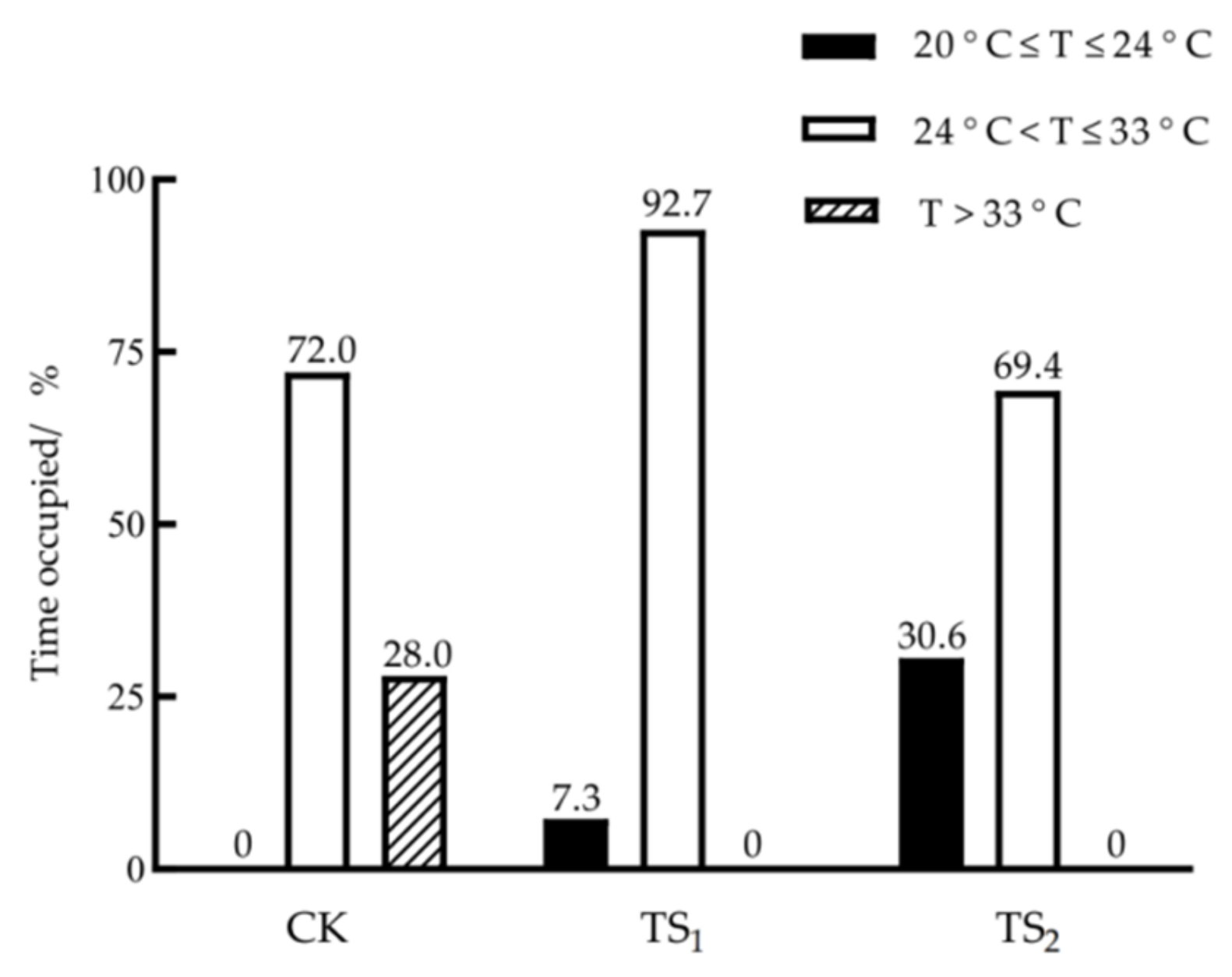

3.1.3. Substrate Temperature for Seven Consecutive Days

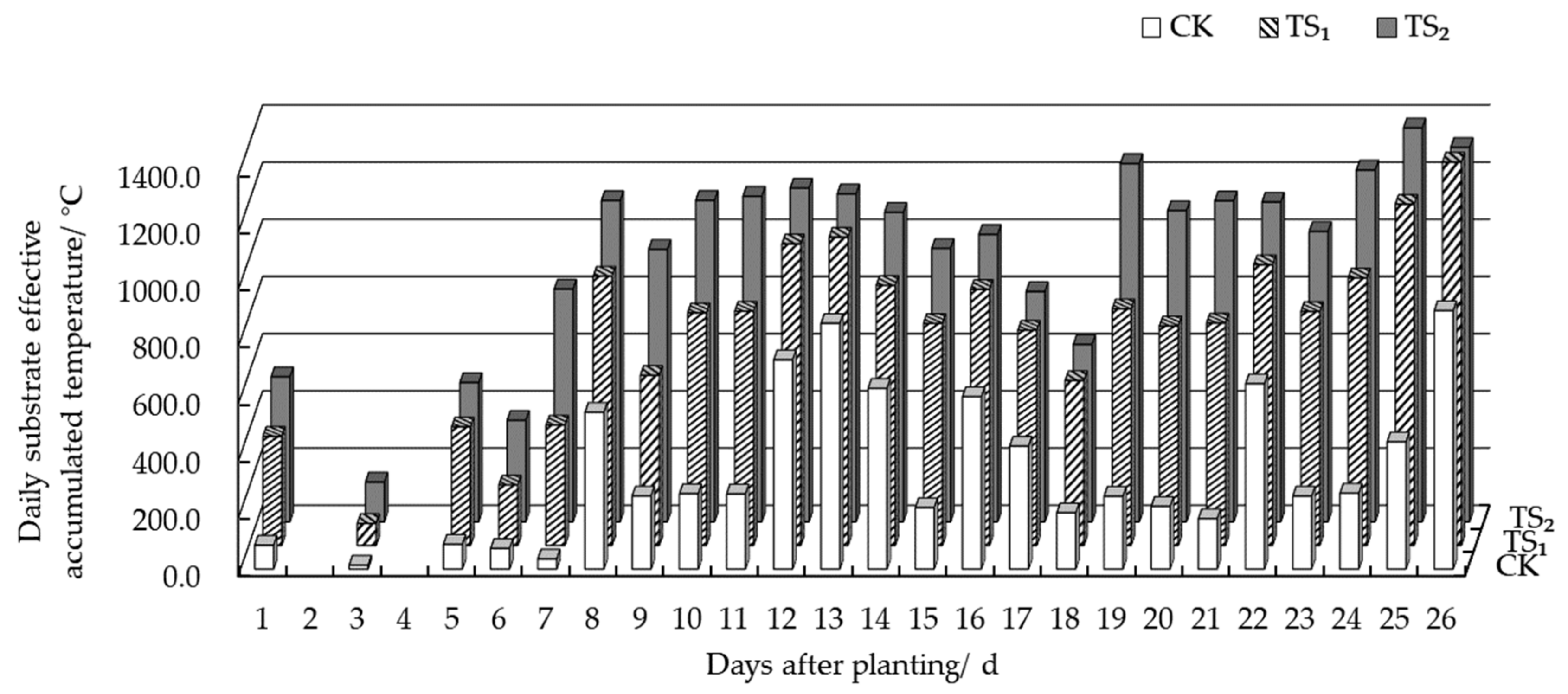

3.1.4. Substrate’s Effective Accumulated Temperature in the Tomato Root Zone

3.2. Effects of WCTRZSCS on Vegetative Growth of Tomato

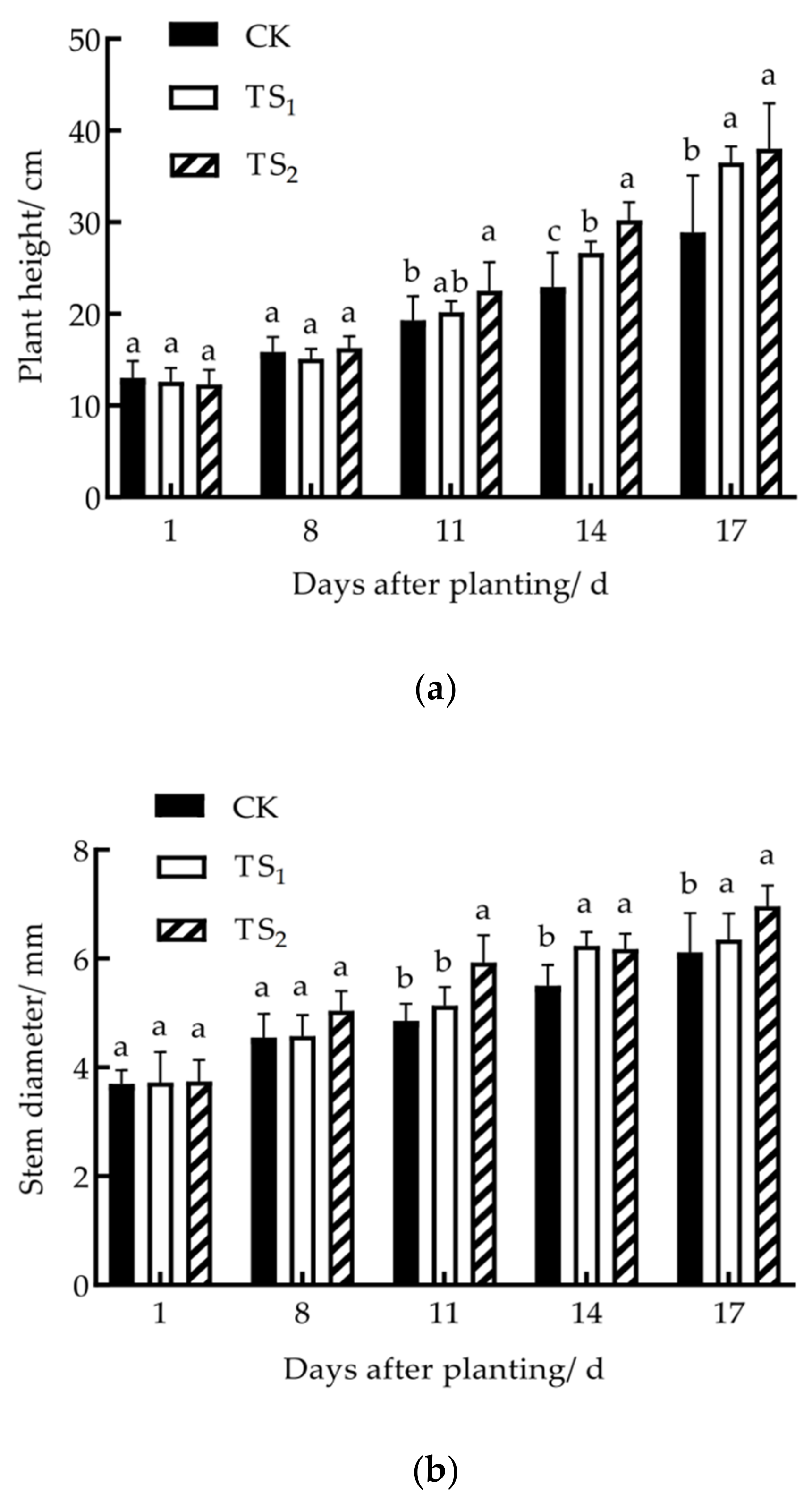

3.2.1. Effects of WCTRZSCS on Tomato Plant Height and Stem Diameter

3.2.2. Effects of WCTRZSCS on Tomato Root Growth

3.2.3. Effects of WCTRZSCS on Tomato Leaf Area, Fresh and Dry Weight, and Net Photosynthetic Rate

3.2.4. Effects of WCTRZSCS on Tomato Growth Rate and Light-Utilization Efficiency

3.3. Effects of WCTRZSCS on Tomato Yield

3.4. Energy Consumption Analysis

3.5. Economic Assessment of WCTRZSCS

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yuan, H.M.; Wang, G.F.; Fan, J.R.; Zhang, B.B.; Zhang, L.; Liu, S. Effect of high temperature stress on growth and floral bud differentiation of tomato seedlings. Acta Bot. Boreali-Occident. Sin. 2019, 39, 1768–1775. [Google Scholar]

- Sun, C.J.; Jin, Y.Z.; Wu, X.; Fan, B.W.; Song, Y.N.; Yang, F.J. Research status on the influence of high temperature stress on photosynthetic system of tomato and mitigating mechanism. J. Heilongjiang Aug. First Land Reclam. Univ. 2021, 33, 13–20. [Google Scholar]

- Central Document No.1 of 2022. Available online: http://www.gov.cn/zhengce/2022-02/22/content_5675035.htm (accessed on 10 July 2022).

- Wang, X.Z.; Zhang, W.J.; Zhang, L.; Guan, Z.F. Analysis of flow field for full open-roof glass greenhouse with nature ventilation in summer based on CFD. Trans. Chin. Soc. Agric. Mach. 2016, 47, 332–337. [Google Scholar]

- Huang, Z.Y.; Gao, H.T.; Zhu, S.L.; Zhao, C.Y.; Cai, C.H. Optimization design of mechanical ventilation for multi-span plastic greenhouses in southern china during summer. Trans. Chin. Soc. Agric. Mach. 2017, 48, 252–259. [Google Scholar]

- Sun, X.C.; Zhang, Z.W.; Huang, L.; Jiang, W.; Chen, W.P.; Yang, L.Y.; Kang, J.; Peng, Y.Q.; Wang, Z. Research progress in and expectation of greenhouse cooling technology. South China Agric. 2021, 15, 42–47. [Google Scholar]

- Ali, I.M.; Albayati, H.D.R. Influence of covering materials and shading on the greenhouse cooling in Iraq. Al-NJES 2017, 20, 262–271. [Google Scholar]

- Shi, Y.; Yao, Q.; Zhang, Y.; Miao, Y.X.; Hou, L.P. Effects of shade-cooling agent on the environment of solar greenhouse. J. Shanxi Agric. Sci. 2019, 47, 598–1602. [Google Scholar]

- Park, S.H.; Moon, J.P.; Kim, J.K.; Kim, S.H. Development of fog cooling control system and cooling effect in greenhouse. Prot. Hortic. Plant Fact. 2020, 29, 265–276. [Google Scholar] [CrossRef]

- Sun, W.T.; Zhou, B.; Xu, F.; Shang, C.; Lu, C.G.; Guo, W.Z. Performance of positive pressure fan-pad cooling system and cooling load model for Chinese solar greenhouse. Trans. Chin. Soc. Agric. Eng. 2019, 35, 214–224. [Google Scholar]

- Liu, Y.J.; Xu, J.T.; Pang, S.R.; Sun, Z.P.; Li, T.L. Design of positive- pressure wet curtain fan system for solar greenhouse and its cooling effects. J. China Agric. Univ. 2019, 24, 130–139. [Google Scholar]

- Li, Y.X.; Li, B.M.; Wang, C.Y.; Shi, Y.P. Effects of Shading and roof sprinkling in venlo-type greenhouse in summer. Trans. Chin. Soc. Agric. Eng. 2002, 2002, 127–130. [Google Scholar]

- Ghoulem, M.; El Moueddeb, K.; Nehdi, E.; Zhong, F.L.; Calautit, J. Design of a passive downdraught evaporative cooling windcatcher (PDEC-WC) system for greenhouses in hot Climates. Energies 2020, 13, 2934. [Google Scholar] [CrossRef]

- McCartney, L.; Lefsrud, M.G. Field trials of the natural ventilation augmented cooling (NVAC) greenhouse. Biosyst. Eng. 2018, 174, 159–172. [Google Scholar] [CrossRef]

- Moreno-Teruel, M.Á.; Molina-Aiz, F.D.; López-Martínez, A.; Marín-Membrive, P.; Peña-Fernández, A.; Valera-Martínez, D.L. The influence of different cooling systems on the microclimate, photosynthetic activity and yield of a tomato crops (Lycopersicum esculentum Mill.) in mediterranean greenhouses. Agronomy 2022, 12, 524. [Google Scholar] [CrossRef]

- Wang, T.; Gao, J.M.; Zhou, Y.; Wang, S.X. The study of cooling technology in totally enclosed solar greenhouse. J. Agric. Mech. Res. 2018, 40, 264–268. [Google Scholar]

- Yuan, D.; Qin, Z.J.; Wu, Z.H.; Liang, H.; Li, Y.Y.; Wang, B.J.; Wang, L.P. Effect of Estival screen-shading and spray cooling on growth and quality of over summer Chinese cabbage in solar greenhouse. China Veg. 2019, 2019, 62–66. [Google Scholar]

- Liu, D.Z. Experiment on the Effect of Heat Exchange System in the Ground on the Summer Cooling Effect of Greenhouse. Master’s Thesis, Northwest A&F University, Xianyang, China, 2019. [Google Scholar]

- Qi, D.; Zhao, C.Y.; Li, S.X.; Chen, R.; Li, A. Numerical assessment of earth to air heat exchanger with variable humidity conditions in greenhouses. Energies 2021, 14, 1368. [Google Scholar] [CrossRef]

- Soussi, M.; Chaibi, M.; Buchholz, B.; Saghrouni, Z. Comprehensive review on climate control and cooling systems in greenhouses under hot and arid conditions. Agronomy 2022, 12, 626. [Google Scholar] [CrossRef]

- Angmo, P.; Phuntsog, N.; Namgail, D.; Chaurasia, O.P.; Stobdan, T. Effect of shading and high temperature amplitude in greenhouse on growth, photosynthesis, yield and phenolic contents of tomato (Lycopersicum esculentum Mill). Physiol. Mol. Biol. Plants 2021, 27, 1539–1546. [Google Scholar] [CrossRef]

- Sun, W.T.; Zhang, Y.; Yang, Q.C.; Xue, X.Z.; Guo, W.Z. Nighttime cooling of solar greenhouse in summer based on water source heat pump system. Res. Agric. Mod. 2017, 38, 885–892. [Google Scholar]

- Karnoutsos, P.; Karagiovanidis, M.; Bantis, F.; Chatzistathis, T.; Koukounaras, A.; Ntinas, G.K. Controlled root-zone temperature effect on baby leaf vegetables yield and quality in a floating system under mild and extreme weather conditions. J. Sci. Food Agric. 2021, 101, 3933–3941. [Google Scholar] [CrossRef]

- Inkham, C.; Hongpakdee, P.; Kajornrungsilp, I.; Thanamatee, C.; Ruamrungsri, S. Root-zone cooling by cold energy from LNG regasification process for quality improvement of flower and bulb of Hippeastrum. Hortic. Environ. Biotechnol. 2020, 61, 643–650. [Google Scholar] [CrossRef]

- Aidoo, M.K.; Sherman, T.; Lazarovitch, N.; Fait, A.; Rachmilevitch, S. Physiology and metabolism of grafted bell pepper in response to low root-zone temperature. Funct. Plant Biol. 2019, 46, 339. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, D.T.P.; Lu, N.; Kagawa, N.; Takagaki, M. Optimization of Photosynthetic Photon Flux Density and Root-Zone Temperature for Enhancing Secondary Metabolite Accumulation and Production of Coriander in Plant Factory. Agronomy 2019, 9, 224. [Google Scholar] [CrossRef]

- Yan, Q.Y.; Duan, Z.Q.; Li, X.; Dong, J.L.; Wang, Y.H.; Xing, P.; Dong, F. Effect of root zone temperature on growth of cucumber and nutrient utilization in soils. Acta Pedol. Sin. 2013, 50, 752–760. [Google Scholar]

- Xia, Z.Q.; Zhang, G.X.; Zhang, S.B.; Wang, Q.; Fu, Y.F.; Lu, H.D. Efficacy of root zone temperature increase in root and shoot development and hormone changes in different maize genotypes. Agriculture 2021, 11, 477. [Google Scholar] [CrossRef]

- Fu, G.H.; Yang, Q.C.; Liu, W.K.; Yan, W.K. Research progress about effects of root zone temperature on physiology and ecology of protected horticulture crops. China Veg. 2016, 10, 20–27. [Google Scholar]

- Shigeoki, M.; Hirotada, N.; Atsushi, I. Partial cooling of strawberry plants by water tube utilizing geo-thermal heat pump. J. Appl. Hortic. 2017, 19, 186–190. [Google Scholar] [CrossRef]

- Oh, W.; Park, J.H.; Kim, H.K.; Rhie, Y.H.; Chun, C.; Kim, K.S. Root-Zone Cooling Improves Growth of Cyclamen persicum under Heat Stress. Hortic. Environ. Biotechnol. 2007, 48, 68–72. [Google Scholar]

- Moon, J.P.; Kang, G.C.; Kwon, J.K.; Lee, S.J.; Lee, J.N. Spot Cooling System Development for Ever-bearing Strawberry by Using Low Density Polyethylene Pipe. J. Korean Soc. Agric. Eng. 2014, 56, 149–158. [Google Scholar]

- Li, S.L.; Zhang, T.; Sun, Z.Q. Root-zone cooling effect of water-cooled seedling bed under different periods and its influences on growth of tomato seedling. Trans. Chin. Soc. Agric. Eng. 2015, 31, 192–196. [Google Scholar]

- Li, S.L.; Shi, X.D.; Xia, Y.Z.; Sun, Z.Q. Root-zone cooling effect of water-cooled seedling bed on growth of tomato seedling. Trans. Chin. Soc. Agric. Eng. 2014, 30, 212–218. [Google Scholar]

- Wang, Y.L.; Zhang, W.J. Empirical analysis of coupling relationship between water environment and economic development in northwest China. J. Water Resour. Water Eng. 2021, 32, 56–60. [Google Scholar]

- MCarmen, G.D.; Jose, S.R.; Daniel, C.M.; Teresa Rocio, T.R.; Alberto, C.-N.; Servando, A.D. Fresnel solar cooling plant for buildings: Optimal operation of an absorption chiller through inverse modelling. Energy Rep. 2022, 8, 3189–3212. [Google Scholar]

- Chen, Y.Z.; Xu, J.Z.; Wang, J.; Lund, P.D. Optimization of a weather-based energy system for high cooling and low heating conditions using different types of water-cooled chiller. Energy 2022, 252, 124094. [Google Scholar] [CrossRef]

- Xu, Y.H.; Luo, X.B.; Tu, Z.K. 4E analysis of a SOFC-CCHP system with a LiBr absorption chiller. Energy Rep. 2022, 8, 5284–5295. [Google Scholar] [CrossRef]

- Yan, Q.T.; Liu, W.; Li, J.B.; Yan, H.Y.; Wang, X.W. Local Cooling Technology of Long Tunnels Based on Air-Cooled Chillers. Tunnel Constr. 2021, 41, 2093–2097. [Google Scholar]

- Xu, Q.; Ji, C.Z.; Jiang, Y.X.; Yu, J.; Xia, Y.J.; Chen, Z. Application of LiBr Absorption Chiller on Passenger Ship. Ship Eng. 2021, 43, 278–281. [Google Scholar]

- He, S.X.; Wu, Y.M.; Li, S.H.; Song, Z.Y.; Shen, L.Y.; Tong, J.D.; Cao, J.Q. Research on energy efficiency improvement of refrigerators in glass fiber industry. Fiber Glass 2021, 6, 27–30. [Google Scholar]

- Chen, Z.B.; Cheng, Y.; Tan, H.; Xie, Q. Spray cooling performance of a spray drum cooler. Iron Steel 2020, 55, 116–123. [Google Scholar]

- Chan, T.S.; Chang, Y.C.; Huang, J.H. Application of artificial neural network and genetic algorithm to the optimization of load distribution for a multiple-type-chiller plant. Build. Simul. 2017, 10, 711–722. [Google Scholar] [CrossRef]

- Karami, M.; Wang, L.P. Particle Swarm optimization for control operation of an all-variable speed water-cooled chiller plant. Appl. Therm. Eng. 2018, 130, 962–978. [Google Scholar] [CrossRef]

- Huang, T.T.; Liang, C.H.; Bai, X.; Feng, Z.H.; Wang, F. Study on the feature-recognition-based modeling approach of chillers. Int. J. Refrig. 2019, 100, 326–334. [Google Scholar] [CrossRef]

- Li, Z.G.; Yang, Q.C.; Cha, L.Y.; Zhang, Y.B.; Liu, W.K. Temperature Characteristics in Root Zone and Inter Plants of Tomato Cultivated with Soil Ridged Substrate- Cultivation in Summer in Chinese Solar Greenhouse. Shandong Agric. Sci. 2018, 50, 41–44. [Google Scholar]

- Zhang, Y.; Ni, X.Y.; Zhang, K.X.; Xu, Y.J. Cooling performance for tomato root zone with intelligent ecological planting matrix temperature control system driven by photovoltaic in greenhouse. Trans. Chin. Soc. Agric. 2020, 36, 212–219. [Google Scholar]

- Ji, F.; Gan, P.D.; Liu, N.; He, D.X.; Yang, P. Effects of LED spectrum and daily light integral on growth and energy use efficiency of tomato seedlings. Trans. Chin. Soc. Agric. Eng. 2020, 36, 231–238. [Google Scholar]

- Li, Y.D. Effects of Cultivation Mode and Plant Growth Regulator on Growth and Development of Tomato. Master’s Thesis, Northeast Agricultural University, Harbin, China, 2018. [Google Scholar]

- Wang, C.X.; Gu, F.; Chen, J.L.; Yang, H.; Jiang, J.J.; Du, T.S.; Zhang, J.H. Assessing the response of yield and comprehensive fruit quality of tomato grown in greenhouse to deficit irrigation and nitrogen application strategies. Agric. Water Manag. 2013, 161, 9–19. [Google Scholar] [CrossRef]

- Tang, M.Z. Technology and application of heat resistant polyethylene (PE-RT Ⅱ) pipe for thermal insulation. China Rubber/Plast. Technol. Equip. 2021, 12, 008. [Google Scholar]

- Li, T.L. Current Situation and Prospects of Green House Industry Development in China. J. Shenyang Agric. Univ. 2005, 2, 131–138. [Google Scholar]

- Liu, J.; Cui, T.; Wang, C.D.; Li, X.; Ma, C.W.; Zhang, T.Z. Cooling Technology of Multi-span Greenhouse in Summer. J. Agric. Mech. Res. 2018, 40, 262–268. [Google Scholar]

- Chen, Y.Q.; Zhao, X.; Liu, Z.X.; Yang, Z.Q. Effect of Difference Between Day and Night Temperature on Fruit Development and Yield of Tomato. North. Hortic. 2014, 24, 38–42. [Google Scholar] [CrossRef]

- Yang, Z.Q.; Wang, X.L.; Peng, X.D.; Zhao, X.; Yuan, X.K.; Han, X.J. Effect of difference between day and night temperature on nutrients and dry mass partitioning of tomato in climate chamber. Trans. Chin. Soc. Agric. 2014, 30, 138–147. [Google Scholar]

- Huang, Y.H.; Li, Y.L.; Wen, X.Z. The effect of different air humidity on vegetative growth of greenhouse tomato under high temperature. North Hortic. 2010, 15, 138–143. [Google Scholar]

- Fan, Y.J.; Jiang, H.M.; Wen, X.Z.; Bai, L.Q.; Li, Y.L. Effects of long-term elevated CO2 coupled high temperature on the photosynthesis and content of starch of tomato leaves. J. Shanxi Agric. Sci. 2022, 50, 41–45. [Google Scholar]

- Anfoka, G.; Moshe, A.; Fridman, L.; Amrani, L.; Rotem, O.; Kolot, M.; Zeidan, M.; Czosnek, H.; Gorovits, R. Tomato yellow leaf curl virus infection mitigates the heat stress response of plants grown at high temperatures. Sci. Rep. 2016, 6, 19715. [Google Scholar] [CrossRef] [PubMed]

is the solar radiation sensor.

is the solar radiation sensor.  is the temperature and humidity sensor.

is the temperature and humidity sensor.  is substrate temperature sensor.

is substrate temperature sensor.  is the water temperature sensor.

is the water temperature sensor.

is the solar radiation sensor.

is the solar radiation sensor.  is the temperature and humidity sensor.

is the temperature and humidity sensor.  is substrate temperature sensor.

is substrate temperature sensor.  is the water temperature sensor.

is the water temperature sensor.

| Sensors | Type/Model | Amount | Measurement Range | Accuracy | Manufacturer |

|---|---|---|---|---|---|

| Substrate temperature sensor | PT100 | 9 | −50~100 °C | 0.2% FS | SONGDAO, Shanghai, China |

| Water temperature sensor | Copper-Copper Nickel T Thermocouple | 9 | −200~200 °C | ±2 °C | ZHUJIANG, Shanghai, China |

| Air temperature and humidity sensor | HSTL-102WS | 1 | −20~50 °C 0% RH~100% RH | / | HUAKONG, Beijing, China |

| Solar radiation sensor | HSTL-FSDJY | 1 | 0–1500 W/m2 | / | HUAKONG, Beijing, China |

| Instruments/Software | Model | Measurement Range | Accuracy | Manufacturer |

|---|---|---|---|---|

| Agilent data acquisition/switch unit | 34970A | / | / | Keysight, Penang, MY |

| Data collection controller | JY-DAM16CC | / | / | JUYING ELECTRONIC, Beijing, China |

| Electricity meter | DDSU666 | / | / | CHINT, Shanghai, China |

| Differential scanning calorimeter | Q100 | / | ±0.05 °C ±1% | TA, USA |

| Photosynthesis system | LI-6400 | / | / | LI-COR, USA |

| Electronic balance | BSA224S | 10 mg~220 g | 0.1 mg | Sartorius, China |

| Leaf area meter | CI-202 | / | / | CID, USA |

| Root analysis software | STD4800 | / | / | Regent, Canada |

| Area | Total Length/cm | Total Projection Area/cm2 | Total Surface Area/cm2 |

|---|---|---|---|

| CK | 330.90 ± 64.99 b | 16.00 ± 1.59 b | 20.54 ± 2.40 b |

| TS1 | 389.15 ± 29.36 a | 17.37 ± 0.41 a | 22.40 ± 1.37 a |

| TS2 | 395.66 ± 12.71 a | 17.77 ± 0.18 a | 22.26 ± 0.72 ab |

| Area | Leaf Area/cm2 | Net Photosynthesis Rate/(μmol·m−2·s−1) | Dry Weight/g | Fresh Weight/g |

|---|---|---|---|---|

| CK | 1100.30 ± 162.12 b | 26.54 ± 4.64 b | 7.21 ± 0.73 b | 76.26 ± 12.30 b |

| TS1 | 1632.73 ± 369.51 a | 32.67 ± 3.00 a | 10.92 ± 3.48 a | 119.04 ± 28.95 a |

| TS2 | 1749.66 ± 227.73 a | 33.91 ± 2.21 a | 12.39 ± 3.05 a | 134.58 ± 23.19 a |

| Area | Growth Rate/g·d−1 | Light-Utilization Efficiency/% |

|---|---|---|

| CK | 2.66 | 0.16 |

| TS1 | 4.26 | 0.25 |

| TS2 | 4.82 | 0.29 |

| Area | Yield/kg·m−2 |

|---|---|

| CK | / |

| TS1 | 0.80 ± 0.02 A |

| TS2 | 0.83 ± 0.03 A |

| Date | Total Solar Radiation/MJ | Average Temperature of the Substrate/°C | Actual Working Time of Cooling System | Power Consumption/kW·h | Refrigeration Capacity of the Whole Cooling System/J | Energy Consumption per Unit Ground Area of the Cooling System/W·m−2 | COP | |||

|---|---|---|---|---|---|---|---|---|---|---|

| TS1 | TS2 | CK | TS1 | TS2 | ||||||

| 21 August 2021 | 13.2 | 27.3 | 24.7 | 36.9 | 10:00~17:00 | 10:00~17:00 | 11.2 | 2.4 × 108 | 60.0 | 6.0 |

| 22 August 2021 | 4.3 | 26.9 | 25.7 | 29.7 | / | / | / | / | / | / |

| 23 August 2021 | 17.3 | 27.9 | 26.1 | 36.9 | 11:00~17:00 | 11:00~17:00 | 9.9 | 1.9 × 108 | 61.9 | 5.3 |

| 24 August 2021 | 18.5 | 27.6 | 25.6 | 38.3 | 11:00~17:00 | 11:00~17:00 | 10.8 | 2.2 × 108 | 67.5 | 5.8 |

| 25 August 2021 | 9.3 | 24.7 | 23.5 | 34.5 | 11:40~17:00 | 11:50~16:00 | 5.0 | 1.6 × 108 | 35.2 | 8.7 |

| Cooling Performance of WCTRZSCS/°C | TS1 | 6.5 |

|---|---|---|

| TS2 | 8.5 | |

| WCTRZSCS initial cost/RMB·m−2·year−1 | Chiller | 5.6 |

| Heat dissipation components (PE-RT pipes) | 0.5 | |

| Water pump | 0.6 | |

| Water storage tank | 0.7 | |

| Installation and maintenance costs | 0.9 | |

| Electric charge/RMB·m−2 | 15.3 | |

| Total costs of the WCTRZSCS/RMB·m−2·year−1 | 23.6 | |

| Yield/m−2 | CK | / |

| TS1 | 0.8 | |

| TS2 | 0.8 | |

| Total profit of the tomato/RMB·m−2 | 1.6 | |

| The benefit of the WCTRZSCS/RMB·m−2 | −22 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Yang, S.; Chen, X.; Liu, S.; Zhou, R.; Guo, L.; Sun, Y.; Cao, Y. Performance Evaluation of a Water-Circulating Tomato Root-Zone Substrate-Cooling System Using a Chiller and Its Effect on Tomato Vegetative Growth in Chinese Solar Greenhouse. Agronomy 2022, 12, 1922. https://doi.org/10.3390/agronomy12081922

Liu X, Yang S, Chen X, Liu S, Zhou R, Guo L, Sun Y, Cao Y. Performance Evaluation of a Water-Circulating Tomato Root-Zone Substrate-Cooling System Using a Chiller and Its Effect on Tomato Vegetative Growth in Chinese Solar Greenhouse. Agronomy. 2022; 12(8):1922. https://doi.org/10.3390/agronomy12081922

Chicago/Turabian StyleLiu, Xin, Shiye Yang, Xinyi Chen, Shengyan Liu, Ruimin Zhou, Liangjie Guo, Yachen Sun, and Yanfei Cao. 2022. "Performance Evaluation of a Water-Circulating Tomato Root-Zone Substrate-Cooling System Using a Chiller and Its Effect on Tomato Vegetative Growth in Chinese Solar Greenhouse" Agronomy 12, no. 8: 1922. https://doi.org/10.3390/agronomy12081922

APA StyleLiu, X., Yang, S., Chen, X., Liu, S., Zhou, R., Guo, L., Sun, Y., & Cao, Y. (2022). Performance Evaluation of a Water-Circulating Tomato Root-Zone Substrate-Cooling System Using a Chiller and Its Effect on Tomato Vegetative Growth in Chinese Solar Greenhouse. Agronomy, 12(8), 1922. https://doi.org/10.3390/agronomy12081922